Abstract

Multiphase fluids are common in many industries, such as oil and petrochemical, and volume fraction measurement of their phases is a vital subject. Hence, there are lots of scientists and researchers who have introduced many methods and equipment in this regard, for example, photon attenuation sensors, capacitance-based sensors, and so on. These approaches are non-invasive and for this reason, are very popular and widely used. In addition, nowadays, artificial neural networks (ANN) are very attractive in a lot of fields and this is because of their accuracy. Therefore, in this paper, to estimate volume proportion of a three-phase homogeneous fluid, a new system is proposed that contains an MLP ANN, standing for multilayer perceptron artificial neural network, a capacitance-based sensor, and a photon attenuation sensor. Through computational methods, capacities and mass attenuation coefficients are obtained, which act as inputs for the proposed network. All of these inputs were divided randomly in two main groups to train and test the presented model. To opt for a suitable network with the lowest rate of mean absolute error (MAE), a number of architectures with different factors were tested in MATLAB software R2023b. After receiving MAEs equal to 0.29, 1.60, and 1.67 for the water, gas, and oil phases, respectively, the network was chosen to be presented in the paper. Hence, based on outcomes, the proposed approach’s novelty is being able to predict all phases of a homogeneous flow with very low error.

1. Introduction

Multiphase fluids can be found in a number of industries, the most common of which are petrochemical, oil, water, and gas. These kind of flows are a mixture of different types of solid, liquid, or gas materials. Measuring volume fractions of phases is imperative in many subjects, such as economic matters, extraction, and so on. Previously, various phases of the fluid inside the pipe had to be separated and then measured. That manner was complex, time consuming, and expensive but was achieved by conventional tools. Hence, a multitude of either electrical or mechanical approaches have been introduced by researchers and scientists to overcome this important issue by utilizing turbo meters, vibrating densitometers, vortex meter, and sampling tubes, etc. [1,2]. One of the most seen multiphase fluids during transition is a combination of water, gas, and oil. For this reason, the importance of measuring volume fractions of such a fluid can be seen. Although there is lots of research related to the mentioned task, it can be considered as a challenge in the oil, petrochemical, and similar industries [3]. That is why a large number of methods and solutions have been introduced, to make it much better in comparison to previous manners. Take, for example, ANN, which stands for artificial neural networks. Due to its precision in many fields, ranging from engineering to medical-oriented concepts, it is one of the noteworthy tools for researchers in the measurement industry. On the other hand, to generate data as inputs for ANN, scientists are enthusiastic in utilizing a wide variety of prior valid sensors, such as capacitance-based sensors, photon attenuation sensors, electrical capacitance tomography (ECT), ultrasonic, and so on.

For instance, ECT as a useful approach in imaging has been used for over two decades [4,5]. The quality of this manner is good but when phases of a flow increases, ECT is faced with challenges. Due to this, it cannot be considered as a good way to investigate in multiphase flows [6]. Furthermore, in a separate investigation, wire-mesh sensors were deployed to assess gas–liquid–liquid flows, demonstrating the sensor’s efficacy in studying three-phase flow with some success. However, its capability was constrained as only a single electrical parameter was measured [7]. The calculation of liquid dielectric properties was often achieved by analyzing inductance, capacitance, or resistance, resulting in volume fraction measurements [8,9]. For instance, the authors of [10] utilized a flow meter based on correlation to determine water content, employing conductance measurement for the three-phase mixture. In [11], by utilizing a microcontroller, the authors have used several electrodes in order to monitor two-phase flows, while in [12], a capacitive sensor equipped with parallel plate (2 × 0.5 m) was used for this important task for a gas–solid flow. Extensive research has been dedicated to gamma radiation techniques for measuring volumes of gas, oil, and water. While many prior studies focused on specific fluids, the current investigation centers on a three-phase homogeneous system encompassing water, oil, and gas. In [13], Salgado and his colleagues employed a method based on gamma using dual-energy emitter radioisotopes to measure a multiphase fluid of gas, oil, and water.

Both capacitance-based sensors and photon attenuation sensors are non-invasive and that is why they are so attractive to use for not only direct measuring, but also producing inputs for ANN models. Authors in [14] measured both flow type and volume fractions by employing a gamma-based sensor along with an MLP ANN, standing for multilayer perceptron artificial neural network. For the proposed model, data were generated from a dual-energy photon source with two distinct detectors. This network could measure all three phases containing gas, water, and oil with an error rate of less than 5% for the former and the latter phases. In other research [15], radial basis function (RBF) network was used to estimate volume fractions of an annular flow containing gas, oil, and water. In this study, authors utilized a gamma-based sensor to generate data for three different RBF models. While the first one was employed to measure water and oil volumes, the second one was used to perform a similar task to that of the gas and water phases. This happened while volume fractions of gas and oil were measured by the third network. By comparing all of three models, the most accurate model was the first one to measure volume fractions of the mentioned flow. In addition, an ANN based on MLP architecture was developed [16] to assess volumetric proportions in homogeneous fluids, irrespective of the specific constitution of the liquid phase. Authors in [17] investigated measuring volume fractions of a two-phase homogeneous fluid regardless of the pressure factor changes along with considering temperature variations. Another study involved the potential of ANN tools and their intrinsic capabilities to uncover inventive strategies and methodologies to enhance a new kind of capacitive sensor’s efficacy [18]. Moreover, researchers in [19] scrutinized air–water and air–water–oil amalgamations with varying gas and liquid velocities. Additionally, feedforward backpropagation (FFBP) and MLP networks were employed to prognosticate pressure drop for both three-phase and two-phase flow scenarios.

