Abstract

Biomass-fueled organic Rankine cycles (ORCs) are widely utilized technologies for power production because of their simplicity, low cost, and relatively high efficiencies. Furthermore, raw material availability and topographical independency make these systems preferable to other renewable-fueled power generation systems. A deep and comprehensive understanding of biomass-fueled organic Rankine cycles will provide researchers with a solid foundation to prioritize their investigations and assist future developments in this field. In this regard, feedstocks and their properties, biomass conversion mechanisms, and biomass-fueled power generation systems are discussed in this study. Power generation technologies based on coal and waste as feedstock have been widely investigated in the literature due to higher energy content and technological maturity. Additionally, depending on the type of biomass available, the scale of the power plant, and economic and environmental considerations, the most common technologies utilized for biomass conversion are combustion, gasification, and anaerobic digestion. Finally, the authors investigate various aspects of biomass-fueled organic Rankine cycles, including working fluids, analysis methods, and environmental issues. Since maximizing product yield is key in biomass-based power generation systems, technical assessment of these systems has been a primary focus of many studies. Further research is required on integrated environmental and socio-economic approaches, along with Machine Learning algorithms. Future advancements focusing on integration of feedstock with other renewable energy sources, efficient working fluids like nanofluids, and high-tech heat exchangers will drive the development of biomass-fueled ORC systems.

1. Introduction

Greenhouse gas (GHG) emissions and the associated rise in global temperatures pose significant risks to living organisms. The use of fossil fuels for power generation is a major contributor to climate change. Consequently, renewable energy sources are increasingly sought as a sustainable alternative for a healthier environment. Biomass utilization is superior to other renewable sources, given the former’s reduced dependency on location and climate, as well as ease of accessibility [1,2]. Additionally, biomass can be stored and transported easily and represents roughly 10% of the world’s total basic energy supply today [3,4]. As a promising energy source, biomass is also preferred in underdeveloped countries for daily life necessities like heating and cooking [5]. According to the International Energy Agency (IEA), it is projected that 2.4 billion people will use biomass for cooking by 2030 [6]. On the other hand, developed countries use biomass as a renewable and sustainable energy source to improve environmental outcomes [5].

In the history of modern biomass utilization, the first successful establishment of a gasifier unit was achieved by Siemens in 1861, whilst a full biomass combustion power plant was located in the USA in the 1980s [7]. Following 2001, the development of biomass gasifiers gained momentum due to their suitability as a substitute for costly oil and growing environmental concerns. This acceleration was also driven by advancements in technology and increased awareness of the need for sustainable energy solutions [5]. Recent studies have uncovered a significant correlation between the use of biomass energy and the ecological footprint, which underscores the critical role of policymakers in advocating for the sustainable consumption of biomass energy. By implementing educational campaigns and raising awareness, policymakers can help promote practices that enhance environmental sustainability and encourage responsible biomass energy use [8].

As a form of chemical energy storage, biomass can be directly burned for heat or converted into gaseous or liquid fuels through various pathways. These conversion pathways include thermochemical processes such as pyrolysis and gasification, biochemical processes like anaerobic digestion and fermentation, and physicochemical processes such as transesterification. Each method offers distinct advantages and applications, enabling the efficient and versatile use of biomass for energy production.

Biomass finds applications across various sectors, including the industrial, transportation, residential, power generation, and commercial sectors. Of particular interest in this research is power generation from biomass, which is a well-established application. In 2020, biomass power generation supplied 718 TWh of electricity, demonstrating a robust average annual growth of 40 TWh over the previous five years. This growth highlights the increasing importance and potential of biomass as a sustainable energy source in the power generation sector [9]. Also, the overall electricalefficiency was reported as approximately 60–90% for integrated biomass-powered plants using combined heating and power (CHP) [10].

Thermal energy as the output of the combustion process can be obtained from any biomass type and converted to electric power through vapor-based cycles generally [11]. Organic Rankine cycles (ORCs) for efficient use of biomass have been introduced as a promising process because of their simplicity as well as their compensating for the efficiency penalties of steam cycles when using low- and medium-energy sources [12].

Additionally, biomass plays a significant role in the production of secondary energy carriers such as hydrogen and ammonia. One of the advantages of using biomass for these purposes is that the industrial processes involved are well-established and have reached a high level of technological maturity. Moreover, the equipment used in biomass-based production is often already part of existing industrial setups, facilitating seamless integration. Consequently, biomass holds considerable potential for implementing clean and sustainable production practices in this domain and could serve as a model for chemical manufacturing facilities [13,14].

Owing to swiftly growing energy requirements and the challenges linked to current energy systems, biomass has gained prominence as a high-potential fuel source for modern energy systems. Consequently, academics and researchers have concentrated on employing biomass as an energy source, integrating it with various established energy systems and power plants. Technologies such as internal combustion engines, gas turbines, ORCs, and solid oxide fuel cells have all been explored in conjunction with biomass and gasification. Ultimately, the technology selection relies on factors such as efficiency, economic viability, and capacity [15].

Novelty and Objectives of Study

This review study aims to assess the current state of the art and future development of ORCs fueled with biomass. In the next section, we categorize the biomass types and corresponding properties in order to identify which biomass type is suited for a specific conversion technology. In Section 3, we discuss the promising novel conversion technologies in detail. Section 4 explains the biomass-based power generation systems, including ORCs, which are the main focus of this study. Section 5 discusses biomass-fueled ORCs from various aspects, comprising the influence of working fluids on the performances of these plants, types of analysis, and environmental issues of the discussed plants. In Section 6, the future trends of this field are discussed.

Employing biomass for power generation through ORCs offers a viable route to sustainable energy production. Harnessing the benefits of biomass along with the efficiency of ORCs can lead to energy solutions that are both eco-friendly and cost-effective. This review aims to showcase the advancements in this field and pinpoint areas for future exploration. The findings will be valuable to researchers, policymakers, and businesses interested in biomass energy utilization.

2. Biomass Types and Characterizations

This section discusses various kinds of biomass and their properties.

2.1. Biomass Types

The critical primary phase in biomass formation is converting CO2 to organic compounds as the further step of absorbing solar radiation by the plant. Researchers have provided several characterizations, but for simplicity, the four main types of biomass are defined below [16]:

- Woody plants.

- Herbaceous plants.

- Wastes.

- Aquatic plants.

Since the technologies related to converting woody and herbaceous plants and wastes are mature, this research will study these types of biomasses.

2.2. Biomass Properties

The physical and chemical properties of a specific type of biomass are significant factors that provide information for selecting the appropriate conversion technology and determining further design and operational barriers. Moreover, the type of required end-use energy is the second aspect that determines the selection of biomass conversion technology. The principal biomass properties are as follows:

2.2.1. Moisture

The moisture of biomass is of interest when it comes to choosing the suitable conversion process. For instance, high-moisture herbaceous plants such as sugarcane are subjected to biochemical conversion technologies (fermentation, anaerobic digestion) with the purpose of producing ethanol or methane. On the other hand, low-moisture woody plants are suitable for thermal conversion processes. The approximate analysis of the representative biomass feedstocks is listed in Table 1.

Table 1.

Approximate analysis of the representative biomass feedstocks (adapted from [17,18,19,20,21,22,23,24,25,26,27,28,29]).

2.2.2. Fixed Carbon, Volatile Matter

Carbonaceous residues which remain after heating the biomass up to 950 °C for seven minutes and the removal of moisture, volatile matter, and ash are called fixed carbon [19]. Gaseous matter, including the moisture leaving the biomass during this process, is named volatile matter. The fixed carbon and volatile matter percentages are obtained as listed in the approximate analysis results in Table 1. The influence of the H/C ratio against the O/C ratio from elemental analysis on the heating value of solid fuels is shown through the Van Krevelen diagram in [30]. The Van Krevelen diagram illustrates the degree of carbonization of solid fuels, revealing that the energy stored in the carbon bonds is more than that between carbon and hydrogen or carbon and oxygen, which adversely affects the heating value of the fuel.

2.2.3. Ash

One of the inorganic components of biomass is ash, which is the solid residue from either thermochemical or biochemical processes. The ash content of different biomass types is listed in Table 1. The ash content influences the attainable energy from the biomass during the process. Moreover, the ash behavior may cause a functional problem in the selected technology by forming slag in combustion or melting under higher temperatures in combustion and gasification.

2.2.4. Alkali Metal

Alkali metal is discharged in the form of gaseous compounds (HCl, KCl, KOH, NaCl, etc.) during the process of gasification or combustion of biomass. They can be damaging to the components through fouling in heat exchangers, erosion of turbine blades, and blocking the burner ports [19].

2.2.5. Heating Value (HV)

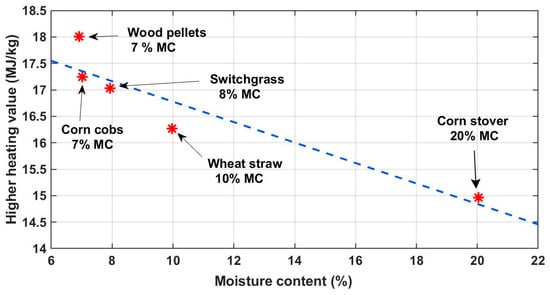

The heating value of a fuel is defined as the chemical energy contained within it which is released when it is combusted in the air. This energy is measured considering the standard reference and is expressed as energy per volume or mass. Figure 1 depicts the effect of moisture on the heating value, revealing the adverse impact of moisture content on the heating value of biomass types.

