Abstract

Sediment erosion of hydraulic turbines is a significant challenge in hydropower plants in mountainous regions like the European Alps, the Andes, and the Himalayan region. The erosive wear of Pelton runner buckets is influenced by a variety of factors, including the size, hardness, and concentration of silt particles; the velocity of the flow and impingement angle of the jet; the properties of the base material; and the operating hours of the turbine. This research aims to identify the locations most susceptible to erosion and to elucidate the mechanisms of erosion propagation in two distinct designs of Pelton runner buckets. The Pelton runner buckets were subjected to static condition tests with particle sizes of 500 microns and a concentration of 14,000 mg/L. The buckets were coated with four layers of paint, sequentially applied in red, yellow, green, and blue. The two Pelton buckets, and , were evaluated for their erosion resistance properties. demonstrated superior erosion resistance, attributed to its geometrical features and material composition, lower erosion rates, less material loss, and improved surface integrity compared with D1. This difference is primarily attributed to factors such as the splitter’s thickness, the jet’s impact angle, the velocity at which particles strike, and the concentration of sand. exhibits a great performance in terms of erosion resistance among the two designs. This study reveals that the angle of jet impingement influences erosion progression and material loss, which is important to consider during a Pelton turbine’s design and operating conditions.

1. Introduction

Hydropower plays a pivotal role in the power generation sector and contributes significantly to the economic development of a country. By the year 2018, the global installed capacity had reached 1929 GW. China emerged as the leading nation in hydropower infrastructure, boasting the largest hydropower plants with a combined capacity of 352.3 GW [1,2]. Numerous rivers worldwide exhibit elevated concentrations of sediment, with the Yellow River standing out for its notably high sediment load with an annual sediment discharge recorded at 168 million tons [3]. Nepal’s mountainous terrain exhibits a delicate geography that contributes significantly to sediment transportation in its rivers. The estimated specific sediment yield stands at approximately 4240 tons per square kilometer annually, placing it among the highest globally [4].

Pelton turbines are designed for high-head applications and can achieve efficiency levels as high as 95%. However, they are susceptible to performance degradation due to the high fluid concentration and material losses occurring in various regions of the buckets and nozzles [5]. Stachowiak et al. investigated seven distinct mechanisms through which solid particle erosion can occur and Thapa (2004) focused on four specific erosion mechanisms, abrasive erosion, fatigue, plastic deformation, and brittle fracture [6]. Padhy et al. developed a correlation between normalized wear W (weight loss divided by original weight) and particle characteristics and operating conditions by using experimental methods in a Pelton turbine bucket, expressed as:

where S denotes the size of silt particles, C represents the concentration of silt, V stands for the velocity of the water jet, and t indicates the operating hours of the turbine [7].

Prasad et al. investigated the erosion mechanisms and identified the most erosion-prone locations within various turbine components, including the muzzle, buckets, seal rings, and deflector [8]. Bajracharya et al. investigated the relationship between the erosion rate of turbine components (needles and buckets) and the subsequent decrease in efficiency at the Chillmi Hydro Electric Plant (CHEP). Their study revealed that an erosion rate of 3.4 mm/year on these components led to a 1.21% efficiency reduction in the first year [9]. Brekke et al. investigated the impact of increasing the splitter width by 1% of the bucket width on the efficiency of a Pelton turbine. Their findings indicated that this modification resulted in a 1% reduction in efficiency at full load [10].

Hassler et al. investigated the correlation between radial erosion on the splitter tip and a reduction in efficiency. Their study revealed a linear relationship between the radial erosion depth, normalized to the jet diameter, and the consequent decrease in efficiency [11]. The Pelton bucket, by its shape, was inherently resistant to cavitation. However, a change in the surface morphology of the bucket due to sediment erosion and cavitation inception led to a synergistic erosion process involving both sediment and cavitation [12,13,14]. The combination of sediment abrasion, cavitation, and corrosion decreased the efficiency and caused greater damage to the metallic components. Additionally, silt erosion led to vibration and fatigue damage, reduced lifespan of units, and higher maintenance expenses. All of these variables have adverse effects on the national economy and power usage [15,16,17,18,19]. Clark and Llewellyn’s investigation revealed a proportional relationship between erosion and the square of velocity, while inversely, erosion decreases with increasing hardness [20].

