Five-Stage Fast Charging of Lithium-Ion Batteries Based on Lamb Waves Depolarization

Abstract

1. Introduction

2. Research Methodology

2.1. Determination of Parameters for Five-Stage Fast Charging

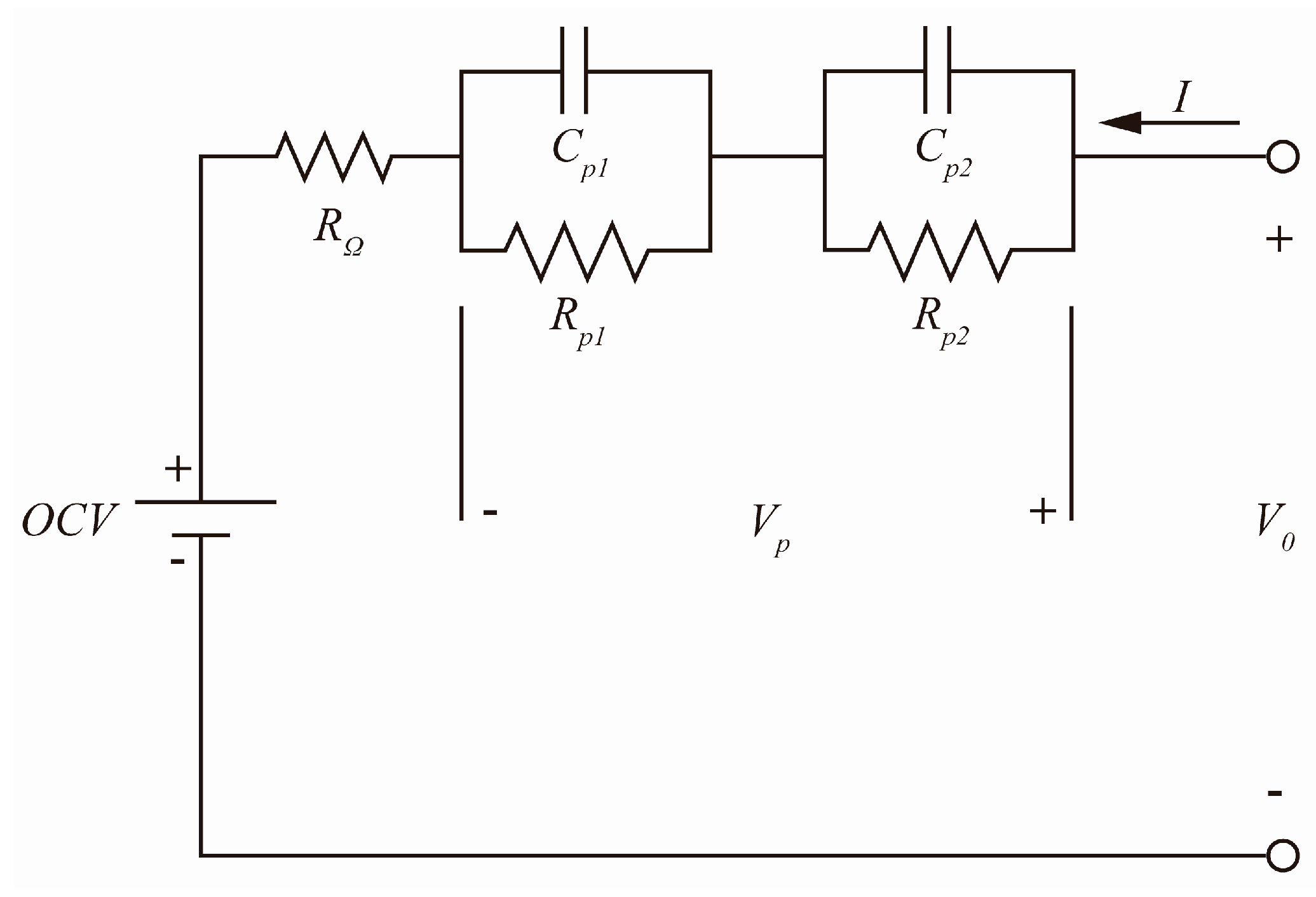

2.2. Description of Polarization Voltage

3. Experiment

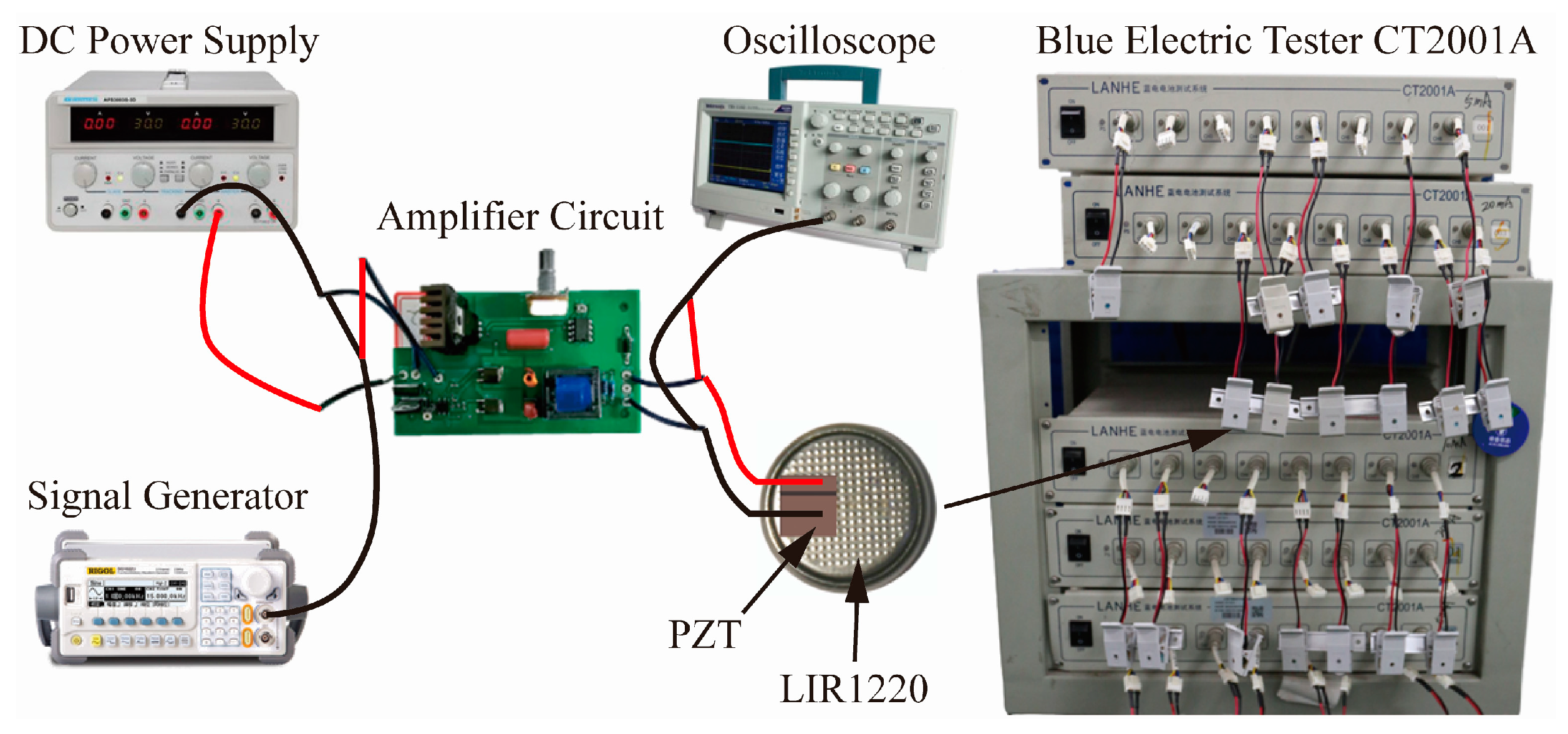

3.1. Experimental Device

3.2. Experimental Procedure

3.2.1. Traditional Five-Stage Constant Current Charging Method Experiment

3.2.2. Experiment on Five-Stage Constant Current Charging Method with Lamb Wave Effect

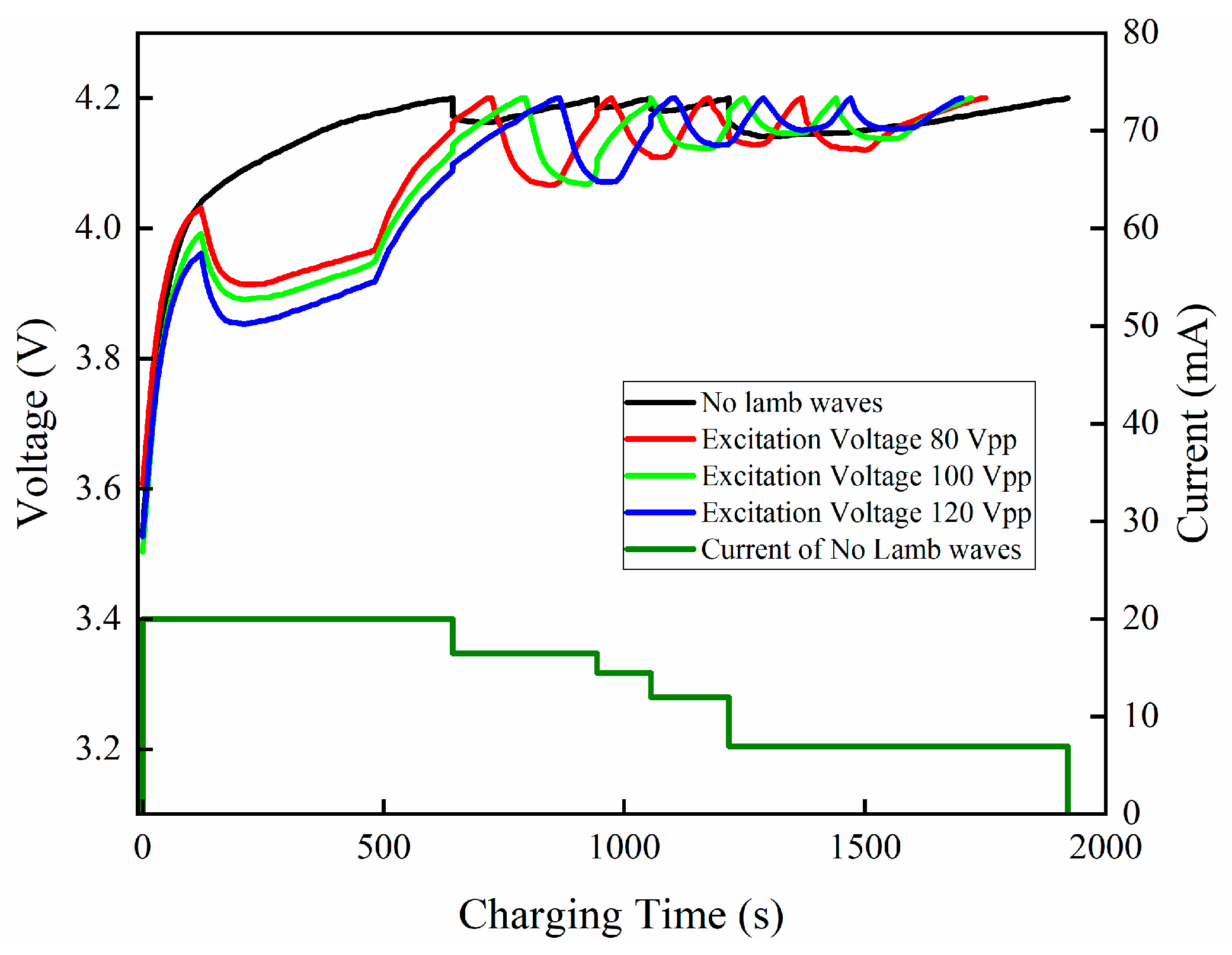

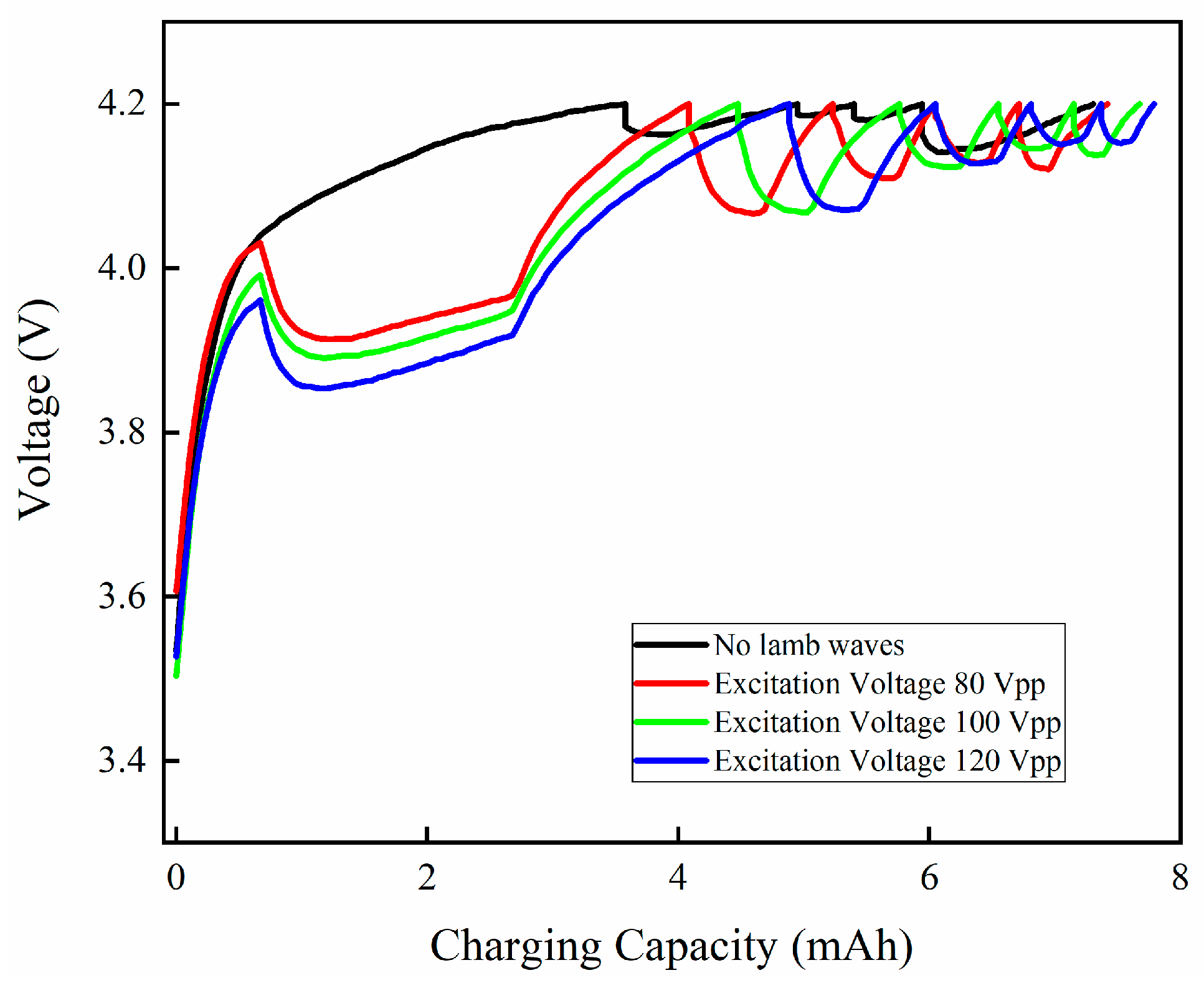

4. Results and Discussion

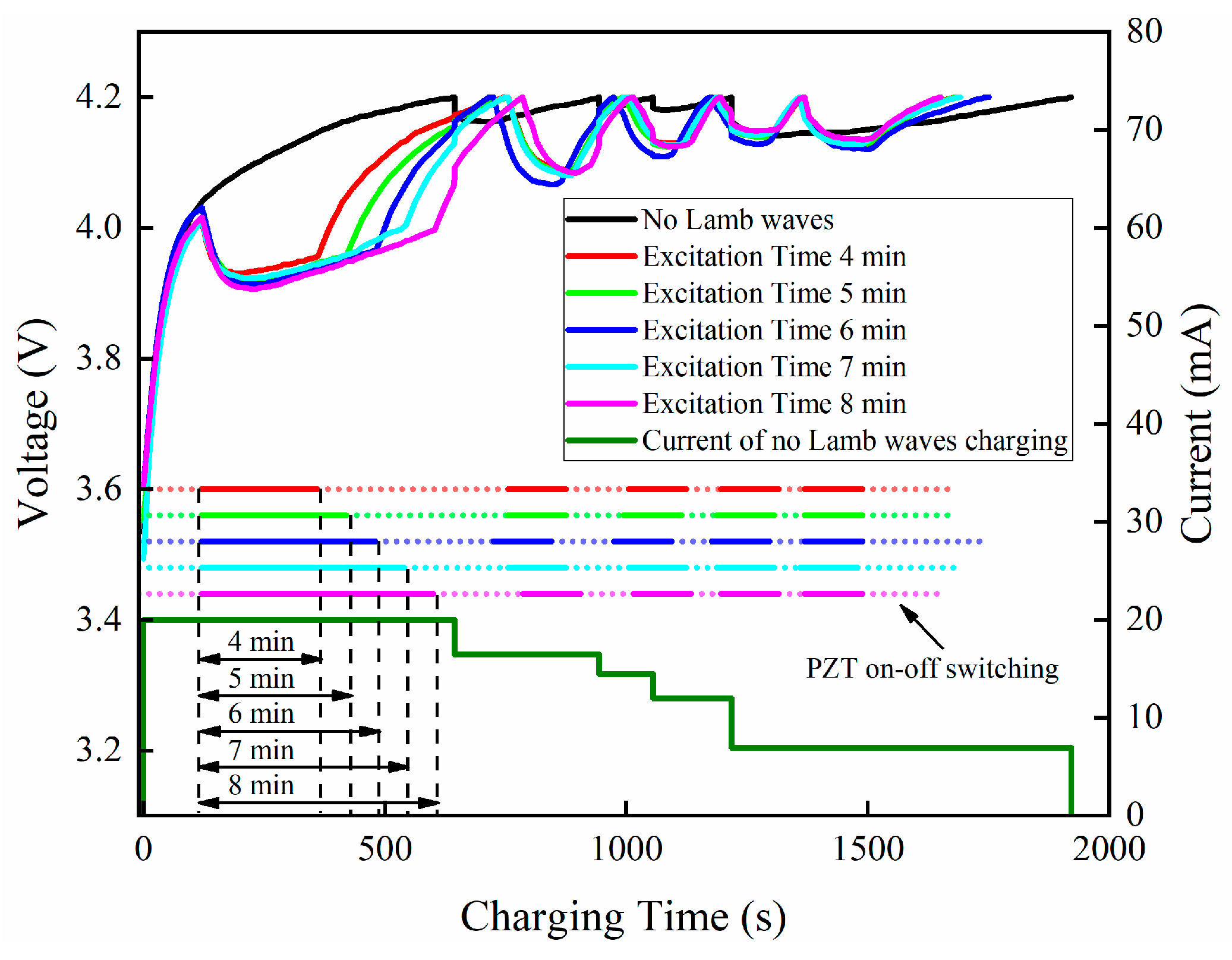

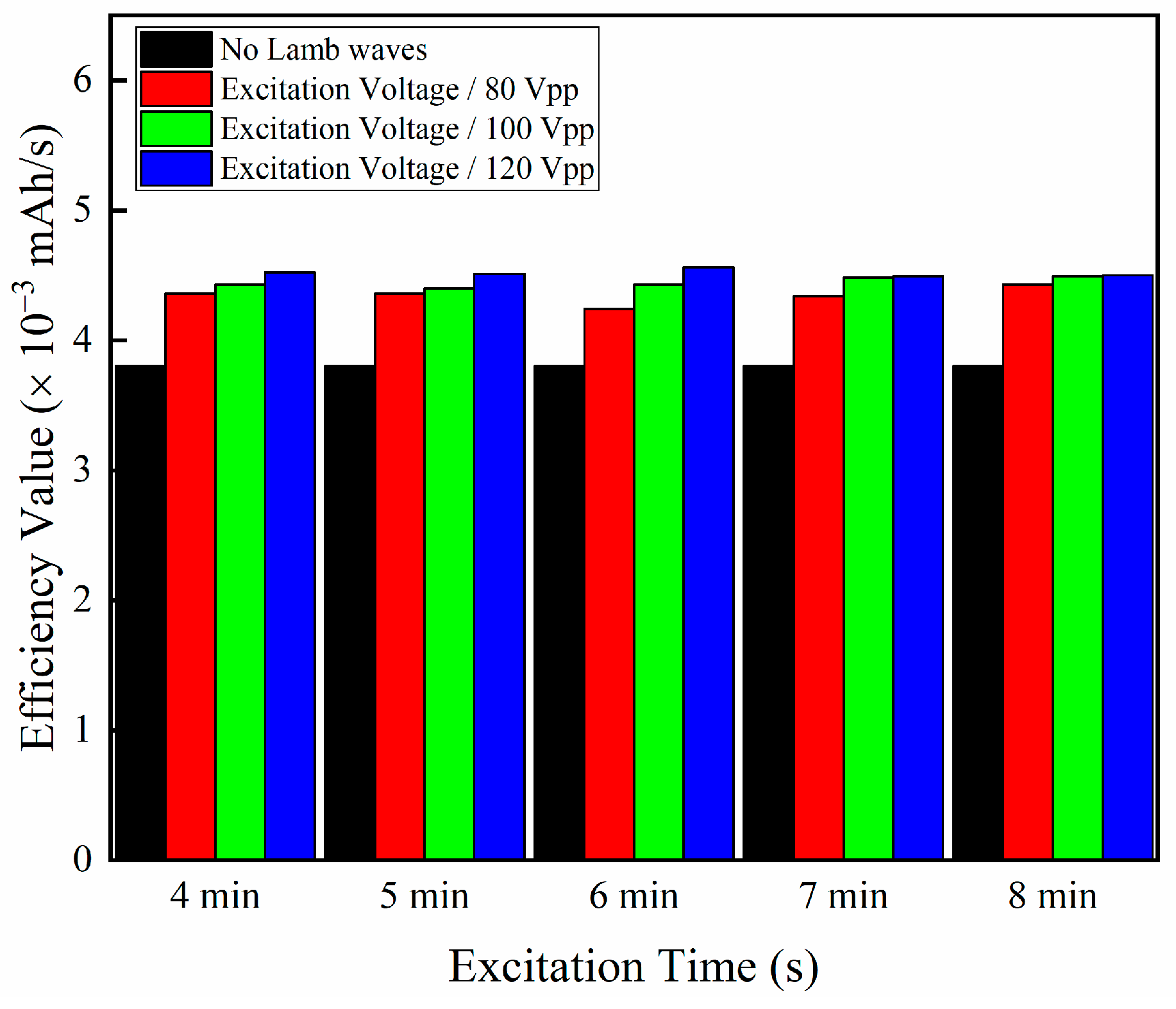

4.1. Relationship between Charging Efficiency and Excitation Time

