1. Introduction

Air distribution is a critical aspect of indoor environmental quality (IEQ) in vehicles, especially in enclosed spaces such as automobiles, trains, buses, and airplanes. This is because it has a large weight to the comfort and well-being of passengers and crew members. Inadequate IEQ can cause health problems and discomfort, and this can accelerate fatigue of the users, which can affect the ability to respond to various stimuli by increasing the user reaction time, which can lead to the occurrence of unwanted and unpleasant events. For example, in [

1] the authors demonstrated that under low humidity conditions, drivers exhibited a higher accuracy in response rate and experienced less overall fatigue compared to situations with higher humidity.

Personalized ventilation in office buildings is increasingly recognized as a crucial factor in enhancing indoor environmental quality (IEQ) and occupant productivity [

2]. Traditional HVAC systems often fail to address the diverse thermal preferences and metabolic rates of individual occupants, leading to discomfort and decreased performance. Even if ideal environmental conditions were created according to Fanger’s theory [

3], aiming for a predicted mean vote (PMV) of 0, it would still be observed that a certain percentage of occupants would remain dissatisfied. Fanger’s predicted percentage of dissatisfaction (PPD) index indicates that at a PMV of 0, approximately 5% of people are likely to be dissatisfied with their thermal environment. This inherent variability in individual thermal comfort underscores the limitations of traditional HVAC systems and the need for more adaptable solutions.

Personalized ventilation systems offer a solution by allowing individuals to control their immediate microenvironment, adjusting airflow and temperature to their specific needs. This tailored approach can reduce the risk of discomfort [

4] and health issues associated with poor air quality, such as headaches, dry eyes, and respiratory problems [

5]. Studies have shown that providing employees with the ability to customize their ventilation can lead to significant improvements in cognitive function, concentration, and overall job satisfaction. For instance, the research highlighted in [

6] acknowledged that the ability to personally control ventilation is a significant factor in enhancing satisfaction with thermal comfort, owing to both its physical benefits and positive psychological effects. For example, in building offices, worker well-being and productivity are highly influenced by workplace conditions. Therefore, it is essential to ensure high indoor environmental quality (IEQ). A key parameter of IEQ is thermal comfort, which is maintained by heating, ventilation, and air conditioning (HVAC) systems [

7].

Thermal comfort is commonly understood as the state of satisfaction a person experiences regarding the temperature and environment within an occupied space, this evaluation being a subjective one. Nevertheless, a precise definition is challenging, and conceiving a universal definition becomes even more complex due to the intertwined nature of human physical and psychological states [

8].

In the last years, the focus on enhancing thermal comfort in vehicles has intensified, coinciding with a significant rise in the time vehicle occupants spend in traffic [

9,

10]. Specialists and researchers in the HVAC field are constantly looking for new models to estimate, predict, or classify the state of thermal comfort in occupied spaces [

11,

12,

13]. The study in [

14] confirmed that thermal sensation is the most commonly utilized metric in the thermal comfort database II [

14], appearing frequently as a central question in almost all thermal comfort research, succeeded by topics such as thermal comfort, thermal preference, and thermal acceptability. Many scientific investigations have prioritized the physiological aspect of thermal comfort, operating under the assumption that it is achievable when the human body’s excess heat is released into the environment, rendering the human thermoregulatory system insignificant.

Passenger comfort in vehicles is of great interest as it directly affects the well-being, safety, and overall travel experience of the occupants. Studies have shown that maintaining optimal comfort levels can significantly reduce fatigue and improve cognitive function, which is critical for ensuring the safe and alert operation of vehicles [

15,

16]. For instance, research on the thermal comfort of passengers in trains has highlighted the necessity of thermal comfort and its impact on passenger satisfaction and performance [

17,

18]. Similarly, in airplanes, maintaining a comfortable cabin environment is very important for passenger health and well-being during long flights [

19,

20]. Additionally, in buses, ensuring a comfortable atmosphere is also important for passenger satisfaction and can reduce the stress associated with travel [

18,

21]. These studies collectively underscore the need for advanced ventilation systems and improved air diffuser designs to enhance passenger comfort across various modes of transportation.

However, studying thermal comfort in vehicle cabins is challenging due to the intensely severe thermal transient states caused by the HVAC system, high air velocities, high thermal gradients, and radiative heat flow. Moreover, differences in cabin volume, glazing area, occupant posture, and physiological factors make estimating thermal comfort even more difficult. Multiple methods exist to enhance thermal comfort within vehicles, including using the HVAC system, ventilating seats, and heated chairs [

22]. Considering that the HVAC system has been identified as the principal system affecting occupants’ thermal comfort, more attention should be directed towards this system.