Figure 1.

The effect of wet basis moisture content (%) on the higher heating value (MJ/kg) of biomass types (adapted from [31]).

2.2.6. Cellulose/Lignin Ratio

Lignin, cellulose, and hemicellulose are the three primary components of the plant cell structure. In woody and herbaceous plants, cellulose is the dominant organic component of about 50 wt %. The portions of hemicellulose and lignin represent about 25% and 25%, respectively, neglecting the moisture and ash of the biomass [19]. The cellulose/lignin ratio is a significant factor in selecting a biomass species for biochemical conversion. Cellulose has more potential for biodegradability while the lignin concentration has a recalcitrant role in biochemical conversions; hence, the plants with higher cellulose can be a good source for the biochemical process [32,33]. The lignin, cellulose, and hemicellulose proportions in the selected biomasses can be seen in Table 2.

Table 2.

Lignin, cellulose, and hemicellulose concentrations of the representative feedstocks (dry wt %) (adapted from [19,34,35,36,37]).

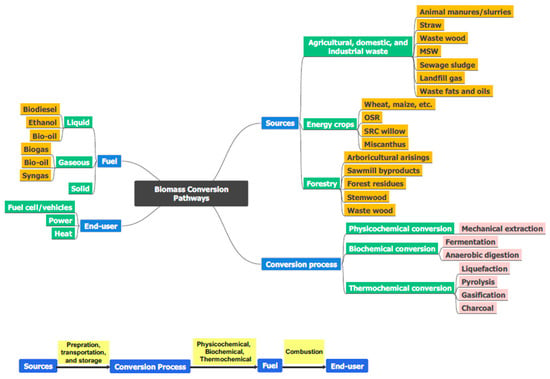

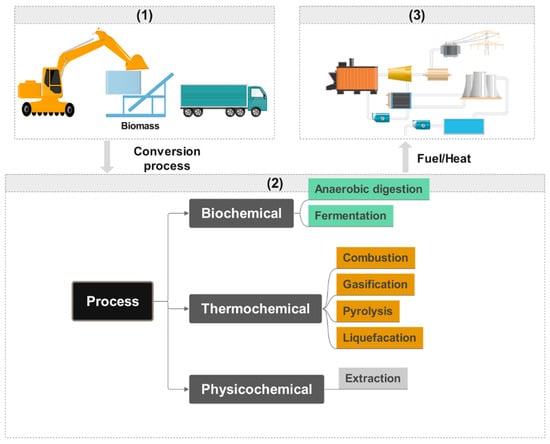

3. Biomass Conversion Technologies

Traditional biomass utilization has been routinized in developing countries accounting for 70% of biomass energy consumption, generally for space heating and cooking with low efficiency [38]. Additionally, modern biomass conversion technologies with upgraded efficiencies have been widely expanded in recent years. According to the IEA (International Energy Agency), an 8% increment occurred in bioenergy electricity generation in 2020, reaching 718 TWh [9]. The substitution of biomass for conventional energy sources requires an appropriate conversion technology, which depends on various parameters such as the characterization and availability of biomass feedstocks (moisture content, heating value, fixed carbon ratio, etc.), the type of energy yield (heat, gas, liquid, etc.), economic barriers, and environmental implications. Among the aforementioned factors, the type of energy yield and availability of biomass feedstocks are significant factors in defining the conversion technology route [39]. Biomass can be converted to bioenergy in terms of three main statuses: heat flow, gaseous or liquid fuels, and organic materials. The scheme of biomass conversion platforms is illustrated in Figure 2.

Figure 2.

The scheme of biomass conversion platforms.

Obtaining bioenergy from biomass is undertaken using three primary processes: thermochemical, biochemical, and physicochemical. Combustion, pyrolysis, gasification, and liquefaction are the four main process options for thermochemical conversion, while biochemical conversion comprises anaerobic digestion (AD) and fermentation as the two primary options. Meanwhile, mechanical extraction is specified as a physicochemical conversion technology. These technologies are briefly described below.

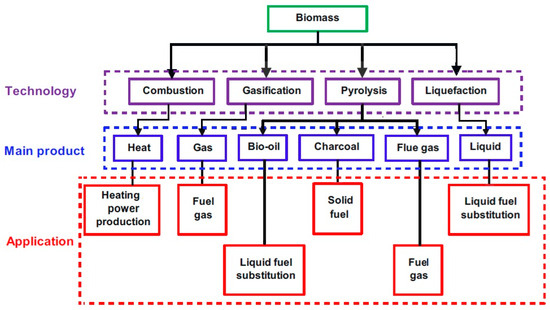

3.1. Thermochemical Process

Biomass turns into bioenergy thermochemically through combustion, gasification, pyrolysis, and liquefaction technologies. Combustion of biomass occurs in the first three subdivisions, with differences in combustion conditions and the form of energy product. Each pathway yields different types of products and is applied for a specific range of applications. These are expressed in Figure 3. Each technology will be discussed in detail in the following subsections:

Figure 3.

Technologies of thermochemical conversion and related products (adapted from [40]).

3.1.1. Combustion

Combustion is the most convenient method to convert biomass to heat or light used by humankind historically, happening via a primary combustion reaction, with the production of water and CO2 as byproducts. Applying combustion for energy production from biomass (at scales ranging from domestic heating to industrial uses) accounts for over 90% of the biomass consumed globally. The capacity of biomass combustion plants varies between domestic and large-scale power plants and has been proven to be a mature and commercially available technology [41]. Any type of biomass appropriate for biochemical processes can be combusted except those with moisture content above 50%. Despite its apparent simplicity, biomass combustion’s technical performance encounters different complexities that have led to various studies. These studies include the chemical reaction throughout the combustion, furnace technologies, efficiency enhancement, and emission reduction [42,43,44,45,46,47,48]. In the combustion process, four substantial stages occur: drying, pyrolysis, volatile gas combustion, and char combustion. Defining the efficiency of biomass combustion based on the wet-based LHV, the efficiency range varies between 56% and 99% [49]. The completeness of the burning process and the amount of heat loss from the furnace are two main parameters impacting combustion efficiency. Two main types of biomass furnaces have existed, namely, the fixed bed and the fluidized bed technologies. Table 3 provides more detail about these technologies. Fluidized beds have some features making them superior to fixed beds, such as the following [50]:

Table 3.

The characteristics of biomass combustion technologies.

- -

- Intensified stirring in fluidized beds, allowing complete combustion to occur, which leads to lower excess air rate and lower heat loss with stack gasses;

- -

- Resilience in utilizing biomasses with different properties, sizes, and shapes;

- -

- Flexibility in using biomasses with higher ash contents (>50%);

- -

- Capability of using biomasses with higher moisture rates of up to 60%;

- -

- Integrated structure of heat exchanger and furnace resulting in effective heat transfer.

3.1.2. Gasification

The turning of biomass with a controlled amount of a gasifying agent (supercritical water, air or oxygen, steam) into a mixture of combustible and non-combustible components in the presence of heat (>700 °C) is called gasification. Generally, a gasification process comprises four overlapped steps in a series and cannot be separated by specific boundaries. These steps are drying, pyrolysis, char gasification, and partial oxidation sequentially [5,51]. The volatile gas from the gasification process, can be combusted directly as an energy input for gas turbines and internal combustion engines. Moreover, it can be applied for generating transportation fuels (e.g., methanol, hydrogen) and value-added chemicals [52]. Gasifiers are categorized according to the means of delivering the biomass to the gasification bed and the type of gasifying agent. On this basis, four principal kinds of gasifiers have been developed: updraft (capacities lower than 10 MW); downdraft (capacities lower than 10 MW); entrained flow (capacities more than 50 MW); and fluid bed (capacities between 5 MW and 100 MW) [53,54].

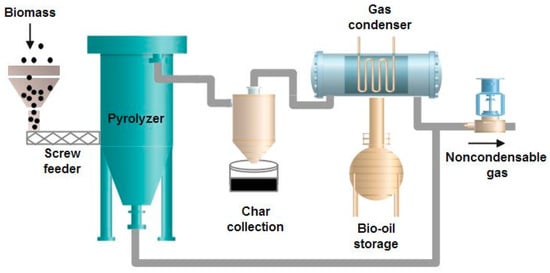

3.1.3. Pyrolysis

Pyrolysis is a fundamental process of all thermochemical conversions since it occurs during these processes to compose gaseous, liquid, and solid products [55]. Pyrolysis is a kind of processing wherein the organic materials are disintegrated in an oxygen-free environment, under pressure and at around 500 °C. The pyrolyzing process is identical to gasification, and the main outputs are bio-oil, charcoal, and flue gas. The schematic of a typical pyrolysis process is depicted in Figure 4.

Figure 4.

The schematic of a typical pyrolysis (adapted from [51]).

It is noteworthy that despite biomass improvements, its heating value is still lower than that of coal. Therefore, biofuel extraction is economically feasible in the case of biomass availability in those regions with inaccessibility of coal resources [38]. Technically, pyrolysis is less mature than gasification and combustion, and these technologies are in the R&D and demonstration stages. Three main types of pyrolysis exist, which are explained in Table 4. These technologies have evolved based on research focusing on the proportions of gas, liquid, and solid products [56,57,58]. This is accomplished by adjusting the reaction conditions, such as the heating rate and the reaction temperature [51].

Table 4.

Details of three types of pyrolysis.

