Carbon Footprint Analysis throughout the Life Cycle of the Continuous Deep Mixing Method (CDMM) Technology

Abstract

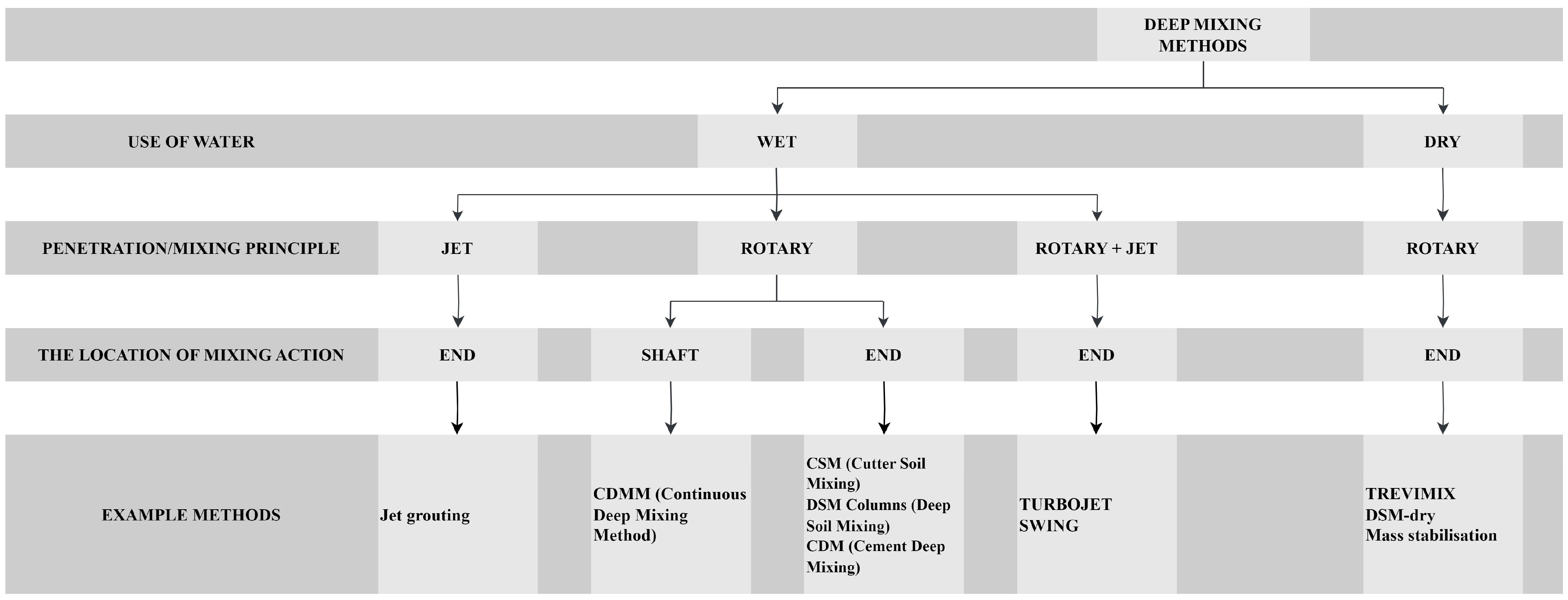

1. Introduction

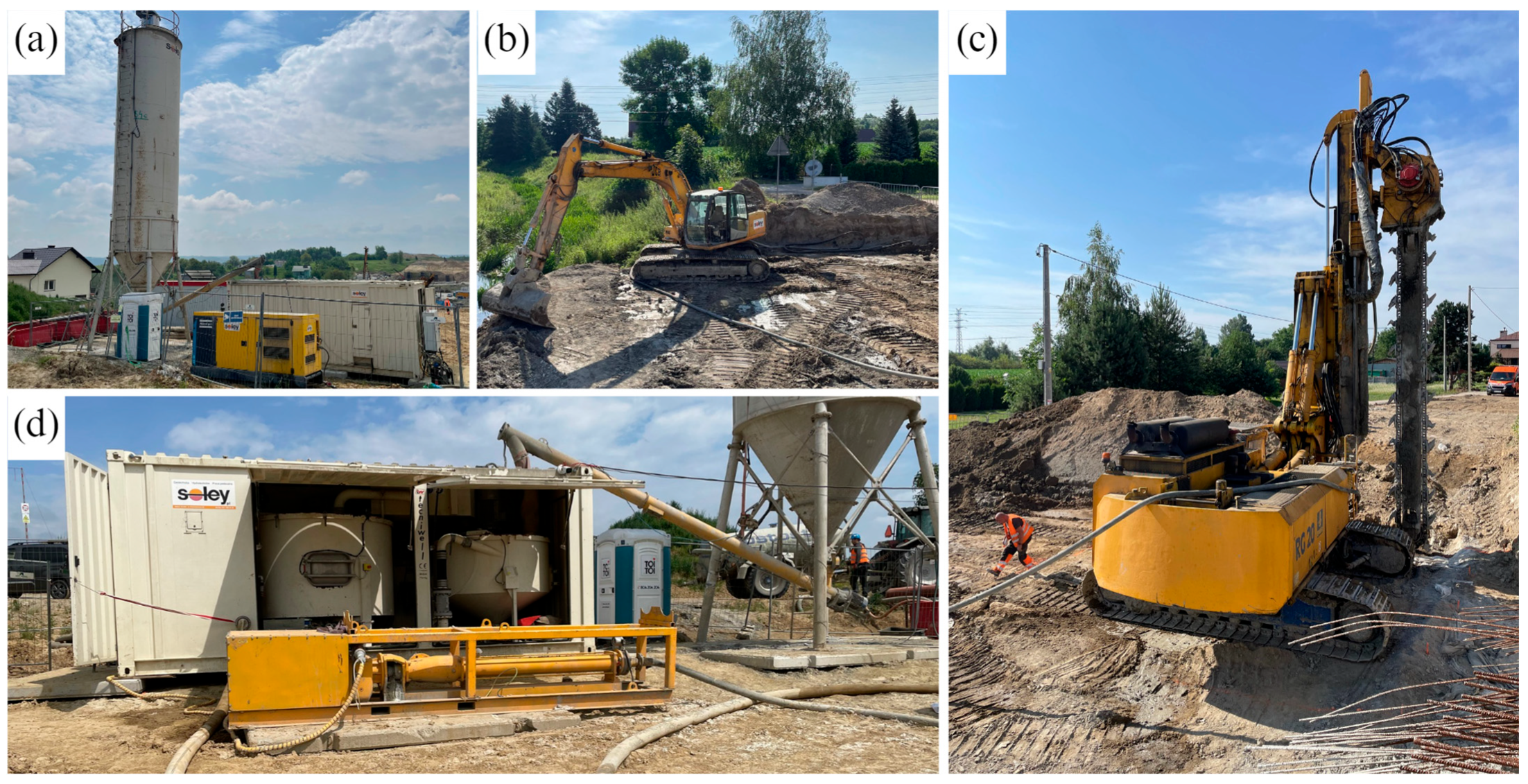

- Preparation of the trenchmixer work site—clearing the land and removing the topsoil.

- Positioning the machine along the axis of the barrier (Figure 3a).

- Beginning of soil excavation (Figure 3b).

- While the soil is being mixed with the slurry, the device moves at a suitably chosen speed to ensure the continuity of the barrier being constructed.

- The finished panel (Figure 3c).

- In hydraulic engineering—for the construction of anti-seepage barriers;

- In cubature construction—temporary retaining walls;

- In environmental protection—barriers against the migration of contaminants;

- In infrastructure—strengthening of the soil substrate under roads and embankments, including railway ones.

