A Novel Multi-Timescale Optimal Scheduling Model for a Power–Gas Mutual Transformation Virtual Power Plant with Power-to-Gas Conversion and Comprehensive Demand Response

Abstract

1. Introduction

1.1. Background and Motivation

1.2. Literature Review

1.3. Contributions

- A P2G-DR-VPP (PD-VPP) system framework is established that contains power–gas mutual transformation and comprehensive demand response. Compared to traditional VPPs, the novel VPP proposed in this paper places greater emphasis on the collaborative optimization among various units.

- A day-ahead optimization scheduling model is established with the objective of maximizing PD-VPP profits. This model formulates the next-day price curve for the PD-VPP and obtains the adjusted load curve after day-ahead scheduling.

- An intraday rolling optimization scheduling model is established with the objective of minimizing PD-VPP operating costs based on the day-ahead optimization results. We conduct multi-timescale rolling optimizations to devise a more accurate optimal output plan for PD-VPPs.

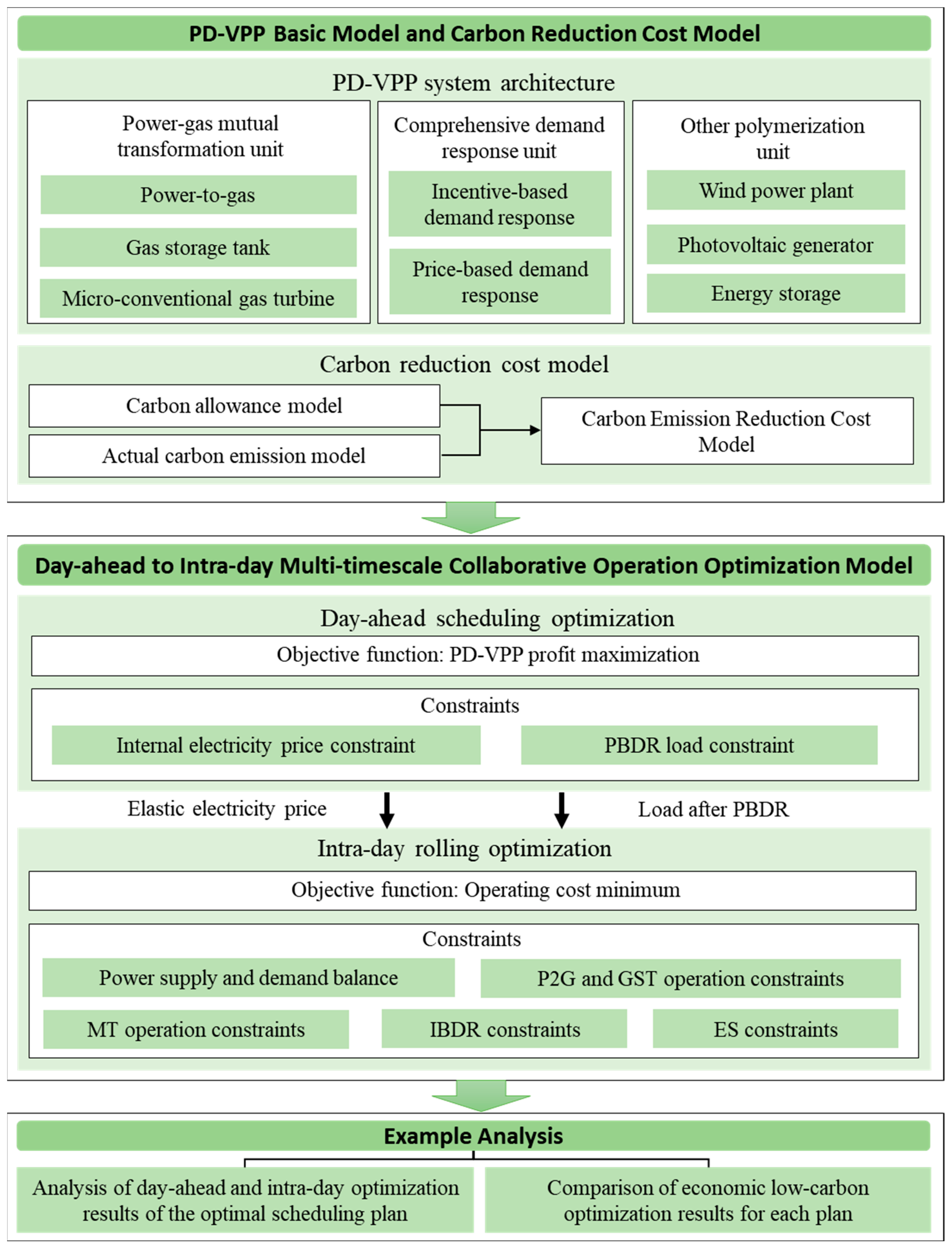

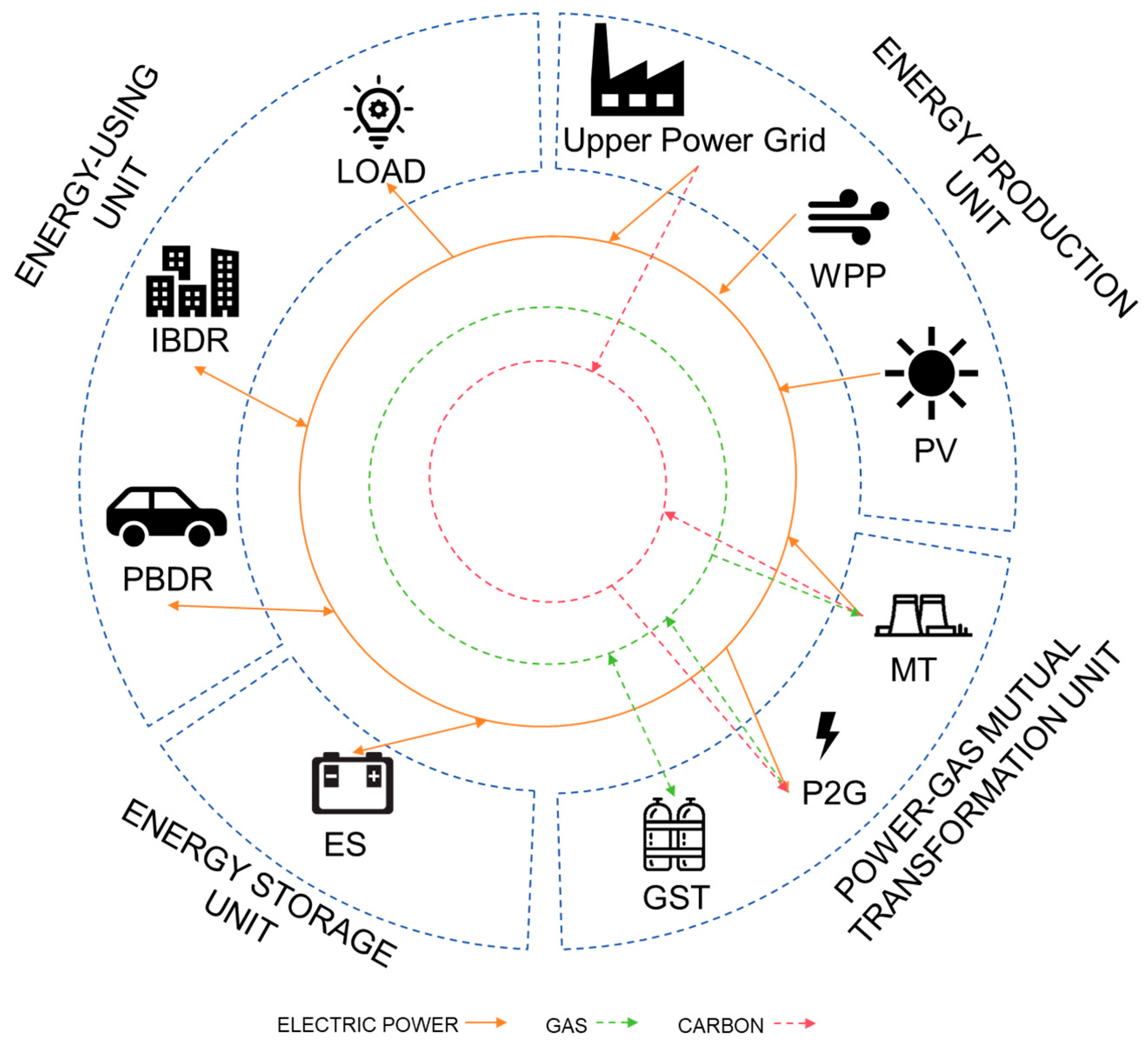

2. PD-VPP Operational Framework