In [20], researchers investigated measuring volume fractions of stratified and annular multiphase fluids by employing X-ray tubes along with a group method of data handling (GMDH). Moreover, the measuring of a three-phase fluid was performed by investigators in [21], who utilized a gamma backscatter technique and an MLP.

Utilizing just a capacitance-based sensor or a gamma-ray attenuation sensor with one detector and one source cannot result in measuring all phases of a multiphase fluid. This is because of the similar relative permittivity of oil and gas and the similar density of water and oil. To overcome this challenge, one of solutions is using multiple sensors relying on various physical characteristics. This manuscript introduces an innovative metering system crafted to independently gauge distinct phases. To apply such a great aim, there is need for employing cutting-edge methods. Hence, a new combination of two sensors along with an ANN was utilized to meet the goal. The presented metering system’s mean absolute error (MAE) for the all phases is under two. This underscores the remarkable precision of the proposed predictive approach. It is to be noted that, in homogeneous multiphase flows, all phases, including liquid and gas, move in the same velocity resulting in a slip ratio of 1, meaning the fluid is without bubble.

The following sections of this manuscript furnish a thorough narrative of the software, and mathematical expressions imperative for data generation in described Section 2. While the proposed network is investigated in Section 3, its results and discussion are shown in the next section. Ultimately, in Section 5, the presented metering system is concluded.

2. The Employed Sensors

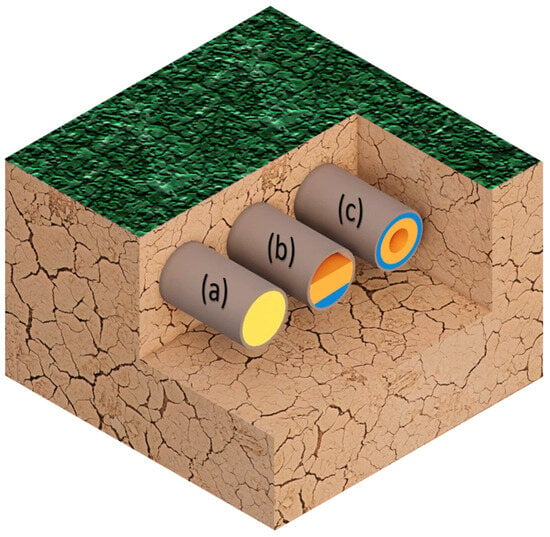

It is an acknowledged truth that many types of equipment and methods exist to measure volume fractions of flows but among all of them, photon attenuation and capacitive sensors are so popular because they have shown a good accuracy in various applications. This is because of their non-invasive manner that can be installed easily without any kind of separation or interruption in the main process. For these reasons, both of them along with an optimized ANN are employed to estimate volume fractions of a multiphase fluid of water, oil, and gas. While many kind of flows exist, they can be considered in three main forms, named as homogeneous, stratified, and annular. These flows can be seen in Figure 1a–c. In these flows, the liquid with a yellow color presents a homogeneous fluid. While the blue color shows water phase, the oil phase is presented with orange. Eventually, the empty section stands for the gas phase.

The base of capacitive sensor is the measured capacities’ variation; that is because of altering in the material between its electrodes, which is called dielectric. When a capacitance-based sensor is utilized, the material inside the pipe is its dielectric. Hence, when there is a change in the proportion of materials and their ratio, the measured capacity of the sensor changes. This is because of materials’ dielectric properties, the most important of which is relative permittivity. This shows the dependence of a capacitive sensor to relative permittivity, which, due to very close relative permittivity of gas and oil, means that this sensor is unable to measure all three phases volume fractions [22]. Hence, there is a need for another sensor that relies on another physical parameter. Gamma-ray attenuation sensors, which rely on density factor, are a good choice but due to very close density of water and oil, measuring all three phases cannot be achieved. While the linear absorption coefficient of the gas phase is the lowest, the problem is other phases being liquids [23]. This way, a gamma sensor cannot measure these liquid phases all by itself. Hence, both sensors, capacitive and gamma, are used beside each other to complete the mission, which is measuring all three phases.

Figure 1.

(a) Homogeneous fluid, (b) stratified fluid, and (c) annular fluid [24].

Opting for a sensor to measure volume fraction is a very important step in the measurement process. The main reason in selecting this kind of sensor in this study was its non-invasive behavior, meaning it can be used without performing separating or interruption in the process. Based on Equation (1), there is a definite link between measured capacity and the relative permittivity (εr) of the material between plates of the sensor. This parameter gives the amount of electrostatic energy related to the material that can be stored per unit after applying voltage. Whilst in the mentioned equation, C presents capacitance, D and A are the gap between two electrodes and area of electrodes, respectively. Finally, ε0 is the relative permittivity of free space, being equal to 8.854 × 10−12 F/m [25].

C = εr × ε0 × A/D

Until today, many different kinds of geometrical shapes related to capacitive sensors have been introduced such as concave, ring, helix, and parallel plates, etc. In this paper, a special shape of capacitance-based sensors named twin rectangular fork-like capacitance sensor (TRFLC) [26] is chosen and simulated in the software. The software that is utilized is the COMSOL Multiphysics(version 6.2.339), which has a great level of precision in its calculations. This software was evaluated through experimental studies, which can be seen in the authors’ pervious work [27]. To benchmark this tool, a static experiment was built and its capacity was measured by an LCR meter. The model of the LCR meter utilized was GPS-3138C (GPS Ltd., London, UK) and the frequency of the measurement was 200 KHz. After that, both experimental and simulation results were compared and illustrated very close outcomes. Hence, this software was benchmarked and its data are completely valid.

