Abstract

Different approaches have been suggested for the waste heat recovery of high-temperature exhausted gas of a solid oxide fuel cell (SOFC). In such systems, mostly gas turbine (GT) and organic Rankine cycle (ORC) are added as bottoming systems to the SOFC (Configuration 1). However, the SOFC-GT-ORC has a considerable amount of waste energy which can be recovered. In the present research, the waste energy of ORC in the heat rejection stage and the residual exhausted gas of the system were recovered by a thermoelectric generator (TEG) and a hot water unit, respectively. Then, the extra produced power in the TEG was directed to a proton exchange membrane electrolyzer and a reverse osmosis desalination unit (RODU) for hydrogen and potable water outputs. The performance of SOFC-GT, Configuration 1, and Configuration 2 was compared through a 4E (energy, exergy, exergy-economic, and environmental) analysis. In the best performance point, the exergy efficiency and unit cost of product (UCOP) of SOFC-GT were obtained as 69.41% and USD 26.53/GJ. The exergy efficiency increased by 2.56% and 2.86%, and the UCOP rose by 0.45% and 12.25% in Configurations 1 and 2. So, the overall performance of Configuration 1 was acceptable and Configuration 2 led to the highest exergy efficiency, while its economic performance was not competitive because of the high investment cost of RODU.

1. Introduction

Finding a suitable method for efficient power generation with low emissions has become a priority due to the world’s growing energy demand and growing environmental concerns [1,2]. Fuel cells are regarded as the fourth generation of power-generating technology, following thermal power, hydropower, and nuclear power, because they have benefits over traditional thermal power generation, such as increased efficiency and lower emissions [3,4]. The solid oxide fuel cell (SOFC) is a highly advantageous fuel cell type due to its diverse range of coupling possibilities with various systems [5,6]. More crucially, combining SOFC with gas turbines (GT) to create SOFC-GT hybrid systems that can reach high electrical and thermal efficiencies is particularly appealing [7,8]. Additionally, SOFCs are utilized in various applications, including combined heat and power systems, where they provide both electricity and useful heat, enhancing overall energy utilization. They are also used in distributed generation setups, providing power at the point of use, which reduces transmission losses and enhances reliability. Furthermore, SOFCs can be integrated with renewable energy sources such as biogas or hydrogen from renewable electrolysis, offering a sustainable and low-carbon energy solution. These versatile applications demonstrate the potential of SOFCs to contribute significantly to both centralized and decentralized power generation strategies, promoting energy efficiency and sustainability.

Bottoming systems were connected to SOFC-GT for extra power generation [9,10]. In this regard, Yan et al. [11] used bottoming ORC to use the topping SOFC-GT waste energy. An LNG module was utilized as a heat rejection medium for the ORC. The highest efficiency of 67.38% was achieved for the combined system. Ebrahimi and Moradpoor [12] performed an energy analysis on a combined SOFC-GT-ORC configuration. In their study, the heat rejection stage in the ORC condenser was utilized for hot water production. Energy analysis showed a maximum efficiency of 65% for the considered system. Ghaffarpour et al. [13] conducted energy, exergy, and economic studies on a combined biomass-fired SOFC-GT-steam Rankine Cycle (SRC). They used three different biomasses for performance comparison. The highest exergy efficiency () and specific cost () were 29.9% and USD 25.82/GJ. Singh et al. [14] compared the outputs of three various organic fluids in a coupled SOFC-GT-ORC layout. R236fa led to the highest energy efficiency () among the three proposed fluids. In this mode, of SOFC-GT was 63.17%, which increased to 75.81% in the SOFC-GT-ORC system. Karimi et al. [15] conducted a thermo-economic optimization on a coupled biomass-fired SOFC-GT-ORC layout. The good values for and total cost rate () were 35.1% and 10.2%, respectively. Emadi et al. [16] embedded a cascade high-temperature ORC, low-temperature ORC–LNG layout for unused heat elimination in a topping SOFC-GT system. The optimized performance of the system was compared with 20 different combinations of ORC working fluids. The best values of and electricity unit cost were reported as 51.6% and USD 33.2/MWh. Cheng et al. [17] used an organic flash system for waste energy elimination in a coupled biomass-fired SOFC-GT system. Multi-target optimization conduced to a and of 47.12% and USD 5.5/GJ. Gholamina and Zare [18] compared the use of ORC and Kalina cycles as bottoming systems for a topping SOFC-GT system and from exergy perspective. The coupled SOFC/GT-ORC layout could achieve a of 62.35%, whereas the combined SOFC/GT-KC layout achieved a of 59.53%. Ouyang et al. [19] used the bottoming CO2 supercritical Brayton cycle (SBC) and Kalina cycle for waste heat elimination by topping SOFC-GT. The SBC and Kalina cycles used the waste energy in a series configuration. and payback period were 71.37% and 7.49 years, respectively. Pirkandi et al. [20] investigated the effect of adding GT and SRC to a SOFC system. Results demonstrated that adding bottoming SRC increased the output power by 15% in comparison to the SOFC-GT system. Roy et al. [21] combine an SOFC with an externally fired GTC. Then, an ORC was utilized for the waste energy recovery of the topping system. Results showed that biomass gasifiers accounted for 38.9% of total exergy destruction. Moreover, the minimum levelized cost of electricity was equal to 0.086 $/kWh. Pan et al. [22] incorporated recompression CO2 SBC with an SOFC-GT topping system. Then, for the waste energy recovery of SBC, three bottoming systems, namely CO2 ORC, the Kalina cycle, and the organic flash cycle, were utilized. The findings showed that, in terms of efficiency, the organic Rankine cycle’s introduction was the most notable because it could achieve the highest of 72.74–53.55% (or of 70.22–27.11%) under a variety of operating situations. Given its lowest capital cost of USD 19.94/h, the coupling of the Kalina cycle was recommended in terms of cost.

