Comparison of Pore Structure Characteristics of Shale-Oil and Tight-Oil Reservoirs in the Fengcheng Formation in Mahu Sag

Abstract

1. Introduction

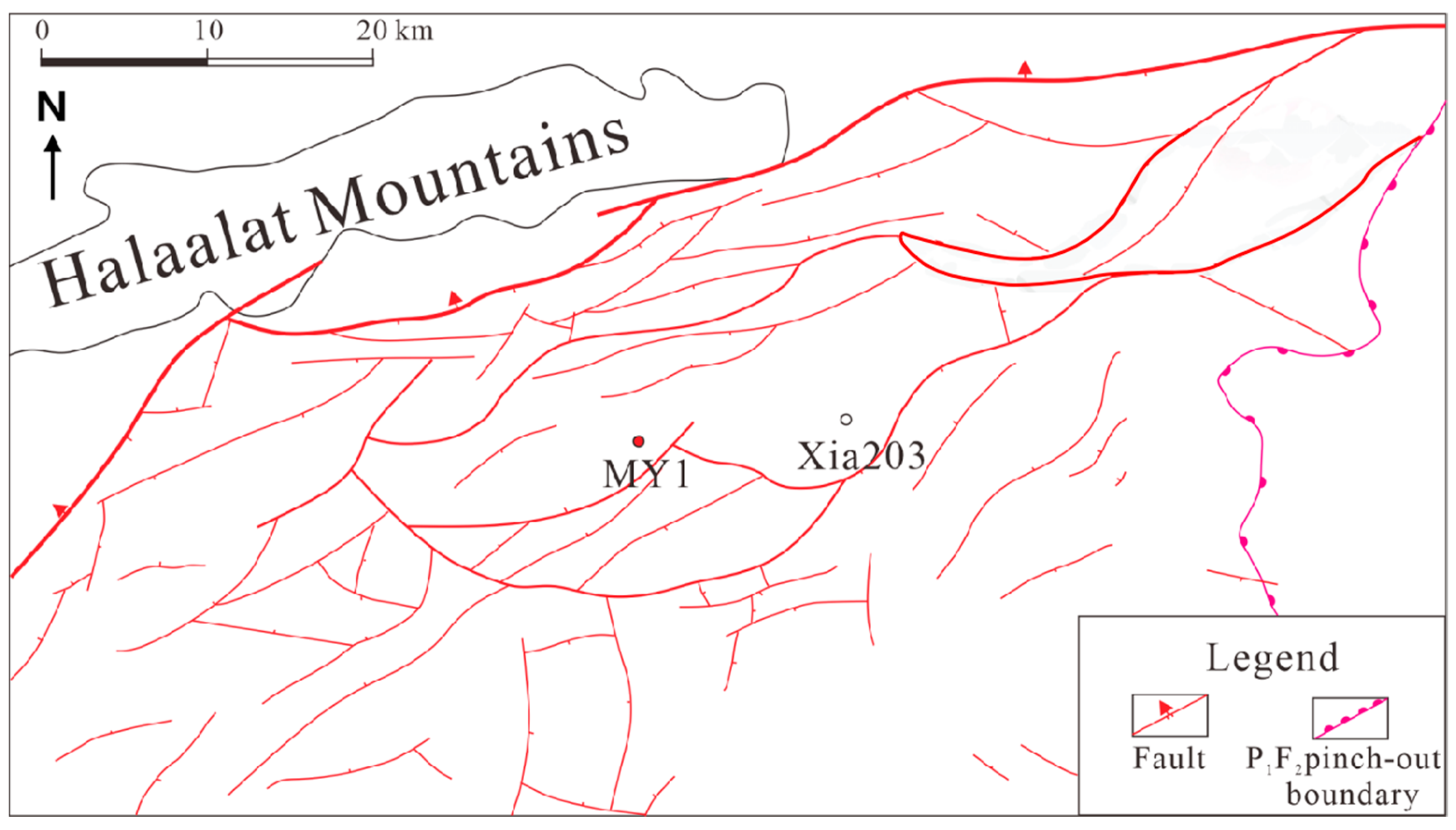

2. Geological Background

3. Samples and Experimental Methods

- (1)

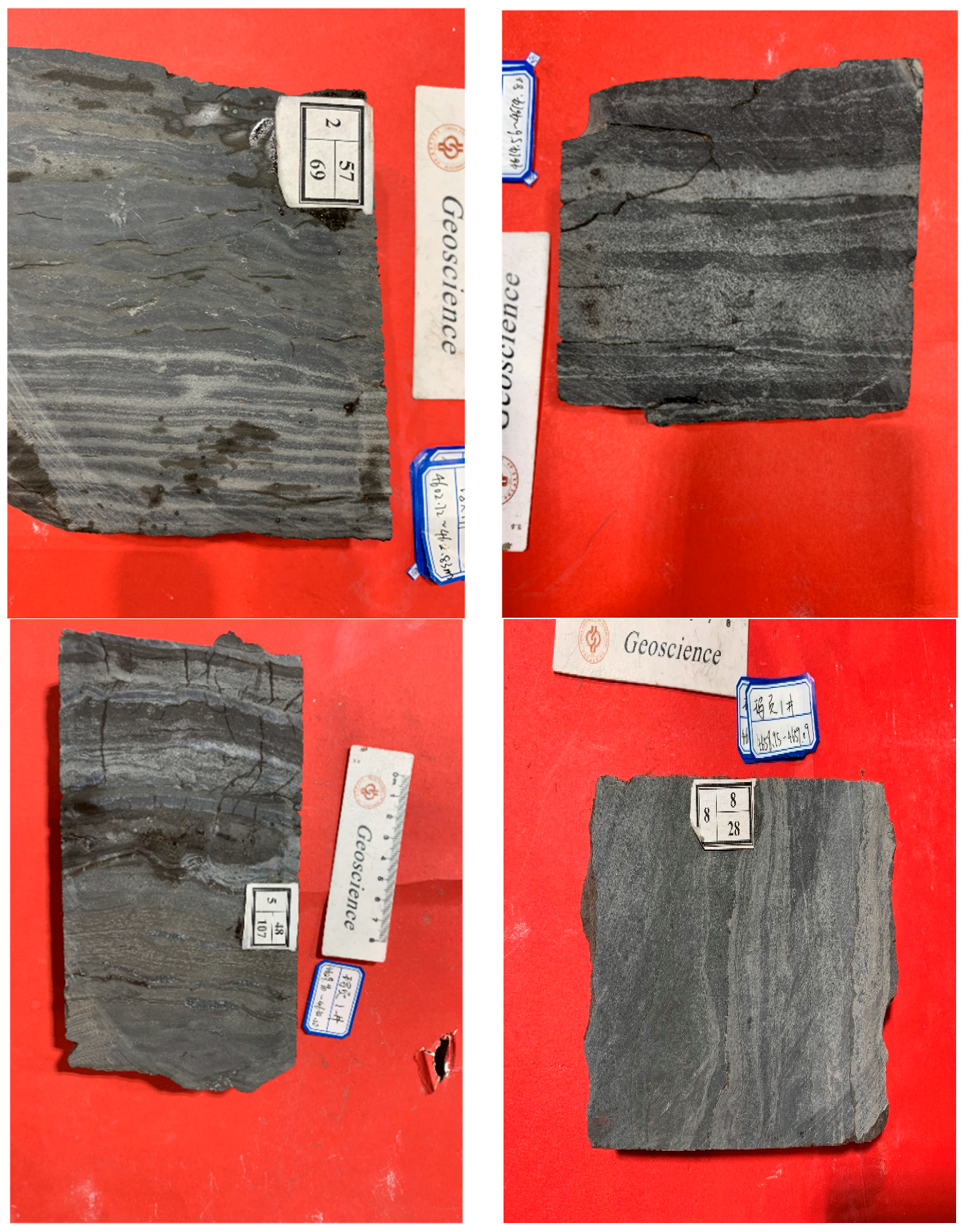

- Samples

- (2)