2.1. PD-VPP System Architecture

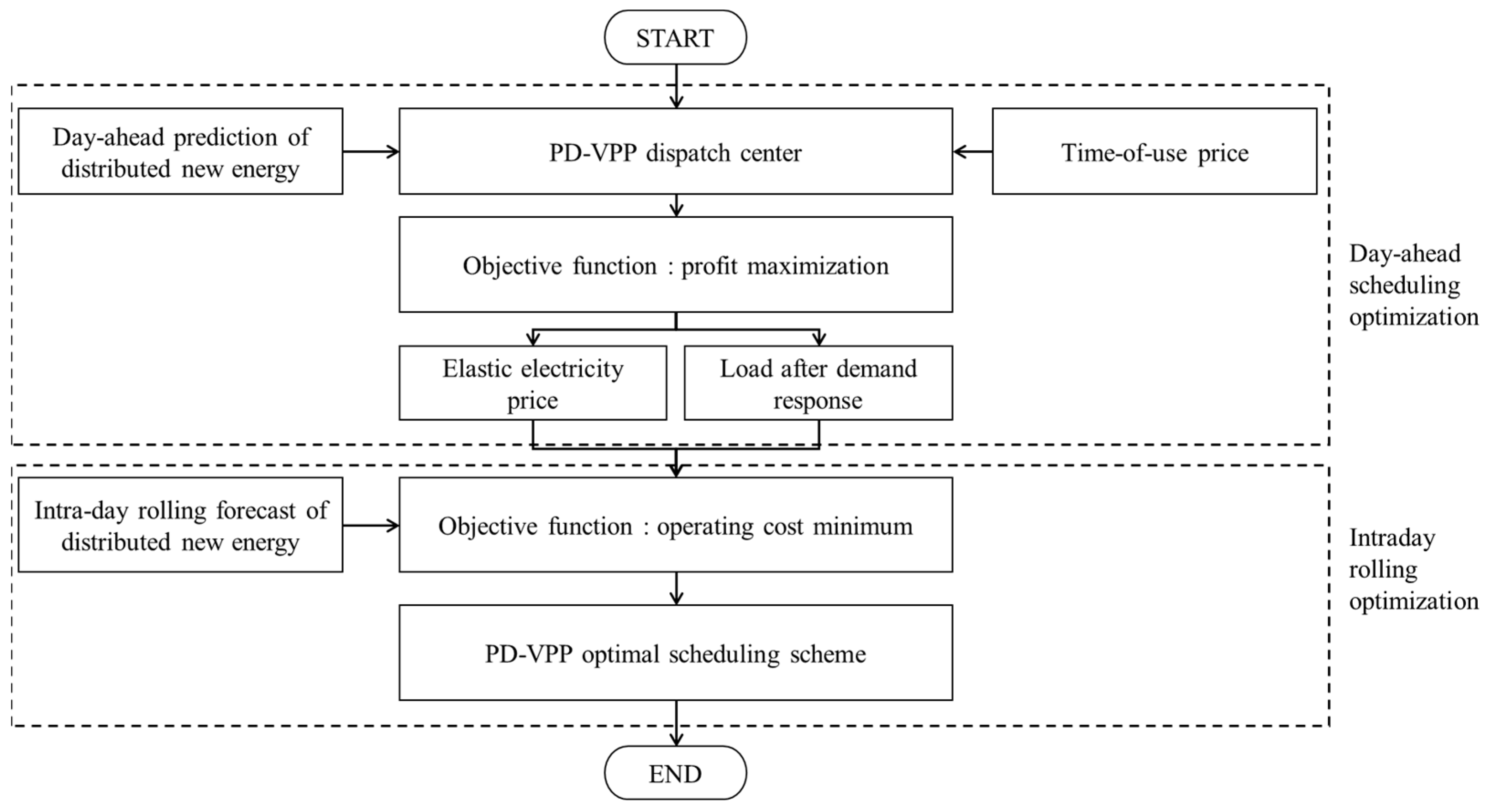

2.2. Day-Ahead to Intraday Multi-Timescale Collaborative Scheduling Architecture

3. Basic PD-VPP Model and Carbon Reduction Cost Model

3.1. VPP Basic Model

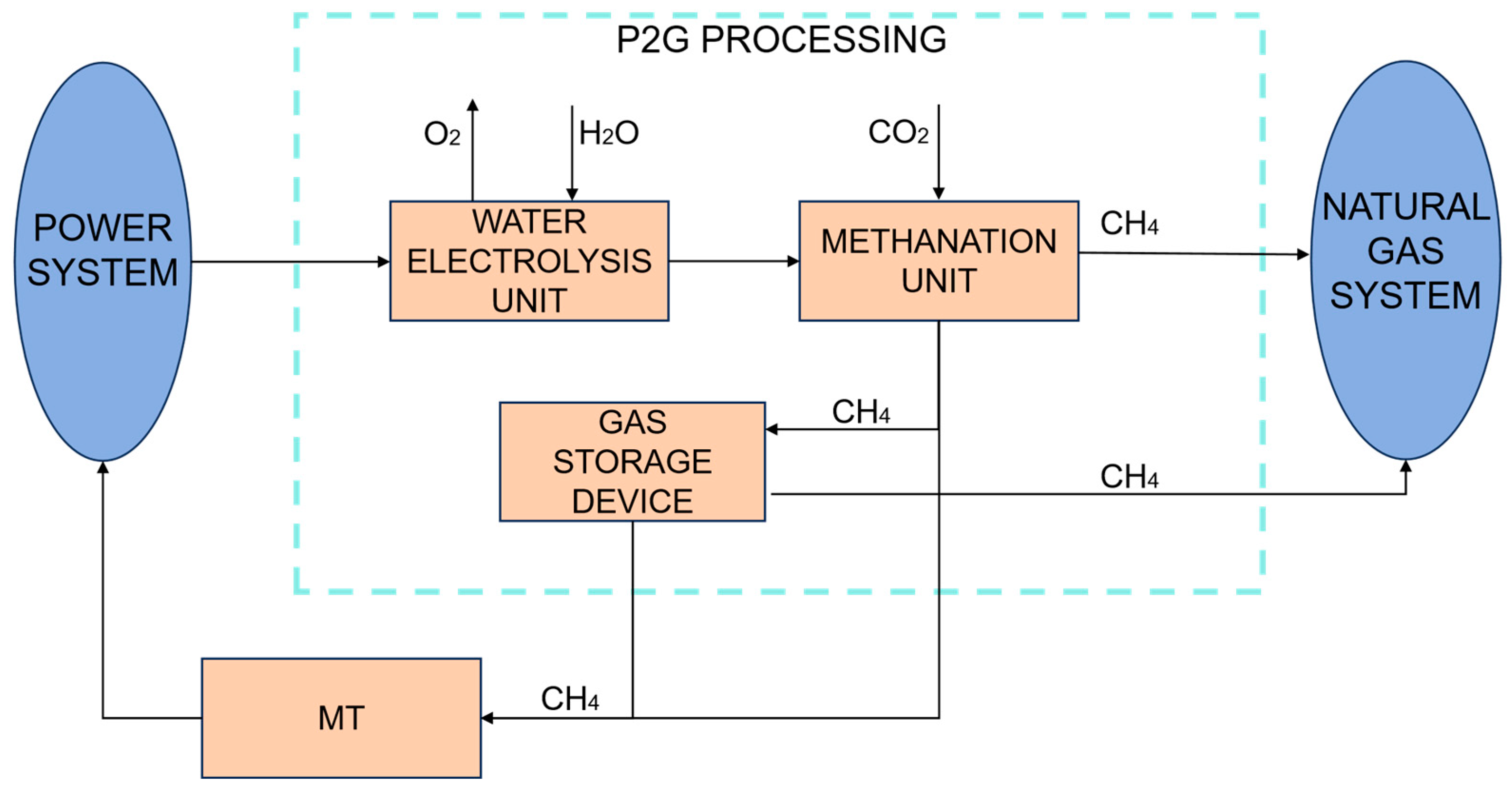

3.1.1. Power–Gas Mutual Transformation Model

3.1.2. Comprehensive Demand Response Model

3.1.3. Other Polymerization Unit Models

3.2. Carbon Reduction Cost Model under the Stepped Carbon Trading Mechanism

3.2.1. Carbon Allowance Model

3.2.2. Actual Carbon Emission Model

3.2.3. Carbon Emission Reduction Cost Model