Because of the high potential of SOFC and SOFC-GT for waste energy recovery, some studies have been conducted on converting them to high-performance tri-generation and multi-generation energy systems, leading to higher energy conversion efficiency [23,24]. In this regard, Al-Suleiman et al. [25] recovered the unused energy of a SOFC layout in a bottoming organic Rankine cycle (ORC). Then, in the energy rejection section of ORC, a hot water unit (HWU) and an absorption chiller (ACH) were used for heating and refrigeration production. The maximum of tri-product layout was 74%. Hou et al. [26] recovered the unused heat of a biomass-fired SOFC layout to increase the performance of a double-flash geothermal system. Furthermore, an HWU and a humidification-dehumidification (HDH) desalination unit were utilized in the geothermal cycle. For the considered tri-product layout, the best and were 64.49% and USD 4.94/GJ. Bali et al. [27] recuperated the unused heat of a topping SOFC-GT system in an ORC and an HDH desalination unit. A portion of the electricity produced was utilized in a proton exchange membrane electrolyzer (PEME) to produce hydrogen. An optimization contributed to the best and of 48.69% and USD 43.98/h. You et al. [28] used an ORC, an ejector cooling system, and an HWU for waste heat elimination in a SOFC-GT system. Optimized and were estimated at 60.68% and USD 7.608/GJ, respectively. Vojdani et al. [29] suggested utilizing a couple tri-pressure level SRC and a multi-effect desalination layout for unused energy utilization of a SOFC-GT system. The optimization outputs revealed an and of 69.46% and USD 29.13/MWh for the combined layout. Ogorure et al. [30] utilized an SRC, an ACH, and an ORC for waste energy elimination of a biomass-fired SOFC-GT. The bottoming systems were fed with exhausted gas in a series configuration. Exergy efficiency and payback period were seen to be 58.46% and 7.5 years. Liang et al. [31] separated the exhausted gas of topping SOFC-GT topping system. One part fed a trans-critical CO2 Rankine cycle and an ORC in a series layout. The other part was sent to an HWU for hot water production. Furthermore, an LNG layout was added as a heat rejection medium in the Rankine cycle with a terminal chilled water heat exchanger. The exergy efficiency was obtained as 53.07%. Zhong et al. [32] used an SOFC system with an external reformer as the topping system. Then, a new CO2 SBC and an ejector refrigeration system were used as bottoming systems for waste heat recovery of the topping system. The best values for and were 63.77% and USD 36.37/GJ for the porposed power-cooling system. Mojaver et al. [33] proposed using coupled CO2 SBC/ORC and an HWU for the waste energy recovery of topping methane-fueled SOFC. Electrical exergy efficiency and the hot water mass were obtained as 43.01 and 2769 gr/s, respectively. Habibollahzadeh et al. [34] sent the waste energy of a biomass-fired SOFC to a Stirling engine. Then, the output power of the engine was consumed in a PEME for hydrogen outputs. Exergy efficiency and unit cost of the system were 38.03% and USD 24.93/GJ. Behzadi et al. [35] used a double-effect ACH for the waste energy recovery of a biomass-based SOFC and GT. Then, the output power of GT was transmitted to a reverse osmosis desalination unit (RODU) for the production of drinkable water. The biomass gasifier was the source of exergy destruction. Furthermore, and were 38.16% and USD 69.47/GJ at the optimum point. The waste heat from topping SOFC-GT was routed by Cao et al. [36] to an HWU and a bottoming recompression CO2 SBC. Additionally, an ACH and a thermoelectric generator (TEG) were included for the purpose of recovering waste energy from SBC. The TEG’s output power was then utilized in a PEME to produce hydrogen. According to the assessments in a basic case, the five subsystems that were used improved the system’s energy and exergy efficiencies by around 14.4% and 2.49 points, respectively, when compared to the combined solid oxide fuel cell and gas turbine system. Nonetheless, they accounted for 23.57% and 17.7% of the system’s overall cost rate and total energy destruction, respectively. Sadat et al. [37] used an ejector refrigeration system and an HWU to measure the waste energy consumption of a topping SOFC-GT. In order to convert to a multi-product system, a PEME used the GT’s output power. The system’s estimated and were 33.92% and USD 897.7/GJ, respectively. Li et al. [38] integrated a CO2 SBC and an ejector refrigeration system with a SOFC-GT topping for waste energy recovery. Furthermore, a humidification–dehumidification desalination system was used as a bottoming system for the SBC. The optimized and were 67.48% and USD 13.94/h.