As previously mentioned, when considering the distinct environmental attributes of vehicles, a notable disparity arises when compared to conventional indoor settings. Vehicle cabins have considerably reduced volumes and can accommodate a greater number of individuals per square meter than in a building case, for example. Furthermore, when assessing the velocity at which the HVAC system introduces fresh air, it becomes apparent that the rate of air changes per hour (ACH) is significantly increased in vehicles compared with building cases. This contrast emphasizes that the flow of air within a vehicle primarily responds to the thermal load primary and is not connected to the indoor air quality (IAQ) within the vehicle.

Chang et al. [

23] confirmed the necessity of having at least 32.4 m

3/h per person (9.21 L/s), which, as known from the measurements, corresponds to a very low ventilation rate in the vehicle. They measured the CO

2 levels within a vehicle and found that following the ASHRAE standard 62.1 guideline, which recommends an outdoor air supply rate of 2.5 L/s per person, results in an average CO

2 concentration of roughly 2850 ppm in the vehicle cabin. Elevating the air supply rate to 4.0 L/s and 9.21 L/s per person, with the goal of improving occupant well-being, was shown to decrease the average CO

2 concentrations to approximately 1810 ppm and 1000 ppm (considered a safe threshold), respectively [

23].

Hence, it can be concluded that enhancing the thorough mixing of fresh air with the surrounding atmosphere presents a potential solution to enhance thermal comfort for occupants within vehicles. This becomes especially significant when taking into account that in summer, the fresh air temperature issued by the heating, ventilation, and air conditioning system of a vehicle can drop below 10 °C [

24], effectively mitigating or, at the very least, diminishing the perception of drafts felt by the passengers within the vehicle. As a result, strategies aimed at optimizing the distribution of air and guaranteeing a more balanced mixture of fresh and ambient air become essential in creating an optimal thermal comfort setting within vehicles.

Moreover, the methodology employed in this research revolves around enhancing the passive mixing of fresh air intake with the vehicle’s interior ambient air. The primary goal is to decrease the temperature and diminish the velocity of this airflow, as these two variables significantly influence both thermal comfort and the sensation of draughts experienced by passengers in vehicles or occupants in enclosed spaces [

25]. The significance of thermal comfort during driving is crucial for all individuals; however, Feng et al. [

26] highlighted that women possess a lower tolerance for thermal sensations, suggesting that thermal comfort may hold greater importance for this demographic.

To attain this objective, an extensive numerical analysis was conducted, which involved the comparison of different air diffuser designs with the aim of identifying a more efficient passive mixing system than the conventional ones typically employed in the automotive industry. The ventilation system in vehicles plays a critical role in providing a steady supply of fresh air and removing the pollutants from the ambient air by diluting it. High-induction air diffusers with lobed orifices are a promising solution for improving IEQ in vehicles [

27]. The same conclusion was pointed out in [

28], where these air diffusers supply fresh air into the ventilated enclosure and mix it with the existing ambient air, thereby lowering pollutant levels and enhancing the overall IEQ. The idea of using lobed orifices in ventilation in terms of high induction is not new. The utilization of the lobed diffuser demonstrated a notable enhancement in thermal comfort when compared to the conventional diffuser [

29]. This improvement was achieved without any increase in pressure drop or sound pressure levels.

In [

30], the authors studied a flow from a tubular radially lobed nozzle at two Reynolds numbers to explore instability mechanisms and vortex dynamics that enhance mixing, confirming the evolution of Kelvin-Helmholtz-like modes and distinct structural changes compared to round nozzles.

High-induction air diffusers can be a solution for other applications as well, for example in the case of isolation rooms, the positioning of a “turbulence high induction” ceiling air diffuser for air inlet is of utmost importance [

31]. The results indicate the ideal conditions for the high-induction air inlet diffuser and the applied pressure scheme in the room, presenting an efficient method for managing airflow that contains virus droplets. In [