3.1.4. Liquefaction or Hydrothermal

Liquefaction or hydrothermal is a process in which large biomass molecules are disintegrated to form a stable and smaller liquid hydrocarbon under high hydrogen pressures (5–20 MPa) and low temperatures (250–330 °C). In this conversion pathway, water operates as a reactant and catalyst [55]. The product contribution in liquefaction is 60–75% wt of liquid, 15–20% wt of gas, and 8–20% wt of solid [66]. Hydrothermal liquefaction is appropriate for biomasses with higher ash and moisture content. It results in the production of bio-crude, which can be improved by catalytic hydrotreatment in order to qualify as the feedstock for refineries [67]. Commercially, liquefaction application is not under the spotlight due to its high cost compared to the pyrolysis process [39,51].

3.2. Biochemical Process

This conversion pathway (biochemical process) comprises two primary technologies: anaerobic digestion, which results in the generation of biogas, and fermentation, which concludes in ethanol production. In anaerobic digestion, the organic materials of the biomass are converted to valuable gas through bacteria in the absence of air. On the other hand, in fermentation, yeast is the medium to form ethanol from the sugar of the biomass. Anaerobic digestion is a mature process known globally and economically viable. In contrast, fermentation suffers from lower process performance and higher costs due to the necessity of diluted alcohol distillation [68].

3.2.1. Anaerobic Digestion

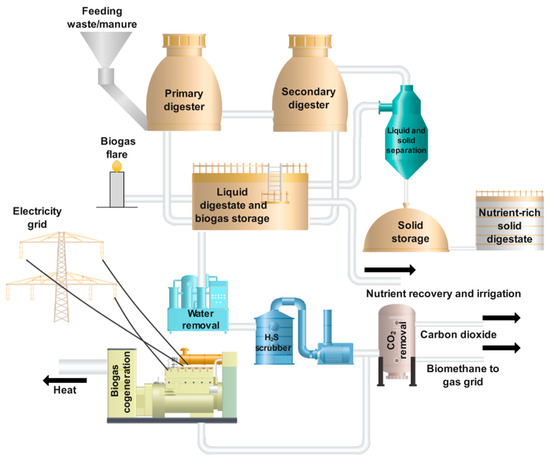

Anaerobic digestion is a process with biogas as an output that comprises 50–60% methane, ~40–50% carbon dioxide, and others (e.g., H2S). Moreover, bio-fertilizer is a by-product of the conversion that is rich in nutrients and can be processed further for other applications. Non-woody biomass is converted to valuable gas via micro-organisms in an oxygen-free environment. High-moisture feedstocks are suitable for anaerobic digesting, a technically feasible technology [68,69]. Figure 5 depicts the typical layout of an anaerobic digestion plant integrated into a cogeneration unit.

Figure 5.

A typical layout of an anaerobic digestion plant integrated into a cogeneration unit (adapted from [69]).

3.2.2. Fermentation

Fermentation is a conventional method to generate bioethanol (from sugar, etc.) [39]. A fermentation plant began to operate in 1937 in Kansas to manufacture anhydrous ethanol for engines [19]. The process of converting sugars to ethanol occurs through enzymes with the assistance of yeast. The yielded ethanol is purified within a distillation process by an energy-intensive technology during the subsequent step. Recently, methods to enhance the energy performance of fermentation technologies have been studied by several researchers [70,71,72,73]. Woody and herbaceous plants are rarely employed for the fermentation process due to their complex molecules, which necessitate enzymatic hydrolysis. [39]. Bioethanol is blended with fuels to reduce petroleum consumption in vehicles and greenhouse gas emissions. Meanwhile, utilizing bioethanol reduces nitrogen oxide (NOx) emissions because it is an oxygenated fuel. As a significant application, bioethanol can be blended with gasoline to boost the octane number of the blended fuel, resulting in the avoidance of knocking and higher combustion efficiency in ICEs [74].

3.3. Physicochemical Process

The physicochemical processing of biomass is accomplished through mechanical extraction, which is used to extract the bio-oil from oil seeds like oilseed rape and linseed. In the following step, bio-diesel is formed as the result of esterification. The byproduct of this process is a residual solid consumed as animal fodder. Along with pyrolysis and fermentation, mechanical extraction is the third primary technique to generate transportation fuel from biomass. The major application of bio-diesel is in mixtures with diesel (from petroleum) as transportation fuel. Production of vegetable oil from seeds through mechanical extraction has been conventional for many years [39,51,69].

4. Biomass-Based Power Generation Systems

Electricity supply has a significant role in the economy and obviously this importance affects the social welfare, economic growth, and sustainable development of a country. The electricity industry is one of the most crucial infrastructure industries, and electricity consumption rose to about 25,027 TWh in 2019 in all sectors worldwide, according to [3]. Also, power generation from renewable energy resources accounted for 29% of global generation in 2020 [75]. The outlook of power generation until 2040 shows that the increase in the share of renewable energy in power generation will continue, whereas coal-driven power generation will be constant or even declining in some scenarios [76]. Several alternatives have been developed for electricity generation since 1884 and the invention of steam cycles by Sir Charles Parsons. Some of these technologies are the steam cycle, gas turbine cycle, gas turbine combined cycle, wind turbine, hydropower, pumped-storage hydroelectricity, photovoltaic panel, fuel cell, tidal power, nuclear fusion, wave power, etc. The steam cycle, as a pioneering technology for power generation, has the potential to be integrated into several energy sources, such as renewable and non-renewable sources [77]. Different classifications of the steam cycle have been introduced, like the ORC. Aspects of ORCs will be discussed in detail in Section 4.1.

A biomass-based power generation project’s economic feasibility fundamentally depends on the feedstock type and supply, biomass conversion technology, and power generation process. Among these three factors, biomass feedstock availability is the most influential factor, including dedicating land use for energy crops, harvesting, pretreatment, and the logistics of delivery. Feedstock cost is estimated according to market indicators; however, the share of feedstock cost in the total levelized cost of electricity (LCOE) generally varies between 20% and 50%. Also, the LCOE of biomass-fueled power plants varies due to the wide range of conversion technologies, capital investment costs, feedstock costs, and capacity factors. But, as a rough estimation, and considering capital costs of between 7.5% and 10% and feedstock costs of 1.50 USD/GJ, the global weighted-average LCOE of direct combustion biomass-fueled power plants commissioned in 2020 was 0.076 USD/kWh [78].

4.1. Organic Rankine Cycle (ORC)

The ORC presents an eminent alternative for electricity production from low- and/or medium-energy sources. The first application of organic fluid in the Rankine cycle was undertaken by Prof. Luigi D’Amelio in 1935 at the University of Naples [79]. The properties of the heat transfer fluid that influence the performance of a saturated steam cycle are molecular mass, the complexity of the molecules, and critical temperature. These properties contribute to the efficiency penalties of steam cycles using low- and medium-energy sources which can be addressed by developing ORCs using organic fluids as the working fluid.

4.1.1. ORC Components and Energy Sources

The existing ORCs in the market have a more straightforward layout than steam cycles, and the complicated ones are only considered in the literature. The basic ORC, reheat ORC, and regenerative ORC are the main configurations, which differ from thermodynamic and economic standpoints. According to a techno-economic analysis performed by Zhar et al. [80], at a heat source temperature of 200 °C, basic ORC and reheat ORC efficiencies range between 13% and 19%. In comparison, the efficiency of the regenerative ORC ranges between 14% and 21% for different working fluids. Also, in this case, the basic ORC with R123 (25.29 USD/MWh) and reheat ORC with Isobutane (33.91 USD/MWh) have the best and worst economic performance in terms of LCOE.

An ORC is applied when the thermal power or temperature of an energy source is limited. Accordingly, several energy sources like geothermal energy (dry steam, single and double flash, and binary), solar (concentrating solar power, concentrating PV/thermal collectors), recovered waste heat (cement and steel industry, internal combustion engine), and biomass energy (combustion, anaerobic digestion, gasification, pyrolysis, etc.), and the hybridization of these sources with each other or with fossil fuels, have potential to be exploited in order to provide energy for ORCs. Moreover, a basic ORC can be integrated into some subsystems with the purpose of multigeneration with a variety of valuable products in addition to power, such as cooling, heating, fresh water, hydrogen, drying, etc. A classification of the literature related to combining different energy sources with ORCs is presented in Table 5.

The plant configuration is so critical in the design of the system from technical and economic viewpoints that several studies have been devoted to comparing different configurations of ORCs to yield the optimum configuration [81,82,83].

Table 5.

A summary of studies on ORCs with different energy sources.

Table 5.