4. Day-Ahead to Intraday Multi-Timescale Collaborative Operation Optimization Model

4.1. Day-Ahead Scheduling Optimization

4.2. Intraday Rolling Optimization

5. Example Analysis

5.1. Example Description

5.2. Analysis of Dispatch Results

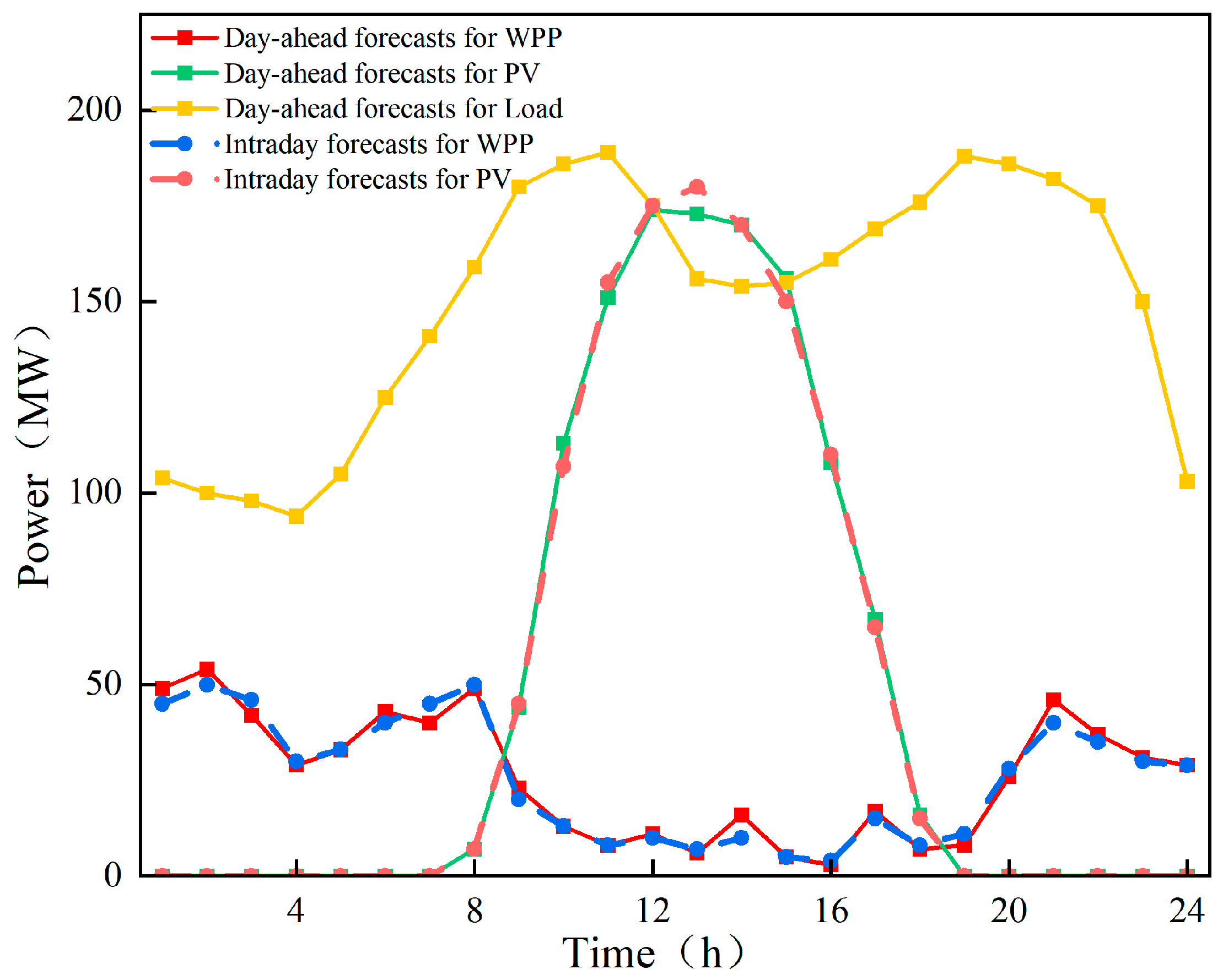

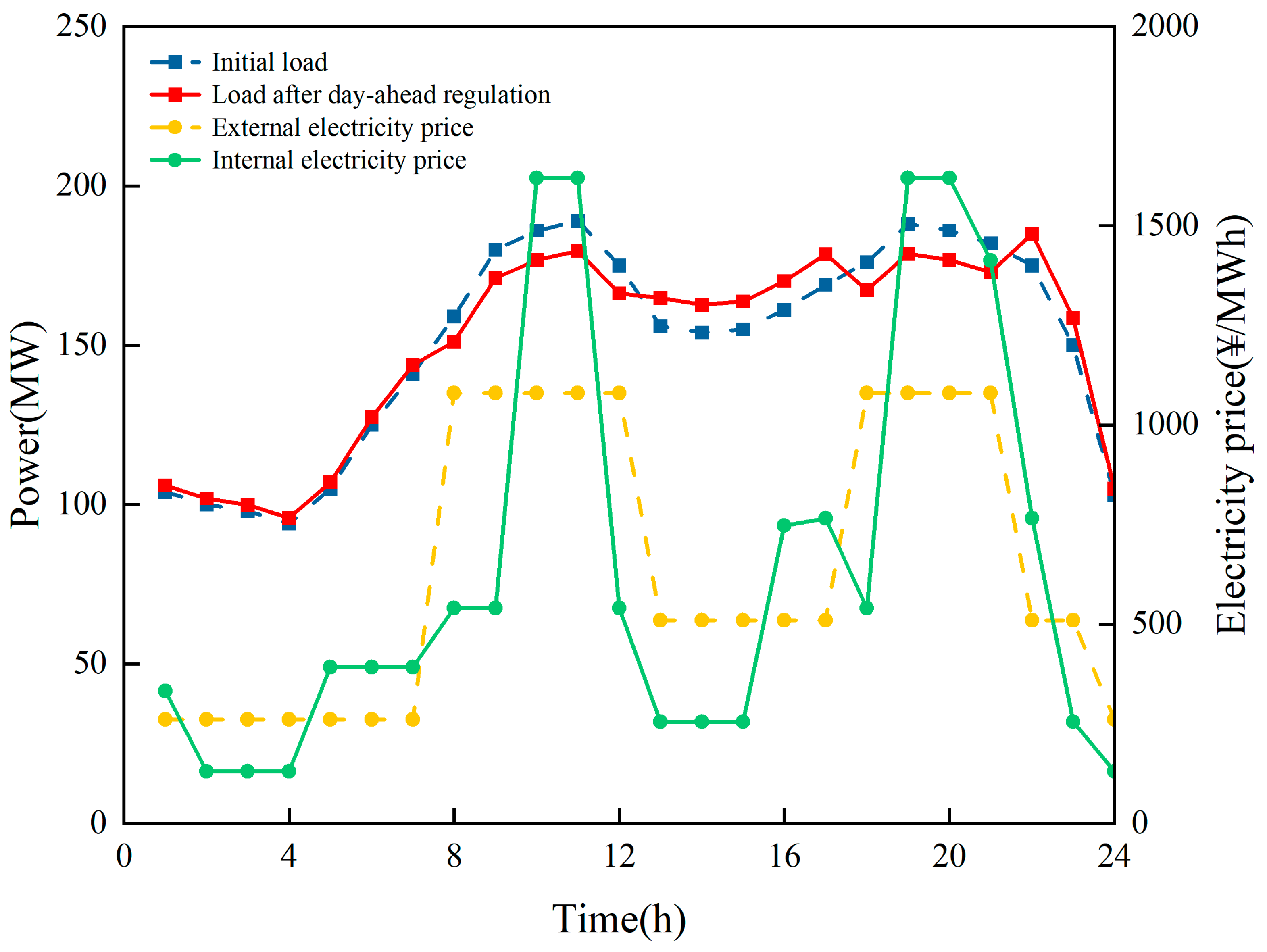

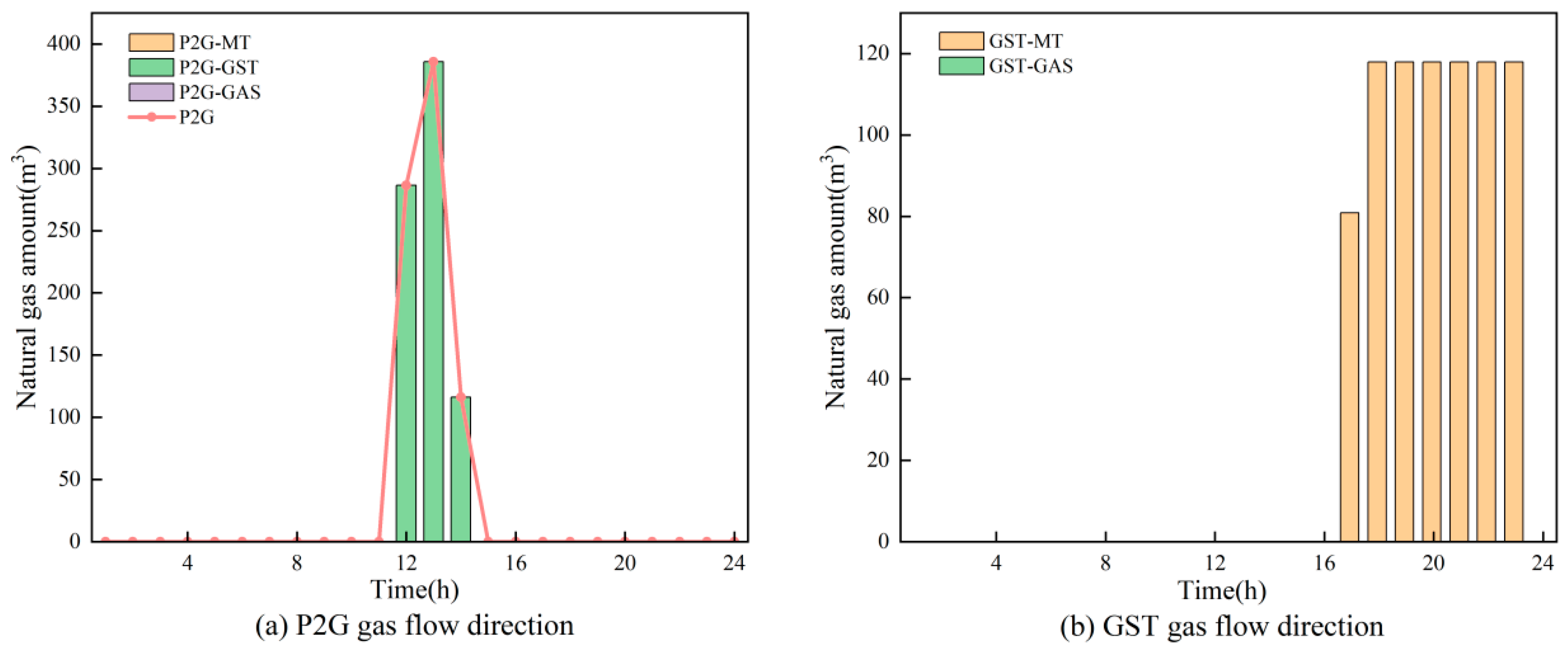

5.2.1. Analysis of the Optimization Results of the Optimal Scheduling Plan

5.2.2. Comparison of Economic Low-Carbon Optimization Results for Each Plan

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Equipment | Capacity/MW | Energy Conversion Efficiency/% |