Desale et al. reported that the erosion wear diminishes as the slurry concentration increases [21]. Kubota and Mugli conducted a numerical and experimental investigation aimed at understanding the intricate nature of fluid flow and erosion mechanism predictions within Pelton turbines. Their findings revealed the complexity of these phenomena and the challenges associated with replicating them accurately [22,23]. The erosion behavior of a target surface is influenced by factors such as the concentration of particles in water, as well as the shape, size, chemical reactivity, hardness, and toughness of the particles and materials [24,25,26,27,28]. Researchers such as Finnie et al., Grant et al., and Neilson et al. have dedicated their efforts to developing erosion models aimed at predicting the erosion behavior of particles on both brittle and ductile materials’ surfaces [29,30,31].

This paper uses an experimental method to study the erosion mechanism and progression in two different designs of Pelton buckets. This investigation provided valuable insights into the mechanisms and progression of material strength and sediment erosion in two different Pelton buckets, as well as their influence on the erosion process and its impact on the design and performance of Pelton turbines.

2. Experimental Setup

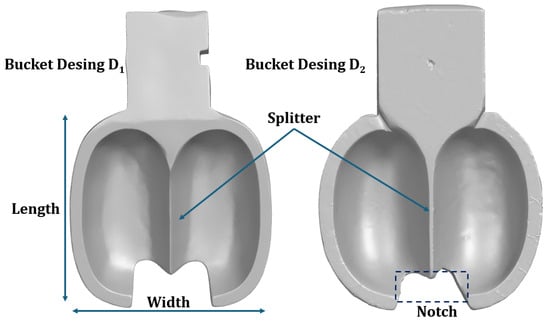

The two distinct bucket designs, and , were evaluated on an erosion test apparatus with fixed positioning to determine the most susceptible erosion areas and evaluate erosion rates. In Figure 1, two different 3D scan designs were labeled and . These buckets have various design features such as structure, character size by length and width, and internal splitter. The main differences between the two buckets are the notch and splitter width, and the bucket brim and depth. Design had been examined to reveal a traditional structure with clear, precise demarcations of its length and width. The splitter’s thickness effectively divides the flow splitting and jet impingement path. The notch locations were prone to erosion and could impact the bucket’s design and performance. Table 1 compares the key design elements of the two buckets, and was the outlet jet diameter of the nozzle. The design had the same structural characteristics, length, and width as , but differed regarding the notch design and splitter thickness. The sediment concentration employed in the experiments was maintained at 14,000 milligrams of sand per liter of water. Detailed descriptions of the test setup and the operating conditions are provided in the following sections.

Figure 1.

A 3D scan of two distinct bucket designs.

Table 1.

Compares the design parameters of two buckets.

2.1. Experimental Test Rig

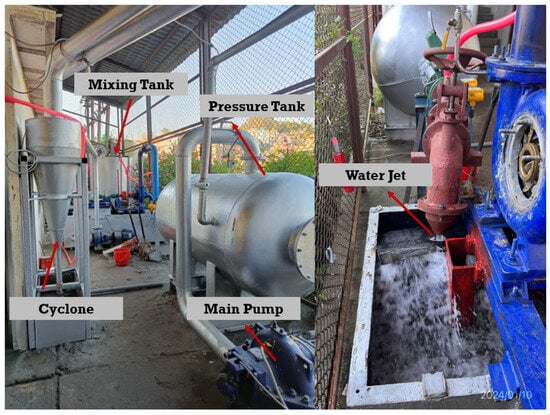

Figure 2 illustrates the erosion testing facility at the Turbine Testing Lab, Kathmandu University, which was used for the erosion experiments. The test section was modified by installing a nozzle and a Pelton bucket in a static condition. The setup included various components: a 200cL water tank, a submersible pump with a max flow rate of 15 L/s, a variable speed stirrer with a max speed of 150 RPM, and a magnetic flow meter. The flow was circulated through a 30 mm diameter pipe, while a 10 mm diameter injector generated a fluid jet. The slurry mixture was created by adding silica particles to water in the storage tank and thoroughly mixing them using a stirrer. The mixture, which included particles that were microns in size and had a concentration of 1.5% (by weight), was then circulated through the experimental system using the submersible pump. A flow meter was installed in the circuit to measure the flow rate. A stationary Pelton bucket was strategically placed in the path of the high-velocity slurry flow. All of the pumps were operated with VFD (variable frequency drives); hence, the flow could be controlled for the main, auxiliary, and peristaltic pumps. The water mixed with sediment slurry passed through the nozzle, hit the bucket, and finally dropped into the sump tank. The mixture from the sump tank was circulated to the hydro-cyclone, which segregated the sediment from the mixture.

