1. Introduction

Faced with the urgent challenges of global climate change and the demand for clean energy, hydrogen energy is increasingly becoming a pivotal force in the energy transition due to its zero carbon emissions and high energy density. It is noteworthy that during the industrialization era, Europe accounted for 90% of global carbon emissions, while the U.S. took over as the top carbon-emitting region in 1916. In the latter half of the 20th century, rapid economic growth in various countries drove up energy demand and consumption, leading to a significant increase in carbon emissions. Currently, China is the world’s largest carbon emitter, making it a crucial area of focus for research and development to reduce carbon emissions.

Throughout human history, our reliance on energy sources has evolved significantly, from the primitive use of firewood to the advent of coal and the steam engine and, later, to the dominance of petroleum and the internal combustion engine. Yet, with escalating concerns over greenhouse gas (GHG) emissions and their impact on the climate, the quest for cleaner energy alternatives has led to a heightened focus on hydrogen—a plentiful, eco-friendly, and versatile form of secondary energy. Hydrogen boasts an impressive mass–energy density of 120 MJ/kg, despite a notably low volumetric energy density of 0.01079 MJ/L [

1]. In the current era, marked by a global surge in technological and industrial revolutions, cutting-edge energy technologies like hydrogen are witnessing rapid iterations like never before. Concurrently, the international political and economic arenas are experiencing profound shifts, which have catalyzed the momentum for energy diversification and decarbonization. This dynamic climate affords a substantial strategic opportunity for the advancement of hydrogen energy.

Globally, more than 20 countries and regions, including economic powerhouses such as South Korea, China, Germany, and the U.S., have established national hydrogen energy strategies. These strategies are designed to stimulate research and development and cultivate industrial expansion within the realms of hydrogen energy and fuel cell technology.

Significant deployment and commercialization programs and funding have been established over the last several years in the U.S., notably through the Bipartisan Infrastructure Law (BIL) and the Inflation Reduction Act (IRA). These initiatives include substantial investments in hydrogen production, infrastructure development, and market stimulation, with goals to create regional hydrogen hubs, support clean hydrogen projects, and incentivize private sector participation.

European nations perceive hydrogen energy as a key agent for profound decarbonization and a transition to clean energy systems. Germany, for instance, has invested heavily in hydrogen infrastructure, fostering the generation of green hydrogen from renewable resources and establishing hydrogen-centric industrial hubs.

South Korea envisions hydrogen energy as its third major pillar of industry with global strategic prowess, enhancing its display and semiconductor sectors. It prioritizes the development of hydrogen fuel cells in its research and development initiatives, aiming to boost its hydrogen power generation capacity to fuel economic advancement.

Traditional energy-exporting nations such as Australia, Russia, and Saudi Arabia are exploring economic diversification through hydrogen exports.

China is proactively establishing hydrogen energy demonstration projects, encouraging research and development, and fostering the integration of hydrogen energy technologies. China’s goal is to ramp up the production of green hydrogen as part of its efforts to reach peak carbon emissions and ultimately achieve carbon neutrality [

2].

Hydrogen, as an energy source, can be utilized both directly and indirectly. Renewable energy sources such as wind and solar power are typically integrated into the electrical grid. With advancements in hydrogen storage technology, excessive renewable energy can now be converted into hydrogen. This conversion offers higher energy density than pumped storage and compressed air storage, allowing for more flexible deployment and storage and enabling a broader range of applications. Further research is needed to integrate hydrogen energy with the grid and other energy systems. Some studies have already provided valuable insights into this area [

3,

4,

5].

The utilization and development of hydrogen energy usually require the establishment of hydrogen supply chains and market commercialization pathways, including production, storage, and transportation.

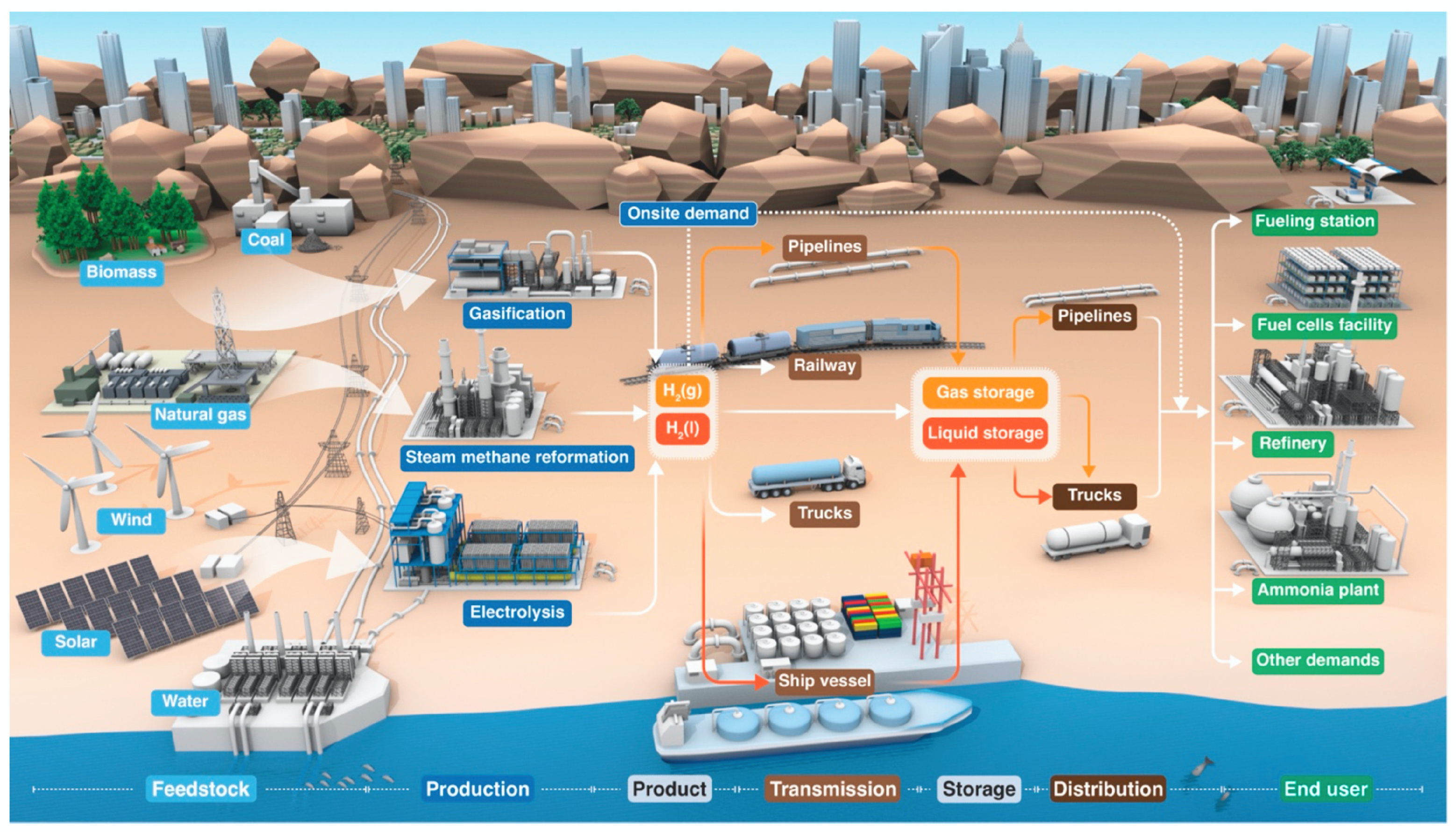

Figure 1 shows the superstructure of the hydrogen supply chain, briefly describing the utilization of hydrogen energy from source to end [

6].

Mastering the production of hydrogen is a prerequisite for its utilization. Over centuries of development, the processes for generating hydrogen have made significant strides. Current hydrogen production can be achieved through various methodologies and techniques:

Steam Methane Reforming (SMR) [

7]: This process entails the reaction of natural gas or liquefied petroleum gas with steam under high-temperature conditions to yield hydrogen and carbon dioxide. SMR stands as the most prevalent and conventional method of industrial hydrogen production.

Water Electrolysis [

8]: This technique employs electrolysis to decompose water into its constituent hydrogen and oxygen atoms. When powered by renewable energy sources such as solar or wind, this method facilitates the generation of low-carbon hydrogen and renewable hydrogen.

Biomass Gasification [

9]: This method utilizes the thermochemical transformation of biomass materials, including wood and agricultural residues, at elevated temperatures to produce hydrogen alongside other gases. This technique allows for hydrogen production via renewable organic waste.

Methane Pyrolysis [

10]: This approach involves the thermal decomposition of methane (natural gas) at high temperatures, resulting in hydrogen and solid carbon by-products. It leverages natural gas reserves for the generation of hydrogen.

Over the past two decades, significant advancements have been made in hydrogen applications across various sectors. In transportation, hydrogen fuel cell vehicles like Toyota’s Mirai, Honda’s Clarity, and Hyundai’s NEXO have been developed, along with hydrogen-powered buses, trucks, trains, and ships. Hydrogen-powered aircraft concepts are also being explored. In the industrial sector, hydrogen is increasingly used in refining, chemical production, and steel manufacturing, with cleaner production methods being adopted to reduce carbon emissions. The steel industry, for example, is integrating hydrogen in direct reduction iron (DRI) technology to lower CO2 emissions. In power and energy storage, fuel cell systems are used for distributed power generation and large-scale power plants, such as those by Hanwha Energy in South Korea. Hydrogen is also utilized for energy storage, produced via water electrolysis and converted back to electricity during peak demand. Blending hydrogen with natural gas in pipelines is being explored to increase renewable energy use. In building and heating, combined heat and power (CHP) systems using fuel cells provide both electricity and heating for residential and commercial buildings. The development of hydrogen infrastructure, including refueling stations and storage facilities, has progressed significantly.

To optimize the entire hydrogen supply chain, storage and transportation become critically important. Therefore, advancements in hydrogen storage and transportation technologies need rapid development. High-pressure compression allows substantial hydrogen volumes to be stored compactly, and this technology has been widely adopted. Cooling hydrogen to cryogenic temperatures turns it into a liquid, increasing storage density, which is especially useful in aerospace and parts of industry. There is an argument that liquid hydrogen (LH

2) is particularly useful in transportation applications, such as medium- and heavy-duty trucking. However, its utility in general industrial applications is debatable, as many industries, such as steel, cement, and ammonia production, find pipeline delivery sufficient and see little cost advantage in LH

2 delivery. Pipelines are a viable option for both long-distance and high-volume hydrogen transportation. In contrast, LH

2 is more suitable for long-distance but lower-volume needs. Furthermore, research on materials like metal–organic frameworks (MOFs) and carbon nanotubes shows promise for future storage solutions, with their exceptional hydrogen adsorption capabilities. Faye et al. [

11] summarized the detailed transfer path of hydrogen atoms in the hydrogen production process and found that hydrogen embrittleness was the main problem in the transportation process. In terms of transportation cost, the supply cost of hydrogen was 2.86 USD/kg through an efficient production process and tubular trailer transportation after the implementation of Carbon Capture, Utilization, and Storage (CCUS) hydrogen production. Ishaq et al. [

12] conducted a detailed review of hydrogen storage, transportation, and infrastructure and concluded that the potential future hydrogen transportation supply chain can be divided into four different categories, namely, on-site, semi-centralized, centralized, and intercontinental hydrogen transportation modes.