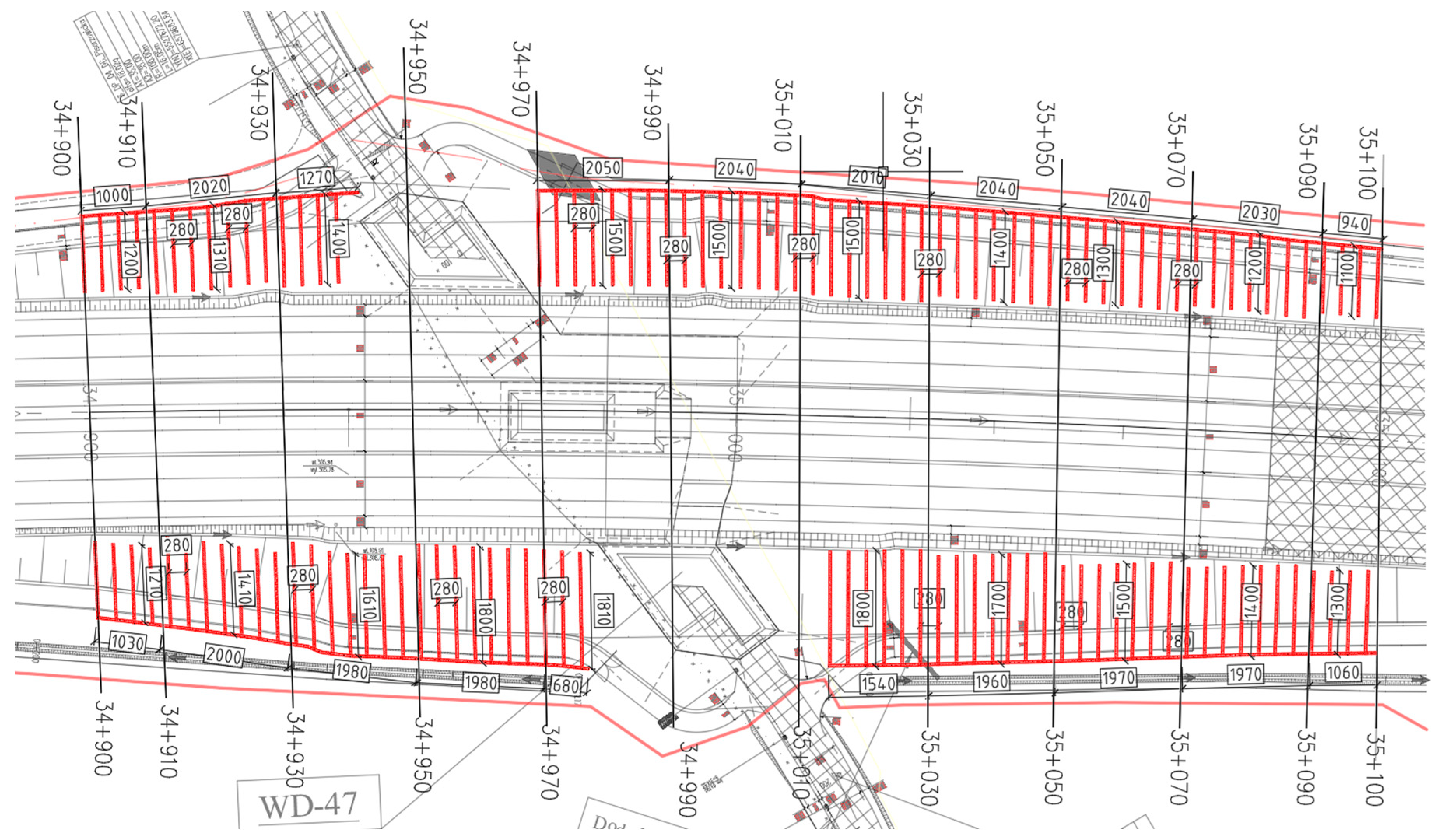

2. Materials and Methods

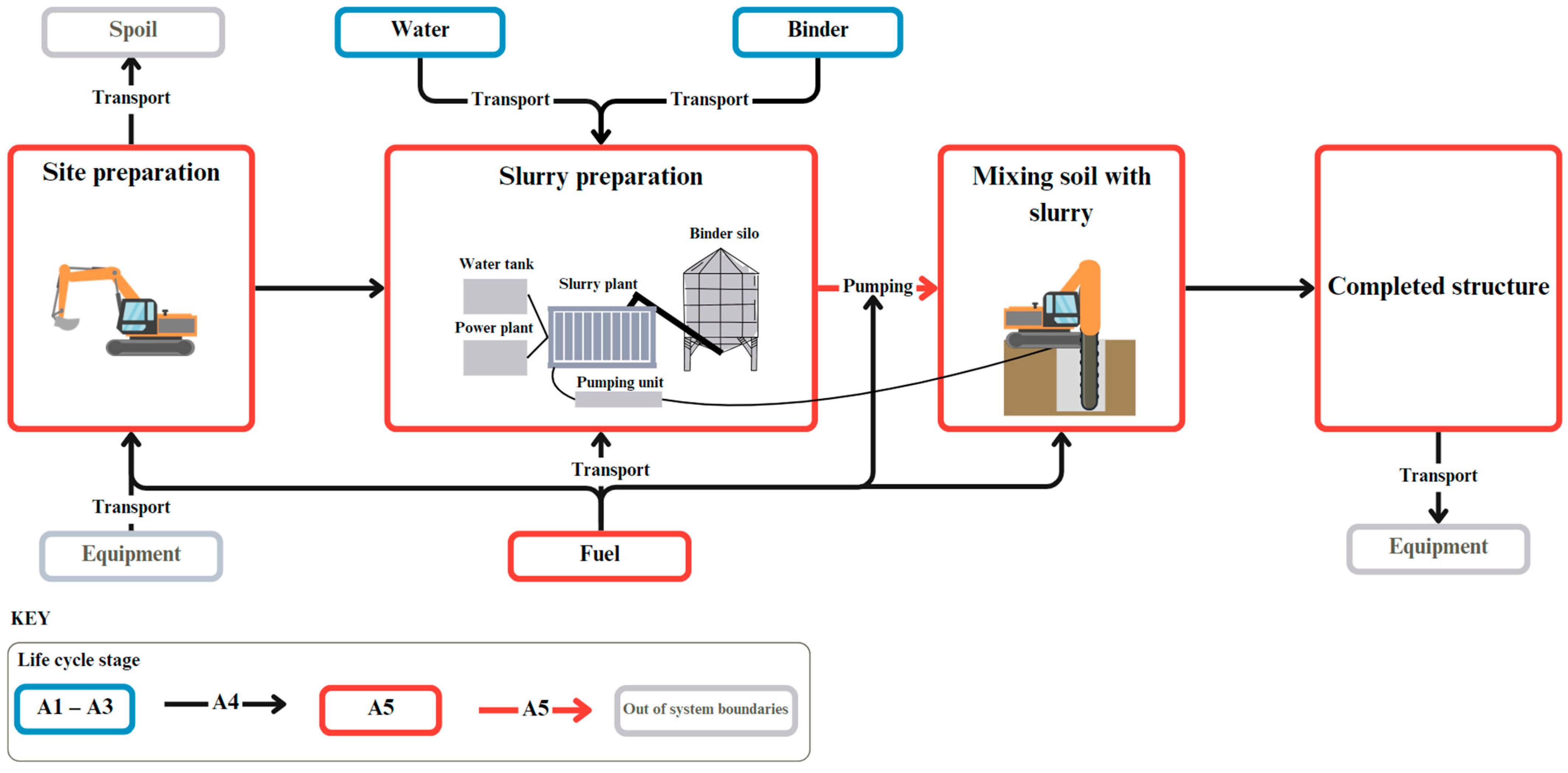

2.1. Goal and Scope Definition

- The production of materials (A1–A3)—water, binder;

- Transport (A4) of equipment (mobilisation, demobilisation), water, binder, fuel;

- The construction process (A5)—site preparation, production of the cement slurry, panel construction.