A summary of studies on ORCs with different energy sources.

| Energy Source | Study | Useful Outputs | Working Fluid |

|---|---|---|---|

| Solar | Noorpoor et al. [84] | Power, cooling, heating | R600a |

| Villarini et al. [85] | Power, cooling, heating | R245fa | |

| Mirbagheri et al. [86] | Power | R245fa | |

| Geothermal | Ganjehsarabi [87] | Power, hydrogen | Mixture of butane, pentane, and iso-pentane |

| Zanellato et al. [88] | Power | R245fa | |

| Eyerer et al. [89] | Power, heating | R1233zd(E) | |

| Waste heat | Heidarnejad et al. [90] | Power, cooling, heating | R123 |

| Kleef et al. [91] | Power | 1,3-butadiene and 4-methyl-2-pentene | |

| Chatzopoulou et al. [92] | Power | R245fa, R1233zd(E), R152a, R1234ze(Z), R1234yf, toluene, butane, pentane, and hexane | |

| Biomass | Borsukiewicz-Gozdur et al. [93] | Power, heating | Octamethyltrisiloxane, methylcyclohexane, methanol, and water |

| Kalina [94] | Power | R123 and R245fa | |

| Swierzewski et al. [95] | Power, heating | MDM (Octamethyltrisiloxane) | |

| Permana et al. [96] | power | R134a | |

| Solar–biomass | Ghasemi et al. [97] | Power, cooling, heating, and fresh water | R123 |

| Cao et al. [98] | Power, cooling, heating, and fresh water | R717 | |

| Solar–geothermal | Ghasemi et al. [99] | Power | Isobutane |

| Cakici et al. [100] | Power | R134a | |

| Geothermal–biomass | Borsukiewicz-Gozdur [101] | Power | R236fa, R245fa, R365mfc, cyclohexane |

| Thain et al. [102] | Power | n-Pentane | |

| Solar–fossil fuel | Boyaghchi et al. [103] | Power and cooling | R123 |

| Li et al. [104] | Power | Isopentane and R125 |

4.1.2. Working Fluids

Based on the thermodynamic perspective, the working fluids could be categorized into three main classifications according to the slope of vapor saturation curves in the diagram of T-s. Positive slopes, negative slopes, and nearly vertical slopes are associated with dry fluid, wet fluid, and isentropic fluid. Isentropic fluids are appropriate for ORCs since the requirement for establishing a regenerator is eliminated because of persistency saturation throughout the expansion [105,106]. The type of working fluid determines the amount of energy source exploitation. Therefore, the selection of an appropriate working fluid is a critical issue. An appropriate organic working fluid must offer encouraging thermophysical, environmental, safety, and economic properties as well as favorable process characteristics [79,107,108,109,110]. Therefore, several researchers have investigated the thermodynamic performance and economic viability of ORCs [87,111,112,113]. Drescher and Bruggemann [114] presented that applying Butylbenzene as the working fluid of a biomass-fueled ORC system has potential to improve the system’s thermal efficiency by about 1–3%, instead of using Octamethyltrisiloxane, Toluene, Ethylbenzene, and Propylbenzene. Liu et al. [115] found the fluid among n-pentane, HFE7000, and HFE7100 that showed the best thermal efficiency through thermodynamic modeling. The results indicated that the type of working fluid affects the performance of the biomass-fueled ORC system and modeling conditions. In the studied system, applying n-pentane as the working fluid yielded 16.6% thermal efficiency. In another study, Pezzuolo et al. [116] determined that a 3 MW biomass-based ORC power plant had the highest thermal and exergy efficiencies when using Toluene as working fluid rather than other fluids like E-benzene and O-xylene in electricity production mode. The properties of candidate working fluids for ORCs such as normal boiling point (Tb), critical temperature (Tcr), global warming potential (GWP), critical pressure (Pcr), and ozone depletion potential (ODP) are listed in Table 6.

Table 6.

Some working fluid properties for ORCs.

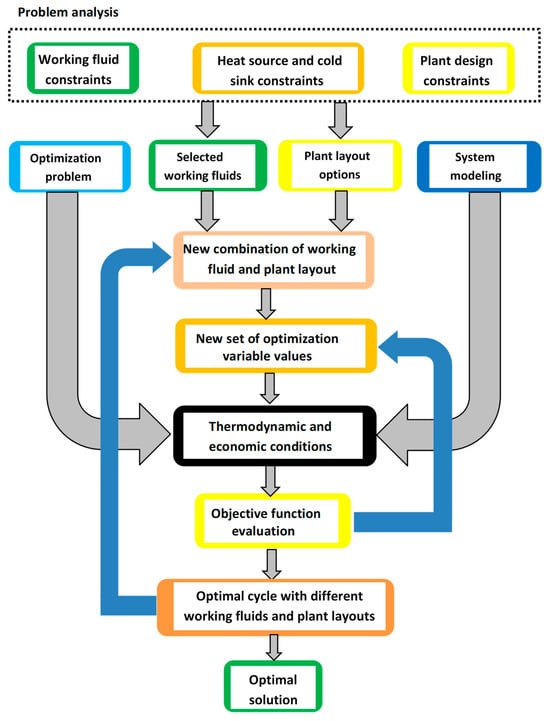

4.1.3. ORC Design and Optimization

The ORCs are likely to seem simple cycles in comparison to steam cycles, but since a complete recognition of the thermophysical properties of the working fluids (which are vast in number), components’ design, and economic considerations are essential to be taken into account, the design and optimization of ORCs is a complicated operation. Generally, the process of design and optimization of an ORC includes three iterative steps: (1) investigation of the problem, (2) choosing the system layout and working fluid, and (3) optimizing the system. Within this process, a robust algorithm along with consideration of technical and economic constraints and other limitations are essential to achieve an optimum design. The simplified sequence of the process is expressed in Figure 6. More details about the design and optimization procedure can be found in Ref. [79]. Defining an objective function is one of the optimization fundamentals that is determined according to the thermodynamic and economic performance of the ORC in most cases which are defined below [79,130]:

Figure 6.

The simplified sequence of the ORC design and optimization process (adapted from [79]).

- ✓

- Net electricity output: This is estimated as the gross output by turbine except for electricity consumption by pumps and other components.

- ✓

- Energy efficiency: The ratio of net electricity output to total energy input.

- ✓

- Exergy efficiency: The ratio of net electricity output to total exergy input.

- ✓

- Levelized cost of electricity: Total expenses related to investment cost, operation, and maintenance, and fuel cost during the lifetime of the system per energy unit of electricity produced by the system.

- ✓

- Discounted cash flow: This considers the time value of money.

- ✓

- Specific cost: This is the total investment cost per net power of the system, neglecting the fuel and operation and maintenance costs.

5. Biomass-Fueled ORCs

This section discusses various kinds of biomass-fueled ORCs.

5.1. Overview

Biomass was one of the conventional fuels used mainly for cooking and heating purposes throughout the world before the industrial revolution, while it was less common for power production [131]. Also, as various types of energy sources, especially those with limited temperature, became prevalent, adopting ORCs as a different class of prime mover became attractive. On the other hand, simple plant configurations, the lower cost of expanders, and reasonable performance in relatively low temperatures are the favorable characteristics of the ORC which have made it an appealing technology to match with renewable energy sources.

The first industrial 300 kW biomass-fueled ORC cogeneration power plant was installed in Switzerland with the purpose of providing heat and power for a Swiss Army training center [79]. Today, approximately 320 biomass-fueled ORC plants have been installed worldwide, mainly by manufacturers such as Turboden, Adoratek, GMK, Exergy, and Triogen. Biomass-fueled ORC plants have five main fields of applications like district heating [132,133,134,135,136,137,138,139,140,141,142,143,144,145,146,147,148], pellet production, olive oil mills [149,150], drying processes in the sawmill and wood industry [93,151], trigeneration [152,153,154,155,156,157,158,159], greenhouses, and electricity production [93,116,160,161,162]. The electric power capacity of biomass-fueled ORC plants is 500 kW–2 MW, and the corresponding thermal power capacity is 2 MW–8 MW [163]. An overall concept of a biomass-fueled ORC system is illustrated in Figure 7.

Figure 7.

An overall concept of a biomass-fueled ORC system (1) Biomass feedstock (2) Biomass conversion technologies (3) Organic Rankine Cycle.

5.2. Analysis of Biomass-Fueled ORC Systems

The ORC fueled with biomass is developed technically in conjunction with studies in this field. Some studies have reviewed the development of small and micro-scale systems [164,165], small CHP systems fueled with biomass [166], and biomass cogeneration technologies [167]. Crucial advancements are in progress in the field of biomass-fueled ORC systems, especially toward increasing the system performance, decreasing irreversibilities, and reducing expenses of the system, including capital and investment costs. These advances are being achieved through thermodynamic analysis (energy and exergy modeling) along with thermoeconomic (exergoeconomic) analysis, which are classified as assessment methods in Table 7a,b.

5.2.1. Thermodynamic Analysis

The majority of studies in the field of biomass-fueled ORC systems have been conducted from the thermodynamic viewpoint to determine the first and second laws of thermodynamics efficiencies and to identify irreversibilities of components and the overall system as well. Several publications are available in the field of thermodynamic modeling of biomass-fueled ORC systems, as given in Table 7a. Estimating first and second laws of thermodynamics efficiencies as the indicators of thermodynamic performance of these systems is a prevalent method in the literature, which is the ratio of output energy and exergy rates to input energy and exergy rates, respectively. Sevinchan et al. [168] evaluated the performance of an ORC-based multigeneration system driven by biogas extracted from chicken manure and agricultural waste. They calculated the energy and exergy efficiencies to be 72.5% and 30.44% and introduced the biogas combustion chamber as the most irreversible component of the system. Sikarwar et al. [169] compared the energy and exergy efficiencies of chemical-looping-based biomass-fired power plants with conventional power plants. They showed that both the suggested unit’s first and second laws of thermodynamics efficiencies improve relative to conventional ones.