However, the understanding of hydrogen storage and transportation as an integrated system remains insufficient. This paper aims to fill this gap by reviewing recent advances in hydrogen storage and transportation methods. Additionally, we compare the costs associated with various transportation modes to identify the most promising approaches that could influence the future direction of hydrogen delivery.

2. Storage of Hydrogen

2.1. Compressed Gaseous Hydrogen Storage

Compressed gaseous hydrogen storage is the most common hydrogen storage method in hydrogen fuel cell vehicles or hydrogen-powered vehicles [

13]. According to several different standards or codes belonging to different associations from fields related to vehicle hydrogen tanks, its related technologies are developing rapidly, and the application range of pressure is up to 70 MPa [

14]. With the rapid development of materials science, there are about five types of tanks for compressed gaseous hydrogen storage, which are shown in

Table 1 [

15]. Type 5 tanks are under development [

16], while Type 3 and Type 4 are primarily used currently. Although there are no actual products of Type 5 hydrogen storage tanks yet, conceptual models already exist [

17].

Types 3 and 4 are now widely circulated in fuel cell vehicle (FCV) applications. Their inner surface consists of metal and polymer liner overwrapped by various layers of carbon fiber composites at different orientations to form stacks [

18]. These stacks provide the required strength and stiffness to the tank. Sapre et al. [

18] designed a Type 4 filament-wound tank with fibers bearing the primary load and the matrix maintaining their position and orientation. High-density polyethylene (HDPE) was used as a liner to contain hydrogen. Finite element analysis confirmed that the simulated burst pressure aligned well with experimental data, indicating safety. HDPE is the most used material for Type 4 tanks. South Korea-based ILJIN Co., Ltd. (Gyeongju-si, Republic of Korea) launched a Type 4 tank that used a polythene–clay nano-composite liner. Toyota Motor Corporation adopted nylon-6 (PA6) as the liner material of a 70 MPa compressed gaseous hydrogen (CGH

2) tank [

19].

As the most direct application of CGH2 storage, FCVs typically require 3 to 5 min to refuel. The amount of hydrogen dispensed during each refueling session is approximately 4 to 6 kg, depending on the vehicle’s hydrogen tank capacity and the pressure provided by the refueling station. The refueling of FCVs is complex due to high pressures and variable temperatures, posing safety concerns.

Maus et al. [

20] reviewed the CGH

2 filling procedures used by nine car manufacturers, noting a largely standardized process. Initially, the high-pressure tank is connected to the vehicle to equalize pressure. The vehicle tank’s residual pressure and volume are then assessed to calculate a heating curve and the necessary final pressure for full refueling. Kim et al. [

21] conducted numerical parametric studies on a 175 L hydrogen tank’s refueling. A relationship between the initial state of charge (SOC) pressure condition and the maximum temperature rise of hydrogen gas showed that the maximum temperature rise increased with decreasing ambient temperature and decreasing SOC. Therefore, when refueling the vehicle tank, the rise in internal gas temperature is a common concern that requires careful management to ensure safety and efficiency.

One effective approach is to pre-cool the hydrogen before it enters the tank, significantly lowering its temperature and mitigating heat buildup. Additionally, staged filling can help, where brief pauses during the process allow the gas to dissipate heat, thus reducing temperature spikes. Controlling the flow rate during filling is also crucial. Lower flow rates can minimize the heat generated by rapid compression, although this may extend the filling time. Modern hydrogen stations are equipped with advanced monitoring and control systems that continuously track the tank’s temperature and pressure, adjusting the filling speed and flow as needed to maintain safe conditions. Hydrogen tanks are typically made from lightweight, high-strength composite materials that offer superior thermal conductivity, enhancing heat dissipation. Some hydrogen stations employ rapid cooling techniques, using liquid nitrogen or other coolants to directly lower the gas temperature during filling. While effective, these methods require additional equipment and stringent safety protocols.

2.2. Cryogenic Liquid Hydrogen Storage

Liquid hydrogen (LH2) is an efficient and clean fuel. It is widely used in various fields, including in space applications as rocket fuel, energy storage, transportation for industrial processes such as metal refining and semiconductor manufacturing, and, increasingly, emerging technologies like fuel cells and hydrogen-powered vehicles. LH2 is a significant direction for the development of new energy technologies. Hydrogen liquefaction is achieved by cooling the hydrogen to below its critical temperature of 33.2 K and compressing it. The process of hydrogen liquefaction is both time-consuming and energy-intensive. Up to 40% of the energy content in hydrogen can be lost during this process, whereas the energy loss for compressed hydrogen is around 10%. In certain scenarios, these energy losses are inevitable to minimize the storage volume.

To minimize energy loss during storage, excellent insulation techniques are crucial. Vacuum insulation technology, known for its low heat flux density, is widely used in cryogenic gas storage tanks. An LH

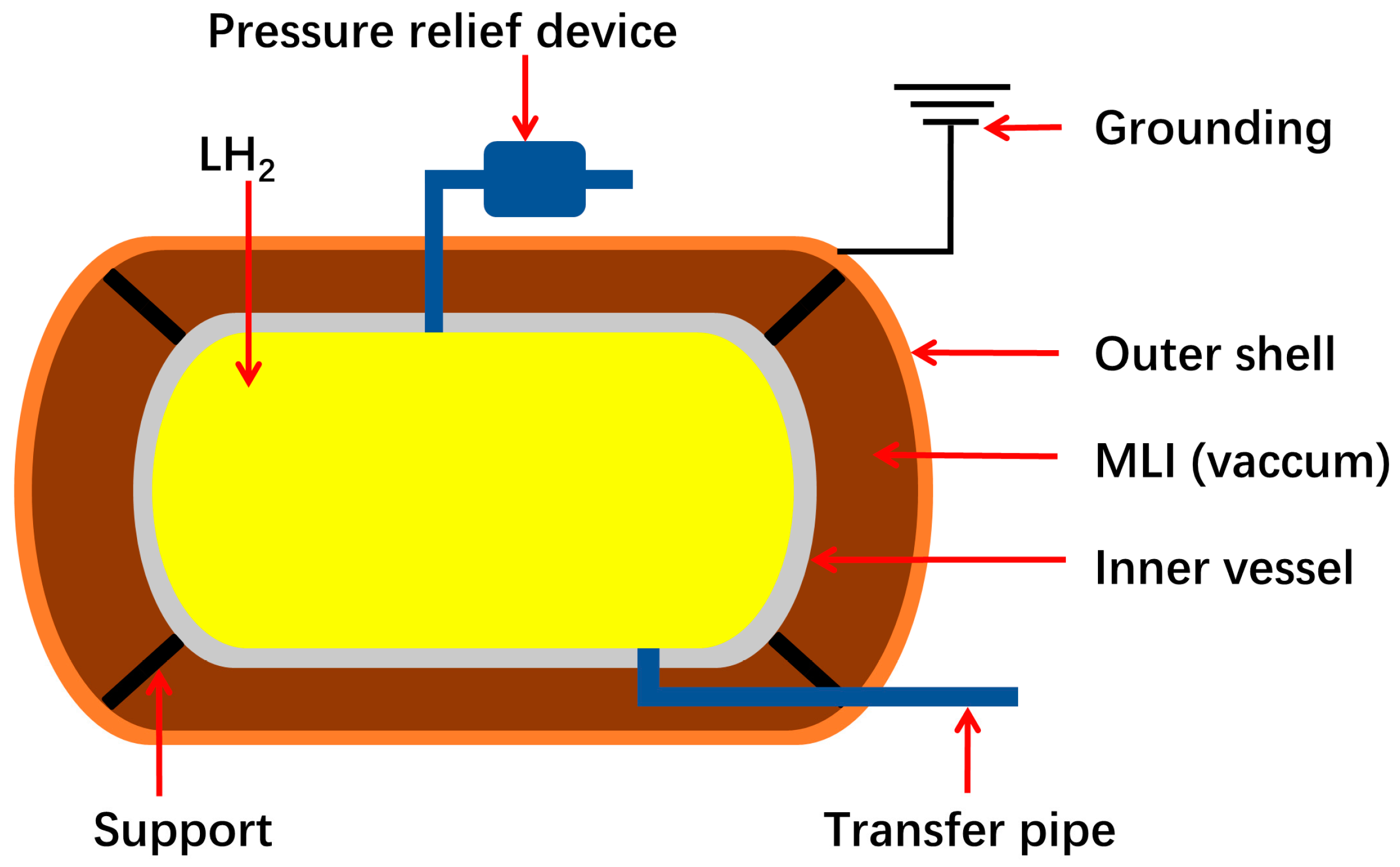

2 storage tank primarily consists of three parts, as shown in

Figure 2: the inner vessel, the insulation layer, and the outer shell. The inner vessel stores the LH

2, while the outer shell protects the inner vessel and connects it to the external structure. A multi-layer insulation (MLI) between the two minimizes radiative heat transfer to the inner vessel. The space between the inner vessel and the outer shell is maintained in a vacuum to minimize conductive and convective heat transfer through the residual gas that fills the gaps in the insulation layers.

For the inner vessel, which comes into direct contact with LH2, it must maintain its mechanical properties at low temperatures and avoid becoming brittle. It also needs to resist corrosion from LH2, withstand internal and external pressure differences, and prevent leaks. Common materials include stainless steel, aluminum alloys, and nickel alloys. Stainless steel and nickel alloys are heavier and more expensive, while aluminum alloys are lighter but require increased thickness to maintain strength. For the outer shell, since it does not come into direct contact with LH2, the performance requirements are slightly lower. Carbon steel can be used with an external anti-corrosion coating to reduce costs. Depending on the external environment, stainless steel and composite materials are also viable options. The intermediate MLI usually consists of metalized films to reflect radiative heat, separated and supported by high-insulation materials like polyester films.

Thermal protection technologies for LH

2 tanks can be classified into active and passive methods. As previously mentioned, the combination of vacuum and MLI represents a passive thermal protection technology. A common issue during the long-term storage of LH

2 is the degradation or even failure of the vacuum environment. In addition to further enhancing vacuum technology, we can incorporate materials that are less sensitive to vacuum levels in conjunction with MLI. For instance, the use of Spray-On Foam Insulation (SOFI) [

22] and High-Performance Glass Microspheres (HGMs) [

23] can significantly improve the overall performance of the system. Active thermal transfer technology is primarily aimed at achieving zero boil-off or lossless storage of LH

2. This is a costly technology and is currently used mainly in space applications such as satellites and space probes. The use of solutions such as embedded cryogenic heat pipes and heat exchangers, spray bars and circulating pumps, and broad area cooling shields with circulating gas pumps can prevent gas–liquid mixing during venting in a microgravity environment.