2.2. Inventory Analysis and Impact Assessment

2.2.1. The Production of Materials (A1–A3)

2.2.2. Transport (A4)

2.2.3. The Construction Process (A5)

3. Results and Discussion

4. Conclusions

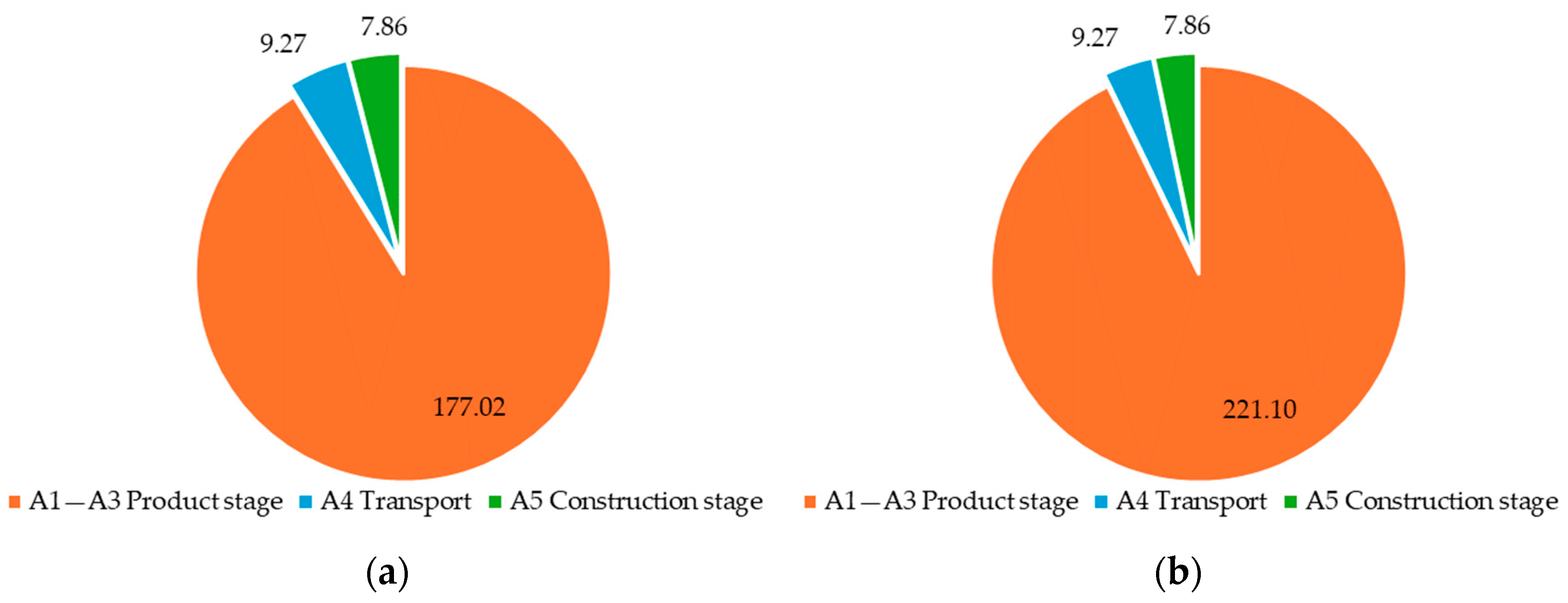

- The total CF for the assessed construction translates to 194 kgCO2e (for CEM II) and 238 kgCO2e (for CEM I) per cubic meter when calculated per functional unit;

- The presented CF results are significant from the perspective of the CDMM’s value as a potential alternative to other DMMs in the context of seeking solutions compliant with integrated design;

- An undeniable advantage of the conducted study is that the inventory data come from an actual implementation. This provides more reliable and representative information about the carbon footprint;