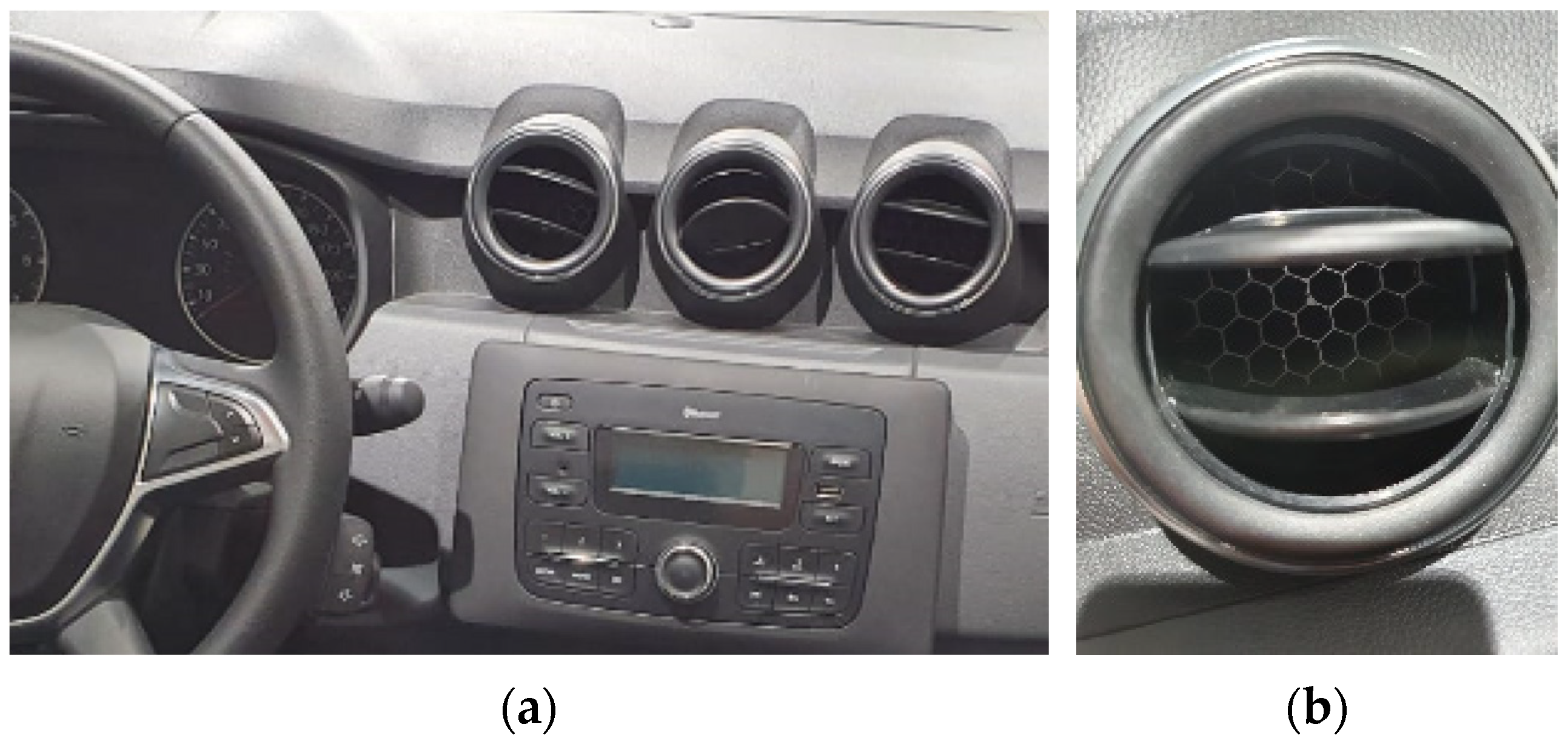

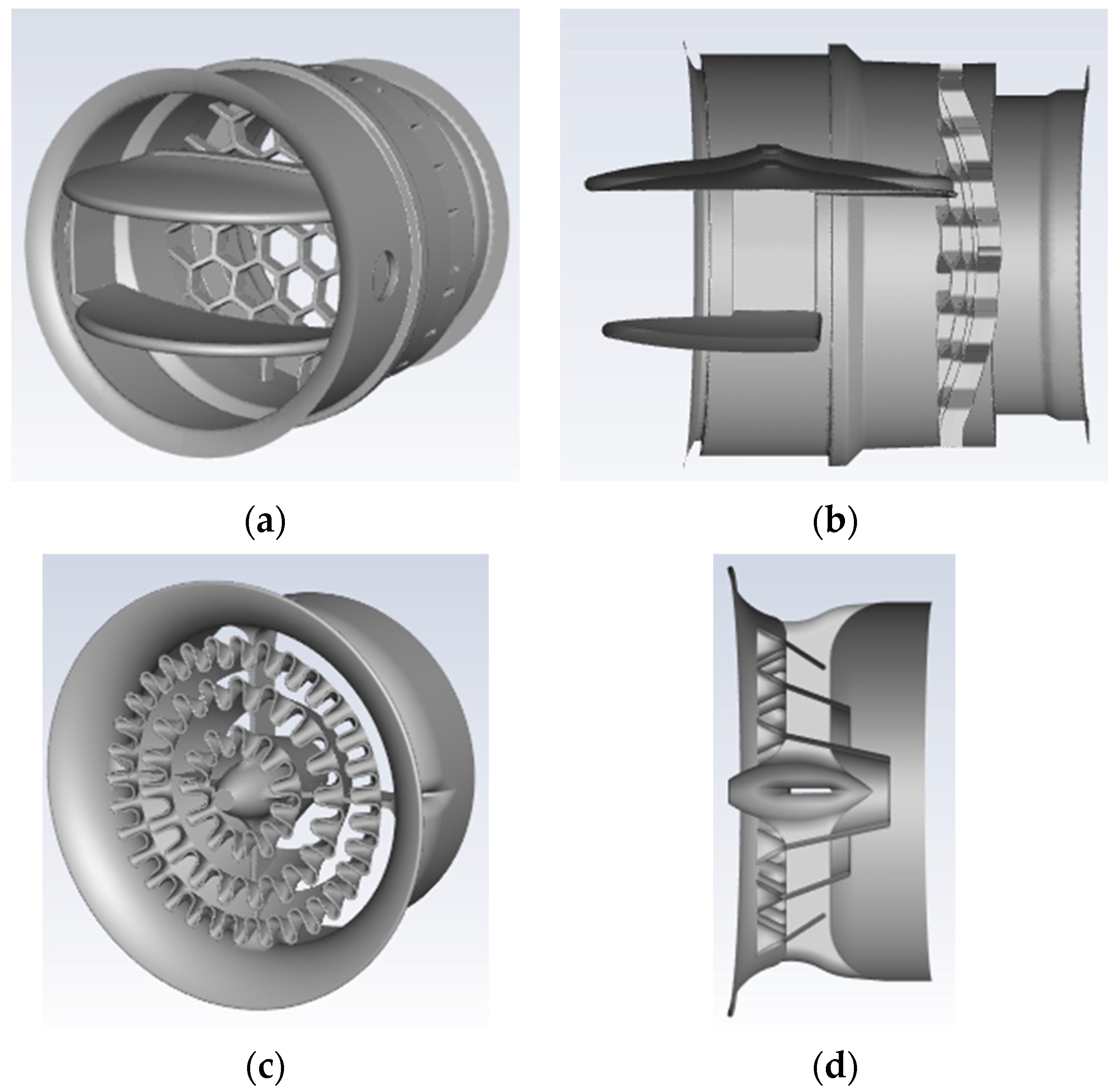

32], the numerical outcomes of four distinct air diffuser geometries were evaluated in comparison to one another, including the original diffuser for the air installed in the Dacia Duster vehicle produced by Renault Group. Among them, the best-studied case, which basically involves the arrangement of three concentric circles with lobes accompanied by guide blades at varying angles, where the lobes are located on the air diffuser’s outer section, emerged as the most effective in terms of entraining in ambient air, exhibiting a 35% increase in air mixing compared to the reference air diffuser. Based on the findings of this research and after a careful examination of the results, the air diffuser geometry was changed, and in a later study [

33], four different novel variants of vehicle air diffusers were compared with the reference one, and the best diffuser had 41% more air induction compared with the reference one. Later, using the same technique, in the study [

34], the air induction reached 43%.

Although the studies reviewed in this paper have predominantly focused on the development of air diffusers for the automotive industry, these diffusers can also be effectively utilized in personalized ventilation applications. Due to their ability to provide individualized control over airflow and temperature, the findings and innovations presented in this article are applicable to both automotive and personalized ventilation systems. This dual applicability highlights the versatility of the enhanced air diffusers, ensuring that the improvements in air entrainment and thermal comfort can benefit not only the vehicle occupants but also individuals in various enclosed spaces, such as office buildings.

This study is part of a larger research project aimed at developing high-induction air diffusers tailored for vehicle ventilation systems. It investigates various innovative air diffuser designs that surpass traditional models in air mixing efficiency, potentially transforming airflow dynamics within vehicles to improve temperature comfort and reduce air velocity. The