For large-scale LH

2 storage, spherical tanks are the standard approach. The spherical design minimizes surface area, reducing heat transfer and evaporation losses while providing uniform stress distribution to enhance structural integrity. Additionally, it is more efficient and economical in terms of material usage. Notably, the largest LH

2 storage facility at NASA’s Kennedy Space Center consists of two spheres, each 21.3 m in diameter and with a capacity of 3200 cubic meters, capable of storing 230 tonnes of LH

2 [

24].

Currently, stainless steel is the prevalent material choice for LH

2 storage and transportation due to its excellent low-temperature performance and resistance to hydrogen embrittlement [

25]. With the growing demand for LH

2 in space applications, research into high-specific-strength cryogenic materials such as aluminum alloys, titanium alloys, and composite materials has been advancing [

26]. Titanium alloys in particular are considered one of the more promising materials for LH

2 storage due to their superior strength-to-weight ratio and exceptional low-temperature mechanical properties. Although preliminary research has been conducted regarding the design of aerospace LH

2 storage and transportation containers, as well as the mechanical properties and selection criteria of related materials, the civilian sector is nearly untouched, and technological development is relatively behind. Therefore, engaging in systematic research to thoroughly understand the types and properties of cryogenic materials for LH

2 storage and transportation containers is imperative to ensure the safety, reliability, long-term operation, and cost reduction of LH

2 storage technologies.

2.3. Organic Liquid Hydrogen Storage

Organic liquid hydrogen storage involves two main steps: the hydrogenation of hydrogen-lean molecules and the dehydrogenation of hydrogen-rich molecules. There are two types of hydrogen-lean molecules: (1) hydrogen-lean molecules that are extracted from atmosphere or exhaust gas mixtures, such as ammonia, methanol, and formic acid, which are also called “circular” hydrogen carriers [

27], and (2) hydrogen-lean organic liquids, also called Liquid Organic Hydrogen Carriers [

28] (LOHCs).

In discussing the round-trip efficiency of organic liquid hydrogen storage systems, we compare the overall energy efficiency of the hydrogenation and dehydrogenation processes, focusing on “circular” hydrogen carriers and LOHCs. The efficiency of circular hydrogen carriers depends on the specific chemicals and technologies used for hydrogenation and dehydrogenation. Although methanol and formic acid offer relatively high efficiency, their synthesis and hydrogen extraction require significant energy. In contrast, LOHCs are advantageous due to their stability and high hydrogen content, with their efficiency influenced by the specific organic liquid and catalytic processes involved. While LOHCs may require higher temperatures or pressures, technological optimizations can enhance their efficiency. Overall, LOHCs generally exhibit higher round-trip efficiency due to their superior hydrogen storage capacity and potential for process optimization, whereas circular hydrogen carriers benefit from established technologies and infrastructure. The choice between these carriers depends on specific application needs, technological advancements, and economic considerations.

Ammonia (NH

3) has a high hydrogen content (17.8 wt%) and can be liquefied at ambient pressure at a reasonable temperature (−33.34 °C). As a well-established chemical product, ammonia has reliable and cost-effective storage systems. The decomposition of ammonia is an endothermic process, requiring high temperatures and noble catalysts (Ru) [

29]. Simultaneously, some non-precious metals (Ni, Fe, Co) have also been gradually developed, enabling reactions to occur at 300–500 °C [

30,

31,

32]. A reliable alternative at lower temperatures consists of amide–imide catalytic systems, although they are not very stable. Lithium amide–imide (Li

2−xNH

1+x) remains solid at temperatures above 400 °C, which minimizes catalyst loss. Conversely, while sodium amide exhibits catalytic performance comparable to Ru, it becomes liquid at these high temperatures, resulting in significant catalyst loss [

33]. Nonthermal plasma, electrolysis, and photocatalysis for NH

3 decomposition have also shown some research progress, but each method has significant drawbacks [

34].

The toluene hydrogenation reaction is a widely used reversible reaction that involves reacting hydrogen gas with liquid toluene to produce liquid methylcyclohexane and hydrogen gas, thereby enabling the storage of hydrogen gas. The equations for the toluene hydrogenation reaction and naphthalene hydrogenation reaction are shown in

Figure 3 [

28].

Several challenges exist within the toluene hydrogenation process. High temperatures and pressures are requisite, complicating and elevating the system’s cost. Additionally, the reaction generates toxic by-products like benzene, raising concerns about sustainability and safety. A deeper grasp of the reaction’s kinetics and thermodynamics is essential. Some advancements in catalysts have been reported recently. Wang et al. [

35] reported a RuNi/TiO

2 catalyst that effectively hydrogenates toluene to methylcyclohexane using crude hydrogen containing 1000–5000 ppm CO at approximately 180 °C and ambient pressure. The Ru-Ni interaction during the reduction process promoted the formation of highly dispersed Ni species, which is supposed to be the main active center for CO-tolerant hydrogenation action. The non-competitive adsorption of CO and toluene on Ru and Ni supports a new route for achieving the goal of raw hydrogen storage. Taiki Hashimoto et al. [

36] also demonstrated that LOHCs can potentially be used for H

2 purification from CO- and CO

2-rich crude H

2, in addition to their well-established use in H

2 storage.

Perhydro-dibenzyltoluene (18H-DBT) is considered one of the most popular LOHCs currently available. It exhibits low volatility and reactivity under ambient pressure and temperature conditions and its dehydrogenation products pose relatively low environmental and health risks. 18H-DBT boasts a theoretical hydrogen storage capacity of 6.2 wt% and its enthalpy of dehydrogenation (65.4 kJ/mol) is slightly lower than that of methylcyclohexane (

Figure 3a). However, both the hydrogenation and dehydrogenation processes of 18H-DBT tend to be incomplete. Currently, the most used catalysts for dibenzyltoluene are platinum-based catalysts adsorbed on a proper support, which is mainly Al

2O

3 [

37].

Naphthalene (

Figure 3b) and N-ethylcarbazole have also been studied. Their primary issues revolve around safety and economic viability. However, utilizing them as components of a mixed LOHC system may potentially mitigate these concerns to some extent and enhance hydrogen storage performance [

38]. Perhydro-N-ethyl carbazole (12H-NEC) offers unique advantages as an LOHC, particularly in terms of safety, environmental friendliness, and the utilization of existing infrastructure. However, challenges such as high-temperature and -pressure dehydrogenation, catalyst costs, and system complexity need to be considered. As reported for this system, Pd supported on alumina was found to be effective compared to Pt, Rh, and Ru [

39].

Zou et al. [

40] researched a hydrogen storage system based on ethylene glycol with a theoretic maximum content of 6.5 wt% for hydrogen storage capacities using a ruthenium pincer complex. Dong et al. [

41] investigated 2,3-dimethylindole (2,3-DMID), a candidate with a hydrogen storage capacity of 5.23 wt%. 2,3-DMID and the hydrogenated product 8H-2,3-DMID are not toxic to humans or the environment and the reaction conditions are relatively mild. 1,2,3,4-tetrahydroquinoline [

42] is also a potential material.

Future research in the field of LOHCs is driven by the pursuit of systems with enhanced hydrogen storage capacity. The aim is to identify materials that not only store hydrogen more densely but also exhibit improved kinetics for rapid hydrogenation/dehydrogenation cycles. Additionally, there is a push to develop advanced catalysts for LOHCs that facilitate hydrogen release at lower temperatures, thereby increasing energy efficiency. The longevity and reusability of LOHCs are also critical, necessitating compounds that remain stable over multiple cycles. Moreover, safety and minimal environmental impact are paramount, with a focus on non-toxic, non-flammable, and environmentally friendly LOHCs. The practical utility of these carriers hinges on their actual hydrogen storage capacity (wt%), which will likely be a focal point in optimizing the LOHC system’s properties for economic viability in commercial settings.

2.4. Solid Material Hydrogen Storage

Currently, the most popular solid hydrogen storage materials include categories represented by magnesium hydride, sodium borohydride, and ammonia borane.

Since the 1960s, the development of metal hydride materials has diversified, encompassing elements such as titanium, zirconium, magnesium, and various rare earth elements. Selection criteria primarily include acquisition costs, hydrogen storage capacity, and hydrogen release temperature. Magnesium-based materials are particularly notable due to their low molecular weight, yielding a high gravimetric hydrogen storage capacity, and magnesium’s abundance in the earth’s crust, which potentially lowers material costs. However, a significant limitation of magnesium-based materials is their high hydrogen release temperature, typically exceeding 300 °C.

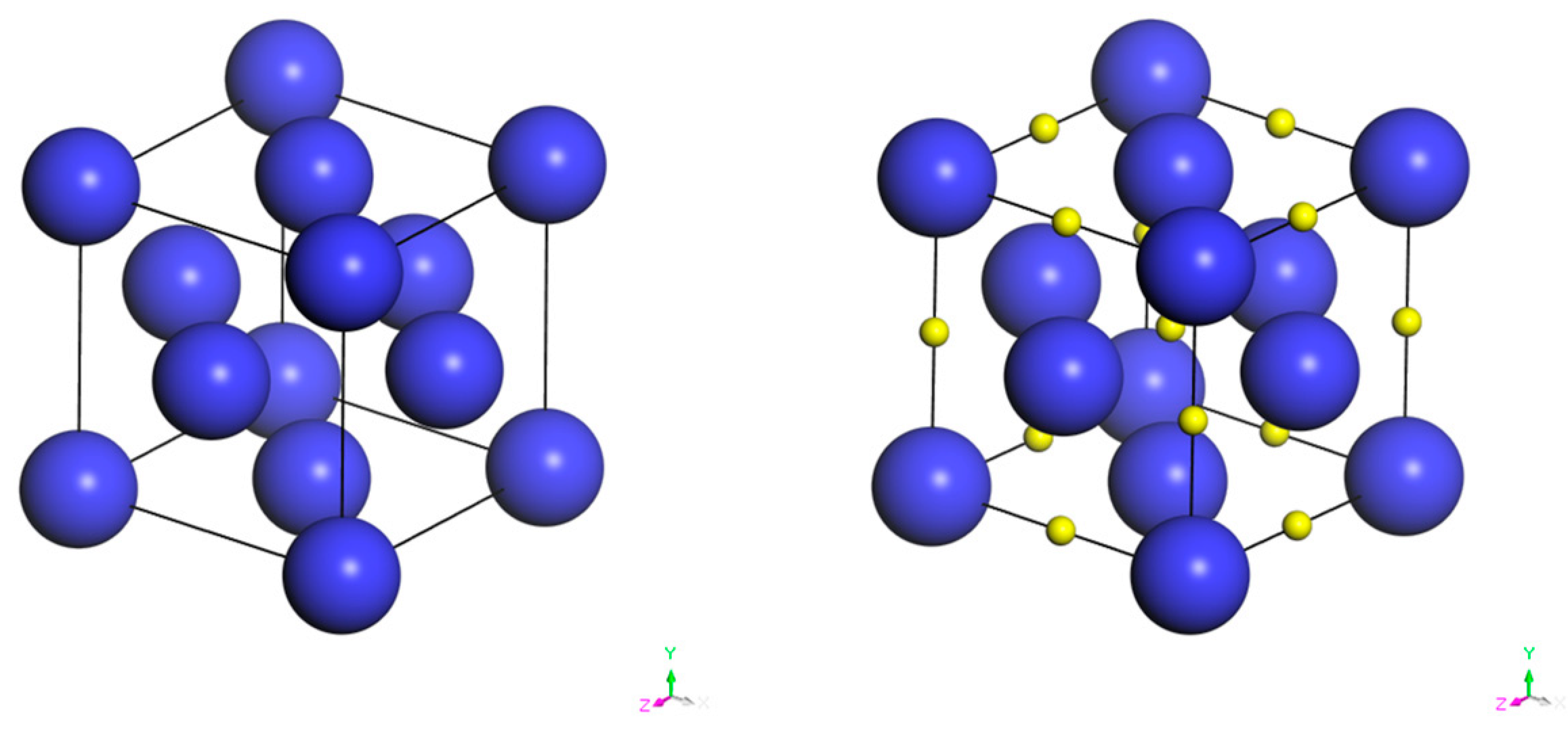

Figure 4 presents a simplified model of the Mg crystal structure to elucidate the hydrogen storage mechanism.

