Assessment of the Use of Carbon Capture and Storage Technology to Reduce CO2 Emissions from a Natural Gas Combined Cycle Power Plant in a Polish Context

Abstract

1. Introduction

- Solvent-based, where an absorption liquid is used;

- Sorbent-based, where adsorption solid particles are used;

- Cryogenic, where different gas condensation temperatures are used;

- Membranes, where solid-state chemical barriers are used.

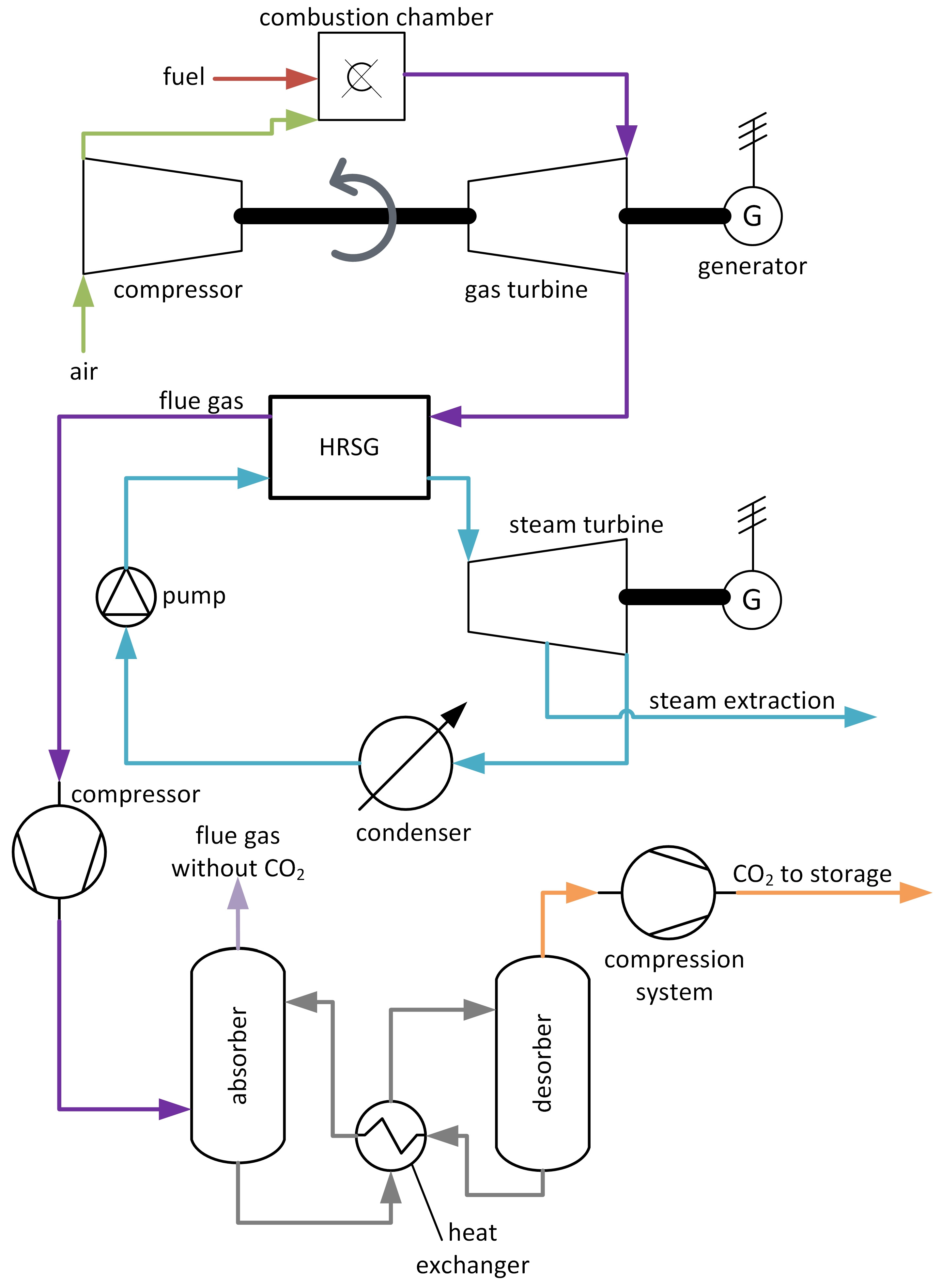

2. Materials and Methods

3. Results and Discussion

3.1. Model Validation

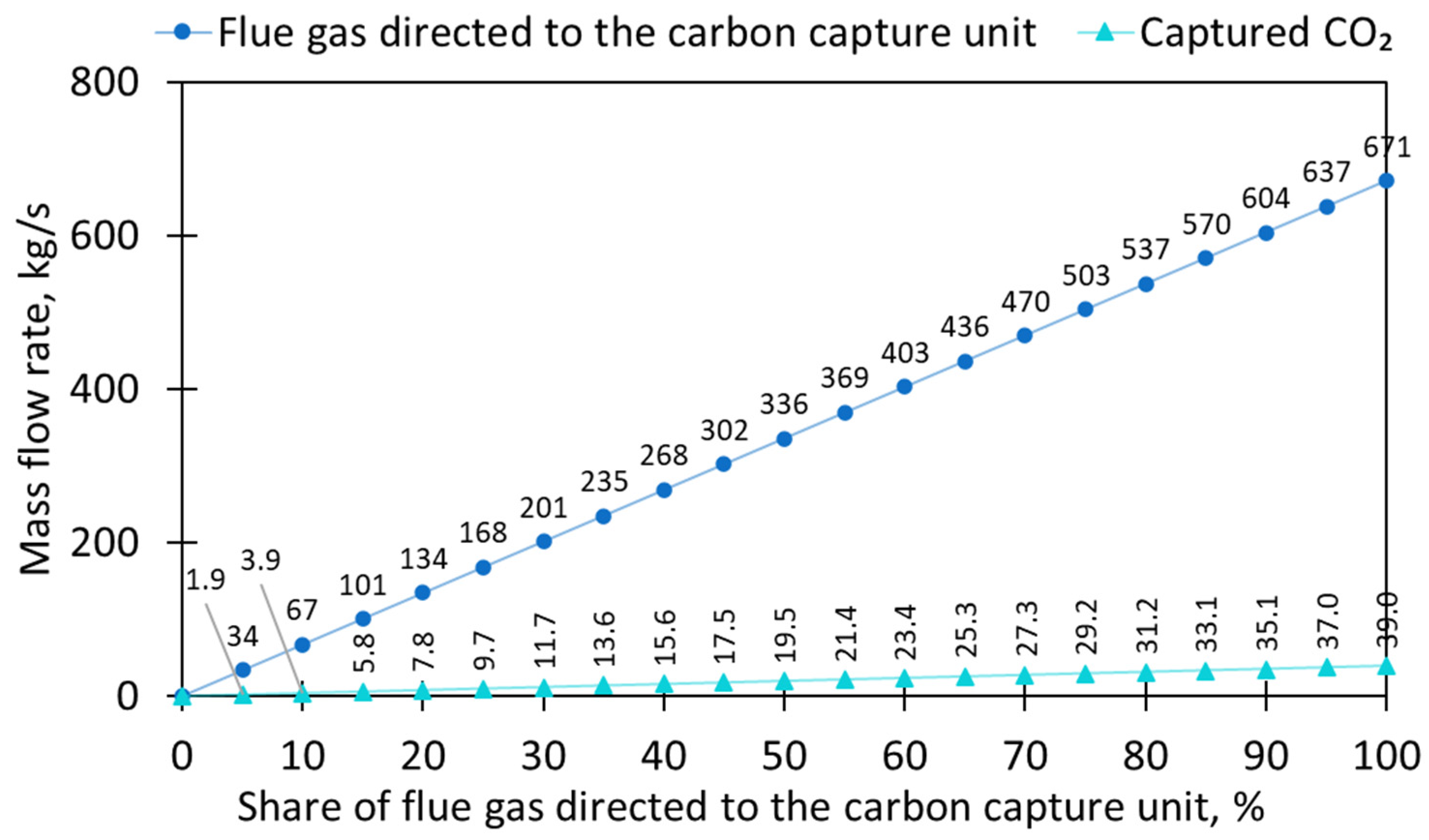

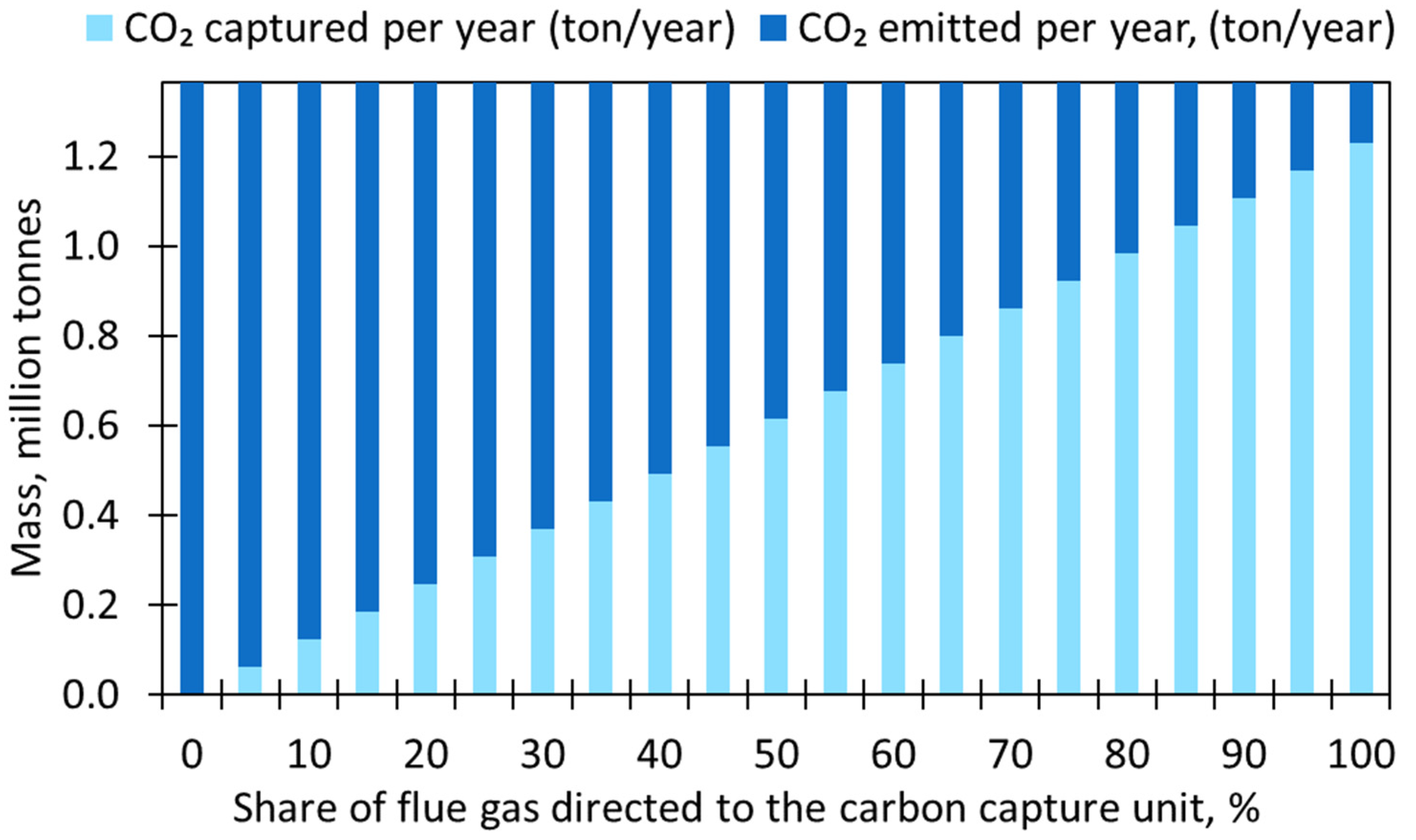

