1. Introduction

Massive greenhouse gas emissions have brought about serious problems such as rising sea levels and extreme weather. The international community reached The Paris Agreement for the sustainable development of the planet in 2015. Countries have made commitments to reduce emissions and are devoted to limiting the whole world’s maximum temperature rise to 1.5 °C by the end of this century [

1]. In 2016, more than 90% of international goods were traded by marine transport [

2], and ports play an important role in marine transport, but generate a lot of greenhouse gasses from ships and handling equipment. The greenhouse gasses generated by the port industry account for approximately 3% of global greenhouse gasses [

3]. For this reason, green ports have become a hot research direction at present. Many researchers believe that the realization of green ports mainly involves utilizing renewable energy for power generation [

4], utilizing clean fuels (for example hydrogen energy) instead of fuel oil [

5,

6], and utilizing electric energy for transportation equipment [

7,

8]. The green port multi-energy microgrid is one of the best ways to apply the above measures to the port.

However, the power of renewable energy is uncertain [

9,

10]. Port load (mainly composed of the quay crane, yard crane, and a ship) is coupled with the logistics system [

11,

12], which has the characteristics of a high peak value, frequent fluctuation, and periodicity. Hydrogen energy is a fine clean fuel, but its production process has high requirements for power quality [

13,

14,

15]. Hence, it is essential to use energy storage systems to absorb the fluctuating power of renewable energy generation systems and port load to maintain the steady work of green port multi-energy micro-grids. Naturally, how to distribute the fluctuating power reasonably and maintain the safe and settled operation of the energy storage system has become the key. The LPF algorithm is used to separate the power fluctuations in renewable energy generation systems into high-frequency fluctuating components and low-frequency fluctuating components in [

16,

17]. In Ref. [

18], wind power signals are decomposed into high-frequency components and low-frequency components, which is based on the wavelet packet decomposition algorithm, and then dispensed to the hybrid energy storage system. Compared with LPF algorithms, the wavelet packet decomposition algorithm has a better local decomposition ability for signals [

19], but the wavelet packet decomposition algorithm needs to change multiple parameters and its control is complicated in the complex application scenario. In the port microgrid, the author considered the SOC of the battery and proposed a rule-based EMS to make sure that the SOC of battery is maintained in a limited extent in [

20,

21]. Fuzzy control theory is widely used in energy management strategies of microgrids due to its good robustness and flexibility. The author of Ref. [

22] uses a fuzzy controller to change the power of fuel cells in electric vehicle power supply systems to improve their lifespan and efficiency. An energy management strategy based on fuzzy control theory is proposed to maintain the safe and steady operation of microgrids in Ref. [

23]. Ref. [

24] uses a fuzzy logic controller to change the input power of renewable energy systems to cope with different atmospheric conditions and prolong the life of a battery, but this can lead to the waste of renewable energy. Ref. [

25] uses a fuzzy controller to maintain the SOC balance of supercapacitors in hybrid energy storage systems of electric vehicles, but it does not consider the SOC of batteries in hybrid energy storage systems. Ref. [

26] aims to address the issues of voltage instability and energy loss in hybrid energy storage systems based on fuzzy control theory, but it does not take into account the efficiency and lifespan of energy storage components. In Ref. [

27], the output power of an energy storage system was regulated after contemplating the wind power fluctuation and the SOC of an energy storage system based on fuzzy control. The SOC of the battery was controlled, which extends the lifespan of the battery. The author of Ref. [

28] proposed to use the power-modifying factor of the fuzzy controller to address the issue of the SOC exceeding limits in energy storage systems, but the power-modifying factor is only decided by the SOC and SOC variation of the energy storage system in the previous time window, which may cause additional high-frequency power fluctuations.

This research examines an EMS of a green port multi-energy microgrid, which is an AC/DC microgrid, and mainly composed of a renewable energy generation system (including a photovoltaic and wind power generation system), hybrid energy storage system, and port load. The lifespan and efficiency of the hybrid energy storage system are affected by the great fluctuating power of the system. To reasonably distribute the fluctuating power of the system and ensure the safe operation of the hybrid energy storage system, an EMS based on two-stage fuzzy control is proposed. The simulation outcome indicates that the fluctuation power of the system is reasonably allocated, and compared with the wavelet packet decomposition algorithm and single-stage fuzzy control algorithm, the EMS proposed in this paper is more reasonable for the control of the SOC of supercapacitors, which makes it have a sufficient charge-and-discharge response ability, and the rate of variance of flywheel power is also controlled below the limit value. Compared with rule-based energy management algorithms and single-stage fuzzy control algorithms, it has a faster SOC automatic adjustment ability, and guarantees the steady and reliable operation of green port multi-energy microgrid systems. This paper is organized as follows:

Section 2 explains the aim and contribution of this paper.

Section 3 explains the structure of the green port multi-energy microgrid and its mathematical model.

Section 4 introduces details of the proposed EMS.