5.2.2. Thermoeconomic (Exergoeconomic) Analysis

Since biomass-fueled ORC systems are combined with other subsystems with the aim of producing various outputs, e.g., power, heating, cooling, chemical substitutes, drying, etc., minimizing the costs related to investment expenses as well as the costs associated with deficiencies of the system performance is a complementary step before optimizing the performance of such systems. Thermoeconomic or exergoeconomic analysis is a combinational method considering energy, exergy, and economic principles widely used in recent literature. The micro-gas turbine (fueled by biogas) with bottoming ORC was assessed from a thermoeconomic viewpoint by Sung et al. [170]. The fuel was produced from food waste. The findings showed that the suggested system provides the maximum net present value despite seasonal change. Also, the system’s economic performance depends on the methane ratio of the produced biogas. Gholizadeh et al. [171] applied exergoeconomic analysis to a biogas-fueled trigeneration system in which different optimization modes, including the unit cost of trigeneration, were considered as the objective function. In both cost optimization design mode and multi-objective optimization design mode, the unit cost of trigeneration decreased relative to the base case model, by 17% and 6%. Zahedi et al. [172] used exergoeconomic and exergy analyses in order to optimize a quadruple combined system based on solar, biogas, steam Rankine cycle, and ORC with methane system. The cost of electricity generation was obtained to be USD 0.0636 per kilowatt-hour. Also, the payback period for the studied system was calculated to be 1.5 years based on the optimization results. Some other studies related to biomass-fueled as well as hybrid biomass/other renewable sources-fueled ORCs, including exergoeconomic analysis, are listed in Table 7a,b.

Table 7.

(a). A summary of studies on biomass-fueled ORCs. (b). A summary of studies on hybrid biomass/other renewable sources-fueled ORCs.

Table 7.

(a). A summary of studies on biomass-fueled ORCs. (b). A summary of studies on hybrid biomass/other renewable sources-fueled ORCs.

| Biomass Conversion Technology | Study | Useful Outputs | Efficiency | Assessment Method |

|---|---|---|---|---|

| (a) | ||||

| Biomass gasification | Huang et al. [173] | Power, heating | 76% (willow chip) 81% (miscanthus) | Techno-economic analysis |

| Behzadi et al. [174] | Power | 12.72% | Energy, exergy, and exergoeconomic analyses | |

| Karimi et al. [175] | Power and heating | 55.2% | Energy, exergy, and economic analyses | |

| Cao et al. [176] | Power and hydrogen | 39.2% | Three-objective optimization | |

| Anaerobic digestion of biomass | Ghaebi et al. [177] | Power and hydrogen | 45.63% | Thermodynamic analysis |

| Gholizadeh et al. [178] | Power | 41.83% | Thermodynamic and thermoeconomic | |

| Adebayo et al. [179] | Power, cooling, and heating | 47.4% | Energy, exergy, and exergoenvironmental | |

| (b) | ||||

| Biomass combustion/Geothermal | Moret et al. [180] | Power and heating | Different efficiencies in different scenarios | Environmental and life cycle assessment analyses |

| Briola et al. [181] | Power | 28.3–42.6% | Exergy and economic analyses | |

| Heidarnejad et al. [182] | Power and desalinated water | 13.9% | Techno-economic and environmental analyses | |

| Chen et al. [183] | Power and heating | 25.47% | Thermodynamic and economic analysis | |

| Dou et al. [184] | Power, heating, cooling, and fresh water | 20.55% | Thermodynamic and economic analysis | |

| Anaerobic digestion of biomass/Solar | Zhao et al. [185] | Power and heating | 11.17% | Exergy and economic analyses |

| Perollese et al. [186] | Power | 10–65% | Techno-economic assessment | |

| Al-Arfi et al. [187] | Power and fresh water | 30.49% | Thermo-economic and design | |

| Biomass combustion/Wind | Bamisile et al. [188] | Power, cooling, hot water, desalinated water, hydrogen, and oxygen | 35.22% | Energy and exergy analyses |

| Biomass combustion/Solar | Islam et al. [189] | Power, cooling, and hydrogen | 67.6% | Energy and exergy analyses |

| Oyekale et al. [190] | Power and heating | 40% | Exergoeconomic analysis | |

5.3. Environmental Issues

Environmental-related issues of biomass-fueled ORCs include two categories:

- (a)

- Environmental issues related to working fluids

GWP and ODP are generally used to assess the effects of working fluids on the environment. Most organic fluids used for ORCs have high GWP, especially the hydrofluorocarbons (GWP > 2000) used in many industries. The working fluids with a high GWP rate are still in use for ORC systems; however, R134a is banned in many countries. Consequently, Siloxanes, as one of the alternatives, are preferred given their high molecule mass and complexity, nontoxicity, and low ODP and GWP rates. However, some of them are flammable and forbidden in some countries. In the past, halogen compounds were used as working fluids due to their better thermodynamic properties, but they were banned in most countries in 1996, though they are not preferred for ORC systems [79].

- (b)

- Environmental issues related to the conversion of fuel to energy

The type and level of the pollutants generated during combustion depend on the biomass type, the combustion unit design, and the control measures applied. In most cases, larger capacity combustors that use perfectly monitored combustion control produce low levels of pollutants. In contrast, smaller capacities with poor mixing, short residence times, and little or no control systems generate high levels of pollutants. Generally, because of the considerable international efforts being made to decrease the negative effect of pollutants, the environmental impact of the biomass-fueled power generation systems is focused on in this research. In this section, environmental issues corresponding to different biomass conversion technologies are discussed, while the health effects of biomass conversion processes are not taken into account.

- ✓

- Combustion:

Direct biomass combustion includes PM2.5 particles, chlorine compounds, Sulphur Oxides (SOx), dioxins, unburned hydrocarbons, volatiles, Nitrogen Oxides (NOx) and other nitrogenous pollutants, trace metals, and especially the interaction of K–Cl–S chemistry and aerosol emissions [191].

- ✓

- Gasification:

Even though biomass gasification is a leading technology in waste utilization because of it exploiting an extensive category of waste materials as feedstock, it emits particulates (PM10 or PM2.5, dioxins), CO, SOx, NOx, polycyclic aromatic hydrocarbons (PAHs), and volatile organic elements [192]. Also, ash and tars are outputs that have the potential to contaminate the environment, while the collected ash from low-temperature Circulating Fluidized Bed (CFB) burners has low PAH impurity and can be utilized as fertilizer. Biomass gasification is better than biomass combustion without SOx and NOx mitigation compared to biomass combustion emissions. Therefore, gasification is favored for biomass exploitation when applying pollution mitigation units [5].

- ✓

- Pyrolysis:

Since bio-oil, charcoal, and flue gas are the main products of the pyrolysis technology, the emissions related to the combustion of these three products are investigated. CO, NOx, SO2, and PM emissions have been detected as the major pollutants of the corresponding burners of all three fuels. Despite these pollutants, bio-oil, char, and gas burners are cleaner than biomass combustion because of their higher efficiency. Optimizing the air/fuel ratio and utilizing a baghouse filter for the burner are two approaches to reducing the PM emissions of the pyrolysis system with no need to use professional emission control measures [193].

- ✓

- Liquefaction:

The emissions related to the liquefaction process are mainly considered under climate change, human toxicity, and acidification categories. The most common emissions during a hydrothermal liquefaction process are CO2 as a prominent emission, CO, volatile organic compounds (VOCs), NOx, PM, SO2, N2O, and CH4 [194].

- ✓

- Anaerobic digestion:

The biogas industry can reduce fossil fuel utilization, greenhouse gas, and global warming effects, although biogas production can produce harmful compounds and air contaminants. Generally, it is noteworthy that the emissions of the biogas industry are categorized under anaerobic digestion and biogas combustion. CH4 emitted during diffusive emission is connected with biomass storage and digestate handling along with incomplete biogas combustion [195]. CO2 is produced as the result of CH4 oxidation during biogas combustion, with an amount of 83.6 kg/GJ, as well as in the transport and storage of biomass [196]. Since the global warming power of CH4 is predicted to be 28–36 times higher than CO2 over 100 years, it is introduced as the most prominent emission in the biogas industry from the viewpoint of its effect on climate change [197]. N2O, as an important GHG, is also considered one of the biogas generation emissions [198,199]. Obviously, carbon monoxide (CO), as the combustion product of all carbon-containing materials, is generated during biogas combustion, varying between 80 and 265 mg CO MJ−1, depending on the unit efficiency [200]. SO2 emission from biogas plants generally depends on the desulfurization degree of the primary biogas. The amount of SO2 emission for a CHP biogas system is predicted to be around 19.2–25 milligrams per megajoule [196]. The comparatively high concentrations of SO2 in the proximity of biogas systems can rest on several factors, e.g., diffusive emissions of H2S oxidation, diesel truck exits, as well as direct emission from biogas combustion [201]. NOx is also another critical emission related to the environmental impact of biogas plants, which is higher when compared to natural gas engines [200]. When the emission factor is revealed as methane depletion, an emission factor of 0.63 and 11.6 g NOx/Nm3CH4 can be presumed for flaring and CHP, accordingly [202]. VOC concentrations in biogas ranges typically between 5 and 500 mg/Nm3, and in some cases up to 1700 mg/Nm3 is recognized, which is higher than natural gas [203,204].

- ✓

- Fermentation:

The emission resulting from fermentation mainly occurs in combustion, fermentation, and wastewater treatment. The overall CO2 emitted from fermentation, digester, and combustion chamber is between 3.7 and 4.9 kg per liter of combusted bioethanol. The anaerobic digestion may cause CH4 fugitive loss of around 3% [205]. As another emission, N2O is emitted from sugarcane fields due to nitrogen (N) fertilization, resulting in an emission factor of 3.87 ± 1.16% [206]. CO and NOx emissions were estimated to be 9.4 × 10−4–2.07 × 10−3 kg per liter of combusted bioethanol. The total sulfur in feedstock and wastewater treatment streams oxidized into sulfur dioxide (SO2) during combustion is estimated to be 1.2–3.46 × 10−3 kg per liter of combusted bioethanol [205].