The literature review makes it clear that some research has been performed on the SOFC-GT-Rankine cycle combination for only power generation. However, these existing systems exhibit key disadvantages such as limited waste heat recovery, single-purpose outputs, and suboptimal exergy efficiency. The present research aims to address these issues by converting the system into a high-performance multi-generation setup. Configuration 1 is composed of SOFC-GT-ORC, while Configuration 2 further recovers unused heat from Configuration 1, using residual exhaust gas for hot water production and embedding a TEG in the ORC heat rejection stage. This TEG-produced energy powers a PEME and a RODU, producing hydrogen and potable water. The benefits of this approach include enhanced waste heat recovery, increased exergy efficiency, and multi-generation capability, providing diverse and valuable outputs. The performance of SOFC-GT with these two configurations is compared using a base case study, parametric analysis, and design optimization. According to the literature, the performance comparison of SOFC-GT, SOFC-GT-ORC, and a multi-generation system based on waste heat energy recovery of SOFC-GT-ORC has not been studied yet. The present study aims to fill this research gap by providing a comprehensive 4E (energy, exergy, exergy-economic, and environmental) analysis and demonstrating the potential for improved overall system performance.

2. Methodology

2.1. Systems Description

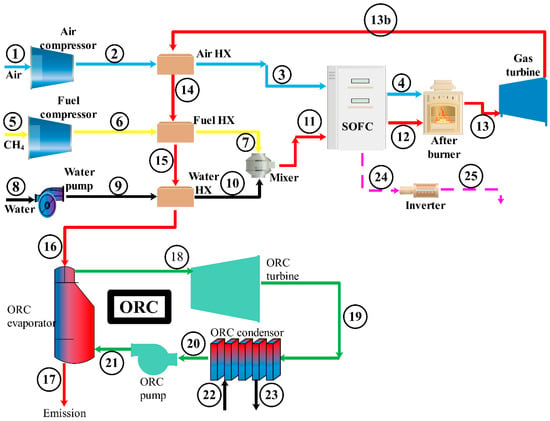

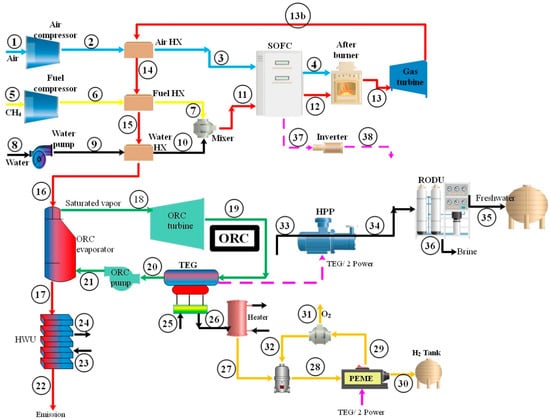

Schematic drawings of the recommended configurations are displayed in Figure 1 and Figure 2. A SOFC-GT powered by natural gas (NG) functions as a topping system in two different configurations. Under Configurations 1 and 2, the primary bottoming system was toluene ORC. Then, in Configuration 2, a TEG was used to generate extra power in the energy rejection stage of the ORC, and an HWU was used to recuperate the residual energy of exhaust gas to 70 °C (minimum temperature of exhausted gas) in hot water. While the output power of TEG was provided to PEME and RODU for the production of hydrogen and drinkable water, the output power of topping SOFC + GT was used to generate electricity through a generator. In order to obtain the desired operational pressure for the SOFC, the air (at Point 1) and methane (CH4) as a fuel source (at Point 5) within the subsystem of the SOFC were passed via compressors (an air compressor and a fuel compressor, respectively) under normal atmospheric circumstances. Similarly, a water pump was used at Point 8 to achieve the required water pressure. Three heat exchangers (HXs) were then used to raise the temperature of these flows to the SOFC’s intake temperature. These HXs removed heat from the exhaust gas that the heater of Turbine 1 produced. Subsequently, the fuel and water vapor were combined and introduced to the anode of the SOFC (at Point 11), where the internal reforming reaction took place. The air entered at Point 3 on the cathode side. Direct current (DC) electricity was produced in the SOFC by the electrochemical reaction of the air with the mixture mentioned before. The DC electricity generated at Point 24 was converted into AC power at Point 25 using an inverter. The remaining methane from the SOFC’s anode at Point 12 was sent into an afterburner (AB) in the exhaust stream. Following their exothermic reaction at Point 4, the fuel and air leaving the SOFC cathode enhanced the temperature of the outgoing stream at Point 13. After entering Turbine 1 to generate electricity, this high-temperature stream acted as a heat source for HXs in the exhaust stream that results. The heat source for bottoming subsystems was the water-based heat exchanger at Point 16, which kept the temperature of its exit gas elevated.