Section 5 presents the simulation outcomes of the EMS.

Section 6 presents the conclusion of the paper.

4. Energy Management Strategy Based on Fuzzy Logic Control

The structure of a green port multi-energy microgrid system is complex, and the output power of a renewable energy generation system and the port load are stochastic, which makes the control of energy resources more difficult. Fuzzy control is a type of nonlinear control. It has good robustness and the exact mathematical model for the controlled object is not needed, and can adapt to complex and uncertain green port multi-energy microgrid systems. In addition, fuzzy control is easy to implement and has great practical value.

There is large power fluctuation in green port multi-energy microgrid systems, which easily leads to the problems of over-charge or over-discharge, low efficiency, and the reduced lifespan of the energy storage system. To solve these problems, an EMS based on dual-stage fuzzy control with a low-pass filter (DSFCLPF) is proposed in this paper.

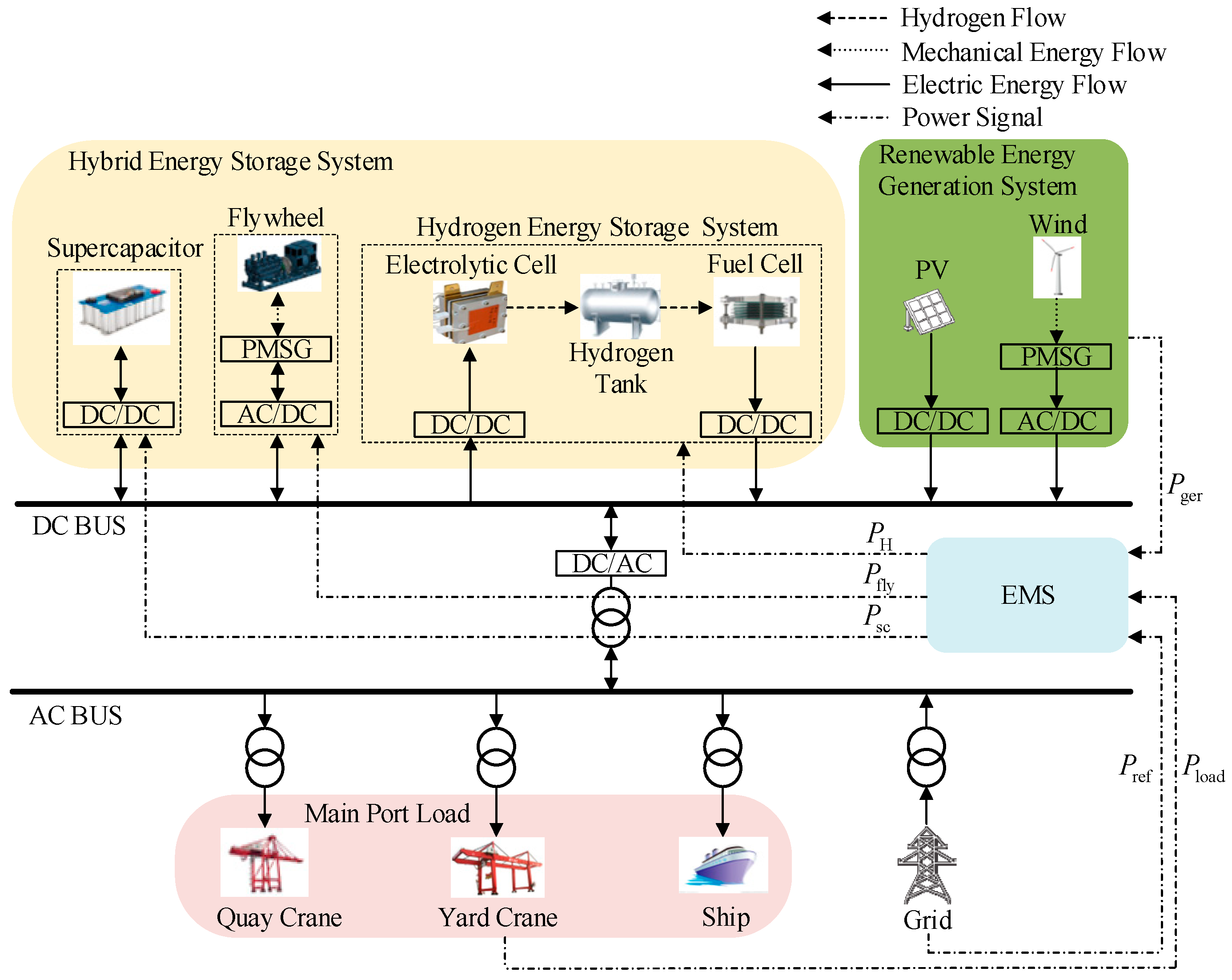

Figure 9 shows the internal structure of the DSFCLPF-EMS.