6. Future Trends

Alongside the experimental research, mathematical studies support biomass-combustion ORC plants in dealing with challenges by addressing their deficiencies. Future studies will be focus on techniques for the pretreatment of biomass in the biomass conversion procedure. Future studies should traverse more preventive measures to decrease the content of ash produced by cleaning and combining the biomass pellets. Other approaches are currently being developed, with complex optimization techniques having been rarely applied. This enhances new opportunities for future research into the unrevealed potential of various biomass types compared to fossil fuels. The prospective studies should examine vital criteria like energy, carbon footprint, and food security.

Moreover, future research should address distinct working limitations such as equipment reliability, policies, regional matters, and acquiescence responsibility. Further subjects can unite environmental and socio-economic approaches to shed light on sustainability elements. Also, optimization of the stochastic formulas can inform future optimization approaches. Progress in the field could occur via additional in-depth research appropriating thermodynamic approaches like exergy, exergoeconomic, plus exergoenvironmental investigations in conjunction with performance simulation [207]. Numerous advances, such as in the process of combusting biomass within boilers, which are acknowledged as “boilers of the future”, aim to improve the biomass combustion process efficiency [208]. Furthermore, the biomass compound, determining the biomass higher heating value, the contrast between biomass and other combustibles, biomass burning, co-burning of coal and biomass, biomass social and economic visions, biomass transport, biomass densification, and the biomass prospect in energy competition [209] are future aspects of the ORC plant fueled by biomass that can strengthen strategic policies for the future. Relying on the best knowledge of the authors, some chief future prospects and challenges in the aforementioned areas are categorized and described in the following section:

6.1. Modeling of Biomass Conversion

The procedure of biomass burning simulation is challenging due to the convolution and difficulty of accessing and controlling the operation of the process. Biomass gasification process simulation and optimization are intricate tasks because models must account for the behavior of fluids and a considerable number of parameters. Therefore, Machine Learning (ML) algorithms with a decreased order model will effectively anticipate and diminish the computations’ costs. Moreover, direct biomass combustion has not been as effective as syngas. It is necessary to attain high temperatures and inhibit heat losses in exhaust gases for direct biomass combustion. Therefore, evaluating the higher heat value is beneficial for optimizing the biomass conversion process. It is anticipated that extensive use of ML in the future may provide new developments in the biomass conversion process, especially for uses where accessibility to details is challenging, time-consuming, or costly [210].

6.2. Environmental Impact of Biomass Conversion

A plentiful and expertly designed database for biomass pre-combustion can assist in improving environmental impact assessment approaches. The establishment of databases needs essays from scholars in this area to prepare the byproducts’ and residuals’ characteristics, rather than just concentrating on the objective outputs and the energy efficiency. It is expected that the energy efficiency and environmental impact will be suitably balanced in the future to utilize biomass effectively [211]. Future progress in biomass-based systems would aim to diminish emissions, raise feedstock versatility, and integrate the resource with different renewables [212]. According to the scenarios presented by the IEA in relation to future worldwide aims of biomass usage for energy production, bioenergy will rise from 60 EJ to 100 EJ by 2060 [213,214].

Furthermore, improvements to the filtration and scrubbing techniques of biomass ORC plants have consistently decreased the particulate matter emissions levels annually, and it is anticipated that this downward trend will be maintained in the future [215]. Generally, the combustion of biomass generates a significant quantity of ash that needs suitable disposal and control for better sustainable development. Therefore, the biomass should be treated and modified to increase the fusion temperature to improve the biomass fly ash generation. The use of biomass in new techniques like catalysis material and energy storage purposes also holds promise. Membrane technology advances reflect progress in reducing biomass fly ash. The membrane technology usage varies from environmental to catalysis for combustibles. Updated techniques that reduce ash quantity and increase carbon mitigation should be considered to help mitigate the impact of ash. The use of bottom ash from fluidized bed combustion (FBC) should be encouraged to reduce the production of ash with high carbon content [216].

6.3. Biomass Economic Aspects and Accessibility

An essential factor impacting biomass employment by industry is its cost [217]. Also, predicting future biomass prices remains challenging and is reliant upon factors like local supply chains, source accessibility, sustainability, policy options, and competing biomass applications. Based on the International Renewable Energy Agency (IRENA)’s estimates for a low energy cost case in the OECD in 2030, the costs of biomass and biomass from energy plants will be 5 and 13 USD/GJ, respectively [218]. The prices can be additionally employed as an index for further collation with different technologies. Furthermore, recognizing the chief obstacles currently obstructing the installation of various techniques can be helpful for future planning and the biomass options can be reconsidered, should the restrictions be eliminated [219]. Also, future endurable biomass access is one of the principal uncertainties and challenges associated with greater industrial biomass uptake.

6.4. Organic Rankine Cycles

The ORC technology has a promising future since it could satisfy energy demands, with arguably minimal environmental impacts. There are few studies considering ORC heat exchangers. Nevertheless, the layout of more well-set and lighter heat exchangers are increasingly important, especially in the emerging area of mobile uses. At this point, many heat transfer improvement techniques have led to new ideas, such as microchannel plus porous heat exchangers. The attachment of nanoparticles to the operating fluid can be helpful for the ORC system for ultra-high heat transfer. Also, heat exchangers with polymeric materials reflect an opportunity in these processes. In many countries, ORC power systems are available for feed-in tariff plans, giving subsidies to new technology adopters. In the future, a significant market could appear in developing countries where biomass fuel with a lower cost has been locally accessible [220]. Concerning the operating fluid, it should be noted that natural operating fluids and fluids with low GWP have to be selected for environmentally benign systems. In the future, it will be important to conduct more research in the area of stabilizing the ORC systems as a stationary and sustainable option. Trigeneration and multigeneration systems will also encourage options for future plans and designs [221].

7. Concluding Remarks

A low- to medium-heat source, such as biomass energy, may be used with the help of ORCs as a power production method. This work presents a comprehensive review and discussion of existing literature studies on ORCs that utilize biomass energy as the primary energy input. Biomass-based power generation technologies such as biomass-fueled ORCs can benefit various biomass types and system configurations to produce useful commodities including electricity, heating power, cooling power, fresh water, hydrogen, and others. A holistic knowledge of the concept along with a comprehensive categorization of the various aspects of biomass-fueled ORC systems are essential for optimization and advancements in a cost-effective manner. The in-depth review throughout this study covers different biomass feedstocks and biomass conversion platforms. Various energy sources and components of ORCs have been investigated to aid the optimization of prospective studies and the processes as a whole. In summary, the following issues have been identified through this review of the available literature on biomass-fueled ORCs:

- Selecting the appropriate conversion technology necessitates being conscious of the properties of a specific type of biomass. For instance, high-moisture species are applicable for fermentation and anaerobic digestion, while low-moisture plants are suitable for combustion. Moreover, the cellulose/lignin ratio is a determining parameter in selecting a biomass feedstock for biochemical conversion.

- Among the various routes for biomass conversion, combustion and anaerobic digestion have been proven to be mature and commercially available technologies due to process simplicity and their ability to handle a wide ranges of feedstocks.

- The share of power generation from renewable energy resources accounted for 29% of global production in 2020, and its increasing trend will continue until 2040, which necessitates the application of ORCs superior to steam cycles in the case of using low- and medium-energy sources.

- Biomass has the potential to combine with other renewable energy sources in order to improve the efficiencies of the systems and to yield a constant-temperature energy source. Based on this study, it appears particularly beneficial to hybridize with geothermal, solar, and wind energy.

- An appropriate working fluid is one of the criteria affecting the performance of an ORC. The fluid selection process is challenging because of technical, cost, and environmental barriers. Octamethyltrisiloxane, methylcyclohexane, R123, and R245fa are the primary working fluids suggested in the literature for biomass-fueled ORCs.

- The performance of a biomass-fueled ORC strongly depends on the type of biomass feedstock, the technology of biomass conversion, and appropriate layout along with suitable working fluid. Also, different input variables and assumptions considering technical, economic, and environmental limitations lead to achieving an optimum design through utilizing robust algorithmic tools.

- Thermodynamic, thermoeconomic, environmental, and life cycle assessments are the prevailing methods to investigate the performance of a biomass-fueled ORC.

- Although most of the organic fluids used for ORCs are not favored from the viewpoint of global warming potential, they are still used for ORC systems. Also, Siloxanes are introduced as one of the alternatives with low ODP and GWP rates.

- According to the emissions related to each biomass conversion technology, all processes result in particulate matter emissions except for anaerobic digestion and fermentation. All investigated technologies in this study have the potential to emit CO, NOx, and SOx during conversion as well as the combustion process. From the global warming effect viewpoint, CH4 and CO2 are formed during liquefaction, anaerobic digestion, and fermentation processes.

- Integration of environmental and socio-economic approaches, and applying more advanced analyses such as exergoenvironmental and Machine Learning algorithms, would be useful for simplifying and making comprehension simulations in the future. Also, future progress in biomass-based systems would go toward more environment-friendly processes, flexibility in feedstock usage, and combination with other renewables. Applying prevailing technologies such as membrane technology and fluidized bed combustion would be promising solutions for eliminating ash. The trend in enhancing the efficiency of biomass-fueled ORC systems involves using more efficient working fluids, such as nanofluids, along with environmentally friendly fluids and advanced heat exchangers.