Figure 1.

The schematic diagrams of the combined SOFC-GT-ORC.

Figure 2.

The schematic diagrams of a multi-generation system based on the waste energy recovery combined SOFC-GT-ORC.

2.2. Mathematical Modeling

Using the relevant correlations in the Engineering Equation Solver (EES), the analysis of energy, exergy, exergy-economic, and environmental simulations (4E) pertaining to the previously described configurations has been carried out. A number of simplifying assumptions have been made for the simulation’s benefit, as listed below [36,39,40,41,42]:

- The conversion equations were presented in the context of steady-state modes.

- A three percent pressure drop was considered to exist in the SOFC, the AB of the SOFC system, and the subsystem HXs.

- All components, as well as the connecting pipes, were insulated.

- The observation has been made regarding the neglect of both the kinetic and potential elements in the energy and exergy equations.

- It was posited that the isentropic efficiencies of all turbomachines persisted unchanging throughout the course of the analysis.

- Correlations pertaining to ideal gas mixtures have been utilized to ascertain the properties of the aforementioned gas mixture.

- The assumed air composition was comprised of 21% O2 and 79% N2 on a volume basis.

- The minimum temperature of the SOFC exhaust gas was expected to be no less than 70 °C.

- The condition of organic fluid subsequent to the ORC evaporator was that of saturated vapor.

- The analysis of exergy was performed while keeping the reference state as the ambient condition.

Table 1 shows the basic equations for the simulation of SOFC, TEG, PEME, and RODU.

Table 1.

Fundamental correlations for a few configuration elements.

2.3. 4E Study

The analysis of energy, exergy, exergy-economic, and environmental simulations (4E) is related to using the pertinent correlations in the Engineering Equation Solver (EES) The formulas for the mass, energy, exergy, and exergy-economic simulations of complete configurations are included in this paper [49,50]:

Table 2 documents the explanation of fuel and product exergies and energy balance equations in various Configuration 2 apparatuses, in accordance with the reference mentioned in [41]. Furthermore, Table 3 presents the exergy-economic and supplementary correlations in tabular form for the different devices of Configuration 2. Additionally, Table 4 elaborates on the constituents’ principal purchase expenses. It should be noted that the cost information for equipment can vary significantly across different regions. This study has based the economic analysis on cost functions derived from multiple sources in the literature to ensure robustness and relevance. Specifically, it reviewed and cross-checked the cost data from at least three different references for each piece of equipment, although it only cited one representative reference per equipment for brevity. By utilizing these established cost functions from the literature, this study aimed to capture a more generalized and widely accepted economic perspective, which enhances the reliability of the economic parameters despite regional cost variations. This approach makes it possible to provide an economic analysis consistent with the methodologies used in related research.