The hybrid energy storage power () is degraded into three parts: low-frequency power, medium-frequency power, and high-frequency power by dual LPF. The low-frequency part is allocated to the hydrogen energy storage system, the mid-frequency part is distributed to the flywheel, and the high-frequency part is distributed to the supercapacitor.

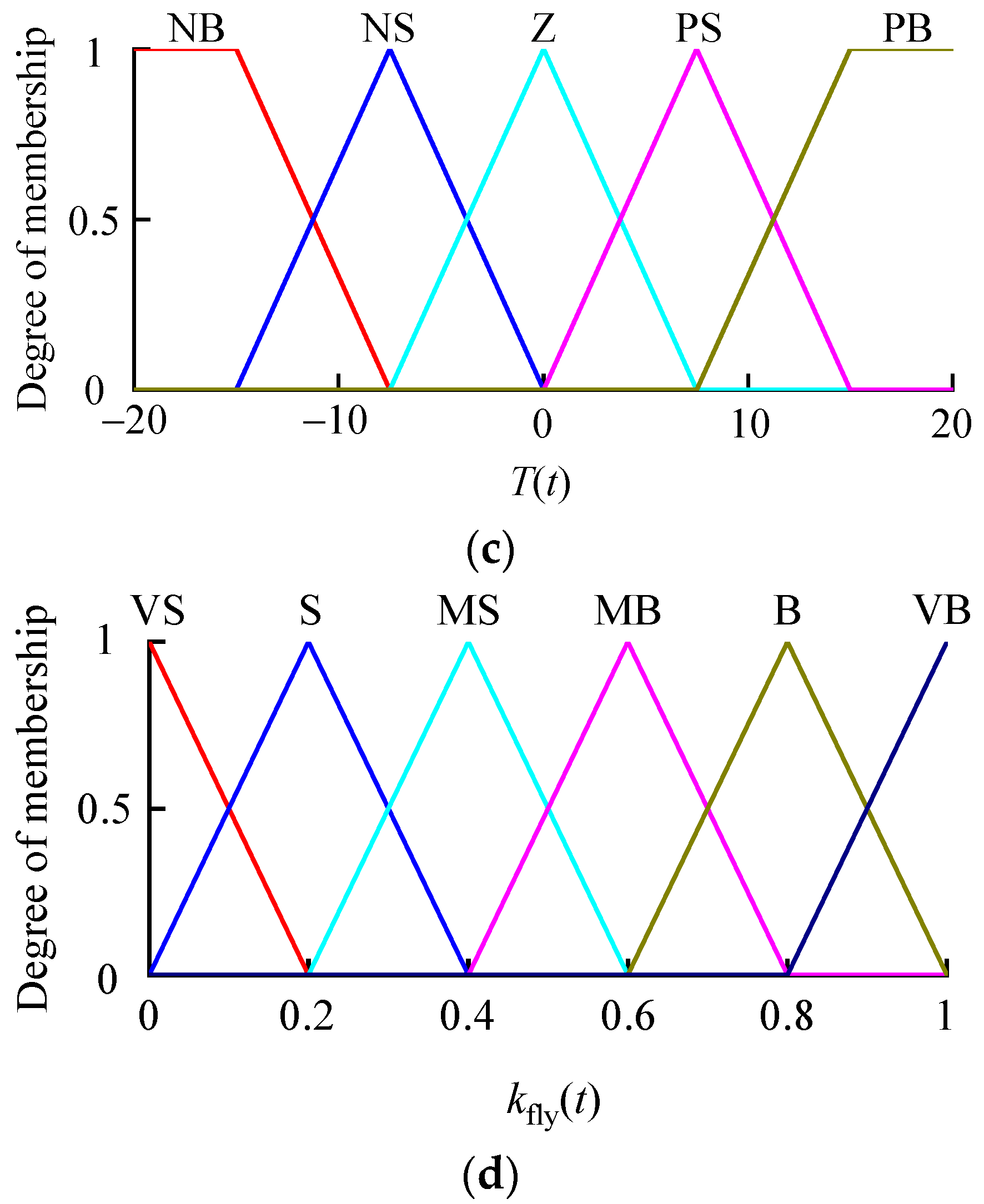

The function of the front-stage fuzzy controller (FSFC) is to adjust the time constant of the LPF based on the change in power, which can reasonably distribute fluctuating power and improve the efficiency of the hybrid energy storage system. The principle of FSFC is increasing the time constant of the LPF when the fluctuation of power is large, and decreasing the time constant of the LPF when it becomes smooth. Therefore, the FSFC inputs the change in the power of the supercapacitor and flywheel in () and outputs the time constant (T(t)) of the second LPF. Negative big (NB), negative middle (NM), negative small (NS), zero (Z), positive small (PS), positive middle (PM), and positive big (PB) are selected as fuzzy sets to describe the . The range of is obtained by dividing its peak value by the quantization factor. The quantification factor is 106 in this paper, and the range of is [−0.4, 0.4].