Table 2 presents the hydrogen desorption behavior of selected Mg-transition metal alloys [

43]. Certainly, apart from magnesium, hydrides based on other metals also exhibit significant hydrogen storage capabilities under suitable conditions.

Variations in microstructure also have a significant impact on hydrogen storage performance. Huang et al. [

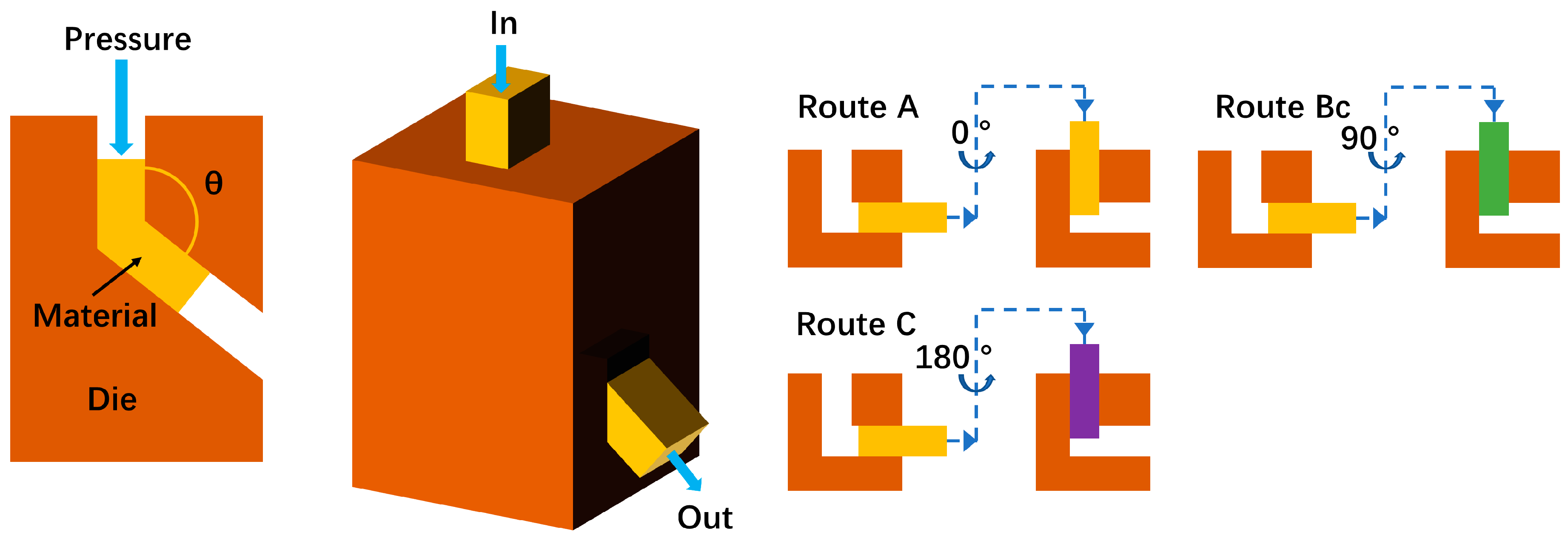

44] utilized the equal-channel angular pressing (ECAP) technique (illustrated in

Figure 5) to achieve microstructure homogenization and grain refinement in both AZ31 and AZ91 alloys, thereby improving their hydrogen storage properties. Chen et al. [

45] synthesized TiO

2 (B) nanosheets with a graphene-like structure and relatively high surface area, which were doped into MgH

2. The high surface area favored hydrogen diffusion, while the introduction of Ti weakened the Mg-H bonds, thereby improving the hydrogen storage properties. Other methods like ball inert gas condensation [

46], ball milling [

47], high-pressure torsion [

48], accumulative roll bonding [

49], crystallization [

50], and electrolytic deposition [

51] may also contribute to this field.

Sodium borohydride (NaBH

4) is a relatively inexpensive hydrogen storage material that is stable at room temperature, which significantly facilitates storage and transportation. Its theoretical hydrogen storage capacity reaches 10.7 wt%, substantially exceeding that of most metal hydrides. However, the release of hydrogen from sodium borohydride is a multi-step process that requires high temperatures and pressures to liberate a significant portion of hydrogen. Additionally, the recycling and regeneration of its by-products are relatively complex. Currently, various new strategies such as nanoengineering, catalysis, destabilization additives, and chemical modifications are being employed to overcome the thermodynamic and kinetic limitations of NaBH

4 thermal decomposition [

52,

53,

54]. Hydrolysis is an effective resolution, but self-hydrolysis of NaBH

4 without any catalyst is very sluggish. The hydrolytic process of NaBH

4 at room temperature is described by the following reaction, where x is the hydration factor [

55]:

This reaction is limited by the excess water requirement x and the low solubility in water of both NaBH

4 and the hydrated metaborate by-product NaBO

2. Mao et al. [

56] incorporated CaH

2 and Ca(BH

4)

2 into NaBH

4, resulting in a lower decomposition temperature and a faster desorption rate. The intermediate product, CaB

6, was identified as the primary factor causing the destabilization of NaBH

4 and enhancing its performance. In contrast, lithium borohydride (LiBH

4) has a higher theoretical hydrogen storage capacity, but its development and application are greatly limited by the high cost of lithium-based materials, poor thermal stability, and certain toxicity and corrosiveness. Javadian et al. [

57] demonstrated that the eutectic melting composite 0.62LiBH

4–0.38NaBH

4, when melt-infiltrated into carbon aerogel scaffolds, exhibits significantly improved hydrogen desorption kinetics and a reduced decomposition temperature. CO

2-activated carbon aerogels (CA-4) facilitate the infiltration of larger quantities of hydride, thereby enhancing the reversibility of hydrogen storage. To improve the hydrogen absorption and desorption cycle in industrial applications, researchers have made significant efforts. Zhu et al. [

54] demonstrated that the hydrolytic product NaBO

2 in aqueous solution reacts with CO

2 to form Na

2B

4O

7·10H

2O and Na

2CO

3, which are then ball-milled with Mg under ambient conditions to produce NaBH

4 at a high yield (close to 80%). This method avoids the use of expensive reducing agents and does not require high-pressure hydrogen, significantly reducing the overall cycle cost.

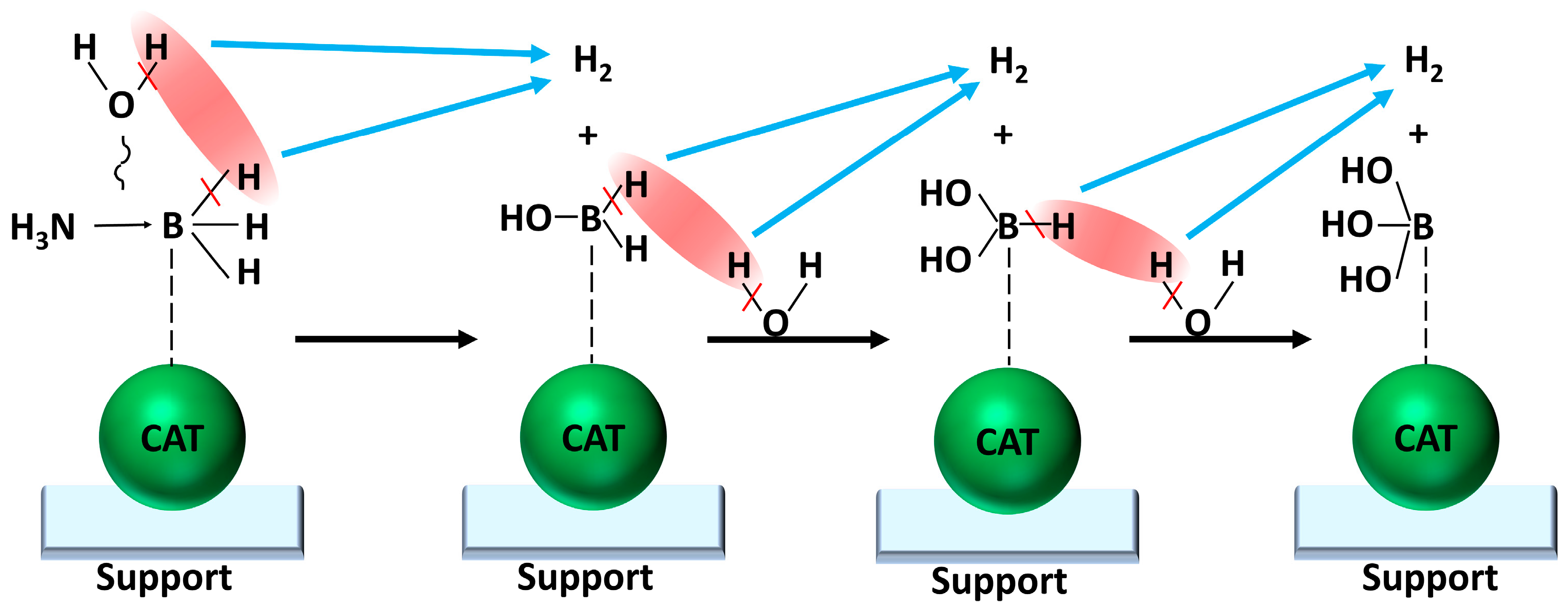

Ammonia borane (NH

3BH

3, AB) possesses a notably high hydrogen content of approximately 19.6 wt% and, under dry and cool conditions, it remains relatively stable [