3.2. Case Scenario for CO2 Capture

3.3. Economic Scenario

3.4. Comparison to the Literature

| Reference | Without CCS | With CCS | ||||

|---|---|---|---|---|---|---|

| Pnet, MW | η, % | MCO2, tons/year | Pnet, MW | η, % | MCO2, tons/year | |

| Strojny et al. [36] | 735.5 | 57.7 | 1,998,435 | 628.4 | 49.3 | 199,843 |

| Oh et al. [34] | 580.4 | 52.6 | 1,844,190 | 484.2 | 43.8 | 90 044 |

| Ystad et al. [37] | 444.0 | 58.26 | n.a. | n.a. | 51.07–52.00 * | n.a. |

| Sipöcz et al. [38] | 442.0 | 58.29 | 1,359,289 | 377.8 | 49.81 | 130,874 |

| Carapellucci et al. [35]—NGCC 1 | 384.0 | 56.1 | 1,240,248 | 343.5 | 50.7 | 122,770 |

| Carapellucci et al. [35]—NGCC 2 | 153.9 | 50.6 | 552,747 | 137.0 | 45.6 | 54,485 |

| Carapellucci et al. [35]—NGCC 3 | 50.0 | 48.5 | 187,683 | 42.8 | 41.9 | 18,484 |

| Lindqvist et al. [39] | 416.4 | 58.13 | 1,294,921 | 354.3 | 51.41 | 124,147 |

| This work | 435.68 | 55.60 | 1,365,501 | 363.47 | 46.39 | 136,556 |

4. Conclusions

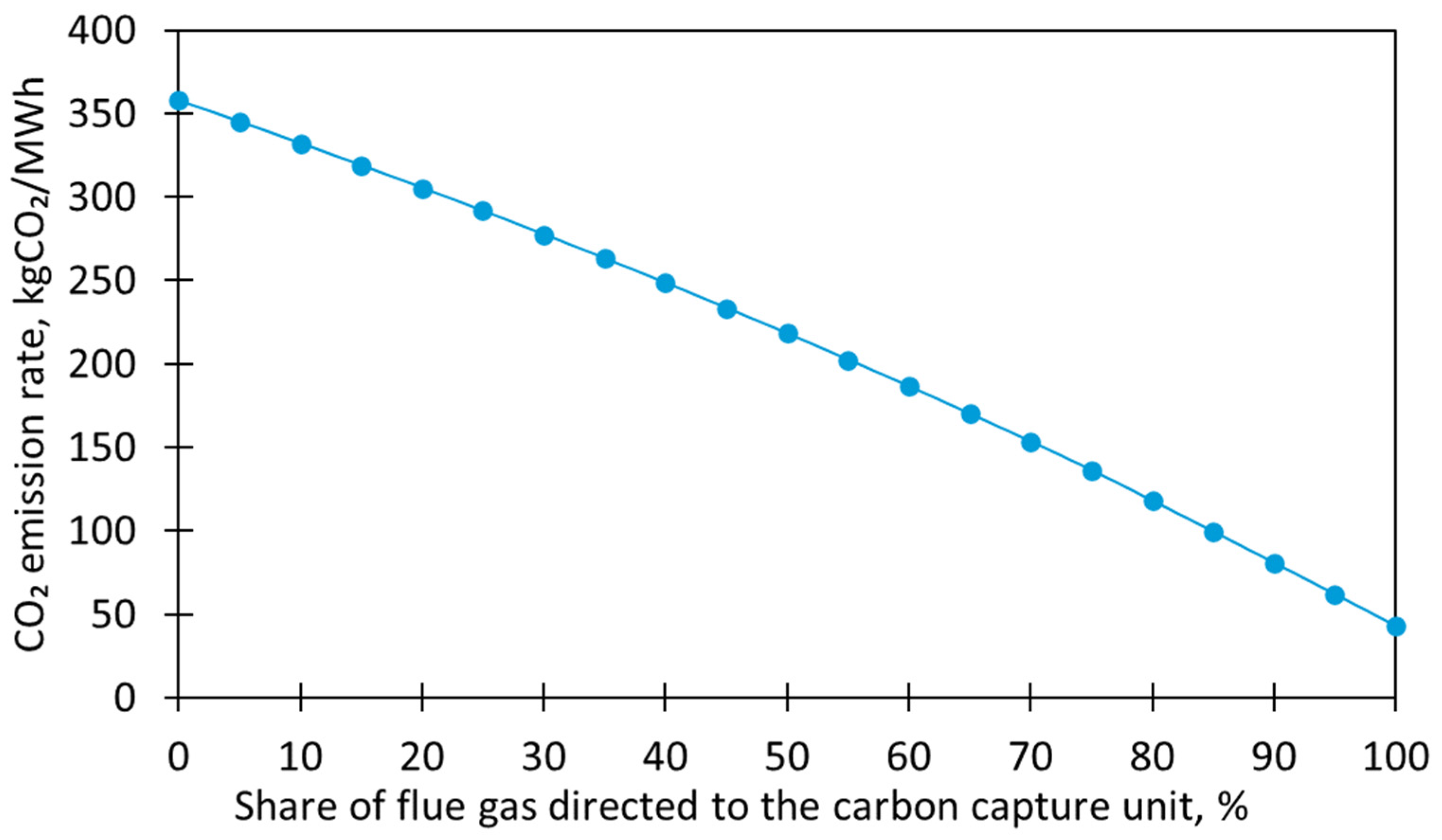

- The annual CO2 emissions from the investigated 435 MW NGCC power plant are 1,365,501 tons when no CCS is used and can be reduced to 136,556 tons if the entire flue gas is directed to the CO2 capture unit with a CO2 capture efficiency of 90%.