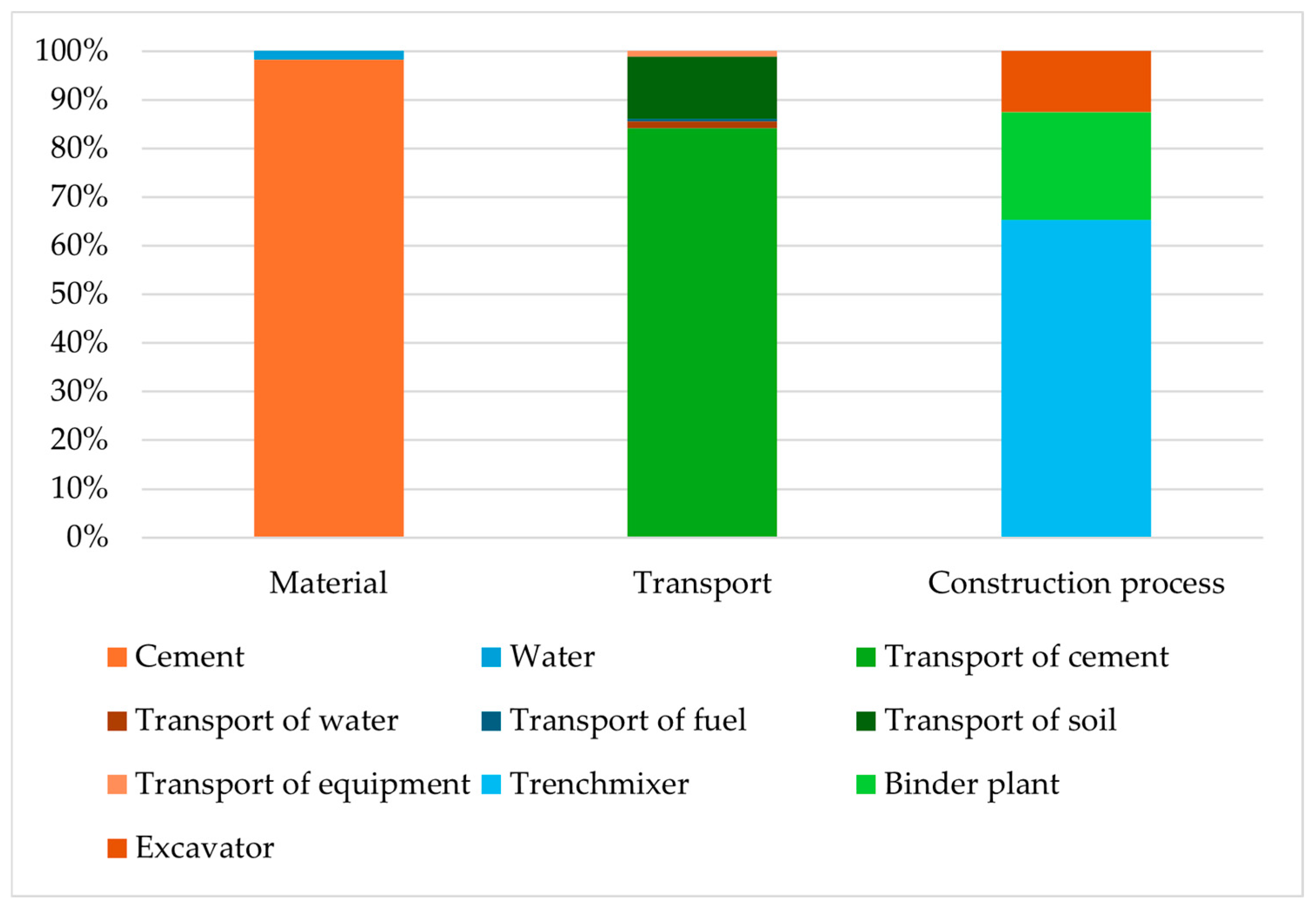

- The analysis demonstrated that the primary source of greenhouse gas (GHG) emissions in CDMM technology is materials (91%), particularly cement. Other sources of emissions, such as energy, transport, mobilisation, and demobilisation, contribute relatively little to the overall emissions. This suggests that the main strategy for emission reduction should focus on materials and the need to implement CF reduction practices proposed in many studies;

- There are observed gaps in the generally available and current databases for a given country regarding emissions related to the operation of construction equipment and logistic processes, which undeniably complicates the promotion and credible environmental assessments in any construction investment.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, X.; Carlsson, C.; Kiilsgaard, R.; Bendz, D.; Kennedy, H. Life Cycle Assessment of Geotechnical Works in Building Construction: A Review and Recommendations. Sustainability 2020, 12, 8442. [Google Scholar] [CrossRef]

- Raymond, A.J.; Kendall, A.; DeJong, J.T. Life Cycle Sustainability Assessment (LCSA): A Research Evaluation Tool for Emerging Geotechnologies. In Proceedings of the Geo-Congress 2020: Biogeotechnics (GSP 320), Minneapolis, MN, USA, 25–28 February 2020; American Society of Civil Engineers: Reston, VA, USA, 2020; pp. 330–339. [Google Scholar] [CrossRef]

- Sugade, O.; Dalvi, R.; Vyas, G. Sustainability Metrics for Ground Improvement Techniques. Proc. Sustain. Infrastruct. Dev. Manag. 2019. [Google Scholar] [CrossRef]

- De Melo, D.L.; Kendall, A.; Dejong, J.T. Evaluation of Life Cycle Assessment (LCA) Use in Geotechnical Engineering. Environ. Res. Infrastruct. Sustain. 2024, 4, 12001. [Google Scholar] [CrossRef]

- European Council. Fit for 55: Delivering on the Proposals. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal/delivering-european-green-deal/fit-55-delivering-proposals_en (accessed on 8 April 2024).

- Atradius, N.V. Industry Trends Construction Credit Risk Outlook Clouded by High Levels of Uncertainty. Available online: www.atradius.com (accessed on 2 January 2024).

- Blumberg, G.; Sibilla, M. A Carbon Accounting and Trading Platform for the UK Construction Industry. Energies 2023, 16, 1566. [Google Scholar] [CrossRef]

- Sbahieh, S.; Zaher Serdar, M.; Al-Ghamdi, S.G. Decarbonization Strategies of Building Materials Used in the Construction Industry. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Jaglan, A.K.; Korde, N. Capturing the Opportunity for Decarbonization in the Construction Industry: Emission-Free, Effective, and Resilient Solutions. Eng. Proc. 2023, 53, 1. [Google Scholar] [CrossRef]

- Kaboré, A.; Maref, W.; Ouellet-Plamondon, C.M. Hygrothermal Performance of the Hemp Concrete Building Envelope. Energies 2024, 17, 1740. [Google Scholar] [CrossRef]

- ISO 14067:2018; Greenhouse Gases—Carbon Footprint of Products—Requirements and Guidelines for Quantification. International Organization for Standardization: Geneva, Switzerland, 2018.