Figure 2.

Erosion testing rig for Pelton runner buckets.

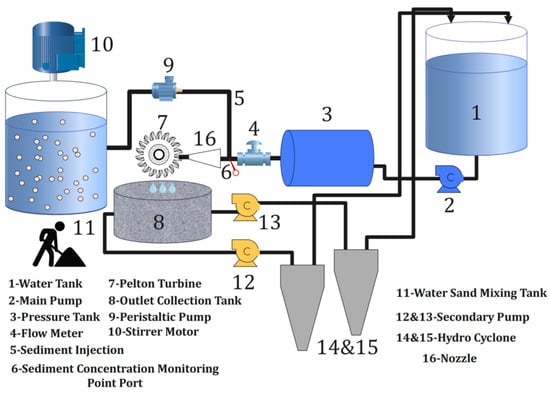

As the slurry flowed through the system, it hit the Pelton bucket and exited back into the storage tank through an outlet. A transparent acrylic shell was built around the Pelton bucket to prevent splashes from spreading into the surrounding environment. A schematic loop of the erosion experimental bench and the Pelton runner buckets is shown in Figure 3. Two different designs of Pelton runner buckets, namely and , were studied for the erosion-prone location and the erosion rate. Both of the buckets were made from the same materials with different bucket profiles. Before conducting erosion testing on the two buckets, the buckets were carefully polished using a grinding wheel and silicon carbide paper. After polishing, the buckets were stored in a desiccator to protect them from surface damage due to corrosive attacks. Before starting the erosion testing, several measurements, such as 3D scanning and weight measurement, were carried out to gather the initial data. Subsequently, erosion tests were conducted, and measurements of the profile and splitter were obtained from various regions of the Pelton runner buckets. The design and material properties’ attributes of the buckets in Pelton turbines directly impacted the turbine’s performance.

Figure 3.

Schematic diagram of the erosion testing lab.

2.2. Erosion Testing Techniques and Procedures

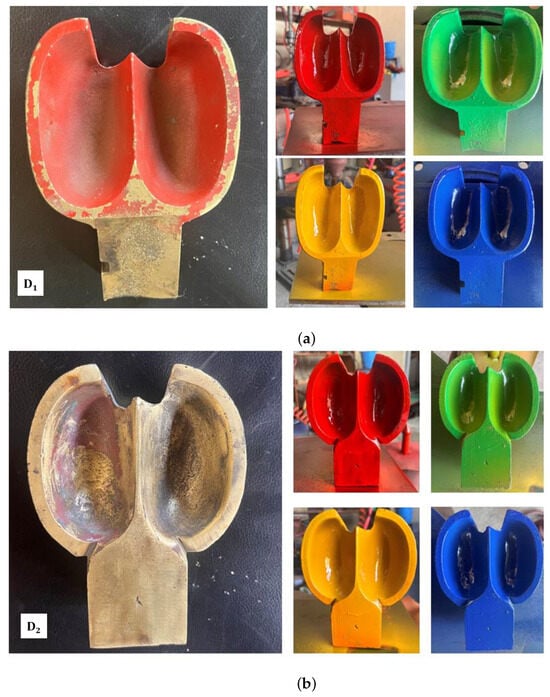

The material point method (MPM) technique qualitatively identifies erosion-prone regions in the Pelton bucket. Figure 4 shows four layers of paint with different colors that were carefully applied to the Pelton bucket surface. Each layer was allowed to dry thoroughly, and an ultrasonic thickness gauge was used to measure the paint layer thickness. Subsequently, an ultrasonic thickness gauge was utilized to measure the thickness of the paint layers. The four paint layers were 15 nm thick, respectively. The eroded buckets were cleaned for analysis after erosion tests to assess the erosive wear in different regions. The Pelton runner buckets were painted with red, yellow, green, and blue enamel using the LVLP (low volume low pressure) spray paint method. The Pelton runner buckets were cleaned with alkaline soap in warm water and then dried in a muffle furnace at 100 °C after LVLP paint spray application.

Figure 4.

(a) and (b) Pelton runner buckets with paint layers.