- X-ray Diffraction

- (3)

- Scanning Electron Microscopy

- (4)

- Low Temperature N2 Adsorption

- (5)

- Mercury Intrusion Capillary Pressure

4. Results and Discussion

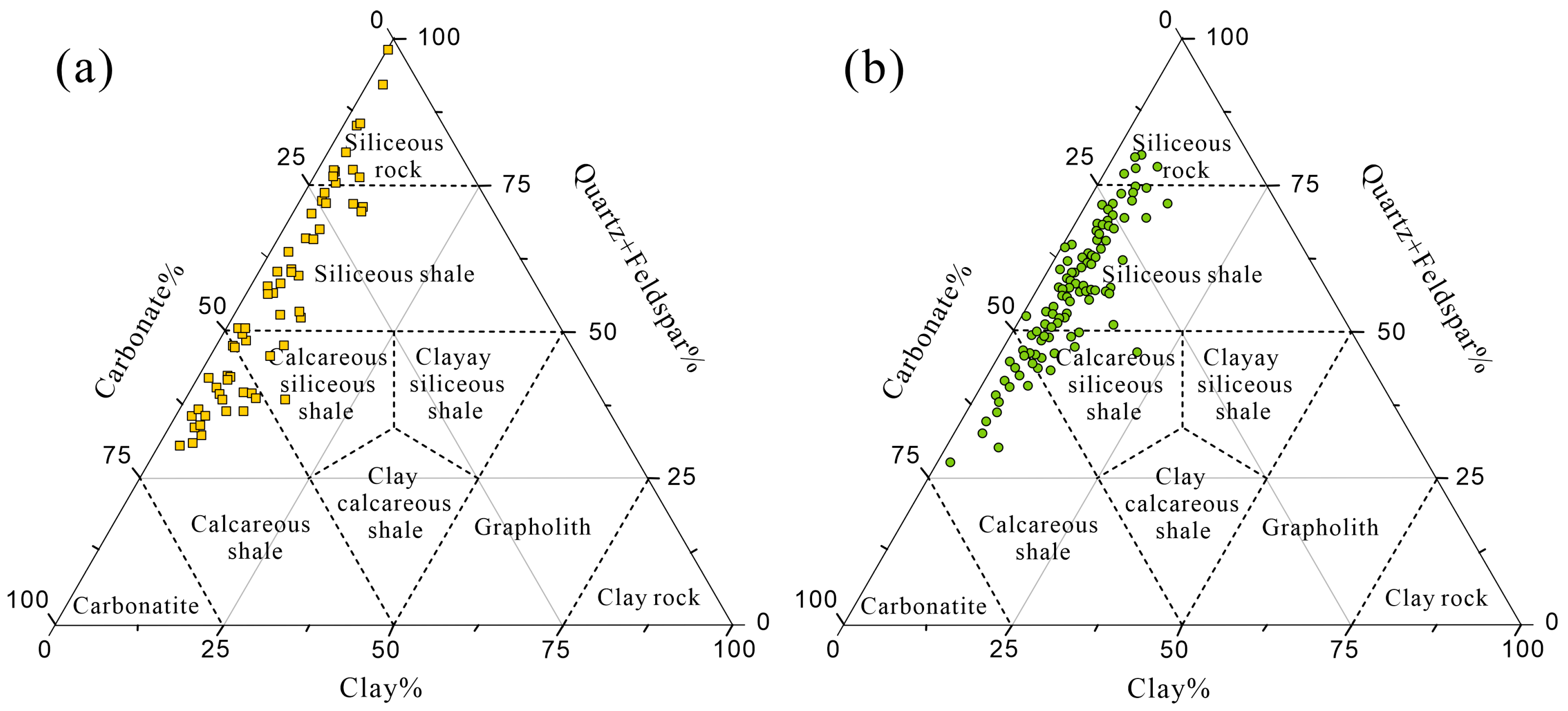

4.1. Mineral Compositions

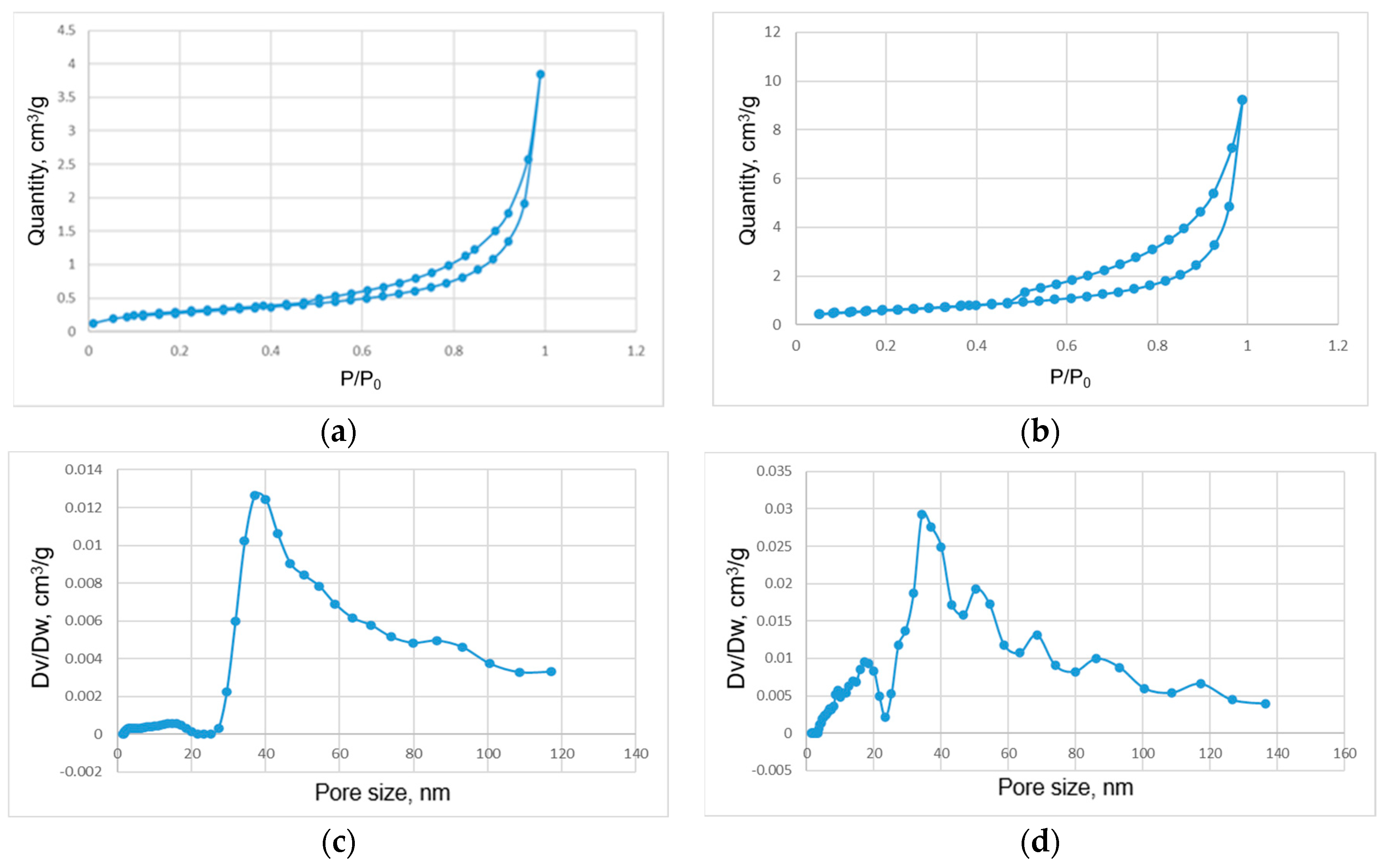

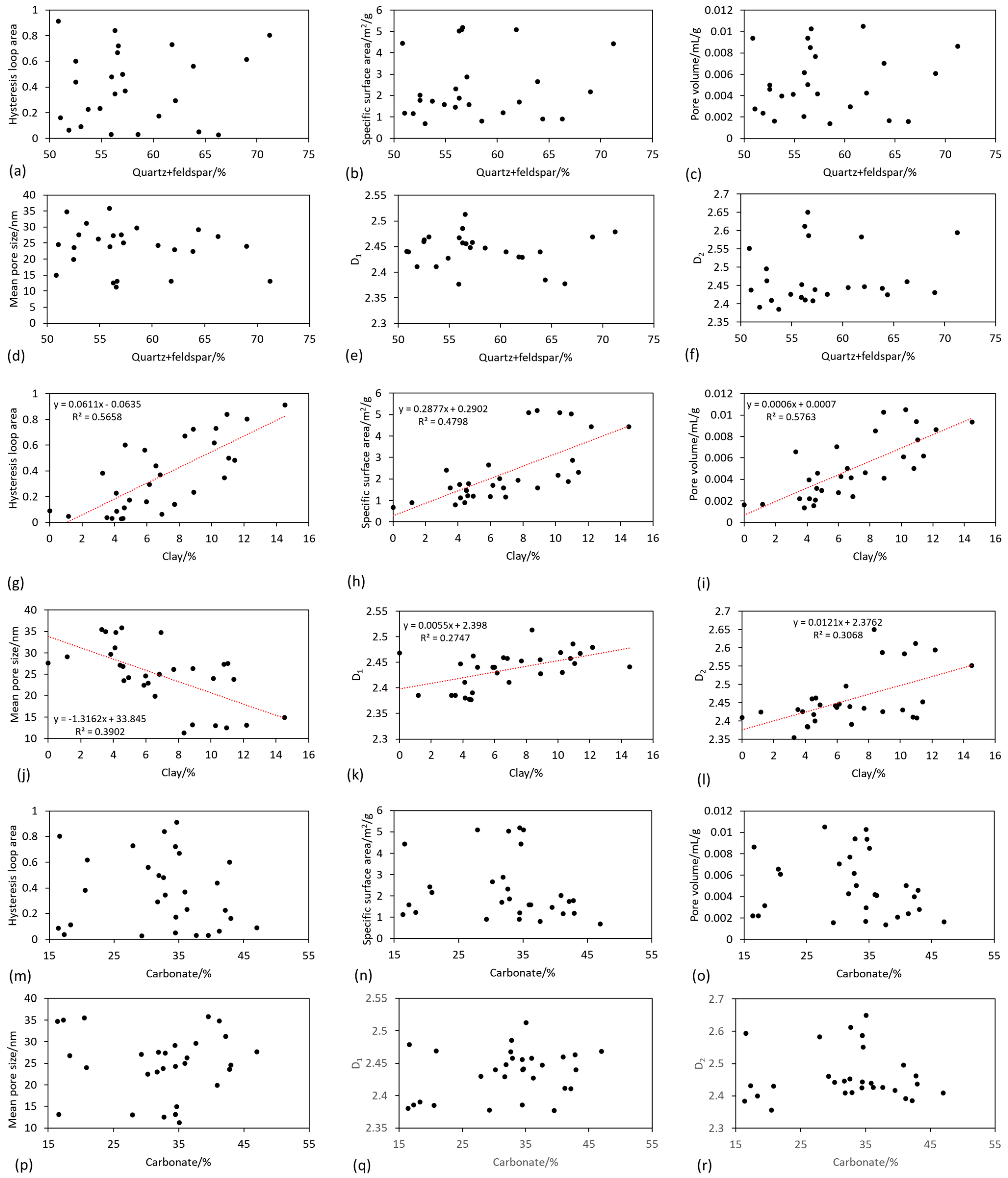

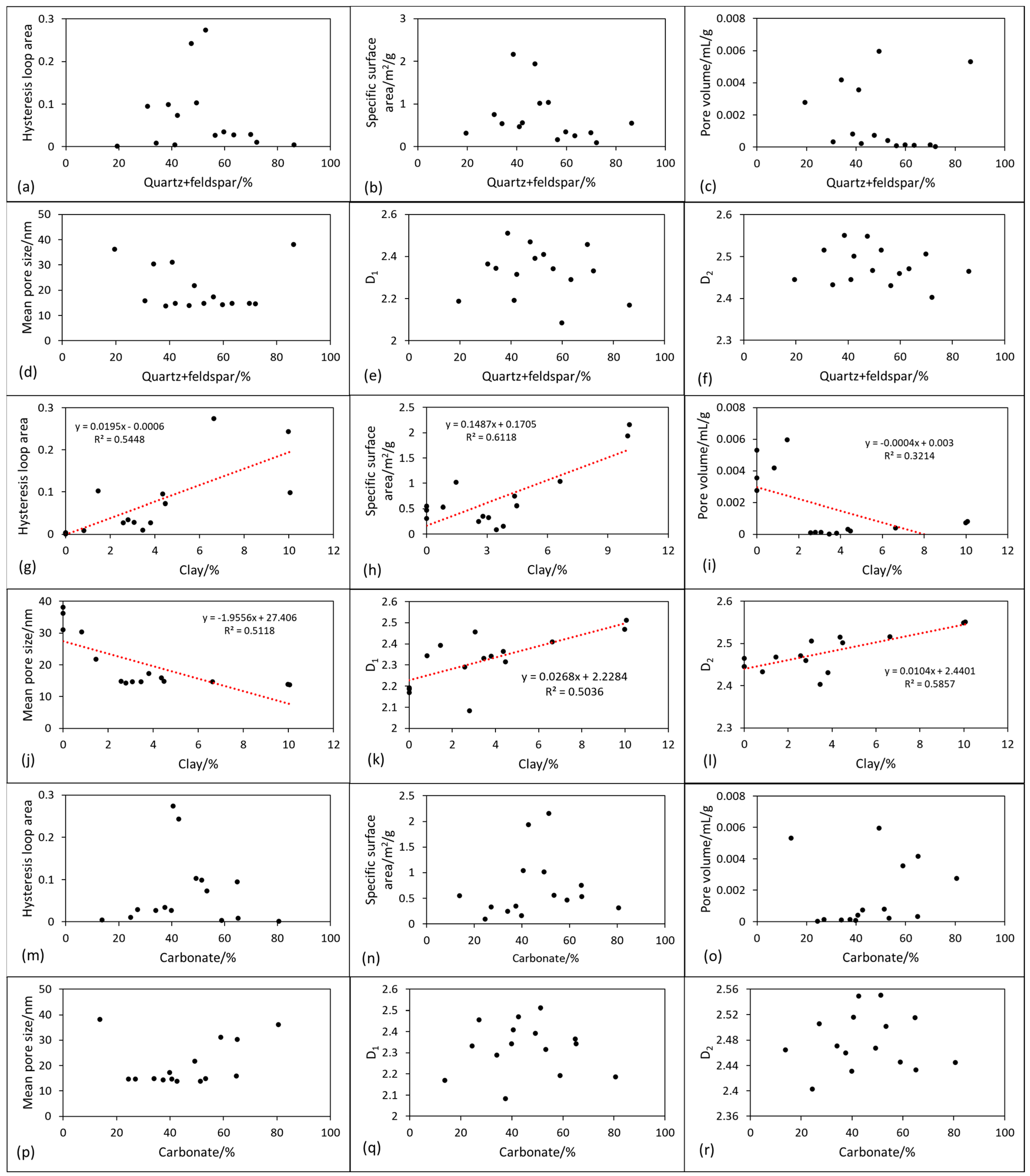

4.2. Pore Structure Comparison from N2 Adsorption Experiment

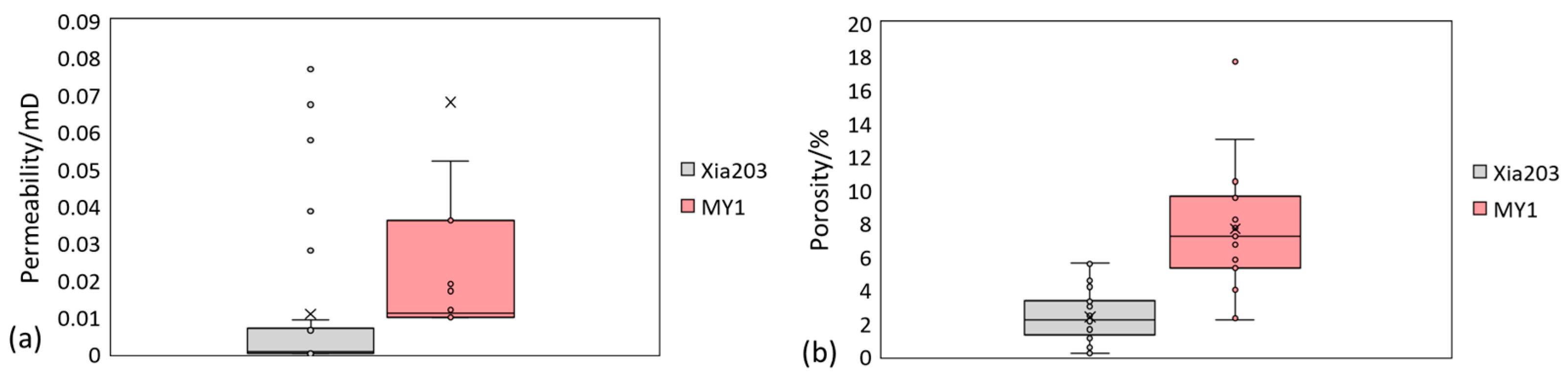

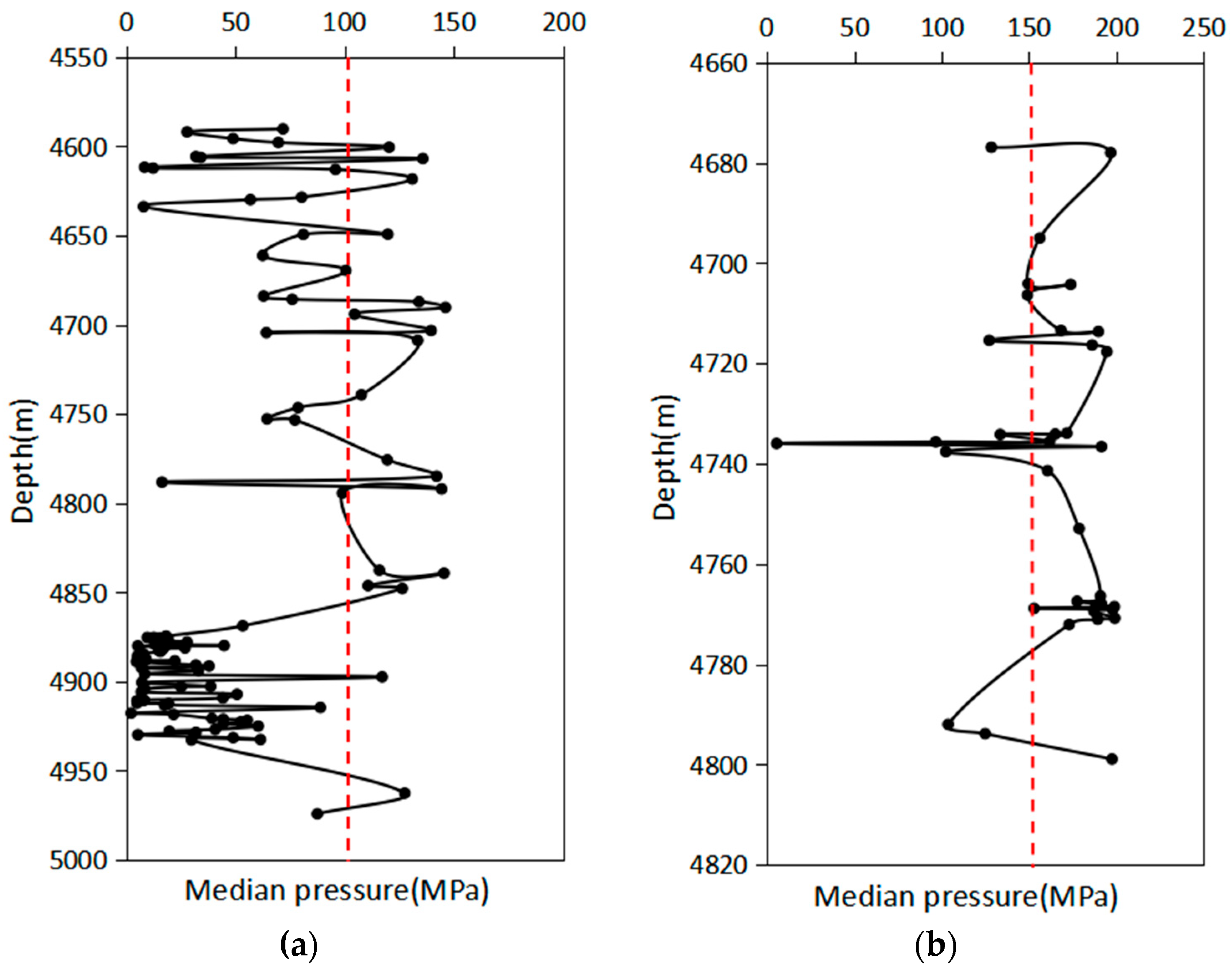

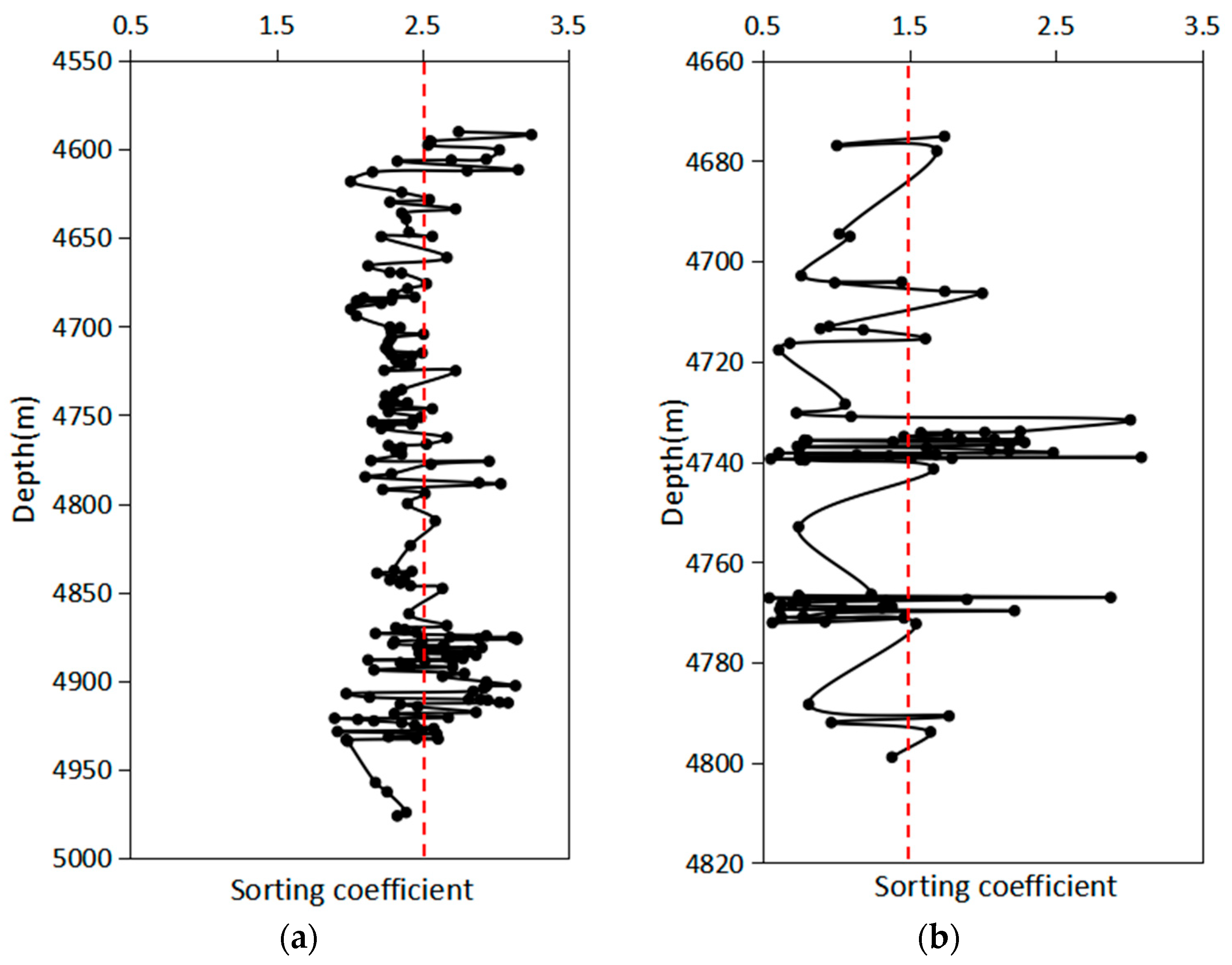

4.3. Pore Structure Comparison from MICP

5. Conclusions

- (1)

- Well Xia 203 and Well Maye 1 in the Fengcheng Formation are primarily composed of quartz, carbonate minerals, and clay minerals. Compared to tight-oil reservoirs, shale-oil reservoirs contain a higher proportion of carbonate minerals.

- (2)

- Regardless of whether it is a tight-oil or shale-oil reservoir, the reservoir samples contain a large number of flat fissures and ink-bottle-shaped pores. The hysteresis loop area, specific surface area, pore volume, average pore diameter, and D1 of Well Xia 203 (tight oil) are higher than those of Well Maye 1 (shale oil).