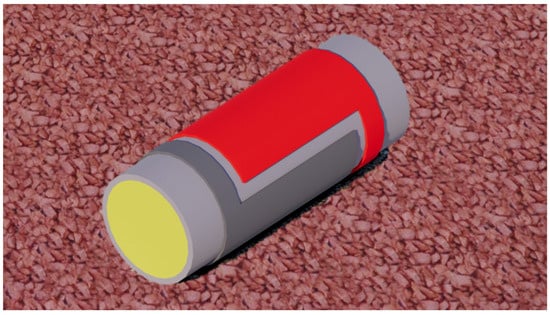

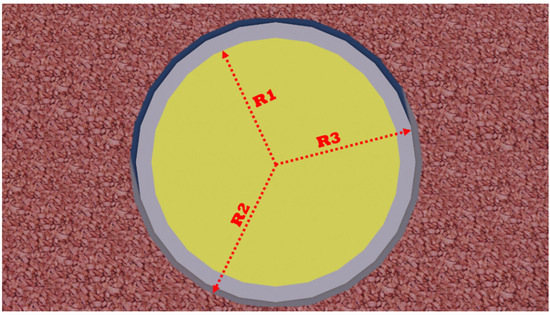

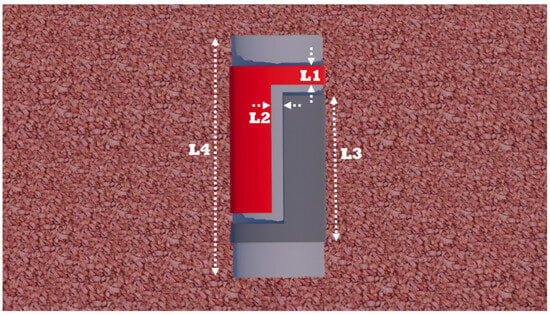

To simulate the aforementioned sensor, the first step is separating other parts from the area with a stable condition and without any kind of noise that the sensor is supposed to create in it. After that, the main parts of the study are added, including a pipe with a relative permittivity equal to 3.4, electrode made from copper, and the liquid inside the pipe, which is shown as a yellow color in Figure 2. In the following steps, the liquid’s εr will be changed according to every ratio and combination of oil, Gas, and water. Next, as is clear in Figure 2, there are two different colors related to electrodes on the surface of the pipe. The red and gray electrodes define VCC and GND sections, respectively. Finally, the mesh and other settings are set and the process of simulating is started. Figure 2 shows a three-dimensional view of the simulated TRFLC sensor in the software. In Figure 3, various radiuses of the simulated sensor are presented. While R1 = 2.6 cm shows internal radius of the pipe, R2 = 3.3 cm shows external radius. The pipe has a thickness equal to 0.6 cm and the electrodes have a thickness equal to 0.1 cm that can be recognized by subtracting R3 = 3.2 cm from R2. About other sections, it is to be noted that the pipe has a length equal to 20 cm, labeled with L4 in Figure 4. This figure also shows each electrode’s length being L3 = 10.5 cm. L2, being the distance between the electrodes, and L1 are equal to 0.5 cm and 1 cm, respectively.

Figure 2.

Three-dimensional view of the TRFLC sensor.

Figure 3.

Different radiuses of the simulated TRFLC sensor.

Figure 4.

Different lengths of the simulated TRFLC sensor.

Simulations were performed 231 times because of the decision to select 5 percent change in the materials’ volume in every ratio. Mesh setting, which is a very important part. was set to “Fine” level to compute capacities with a great level of accuracy. After this simulation, the first input of the proposed network was generated and in the next step, gamma-ray attenuation sensor, the second input is produced.

Another critical determinant significantly influencing the gamma-ray attenuation sensor is density, denoting the mass of a material per unit volume. Essentially, higher particle concentration per unit volume results in a higher amount of density. This parameter plays a pivotal role in gamma-based sensor measurements. To gauge volumes using this approach, a ray traverses the liquid, and upon reaching the opposite side, the tally of received rays is recorded. Therefore, it becomes apparent that greater material density anticipates a lower count of rays due to a higher particles count.

Subsequent to material passage, interactions, notably photoelectric absorption, pair production, and Compton scattering, occur between the ray and the substance. These interactions underscore the density’s impact on this method, as depicted in Equation (2), recognized as the absorption law. Within this equation, I0(E), I(E), η, E, Z, ρ, and L denote the emitted ray’s intensity, detected ray’s intensity, absorption coefficient, gamma-ray’s energy, atomic number, density, and liquid thickness, respectively [28]. Evidently, an inverse correlation exists between density and the number of rays reaching detectors. Equation (3) incorporates µ(E), the linear attenuation coefficients, into Equation (2), leading to the derivation of Equation (4), facilitating the calculation of I(E)/I0(E), the second input for the network. Equation (5) provides a means to compute Equation (4) for the specified liquid, where α, β, and γ represent the volume fractions of oil, water, and gas, respectively, and the sum of them is equal to 1. While µ(E)o is the linear attenuation coefficient of oil, µ(E)w and µ(E)g are the same parameters of water and gas, respectively. Equation (6) presents the main formula being used to generate data from the water–oil–gas flow for the network. It is to be noted that the length of the pipe is 5.2 cm.