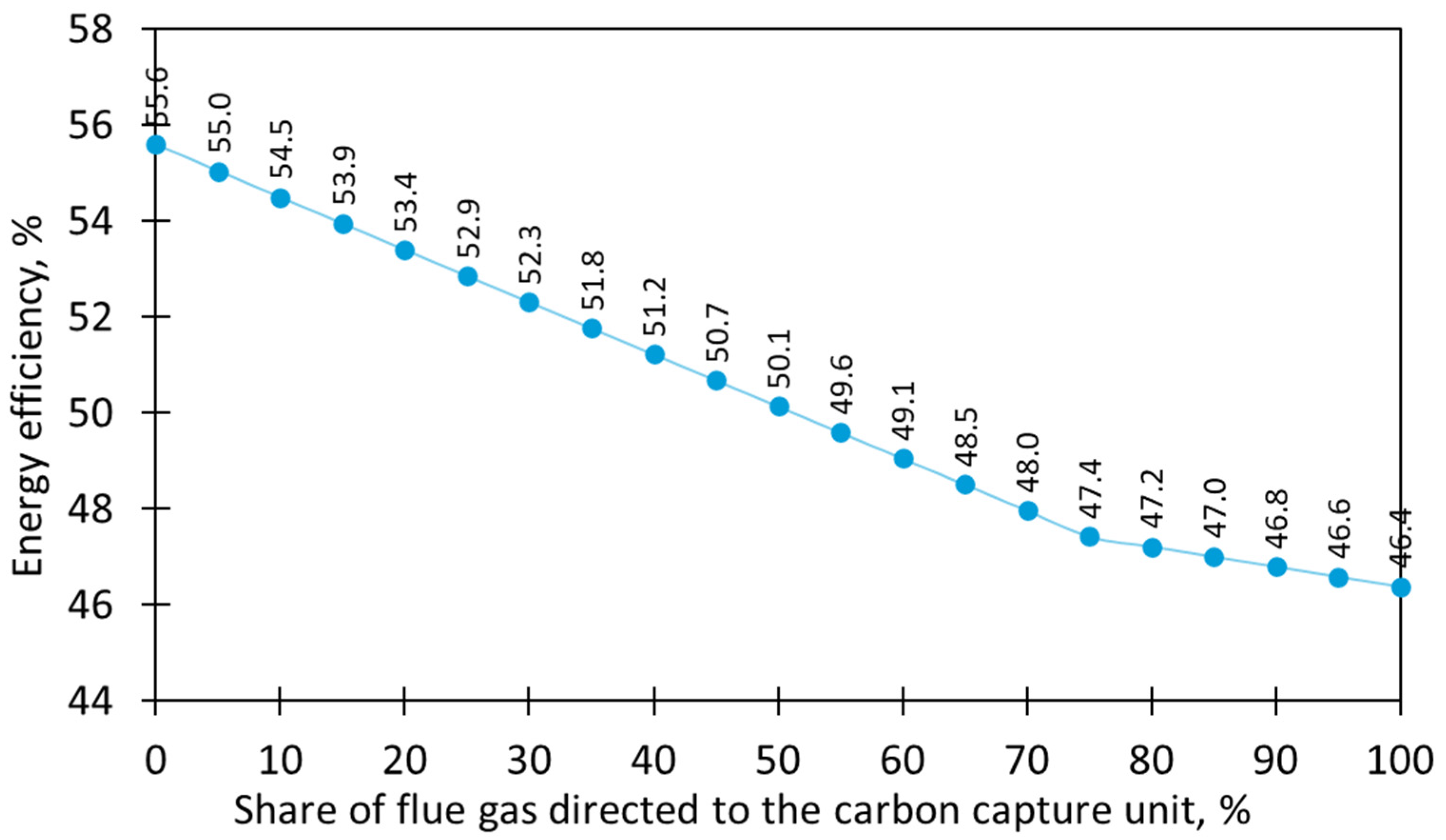

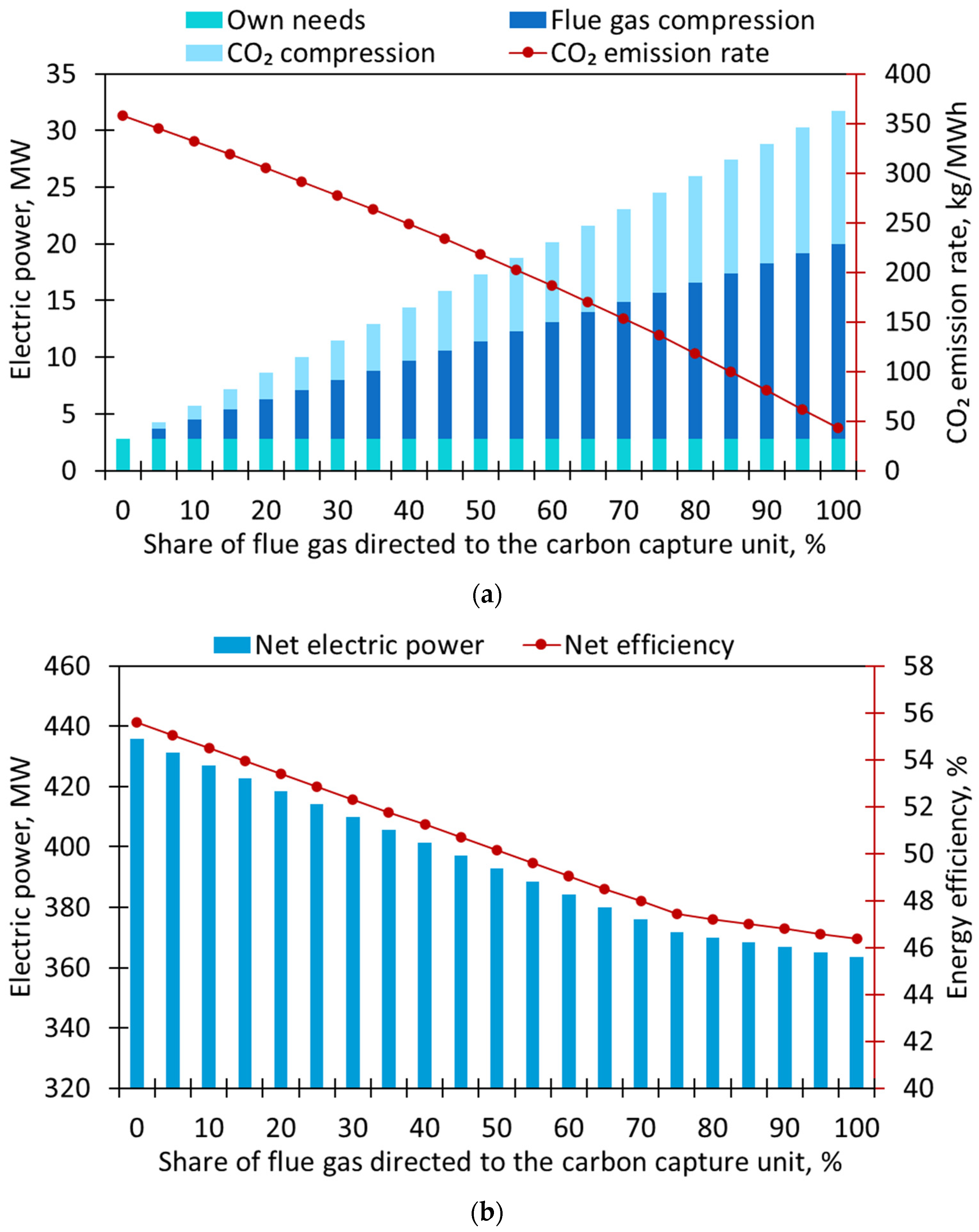

- Using CCS technology impacts the NGCC power plant’s operational parameters, particularly in terms of energy efficiency, energy consumption, and power generation.

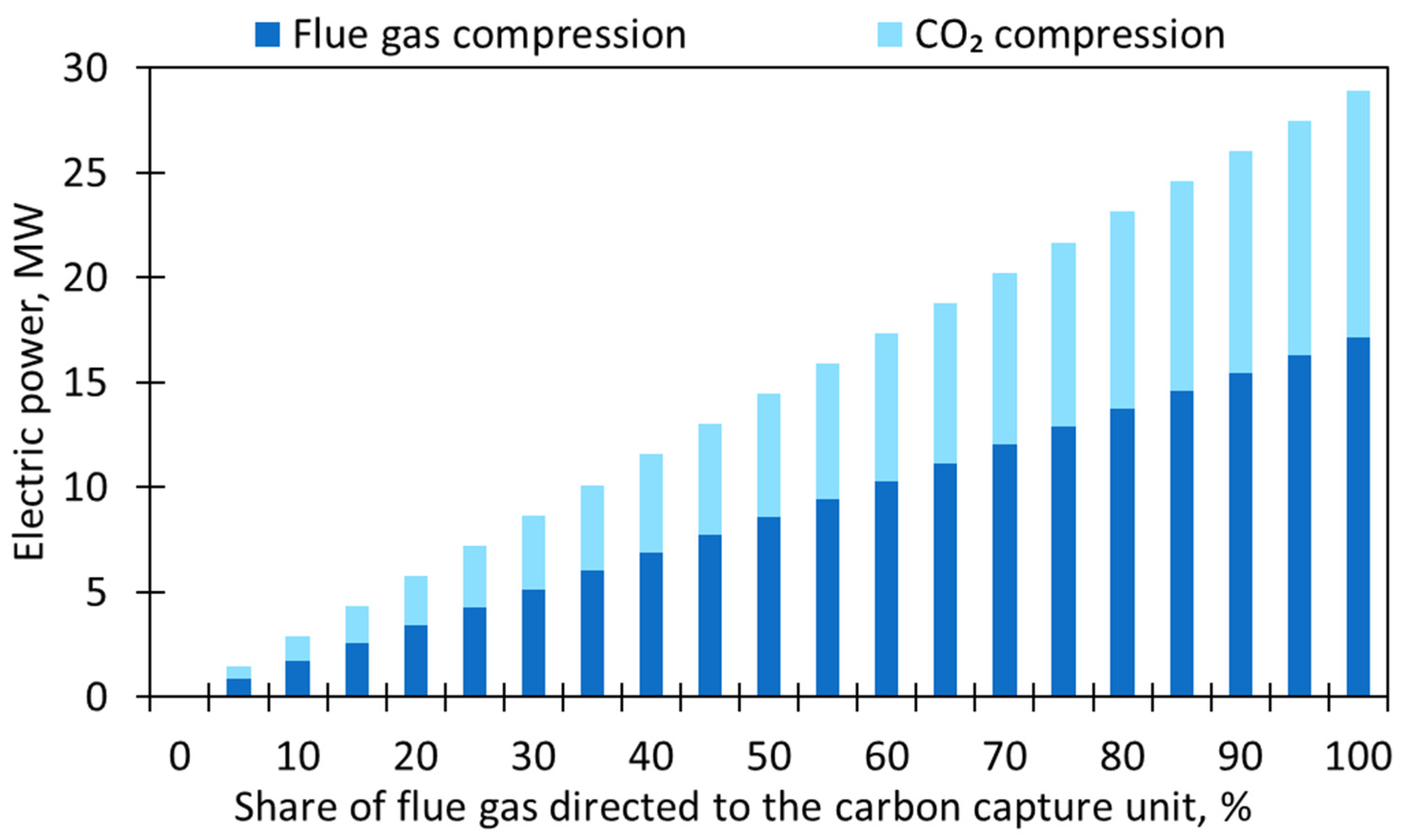

- CCS technology comes with increased energy demands, both electric and thermal. Thermal energy, in the form of steam, is used for sorbent regeneration in the CO2 capture unit. The mass flow rate of the steam increases linearly to 47.61 kg/s (for a 100% share of flue gas). The electric power demand for both flue gas and CO2 compression rises to 28.9 MW when 100% of the flue gas is directed towards the CO2 capture unit.