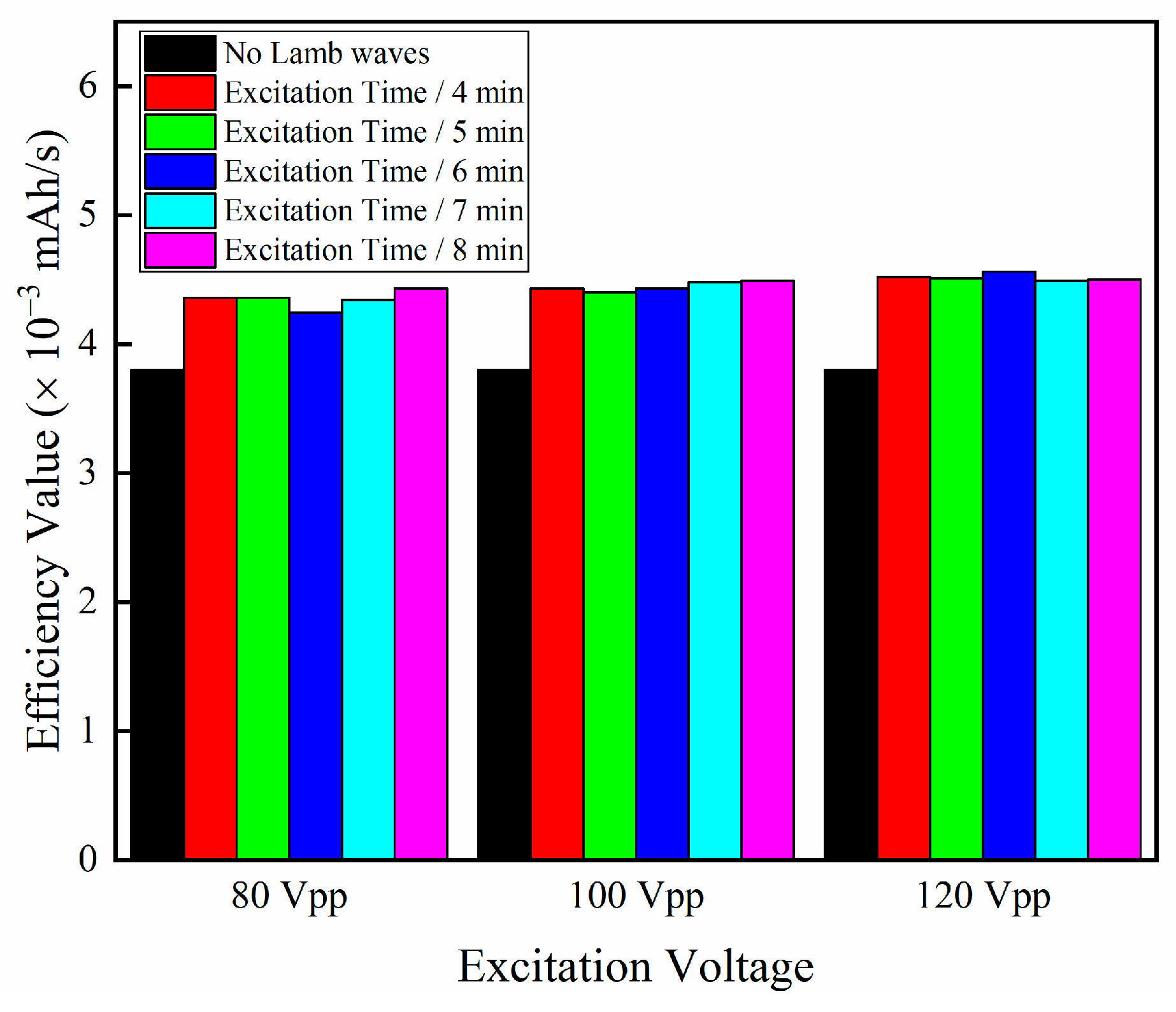

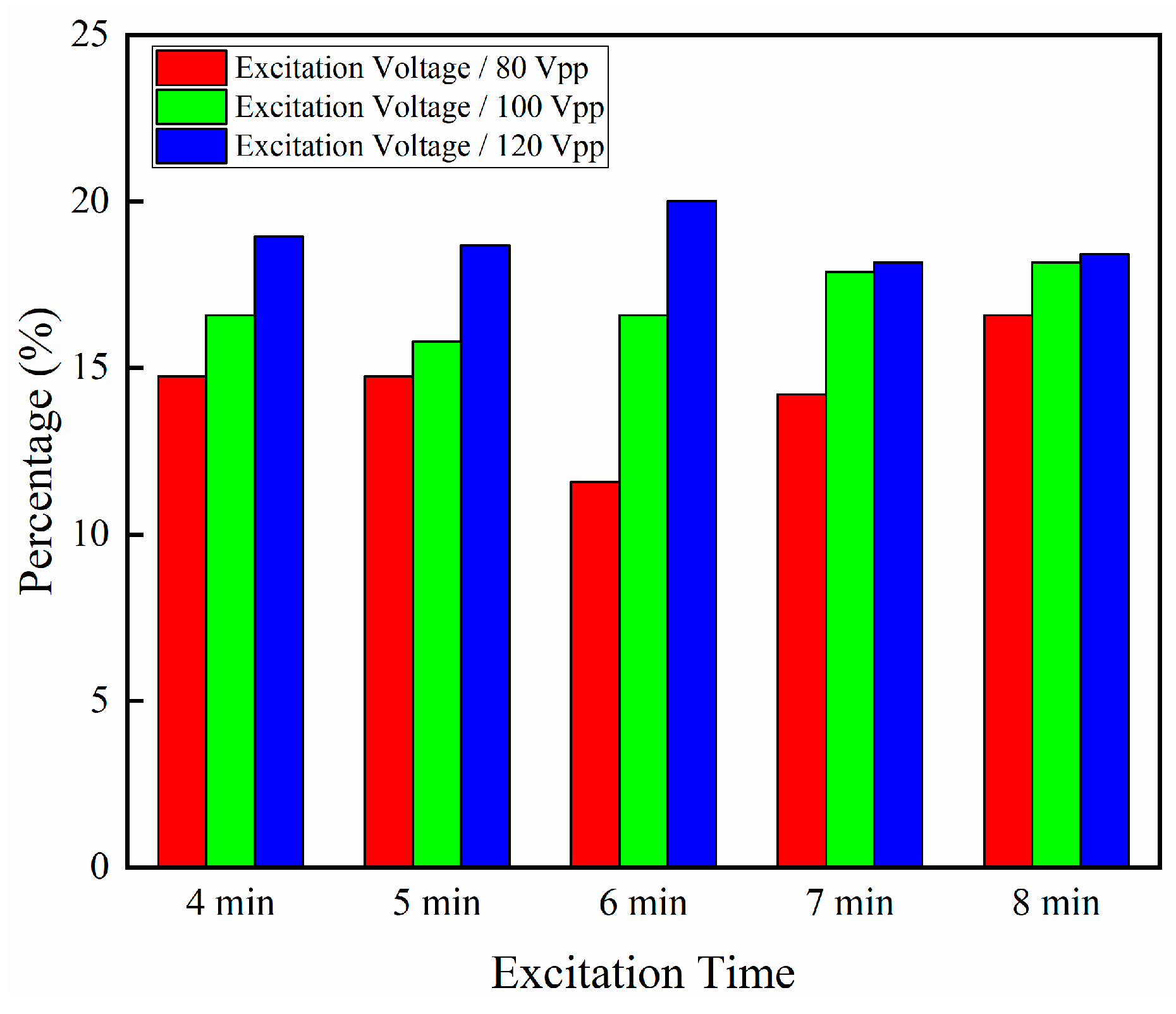

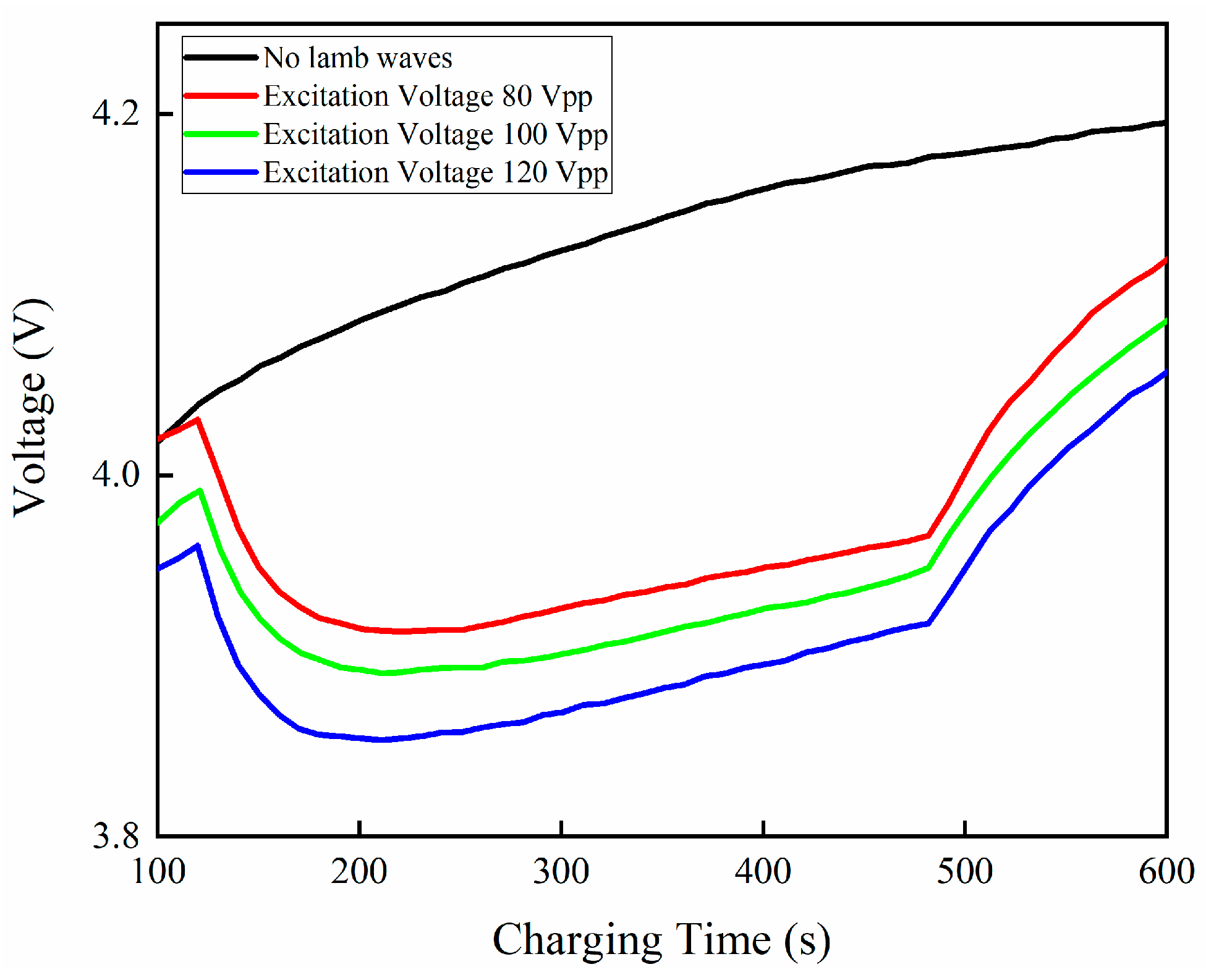

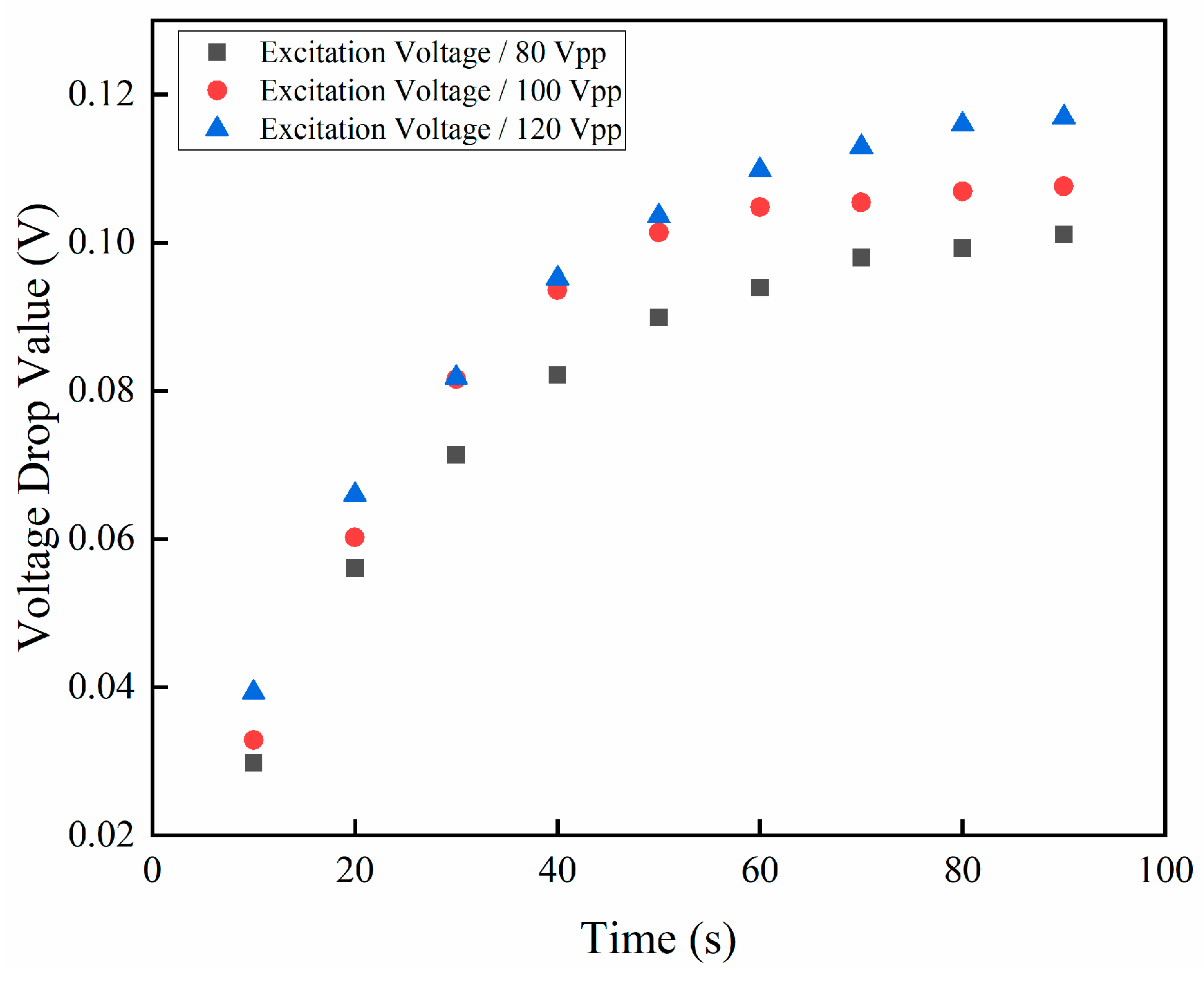

4.2. Relationship between Charging Efficiency and Excitation Voltage

4.3. Relationship between Lamb Wave Depolarization and Excitation Voltage

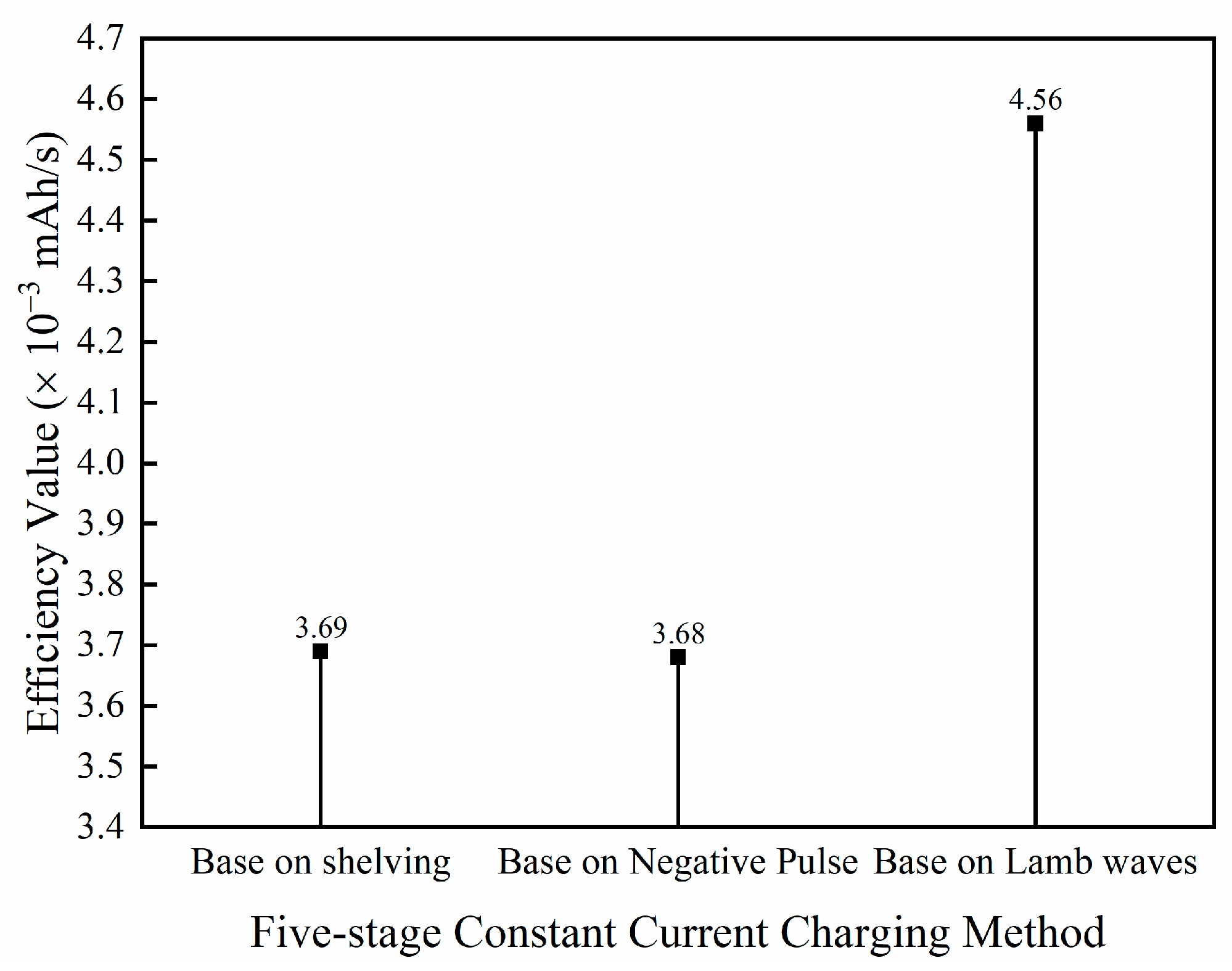

4.4. Comparison with Traditional Five-Stage Constant Current Depolarization Charging Method

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Scrosati, B.; Garche, J. Lithium batteries: Status, prospects and future. J. Power Sources 2010, 195, 2419–2430. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S.; Zhang, G. Simulation and experiment of thermal energy management with phase change material for ageing LiFePO4 power battery. Energy Convers. Manag. 2011, 52, 3408–3414. [Google Scholar]