Author Contributions

Conceptualization, P.H., H.G. and N.H.; methodology, P.H., H.G. and N.H.; formal analysis, P.H., H.G. and N.H.; investigation, P.H., H.G., N.H., M.A. and M.A.-R.; resources, M.A.-R.; data curation, P.H. and H.G.; writing—original draft preparation, P.H., H.G. and N.H.; writing—review and editing, P.H., H.G., N.H., M.A. and M.A.-R.; visualization, P.H., H.G. and N.H.; supervision, M.A. and M.A.-R.; project administration, M.A.-R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare that there are no known financial conflicts of interest or personal relationships that could have influenced the work presented in this paper.

Nomenclature

| AD | Anaerobic digestion |

| CHP | Combined heating and power |

| GHG | Greenhouse gas |

| GWP | Global warming potential |

| HFEs | Hydrofluoroethers |

| HV | Heating value |

| IEA | International Energy Agency |

| ICE | Internal combustion engine |

| LCOE | Levelized cost of electricity |

| LHV | Lower heating value |

| NOXs | Nitrogen oxides |

| ODP | Ozone depletion potential |

| ORC | Organic Rankine cycle |

| PAHs | Polycyclic aromatic hydrocarbons |

| SOX | Sulfide oxide |

| VOCs | Volatile organic compounds |

References

- Paul, S.; Mazumder, C.; Mukherjee, S. Challenges faced in commercialization of biofuel from biomass energy resources. Biocatal. Agric. Biotechnol. 2024, 103312. [Google Scholar] [CrossRef]

- Al Asi, A.; Khashehchi, M.; Thangavel, S.; Kumar, A.; Prasad, A. Strategic approach to biomass energy production: Feasibility, challenges, and opportunities. In Biodegradable Waste Processing for Sustainable Developments; CRC Press: Boca Raton, FL, USA, 2025; pp. 87–112. [Google Scholar]

- IEA. Key World Energy Statistics 2021. 2021. Available online: https://www.iea.org/reports/key-world-energy-statistics-2021 (accessed on 21 August 2022).

- Popp, J.; Kovács, S.; Oláh, J.; Divéki, Z.; Balázs, E. Bioeconomy: Biomass and biomass-based energy supply and demand. New Biotechnol. 2021, 60, 76–84. [Google Scholar] [CrossRef] [PubMed]

- Sikarwar, V.S.; Zhao, M.; Clough, P.; Yao, J.; Zhong, X.; Memon, M.Z.; Shah, N.; Anthony, E.J.; Fennell, P.S. An overview of advances in biomass gasification. Energy Environ. Sci. 2016, 9, 2939–2977. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2020. 2020. Available online: https://www.iea.org/reports/world-energy-outlook-2020 (accessed on 21 August 2022).

- Morris, G. Biomass Energy Production in California: The Case for a Biomass Policy Initiative. 2000. Available online: https://www.osti.gov/biblio/772427 (accessed on 23 July 2022).

- Nguea, S.M.; Fotio, H.K. Synthesizing the role of biomass energy consumption and human development in achieving environmental sustainability. Energy 2024, 293, 130500. [Google Scholar] [CrossRef]

- Bojek, P.; Moorhouse, J. Bioenergy Power Generation. 2021. Available online: https://www.iea.org/reports/bioenergy-power-generation (accessed on 22 September 2022).

- Abouemara, K.; Shahbaz, M.; Mckay, G.; Al-Ansari, T. The review of power generation from integrated biomass gasification and solid oxide fuel cells: Current status and future directions. Fuel 2024, 360, 130511. [Google Scholar] [CrossRef]

- Hashemian, N.; Noorpoor, A. Optimization and multi-aspect evaluation of a solar/biomass-powered multi-generation plant with an integrated thermoelectric generator unit. Sustain. Energy Technol. Assess. 2023, 56, 102998. [Google Scholar] [CrossRef]

- Qi, X.; Yang, C.; Huang, M.; Ma, Z.; Hnydiuk-Stefan, A.; Feng, K.; Siarry, P.; Królczyk, G.; Li, Z. Conventional and advanced exergy-exergoeconomic-exergoenvironmental analyses of an organic Rankine cycle integrated with solar and biomass energy sources. Energy 2024, 288, 129657. [Google Scholar] [CrossRef]

- Martín, M.; Sánchez, A. Biomass Pathways to Produce Green Ammonia and Urea. Curr. Opin. Green Sustain. Chem. 2024, 47, 100933. [Google Scholar] [CrossRef]

- Gu, Z.; Liu, Z.; Yang, S.; Xie, N.; Ma, K. Exergy and environmental footprint analysis for a green ammonia production process. J. Clean. Prod. 2024, 455, 142357. [Google Scholar] [CrossRef]

- Malico, I. Biomass for Power Production and Cogeneration. In Forest Bioenergy: From Wood Production to Energy Use; Springer: Berlin/Heidelberg, Germany, 2024; pp. 271–291. [Google Scholar]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Kumar, R.; Pandey, K.; Chandrashekar, N.; Mohan, S. Effect of tree-age on calorific value and other fuel properties of Eucalyptus hybrid. J. For. Res. 2010, 21, 514–516. [Google Scholar] [CrossRef]

- Rodrigues, A.; Loureiro, L.; Nunes, L.J.R. Torrefaction of woody biomasses from poplar SRC and Portuguese roundwood: Properties of torrefied products. Biomass Bioenergy 2018, 108, 55–65. [Google Scholar] [CrossRef]

- Klass, D.L. Biomass for Renewable Energy, Fuels, and Chemicals; Elsevier: Amsterdam, The Netherlands, 1998. [Google Scholar]

- Sudaryanto, Y.; Hartono, S.B.; Irawaty, W.; Hindarso, H.; Ismadji, S. High surface area activated carbon prepared from cassava peel by chemical activation. Bioresur. Technol. 2006, 97, 734–739. [Google Scholar] [CrossRef] [PubMed]

- Yin, R.; Liu, R.; Mei, Y.; Fei, W.; Sun, X. Characterization of bio-oil and bio-char obtained from sweet sorghum bagasse fast pyrolysis with fractional condensers. Fuel 2013, 112, 96–104. [Google Scholar] [CrossRef]

- Zhu, Z.; Toor, S.S.; Rosendahl, L.; Yu, D.; Chen, G. Influence of alkali catalyst on product yield and properties via hydrothermal liquefaction of barley straw. Energy 2015, 80, 284–292. [Google Scholar] [CrossRef]

- Demirbaş, A. Calculation of higher heating values of biomass fuels. Fuel 1997, 76, 431–434. [Google Scholar] [CrossRef]

- Sweeten, J.M.; Annamalai, K.; Thien, B.; McDonald, L.A. Co-firing of coal and cattle feedlot biomass (FB) fuels. Part I. Feedlot biomass (cattle manure) fuel quality and characteristics. Fuel 2003, 82, 1167–1182. [Google Scholar] [CrossRef]

- Taylor, R.; Ray, R.; Chapman, C. Advanced thermal treatment of auto shredder residue and refuse derived fuel. Fuel 2013, 106, 401–409. [Google Scholar] [CrossRef]

- Chandrasekaran, S.R.; Sharma, B.K.; Hopke, P.K.; Rajagopalan, N. Combustion of Switchgrass in Biomass Home Heating Systems: Emissions and Ash Behavior. Energy Fuels 2016, 30, 2958–2967. [Google Scholar] [CrossRef]

- Choi, H.L.; Sudiarto, S.I.A.; Renggaman, A. Prediction of livestock manure and mixture higher heating value based on fundamental analysis. Fuel 2014, 116, 772–780. [Google Scholar] [CrossRef]

- Tumuluru, J.S. Comparison of Chemical Composition and Energy Property of Torrefied Switchgrass and Corn Stover. Front. Energy Res. 2015, 3, 46. [Google Scholar] [CrossRef]

- Aplan, F.F. 1992 Gaudin Lecture: Coal properties dictate coal flotation strategies. Min. Eng. 1993, 45, 83–96. [Google Scholar]

- Agraniotis, M.; Bergins, C.; Stein-Cichoszewska, M.; Kakaras, E. 5—High-efficiency pulverized coal power generation using low-rank coals. In Low-Rank Coals for Power Generation, Fuel and Chemical Production; Luo, Z., Agraniotis, M., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 95–124. [Google Scholar] [CrossRef]

- Quaak, P.; Knoef, H.; Stassen, H.E. Energy from Biomass: A Review of Combustion and Gasification Technologies; 1999; Available online: https://documents.worldbank.org/en/publication/documents-reports/documentdetail/936651468740985551/energy-from-biomass-a-review-of-combustion-and-gasification-technologies (accessed on 21 September 2022).