58,

59]. This stability makes it an exceptionally effective medium for hydrogen storage, suitable for long-term storage and transportation. However, the synthesis of AB involves relatively high costs and technical demands, making it unsuitable for cyclic processes. Neat AB decomposes more than dehydrogenates. It follows a complex mechanism, producing a variety of reaction intermediates, volatile products, and polymeric residues. Consequently, certain strategies are required to destabilize AB, thereby favoring and enhancing the selectivity of the dehydrogenation reaction. These strategies primarily include four categories: catalysis, doping, nanostructural adjustments, and solubilization in an aprotic solvent [

60]. Hydrolysis is the most popular method to release hydrogen from AB because of its lower production cost, faster hydrogen liberation rate, and lower reaction temperature. Drawing inspiration from [

61], we refined and developed

Figure 6 to effectively illustrate the mechanism of this process. Initially, AB interacts with the catalyst surface, forming a hydrogen-bonded complex. Subsequently, a water molecule attacks the transition state B-H, wherein both AB and H

2O each lose a hydrogen atom, resulting in the generation of hydrogen [

60]. Supported noble metal catalysts (such as Pt, Rh, and Ru) exhibit high catalytic activity for the hydrolysis of AB to generate H

2 under mild conditions, but their high cost hinders commercialization. Meng et al. [

62] developed a stable and cost-effective Pt

0.1%Co

3%/TiO

2 catalyst that demonstrates a super-high H

2 generation rate from AB hydrolysis. The introduction of CoO leads to the formation of electron vacancies in the Pt species at the interfacial region, which significantly promotes the chemisorption and dissociation of water molecules, thereby accelerating H

2 generation.

The primary focus of current research is the identification of potential materials that offer both high hydrogen storage capacity and safety with non-toxic characteristics. In this regard, metal hydrides and borohydrides, including their derivatives, which have lower atomic numbers, show considerable advantages. Subsequently, the reduction of desorption temperatures and the enhancement of decomposition rates are pursued through catalysis, doping, and microstructural modifications. Finally, the refinement of the recycling processes is essential for reducing costs. In fact, the theoretical maximum hydrogen storage capacity is almost never achieved as the use of catalysts and dopants inevitably reduces the storage capacity, but these modifications are necessary for enhanced hydrogen storage performance. In some cases, to lower costs and improve the process cycle, it is not feasible to solely pursue high hydrogen storage capacities. For example, the complete dehydrogenation of AB results in the formation of stable boron nitride, which is highly detrimental to recovery.

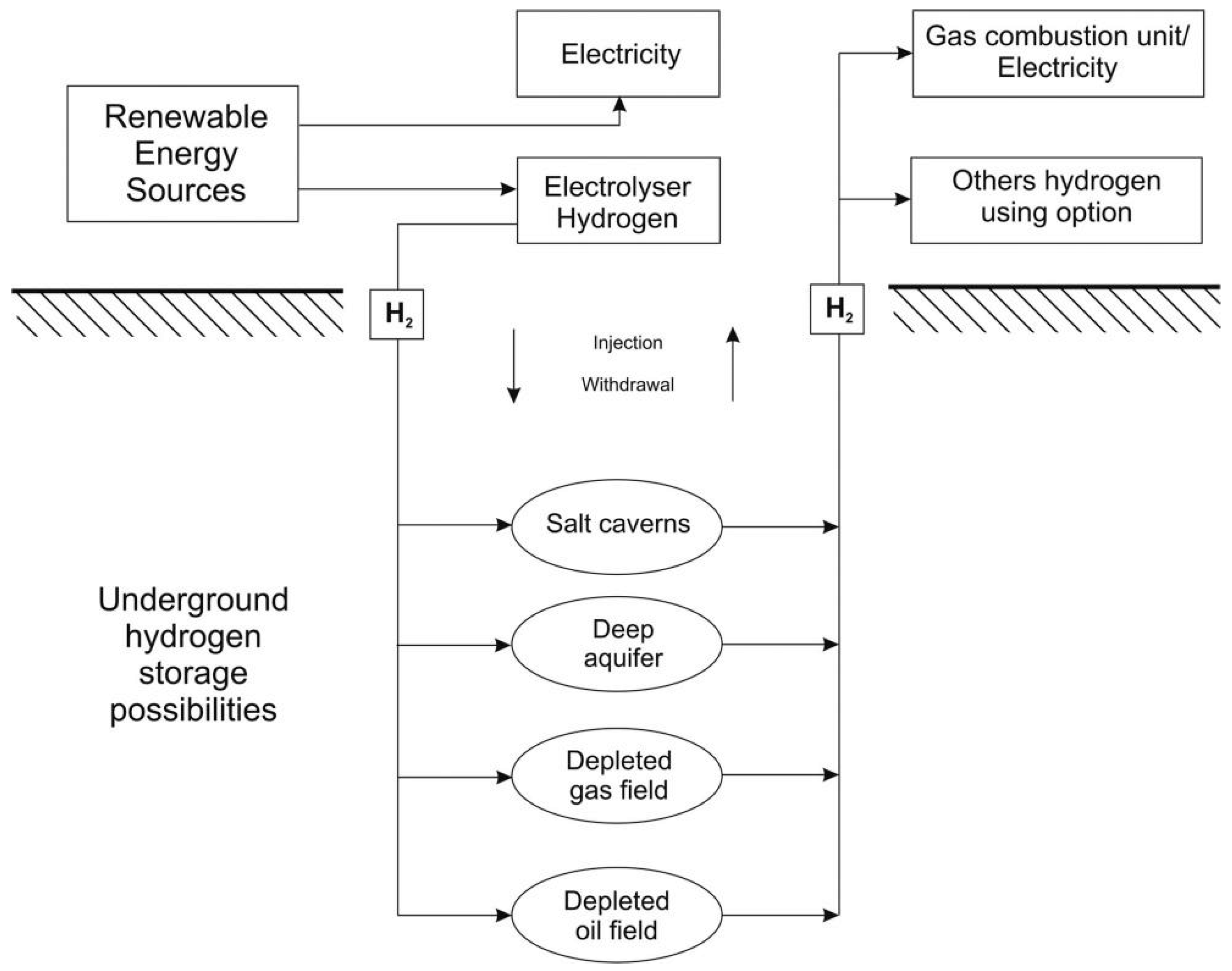

2.5. Underground Hydrogen Storage

Underground hydrogen storage (UHS) is a technique that involves storing hydrogen gas in underground reservoirs or salt caverns. It is considered a potential solution for hydrogen energy storage and dispatchability as hydrogen gas has a large volume at ambient conditions and requires high-pressure or cryogenic storage to meet energy demands. Its primary goal is to store surplus electricity generated from renewable sources, converting it into hydrogen and releasing it for energy use when needed. UHS facilities are capital-intensive investments, so the economic viability will be affected by the cost of electricity for water electrolysis and expenditure on the construction of storage sites [

63,

64].

Currently, four primary UHS methods exist: storage in depleted gas/oil fields, aquifers, salt caverns, and rock caverns. Gas composition and hydrogen purity necessitate careful geological screening; for instance, depleted oil fields may be unsuitable for storing high-purity hydrogen due to potential reactions with residual oil. Storage in deep aquifers requires suitable reservoir properties and an impermeable cap rock [

65].

Figure 7 shows a typical UHS system model [

65].

Depleted natural gas and oil reservoirs are ideal for hydrogen storage due to their proven impermeability, large areas, and extensive geological data from previous drilling. These data aid in understanding H

2 behavior and interactions with reservoir materials. Injecting H

2 displaces existing fluids, initially mixing with them, but this mixture decreases over successive cycles. Depleted fields require less cushion gas compared to aquifers, provided the cushion gas does not compromise H

2 purity. Non-H

2 gases like CH

4, CO

2, and N

2 are cost-effective options, with CO

2 also reducing greenhouse gas emissions. These reservoirs offer a higher storage capacity than salt caverns, gasometer tanks, and pipelines [

66]. However, factors like anthropogenic activity, biological transformation, and gas mixing can affect gas quality and storage cycles. Using appropriate additives can minimize these issues.

Salt caverns offer a chemically stable environment with salinity that limits microbial hydrogen consumption. Storage capacity in these caverns increases with depth due to higher pressure, but this also escalates pipeline costs. At shallower depths, less buffer gas is needed [

67]. The construction of hydrogen storage salt caverns begins with drilling a borehole from the surface through the salt formation to the required depth, a process similar to that used in oil and gas drilling. An annular pipe is then installed and lowered to the middle of the cavity. Fresh water is pumped through the inner tubing to dissolve the salt, and the resulting brine is removed through another pipe, creating the cavern. Once the cavern is formed, a mechanical integrity test (MIT) is conducted to ensure gas tightness. The debrining process, which uses gas pressure to displace the remaining brine, completes the cavern preparation [

68]. The Linde Group, a leading industrial gases and engineering company based in Germany (hereafter referred to as “Linde”), has been operating the world’s first commercial hydrogen high-purity cavern in Texas, U.S., since 2007. The UHS cavern provides customers with hydrogen during periods of planned and unplanned peak demand, utilizing Linde’s 545 km hydrogen pipeline. This UHS cavern has a total capacity of approximately 6000 metric tons (MT) and a working capacity equivalent to over 14 days of production from a world-scale steam methane reformer (SMR) [

69].

The hydrogen storage rock cavern system consists of a cavern, a steel liner, and a concrete layer. These rock caverns are interconnected by shafts or tunnels. To prevent water infiltration, a drainage system is installed outside the concrete layer. The storage capacity is determined by the quality and depth of the rock formation. Typically, a depth of 150 m can withstand pressures exceeding 30 MPa [

68]. Rock caverns are not yet commercially applied and remain in the development stage.

UHS primarily aims to minimize costs. Capital costs overall are mainly comprised of site selection, gas separation, risk assessment, exploration of bacterial activity, injection and withdrawal periods, and infrastructural and labor costs [

70]. Despite its advancement, UHS is not yet widely adopted and requires further technical and financial investment.