|---|---|---|

| P2G | 10 | 60 |

| MTs | 100 | 98 |

| ES | 5 | 95 |

References

- National Development and Reform Commission, National Energy Administration. Opinions on Improving Institutional Mechanisms and Policy Measures for Green and Low-Carbon Energy Transition [EB/OL]. Available online: https://www.gov.cn/zhengce/zhengceku/2022-02/11/content_5673015.htm (accessed on 21 July 2024).

- Kang, C.; Du, E.; Li, Y.; Zhang, N.; Chen, Q.; Hongye, G.; Peng, W. “Carbon Perspective” of the New Power System: Scientific Issues and Research Framework. Power Syst. Technol. 2022, 46, 821–833. [Google Scholar] [CrossRef]

- National Energy Administration. Policy Interpretation of Notice on Carrying out Pilot Work of Wind and Photovoltaic Power Generation Resource Census [EB/OL]. Available online: https://www.nea.gov.cn/2024-06/06/c_1310777428.htm (accessed on 6 June 2024).

- The Central Committee of the Communist Party of China, the State Council. Opinions on Fully Implementing the New Development Concept and Achieving Carbon Peak and Carbon Neutrality [EB/OL]. Available online: http://www.gov.cn/zhengce/2021-10/24/content_5644613.htm (accessed on 22 September 2021).