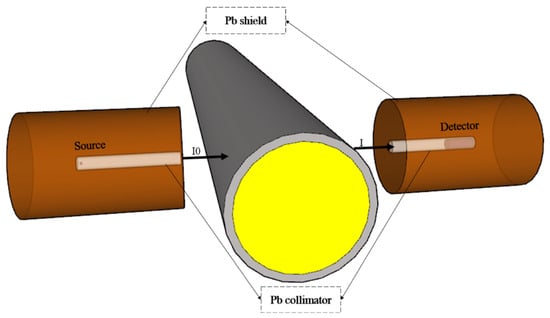

The determination of the source gamma-ray type is essential for calculations, and this study employed Cesium-137 emitting 0.662 MeV. Figure 5 illustrates the process of the ray traversing the liquid and reaching the detector. Drawing from data in [29], the linear attenuation coefficients of gas, oil, and water were considered and applied to Equation (6) to generate the required data for the network’s second input.

I(E) = I0(E)exp(−η(ZE)ρ × L)

µ(E) = η(ZE)ρ

I(E) = I0(E)exp(−µ(E) × L)

µ(E) = α × µ(E)o + β × µ(E)w + γ × µ(E)g

Ln (I/I0) = −[α × µ(E)o + β × µ(E)w + γ × µ(E)g] × L

Figure 5.

The way that a gamma-ray attenuation sensor counts.

3. Artificial Neural Network

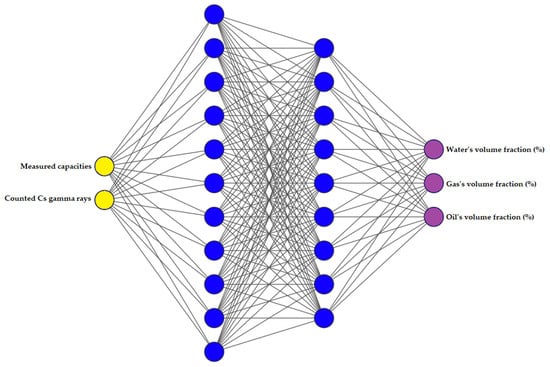

In contemporary times, intelligent measurement finds applications across diverse fields, extending beyond electrical engineering and similar disciplines. Notably, research is evident in financial studies, medical investigations, transportation, and more [30]. Within the realm of artificial intelligence (AI), ANN encompass various types, including the MLP and radial basis function (RBF). The MLP ANN, distinguished by its simplicity, faithful precision, and significant capacity for accurate measurements, stands as a widely utilized variant [31]. Previous works in the measurement domain frequently employed MLP ANN [15,16,17,18,19]. The MLP ANN of the current study comprises the three following primary layers: the input layer, receiving data from the TRFLC sensor and gamma-ray sensor; the hidden layer, where calculations predominantly occur; and the output layer, presenting the predicted volume fractions. Data in this model are categorized into train and test sets, with the former facilitating network training and the latter assessing performance [32].

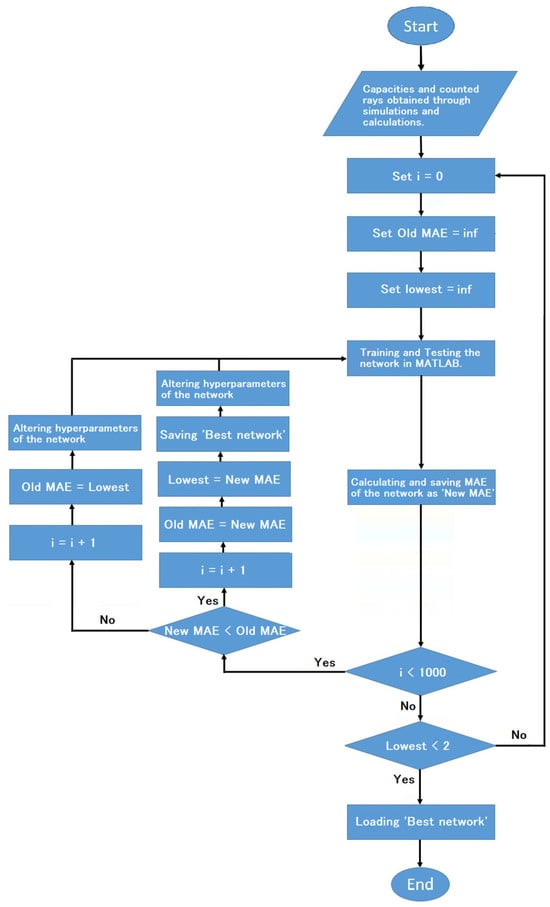

To identify the most accurate network configuration, extensive MATLAB coding and investigation of numerous networks with various hyperparameters led to the identification of the best network capable of accurately predicting the volume fractions of a water–oil–gas homogeneous flow. The main code incorporated several loops, each with varying different characteristics to find the network with the lowest mean absolute error (MAE) for all three phases. In each experiment, one hyperparameter was adjusted, such as the number of hidden layers, neurons in each hidden layer, activation functions, and the number of epochs. The model with the lowest error rate was selected and was explained in this paper. For the chosen model, 3 neurons are used in the output layer to represent gas, water, and oil amounts, with 11 neurons in the first hidden layer and 9 in the second hidden layer. Also, the network’s two inputs involve capacities generated by simulating the TRFLC sensor in COMSOL Multiphysics and counted Cs gamma rays from the gamma-ray sensor, obtained through various calculations. While 30% of all data was considered for testing the network, the rest of them (161 out of 231 data) were chosen for training. Additionally, a 5% material ratio change was applied across simulations and calculations. In Figure 6, all taken steps regarding the proposal of the best structure are shown. The activation function for input and output layers was “Purelin”, while “Tansig” served this crucial function for both hidden layers. The network’s learning method was based on Levenberg–Marquardt [33,34], utilizing 1600 epochs to achieve the desired outcome. In summary, the illustrated network in Figure 7 proficiently predicts volume fractions in a three-phase homogeneous fluid (gas, water, and oil) with minimal MAE across all phases.