- Caban, J.; Małek, A.; Šarkan, B. Strategic model for charging a fleet of electric vehicles with energy from renewable energy sources. Energies 2024, 5, 1264. [Google Scholar] [CrossRef]

- Seddig, K.; Jochem, P.; Fichtner, W. Two-stage stochastic optimization for cost-minimal charging of electric vehicles at public charging stations with photovoltaics. Appl. Energy 2019, 242, 769–781. [Google Scholar] [CrossRef]

- Saw, L.H.; Ye, Y.; Tay, A.A.O. Integration issues of lithium-ion battery into electric vehicles battery pack. J. Clean. Prod. 2016, 113, 1032–1045. [Google Scholar] [CrossRef]

- Lee, C.H.; Chen, M.Y.; Hsu, S.H.; Jiang, J.A. Implementation of an SOC-based four-stage constant current charger for Li-ion batteries. J. Energy Storage 2018, 18, 528–537. [Google Scholar] [CrossRef]

- Liu, Y.H.; Teng, J.H.; Lin, Y.C. Search for an optimal rapid charging pattern for lithium-ion batteries using ant colony system algorithm. IEEE Trans. Ind. Electron. 2005, 52, 1328–1336. [Google Scholar] [CrossRef]

- Hussein, A.A.H.; Batarseh, I. A review of charging algorithms for nickel and lithium battery chargers. IEEE Trans. Veh. Technol. 2011, 60, 830–838. [Google Scholar] [CrossRef]

- Shen, W.; Vo, T.T.; Kapoor, A. Charging algorithms of lithium-ion batteries: An overview. In Proceedings of the 2012 7th IEEE Conference on Industrial Electronics and Applications (ICIEA), Singapore, 18–20 July 2012; pp. 1567–1572. [Google Scholar]

- Koleti, U.R.; Bui, T.N.M.; Dinh, T.Q.; Marco, J. The development of optimal charging protocols for lithium-ion batteries to reduce lithium plating. J. Energy Storage 2021, 39, 102573. [Google Scholar] [CrossRef]