- Naval, N.; Yusta, J.M. Virtual power plant models and electricity markets-A review. Renew. Sustain. Energy Rev. 2021, 149, 111393. [Google Scholar] [CrossRef]

- Dong, Z.; Zhang, Z.; Huang, M.; Yang, S.; Zhu, J.; Zhang, M.; Chen, D. Research on day-ahead optimal dispatching of virtual power plants considering the coordinated operation of diverse flexible loads and new energy. Energy 2024, 297, 131235. [Google Scholar] [CrossRef]

- Li, Z.; Xu, Y.; Fang, S.; Mazzoni, S. Optimal placement of heterogeneous distributed generators in a grid-connected multi-energy microgrid under uncertainties. IET Renew. Power Gener. 2019, 13, 2623–2633. [Google Scholar] [CrossRef]

- Li, Y.; Deng, Y.; Wang, Y.; Jiang, L.; Shahidehpour, M. Robust bidding strategy for multi-energy virtual power plant in peak-regulation ancillary service market considering uncertainties. Int. J. Electr. Power Energy Syst. 2023, 151, 109101. [Google Scholar] [CrossRef]

- Li, J.; Mo, H.; Sun, Q.; Wei, W.; Yin, K. Distributed optimal scheduling for virtual power plant with high penetration of renewable energy. Int. J. Electr. Power Energy Syst. 2024, 160, 110103. [Google Scholar] [CrossRef]

- Xia, Y.; Xu, Q.; Li, Y.; Fu, H.; Shi, L.; Lin, K.; Wu, F.; Xia, Y.; Xu, Q.; Li, Y.; et al. Peer-to-peer energy trading participating in ancillary service market as federated power plants. Int. J. Electr. Power Energy Syst. 2024, 157, 109859. [Google Scholar] [CrossRef]

- Ju, L.; Tan, Q.; Lu, Y.; Tan, Z.; Zhang, Y.; Tan, Q. A CVaR-robust-based multi-objective optimization model and three-stage solution algorithm for a virtual power plant considering uncertainties and carbon emission allowances. Int. J. Electr. Power Energy Syst. 2019, 107, 628–643. [Google Scholar] [CrossRef]

- Tan, Y.; Zhi, Y.; Luo, Z.; Fan, H.; Wan, J.; Zhang, T. Optimal Scheduling of Virtual Power Plant with Flexibility Margin Considering Demand Response and Uncertainties. Energies 2023, 16, 5833. [Google Scholar] [CrossRef]

- Li, J.; Sun, Z.; Niu, X.; Li, S.; Li, J.; Sun, Z.; Niu, X.; Li, S. Economic optimization scheduling of virtual power plants considering an incentive based tiered carbon price. Energy 2024, 2024, 132080. [Google Scholar] [CrossRef]

- Liu, X.; Ni, Y.; Sun, Y.; Wang, J.; Wang, R.; Sun, Q. Multi-VPPs power-carbon joint trading optimization considering low-carbon operation mode. J. Energy Storage 2024, 83, 110786. [Google Scholar] [CrossRef]

- Ju, L.; Lv, S.; Zhang, Z.; Li, G.; Gan, W.; Fang, J. Data-driven two-stage robust optimization dispatching model and benefit allocation strategy for a novel virtual power plant considering carbon-green certificate equivalence conversion mechanism. Appl. Energy 2024, 362, 122974. [Google Scholar] [CrossRef]

- Pignataro, V.; Liponi, A.; Bargiacchi, E.; Ferrari, L. Dynamic model of a Power-to-Gas system: Role of hydrogen storage and management strategies. Renew. Energy 2024, 230, 120789. [Google Scholar] [CrossRef]

- Shao, Y.; Wang, J.; Ding, J.; Zhang, Y. Stochastic scheduling optimization of integrated energy system based on hybrid power to gas and hydrogen injection into gas grid. Int. J. Hydrog. Energy 2024, 80, 381–393. [Google Scholar] [CrossRef]

- Cheng, Y.; Liu, M.; Chen, H.; Yang, Z. Optimization of multi-carrier energy system based on new operation mechanism modelling of power-to-gas integrated with CO2-based electrothermal energy storage. Energy 2021, 216, 119269. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Ji, X.; Xu, H.; Yang, C.; Meng, X. Hybrid energy storage capacity configuration strategy for virtual power plants based on variable-ratio natural gas-hydrogen blending. Int. J. Hydrog. Energy 2024, 58, 433–445. [Google Scholar] [CrossRef]

- Li, H.; Fan, W.; Li, N.; Tan, C.; Xu, D.; Ju, L. Near-Zero Carbon Dispatching Optimization Model of Virtual Power Plant Connected with Power-to-Gas Considering Uncertainties of Wind and Photovoltaic Power. Electr. Power Constr. 2020, 41, 10–19. [Google Scholar]

- Sun, H.; Liu, Y.; Peng, C.; Meng, J. Optimization Scheduling of Carbon Capture and Waste Incineration Virtual Power Plants Considering Electricity to Gas Synergy. Power Syst. Technol. 2021, 45, 3534–3545. [Google Scholar] [CrossRef]

- Li, Q.; Zhou, Y.; Wei, F.; Li, S.; Wang, Z.; Li, J.; Zhou, G.; Liu, J.; Yan, P.; Yu, D. Multi-time scale scheduling for virtual power plants: Integrating the flexibility of power generation and multi-user loads while considering the capacity degradation of energy storage systems. Appl. Energy 2024, 362, 122980. [Google Scholar] [CrossRef]