The static buckets were exposed to the sediment–water jet for a total of 30 min. Observations were made for erosion after 5 min. Photographs were taken every 5 min while the test rig was in operation. After the erosion tests, the eroded buckets were removed and cleaned extensively to assess the extent of erosive wear in different areas of the Pelton bucket. Evaluating sand erosion in the Pelton bucket involved assessing both the mass loss and thickness reduction of the paint and material. The mass loss was calculated by weighing the complete bucket before and after the erosion experiment with an analytical balance. It utilized an ultrasonic thickness (UT) gauge to evaluate the thickness reduction in the erosion-prone areas on the bucket during the MPM test. The data on mass loss aided in determining the erosion rate (ER) using Equation (2):

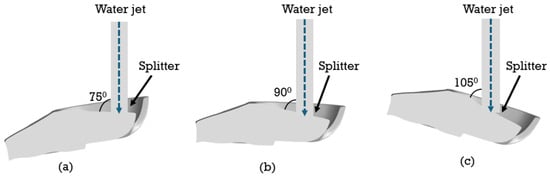

Figure 5 illustrates the interaction of the water jet with the splitter in the Pelton runner buckets. The different angles of the jet interacting with the splitter can significantly affect the efficiency and effectiveness of the cutting process. Three different angles of jet interactions were considered: 75°, 90°, and 105°. At a 75° angle, the water jet impacted the splitter sharply, simulating scenarios where it cut through the material with minimal resistance but may cause higher wear on the splitter. The 90° angle allowed for maximum energy transfer and effective cutting at the splitter with reduced deflection and wear. At 105°, this angle represented an obtuse interaction where the water jet impacted the splitter at a wider angle. This can be useful for evaluating how the jet performed when cutting through thicker or more resistant materials, where a wider angle may help reduce clogging or buildup on the splitter. Analyzing these angles helps understand the behavior of the water jet under various conditions, which, in turn, informs the design and optimization of the splitter for different cutting applications.

Figure 5.

Interaction of the water jet with the splitter at different angles (a) (b) (c) .

3. Results and Discussion

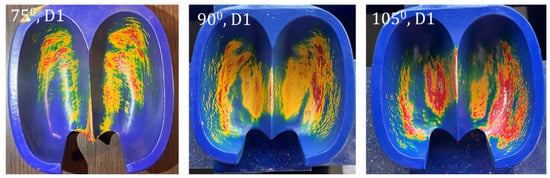

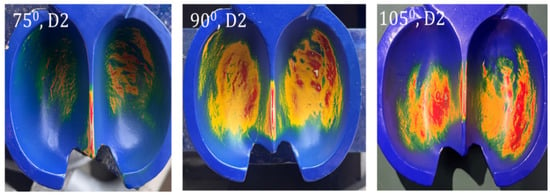

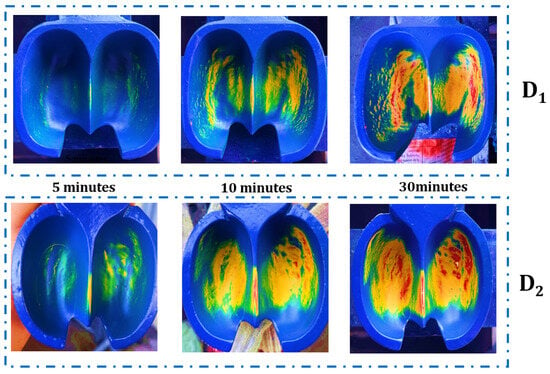

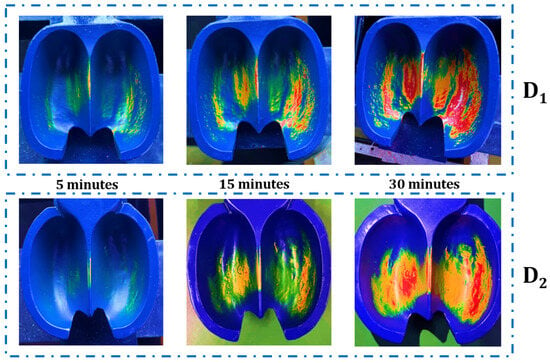

The change in color pattern in the buckets was observed at intervals of five minutes. The erosion test findings after 30 min are illustrated in Figure 6 and Figure 7. These figures identify the areas in the Pelton runner buckets of designs, and , that are susceptible to erosion after 30 min of exposure to jet angles of , , and .

Figure 6.

Erosion patterns observed for bucket design in , , and jet anglesafter 30 min of operation.

Figure 7.

Erosion patterns observed for the bucket design in ,, and jet angles after 30 min of operation.