Table 2.

Configuration 2 energy equations and fuel-product energy flows.

Table 3.

Formulary cost group for Configuration 2.

Table 4.

Purchase cost equations of Configuration 2.

2.4. Output Parameters

The following formulas were used to calculate the net output power and exergy efficiency:

The following formula determined both the price rate of the consumed NG and the price rate of the environment [58]:

Then, for exergy-economic evaluation, the unit cost of product (UCOP) was calculated as below:

2.5. Validation

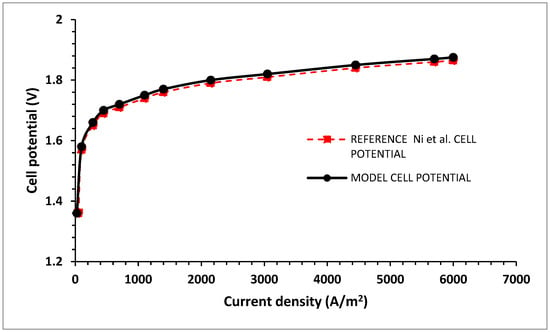

The entire investigation was simulated using the EES. In Table 5 and Table 6, respectively, the outcomes of the RODU and SOFC subsystem are first compared with earlier research. In addition, Figure 3 juxtaposes PEME’s cell potential-current density with a comparable study. With relatively small variations in the output settings, the simulation seems to be correct.

Table 5.

Verification of the system modeling for SOFC.

Table 5.

Verification of the system modeling for SOFC.

| Parameter | Result | Ref. [37] | Deviation (%) |

|---|---|---|---|

| 4.45 | 4.38 | +1.6 | |

| 220.6 | 233 | −5.3 | |

| 0.015 | 0.014 | +7.1 | |

| 435.1 | 437.5 | −0.5 |

Table 6.

Verification of the RODU model.

Table 6.

Verification of the RODU model.

| Variables | This Sutdy | Nemati et al. [59] | Nafey and Sharaf [60] |

|---|---|---|---|

| Input variables: | |||

| 485.9 | 485.9 | 485.9 | |

| SR | 0.994 | 0.994 | 0.994 |

| Output parameters: | |||

| 1126 | 1185 | 1131 | |

| 64.17 | 64.16 | 64.18 | |

| 0.27 | 0.252 | 0.25 | |

| 6843 | 6843 | 6850 |

Figure 3.

Comparing PEME’s cell potential-current density to that of Ni et al. [61].

3. Results and Discussion

3.1. Inputs for Baseline Conditions

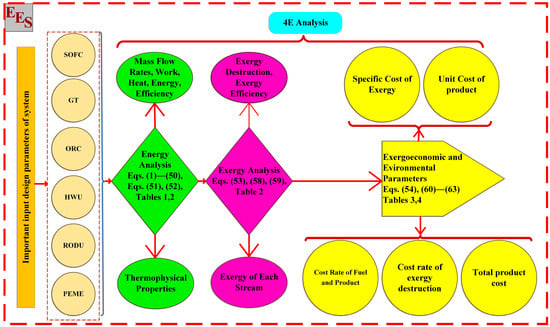

Table 7 lists the essential prerequisites needed to run the simulation, while Figure 4 outlines the complete process of simulation using EES software Version 11.644. As can be seen, the green section shows the energy model, the purple section shows the exergy model, and the yellow section is related to the cost analysis. For example, in the energy model section (green color), Equations (1)–(50), Equations (51) and (52), and Table 1 and Table 2 should be solved simultaneously as a group of equations for calculating mass flow rate, work, and heat transfer of different components of the system.

Table 7.

Data input for the initial state.

Figure 4.

The flow chart of the simulation in EES.