- Lopes, R.; Silva, D.; Rivero-Camacho, C.; Rusu, D.; Marrero, M. Methodology for Improving the Sustainability of Industrial Buildings via Matrix of Combinations Water and Carbon Footprint Assessment. Sustainability 2022, 14, 15297. [Google Scholar] [CrossRef]

- Benalcázar-Murillo, D.; Vilcekova, S.; Pardo, M.Á. Analysis of Equivalent CO2 Emissions of the Irrigation System—A Case Study. Sustainability 2023, 15, 16240. [Google Scholar] [CrossRef]

- Kitazume, M.; Terashi, M. The Deep Mixing Method; CRC Press/Balkema: London, UK, 2013. [Google Scholar]

- Denies, N.; Huybrechts, N. Deep Mixing Method: Equipment and Field of Applications. In Ground Improvement Case Histories Chemical, Electrokinetic, Thermal and Bioengineering; Butterworth-Heinemann: Oxford, UK, 2015; pp. 311–350. ISBN 9780081002384. [Google Scholar]

- Bruce, A.; Geosystems, E.C.O. An Introduction to the Deep Soil Mixing Methods as Used in Geotechnical Applications; Federal Highway Administration. Office of Infrastructure Research and Development: Washington, DC, USA, 2000. [Google Scholar]

- Guimond-Barrett, A. Influence of Mixing and Curing Conditions on the Characteristics and Durability of Soils Stabilised by Deep Mixing. Ph.D. Thesis, Géotechnique, Université du Havre, Le Havre, France, 2013. [Google Scholar]

- Głowacki, P.; Chmielewski, M. Trenchmix—Technology for Strengthening the Ground Medium under Road and Railway Embankments. NBI 2017, 4, 64–66. (In Polish) [Google Scholar]

- Hoffmann, M. Geomix Trenchmix—Innovative Technologies of Deep Soils Mixing by Soletanche Polska. GTMT 2008, 2, 68–72. (In Polish) [Google Scholar]

- Hanke, R.; Trybocka, K.; Jończyk-Szostek, M.; Kanty, P. Innowacyjna Technologia Gruntu. Mater. Bud. 2020, 2, 16–18. [Google Scholar] [CrossRef]

- Purdy, C.M.; Raymond, A.J.; Dejong, J.T.; Kendall, A.; Krage, C.; Sharp, J. Life-Cycle Sustainability Assessment of Geotechnical Site Investigation. Can. Geotech. J. 2022, 59, 863–877. [Google Scholar] [CrossRef]

- Wałach, D.; Sagan, J.; Jaskowska-Lemańska, J.; Dybeł, P. Comparative Analysis of Environmental Impacts of Municipal Road Structures. In Infrastructure and Environment; Krakowiak-Bal, A., Vaverkova, M., Eds.; Springer: Cham, Switzerland, 2019; pp. 9–14. [Google Scholar]

- Mach, A.; Wałach, D. Implementation of Integrated Life Cycle Design Principles in Ground Improvement and Piling Methods—A Review. Sustainability 2024, 16, 659. [Google Scholar] [CrossRef]

- Belaïd, F. How Does Concrete and Cement Industry Transformation Contribute to Mitigating Climate Change Challenges? RCR Adv. 2022, 15, 200084. [Google Scholar] [CrossRef]

- Chang, I.; Lee, M.; Cho, G.C. Global CO2 Emission-Related Geotechnical Engineering Hazards and the Mission for Sustainable Geotechnical Engineering. Energies 2019, 12, 2567. [Google Scholar] [CrossRef]

- Li, Y.; Eyley, S.; Thielemans, W.; Yuan, Q.; Li, J. Valorization of Deep Soil Mixing Residue in Cement-Based Materials. Resour. Conserv. Recycl. 2022, 187, 106597. [Google Scholar] [CrossRef]

- Wałach, D.; Mach, A. Effect of Concrete Mix Composition on Greenhouse Gas Emissions over the Full Life Cycle of a Structure. Energies 2023, 16, 3229. [Google Scholar] [CrossRef]

- Walach, D. Economic and Environmental Assessment of New Generation Concretes. IOP Conf. Ser. Mater. Sci. Eng. 2020, 960, 042013. [Google Scholar] [CrossRef]

- Kravchenko, E.; Lu, W.; Sauerwein, M.; Wong, A.H.K. Life Cycle Assessment of Waste Materials in Deep Cement Mixing for Land Reclamation in Hong Kong. Environ. Impact. Assess. Rev. 2024, 105, 107398. [Google Scholar] [CrossRef]

- Sargent, P.; Hughes, P.N.; Rouainia, M. A New Low Carbon Cementitious Binder for Stabilising Weak Ground Conditions through Deep Soil Mixing. Soils Found. 2016, 56, 1021–1034. [Google Scholar] [CrossRef]

- Al-Subari, L.; Hilal, A.; Ekinci, A. Life Cycle Assessment of Soil Stabilization Using Cement and Waste Additives. Constr. Build. Mater. 2023, 403, 133045. [Google Scholar] [CrossRef]

- Koch, E.; Major, Z.; Szigeti, C. Investigating the Ecological Footprint of Deep Mixing. Chem. Eng. Trans. 2023, 107, 349–354. [Google Scholar] [CrossRef]

- Shillaber, C.M.; Mitchell, J.K.; Dove, J.E. Energy and Carbon Assessment of Ground Improvement Works. II: Working Model and Example. J. Geotech. Geoenviron. 2016, 142, 04015084. [Google Scholar] [CrossRef]

- Chang, N. Sustainability in Geotechnical Construction. Available online: https://www.keller-africa.co.za/news/sustainability-geotechnical-construction (accessed on 12 June 2023).