- Bui, T.M.; Sheikh, M.; Dinh, T.Q.; Gupta, A.; Widanalage, D.W.; Marco, J. A study of reduced battery degradation through state-of-charge pre-conditioning for vehicle-to-grid operations. IEEE Access 2021, 9, 155871–155896. [Google Scholar] [CrossRef]

- Ikeya, T.; Sawada, N.; Murakami, J.; Kobayashi, K.; Hattori, M.; Ujiie, S.; Kajiyama, K.; Nasu, H.; Narisoko, H.; Tomaki, Y.; et al. Multi-step constant-current charging method for an electric vehicle nickel/metal hydride battery with high-energy efficiency and long cycle life. J. Power Sources 2002, 105, 6–12. [Google Scholar] [CrossRef]

- Dung, L.R.; Yen, J.H. ILP-based algorithm for Lithium-ion battery charging profile. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics, Bari, Italy, 4–7 July 2010; pp. 2286–2291. [Google Scholar]

- Zhang, S.S. The effect of the charging protocol on the cycle life of a Li-ion battery. J. Power Sources 2006, 161, 1385–1391. [Google Scholar] [CrossRef]

- Liu, Y.H.; Hsieh, C.H.; Luo, Y.F. Search for an optimal five-step charging pattern for Li-ion batteries using consecutive orthogonal arrays. IEEE Trans. Energy Convers. 2011, 26, 654–661. [Google Scholar] [CrossRef]

- Hsieh, G.C.; Chen, L.R.; Huang, K.S. Fuzzy-controlled Li-ion battery charge system with active state-of-charge controller. IEEE Trans. Ind. Electron. 2001, 48, 585–593. [Google Scholar] [CrossRef]

- Jin, Q.Y. Design of Fast Charge System for Lithium-Ion Batteries. Master’s Thesis, Hunan University, Changsha, China, 2017. [Google Scholar]

- Kannan, D.R.R.; Weatherspoon, M.H. The effect of pulse charging on commercial lithium nickel cobalt oxide (NMC) cathode lithium-ion batteries. J. Power Sources 2020, 479, 229085. [Google Scholar] [CrossRef]

- Lu, Y.H.; Deng, J. Design and implementation of a fast charging method for lithium batteries. Electron. Des. Eng. 2020, 28, 113–117. [Google Scholar]

- Huang, A.; Liu, H.; Manor, O.; Liu, P.; Friend, J. Enabling rapid charging lithium metal batteries via surface acoustic wave-driven electrolyte flow. Adv. Mater. 2020, 32, 1907516. [Google Scholar] [CrossRef]

- Connacher, W.; Zhang, N.; Huang, A.; Mei, J.; Zhang, S.; Gopesh, T.; Friend, J. Micro/nano acoustofluidics: Materials, phenomena, design, devices, and applications. Lab Chip 2018, 14, 1952–1996. [Google Scholar] [CrossRef]