Figure 6.

The way that the best network was chosen.

Figure 7.

Architecture of the presented network.

4. Results and Discussion

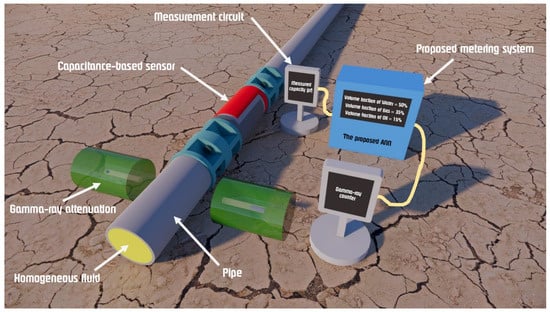

In this section, the results from the implemented network are examined. The network used two inputs: one from simulations with the TRFLC sensor using COMSOL software, and the other from calculations based on equations related to the gamma-ray attenuation sensor. This resulted in 231 data points, each connected to a specific phase ratio. These data points were then divided for training and testing. Figure 8 shows the complete diagram of the new metering system, which includes the TRFLC sensor, a gamma-ray attenuation sensor, and an MLP ANN.

Figure 8.

The schematic of the presented metering system.

There are different material ratios where the capacitance-based sensor generates very similar capacities, and this is because of the εr, which is the martial between its electrodes. Relative permittivity of water, gas, and oil is equal to 81, 1, and 2.2 [16], respectively, and due to this difference, this type of sensor can solely predict the volume fraction of water in diverse states. To address this limitation and propose a system being capable of predicting all three phases, another sensor relying on a different physical concept must be utilized. Hence, a gamma-ray attenuation sensor was incorporated because density exerts a significant influence on the measurement. This sensor adeptly measures the gas phase’s volume fraction due to the closely matched densities of water = 1 gr/cm3 and oil = 0.9 gr/cm3, which are much higher than that of gas, being 0.001 gr/cm3 [35].

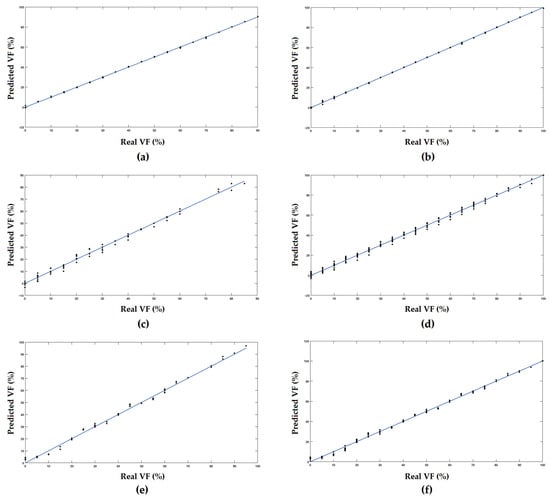

Figure 9 depicts the train and test results produced by the implemented network, revealing accurate predictions for the water, gas, and oil phases without signs of overfitting or underfitting.

Figure 9.

(a) Water’s test data regression diagram, (b) water’s train data regression diagram, (c) gas’s test data regression diagram, (d) gas’s train data regression diagram, (e) oil’s test data regression diagram, and (f) oil’s train data regression diagram.

In fluid flow, Prandtl and Reynolds dimensionless numbers are utilized to describe the flow characteristics. According to Equation (7), the Prandtl can be calculated, and the Reynolds number can be obtained by Equation (8) [36].

In these equations, Pr, Re, , , , , , and are Prantdl number, Reynolds number, dynamic viscosity, specific heat capacity, thermal conductivity, density, characteristic velocity, and characteristic length, respectively. Due to the type of the fluid, which is a multiphase flow, effective values of each parameter were placed in equations. In Table 1, values of all of variables are presented except u and l, considered to be 10 m/s and 0.5 m, respectively. To calculate effective values, Equations (9) to (12) must be used [36]. Table 2 presents the obtained outputs and their disparities from the actual values. In Table 2, colors show the amount of error in each ratio and for each phase. Green shows the lowest error and yellow is the highest.

Table 1.

Various parameters for calculating Prandtl and Reynolds number at 20 degrees centigrade [36].

Table 2.

Predicted volume fractions of all three phases by the presented network in comparison with their real amounts.

As is clear, for every ratio of all three phases, both Pr and Re numbers can be calculated. For example, for the ratio when gas’s VF = 75%, water’s VF = 15%, and oil’s VF = 10%, Pr and Re numbers are equal to 1372 and 23510, respectively. The obtained Reynolds number indicates a highly turbulent flow regime, showing a uniformly distributed mixing, facilitating more accurate measurements and analysis.

Based on the outcomes, the accuracy of the proposed metering system can be observed because the MAE of the water, gas, and oil phases are equal to 0.29, 1.60, and 1.67, respectively. By solving Equations (13) and (14), MAE and root mean square error (RMSE) for the network can be calculated. In these equations n, Xi, and Yi are the count of observations, the simulated (COMSOL Multiphysics), and predicted (MLP) values, respectively [24]. The errors of the proposed metering system are presented in Table 3.