3.1. Erosion Pattern Observed in Design and at Different Jet Angles

The erosion patterns on the Pelton bucket resulting from different jet angles are compared in Figure 5 after 30 min of jet operation with water containing heavy silt. The erosion locations and patterns on the buckets varied significantly with different jet angles. The erosion-prone area shifted towards the bucket’s arm at a jet incidence. The degradation of the splitter was noticeable in the notch zone at this jet angle. Similarly, at a incidence angle, the center of the bucket experienced the most erosion, with the core region and splitter section being particularly affected. In addition, erosion was noted in the splitter region furthest from the notch, and at a jet incidence, erosion occured in the lower bucket region closer to the notch.

After 30 min of jet operation with sediment-laden water, Figure 6 illustrates the distinct erosion patterns for the Pelton bucket at various jet angles. The erosion patterns and locations on the buckets change based on the impingement angles at which the jet hits the bucket. In design , at a jet incidence, there was more erosion towards the edge of the bucket, at the erosion was more towards the bucket’s center, and at , it was closer to the notch. Meanwhile, in design , there was more erosion at . In , the erosion accumulated in a single region of the bucket, while in , it was scattered around the bucket.

3.2. Evaluation of Erosion Patterns: A Comparative Analysis of Two Pelton Buckets

The erosion patterns observed in bucket and at a jet incidence are illustrated in Figure 8. It is clearly shown that the erosion was more severe in the case of . After 30 min of erosion, a substantial erosion region could be seen in the bucket. The flow striking the splitter spread from the region near the notch to the farthest end of the bucket. The size of the area affected by the erosion and the intensity of the erosion were particularly evident in the design of the bucket.

Figure 8.

Erosion pattern comparison between design and at .

In Figure 9, the erosion patterns observed in buckets and at a jet incidence were compared. It is evident from the figure that the erosion area in was larger than in . The most severely eroded areas in both and were primarily located in the regions where the water flowed outward. After 30 min of erosion, a larger area of erosion was seen in bucket . The flow striking the splitter extended from the region near the notch to the farthest end of the bucket. This comparison showed that bucket demonstrated superior erosion resistance at a jet incidence.

Figure 9.

Erosion pattern comparison between designs and at .

In Figure 10, the erosion patterns observed in buckets and at a jet incidence are depicted. The figure indicates that the most severe erosion patterns occurred in D1 after 30 min of operation in sand-laden conditions. The eroded areas in bucket were larger compared to , and the overall coverage of erosion patterns was also greater in . This clearly shows that at a angle, design outperformed in resisting sediment erosion.

Figure 10.

Erosion patterns comparison between design and at .