- (3)

- The permeability of Fengcheng Formation samples of Well Maye 1 is higher than that of Well Xia 203’s samples, with lower displacement pressure, lower median pressure, and higher selectivity coefficient. The superior permeability of shale-oil reservoirs in the Mahu Sag’s Fengcheng Formation compared to tight-oil reservoirs is mainly due to its rich laminated structure. There are significant differences in the storage space between shale-oil reservoirs and tight-oil reservoirs in the Mahu Sag’s Fengcheng Formation. Separate evaluation criteria should be established for shale-oil reservoirs and tight-oil reservoirs in sweet-spot evaluation and other aspects.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jia, C.; Zou, C.; Li, J.; Li, D. Assessment criteria, main types, basic features and resource prospects of the tight oil in China. Shiyou Xuebao/Acta Pet. Sin. 2012, 33, 343–350. [Google Scholar]

- Sun, L.; Zou, C.; Jia, A.; Wei, Y.; Zhu, R.; Wu, S.; Guo, Z. Development characteristics and orientation of tight oil and gas in China. Pet. Explor. Dev. 2019, 46, 1073–1087. [Google Scholar] [CrossRef]

- Zhao, W.; Hu, S.; Hou, L.; Yang, T. Types and resource potential of continental shale oil in China and its boundary with tight oil. Pet. Explor. Dev. 2020, 47, 1–11. [Google Scholar] [CrossRef]

- Yang, H.; Li, S.; Liu, X. Characteristics and resource prospects of tight oil in Ordos Basin, China. Pet. Res. 2016, 1, 27–38. [Google Scholar] [CrossRef]

- Fu, J.; Yu, J.; Xu, L.; Niu, X.; Feng, S.; Wang, X.; You, Y.; Li, T. New Progress in Exploration and Development of Tight Oil in Ordos Basin and Main Controlling Factors of Largescale Enrichment and Exploitable Capacity. China Pet. Explor. 2015, 20, 9–19. [Google Scholar]

- Yao, J.; Deng, X.; Zhao, Y.; Han, T.; Chu, M.; Pang, J. Characteristics of tight oil in Triassic Yanchang Formation, Ordos Basin. Pet. Explor. Dev. 2013, 40, 161–169. [Google Scholar] [CrossRef]

- Bai, X.; Liang, J.; Meng, Q.A.; Peng, J.; Wang, J.; Wang, Y.; Xue, T. Tight Oil Exploration in Northern Songliao Basin. China Pet. Explor. 2015, 20, 44–53. [Google Scholar]