The significant results of the configurations taken into consideration in the base case are shown in Table 8. In both configurations, the generated electricity of the SOFC subsystem, GT, and ORC were 500 kW, 392.3 kW, and 25.85 kW, respectively. The waste heat elimination in Configuration 1 resulted in the output of 1.77 kW of extra power in the TEG and 42.67 kW of heating in the HWU. The TEG power could generate 0.054 kg/s potable water and 0.017 kg/h hydrogen in RODU and PEME. The exergy of fuel was equal to 1314 kW in both configurations, while the product exergy was higher in Configuration 2 (921.2 kW) in comparison with Configuration 1 (918.2 kW). The of Configuration 2 (346.1 kW) was higher than that of Configuration 1 (341.5 kW) because of more components, while the waste heat elimination of Configuration 1 considerably reduced (from 54.26 kW in Configuration 1 to 46.63 kW in Configuration 2), leading to a lower in Configuration 2. Furthermore, of Configuration 2 (70.11%) was higher than Configuration 1 (69.88%) because of more products and lower in the Configuration 2. The Configuration 2 (20.8 $/h) was considerably higher than that of Configuration 1 (USD 9.91/h). The main reason here is the investment cost of RODU, which comprised about 52.06% of the total investment cost of Configuration 2 in the base case condition. The of Configuration 2 (USD 19.41/h) was slightly higher than that of Configuration 1 (USD 19.11/h). The above-mentioned parameters conduced to a higher in Configuration 2, leading to a higher UCOP in Configuration 2 (USD 30.6/GJ) in comparison with Configuration 1 (USD 27.32/GJ).

Table 8.

The principal results of the design spanning multiple generations.

3.2. Sensitivity Analysis

This section looks into the effects of altering significant parameters on and UCOP. It is significant to observe that only the parameter under consideration changed within the targeted range; other values remained unchanged, as Table 8 shows.

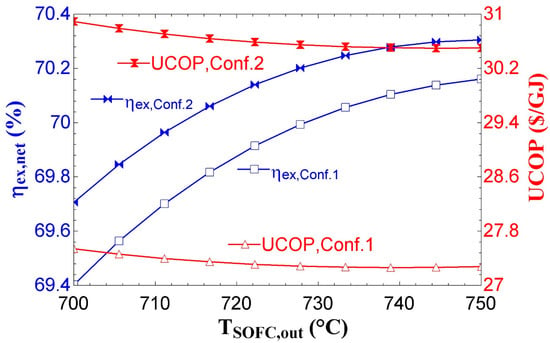

Figure 5 shows the impact of changing the TSOFC from 700 °C to 750 °C on the system’s performance. An upsurge in the outlet temperature of SOFC led to a considerable drop in the input power of the air compressor, bringing about an increase in SOFC subsystem output power. Despite a rise in inlet temperature, a drop in GT passing gas stream conduced to a dip in its generated power. Then, in ORC, an increase in T16 was the primary cause of the ORC output power increase. Although the increased, an expansion in was the main cause for the enhancement of from 69.4% to 70.16%. An increase in and (due to a rise in input methane flow rate), along with an upsurge in and , led to a rise in . On the other hand, an upsurge in had a powerful effect, leading to a dip in the UCOP of Configuration 1 from USD 27.54/GJ to USD 27.28/GJ. In Configuration 2, a rise in TEG output power resulted in an augmentation in output hydrogen and freshwater. But a dip in and led to a dip in hot water production. In this case, the augmentation of the SOFC subsystem, ORC, and TEG contributed to an upsurge in from 69.71% to 70.31%. Then, remained relatively unchanged because of opposite trends in different components, but an ascent in brought about a fall in the UCOP of Configuration 2 from USD 30.89/GJ to USD 30.5/GJ.

Figure 5.

The effect of change in TSOFC,out on the exergy efficiency and UCOP of the two configurations.