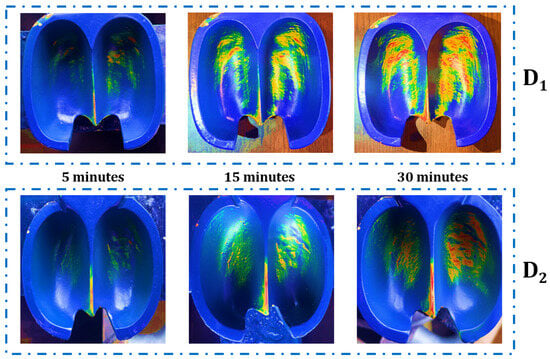

3.3. Mechanism of Erosion Progression in Pelton Turbine Buckets

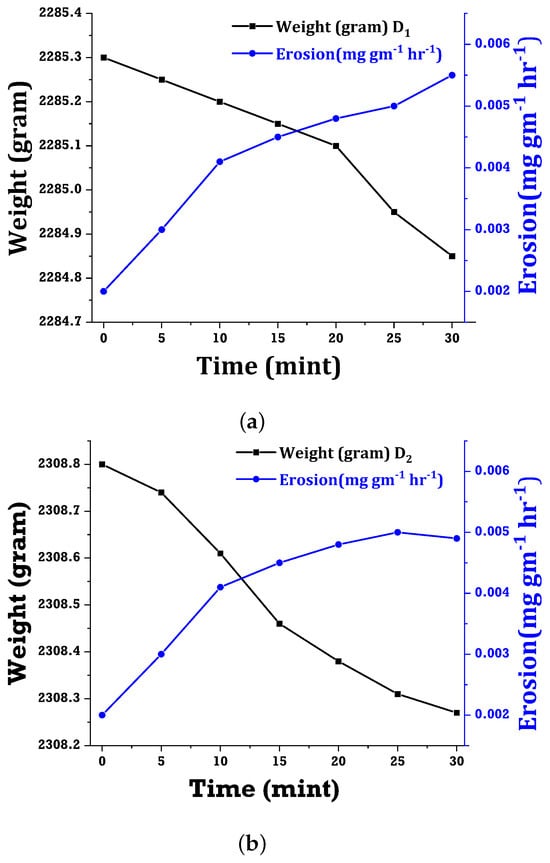

Figure 11 illustrates that in identifying the erosion-vulnerable zone in Pelton runner buckets, the erosion rates of the bucket material were recorded over a 30 min operation period, with data were collected every 5 min. The erosion rates and weight loss are depicted in the graph. It was observed that after 30 min of operation in sediment-laden conditions, bucket exhibited a maximum erosion rate of 0.0046 mg , and bucket exhibited a rate of 0.0056 mg . The data also show that experienced a lower erosion rate under similar sediment concentrations and operating conditions as .

Figure 11.

Eroded weight measurement of two different buckets (a) and (b) at .

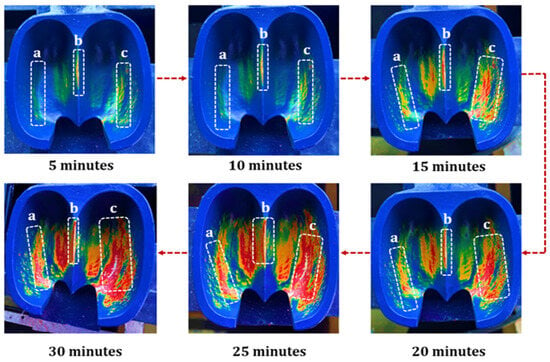

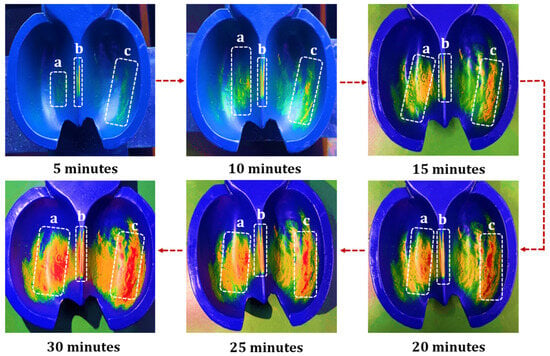

Figure 12 chronicles the progression of erosion within Pelton turbine buckets over a 30 min interval, providing an in-depth analysis of the erosion dynamics at critical surface regions labeled “a”, “b”, and “c”. At 5 min, the erosion was barely visible, predominantly concentrated in region “b”, indicative of the initial impact sites where high-velocity water jets impinged. At 10 and 15 min, the erosion extended noticeably into regions “a” and “c”, near to the notch, reflecting the lateral spread of erosive forces and the onset of material degradation across the bucket surfaces due to complex fluid dynamics and particle interaction. As the timeline advanced to 20 and 25 min, the images revealed a significant increase in the intensity and coverage of erosion, with region “b” experiencing accelerated wear, signifying the compounded effect of continuous jet impact and abrasive particle influence. After 30 min, the erosion had marked the different locations of the buckets with a removal color and dominating surface roughness.

Figure 12.

Progression pattern in at .

Figure 13 illustrates the progression pattern of erosion in the design Pelton buckets. The results indicate a dynamic and rapid increase in the erosion progression mechanism, impacting the bucket material and design performance. After 5 min, paint degradation was observed at the splitter zone “b”, where water first made contact, leading to the initial formation of erosion. Over a 10 to 15 min period, while maintaining a constant flow velocity of water and sand concentrations, erosion advanced and extended to areas “a” and “c”. Region “c” experienced more severe erosion due to the jet impingement angle 105°. Erosion spread locations in the lower part near to notch of the bucket were identified using four different colors, with red indicating the primary damage to the material, resulting in a degradation in the bucket’s design and performance.

Figure 13.

Progression pattern in at .

During the 20 to 25 min, the erosion rapidly increased near the lower edge of the bucket. The red color became more dominant because of the water jet’s impact and its interactions with the sand particles on the bucket’s surface. After 30 min, the top of the bucket’s “c” region showed increased erosion, with the red color fading, the surface becoming rougher, and visible damage to the bucket material and performance. This investigation revealed that proper maintenance and material selection for the bucket design could extend the operational life of the Pelton turbine components.

4. Conclusions

The investigation showed wear and erosion patterns for two bucket designs at different incident angles, as well as design optimization, material damage, and the resulting degradation in turbine performance. The unequal distribution of erosion patterns showed areas of higher erosion at the bucket’s splitter and upper and center near the brim at , , and . The region of the bucket near the splitter, upper and center areas close to the brim, and lower areas near the notch experienced greater erosion due to the high-velocity water jet carrying sediment and impacting at different angles at the bucket.