- Huang, W.; Liang, J.; Zhao, B.; Sun, G.; Yang, Q. Main controlling factors of tight oil accumulations in the Fuyu Layer of Cretaceous Quantou Formation in northern Songliao Basin. J. Palaeogeogr. 2013, 15, 635–644. [Google Scholar]

- Lin, T.; Kang, D.; Jiang, L. Geological characteristics and exploration potential of the tight oil in Fuyu oil reservoirs of North Songliao Basin. Pet. Geol. Oilfield Dev. Daqing 2019, 38, 94–100. [Google Scholar]

- Kuang, L.; Yong, T.; Dewen, L.; Chang, Q.; Ouyang, M.; Lianhua, H.; Deguang, L. Formation conditions and exploration potential of tight oil in the Permian saline lacustrine dolomitic rock, Junggar Basin, NW China. Pet. Explor. Dev. 2012, 39, 700–711. [Google Scholar] [CrossRef]

- Kuang, L.; Wang, X.; Guo, X.; Chang, Q.; Jia, X. Geological characteristics and exploration practice of tight oil of Lucaogou Formation in Jimsar Sag. Xinjiang Pet. Geol. 2015, 36, 1. [Google Scholar]

- Pang, H.; You, X.; Hu, T.; Bai, H. Forming conditions and distribution prediction of deep tight reservoir in Junggar Basin: A case study from tight reservoir of Fengcheng Formation in the west slope of Mahu sag. Acta Pet. Sin. 2015, 36, 176. [Google Scholar]