Table 3.

Obtained results of the proposed metering system including MAE and RMSE for all three phases.

To show the merits of the proposed metering approach, Table 4 acts as a comparison table, which compares the proposed metering approach with eight similar studies. In this table, green color is the lowest error and red is the highest.

Table 4.

Comparing various details of the proposed method with that of other similar studies.

The MAE is a crucial metric showing the accuracy of systems, and the approach detailed here outperforms others in measuring water, oil, and gas phases in comparison with some of them, particularly excelling in assessing water in water–oil–gas flows. All factors of a gamma ray attenuation sensor, such as its performance and accuracy, are influenced by the number of detectors and sources it contains. Hence, the more detectors and sources, the more accurate a measurement to be expected. On the other hand, increasing the number of detectors and sources raises some unwanted factors, such as the system’s complexity and cost and power consumption, etc. Additionally, by utilizing more gamma sources, a system becomes more dangerous in the aspect of safety risks and regularity challenges, because governing radioactive materials is a hard task to achieve. In the current study, the fewest number of detectors and sources was employed, being more cost-effective and easier to manage. All references, except [21,24,37], have utilized two detectors, but in the proposed approach there is just one detector and one source, which is one of the most important merits of it. In [22], which was just based on capacitive sensors, and [37], just one phase of a multiphase flow has been reported, but in this manuscript, all three phases, water, gas, and oil, have been reported, which is another advantage for it. Furthermore, in [21,38], an X-ray tube was used as the source. While X-ray tubes can adjust energy levels and beam intensity by accelerating electrons onto a metal target, they depend on a stable power supply and require regular maintenance and calibration. In contrast, the proposed approach uses gamma ray sensors with radioactive isotopes to emit gamma rays. These sensors are portable, have a long operational life, and do not need an external power source. In [24], a Baruim-133 source has been utilized, which in the presented metering system, means that there is a 0.04, 2.08, and 2.08 decrease for the MAE of the water, gas, and oil, respectively. This is because of the higher Cs gamma ray’s energy, which due to greater penetration. Compton scattering is the primary interaction for it, and makes the attenuation highly dependent on material’s density, but for Ba there is a lower level of energy and dependence on material’s atomic number. Photoelectric absorption is happening and it is less sensitive to the density of the material. Moreover, the utilized capacitance-based sensor in the current study was the TRFLC sensor and it has a higher rate of sensitivity in comparison to that of the concave sensor utilized in [24]. Consequently, the introduced combined approach, incorporating the gamma-ray attenuation sensor, capacitance-based sensor, and MLP ANN, emerges as a highly effective method in relevant fields. According to these comparisons, the presented metering system, which a conjunction of two sensors, capacitance-based and photon attenuation with one source and one detector, along with the optimized MLP model formed, is a great solution to measure volume fractions of a multiphase fluid.

5. Conclusions

Various industries encounter different types of fluids, such as oil and petroleum. The measurement of these fluids is a critical task in various sectors, including financial matters, and is often accompanied by numerous challenges. Many methods have been introduced to address this, each with its own advantages and disadvantages. The proposed metering system, containing photon attenuation and capacitive sensors along with an MLP, had two inputs; the first input, the TRFLC sensor, was simulated in COMSOL Multiphysics software, generating capacities related to various material volumes. The second input involved a gamma-ray sensor with Cesium-137, considering different situations and calculations using relevant equations. Obtained data were utilized to train and test data with 70% and 30% of all data, respectively. The proposed network, which was run in MATLAB software and was selected after considering many architectures, produced highly accurate outputs with a very low MAE for water, oil, and gas, recorded as 0.29, 1.67, and 1.60, respectively. These results highlight the system’s remarkable accuracy in measuring volume fractions in a three-phase water–oil–gas homogeneous regime.

Author Contributions

Conceptualization, A.M.M. and R.H.; Methodology, M.P.; Software, M.A.M.; Validation, F.F., M.P. and M.R.R.; Formal analysis, A.M.M., F.F., R.H., M.P. and S.A.M.; Investigation, A.M.M., F.F., M.R.R., M.A.M. and S.A.M.; Data curation, M.R.R. and M.A.M.; Writing—original draft, M.A.M.; Writing—review & editing, A.M.M., F.F., R.H., M.P., M.R.R. and S.A.M.; Supervision, R.H.; Funding acquisition, A.M.M. and R.H. All authors have read and agreed to the published version of the manuscript.

Funding

The authors extend their appreciation to the Deanship of Scientific Research at King Khalid University for funding this work through large group Research Project under grant number RGP2/191/45. The authors also thank the support from Rzeszów University of Technology, project number PB22.EM.24.001.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

There are no conflicts of interest.