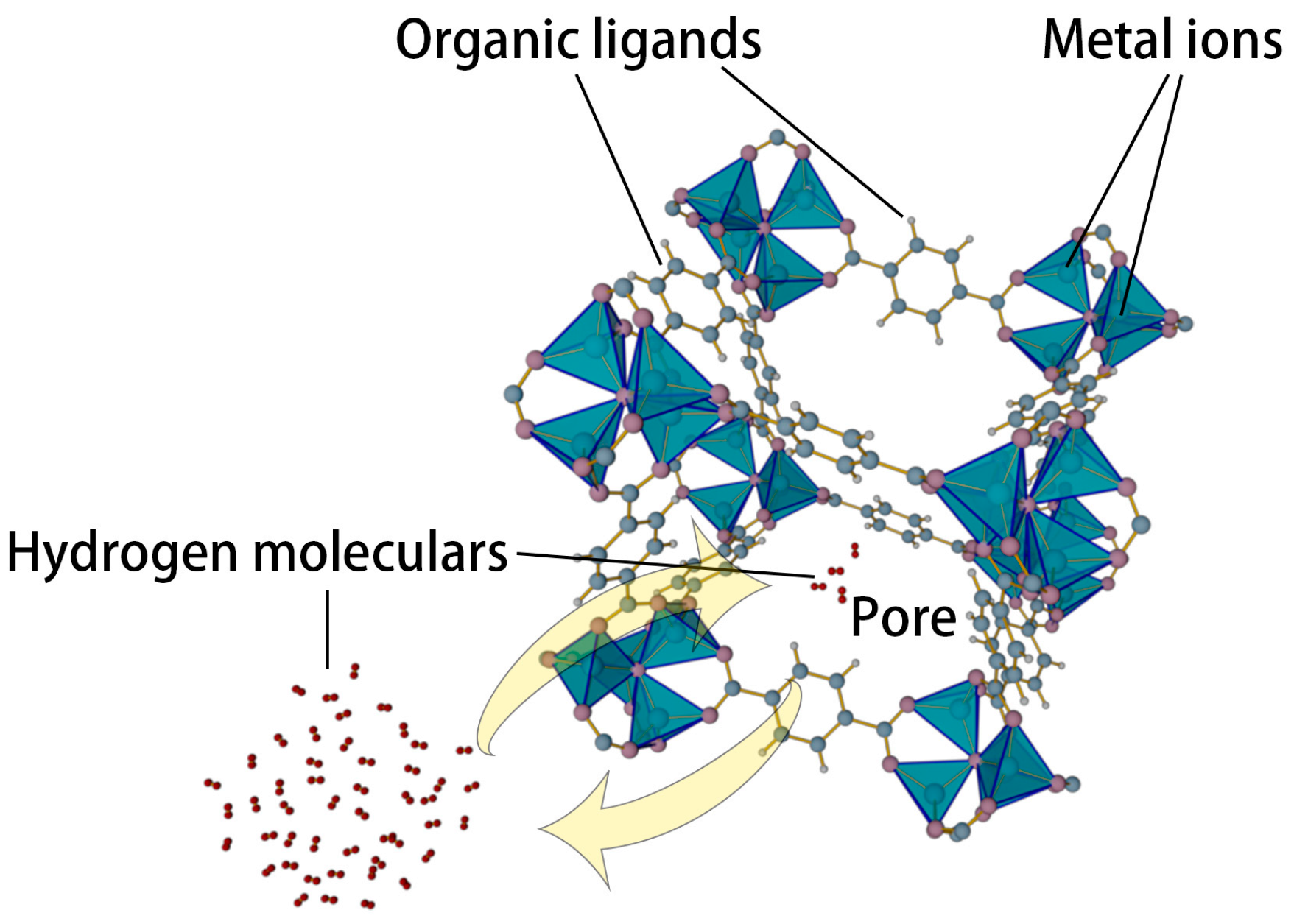

2.6. Metal–Organic Framework Hydrogen Storage

Metal–organic framework materials (MOFs) are porous materials with a periodic network structure formed by the assembly of metal ions and organic ligands through coordination interactions. In MOFs, metal ions typically serve as nodes or central points, while organic ligands generally function as linkers. They possess a larger specific surface area (shown in

Table 3) and higher porosity compared to traditional porous materials. Additionally, the presence of organic components in these materials allows for designability, tailorable properties, adjustable pore sizes, and facile surface functionalization.

While MOFs have been extensively studied for gas storage, their application in hydrogen storage still faces challenges. The principle behind using MOFs for hydrogen storage lies in their highly porous structure, which enables the adsorption and storage of hydrogen molecules. MOFs typically possess a large number of micropores and mesopores, providing a high specific surface area that enhances the contact between hydrogen molecules and the MOFs, facilitating hydrogen adsorption.

The hydrogen storage mechanism in MOFs can be categorized into physical adsorption and chemical adsorption. Physical adsorption primarily relies on intermolecular forces, and hydrogen molecules interact with the surface of MOF materials through van der Waals forces, getting adsorbed and stored in the pores. Chemical adsorption is achieved through chemical bonding, which involves electron sharing or electron transfer, similar to chemical reactions. Therefore, chemical adsorption generally exhibits stronger bonding forces compared to physical adsorption. The simple mechanism of hydrogen adsorption and desorption is shown in

Figure 8.

To enhance the hydrogen storage performance of MOFs, researchers have explored various improvements. Pressure and temperature have significant effects on MOFs, and, within a certain range, lower temperatures and higher pressures can increase the hydrogen storage capacity [

78].

Table 4 shows the characteristics of different MOFs [

78]. Additionally, altering the choice of metal ions or organic ligands in MOFs can influence their hydrogen storage performance. Furthermore, researchers have also attempted surface modifications, doping, or structural designs to improve the hydrogen storage properties of MOF materials [

79]. Compared to other hydrogen storage methods, MOFs have also demonstrated their hydrogen storage capabilities. Jaramillo et al. [

80] achieved densities greater than that achievable with CGH

2 at 70 MPa using vanadium (II)–dihydrogen complexation in the V

2Cl

2.8 (btdd) framework. The economic feasibility of utilizing MOFs in hydrogen fuel cells has also been verified [

81]. Generally, the application of moderate pressure and temperature conditions holds great promise for enhancing hydrogen storage in MOFs. Molecular simulations can be utilized to predict, design, and discover new MOFs. Additionally, high-throughput computational screening and machine learning are extensively applied, significantly aiding the development of hydrogen storage in MOFs [

82].

2.7. Energy Density

We have summarized the energy densities of the primary hydrogen storage methods/materials mentioned above, as shown in

Table 5.

Pure hydrogen exhibits a significant advantage in terms of gravimetric energy density, outperforming other storage methods by a factor of 5 to 15. However, due to the intrinsic properties of hydrogen, both compression and liquefaction require substantial energy consumption, which undermines the very purpose of utilizing hydrogen as an energy source. To address this issue, alternative storage methods must be investigated. Although the inclusion of carriers substantially reduces the gravimetric energy density, it markedly improves the volumetric energy density and significantly lowers the energy consumption during the storage process. This approach is likely to become the predominant direction for hydrogen storage development in the future.

3. Transportation of Hydrogen

In addition to hydrogen storage, hydrogen transportation plays a crucial role in the entire hydrogen supply chain. As the demand for hydrogen varies from region to region, the primary consideration for hydrogen transportation is cost. Furthermore, due to the complex physicochemical properties of hydrogen, any process involving hydrogen requires careful handling. Hydrogen transport takes place in less stable environments than storage, and safety concerns also need to be considered.

Given the diverse properties of hydrogen in different states, it is important to carefully select the appropriate transportation methods that align with these characteristics. In this regard, we can draw inspiration from hydrogen storage and make appropriate improvements to the transportation processes. Hydrogen is transported in three main ways, by road using trucks and trailers, by pipeline, and by large vessels. Rail transport is also considered a form of road transportation. Due to its similarities with truck trailer transport in terms of hydrogen transportation principles and economic effects, it will not be separately discussed. Primary hydrogen transport modes and process models are shown in

Figure 9. Some novel and cost-effective methods are also being investigated. Hunt et al. [

83] has investigated balloon hydrogen transportation. Genovese et al. [

84] studied the economic feasibility of hydrogen transportation by marine pipeline.

3.1. Road Transportation

Due to the limited load and capacity of trucks and trailers, two factors have a significant impact on the cost and energy consumption of transportation: the proportion of hydrogen in the total payload of a vehicle and the energy density. At present, the mainstream direction of road transportation is to maximize the hydrogen storage capacity per unit volume and reduce the weight of the tank. However, in the actual commercialization process, it is more important to consider reducing costs.

For high-pressure transportation, hydrogen is transported through trucks or trailers using gas cylinders under pressure in the range of 20 to 50 MPa. It is more common to use Type 1 or Type 2 tanks (

Table 1) with storage pressures below 30 MPa. Horizontal hydrogen storage tanks are typically placed together on trucks or trailers, while vertical hydrogen storage tanks (hydrogen cylinders) are packaged and secured in metal frames before being placed on trucks or trailers.

Figure 10 shows the process of transporting CGH

2 [

85].

In most cases, it is considered highly desirable for the weight of hydrogen to constitute 2% of the total payload weight, but, for practical commercial applications, hydrogen needs to make up 10 to 15 percent of the total payload weight [

86]. To increase the amount of transported hydrogen, lighter tank materials that can operate at higher pressures should be manufactured. Type 3 (30–70 MPa) and Type 4 (>70 MPa) will also be gradually applied in transportation. The filling and venting processes of high-pressure hydrogen tanks require special attention. Temperature and pressure variations should not occur too rapidly and should be controlled within appropriate ranges to prevent hazardous situations.

As mentioned earlier for liquid hydrogen storage, for low-temperature liquid hydrogen, the tank structure usually consists of a double-walled container, where the inner wall is used to store LH

2 and the outer wall provides insulation and protection. The inner wall is typically made of materials such as stainless steel or aluminum alloy to ensure the sealability and corrosion resistance of the LH

2. The outer wall is composed of insulation materials and protective layers to minimize heat transfer and external environmental effects. When transporting LH

2 tanks, it is essential to securely fasten them to prevent tank movement and collisions. Adequate protective measures, such as protective covers or structures, should be employed to safeguard the tanks from external damage. In the LH

2 transportation mode shown in

Figure 11 [

87], we can see a similar structure.

As previously mentioned, cryogenic liquid hydrogen can achieve a higher energy density, allowing for a greater amount of hydrogen to be transported compared to CGH

2 trailers (approximately 10 times). A cryogenic LH

2 trailer can carry 50,000–60,000 L, equivalent to 4000 kg of hydrogen in a single trip. Therefore, the cost of transporting LH

2 is significantly lower than the cost of transporting CGH

2. Currently, evaporation in the hydrogen liquefaction process causes a high hydrogen loss rate (~1–5%) [

88], significantly increasing the overall cost. Additionally, the evaporation or boil-off of LH

2 results in the loss of stored hydrogen. If the total transportation distance is long enough, LH

2 transport can offer better economic benefits. On the other hand, if the total transportation distance is short, CGH

2 would be more economical.

3.2. Pipeline Transportation

In comparison to road transportation, pipeline transportation represents a more cost-effective method for transporting substantial volumes of hydrogen gas [

89]. If hydrogen energy is to become a viable alternative to fossil fuels in the future, the construction of large-scale hydrogen pipeline infrastructure is essential [

90]. However, the existing dedicated hydrogen pipeline infrastructure is relatively small in scale and primarily operated by large commercial hydrogen suppliers. These pipelines are predominantly dedicated industrial pipelines supplying hydrogen to refineries and chemical plants.

Figure 12 shows the schematic diagram of hydrogen transportation by pipeline [

91].