The erosion progression distribution varied during operation in two different bucket designs. The at and incident exhibited more erosion in the lower region near the notch and center near the brim of the buckets. At the same time, the design demonstrated strong material strength and erosion resistance at the same angles.

The analysis of the splitter thickness and material hardness at suggests that it was more resistant to erosion progression compared with . Erosion progression at rapidly increased near the notch and lower side of the bucket, indicating that the progression varied with time and depended on the jet impingement angle, particle size, concentration, and surface hardness. These factors showed that the design was more erosion resistive than , which could improve the understanding when selecting the material for bucket design and influence the performance of the Pelton turbine.

This study considered erosion and progression mechanisms with different jet angles and the practical aspects of measuring these parameters in field conditions. The erosion of bucket areas was primarily caused by different jet impingement angles and sedimentation, highlighting the most susceptible erosion areas in buckets. This paper presents valuable quantitative data that can be used to better understand erosion prevention methods and mitigate hydro-abrasive erosion in Pelton turbines.

Author Contributions

Conceptualization, Z.W. and B.T.; Methodology, B.M.U., S.C., X.H. and A.K.; Software, B.M.U., X.H., R.P. and A.K.; Validation, B.M.U., S.C. and X.H.; Formal analysis, B.M.U. and S.C.; Investigation, B.M.U., S.C., R.P. and A.K.; Resources, S.C. and B.T.; Data curation, B.M.U., R.P. and A.K.;Writing—original draft, B.M.U. and X.H.; Visualization, X.H.; Supervision, Z.W.; Project administration, Zhengwei Wang and B.T.; Funding acquisition, Z.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Key Research and Development Program of China (2023YFB3408400).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bekchanov, M. A Global Hydropower Generation, Potentials, and Externalities. In Handbook of Energy Transitions; CRC Press: Boca Raton, FL, USA, 2022; pp. 95–107. [Google Scholar]

- Sun, X.; Wang, X.; Liu, L.; Fu, R. Development and present situation of hydropower in China. Water Policy 2019, 21, 565–581. [Google Scholar] [CrossRef]

- Guo, L.; Su, N.; Townend, I.; Wang, Z.B.; Zhu, C.; Wang, X.; Zhang, Y.; He, Q. From the headwater to the delta: A synthesis of the basin-scale sediment load regime in the Changjiang River. Earth-Sci. Rev. 2019, 197, 102900. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2022; International Energy Agency (IEA): Paris, France, 2022. [Google Scholar]

- Aggidis, G.; Židonis, A.; Burtenshaw, L.; Dubois, M.; Orritt, S.; Pickston, D.; Prigov, G.; Wilmot, L. Methodology for the Optimization of a Novel Hydro Turbine with a Case Study. Energies 2023, 16, 7591. [Google Scholar] [CrossRef]

- Stachowiak, G.; Batchelor, A.W. Engineering Tribology; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Padhy, M.; Saini, R. Effect of size and concentration of silt particles on erosion of Pelton turbine buckets. Energy 2009, 34, 1477–1483. [Google Scholar] [CrossRef]

- Neopane, H.P. Sediment Erosion in Hydro Turbines; NTNU: Trondheim, Norway, 2010. [Google Scholar]

- Bajracharya, T.R.; Acharya, B.; Joshi, C.B.; Saini, R.P.; Dahlhaug, O.G. Sand erosion of Pelton turbine nozzles and buckets: A case study of Chilime Hydropower Plant. Wear 2008, 264, 177–184. [Google Scholar] [CrossRef]

- Brekke, H.; Wu, Y.; Cai, B. Design of Hydraulic Machinery Working in Sand Laden Water; Imperial College Press: London, UK, 2003; pp. 155–233. [Google Scholar]

- Hassler, P.; Schnablegger, W. Pelton runner maintenance and its results at Verbund-Austrian Hydro Power AG. In Proceedings of the 14th International Seminar on HPPs, Vienna, Austria, 12 May 2006. [Google Scholar]

- Khurana, S.; Varun; Kumar, A. Silt erosion study on the performance of an impulse turbine in small hydropower. Int. J. Ambient. Energy 2016, 37, 520–527. [Google Scholar] [CrossRef]

- Wood, R.J.K.; Wharton, J.A.; Speyer, A.J.; Tan, K.S. Investigation of erosion–corrosion processes using electrochemical noise measurements. Tribol. Int. 2002, 35, 631–641. [Google Scholar] [CrossRef]