References

- Chen, X.; Chen, L.; Zhou, F.; Lin, F. Crude Oil/Natural gas/Water Three-Phase Flow meter. In Proceedings of the SPE, 63rd Annual Technical Conference and Exhibition of the Society of Petroleum Engineers, Houston, TX, USA, 2–5 October 1988. [Google Scholar]

- Thorn, R.; Johansen, G.A.; Hammer, E.A. Recent developments in three-phase flow measurement. Meas. Sci. Technol. 1997, 8, 691. [Google Scholar] [CrossRef]

- Thorn, R.; Johansen, G.A.; Hjertaker, B.T. Three-phase flow measurement in the petroleum industry. Meas. Sci. Technol. 2012, 24, 012003. [Google Scholar] [CrossRef]

- Huang, S.M.; Plaskowski, A.B.; Xie, C.G.; Beck, M.S. Capacitance-based tomographic flow imaging system. Electron Lett. 1988, 24, 418. [Google Scholar] [CrossRef]

- Liu, S.; Chen, Q.; Wang, H.G.; Jiang, F.; Ismail, I.; Yang, W.Q. Electrical capacitance tomography for gas–solids flow measurement for circulating fluidized beds. Flow Meas. Instrum. 2005, 16, 135–144. [Google Scholar] [CrossRef]

- Hossain, M.S.; Abir, M.T.; Alam, M.S.; Volakis, J.L.; Islam, M.A. An algorithm to image individual phase fractions of multiphase flows using electrical capacitance tomography. IEEE Sens. J. 2020, 20, 14924–14931. [Google Scholar] [CrossRef]

- Dias, F.D.; dos Santos, E.N.; da Silva, M.J.; Schleicher, E.; Morales, R.E.; Hewakandamby, B.; Hampel, U. New algorithm to discriminate phase distribution of gas-oil-water pipe flow with dual-modality wire-mesh sensor. IEEE Access 2020, 8, 125163–125178. [Google Scholar] [CrossRef]

- Isaksen, O. Three Phase Pipe Flow Imaging Using a Capacitance Tomography System. In Proceedings of the IEE Colloquium on Advances in Sensors for Fluid Flow Measurements, London, UK, 18 April 1996; pp. 11/1–11/6. [Google Scholar]

- Qu, Z.; Zhao, Q.; Meng, Y. On oil measurement of water concentration of oil-water mixture in the flow of pipeline by using eddy current. J. Meas. Sci. Technol. 2012, 24, 125304. [Google Scholar] [CrossRef]

- Sheikh, S.I.; Al-Quraish, K.; Ragheb, H.A.; Babelli, I. Simple Microwave Method for Detecting Water Holdup. Microw. Opt. Technol. Lett. 2008, 50, 354–355. [Google Scholar] [CrossRef]

- Libert, N.; Da Silva, M.J. Capacitive measuring system for two-phase flow monitoring. Part 1: Hardware design and evaluation. Flow Meas. Instrum. 2016, 47, 90–99. [Google Scholar] [CrossRef]

- Yang, D.; Pu, H.; Han, H.; Liu, L.; Yan, C. Huge-scale capacitance mass flowmeter in gas/solid two-phase flow with rectangular vertical pipeline. Measurement 2020, 151, 107235. [Google Scholar] [CrossRef]

- Salgado, C.M.; Pereira, C.M.; Schirru, R.; Brandão, L.E. Flow regime identification and volume fraction prediction in multiphase flows by means of gamma-ray attenuation and artificial neural networks. Prog. Nucl. Energy 2010, 52, 555–562. [Google Scholar] [CrossRef]

- Salgado, W.L.; Dam, R.S.; Salgado, C.M. Optimization of a flow regime identification system and prediction of volume fractions in three-phase systems using gamma-rays and artificial neural network. Appl. Radiat. Isot. 2021, 169, 109552. [Google Scholar] [CrossRef] [PubMed]

- Roshani, G.; Karami, A.; Salehizadeh, A.; Nazemi, E. The capability of radial basis function to forecast the volume fractions of the annular three-phase flow of gas-oil-water. Appl. Radiat. Isot. 2017, 129, 156–162. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.-C.; Alizadeh, S.M.; Alanazi, A.K.; Grimaldo Guerrero, J.W.; Abo-Dief, H.M.; Eftekhari-Zadeh, E.; Fouladinia, F. Using ANN and Combined Capacitive Sensors to Predict the Void Fraction for a Two-Phase Homogeneous Fluid Independent of the Liquid Phase Type. Processes 2023, 11, 940. [Google Scholar] [CrossRef]

- Qaisi, R.M.; Fouladinia, F.; Mayet, A.M.; Guerrero, J.W.; Loukil, H.; Raja, M.R.; Muqeet, M.A.; Eftekhari-Zadeh, E. Intelligent measuring of the volume fraction considering temperature changes and independent pressure variations for a two-phase homogeneous fluid using an 8-electrode sensor and an ANN. Sensors 2023, 23, 6959. [Google Scholar] [CrossRef] [PubMed]

- Syah, R.B.Y.; Veisi, A.; Hasibuan, Z.A.; Al-Fayoumi, M.A.; Daoud, M.S. A Novel Smart Optimized Capacitance-Based Sensor for Annular Two-Phase Flow Metering with High Sensitivity. IEEE Access 2023, 11, 60709–60716. [Google Scholar] [CrossRef]

- Ribeiro, J.X.; Liao, R.; Aliyu, A.M.; Liu, Z. Prediction of pressure gradient in two and three-phase flows in vertical pipes using an artificial neural network model. Int. J. Eng. Technol. Innov. 2019, 9, 155–170. [Google Scholar]

- Roshani, G.H.; Muhammad Ali, P.J.; Mohammed, S.; Hanus, R.; Abdulkareem, L.; Alanezi, A.A.; Nazemi, E.; Eftekhari-Zadeh, E.; Kalmoun, E.M. Feasibility study of using X-ray tube and GMDH for measuring volume fractions of annular and stratified regimes in three-phase flows. Symmetry 2021, 13, 613. [Google Scholar] [CrossRef]