LOHC technology offers the feasibility and benefits of utilizing existing oil and gas pipelines for transportation. This is primarily due to its physical properties, which are similar to traditional liquid hydrocarbons like crude oil and refined products, allowing it to remain liquid at ambient temperature and pressure and ensuring safe transport. The current network of oil and gas pipelines and associated infrastructure, such as pumping stations and storage facilities, can be directly used for LOHC transportation without significant modifications. This greatly reduces the high costs associated with constructing new, dedicated hydrogen pipelines. Moreover, LOHC can be transported in its hydrogenated state through these pipelines to the destination, where it can release hydrogen through a dehydrogenation process, and the carrier can be recycled and reused. Utilizing existing oil and gas pipelines for LOHC transport enables the long-distance and large-scale distribution of hydrogen, significantly cutting down infrastructure construction and maintenance costs. This approach enhances transport flexibility and economic efficiency, thereby accelerating the widespread adoption and application of hydrogen energy.

The proposal of blending hydrogen gas with natural gas and transporting it through natural gas pipelines has also received significant attention [

92]. However, unlike the direct compatibility of LOHC, hydrogen–natural gas blending requires certain modifications to the existing pipelines. This is because hydrogen molecules are smaller than natural gas molecules, which can lead to pipeline material embrittlement and an increased risk of leakage. Therefore, blending requires material upgrades, improvements in sealing, and adjustments in pressure management, making the modifications more complex and costly. Theoretically, natural gas and hydrogen should be in a completely blended state during transportation. However, in reality, significant variations occur due to the differences in their physical properties. Blended gas tends to stratify, particularly at lower speeds, higher pressures, lower temperatures, and higher hydrogen blending volume fractions. Additionally, stratification is more likely to occur in upstream sections of pipelines compared to downstream sections [

93]. The concentration gradient resulting from stratification can lead to a dangerous concentration of hydrogen gas, accompanied by significant safety hazards. At the same time, the accumulation of hydrogen gas can intensify localized hydrogen embrittlement (HE) failure [

94] and reduce the service life of pipelines.

The United States and Europe were the first to establish and deploy hydrogen pipeline networks. Currently, the total length of hydrogen transportation pipelines worldwide exceeds 5000 km, with the United States having the largest number of hydrogen pipelines, totaling over 2700 km. Europe’s hydrogen transportation pipeline networks have also reached 1770 km. China’s total length of hydrogen transportation pipelines is approximately 400 km [

95].

3.3. Seaborne Transportation

Generally, hydrogen is transported domestically through two mainstream methods: pipeline transportation and road transportation. However, long-distance overseas transportation of hydrogen is usually carried out by ocean vessels. Similar to the common transportation of petroleum and liquefied natural gas, the physical and chemical storage of LH

2 has economic benefits for long-distance overseas transportation due to its small footprint and the completeness of transportation infrastructure [

96]. In addition to traditional transportation of LH

2, LOHCs and MOFs are also considered in overseas transportation for the future. For the current stage, the challenge of transporting LH

2 lies not in the distance of transportation but in the complexity of storage. Compared to CGH

2, LH

2 has a higher density of 71 kg/m

3 and an energy content of up to 2.4 kWh/L. Aside from its significant liquefaction energy requirements, a major disadvantage of LH

2 transportation is that it occurs at a temperature of 20 K. This necessitates the use of specialized cryogenic containers to maintain low temperatures and ensure safety [

97]. The world’s first LH

2 carrier, the Suiso Frontier, was involved in a fire accident [

98].

Transporting LH2 faces the challenge of boil-off gas (BOG), where heat causes some hydrogen to vaporize, increasing tank pressure. To address this, for hydrogen carriers, researchers are exploring the use of BOG as fuel, which reduces waste, improves energy efficiency, and lowers costs. The BOG capture and management system collects vaporized hydrogen during transport and stores it in high-pressure tanks. This BOG can then be used in fuel cell systems or hydrogen internal combustion engines.

Fuel cell systems convert BOG into electricity through electrochemical reactions, providing power to the ship. For example, NYK Line and Kawasaki Heavy Industries have used fuel cells on the “Suiso Frontier” to generate auxiliary power from BOG [

99]. Improvements in power density and materials have enhanced fuel cell efficiency and lifespan. Hydrogen internal combustion engines burn BOG to produce mechanical power. Companies like MAN Energy Solutions and Caterpillar are developing these engines, optimizing combustion, using durable materials, and implementing advanced emission controls to boost efficiency and meet environmental standards.

For countries importing renewable energy, seaborne transportation is a very important option. Compared with long-term utilization and high dependence on natural gas pipeline networks, different countries seek more flexible options (e.g., Australia to Japan and Algeria to Spain and Portugal).

Figure 13 shows a schematic diagram of the utilization of hydrogen transported by sea to land [

100]. In addition, due to safety, economic, and end-use compatibility concerns, the use of mixed hydrogen/natural gas pipeline transportation is limited. Different countries have different advantages and disadvantages. For example, in Asia and Europe, some countries have abundant energy resources and geographical advantages, while others have high technological and economic capabilities. The two can complement each other. Therefore, if an international hydrogen transportation system is established, it can solve the energy problem for both sides and even countries along the route [

101].

4. Transportation Costing Assessment

The global long-distance trade of clean hydrogen is expected to accelerate significantly by 2030, reaching an estimated 18 million tons per year [

102]. Given the global landscape that hydrogen now faces, there is an urgent need for a detailed economic analysis of hydrogen systems, focusing on changing levelized costs and the impact of technological innovations.

The life-cycle cost (LCC) is used here to assess hydrogen transportation. In addition, the economic analysis used in this study is based on the LCC of hydrogen transport from a builder’s perspective.

The overall LCC of hydrogen transport is measured as a net present value cost evenly distributed per kilometer (km), as shown in Equations (2) and (3):

where

LCC,

Ca, Cp,

Cc,

Cs,

Ct, and

Cd represent transport cost per kilometer in the whole life cycle, total annual cost, sum of all costs, compression process cost, storage cost, transport cost, and distribution terminal cost, respectively.

M is the proportion of annual maintenance cost to total cost,

T is the life cycle of the project in years, and

r is the discount rate, which calculates the present value of future costs. According to the above formulas, the present value of the total cost of hydrogen transportation can be obtained in this study, and we can use this result as an indicator to evaluate the economic feasibility of hydrogen transportation solutions.

Pipeline transportation is a good solution for long-distance H

2 transportation [

103]. One major advantage of pipeline transportation is the ability to refurbish existing natural gas pipelines to transport LOHC and even pure hydrogen gas [

90]. Generally speaking, the pressure of hydrogen gas decreases after passing through pipelines, and it needs to be re-compressed at regular intervals. The specific data for the pipeline are shown in

Table 6. Due to the continuous maintenance of compression devices and pipelines, it is assumed that 5% of the gross revenue of the CGH

2 transported by the pipeline each year is used for maintenance work [

104].

Table 7 lists data about tank type, volume, weight, and storage capacity. Truck transportation of hydrogen gas is generally divided into two types: CGH

2 and LH

2, with a common feature being that they all need to be compressed before loading. The energy consumed by compression mainly depends on the state of hydrogen gas, such as pressure, temperature, etc., among which, the main factor is pressure. Generally speaking, compressing 1 kg of hydrogen gas to 20 MPa requires 0.7 kWh of electricity, and compressing to 25 MPa requires 0.9 kWh/kg of electricity [

105]. The electricity it requires mainly comes from the public power grid. In addition, when CGH

2 is discharged from the steel cylinder, there is still a small amount of residual hydrogen gas in the transportation unit, accounting for approximately 5% [

106]. Therefore, these can reduce the net content required for transporting hydrogen gas.

In summary, approximately 1000 kg of CGH2 can be transported to the refueling station during each transportation. If we use a hydrogen demand of 1200 kg/day, we need to transport hydrogen at least twice a day to ensure the smooth operation of the supply chain.

There are two types of liquefied hydrogen transportation by truck: LH

2 and LOHCs. However, the use of LOHCs to transport hydrogen to a destination requires further processing and is nearly devoid of commercialization and application. The current international push for LOHC transport comes from Europe’s Orion Project, which aims to achieve a huge annual capacity of 32 TWh of low-carbon and renewable hydrogen and has the longest project duration, until 2050 and beyond [

107]. The estimated LH

2 quantity for each transportation supply task is approximately 4000 kg. The transportation capacity of a truck is 4500 kg of LH

2, of which approximately 5% of the capacity cannot be fully utilized [

108]. A standard hydrogen refueling station needs to provide 1200 kg of hydrogen gas per day approximately every two to three days. To investigate this, we set the distance from the hydrogen production plant to the hydrogen refueling station as 100 km. The truck left with a full load and, when it returned, the fuel tank was empty. In each case, the vehicle under consideration was a 40-ton freight truck that met Euro 5 emission standards [

86]. We calculated the transportation cost of LH

2 based on the above data. In this study, we used a capacity of 1200 kg for all fueling stations. The amounts of hydrogen that can be transported in a single trip by different means of transportation are listed in

Table 8.

5. Result Analysis and Discussion

Due to the different constraints of different modes of transportation, we divided the modes of transportation into two categories: short distance and long distance. At the same time, for the convenience of comparison, the hydrogen source was uniformly set as low-carbon and renewable hydrogen, and the average production cost was 4.36 USD/kg, which was within the predicted range [

111]. Based on this, we calculated that the hydrogen LCC value for the period 2030–2050 would fluctuate in the range of 30.23–52.9 USD/kg, which includes all the hydrogen transport modes we discussed above.

The transportation of CGH2 uses trucks, and the cost of transportation increases significantly with distance. When the transportation distance is 50 km, the transportation cost of hydrogen is 0.75 USD/kg. As the transportation distance increases, the cost of long-tube trailer transportation gradually increases. When the distance is 500 km, the transportation cost reaches 2.80 USD/kg. Considering economic issues, long-tube trailer transportation of CGH2 is generally suitable for short-distance transportation within 200 km.

Based on the above data, it can be estimated that the cost of hydrogen transportation for a hydrogen refueling station with a capacity of 500 kg/d and a distance of 100 km from the hydrogen source point is 1.89 USD/kg. The cost changes of LH2 tankers are not sensitive to distance. When the distance between the hydrogen refueling station and the hydrogen source point is 50–500 km, the transportation price of LH2 tankers increases slightly within the range of 1.88–1.95 USD/kg. Although transportation costs increase with distance, the increase is not significant. This is because the electricity consumption for liquefaction, which accounts for the largest proportion of the cost (about 60%), is only related to the hydrogen load, not the distance. The oil and road tolls that are positively correlated with distance account for a small proportion, so LH2 tankers have a cost advantage in long-distance transportation.