- Li, Q.; Cheng, Y.; Li, Q.; Zhang, C.; Ansari, U.; Song, B. Establishment and evaluation of strength criterion for clayey silt hydrate-bearing sediments. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 742–750. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, F.; Wu, J.; Usman Tahir, M.; Li, Q.; Yuan, L.; Liu, Z. Effect of thickener and reservoir parameters on the filtration property of CO2 fracturing fluid. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 1705–1715. [Google Scholar] [CrossRef]

- Ji, W.; Song, Y.; Jiang, Z.; Wang, X.; Bai, Y.; Xing, J. Geological controls and estimation algorithms of lacustrine shale gas adsorption capacity: A case study of the Triassic strata in the southeastern Ordos Basin, China. Int. J. Coal Geol. 2014, 134–135, 61–73. [Google Scholar] [CrossRef]

- Li, X.; Zhu, H.; Zhang, K.; Li, Z.; Yu, Y.; Feng, X.; Wang, Z. Pore characteristics and pore structure deformation evolution of ductile deformed shales in the Wufeng-Longmaxi Formation, southern China. Mar. Pet. Geol. 2021, 127, 104992. [Google Scholar] [CrossRef]

- Wu, J.; Wu, Q.; Xu, L.; Yang, Y.; Liu, J.; Yin, Y.; Jiang, Z.; Tang, X.; Miao, H. Pore Structure and Migration Ability of Deep Shale Reservoirs in the Southern Sichuan Basin. Minerals 2024, 14, 100. [Google Scholar] [CrossRef]

- Zhou, J.; Yin, C.; Zeng, L.; Hu, C.; Wu, D.; Yu, Z.; Li, W.; Tang, J.; Liu, Y.; Jia, J. Development characteristics of grain shoals and favorable gas exploration areas in the 4th Member of Ordovician Majiagou Formation in the Ordos Basin. Nat. Gas Ind. 2022, 42, 17–30. [Google Scholar] [CrossRef]

- Liu, D.; Guo, J.; Pan, Z.; Du, W.; Zhao, F.; Chen, Y.; Shi, F.; Song, Y.; Jiang, Z. Overpressure evolution process in shale gas reservoir: Evidence from the fluid inclusions in the fractures of Wufeng Formation-Longmaxi Formation in the southern Sichuan Basin. Nat. Gas Ind. 2021, 41, 12–22. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, K.; Wang, Z.; Luo, F.; Zhang, H. Detailed Characterization of Pore Results of Continental Shale Reservoir in Fengcheng Formation, Mahu Sag. ACS Omega 2024, 9, 22923–22940. [Google Scholar] [CrossRef] [PubMed]

- Zhang, P.; Yin, Y.; Lu, S.; Li, J.; Chang, X.; Zhang, J.; Pang, Y.; Chen, G.; Liu, Y.; Li, Z. Insights into Pore Structures and Multifractal Characteristics of Shale Oil Reservoirs: A Case Study from Dongying Sag, Bohai Bay Basin, China. Energy Fuels 2022, 36, 8224–8237. [Google Scholar] [CrossRef]

- Xu, Y.; Lun, Z.; Pan, Z.; Wang, H.; Zhou, X.; Zhao, C.; Zhang, D. Occurrence space and state of shale oil: A review. J. Pet. Sci. Eng. 2022, 211, 110183. [Google Scholar] [CrossRef]

- Guo, X.; Hu, D.; Li, Y.; Wei, Z.; Wei, X.; Liu, Z. Geological factors controlling shale gas enrichment and high production in Fuling shale gas field. Pet. Explor. Dev. 2017, 44, 513–523. [Google Scholar] [CrossRef]

- Ailin, J.; Junlei, W.; Yunsheng, W.; Wenzhi, Z.; Hanqing, Z. Progress in shale gas exploration in China and Prospects for future development. China Pet. Explor. 2020, 25, 31–44. [Google Scholar] [CrossRef]

- Guo, T. Key geological issues and main controls on accumulation and enrichment of Chinese shale gas. Pet. Explor. Dev. 2016, 43, 349–359. [Google Scholar] [CrossRef]

- Ambrose, R.J.; Hartman, R.C.; Diaz-Campos, M.; Akkutlu, I.Y.; Sondergeld, C.H. New Pore-scale Considerations for Shale Gas in Place Calculations. In Proceedings of the SPE Unconventional Gas Conference, Pittsburgh, PA, USA, 23–25 February 2010. [Google Scholar]

- Jiao, K.; Yao, S.; Liu, C.; Gao, Y.; Wu, H.; Li, M.; Tang, Z. The characterization and quantitative analysis of nanopores in unconventional gas reservoirs utilizing FESEM–FIB and image processing: An example from the lower Silurian Longmaxi Shale, upper Yangtze region, China. Int. J. Coal Geol. 2014, 128–129, 1–11. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Jarvie, D.M. Morphology, Genesis, and Distribution of Nanometer-Scale Pores in Siliceous Mudstones of the Mississippian Barnett Shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- Curtis, M.E.; Sondergeld, C.H.; Ambrose, R.J.; Rai, C.S. Microstructural investigation of gas shales in two and three dimensions using nanometer-scale resolution imaging. AAPG Bull. 2012, 96, 665–677. [Google Scholar] [CrossRef]

- Gao, H.; Li, H.A. Pore structure characterization, permeability evaluation and enhanced gas recovery techniques of tight gas sandstones. J. Nat. Gas Sci. Eng. 2016, 28, 536–547. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, Y.; Meng, X.; Li, Z.; Xie, Z.; Li, M. Characterization of micro-nano pore networks in shale oil reservoirs of Paleogene Shahejie Formation in Dongying Sag of Bohai Bay Basin, East China. Pet. Explor. Dev. 2017, 44, 720–730. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M.; Zhou, J.; Gentzis, T.; Rezaee, R. Nanoscale pore structure characterization of the Bakken shale in the USA. Fuel 2017, 209, 567–578. [Google Scholar] [CrossRef]

- Kuila, U.; Prasad, M. Specific surface area and pore-size distribution in clays and shales. Geophys. Prospect. 2013, 61, 341–362. [Google Scholar] [CrossRef]

- Shan, C.; Zhao, W.; Wang, F.; Zhang, K.; Feng, Z.; Guo, L.; Ma, X.; Liao, T. Nanoscale pore structure heterogeneity and its quantitative characterization in Chang7 lacustrine shale of the southeastern Ordos Basin, China. J. Pet. Sci. Eng. 2020, 187, 106754. [Google Scholar] [CrossRef]

- Chen, Y.; Wei, L.; Mastalerz, M.; Schimmelmann, A. The effect of analytical particle size on gas adsorption porosimetry of shale. Int. J. Coal Geol. 2015, 138, 103–112. [Google Scholar] [CrossRef]

- Hazra, B.; Wood, D.A.; Vishal, V.; Singh, A.K. Pore Characteristics of Distinct Thermally Mature Shales: Influence of Particle Size on Low-Pressure CO2 and N2 Adsorption. Energy Fuels 2018, 32, 8175–8186. [Google Scholar] [CrossRef]

- Liang, F.; Zhang, Q.; Lu, B.; Chen, P.; Su, C.; Zhang, Y.; Liu, Y. Pore Structure in Shale Tested by Low Pressure N2 Adsorption Experiments: Mechanism, Geological Control and Application. Energies 2022, 15, 4875. [Google Scholar] [CrossRef]

- Zheng, H.; Yang, F.; Guo, Q.; Pan, S.; Jiang, S.; Wang, H. Multi-scale pore structure, pore network and pore connectivity of tight shale oil reservoir from Triassic Yanchang Formation, Ordos Basin. J. Pet. Sci. Eng. 2022, 212, 110283. [Google Scholar] [CrossRef]