- Topolnicki, M. Ground Improvement Instead of Piling—Effective Design Solutions for Heavily Loaded Structures. In Proceedings of the International Conference on Deep Foundations and Ground Improvement, Rome, Italy, 5–8 June 2018; pp. 1128–1137. [Google Scholar]

- Selvaraju, S.; Tang, C.; Raj, D. Effective Ways to Reduce Carbon Footprint in a Deep Soil Mixing Solution—A Case Study from Singapore. In Proceedings of the Conference on Foundation Decarbonization and Re-Use, Amsterdam, The Netherlands, 21–23 March 2023. [Google Scholar]

- Egorova, A.A.; Rybak, J.; Stefaniuk, D.; Zajączkowski, P. Basic Aspects of Deep Soil Mixing Technology Control. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 022019. [Google Scholar] [CrossRef]

- Kurochkina, V.; Yakovleva, I. Effectiveness of the Method of Soil Substitution under the Foundations during the Construction of a Secondary School. E3S Web. Conf. 2019, 135, 03032. [Google Scholar] [CrossRef]

- Gurpersaud, N.; Shah, F.R. The Application and Development of Continuous Flight Auger (CFA) Piles in the Prairies. In Proceedings of the Geo-Virtual conference Resilience and Innovation, Calgary, AB, Canada, 14–16 September 2020. [Google Scholar]

- Jayapal, J.; Rajagopal, K. A Short Review of Geosynthetic Granular Column Treatment of Soft Clay Soils. In Lecture Notes in Civil Engineering; Springer: Berlin/Heidelberg, Germany, 2019; Volume 14, pp. 373–380. [Google Scholar]

- Ter-Martirosyan, Z.G.; Ter-Martirosyan, A.Z.; Angelo, G.O. Interaction of Gravel Piles with the Surrounding Soil and Raft. Soil Mech. Found. Eng. 2019, 56, 151–156. [Google Scholar] [CrossRef]

- OpenAI. ChatGPT. Available online: https://openai.com/index/chatgpt/ (accessed on 26 June 2024).

- Forster, P.; Alterskjaer, K.; Smith, C.; Colman, R.; Damon Matthews, H.; Ramaswamy, V.; Storelvmo, T.; Armour, K.; Collins, W.; Dufresne, J.; et al. The Earth’s Energy Budget, Climate Feedbacks and Climate Sensitivity. In Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2021; pp. 923–1054. [Google Scholar]

- Prussi, M.; Yugo, M.; De Prada, L.; Padella, M.; Edwards, R.; Laura, L. JEC Well-to-Tank Report V5; EUR 30269 EN; Publications Office of the European Union: Luxembourg, 2020; ISBN 978-92-76-19926-7. [Google Scholar]

- Ntziachristos, L.; Samaras, Z. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2023 1.A.3.b.i-Iv Road Transport 2023. Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2023/part-b-sectoral-guidance-chapters/1-energy/1-a-combustion/1-a-3-b-i/view (accessed on 9 April 2024).

- Winther, M.; Dore, C. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2023 1.A.4 Non Road Mobile Machinery 2023. Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2023/part-b-sectoral-guidance-chapters/1-energy/1-a-combustion/1-a-4-non-road/view (accessed on 9 April 2024).

- Stowarzyszenie Producentów Cementu Environmental Product Declaration (EPD) Type III CEM I, CEM II, CEM III, CEM IV, CEM V Produced in Poland. Available online: https://www.polskicement.pl/epd-cement/ (accessed on 9 April 2024).

- A WINT White paper The Carbon Impact of Water. Available online: https://wint.ai/blog/the-carbon-footprint-of-water/ (accessed on 9 April 2024).

- Gustafsson, M.; Svensson, N.; Eklund, M.; Dahl Öberg, J.; Vehabovic, A. Well-to-Wheel Greenhouse Gas Emissions of Heavy-Duty Transports: Influence of Electricity Carbon Intensity. Transp. Res. D Transp. Environ. 2021, 93, 102757. [Google Scholar] [CrossRef]

- Beckhaus, K.; Jäger, S.; Ibuk, H. Geothermal Activation of Geotechnical Elements Using the Mixed-in-Place Technology. Geotechnik 2024, 47, 37–41. [Google Scholar]

- Sondermann, W. Ground Improvement as Alternative to Piling—Effective Design Solutions for Heavily Loaded Structures. In Latest Thoughts on Ground Improvement Techniques; Shehata, H., Poulos, H., Eds.; Springer Nature: Cham, Switzerland, 2019. [Google Scholar]

- Yao, Y.; Xu, P.; Li, J.; Hu, H.; Qi, Q. Advancements and Applications of Life Cycle Assessment in Slope Treatment: A Comprehensive Review. Sustainability 2024, 16, 398. [Google Scholar] [CrossRef]

- EPD Ireland Product Specific EPD Breedon Cement CEM II/A-L 42,5 N Bulk Cement. Available online: https://www.igbc.ie/epd/breedon-cement-cem-ii-a-l-425-n-bulk-cement/ (accessed on 9 April 2024).