- Li, H.; Friend, J.R.; Yeo, L.Y. Surface acoustic wave concentration of particle and bioparticle suspensions. Biomed. Microdevices 2007, 9, 647–656. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L.; Lu, Y. Guided Lamb waves for identification of damage in composite structures: A review. J. Sound Vib. 2006, 295, 753–780. [Google Scholar] [CrossRef]

- Liang, W.; Lindner, G. Investigations of droplet movement excited by Lamb waves on a non-piezoelectric substrate. J. Appl. Phys. 2013, 114, 044501. [Google Scholar] [CrossRef]

- Gan, T.H.; Hutchins, D.A.; Billson, D.R.; Schindel, D.W. The use of broadband acoustic transducers and pulse-compression techniques for air-coupled ultrasonic imaging. Ultrasonics 2001, 39, 181–194. [Google Scholar] [CrossRef] [PubMed]

- Alghane, M.; Chen, B.X.; Fu, Y.Q.; Li, Y.; Luo, J.K.; Walton, A.J. Experimental and numerical investigation of acoustic streaming excited by using a surface acoustic wave device on a 128° YX-LiNbO3 substrate. J. Micromech. Microeng. 2010, 21, 015005. [Google Scholar] [CrossRef]

- Dong, W. Research on Management Technology of Lithium Battery Remaining Power in Electric Vehicle. Master’s Thesis, Shenyang Ligong University, Shenyang, China, 2012. [Google Scholar]

- Tietze, S.; Reißenweber, M.; Schlemmer, J.; Lindner, G. Investigation of the surface condition of an electrode after electropolishing under the influence of surface acoustic waves. Phys. Procedia 2015, 70, 1039–1042. [Google Scholar] [CrossRef]

- Chen, Y. Inhibition of Lithium Dendrites via Manipulating Chemical Reaction and Diffusion. Ph.D. Thesis, University of Chinese Academy of Sciences, Beijing, China, 2019. [Google Scholar]

- Han, J.G.; Jeong, M.Y.; Kim, K.; Park, C.; Sung, C.H.; Bak, D.W.; Kim, K.H.; Jeong, K.M.; Choi, N.S. An electrolyte additive capable of scavenging HF and PF5 enables fast charging of lithium-ion batteries in LiPF6-based electrolytes. J. Power Sources 2020, 446, 227366. [Google Scholar] [CrossRef]

- Bai, T. Research on the Optimization Fast Charging Method of Lithium-Ion Battery with Intermittent-Positive and Negative Pulse. Master’s Thesis, Hubei University of Technology, Wuhan, China, 2014. [Google Scholar]

- Chen, Y. The Study of Fast-Charging Control Strategy of Lithium-Ion Battery on Electrical Vehicle. Master’s Thesis, Jiangnan University, Wuxi, China, 2018. [Google Scholar]

| Capacity (mAh) | Nominal Voltage (V) | Cut-off Charging Voltage (V) | Cut-off Discharging Voltage (V) | Thickness (mm) | Diameter (mm) | Weight (g) |

|---|---|---|---|---|---|---|

| 10 | 3.6 | 4.2 | 2.75 | 2 | 12 | 1.1 |

| No. | Alternative Current Value (Unit in C Rate) | ||||

|---|---|---|---|---|---|

| 1 | 2.0 | 1.95 | 1.9 | 1.85 | 1.8 |

| 2 | 1.75 | 1.7 | 1.65 | 1.6 | 1.55 |

| 3 | 1.5 | 1.45 | 1.4 | 1.35 | 1.3 |

| 4 | 1.25 | 1.2 | 1.15 | 1.1 | 1.05 |

| 5 | 1 | 0.95 | 0.9 | 0.85 | 0.8 |

| No. | Level | ||||

|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 1 | 2 | 2 | 2 |

| 3 | 1 | 1 | 3 | 3 | 3 |

| 4 | 1 | 2 | 1 | 1 | 2 |

| 5 | 1 | 2 | 2 | 2 | 3 |

| 6 | 1 | 2 | 3 | 3 | 1 |

| 7 | 1 | 3 | 1 | 2 | 1 |

| 8 | 1 | 3 | 2 | 3 | 2 |

| 9 | 1 | 3 | 3 | 1 | 3 |

| 10 | 2 | 1 | 1 | 3 | 3 |

| 11 | 2 | 1 | 2 | 1 | 1 |

| 12 | 2 | 1 | 3 | 2 | 2 |

| 13 | 2 | 2 | 1 | 2 | 3 |

| 14 | 2 | 2 | 2 | 3 | 1 |

| 15 | 2 | 2 | 3 | 1 | 2 |

| 16 | 2 | 3 | 1 | 3 | 2 |

| 17 | 2 | 3 | 2 | 1 | 3 |

| 18 | 2 | 3 | 3 | 2 | 1 |

| Level | Alternative Current Value (Unit in C Rate) | ||||

|---|---|---|---|---|---|

| I1 | I2 | I3 | I4 | I5 | |

| 1 | 2.0 | 1.75 | 1.5 | 1.25 | 1 |

| 2 | 1.9 | 1.65 | 1.4 | 1.15 | 0.9 |

| 3 | 1.8 | 1.55 | 1.3 | 1.05 | 0.8 |

| Level | Alternative Current Value (Unit in C Rate) | ||||

|---|---|---|---|---|---|

| I1 | I2 | I3 | I4 | I5 | |

| 1 | 2.0 | 1.7 | 1.5 | 1.25 | 0.75 |

| 2 | 1.95 | 1.65 | 1.45 | 1.2 | 0.7 |

| 3 | 1.9 | 1.6 | 1.4 | 1.15 | 0.65 |

| Excttion Voltage (Vpp) | Time (s) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | |

| 80 | 0.0298 | 0.0561 | 0.0713 | 0.0821 | 0.0899 | 0.0939 | 0.098 | 0.0992 | 0.1011 |

| 100 | 0.0329 | 0.0602 | 0.0816 | 0.0936 | 0.1014 | 0.1048 | 0.1054 | 0.1069 | 0.1076 |

| 120 | 0.0393 | 0.066 | 0.0818 | 0.0952 | 0.1036 | 0.1098 | 0.1129 | 0.116 | 0.1169 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Liang, W. Five-Stage Fast Charging of Lithium-Ion Batteries Based on Lamb Waves Depolarization. Energies 2024, 17, 2992. https://doi.org/10.3390/en17122992

Wang T, Liang W. Five-Stage Fast Charging of Lithium-Ion Batteries Based on Lamb Waves Depolarization. Energies. 2024; 17(12):2992. https://doi.org/10.3390/en17122992

Chicago/Turabian StyleWang, Tong, and Wei Liang. 2024. "Five-Stage Fast Charging of Lithium-Ion Batteries Based on Lamb Waves Depolarization" Energies 17, no. 12: 2992. https://doi.org/10.3390/en17122992

APA StyleWang, T., & Liang, W. (2024). Five-Stage Fast Charging of Lithium-Ion Batteries Based on Lamb Waves Depolarization. Energies, 17(12), 2992. https://doi.org/10.3390/en17122992