- Labani, M.M.; Rezaee, R.; Saeedi, A.; Hinai, A.A. Evaluation of pore size spectrum of gas shale reservoirs using low pressure nitrogen adsorption, gas expansion and mercury porosimetry: A case study from the Perth and Canning Basins, Western Australia. J. Pet. Sci. Eng. 2013, 112, 7–16. [Google Scholar] [CrossRef]

- Lin, B.; Chen, M.; Jin, Y.; Pang, H. Modeling pore size distribution of southern Sichuan shale gas reservoirs. J. Nat. Gas Sci. Eng. 2015, 26, 883–894. [Google Scholar] [CrossRef]

- Sun, C.; Yao, S. Pore structure and characterization methods of shale oil reservoir. Pet. Geol. Recovery Effic. 2019, 26, 153–164. [Google Scholar]

- Fu, J.; Niu, X.; Dan, W.; Feng, S.; Liang, X.; Xin, H.; You, Y. The geological characteristics and the progress on exploration and development of shale oil in Chang7 Member of Mesozoic Yanchang Formation, Ordos Basin. China Pet. Explor. 2019, 24, 601. [Google Scholar]

- Yang, H.; Niu, X.; Xu, L.; Feng, S.; You, Y.; Liang, X.; Wang, F.; Zhang, D. Exploration potential of shale oil in Chang7 member, upper Triassic Yanchang formation, Ordos Basin, NW China. Pet. Explor. Dev. 2016, 43, 560–569. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, J.; Zhang, J.; Zhao, B.; Zhao, Y.; Liu, X.; Xia, D. Resource potential and exploration direction of Gulong shale oil in Songliao Basin. Pet. Geol. Oilfield Dev. Daqing 2020, 39, 20–34. [Google Scholar]

- Feng, Z.; Liu, B.; Shao, H.; Wang, C.; Hong, S.; Wang, J.; Pan, H.; Wang, Y.; Zhang, A.; Tian, S. The diagenesis evolution and accumulating performance of the mud shale in Qingshankou Formation in Gulong area, Songliao Basin. Pet. Geol. Oilfield Dev. Daqing 2020, 39, 72–85. [Google Scholar]

- Li, S.; Zhang, J.; Gong, F.; Zhu, H.; Bai, Y. The characteristics of mudstones of Upper Cretaceous Qingshankou Formation and favorable area optimization of shale oil in the north of Songliao Basin. Geol. Bull. China 2017, 36, 654–663. [Google Scholar]

- Zhi, D.; Tang, Y.; Yang, Z.; Guo, X.; Zheng, M.; Wan, M.; Huang, L. Geological characteristics and accumulation mechanism of continental shale oil in Jimusaer sag, Junggar Basin. Oil Gas Geol. 2019, 40, 524–534. [Google Scholar]

- Huo, J.; He, J.; Gao, Y.; Dong, Y.; Xu, D.; Li, Y. Difficulties and countermeasures of shale oil development in Lucaogou Formation of Jimsar Sag. Xinjiang Pet. Geol. 2019, 40, 379. [Google Scholar]

- Zhu, R.; Wu, S.; Su, L.; Cui, J.; Mao, Z.; Zhang, X. Problems and future works of porous texture characterization of tight reservoirs in China. Acta Pet. Sin. 2016, 37, 1323. [Google Scholar]

- Lu, S. The Main Control Factor for Oil Rich Integration in Yanchang Oil Field in the Ordos Basin. Master Thesis, China University of Petroleum, Beijing, China, 2017. [Google Scholar]

- Meng, X.; Meng, W.; Chen, L.; Wang, C.; Leng, D.; Wang, D. The Reservoir Characteristics of Chang 6 and Chang 9 Reservoirs in the Fuxian-Ganquan Area of Ordos Basin. J. Chang. Univ. (Nat. Sci. Eds.) 2018, 15, 17–20+15. [Google Scholar]

- Wang, X.; Wang, M.; Zhao, A. Microscopic characteristics of Chang 7 tight sandstone reservoir in Ordos Basin. Lithol. Reserv. 2014, 26, 79–83. [Google Scholar]

- Wang, X.; Guo, Y.; Fu, J.; Liu, H.; Chen, Q.; Li, T.; Liao, J.; Zhang, C. Control factors for forming higher porosity and permeability sandstone reservoirs in Chang 8 member of Yanchang Formation, Ordos Basin. Pet. Explor. Dev. 2005, 32, 35–38. [Google Scholar]

- Zhu, X.; Zeng, H.; Li, S.; Dong, Y.; Zhu, S.; Zhao, D.; Huang, W. Sedimentary characteristics and seismic geomorphologic responses of a shallow-water delta in the Qingshankou Formation from the Songliao Basin, China. Mar. Pet. Geol. 2017, 79, 131–148. [Google Scholar] [CrossRef]

- Shi, L.; Wang, Z.; Zhang, G.; Zhang, Y.; Xing, E. Distribution and formation of tight oil in Qijia area, Songliao Basin, NE China. Pet. Explor. Dev. 2015, 42, 48–55. [Google Scholar] [CrossRef]

- Wang, S. Formation and Distribution Rule of Tight Oil in Fuyu Oil Layer of the Sanzhao Area. J. Petrochem. Univ. 2018, 31, 46. [Google Scholar]

- Cao, Y.; Zhu, N.; Zhang, S.; Xi, K.; Xue, X. Diagenesis and reserving space characteristics of tight oil reservoirs of Permian Lucaogou Formation in Jimusar Sag of Junggar Basin. J. Earth Sci. Environ. 2019, 41, 253–266. [Google Scholar]

- Kuang, L.; Hu, W.; Wang, X.; Tun, H.; Wang, X. Research of the tight oil reservoir in the Lucaogou Formation in Jimusar Sag: Analysis of lithology and porosity characteristics. Geol. J. China Univ. 2013, 19, 529. [Google Scholar]

- Zhang, T.; Fan, G.; Li, Y.-W.; Yu, C. Pore-throat characterization of tight oil reservoir in the Lucaogou formation, Jimusar sag. CT Theory Appl. 2016, 25, 425–434. [Google Scholar]

- Ma, Q.; Yang, S.; Yang, L. Characteristics of the micro-pore in Lucaogou-Formation tight reservoir of Jimsar Sag, Junggar Basin. Pet. Geol. Oilfield Dev. Daqing 2020, 39, 13–20. [Google Scholar]

- Li, H.; Mao, X.; Hu, G.; Chen, C.; Feng, M.; Wang, Q. Characteristics and productivity prediction of tight reservoirs in Lucaogou Formation of Jimusa’er Sag in Junggar Basin. J. Oil Gas Technol. 2014, 36, 40–44. [Google Scholar]

- Liu, Y.; Zhu, X.; Zhu, M.; Liao, Z.; Wang, X.; Wang, J. Characteristics of tight oil reservoirs of the Permian Fengcheng Formation in Wu-Xia area, Junggar Basin. Lithol. Reserv. 2014, 26, 66–72. [Google Scholar]

- Xu, L.; Chang, Q.; Feng, L.; Zhang, N.; Liu, H. The reservoir characteristics and control factors of shale oil in Permian Fengcheng Formation of Mahu Sag, Junggar Basin. China Pet. Explor. 2019, 24, 649. [Google Scholar]

- Yang, F.; Meng, X.; Wang, X.; Yu, P.; Shao, G.; Chen, H. Micro-Pore characteristics and influencing factors of Fengcheng Formation shale in well Maye-1. Xinjiang Pet. Geol. 2022, 43, 1–10. [Google Scholar]