- Stichting MRPI Environmental Product Declaration Spenner CEM II/B-S 42,5 N. Available online: https://spenner-zement.de/produkte/zement/portlandkompositzement-cem-iic-m-s-ll-425-n-na/ (accessed on 9 April 2024).

- BRE Global Environmental Product Declaration Hanson Multicem CEM II. Available online: https://www.greenbooklive.com/search/scheme.jsp?id=347 (accessed on 9 April 2024).

- EPD International AB Environmental Product Declaration II A/LL 42,5 R Cement. Available online: www.environdec.com (accessed on 9 April 2024).

- EPD Norway Environmental Product Declaration CEM II/B-M (V-L) 42,5 R. Available online: https://www.epd-norge.no/ (accessed on 9 April 2024).

- Lončarević, Š.; Ilinčić, P.; Šagi, G.; Lulić, Z. Problems and Directions in Creating a National Non-Road Mobile Machinery Emission Inventory: A Critical Review. Sustainability 2022, 14, 3471. [Google Scholar] [CrossRef]

- Fan-Ren, L.Y.U.; Hong-Cai, S.; Wen, Z. A Contrastive Analysis of Carbon Emissions in Different Solutions to Battered Piles. IOP Conf. Ser. Earth Environ. Sci. 2021, 634, 012007. [Google Scholar] [CrossRef]

- Greenhouse Gas Reporting: Conversion Factors 2023—GOV.UK. Available online: https://www.gov.uk/government/publications/greenhouse-gas-reporting-conversion-factors-2023 (accessed on 22 March 2024).

| Pollutant | GWP100 |

|---|---|

| CO2 | 1 |

| CH4—fossil origin | 29.8 |

| CH4—non-fossil origin | 27.2 |

| NO2 | 273 |

| Material | Amount qj | Unit | Source of Emission Factor |

|---|---|---|---|

| Cement—CEM II/CEM I | 1975 | t | [47] |

| Water—Fresh water | 1975 | t | [48] |

| Transport of | Vehicle Category k | Legislation/Technology l | Total Distance l [km] | Source of Emission Factor |

|---|---|---|---|---|

| Equipment | Heavy-duty trucks Diesel 16–32 t | Euro 6 a/b/c | 640 | [45] |

| Equipment | Heavy-duty trucks Diesel > 32 t | Euro 6 a/b/c | 160 | |

| Cement | Heavy-duty trucks Diesel 16–32 t | Euro 6 a/b/c | 68,200 | |

| Water | Heavy-duty trucks Diesel 16–32 | Euro 6 a/b/c | 1240 | |

| Fuel | Heavy-duty trucks Diesel ≤ 7.5 t | Euro 6 a/b/c | 680 | |

| Excavated material | Heavy-duty trucks Diesel 16–32 t | Euro 6 a/b/c | 10,440 |

| Equipment | NFR Sector | Fuel Consumption FC [L] | Fuel Type m | Off-Road Equipment Technology t | Source of Emission Factor |

|---|---|---|---|---|---|

| Excavator | 1.A.2.g vii | 2105 | Disel | Stage IV | [46] |

| Binder plant | 1.A.2.g vii | 3750 | Disel | Stage IV | |

| Trenchmixer | 1.A.2.g vii | 11,015 | Disel | Stage IV |

| Technology | Source | FU | Emissions Involve in Analysis | Mind Emission | |

|---|---|---|---|---|---|

| CDMM | Our study | m3 CDMM panel | Materials, energy, freight, mob/demobilisation | Materials | 91% |

| DCM | [29] | t binder | Material preparation, material transportation, DCM installation, and other auxiliary construction processes | Materials | 64% |

| Deep dry soil mixing | [31] | 1 m3 of waste–cement–clay blends | Material production, transportation, and site application of the mixtures | — | — |

| Mixed-In-Place retaining wall and BAUER LWS silicate gel grout plug | [50] | — | Materials, energy, transports for supply, mob/demobilisation, people’s transportation, assets, transports for disposal | Materials | 88% |

| DSM | [35] | — | Materials, energy, freight, mob/demobilisation, people’s transportation, assets, waste | Materials | 85% |

| DSM and Jet Grouting | [36] | — | Materials, energy, freight, mob/demobilisation, people’s transportation, assets, waste | Materials | 68% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mach, A.; Szczygielski, M. Carbon Footprint Analysis throughout the Life Cycle of the Continuous Deep Mixing Method (CDMM) Technology. Energies 2024, 17, 3294. https://doi.org/10.3390/en17133294

Mach A, Szczygielski M. Carbon Footprint Analysis throughout the Life Cycle of the Continuous Deep Mixing Method (CDMM) Technology. Energies. 2024; 17(13):3294. https://doi.org/10.3390/en17133294

Chicago/Turabian StyleMach, Aleksandra, and Maciej Szczygielski. 2024. "Carbon Footprint Analysis throughout the Life Cycle of the Continuous Deep Mixing Method (CDMM) Technology" Energies 17, no. 13: 3294. https://doi.org/10.3390/en17133294

APA StyleMach, A., & Szczygielski, M. (2024). Carbon Footprint Analysis throughout the Life Cycle of the Continuous Deep Mixing Method (CDMM) Technology. Energies, 17(13), 3294. https://doi.org/10.3390/en17133294