main focus of this study is on a particularly promising diffuser design, evaluating its unique features and the significant improvement it offers in driving comfort through the improved integration of fresh air into the vehicle’s internal environment. This involves achieving more consistent airflow temperatures and reducing velocity, both with great impact on thermal comfort and minimizing draught sensations.

Furthering previous inquiries, this research compares different high-induction air diffuser geometries to identify an optimal passive mixing solution for the automotive sector. The present study presents the development and testing of a new air diffuser model that promises to elevate thermal comfort across various vehicles, including electric ones. Experimental validation was conducted on a Dacia Renault Duster, thanks to a partnership with a leading automotive manufacturer, demonstrating the generalizability of these findings. The study emphasizes the importance of experimental data to support numerical predictions, with validated results on a specific vehicle model offering broad applicability across different vehicle types. This reflects the universal relevance of this study’s findings to the domain of automotive thermal comfort, highlighting the comparable design and functionality of HVAC systems and air diffusers in vehicles with diverse powertrains.

The novelty of this work lies in the development and evaluation of an innovative high-induction air diffuser specifically designed for vehicle applications, demonstrating an increase in air entrainment compared to traditional models. This study uniquely combines advanced numerical simulations with experimental validations using laser Doppler velocimetry (LDV) to verify the performance enhancements. The new diffuser design aims to improve thermal comfort by ensuring the improved mixing of fresh and cabin air. Furthermore, the principles and design innovations introduced have broad applications, extending beyond automotive use to personalized ventilation systems in various enclosed environments, thereby contributing significantly to the fields of indoor air quality and thermal comfort.