Through fast Fourier transform (FFT) analysis of the load power of the port, the result shows that the high-frequency fluctuating power frequency of the port load is generally in the range of 0.01 Hz–1 Hz. The relationship between the time constant and the signal frequency [

17] is shown as follows:

The upper limit of

T is set to 20 in this paper, which means that the filter can pass fluctuating power with a frequency less than 0.008 Hz. In order for

T to represent the direction of power change,

T is signed and it will take an absolute value before being passed to the LPF. Seven fuzzy sets (negative big (NB), negative middle (NM), negative small (NS), zero (Z), positive small (PS), positive middle (PM), and positive big (PB)) are selected to cover the interval [−20, 20]. The membership function of FSFC comprises triangular and trapezoidal membership functions. The membership and control rule of the FSFC are shown in

Figure 10 and

Table 12, respectively. The value of

is 0.12 s.

The primary distribution of power controls the power instruction of the energy storage system based on the frequency characteristics of the absorbed power of each energy storage system, and improves the efficiency of the hybrid energy storage system. However, it does not consider the problem of over-charge and over-discharge during the actual working of the hybrid energy storage system. For power-type energy storage units, this problem is more likely to occur. Hence, to impede the over-charge and over-discharge of the supercapacitor and flywheel, it is necessary to adjust the result of the primary distribution of power.

For the secondary power adjustment of the supercapacitor, the principles are as follows:

When the SOC of the supercapacitor is moderate, the supercapacitor operates according to the primary distribution of power.

When the SOC of the supercapacitor is large, if the supercapacitor is charging, it is necessary to reduce the power of the supercapacitor and adjust the power of the flywheel. If the supercapacitor is discharging, it is not necessary to adjust the power of the supercapacitor.

When the SOC of the supercapacitor is small, if the supercapacitor is discharging, it is necessary to increase the power of the supercapacitor and adjust the power of the flywheel. If the supercapacitor is charging, it is not necessary to adjust the power of supercapacitor.