- Dumitrache, L.; Roy, A.; Bird, A.; Goktas, B.; Sorgi, C.; Stanley, R.; De Gennaro, V.; Eswein, E.; Abbott, J. A Multidisciplinary Approach to Production Optimization through Hydraulic Fracturing Stimulation and Geomechanical Modelling in Clair Field. In Proceedings of the International Petroleum Technology Conference, Riyadh, Saudi Arabia, 21–23 February 2022. [Google Scholar]

- Zhi, D.; Cao, J.; Xiang, B.; Qin, Z.; Wang, T. Fengcheng alkaline lacustrine source rocks of Lower Permian in Mahu Sag in Junggar Basin: Hydrocarbon generation mechanism and petroleum resources reestimation. Xinjiang Pet. Geol. 2016, 37, 1. [Google Scholar]

- Zhang, Y.; Li, W.; Tang, W. Tectonic setting and environment of alkaline lacustrine source rocks in the Lower Permian Fengcheng Formation of Mahu Sag. Xinjiang Pet. Geol. 2018, 39, 48–54. [Google Scholar]

- Jiang, F.; Meiling, H.; Tao, H.; Jiahao, L.; Huang, L.; Chenglin, L.; Jiang, Z.; Huang, R.; Zhang, C.; Guanyun, W. Controlling factors and models of shale oil enrichment in Lower Permian Fengcheng Formation, Mahu Sag, Junggar Basin, NW China. Pet. Explor. Dev. 2023, 50, 812–825. [Google Scholar] [CrossRef]

- Lei, D.; Chen, G.; Liu, H.; Li, X.; Abulimit, T.; Cao, J. Study on the forming conditions and exploration fields of the Mahu giant oil (gas) province, Junggar Basin. Acta Geol. Sin. 2017, 91, 1604–1619. [Google Scholar]

- Zhi, D.; Tang, Y.; He, W.; Guo, X.; Zheng, M.; Huang, L. Orderly coexistence and accumulation models of conventional and unconventional hydrocarbons in Lower Permian Fengcheng Formation, Mahu Sag, Junggar Basin. Pet. Explor. Dev. 2021, 48, 43–59. [Google Scholar] [CrossRef]

- Xia, L.; Cao, J.; Stüeken, E.E.; Zhi, D.; Wang, T.; Li, W. Unsynchronized evolution of salinity and pH of a Permian alkaline lake influenced by hydrothermal fluids: A multi-proxy geochemical study. Chem. Geol. 2020, 541, 119581. [Google Scholar] [CrossRef]

- Zhang, Z.; Yuan, X.; Wang, M.; Zhou, C.; Tang, Y.; Chen, X.; Lin, M.; Cheng, D. Alkaline-lacustrine deposition and paleoenvironmental evolution in Permian Fengcheng Formation at the Mahu sag, Junggar Basin, NW China. Pet. Explor. Dev. 2018, 45, 1036–1049. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, Z.; Zhou, C.; Yuan, X.; Lin, M.; Liu, Y.; Cheng, D. Lithological characteristics and origin of alkaline lacustrine of the Lower Permian Fengcheng Formation in Mahu Sag, Junggar Basin. J. Palaeogeogr. 2018, 20, 147–162. [Google Scholar]

- Cao, J.; Zhang, Y.; Hu, W.; Yao, S.; Wang, X.; Zhang, Y.; Tang, Y. The Permian hybrid petroleum system in the northwest margin of the Junggar Basin, northwest China. Mar. Pet. Geol. 2005, 22, 331–349. [Google Scholar] [CrossRef]

- Barrett, E.P.; Joyner, L.G.; Halenda, P.P. The Determination of Pore Volume and Area Distributions in Porous Substances. I. Computations from Nitrogen Isotherms. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar] [CrossRef]

- Pfeifer, P.; Avnir, D. Chemistry in noninteger dimensions between two and three. I. Fractal theory of heterogeneous surfaces. J. Chem. Phys. 1983, 79, 3558–3565. [Google Scholar] [CrossRef]

- Avnir, D.; Jaroniec, M. An isotherm equation for adsorption on fractal surfaces of heterogeneous porous materials. Langmuir 1989, 5, 1431–1433. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, Q.; Pan, D.; Pan, N. Fractal Aperture Distribution of Activated Carbon Fiber and Adsorption Behavior to Low-Density Benzene Steam. J. Dispers. Sci. Technol. 2006, 27, 1157–1160. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Tang, D.; Tang, S.; Huang, W. Fractal characterization of adsorption-pores of coals from North China: An investigation on CH4 adsorption capacity of coals. Int. J. Coal Geol. 2008, 73, 27–42. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.; Liu, H. Fractal characteristics of shales from a shale gas reservoir in the Sichuan Basin, China. Fuel 2014, 115, 378–384. [Google Scholar] [CrossRef]

- Mendhe, V.A.; Bannerjee, M.; Varma, A.K.; Kamble, A.D.; Mishra, S.; Singh, B.D. Fractal and pore dispositions of coal seams with significance to coalbed methane plays of East Bokaro, Jharkhand, India. J. Nat. Gas Sci. Eng. 2017, 38, 412–433. [Google Scholar] [CrossRef]

- Xiong, J.; Liu, X.; Liang, L. An investigation of fractal characteristics of marine shales in the Southern China from nitrogen adsorption data. J. Chem. 2015, 2015, 303164. [Google Scholar] [CrossRef]

- Hazra, B.; Wood, D.A.; Vishal, V.; Varma, A.K.; Sakha, D.; Singh, A.K. Porosity controls and fractal disposition of organic-rich Permian shales using low-pressure adsorption techniques. Fuel 2018, 220, 837–848. [Google Scholar] [CrossRef]

- Rouquerol, J.; Avnir, D.; Fairbridge, C.W.; Everett, D.H.; Haynes, J.; Pernicone, N.; Ramsay, J.D.; Sing, K.S.W.; Unger, K.K. Recommendations for the characterization of porous solids (Technical Report). Pure Appl. Chem. 1994, 66, 1739–1758. [Google Scholar] [CrossRef]

- Sing, K.S. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Tang, Y.; Liu, K.; Liu, Z.; Zhu, T.; Zou, Y.; Liu, X.; Yang, S.; Xie, A. Comparison of Pore Structure Characteristics of Shale-Oil and Tight-Oil Reservoirs in the Fengcheng Formation in Mahu Sag. Energies 2024, 17, 4027. https://doi.org/10.3390/en17164027

Liu G, Tang Y, Liu K, Liu Z, Zhu T, Zou Y, Liu X, Yang S, Xie A. Comparison of Pore Structure Characteristics of Shale-Oil and Tight-Oil Reservoirs in the Fengcheng Formation in Mahu Sag. Energies. 2024; 17(16):4027. https://doi.org/10.3390/en17164027

Chicago/Turabian StyleLiu, Guoyong, Yong Tang, Kouqi Liu, Zuoqiang Liu, Tao Zhu, Yang Zou, Xinlong Liu, Sen Yang, and An Xie. 2024. "Comparison of Pore Structure Characteristics of Shale-Oil and Tight-Oil Reservoirs in the Fengcheng Formation in Mahu Sag" Energies 17, no. 16: 4027. https://doi.org/10.3390/en17164027

APA StyleLiu, G., Tang, Y., Liu, K., Liu, Z., Zhu, T., Zou, Y., Liu, X., Yang, S., & Xie, A. (2024). Comparison of Pore Structure Characteristics of Shale-Oil and Tight-Oil Reservoirs in the Fengcheng Formation in Mahu Sag. Energies, 17(16), 4027. https://doi.org/10.3390/en17164027