3. Results and Discussion

3.1. Increasing Air Mixing

When considering the ventilation of vehicles, a pertinent question arises: is the mixing of fresh air with cabin air beneficial for the occupant’s health and comfort? Understanding the dynamics of air exchange in vehicles is very important when addressing this question. In this part of the study, it was investigated whether the high rates of air change typically seen in vehicles, driven by the need to manage thermal loads, actually contribute to better air quality for the occupants or if they simply serve to maintain thermal comfort.

For example, it is known that the suggested frequency of air exchange in building ventilation can vary depending on factors such as the building’s category, its intended purpose, and its compliance with local or international regulations. Nevertheless, as a broad recommendation, it is prudent to target a range of 4–8 full air replacements per hour for residential or office structures. It is essential to recognize that, for buildings, this range serves not only to maintain satisfactory indoor air quality but also plays a substantial role in preserving a wholesome and healthful indoor atmosphere.

Based on the airflow measurements taken with a funnel anemometer (Testo), when discussing air changes per hour (ACH) in vehicles, it was determined that the range can vary from 48 to 144 ACH, depending on the HVAC airflow settings, specifically V1–V4, in the case of the SUV vehicle Dacia/Renault Duster. These values are significantly higher than those typically encountered in building ventilation scenarios, being 12–18 times greater. This discrepancy highlights a very high difference: in vehicles, the airflow rate is more closely correlated with the thermal load to be removed rather than the requirement for fresh air. Consequently, it can be confidently asserted that there is no need for concern regarding the accumulation of unhealthy compounds due to insufficient ventilation, even when using the lowest ventilation setting in a vehicle.

In this assessment, the interior air volume of an unoccupied Dacia/Renault Duster was approximately 2.5456 cubic meters, and with one occupant, it reduced to about 2.487 cubic meters. This calculation formed the basis for the previously mentioned ACH values. It is worth noting that this value has also been corroborated by Renault Technologie Roumanie, part of the Renault group. Therefore, despite the high air exchange rates, the improved mixing of fresh air with cabin air does not influence the air quality experienced by the occupants, as the primary function of this high airflow is to manage thermal loads rather than to increase the fresh air supply.

3.2. Experimental Validation of the Numerical Results

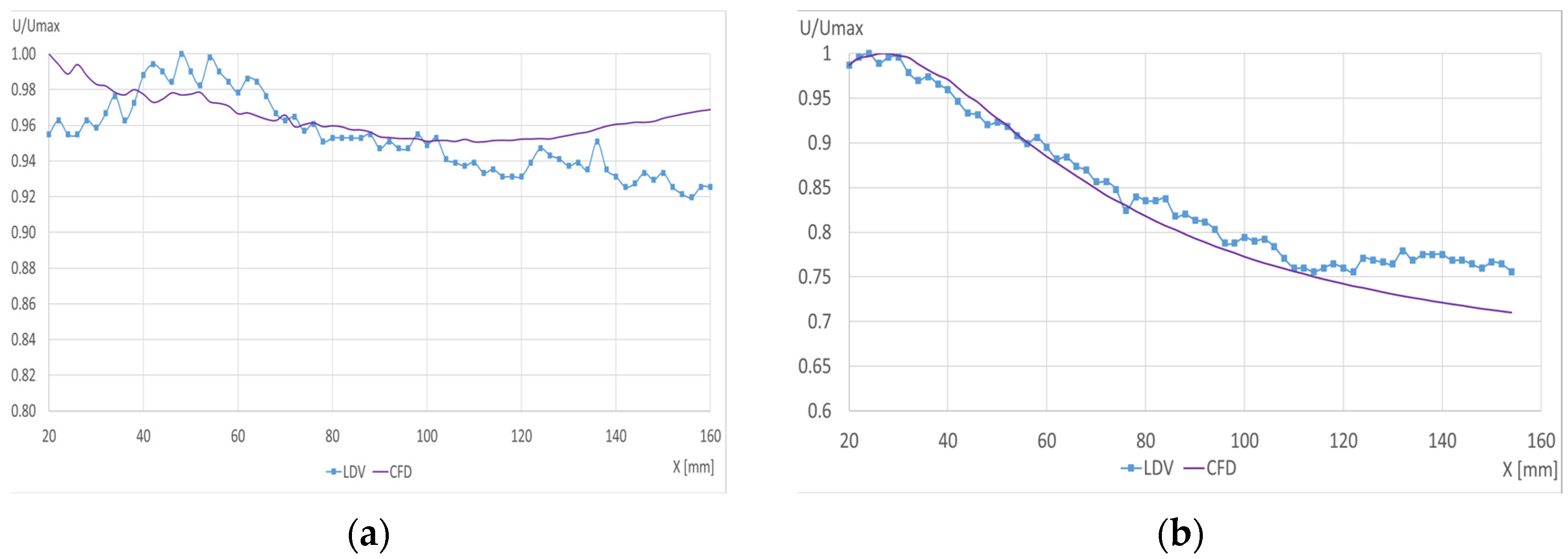

Laser Doppler velocimetry (LDV) measurements were conducted for both air diffusers: the reference (case A) and the lobed configuration (case V). The axial velocity decay was measured in both cases, and the results were compared with the outcomes obtained from the numerical simulations.