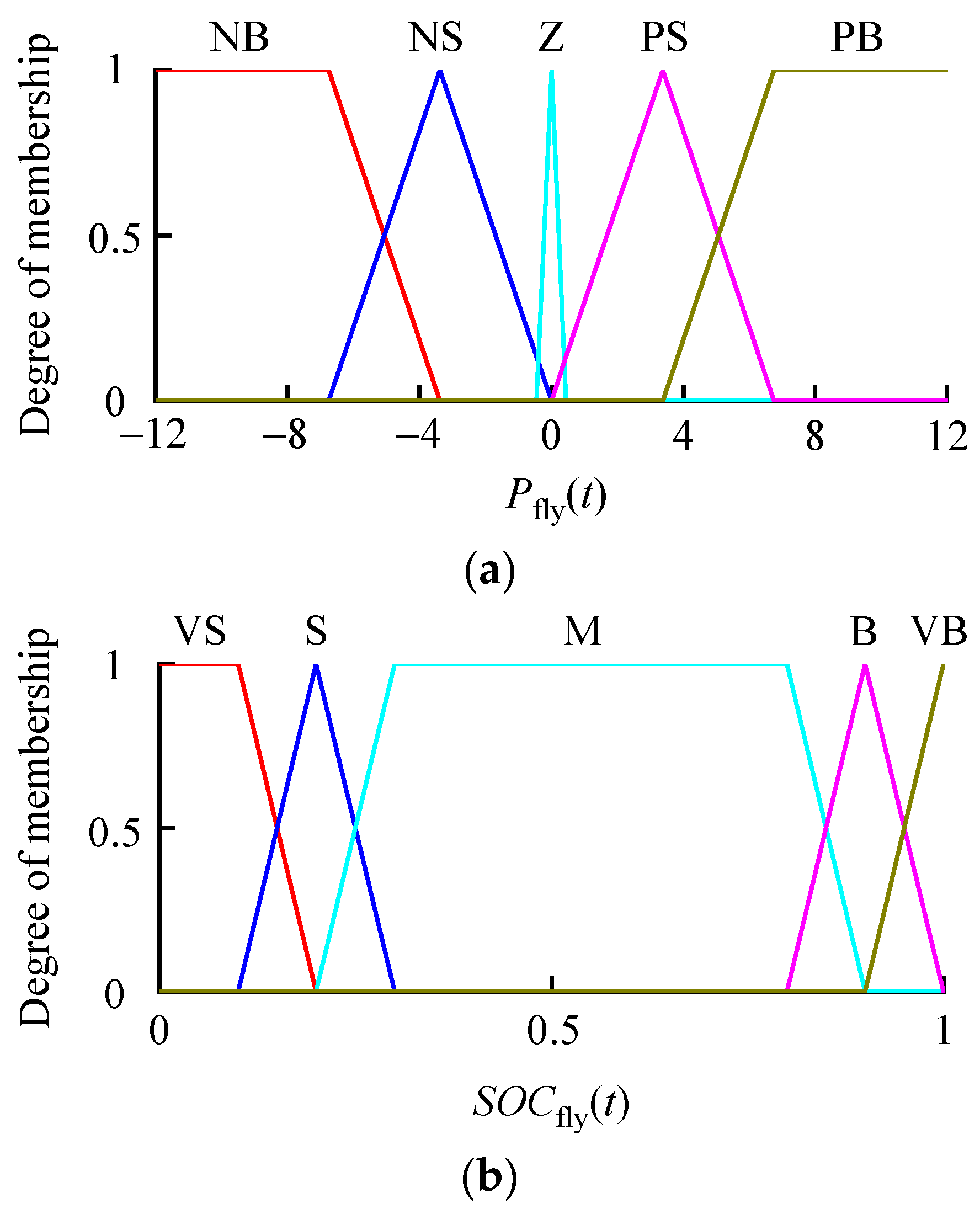

The principles of the flywheel are similar to those of the supercapacitor. According to these principles, this paper designed the fuzzy controller of the supercapacitor and flywheel to adjust the result of the primary distribution of power. The supercapacitor-post-stage fuzzy controller (SC-PSFC) input the power of the supercapacitor (), the SOC of supercapacitor (), and the time constant of the LPF (), and output the power adjustment factor of the supercapacitor (). can reflect the trend in the , which can make the power adjustment factor more accurate. Five fuzzy sets (negative big (NB), negative small (NS), zero (Z), positive small (PS), and positive big (PB)) are selected to cover the interval [−8, 8] of . Five fuzzy sets (very small (VS), small (S), middle (M), big (B), and very big (VB)) are selected to cover the interval [0, 1] of . Five fuzzy sets (negative big (NB), negative small (NS), zero (Z), positive small (PS), and positive big (PB)) are selected to cover the interval [−20, 20] of . Six fuzzy sets (very small (VS), small (S), middle small (MS), middle big (MB), big (B), and very big (VB)) are selected to cover the interval [0, 1] of . The membership function of SC-PSFC comprises triangular and trapezoidal membership functions. This paper uses the centroid method to fulfill defuzzification.

The power adjustment formula of SC-PSFC is shown as follows:

where

and

are the power of the supercapacitor and of the flywheel of the primary distribution. The membership and control rule of the SC-PSFC are shown in

Figure 11 and

Table A1, respectively.

Given the presence of fuzzy rules in this paper, two fuzzy rules of SC-PSFC will be explained as follows:

When the SOC is very big (VB), the is positive small (PS), and the is negative big (NB), this means that although the supercapacitor is discharging, the discharge power is rapidly decreasing and there may even be charging. Then, the SC-PSFC needs to output a very small (VS) .

When the SOC is small (S), the is positive small (PS), and the is negative big (NB), this means that although the supercapacitor is discharging, the charge power is rapidly decreasing. Then, the SC-PSFC needs to output a very big (VB) .

The structure of the flywheel-post-stage fuzzy controller (F-PSFC) is similar to that of the SC-PSFC, and the power adjustment formula of the SC-PSFC is shown as follows:

The membership and control rule of the F-PSFC are shown in

Figure A1 and

Table A2, respectively.

Obviously, both the SC-PSFC and F-PSFC can adjust the primary distribution of power. But the SC-PSFC and F-PSFC cannot operate at the same time, which may cause power imbalance. Therefore, it is necessary to set the PSFC operating standard (shown in

Table 13) to ensure that two PSFCs will not be operating at the same time.

When the SOC of the supercapacitor and flywheel are both large or small, it indicates that the energy storage system does not have the ability to absorb the fluctuating power, and the energy storage system needs to be controlled out of operation.

The calculation time and resource consumption of fuzzy control algorithms mainly focus on the calculation of input–output membership functions and fuzzy inference. When there are more membership functions and fuzzy rules, the computation time and resource consumption of the algorithm also increase. The calculation steps and temporary data of the algorithm proposed in this paper mainly focus on the PSFC. Although each PSFC has three input variables (each variable has five membership functions), one output variable (six membership functions), and 125 fuzzy rules, regardless of the scale of the input data, its calculation steps and temporary data are always fixed, which means that its time and space complexity are both O (1). In real work, to reduce computation time and memory requirements, computer simulation models can be used to obtain query tables, and the controller can obtain results based on the query tables.

5. Simulation and Results

The simulation model of a green port multi-energy microgrid system is established in Matlab 2016a/Simulink in this paper, as shown in

Figure 12. A renewable energy generation system and hybrid energy storage system are connected with the DC bus. The electricity in the port is provided by the AC bus and connected to the power grid. The EMS obtains the power information of each subsystem and the charge state information of the energy storage system, then transmits power instructions to the hybrid energy storage system. Finally, the hybrid energy storage system charges and discharges according to the power instructions of the EMS and maintains a stable system operation. The parameter of the simulation model is shown in

Table 14.

is derived from the load power through the inertial element.