- Zeng, Y.; Zhao, S.; Yang, S.; Ding, S.-Y. Lignin plays a negative role in the biochemical process for producing lignocellulosic biofuels. Curr. Opin. Biotechnol. 2014, 27, 38–45. [Google Scholar] [CrossRef] [PubMed]

- Boateng, A.A.; Weimer, P.J.; Jung, H.G.; Lamb, J.F.S. Response of Thermochemical and Biochemical Conversion Processes to Lignin Concentration in Alfalfa Stems. Energy Fuels 2008, 22, 2810–2815. [Google Scholar] [CrossRef]

- Öhgren, K.; Bura, R.; Saddler, J.; Zacchi, G. Effect of hemicellulose and lignin removal on enzymatic hydrolysis of steam pretreated corn stover. Bioresur. Technol. 2007, 98, 2503–2510. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.H.; Lee, Y.Y. Fractionation of corn stover by hot-water and aqueous ammonia treatment. Bioresur. Technol. 2006, 97, 224–232. [Google Scholar] [CrossRef] [PubMed]

- Saha, B.C.; Iten, L.B.; Cotta, M.A.; Wu, Y.V. Dilute acid pretreatment, enzymatic saccharification and fermentation of wheat straw to ethanol. Process Biochem. 2005, 40, 3693–3700. [Google Scholar] [CrossRef]

- Jin, S.; Chen, H. Structural properties and enzymatic hydrolysis of rice straw. Process Biochem. 2006, 41, 1261–1264. [Google Scholar] [CrossRef]

- IRENA-ETSAP. Biomass for Heat and Power; 2015. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2015/IRENA-ETSAP_Tech_Brief_E05_Biomass-for-Heat-and-Power.pdf (accessed on 10 July 2024).

- McKendry, P. Energy production from biomass (part 2): Conversion technologies. Bioresur. Technol. 2002, 83, 47–54. [Google Scholar] [CrossRef]

- Bridgwater, A.V.; Bridge, S.A. A Review of Biomass Pyrolysis and Pyrolysis Technologies. In Biomass Pyrolysis Liquids Upgrading and Utilization; Bridgwater, A.V., Grassi, G., Eds.; Springer: Dordrecht, The Netherlands, 1991; pp. 11–92. [Google Scholar] [CrossRef]

- Gielen, D. Renewable energy technologies: Cost analysis series. Biomass Power Gener. 2012, 1, 1–60. [Google Scholar]

- Belviso, C. State-of-the-art applications of fly ash from coal and biomass: A focus on zeolite synthesis processes and issues. Prog. Energy Combust. Sci. 2018, 65, 109–135. [Google Scholar] [CrossRef]

- Dai, J.; Cui, H.; Grace, J.R. Biomass feeding for thermochemical reactors. Prog. Energy Combust. Sci. 2012, 38, 716–736. [Google Scholar] [CrossRef]

- Williams, A.; Jones, J.M.; Ma, L.; Pourkashanian, M. Pollutants from the combustion of solid biomass fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- Demirbas, A. Potential applications of renewable energy sources, biomass combustion problems in boiler power systems and combustion related environmental issues. Prog. Energy Combust. Sci. 2005, 31, 171–192. [Google Scholar] [CrossRef]

- Kleinhans, U.; Wieland, C.; Frandsen, F.J.; Spliethoff, H. Ash formation and deposition in coal and biomass fired combustion systems: Progress and challenges in the field of ash particle sticking and rebound behavior. Prog. Energy Combust. Sci. 2018, 68, 65–168. [Google Scholar] [CrossRef]

- Sukumaran, S.; Kong, S.-C. Modeling fuel NOx formation from combustion of biomass-derived producer gas in a large-scale burner. Combust. Flame 2013, 160, 2159–2168. [Google Scholar] [CrossRef]

- Smith, J.D.; Sreedharan, V.; Landon, M.; Smith, Z.P. Advanced design optimization of combustion equipment for biomass combustion. Renew. Energy 2020, 145, 1597–1607. [Google Scholar] [CrossRef]

- US Energy Department, Office of Energy Efficiency & Renewable Energy. Energy Saver, Furnaces and Boilers. 2019. Available online: https://www.energy.gov/energysaver/home-heating-systems/furnaces-and-boilers (accessed on 25 September 2020).

- Quaak, P.K. Harrie Stassen, Hubert. In Energy from Biomass; World Bank Group: Washington, DC, USA, 1999. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification and Pyrolysis: Practical Design and Theory; Academic Press: Cambridge, MA, USA, 2010. [Google Scholar]

- Rauch, R.; Hrbek, J.; Hofbauer, H. Biomass gasification for synthesis gas production and applications of the syngas. WIREs Energy Environ. 2014, 3, 343–362. [Google Scholar] [CrossRef]

- Maniatis, K. Progress in biomass gasification: An overview. In Progress in Thermochemical Biomass Conversion; Wiley: Hoboken, NJ, USA, 2008; Volume 1. [Google Scholar]

- Knoef, H.; Ahrenfeldt, J. Handbook Biomass Gasification; BTG Biomass Technology Group: Enschede, The Netherlands, 2005. [Google Scholar]

- Patel, M.; Zhang, X.; Kumar, A. Techno-economic and life cycle assessment on lignocellulosic biomass thermochemical conversion technologies: A review. Renew. Sustain. Energy Rev. 2016, 53, 1486–1499. [Google Scholar] [CrossRef]

- Neves, D.; Thunman, H.; Matos, A.; Tarelho, L.; Gómez-Barea, A. Characterization and prediction of biomass pyrolysis products. Prog. Energy Combust. Sci. 2011, 37, 611–630. [Google Scholar] [CrossRef]

- Onay, O.; Kockar, O.M. Slow, fast and flash pyrolysis of rapeseed. Renew. Energy 2003, 28, 2417–2433. [Google Scholar] [CrossRef]

- Sun, T.; Li, Z.; Zhang, Z.; Wang, Z.; Yang, S.; Yang, Y.; Wang, X.; Liu, S.; Zhang, Q.; Lei, T. Fast corn stalk pyrolysis and the influence of catalysts on product distribution. Bioresur. Technol. 2020, 301, 122739. [Google Scholar] [CrossRef]

- Williams, P.T.; Besler, S. The influence of temperature and heating rate on the slow pyrolysis of biomass. Renew. Energy 1996, 7, 233–250. [Google Scholar] [CrossRef]

- Nachenius, R.W.; Ronsse, F.; Venderbosch, R.H.; Prins, W. Chapter Two—Biomass Pyrolysis. In Advances in Chemical Engineering; Murzin, D.Y., Ed.; Academic Press: Cambridge, MA, USA, 2013; Volume 42, pp. 75–139. [Google Scholar]

- Czernik, S.; Bridgwater, A.V. Overview of Applications of Biomass Fast Pyrolysis Oil. Energy Fuels 2004, 18, 590–598. [Google Scholar] [CrossRef]

- Isahak, W.N.R.W.; Hisham, M.W.M.; Yarmo, M.A.; Yun Hin, T.-Y. A review on bio-oil production from biomass by using pyrolysis method. Renew. Sustain. Energy Rev. 2012, 16, 5910–5923. [Google Scholar] [CrossRef]

- Iribarren, D.; Peters, J.F.; Dufour, J. Life cycle assessment of transportation fuels from biomass pyrolysis. Fuel 2012, 97, 812–821. [Google Scholar] [CrossRef]

- Maggi, R.; Delmon, B. Comparison between ‘slow’ and ‘flash’ pyrolysis oils from biomass. Fuel 1994, 73, 671–677. [Google Scholar] [CrossRef]

- Horne, P.A.; Williams, P.T. Influence of temperature on the products from the flash pyrolysis of biomass. Fuel 1996, 75, 1051–1059. [Google Scholar] [CrossRef]

- Zhang, B.; von Keitz, M.; Valentas, K. Thermochemical liquefaction of high-diversity grassland perennials. J. Anal. Appl. Pyrolysis 2009, 84, 18–24. [Google Scholar] [CrossRef]

- Biller, P.; Sharma, B.K.; Kunwar, B.; Ross, A.B. Hydroprocessing of bio-crude from continuous hydrothermal liquefaction of microalgae. Fuel 2015, 159, 197–205. [Google Scholar] [CrossRef]

- Deublein, D.; Steinhauser, A. Biogas from Waste and Renewable Resources: An Introduction; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Adams, P.; Bridgwater, T.; Lea-Langton, A.; Ross, A.; Watson, I. Biomass conversion technologies. In Greenhouse Gas Balances of Bioenergy Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 107–139. [Google Scholar]

- Lu, X.; Xi, B.; Zhang, Y.; Angelidaki, I. Microwave pretreatment of rape straw for bioethanol production: Focus on energy efficiency. Bioresur. Technol. 2011, 102, 7937–7940. [Google Scholar] [CrossRef]

- Wang, M.; Chen, Y.; Xia, X.; Li, J.; Liu, J. Energy efficiency and environmental performance of bioethanol production from sweet sorghum stem based on life cycle analysis. Bioresur. Technol. 2014, 163, 74–81. [Google Scholar] [CrossRef]

- Larnaudie, V.; Rochón, E.; Ferrari, M.D.; Lareo, C. Energy evaluation of fuel bioethanol production from sweet sorghum using very high gravity (VHG) conditions. Renew. Energy 2016, 88, 280–287. [Google Scholar] [CrossRef]

- Granjo, J.F.O.; Nunes, D.S.; Duarte, B.P.M.; Oliveira, N.M.C. A comparison of process alternatives for energy-efficient bioethanol downstream processing. Sep. Purif. Technol. 2020, 238, 116414. [Google Scholar] [CrossRef]

- Balat, M.; Balat, H.; Öz, C. Progress in bioethanol processing. Prog. Energy Combust. Sci. 2008, 34, 551–573. [Google Scholar] [CrossRef]

- IEA. Global Generation Shares from Coal and Low-Carbon Sources; IEA: Paris, France, 2020. [Google Scholar]

- IEA. Electricity Generation by Fuel and Scenario; IEA: Paris, France, 2019. [Google Scholar]