Figure 5a presents the comparison between the LDV measurements and CFD results for the reference case, and

Figure 5 demonstrates the lobed air diffuser results.

A notable resemblance can be observed in the compared values for both the reference diffuser and the lobed diffuser configurations. The maximum error is below 5% for the reference diffuser and is a maximum of 6% for the lobed diffuser case.

Furthermore, a significant reduction in velocity is evident with the lobed diffuser, consistent with the preliminary hypotheses. Thus, with an increase in the entrainment rate, a drop in velocity is anticipated because of the momentum exchange between the jet air and the surrounding air. This trend is consistent with the initial assumptions and with the numerical results regarding the lobed diffuser behavior and confirms the significant influence of the entrainment rate on the velocity profile in this specific context.

3.3. Velocity Field

The outcomes of the numerical simulations were analyzed using Ansys Fluent 19.2 and Tecplot 2021 software.

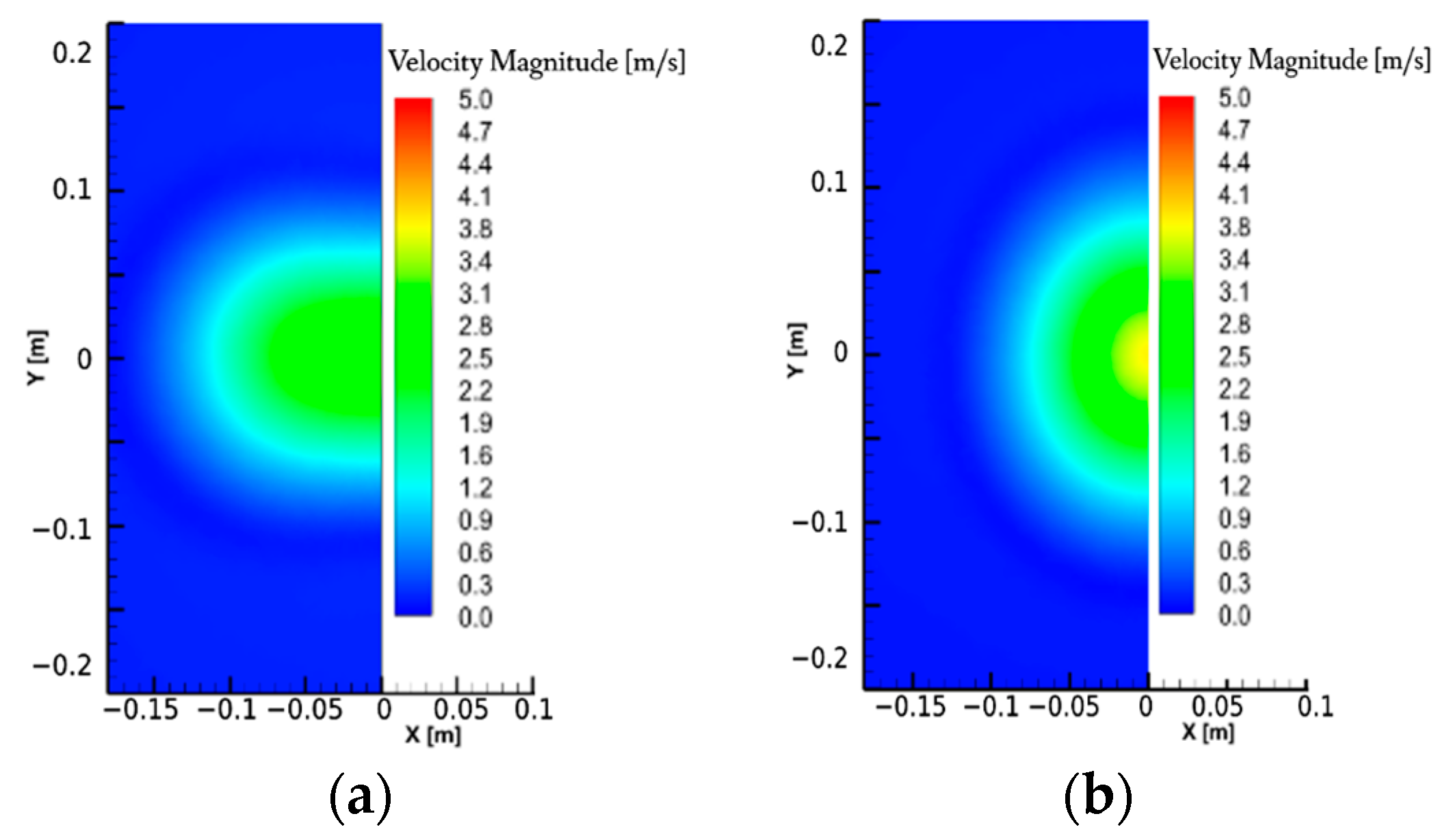

Figure 6 illustrates the velocity contours on the longitudinal plane across all the air diffusers examined.