- As a result of steam intake and electricity demand for compression, the net electric power of the NGCC decreases from 435.68 MW (no CCS) to 363.47 MW (with CCS, 100% share of flue gas directed to the capture unit). Also, the net energy efficiency declines from 55.60% to 46.39% after CCS integration. This reduction in efficiency is primarily attributed to the energy requirements of CCS operations, underscoring the trade-off between reducing emissions and maintaining energy efficiency. It is advisable to set the capture rate for the NGCC at a level higher than 80%, as there is no significant impact on efficiency beyond this threshold.

- The cost of emission of 1,365,501 tons of CO2 is EUR 95,585.10 when subject to a tax rate of EUR 0.07 per ton of CO2 in Poland. However, this cost increases to EUR 32,772,033.90 if the same NGCC plant were situated in Portugal, EUR 58,402,495.42 when subjected to the EU average carbon tax rate, EUR 115,739,899.74 if the same NGCC plant were situated in Norway, and EUR 121,529,625.73 under the EU ETS. The application of the CCS technology in the analyzed NGCC power plant can reduce those costs by up to 90%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Canadell, J.G.; Monteiro, P.M.S.; Costa, M.H.; Cotrim da Cunha, L.; Cox, P.M.; Eliseev, A.V.; Henson, S.; Ishii, M.; Jaccard, S.; Koven, C.; et al. (Eds.) Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. In Climate Change 2021–The Physical Science Basis; 2021: Global Carbon and other Biogeo; Cambridge University Press: Cambridge, UK, 2023; pp. 673–816. [Google Scholar]

- IEA. CO2 Emissions in 2022; IEA: Paris, France, 2023. [Google Scholar]

- Ministry of Climate and Environment. Energy Policy of Poland Until 2040; Ministry of Climate and Environment: Warsaw, Poland, 2021. [Google Scholar]

- IEA. CCUS in Clean Energy Transitions; IEA: Paris, France, 2020. [Google Scholar]

- Metz, B.; Davidson, O.; de Coninck, H.; Loos, M.; Meyer, L. IPCC Special Report on Carbon Dioxide Capture and Storage. Prepared by Working Group III of the Intergovernmental Panel on Climate Change; Metz, B., Davidson, O., de Coninck, H., Loos, M., Meyer, L., Eds.; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Forum Energii. Energy Transition in Poland. 2023 Edition; Forum Energii: Warsaw, Poland, 2023. [Google Scholar]

- Rao, A.B.; Rubin, E.S.; Berkenpas, M.B. An Integrated Modeling Framework for Carbon Management Technologies. Volume 1–Technical Documentation: Amine-Based CO2 Capture and Storage Systems for Fossil Fuel Power Plant; Carnegie Mellon University: Pittsburgh, PA, USA, 2004. [Google Scholar]

- Anwar, M.N.; Fayyaz, A.; Sohail, N.F.; Khokhar, M.F.; Baqar, M.; Yasar, A.; Rasool, K.; Nazir, A.; Raja, M.U.F.; Rehan, M.; et al. CO2 utilization: Turning greenhouse gas into fuels and valuable products. J. Environ. Manag. 2020, 260, 110059. [Google Scholar] [CrossRef] [PubMed]

- Oreggioni, G.D.; Luberti, M.; Tassou, S.A. Agricultural greenhouse CO2 utilization in anaerobic-digestion-based biomethane production plants: A techno-economic and environmental assessment and comparison with CO2 geological storage. Appl. Energy 2019, 242, 1753–1766. [Google Scholar] [CrossRef]

- Ajayi, T.; Gomes, J.S.; Bera, A. A review of CO2 storage in geological formations emphasizing modeling, monitoring and capacity estimation approaches. Pet. Sci. 2019, 16, 1028–1063. [Google Scholar] [CrossRef]

- Al Baroudi, H.; Awoyomi, A.; Patchigolla, K.; Jonnalagadda, K.; Anthony, E.J. A review of large-scale CO2 shipping and marine emissions management for carbon capture, utilisation and storage. Appl. Energy 2021, 287, 116510. [Google Scholar] [CrossRef]

- Hong, W.Y. A techno-economic review on carbon capture, utilisation and storage systems for achieving a net-zero CO2 emissions future. Carbon Capture Sci. Technol. 2022, 3, 100044. [Google Scholar] [CrossRef]

- Chai, S.Y.W.; Ngu, L.H.; How, B.S. Review of carbon capture absorbents for CO2 utilization. Greenh. Gases Sci. Technol. 2022, 12, 394–427. [Google Scholar] [CrossRef]

- Liang, Z.H.; Rongwong, W.; Liu, H.; Fu, K.; Gao, H.; Cao, F.; Zhang, R.; Sema, T.; Henni, A.; Sumon, K.; et al. Recent progress and new developments in post-combustion carbon-capture technology with amine based solvents. Int. J. Greenh. Gas Control 2015, 40, 26–54. [Google Scholar] [CrossRef]

- Ping, T.; Dong, Y.; Shen, S. Energy-Efficient CO2 Capture Using Nonaqueous Absorbents of Secondary Alkanolamines with a 2-Butoxyethanol Cosolvent. ACS Sustain. Chem. Eng. 2020, 8, 18071–18082. [Google Scholar] [CrossRef]

- Li, H.; Guo, H.; Shen, S. Low-Energy-Consumption CO2 Capture by Liquid–Solid Phase Change Absorption Using Water-Lean Blends of Amino Acid Salts and 2-Alkoxyethanols. ACS Sustain. Chem. Eng. 2020, 8, 12956–12967. [Google Scholar] [CrossRef]