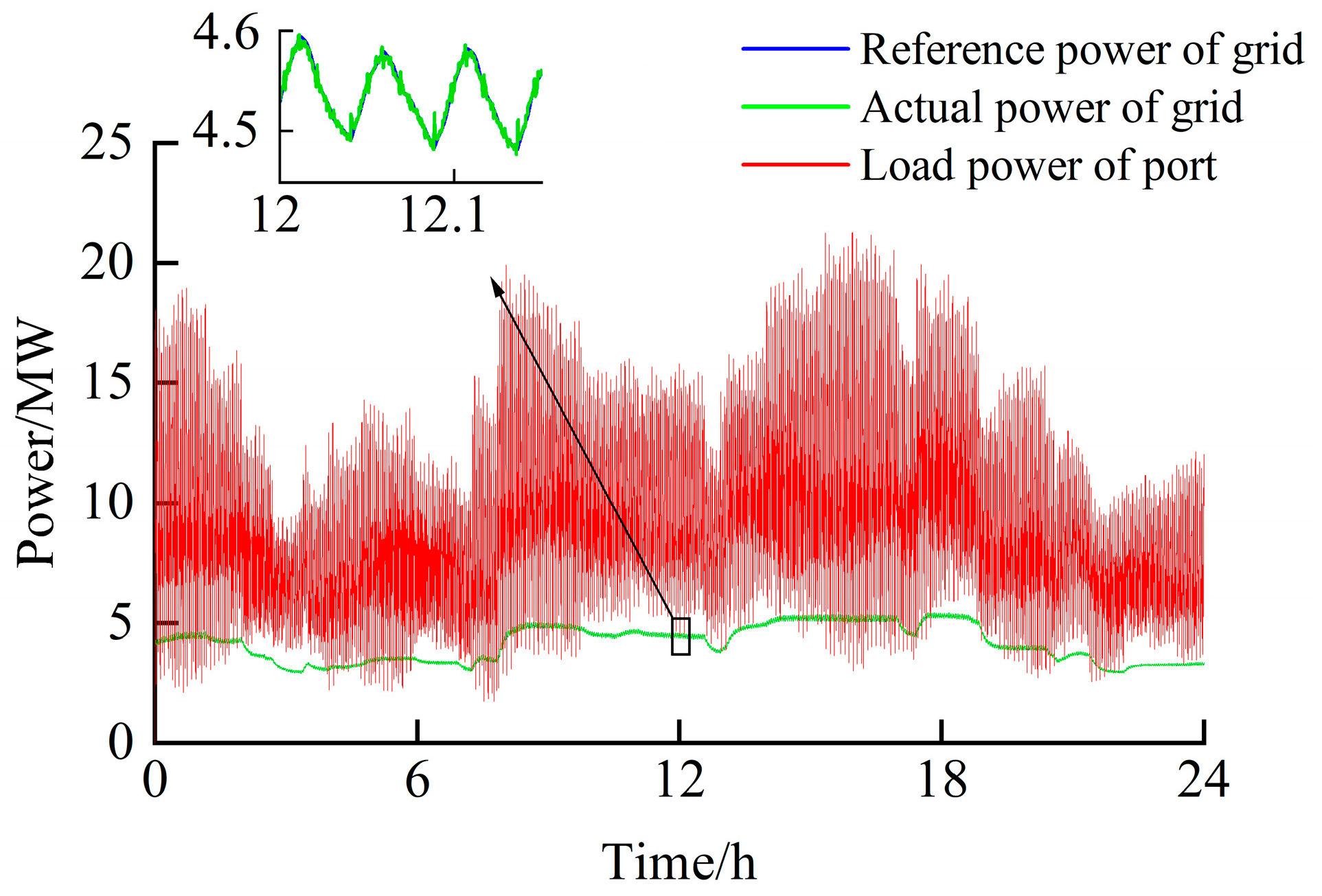

The simulation results of load power, grid power, and the partial hybrid energy storage system are shown in

Figure 13 and

Figure 14. It is evident that the actual grid power follows the reference power instructions of the grid, and that the fluctuating power is distributed to different energy storage systems according to different frequencies. In addition, the port’s electricity consumption is reduced and the fluctuation of load power is greatly reduced, which leads to less impact on the grid.

Figure 15 shows the time constant of a partial LPF and the corresponding power curves of the supercapacitor and flywheel. When the power curve fluctuates dramatically, the time constant increases rapidly, which leads to the supercapacitor absorbing more high-frequency power. Conversely, when the power curve does not fluctuate much, the time constant is in a small range, which causes the flywheel to absorb more medium-frequency power.

In this paper, a DSFCLPF is compared with a single-stage fuzzy control algorithm (SFC) and a wavelet packet decomposition algorithm (WPD). An SFC is proposed in [

28]. A WPD uses a db6 wavelet to degrade the hybrid energy storage power into 10 layers, and the low-frequency power is

, the mid-frequency power is

,

, and

, and the high-frequency power is

(

i = 5, 6, 7⋯1024).