Figure 7 presents the velocity contours on a transversal plane positioned 100 mm away from the analyzed air diffusers.

Figure 8 depicts the velocity contours on a transversal plane 600 mm from the tip of the air diffusers. The chosen length is near the driver’s face position within the vehicle, which is considered a relevant plan for investigating the velocity field.

Upon analyzing the velocity fields from

Figure 7 and

Figure 8, it becomes evident that the results demonstrate qualitative similarities. Notably, the standard air diffuser demonstrates the shortest potential core length. Additionally, jet expansion commences later for the standard air diffuser compared with the lobed air diffuser. Analyzing the transverse velocity field, noticeable differences in the jet shape can be observed at 600 mm among the studied air diffusers. Case V exhibits a broader spread compared to case A. This broader spread is desirable as it indicates a higher induction air diffuser, aligning with the intended objective of the work.

3.4. Entrainment Rate

Tecplot 2021 software was used for the entrainment rate calculation at a distance of 600 mm from the dashboard (

Figure 9). This specific distance was chosen because it corresponds to the average breathing zone distance from the dashboard for the occupants seated in the front seats of the Dacia/Renault Duster vehicle.

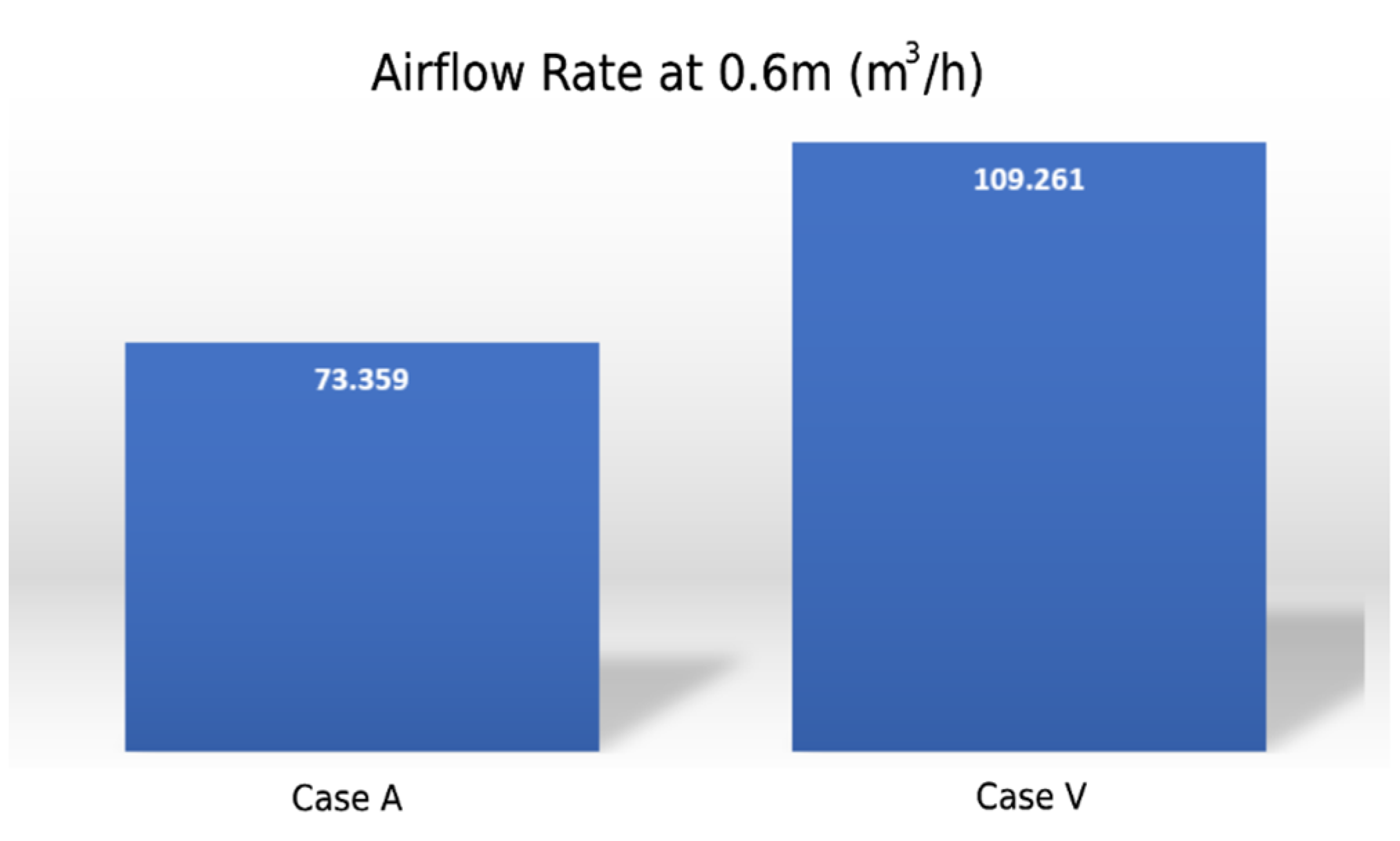

For the lobed air diffuser, there is an increase in the induction rate when juxtaposed with the standard air diffuser, particularly at a distance of 600 mm from the dashboard. Consequently, the entrained airflow for this novel air diffuser registers a substantial enhancement, precisely amounting to a 48% increase compared to the reference configuration. This substantial improvement underscores the efficacy of the case V air diffuser in optimizing airflow dynamics. For example, one can see that for a measured fresh airflow rate of 31.79 m3/h, the total air entrainment rate at 0.6 m for the standard air diffuser is 73.36 m3/h, while for the innovative air diffuser, it is 109.26 m3/h.

The results of this study suggest practical directions for the design of HVAC systems in vehicles, focusing on the potential to improve passenger comfort while maintaining energy efficiency. The enhanced air diffuser design, with its increased ambient air induction capabilities, demonstrates a method for improving thermal comfort that does not necessarily lead to higher energy consumption. Achieving a balance between the cooling and heating needs within a vehicle’s cabin by optimizing the blending of cool air from the HVAC system with the internal air can lead to a more even distribution of the temperature.

This approach reduces the extremes of cooling or heating that are often required. Moreover, the possibility of integrating high-induction air diffusers with other vehicle systems, such as adaptive climate controls that adjust based on real-time occupancy and external environmental conditions, offers a route to fine-tune the vehicle’s internal climate. This integration aims to create a more comfortable thermal environment for passengers while also supporting energy conservation efforts.

4. Conclusions