- Thapa, B.; Chaudhary, P.; Dahlhaug, O.G.; Upadhyay, P. Study of combined effect of sand erosion and cavitation in hydraulic turbines. In Proceedings of the International Conference on Small Hydropower, Hydro, Sri Lanka, 22–24 October 2007. [Google Scholar]

- Padhy, M.K.; Saini, R. A review on silt erosion in hydro turbines. Renew. Sustain. Energy Rev. 2008, 12, 1974–1987. [Google Scholar] [CrossRef]

- Ge, X.; Sun, J.; Chu, D.; Liu, J.; Zhou, Y.; Zhang, H.; Zhang, L.; Chen, H.; Kan, K.; Binama, M.; et al. Sediment erosion on pelton turbines: A review. Chin. J. Mech. Eng. 2023, 36, 64. [Google Scholar] [CrossRef]

- Lu, L.; Liu, J.; Yi, Y.L.; Liu, G. Evaluation on sand abrasion to Baihetan hydraulic turbines. J. Hydroelectr. Eng. 2016, 35, 67–74. [Google Scholar]

- Liu, J.; Yu, J.; Jiang, C. Evaluation on sediment erosion of Pelton turbine flow passage component. Iop Conf. Ser. Earth Environ. Sci. 2019, 240, 022027. [Google Scholar] [CrossRef]

- Duan, C.; Karelin, V. Abrasive Erosion and Corrosion of Hydraulic Machinery; World Scientific: Singapore, 2003; Volume 2. [Google Scholar]

- Clark, H.M.; Llewellyn, R. Assessment of the erosion resistance of steels used for slurry handling and transport in mineral processing applications. Wear 2001, 250, 32–44. [Google Scholar] [CrossRef]

- Desale, G.R.; Gandhi, B.K.; Jain, S. Effect of erodent properties on erosion wear of ductile type materials. Wear 2006, 261, 914–921. [Google Scholar] [CrossRef]

- Kubota, T.; Xia, J.; Takeuchi, H.; Saito, T.; Masuda, J.; Nakanishi, Y. Numerical analysis of free water sheet flow on Pelton runner buckets. In Proceedings of the 19th IAHR Symposium, Singapore, 9–11 September 1998. [Google Scholar]

- Muggli, F.; Zhang, Z. Numerical and Experimental Analysis of Pelton Turbine Flow, Part 2: The Free Surface Jet Flow. In Proceedings of the CFD-F20, Hydraulic Machinery and Systems, 20th IAHR Symposium, Charlotte, NC, USA, 6–9 August 2000. [Google Scholar]

- Stack, M.; El-Badia, T.A. Some comments on mapping the combined effects of slurry concentration, impact velocity and electrochemical potential on the erosion–corrosion of WC/Co–Cr coatings. Wear 2008, 264, 826–837. [Google Scholar] [CrossRef]

- Al-Bukhaiti, M.A.; Ahmed, S.M.; Badran, F.M.F.; Emara, K.M. Effect of impingement angle on slurry erosion behaviour and mechanisms of 1017 steel and high-chromium white cast iron. Wear 2007, 262, 1187–1198. [Google Scholar] [CrossRef]

- Xu, X.; Zwaag, S.v.; Xu, W. The effect of ferrite–martensite morphology on the scratch and abrasive wear behaviour of a dual phase construction steel. Wear 2016, 348, 148–157. [Google Scholar] [CrossRef]

- Cai, F.; Huang, X.; Yang, Q. Mechanical properties, sliding wear and solid particle erosion behaviors of plasma enhanced magnetron sputtering CrSiCN coating systems. Wear 2015, 324, 27–35. [Google Scholar] [CrossRef]

- Burstein, G.; Sasaki, K. Effect of impact angle on the slurry erosion–corrosion of 304L stainless steel. Wear 2000, 240, 80–94. [Google Scholar] [CrossRef]

- Finnie, I. The mechanism of erosion of ductile metals. In Proceedings of the 3rd National Congress Of Applied Mechanics, Providence, RI, USA, 11–14 June 1958; pp. 527–532. [Google Scholar]

- Grant, G.; Tabakoff, W. Erosion prediction in turbomachinery resulting from environmental solid particles. J. Aircr. 1975, 12, 471–478. [Google Scholar] [CrossRef]

- Neilson, J.; Gilchrist, A. Erosion by a stream of solid particles. Wear 1968, 11, 111–122. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).