- Yi, Z.; Xu, Y.; Gu, W.; Wu, W. A multi-time-scale economic scheduling strategy for virtual power plant based on deferrable loads aggregation and disaggregation. IEEE Trans. Sustain. Energy 2019, 11, 1332–1346. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, D.; Lyu, L.; Zhang, L.; Du, H.; Luan, H.; Zheng, L. Multi-Time-Scale Low-Carbon Economic Dispatch Method for Virtual Power Plants Considering Pumped Storage Coordination. Energies 2024, 17, 2348. [Google Scholar] [CrossRef]

- Shi, X.; Bai, X.; Wang, P.; Shang, Q. Multi-Time-Scale Rolling Optimal Scheduling of Virtual Power Plants in Energy and Flexible Ramping Product Markets. Energies 2023, 16, 6806. [Google Scholar] [CrossRef]

- Sheng, S.; Gu, Q. A day-ahead and day-in decision model considering the uncertainty of multiple kinds of demand response. Energies 2019, 12, 1711. [Google Scholar] [CrossRef]

- Ju, L.; Yin, Z.; Zhou, Q.; Li, Q.; Wang, P.; Tian, W.; Li, P.; Tan, Z. Nearly-zero carbon optimal operation model and benefit allocation strategy for a novel virtual power plant using carbon capture, power-to-gas, and waste incineration power in rural areas. Appl. Energy 2022, 310, 118618. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, H.; Hong, F.; Yang, J.; Chen, Z.; Cui, H.; Feng, J. Modeling and optimization of combined heat and power with power-to-gas and carbon capture system in integrated energy system. Energy 2021, 236, 121392. [Google Scholar] [CrossRef]

- Liu, C.; Pang, P.; Shi, W.; Shen, J.; Sun, Y.; Bao, H. Taking into Account Carbon Neutrality Benefit and Clean Energy Consumption of Virtual Power Plant Two-layer Cooperative Optimization Dispatching. Distrib. Util. 2021, 38, 19–27. [Google Scholar] [CrossRef]

- Chen, J.; Hu, Z.; Chen, Y.; Chen, J.; Chen, W.; Gao, M.; Lin, M.; Du, Y. Thermoelectric optimization of integrated energy system considering ladder-type carbon trading mechanism and electric hydrogen production. Electr. Power Autom. Equip. 2021, 41, 48–55. [Google Scholar] [CrossRef]

| Type | Time Interval | Electricity Price/CNY |

|---|---|---|

| Hourly electricity price | 01:00–07:00, 23:00–24:00 | 0.261 |

| 08:00–12:00, 18:00–21:00 | 1.08 | |

| 13:00–17:00, 22:00–23:00 | 0.51 | |

| Natural gas price | 00:00–24:00 | 2 |

| Plan | Day-Ahead Scheduling Optimization | PBDR | Intraday Rolling Optimization | P2G |

|---|---|---|---|---|

| 1 | √ | × | × | × |

| 2 | √ | × | × | √ |

| 3 | √ | √ | √ | × |

| 4 | √ | √ | √ | √ |

| Plan | Profit/CNY 10,000 | Operating Cost/CNY 10,000 |

|---|---|---|

| 1 | 150.22 | 101.88 |

| 2 | 153.24 | 98.90 |

| 3 | 154.68 | 97.80 |

| 4 | 168.45 | 84.03 |

| Plan | Carbon Emission Reduction Cost/CNY 10,000 | Wind and Photovoltaic Utilization Rate/% |

|---|---|---|

| 1 | 33.19 | 97.90 |

| 2 | 32.22 | 98.94 |

| 3 | 33.04 | 98.43 |

| 4 | 20.88 | 99.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, S.; He, Y.; Li, Z.; Li, S.; Wang, P.; Chen, Z. A Novel Multi-Timescale Optimal Scheduling Model for a Power–Gas Mutual Transformation Virtual Power Plant with Power-to-Gas Conversion and Comprehensive Demand Response. Energies 2024, 17, 3805. https://doi.org/10.3390/en17153805

Yin S, He Y, Li Z, Li S, Wang P, Chen Z. A Novel Multi-Timescale Optimal Scheduling Model for a Power–Gas Mutual Transformation Virtual Power Plant with Power-to-Gas Conversion and Comprehensive Demand Response. Energies. 2024; 17(15):3805. https://doi.org/10.3390/en17153805

Chicago/Turabian StyleYin, Shuo, Yang He, Zhiheng Li, Senmao Li, Peng Wang, and Ziyi Chen. 2024. "A Novel Multi-Timescale Optimal Scheduling Model for a Power–Gas Mutual Transformation Virtual Power Plant with Power-to-Gas Conversion and Comprehensive Demand Response" Energies 17, no. 15: 3805. https://doi.org/10.3390/en17153805

APA StyleYin, S., He, Y., Li, Z., Li, S., Wang, P., & Chen, Z. (2024). A Novel Multi-Timescale Optimal Scheduling Model for a Power–Gas Mutual Transformation Virtual Power Plant with Power-to-Gas Conversion and Comprehensive Demand Response. Energies, 17(15), 3805. https://doi.org/10.3390/en17153805