- Peyvandi, R.G.; Rad, S.Z.I. Application of artificial neural networks for the prediction of volume fraction using spectra of gammarays backscattered by three-phase flows. Eur. Phys. J. Plus 2017, 132, 511. [Google Scholar] [CrossRef]

- Mayet, A.M.; Fouladinia, F.; Alizadeh, S.M.; Alhashim, H.H.; Guerrero, J.W.; Loukil, H.; Parayangat, M.; Nazemi, E.; Shukla, N.K. Measuring volume fractions of a three-phase flow without separation utilizing an approach based on artificial intelligence and capacitive sensors. PLoS ONE 2024, 19, e0301437. [Google Scholar] [CrossRef] [PubMed]

- Falcone, G. Key multiphase flow metering techniques. Dev. Pet. Sci. 2009, 54, 47–190. [Google Scholar]

- Fouladinia, F.; Alizadeh, S.M.; Gorelkina, E.I.; Hameed Shah, U.; Nazemi, E.; Guerrero, J.W.G.; Roshani, G.H.; Imran, A. A novel metering system consists of capacitance-based sensor, gamma-ray sensor and ANN for measuring volume fractions of three-phase homogeneous flows. Nondestruct. Test. Eval. 2024, 8, 1–27. [Google Scholar] [CrossRef]

- Terzic, E.; Terzic, J.; Nagarajah, R.; Alamgir, M.; Terzic, E.; Terzic, J.; Nagarajah, R.; Alamgir, M. Capacitive sensing technology. In A Neural Network Approach to Fluid Quantity Measurement in Dynamic Environments; Springer: London, UK, 2012; pp. 11–37. [Google Scholar]

- Salehi, S.M.; Karimi, H.; Dastranj, A.A.; Moosavi, R. Twin rectangular fork-like capacitance sensor to flow regime identification in horizontal co-current gas–liquid two-phase flow. IEEE Sens. J. 2017, 17, 4834–4842. [Google Scholar] [CrossRef]

- Iliyasu, A.M.; Fouladinia, F.; Salama, A.S.; Roshani, G.H.; Hirota, K. Intelligent Measurement of Void Fractions in Homogeneous Regime of Two-Phase Flows Independent of the Liquid Phase Density Changes. Fractal Fract. 2023, 7, 179. [Google Scholar] [CrossRef]

- Li, D.H.; Wu, Y.X.; Li, Z.B.; Zhong, X.F. Volumetric fraction measurement in oil-water-gas multiphase flow with dual energy gamma-ray system. J. Zhejiang Univ. Sci. A 2005, 6, 1405–1411. [Google Scholar]

- Available online: https://physics.nist.gov/PhysRefData/Xcom/html/xcom1.html (accessed on 20 February 2024).

- Esteva, A.; Robicquet, A.; Ramsundar, B.; Kuleshov, V.; DePristo, M.; Chou, K.; Cui, C.; Corrado, G.; Thrun, S.; Dean, J. A guide to deep learning in healthcare. Nat. Med. 2019, 25, 24–29. [Google Scholar] [CrossRef] [PubMed]

- Gallant, A.R.; White, H. On learning the derivatives of an unknown mapping with multilayer feedforward networks. Neural Netw. 1992, 5, 129–138. [Google Scholar] [CrossRef]

- Salgado, C.M.; Brandão, L.E.; Schirru, R.; Pereira, C.M.; da Silva, A.X.; Ramos, R. Prediction of volume fractions in three-phase flows using nuclear technique and artificial neural network. Appl. Radiat. Isot. 2009, 67, 1812–1818. [Google Scholar] [CrossRef] [PubMed]

- Marquardt, D.W. An algorithm for least-squares estimation of nonlinear parameters. J. Soc. Ind. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

- Levenberg, K. A method for the solution of certain non-linear problems in least squares. Q. Appl. Math. 1944, 2, 164–168. [Google Scholar] [CrossRef]

- Salgado, C.M.; Brandão, L.E.; Conti, C.C.; Salgado, W.L. Density prediction for petroleum and derivatives by gamma-ray attenuation and artificial neural networks. Appl. Radiat. Isot. 2016, 116, 143–149. [Google Scholar] [CrossRef] [PubMed]

- Engineering ToolBox. 2001. Available online: https://www.engineeringtoolbox.com (accessed on 1 July 2024).

- Roshani, M.; Phan, G.; Roshani, G.H.; Hanus, R.; Nazemi, B.; Corniani, E.; Nazemi, E. Combination of X-ray tube and GMDH neural network as a nondestructive and potential technique for measuring characteristics of gas-oil–water three phase flows. Measurement 2021, 168, 108427. [Google Scholar] [CrossRef]

- Pan, Y.; Li, C.; Ma, Y.; Huang, S.; Wang, D. Gas flow rate measurement in low-quality multiphase flows using Venturi and gamma ray. Exp. Therm. Fluid Sci. 2019, 100, 319–327. [Google Scholar] [CrossRef]

- Taylan, O.; Sattari, M.A.; Elhachfi Essoussi, I.; Nazemi, E. Frequency domain feature extraction investigation to increase the accuracy of an intelligent nondestructive system for volume fraction and regime determination of gas-water-oil three-phase flows. Mathematics 2021, 9, 2091. [Google Scholar] [CrossRef]

- Roshani, G.H.; Nazemi, E.; Roshani, M.M. Intelligent recognition of gas-oil-water three-phase flow regime and determination of volume fraction using radial basis function. Flow Meas. Instrum. 2017, 54, 39–45. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).