For seaborne transportation, we set the starting point in Shanghai, China, and the destinations as far away as Los Angeles, U.S. (10,893 km) and as close as Incheon, South Korea (908 km) [

112]. The final result was obvious. Seaborne transportation is the most ideal way to transport hydrogen, even for the trip to South Korea, where the cost of transporting hydrogen was only 0.0009 USD/kg/km. However, due to geographical factors, seaborne transportation is more cost-effective for large-scale, long-distance transnational and transoceanic transport, while pipeline transportation is cheaper for domestic long-distance hydrogen transportation (more than 100 km) [

113]. Although our data show that road transportation costs are higher than pipeline transportation, this was calculated by ignoring time and demand costs. In short-term supply, truck transportation is the most economical choice. Our final results are within the range of those obtained by the International Energy Agency using the levelized costs [

114].

Table 9 shows the cost of different hydrogen transportation modes, which has certain reference significance for our calculation results.

6. Challenges and Future Perspectives

Compressed gaseous hydrogen storage, commonly used in hydrogen FCVs, faces several key challenges. These include safety concerns due to high pressures, material limitations such as hydrogen embrittlement and corrosion in metallic tanks, and the high cost of advanced materials like carbon fiber composites used in Type 3 and 4 tanks. The complex refueling process also poses risks, requiring the careful management of temperature and pressure to ensure safety. Infrastructure development is another significant barrier, with a limited number of refueling stations capable of handling high-pressure hydrogen. Expanding this infrastructure is crucial for the broader adoption of FCVs. Despite these challenges, there are promising prospects. Advances in materials science could lead to safer and more cost-effective storage solutions, such as the development of Type 5 linerless carbon fiber composite tanks. Innovations in refueling technology, like pre-cooling hydrogen and advanced monitoring systems, can improve safety and efficiency. Standardization and regulation can help ensure consistent safety and reliability across the industry. Investing in infrastructure and ongoing research is essential. By addressing these challenges, compressed gaseous hydrogen storage can become a more viable and widespread technology, significantly contributing to the global energy transition and efforts to mitigate climate change.

LH2 storage faces several significant challenges. Maintaining LH2 at cryogenic temperatures requires excellent insulation, but keeping the vacuum environment intact over long periods can be difficult, leading to increased heat transfer and boil-off losses. Materials used for LH2 storage must retain mechanical properties at low temperatures, resist corrosion, and withstand pressure differences. Stainless steel, aluminum alloys, and nickel alloys are commonly used, but each has trade-offs in terms of weight, cost, and strength. Developing high-performance materials that are cost-effective remains a challenge. Additionally, active thermal protection technologies aimed at zero boil-off storage are costly and currently limited to space applications. The infrastructure for large-scale LH2 storage and transportation is underdeveloped, particularly in the civilian sector, necessitating significant investment and technological advancements. Despite these challenges, the future of LH2 storage holds promise. Research into new insulation materials can enhance the efficiency and reliability of thermal protection systems, reducing boil-off and energy losses. Advances in materials science could lead to the development of new materials with better strength-to-weight ratios and superior low-temperature mechanical properties, with titanium alloys showing particular promise. Innovations in active thermal protection technologies, such as embedded cryogenic heat pipes, heat exchangers, and broad area cooling shields, could make zero boil-off storage more feasible and cost-effective beyond space applications.

Organic liquid hydrogen storage presents several notable challenges. Ammonia, with its high hydrogen content and established storage systems, faces hurdles due to its endothermic decomposition process, which demands high temperatures and noble catalysts. While some non-precious metals have been developed to facilitate reactions at lower temperatures, they are not yet as effective or stable. For LOHCs, the high temperatures and pressures required for hydrogenation and dehydrogenation complicate the process and increase costs. Additionally, reactions like toluene hydrogenation produce toxic by-products, raising sustainability and safety concerns. The efficiency of LOHCs is heavily influenced by the specific organic liquid and catalytic processes, and challenges persist in optimizing catalysts to achieve higher efficiency and CO tolerance. Specific LOHCs such as 18H-DBT and 12H-NEC show promise but face issues related to incomplete hydrogenation/dehydrogenation and the need for high-temperature and pressure operations. The development of effective and stable catalysts, such as platinum-based catalysts for dibenzyltoluene, is crucial. Additionally, safety and economic viability concerns must be addressed for these carriers to be practical. The future of organic liquid hydrogen storage hinges on overcoming these challenges through targeted research and development. Efforts are focused on identifying materials that can store hydrogen more densely and exhibit improved kinetics for rapid hydrogenation and dehydrogenation cycles. Developing advanced catalysts that facilitate hydrogen release at lower temperatures is crucial for increasing energy efficiency. The longevity and reusability of LOHCs are also critical, necessitating the discovery of compounds that remain stable over multiple cycles. The development of non-toxic, non-flammable, and environmentally friendly hydrogen carriers is essential for broader adoption, with a focus on optimizing their properties for economic viability in commercial settings.

The development of solid hydrogen storage materials, while promising, is fraught with numerous challenges. One primary challenge is the high hydrogen release temperature of magnesium-based materials, thus demanding significant energy input. This limitation underscores the need for advanced material engineering techniques, such as nano-structuring and catalyst incorporation, to lower these operational temperatures. In the case of NaBH4 and NH3BH3, while they offer a high theoretical hydrogen storage capacity and stability at room temperature, their practical application is hindered by complex hydrogen release mechanisms that require high temperatures and pressures, as well as intricate recycling processes of their by-products. Future research must focus on enhancing the thermodynamic and kinetic properties of NaBH4 and NH3BH3 through innovative strategies like nanoengineering, chemical modifications, and the introduction of destabilization additives. The integration of catalytic systems will be crucial in improving hydrogen release rates and lowering operational costs. The overarching goal for future research and development in solid hydrogen storage materials is the identification and optimization of materials that offer both high hydrogen storage capacity and safety with non-toxic characteristics. Emphasis should be placed on reducing desorption temperatures and enhancing decomposition rates through advanced catalysis, doping, and microstructural modifications. Furthermore, refining the recycling processes is paramount to lowering overall costs and improving the sustainability of these technologies. Innovative approaches such as the use of novel composite materials, the exploration of low-cost and abundant elements, and the application of state-of-the-art material synthesis techniques will drive progress in this field. For instance, the development of eutectic melting composites and their infiltration into carbon aerogel scaffolds has shown promise in improving hydrogen desorption kinetics and reducing decomposition temperatures. Such interdisciplinary methodologies, combining materials science, chemistry, and engineering, will be instrumental in overcoming current limitations.

UHS is a promising technology for large-scale hydrogen energy storage, but it faces several challenges. The economic viability of UHS is hindered by high capital costs associated with site selection, construction, and maintenance. Future research should focus on reducing these costs through technological advancements and economies of scale. Advancements in geological screening, sealing materials, and monitoring technologies will be essential to ensure safe and efficient storage. Salt caverns, while chemically stable, require significant infrastructure investment. Hydrogen purity and gas composition are crucial, necessitating advanced separation technologies. Integrating UHS with renewable energy sources can buffer against the intermittency of renewables, and optimizing electrolysis processes will be key. Finally, addressing regulatory and safety concerns through comprehensive frameworks and improved risk assessment models will be essential for the commercial viability of UHS.

MOFs show great promise for hydrogen storage due to their high surface area and tunable properties. However, challenges remain. One key issue is optimizing the balance between physical and chemical adsorption to maximize hydrogen uptake and release efficiency. Future research should focus on selecting and combining metal ions and organic ligands to enhance these interactions. Stability under varying pressure and temperature conditions is another concern. While MOFs perform well at cryogenic temperatures and high pressures, practical applications require effectiveness at ambient conditions. Developing hybrid structures or stronger bonding sites may help achieve this. Surface modifications and doping offer additional pathways to improve hydrogen storage properties. Introducing functional groups or different elements can enhance adsorption capacity and kinetics. Novel functionalization techniques and dopant effects warrant further exploration. Economic feasibility and scalability are also critical. Though cost-effective production and integration into fuel cells have been shown, large-scale synthesis and deployment remain challenging. Research should aim to develop cost-efficient and scalable manufacturing methods. Optimizing adsorption mechanisms, enhancing stability, exploring surface modifications, and addressing economic feasibility are essential steps to advance MOFs as a viable hydrogen storage solution.

For road transportation, future research should focus on advanced composite materials and innovative tank designs. Additionally, optimizing the filling and venting processes to manage temperature and pressure variations will be crucial to prevent hazardous situations. Pipeline transportation offers a cost-effective method for large-scale hydrogen distribution, but it requires substantial infrastructure development. The future outlook involves both expanding dedicated hydrogen pipelines and retrofitting existing natural gas pipelines to accommodate hydrogen. This will necessitate advancements in pipeline materials to prevent embrittlement, as well as improved sealing and pressure management techniques. Moreover, the integration of LOHC technology could leverage existing oil and gas infrastructure, reducing the need for new pipeline construction and enabling safer and more flexible hydrogen transport. Seaborne transportation, especially for long distances, relies heavily on LH2 due to its higher energy density. Future advancements should focus on improving cryogenic container design to minimize BOG losses and enhance safety. The development of efficient BOG management systems, including the use of BOG as fuel for fuel cells or internal combustion engines, will be critical to improving energy efficiency and reducing transportation costs. Additionally, international collaboration on hydrogen transport infrastructure can facilitate the establishment of a global hydrogen supply chain, addressing energy needs across regions with varying resources and technological capabilities.

We anticipate that in the future, compressed hydrogen and liquid hydrogen will remain prevalent due to their application demands. However, their high energy consumption during compression and liquefaction poses a significant challenge. To address this, promising approaches include the development of advanced compression technologies such as isothermal compression and innovative compressor designs, optimizing cooling cycles, and utilizing more efficient refrigerants in liquefaction processes. Additionally, energy recovery and utilization techniques, such as reclaiming waste heat and cold energy, can enhance overall efficiency. Integrating renewable energy sources to power these processes, coupled with smart energy management systems and comprehensive energy systems, further bolsters efficiency improvements.

The emergence of superior hydrogen carriers provides new opportunities for hydrogen storage and transportation. Combining traditional compressed and liquid hydrogen technologies with hydrogen carriers, such as incorporating MOF hydrogen storage materials in high-pressure tanks, can increase storage capacity without further increasing pressure. This approach is particularly promising for applications requiring pure hydrogen. For long-distance, large-scale transportation, more efficient hydrogen carriers entail lower requirements than transporting hydrogen itself, potentially leading to more economical transportation infrastructure designs. The development of pipeline networks can enhance the scale and efficiency of hydrogen transportation while addressing the issue of uneven hydrogen resource distribution.

Hydrogen storage and transportation are pivotal components of the hydrogen supply chain, intricately linked with hydrogen production and utilization. These processes mutually influence and drive each other. Therefore, it is both necessary and forward-thinking to invest significantly in the development of hydrogen storage and transportation technologies.

7. Conclusions

As we survey the research progress and practical applications in the field of hydrogen storage and transportation globally, it is apparent that the potential of hydrogen as a clean energy carrier is being progressively unlocked, alongside technological advancements, innovations, strategic collaborations, and policy support among nations.