Figure 16 shows the change rates of the flywheel power of the three algorithms. The limit of the power change rate is set as 600 kW/s in this paper. Obviously, under the control of both a WPD and an SFC, the flywheel power change rate will exceed the limit, which means that there is more high-frequency power in it. The flywheel cannot absorb this high-frequency power, which will affect the fixity of the DC bus voltage.

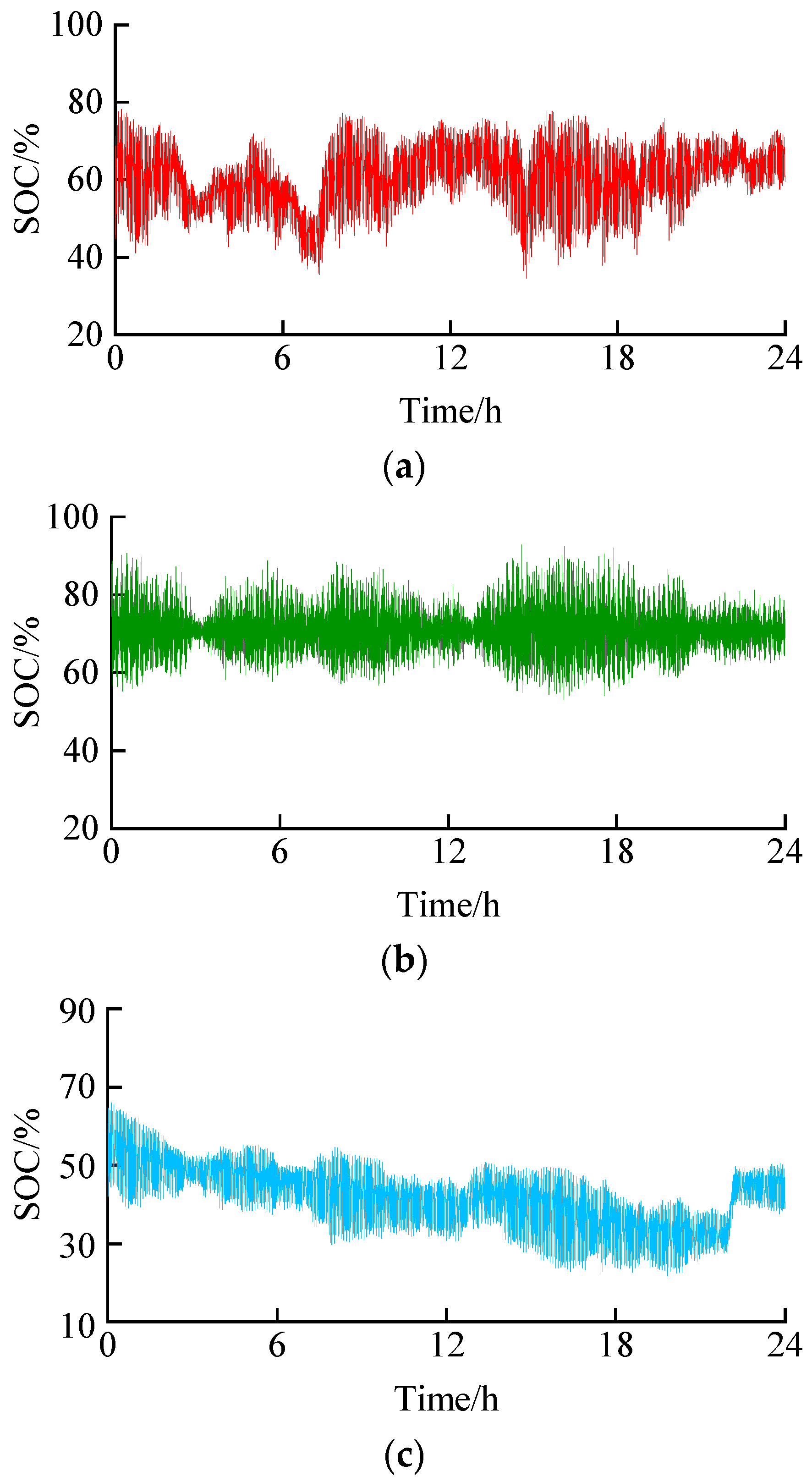

Figure 17 shows the SOC curves of supercapacitors under the three algorithms. Under the control of the DSFCLPF algorithm, the SOC of the supercapacitor is controlled within the reasonable extent of 34–78%. For the WPD, the SOC of the supercapacitor is controlled within a range of 57–93%, which has the potential of over-charging. For the SFC, the SOC of the supercapacitor is controlled within the range of 67–21%, which has the potential of over-discharging.

Taking the calculation formula of the maximum fluctuation of the output power of turbine generation proposed in [

37] as a reference, the maximum fluctuation of the SOC of supercapacitors is defined as follows:

where

i is the sampling point. The range of

i is [1,

n], and

n is related to the sampling interval (

).