- Bravo, J.; Drapanauskaite, D.; Sarunac, N.; Romero, C.; Jesikiewicz, T.; Baltrusaitis, J. Optimization of energy requirements for CO2 post-combustion capture process through advanced thermal integration. Fuel 2021, 283, 118940. [Google Scholar] [CrossRef]

- Oh, S.Y.; Binns, M.; Cho, H.; Kim, J.K. Energy minimization of MEA-based CO2 capture process. Appl. Energy 2016, 169, 353–362. [Google Scholar] [CrossRef]

- Adu, E.; Zhang, Y.D.; Liu, D.; Tontiwachwuthikul, P. Parametric process design and economic analysis of post-combustion CO2 capture and compression for coal- and natural gas-fired power plants. Energies 2020, 13, 2519. [Google Scholar] [CrossRef]

- Arshad, N.; Alhajaj, A. Process synthesis for amine-based CO2 capture from combined cycle gas turbine power plant. Energy 2023, 274, 127391. [Google Scholar] [CrossRef]

- Asadi, J.; Kazempoor, P. Economic and operational assessment of solar-assisted hybrid carbon capture system for combined cycle power plants. Energy 2024, 303, 131861. [Google Scholar] [CrossRef]

- Zhang, Z.; Oh, D.H.; Dat Nguyen, V.; Lee, C.H.; Lee, J.C. Techno-Economic Assessment of Natural Gas Combined Cycle Power Plants with Carbon Capture and Utilization. Energy Fuels 2023, 37, 5961–5975. [Google Scholar] [CrossRef]

- Omehia, K.C.; Clements, A.G.; Michailos, S.; Hughes, K.J.; Ingham, D.B.; Pourkashanian, M. Techno-economic assessment on the fuel flexibility of a commercial scale combined cycle gas turbine integrated with a CO2 capture plant. Int. J. Energy Res. 2020, 44, 9127–9140. [Google Scholar] [CrossRef]

- Berstad, D.; Arasto, A.; Jordal, K.; Haugen, G. Parametric study and benchmarking of NGCC, coal and biomass power cycles integrated with MEA-based post-combustion CO2 capture. Energy Procedia 2011, 4, 1737–1744. [Google Scholar] [CrossRef]

- Hammond, G.P.; Akwe, O.S.O.; Williams, S. Techno-economic appraisal of fossil-fuelled power generation systems with carbon dioxide capture and storage. Energy 2011, 36, 975–984. [Google Scholar] [CrossRef]

- Cheng, P.; Thierry, D.M.; Hendrix, H.; Dombrowski, K.D.; Sachde, D.J.; Realff, M.J.; Scott, J.K. Modeling and optimization of carbon-negative NGCC plant enabled by modular direct air capture. Appl. Energy 2023, 341, 121076. [Google Scholar] [CrossRef]

- Mohammed, R.K.; Farzaneh, H. Life Cycle Environmental Impacts Assessment of Post-Combustion Carbon Capture for Natural Gas Combined Cycle Power Plant in Iraq, Considering Grassroots and Retrofit Design. Energies 2023, 16, 1545. [Google Scholar] [CrossRef]

- Shao, Y.; He, X.; Yang, C.; Zhu, Y.; Liu, C.; Shao, L.; Ni, Y.; Zheng, C.; Gao, X. Techno-economic evaluation of CO2 capture and storage retrofit in decarbonizing different thermal power plants: A case study in China. Appl. Therm. Eng. 2024, 242, 122380. [Google Scholar] [CrossRef]

- Decyzja ŚG-IV.7222.3.2014.AMK; Marszałek Województwa Kujawko-Pomorskiego: Toruń, Poland, 2015.

- US DoE/NETL Quality Guidelines for Energy System Studies. Process Modeling Design Parameters. 2019. Available online: https://www.osti.gov/servlets/purl/1570826/ (accessed on 12 May 2023).

- National Energy Technology Laboratory. Cost And Performance Baseline for Fossil Energy Plants Volume 1: Bituminous Coal and Natural Gas to Electricity; National Energy Technology Laboratory: Pittsburgh, PA, USA; Morgantown, WV, USA; Albany, OR, USA, 2019. [Google Scholar]

- Heavy Duty Gas Turbines. Available online: https://www.gevernova.com/gas-power/products/gas-turbines (accessed on 5 April 2024).

- World Bank Group. State and Trends of Carbon Pricing 2023. 2023. Available online: http://hdl.handle.net/10986/39796 (accessed on 10 January 2024).

- Oh, D.H.; Lee, C.H.; Lee, J.C. Performance and Cost Analysis of Natural Gas Combined Cycle Plants with Chemical Looping Combustion. ACS Omega 2021, 6, 21043–21058. [Google Scholar] [CrossRef] [PubMed]

- Carapellucci, R.; Giordano, L.; Vaccarelli, M. Application of an amine-based CO2 capture system in retrofitting combined gas-steam power plants. Energy 2017, 118, 808–826. [Google Scholar] [CrossRef]

- Strojny, M.; Gładysz, P.; Hanak, D.P.; Nowak, W. Comparative analysis of CO2 capture technologies using amine absorption and calcium looping integrated with natural gas combined cycle power plant. Energy 2023, 284, 128599. [Google Scholar] [CrossRef]

- Ystad, P.A.M.; Bolland, O.; Hillestad, M. NGCC and hard-coal power plant with CO2 capture based on absorption. Energy Procedia 2012, 23, 33–44. [Google Scholar] [CrossRef][Green Version]

- Sipöcz, N.; Tobiesen, A.; Assadi, M. Integrated modelling and simulation of a 400 MW NGCC power plant with CO2 capture. Energy Procedia 2011, 4, 1941–1948. [Google Scholar] [CrossRef]