The comfort of vehicle occupants, particularly in thermal terms, is one of the essential parameters for a pleasant travel experience and safety. An uncomfortable thermal environment can lead to increased stress levels, potentially compromising the driver’s attention and reaction times. This situation elevates the risk of accidents. Moreover, improved thermal comfort for the driver can decrease fatigue, thereby enhancing concentration and reducing the likelihood of hazardous incidents.

One of the investigations carried out in this study was whether the high air exchange rates in vehicles, primarily driven by the need to manage thermal loads, contribute to better air quality or merely maintain thermal comfort. It highlights that the air change rates in vehicles are significantly higher than in buildings cases (12–18 times, reaching 48 to 144 ACH), emphasizing that the airflow in vehicles is more closely tied to thermal load removal rather than fresh air requirements. Consequently, even at the lowest ventilation settings, there is no concern for the accumulation of unhealthy compounds when air mixing is performed, as the primary function of this high airflow is thermal management.

High-induction air diffusers are, therefore, a promising solution for improving indoor air quality (IAQ) in vehicles. This study focused on improving the passive mixing of cooled air from the vehicle’s HVAC system with cabin air during summer conditions. The aim was to enhance the entrainment rate of airflow, minimizing the temperature gradient caused by the HVAC system’s output. This approach seeks to maintain occupant comfort while efficiently addressing the thermal load requirements.

Through numerical analyses, the performance of a novel air diffuser design was evaluated against the standard model installed in the Dacia/Renault Duster. The innovative lobed air diffuser demonstrated superior performance, achieving a 48% higher rate of ambient air entrainment in the occupants’ breathing zone than the conventional diffuser. This result indicates a significant improvement in the mixing of air within the vehicle cabin, directly impacting thermal comfort.

The implications of the research extend beyond the specific vehicle model studied, suggesting broad applicability across various vehicle types, including electric vehicles (EVs). The enhanced air mixing capability of the novel diffuser design could reduce the need for fresh air intake, potentially lowering HVAC system energy consumption. This reduction is particularly relevant for EVs, as it may contribute to increased vehicle autonomy by optimizing energy use, thus addressing a critical challenge in EV design without compromising interior comfort. This is a subject worth studying in the future.

By addressing thermal comfort optimization, this study offers a method for mitigating temperature disparities within a vehicle cabin. This improvement in air mixing not only promises to enhance occupant comfort but also supports safer driving conditions by reducing driver fatigue. Consequently, these findings contribute to the ongoing development of vehicle design and operation, aiming to improve the overall travel experience and safety, as well as the environmental impact of automotive HVAC systems. Additionally, the principles and innovations demonstrated in this research have potential applications in personalized ventilation systems, further enhancing indoor air quality and thermal comfort in various enclosed environments, such as office buildings.