The maximum fluctuation in 1 min is calculated in this paper, so the value of

is 0.6 s, and the value of

n is 100. The average of the maximum fluctuation (

μ) of the SOC of supercapacitors is determined by Equation (28). The value of

μ of the three algorithms is shown in

Table 15.

Both the

μ of the DSFCLPF and WPD is greater than the

μ of the SFC. This is due to the fact that the DSFCLPF and WPD allocate more high-frequency fluctuating power to the supercapacitor. According to

Figure 16 and

Table 14, the flywheel power change rate of the WPD exceeds the limit value, and the

u of the WPD is greater than the

u of the DSFCLPF, so it can be concluded that the WPD allocates part of the medium-frequency fluctuation power to the supercapacitor. So, the DSFCLPF algorithm is more reasonable in allocating the fluctuating power of the system, which is beneficial for improving the working efficiency of hybrid energy storage systems.

To verify the automatic adjustment capability of the DSFCLPF under the extreme working conditions of the energy storage system, the initial value of the supercapacitor’s SOC is set to 90% and 10%, respectively.

Figure 18 shows the SOC curve of the supercapacitor of the DSFCLPF algorithm, the SFC, and the rule-based energy management algorithms (RB) [

20], for an extreme initial SOC value.

This paper defines the reasonable range of the supercapacitor SOC as 30–75%.

Figure 18 shows that all three algorithms have the ability to automatically adjust the SOC of the energy storage system, but the adjustment mechanism and speed are different. The RB algorithm adjusts the SOC of the energy storage system by setting SOC limits and controlling the system for exit operations. This method can quickly free the energy storage system from the danger of overcharging or discharging, but during the time when the energy storage system stops working, the fluctuating power of the system cannot be absorbed, which can easily lead to unstable DC bus voltage and damage to other electrical equipment in the system. The long-term shutdown of energy storage systems may even lead to the collapse of microgrids. The DSFCLPF algorithm and SFC adjust the SOC of energy storage systems by optimizing power instructions. It can greatly prevent the energy storage system from ceasing operation due to excessive or insufficient SOC, which is helpful for maintaining the steady working of the system.

Table 16 shows the time required for three algorithms to adjust the SOC of supercapacitors to the reasonable range. It can be concluded that the DSFCLPF algorithm adjusts the SOC of the energy storage system more quickly, which is beneficial for the energy storage system to avoid overcharging or discharging problems and maintain the secure and steady operation of the system.

In order to further validate the effectiveness of the method proposed in the paper, one month of port data simulation was added, and the simulation results are shown in

Figure 19 and

Figure 20.

It can be seen from

Figure 19 and

Figure 20 that the SOC of the supercapacitor is maintained within a reasonable range of 31–81%, and the rate of change in flywheel power still does not exceed the limit value within a month. This implies that the DSFCLPF algorithm still has good control performance under different conditions, and attests that the DSFCLPF has good robustness and is effective.

6. Conclusions

In this work, an EMS based on fuzzy logic control was proposed to distribute the fluctuating power in a green port multi-energy microgrid system, maintain the SOC of the energy storage system, prolong the lifespan of the energy storage system, and ensure the steady operation of green port multi-energy microgrid systems. Firstly, this paper analyzed the structure of the green port multi-energy microgrid system and established the mathematical model of the system in MATLAB/SIMULINK. Moreover, this paper elaborated on the principle of modeling the quantity of logistics transportation energy at the port, and the main load of the port within a day was obtained based on the principle. Then, this paper provided a detailed design of variables and fuzzy rules of the fuzzy controller. The FSFC was used to change the time constant of the LPF. The PSFC was used to regulate the result of the primary distribution of power. Finally, the simulation results indicated that compared to traditional port systems, the green port multi-energy microgrid system has less electricity consumption and fluctuations of load power. After comparing the results with other EMS algorithms, the conclusion was that, under the control of the EMS proposed in this paper, the rate of change in flywheel power was controlled below the limit value, the high-frequency component in the flywheel power was less, and the SOC of the supercapacitor was reasonably maintained within 34–78%, which extends the lifespan of the flywheel and supercapacitor. Moreover, the medium- and high-frequency energy storage unit had a faster SOC automatic adjustment ability, which ensures the settled and safe operation of green port multi-energy microgrid systems.

The level of the author in this paper is limited, and there are some aspects that were not considered. Future research should focus on the following points:

It is necessary to provide a more detailed model of the quantification of logistics transportation energy at the port. This paper only considered the transportation characteristics and quantity limits of electric cranes, but the electric crane is influenced by many factors, such as the impact of wind speed on the quay cranes’ transportation process and the randomness of ship arrival time.

The fuzzy controller in this paper has not been trained. It is possible to consider the factors of port weather and use neural network algorithms to train fuzzy rules to improve the acclimatization of the EMS in the face of extreme weather.

The price of electricity can be used as inputs for fuzzy controllers to elevate the economy of the system.