- Lindqvist, K.; Jordal, K.; Haugen, G.; Hoff, K.A.; Anantharaman, R. Integration aspects of reactive absorption for post-combustion CO2 capture from NGCC (natural gas combined cycle) power plants. Energy 2014, 78, 758–767. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Fuel | - | Natural gas |

| Fuel composition: | ||

| C2H6 | kg/kg | 0.0391 |

| C3H8 | kg/kg | 0.0062 |

| CH4 | kg/kg | 0.9399 |

| CO2 | kg/kg | 0.0061 |

| N2 | kg/kg | 0.0087 |

| Fuel mass flow rate | kg/s | 16 |

| Gas turbine isentropic efficiency | % | 90 [30] |

| Gas turbine pressure ratio | - | 18.3 [32] |

| Unit heat consumption in the CO2 capture unit | kJ/kgCO2 | 2900 [31] |

| CO2 capture efficiency | % | 90 [31] |

| Compressors’ isentropic efficiency | % | 80 [30] |

| Parameter | Real Data [29,32] | Simulation Results | Percentage Difference, % |

|---|---|---|---|

| Gross gas turbine electrical power, MWe | 288 | 303.1 | 5.26 |

| Total gross electric power, MWe | 443 | 438.5 | −1.02 |

| Gas turbine net efficiency (referenced to LHV), % | 38.70 | 38.68 | −0.05 |

| Net power plant efficiency (referenced to LHV), % | 60.20 | 55.96 | −7.04 |

| Share of Flue Gas Directed to the Carbon Capture Unit, % | Pown, MW | Pfg, MW | PCO2, MW | PCCS, MW | Pnet, MW | η, % | ECO2, kgCO2/MWh |

|---|---|---|---|---|---|---|---|

| 0 | 2.82 | 0.00 | 0.00 | 0.00 | 435.68 | 55.60 | 357.8 |

| 5 | 2.82 | 0.86 | 0.59 | 1.45 | 431.35 | 55.05 | 345.1 |

| 10 | 2.82 | 1.72 | 1.17 | 2.89 | 427.04 | 54.50 | 332.2 |

| 15 | 2.82 | 2.57 | 1.76 | 4.34 | 422.74 | 53.95 | 319.0 |

| 20 | 2.82 | 3.43 | 2.35 | 5.78 | 418.45 | 53.40 | 305.5 |

| 25 | 2.82 | 4.29 | 2.94 | 7.23 | 414.17 | 52.85 | 291.7 |

| 30 | 2.82 | 5.15 | 3.52 | 8.67 | 409.90 | 52.31 | 277.6 |

| 35 | 2.82 | 6.01 | 4.11 | 10.12 | 405.64 | 51.77 | 263.2 |

| 40 | 2.82 | 6.87 | 4.70 | 11.56 | 401.37 | 51.22 | 248.6 |

| 45 | 2.82 | 7.72 | 5.28 | 13.01 | 397.12 | 50.68 | 233.6 |

| 50 | 2.82 | 8.58 | 5.87 | 14.45 | 392.87 | 50.14 | 218.2 |

| 55 | 2.82 | 9.44 | 6.46 | 15.90 | 388.62 | 49.59 | 202.6 |

| 60 | 2.82 | 10.30 | 7.05 | 17.35 | 384.37 | 49.05 | 186.6 |

| 65 | 2.82 | 11.16 | 7.63 | 18.79 | 380.12 | 48.51 | 170.2 |

| 70 | 2.82 | 12.02 | 8.22 | 20.24 | 375.88 | 47.97 | 153.4 |

| 75 | 2.82 | 12.87 | 8.81 | 21.68 | 371.63 | 47.43 | 136.3 |

| 80 | 2.82 | 13.73 | 9.40 | 23.13 | 370.00 | 47.22 | 118.0 |

| 85 | 2.82 | 14.59 | 9.98 | 24.57 | 368.36 | 47.01 | 99.4 |

| 90 | 2.82 | 15.45 | 10.57 | 26.02 | 366.73 | 46.80 | 80.8 |

| 95 | 2.82 | 16.31 | 11.16 | 27.46 | 365.11 | 46.59 | 61.9 |

| 100 | 2.82 | 17.16 | 11.74 | 28.91 | 363.47 | 46.39 | 42.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcés, L.F.P.; Sztekler, K.; Azevedo, L.; Boruta, P.; Bujok, T.; Radomska, E.; Mlonka-Mędrala, A.; Mika, Ł.; Chmielniak, T. Assessment of the Use of Carbon Capture and Storage Technology to Reduce CO2 Emissions from a Natural Gas Combined Cycle Power Plant in a Polish Context. Energies 2024, 17, 3306. https://doi.org/10.3390/en17133306

Garcés LFP, Sztekler K, Azevedo L, Boruta P, Bujok T, Radomska E, Mlonka-Mędrala A, Mika Ł, Chmielniak T. Assessment of the Use of Carbon Capture and Storage Technology to Reduce CO2 Emissions from a Natural Gas Combined Cycle Power Plant in a Polish Context. Energies. 2024; 17(13):3306. https://doi.org/10.3390/en17133306

Chicago/Turabian StyleGarcés, Lucia F. Pérez, Karol Sztekler, Leonardo Azevedo, Piotr Boruta, Tomasz Bujok, Ewelina Radomska, Agata Mlonka-Mędrala, Łukasz Mika, and Tomasz Chmielniak. 2024. "Assessment of the Use of Carbon Capture and Storage Technology to Reduce CO2 Emissions from a Natural Gas Combined Cycle Power Plant in a Polish Context" Energies 17, no. 13: 3306. https://doi.org/10.3390/en17133306

APA StyleGarcés, L. F. P., Sztekler, K., Azevedo, L., Boruta, P., Bujok, T., Radomska, E., Mlonka-Mędrala, A., Mika, Ł., & Chmielniak, T. (2024). Assessment of the Use of Carbon Capture and Storage Technology to Reduce CO2 Emissions from a Natural Gas Combined Cycle Power Plant in a Polish Context. Energies, 17(13), 3306. https://doi.org/10.3390/en17133306