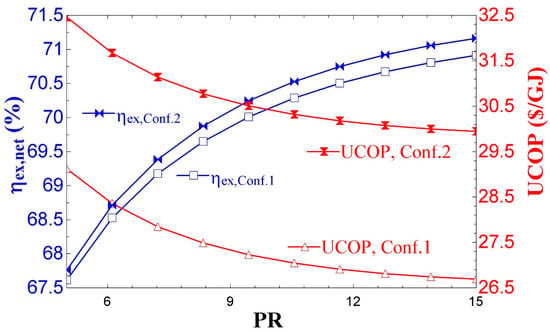

The impact of the pressure ratio (PR) in the SOFC subsystem, varying from 5 to 15, on the systems’ performance is demonstrated in Figure 6. The ORC output power decreased because of a drop in and , while this increase in PR brought about a rise in the SOFC subsystem and GT output power. In this case, the input (and fuel exergy of the system) remained unchanged, and of Configuration 1 increased from 67.61% to 70.91%. Regarding the cost rates, and increased and decreased, respectively. This contributed to a dip in , which, along with a rise in product exergy, led to a drop in UCOP Configuration 1 from USD 29.12/GJ to USD 26.69/GJ. In Configuration 2, a drop in TEG output power led to a dip in potable water and hydrogen mass flow rates, but an expansion in T17 was the main reason for the augmentation of output heating. Finally, of Configuration 2 increased from 67.76% to 71.17%. Moreover, a drop in coincided with a climb in , leading to a drop in the UCOP of Configuration 2 from USD 32.46/GJ to USD 29.95/GJ.

Figure 6.

The effect of change in the PR on the exergy efficiency and UCOP of the two configurations.

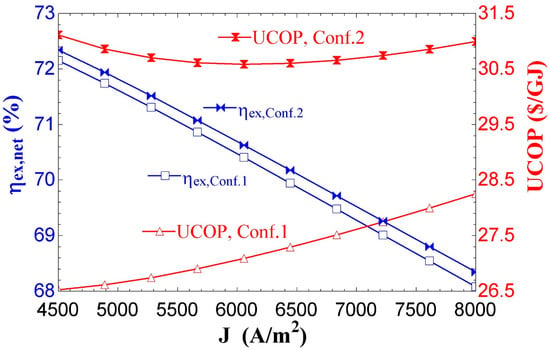

The impact of changes in the SOFC’s current density on the systems’ performance is shown in Figure 7. In Configuration 1, a rise in current density brought about an upsurge in SOFC subsystem, GT, and ORC output power, leading to a climb in . But a rise in the input resulted in a considerable upsurge in , bringing about a dip in of Configuration 1 from 72.15% to 68.08%. In this situation, all the cost rates in Configuration 1 increased, which, despite an ascent in the product exergy of the system, led to an enhancement in UCOP from USD 26.53/GJ to USD 28.25/GJ. In Configuration 2, a rise in TEG power led to a climb in potable water and hydrogen mass flow rates. Moreover, a climb in and was the main reason for the enhancement of hot output water. In this case, a rise in fuel methane exergy had a powerful effect, resulting in a dip in of Configuration 2 from 72.34% to 68.35%. Furthermore, the opposite trend of an increase in and in Configuration 2 led to a minimum value of USD 30.58/GJ for UCOP in the current density of 6056 A/m2.

Figure 7.

The effect of change in the current density of the SOFC on the exergy efficiency and UCOP of the two configurations.

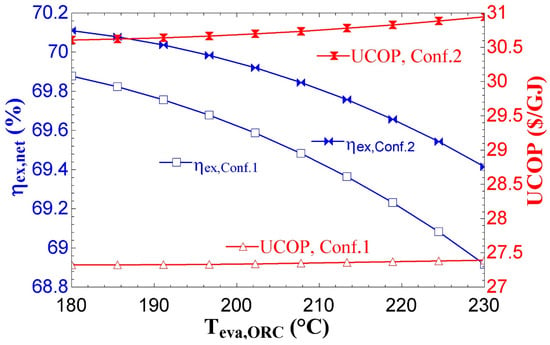

The impact of changing the ORC’s evaporator temperature from 180 °C to 230 °C on the systems’ performance is shown in Figure 8. In Configuration 1, this increase led to a drop in ORC passing stream and output power, resulting in a dip in from 69.88% to 68.92%. A reduction in ORC passing stream was the main reason for a decline in its cost rate and, consequently, . But in this situation, a drop in had a powerful effect, resulting in a negligible rise in the UCOP of Configuration 1 from USD 27.32/GJ to USD 27.39/GJ. In Configuration 2, a rise in evaporator temperature caused a dip in ORC and TEG output power. A drop in TEG power led to a drop in hydrogen and drinkable water outputs. Then, a rise in T17 brought about an expansion in output heating. Ultimately, a decrease in ORC and TEG power had a significant impact, which caused Configuration 2’s to drop from 70.11% to 69.41%. In this case, and dropped, resulting in remaining unchanged. But a dip in of Configuration 2 led to a rise in UCOP from USD 30.61/GJ to USD 30.95/GJ.

Figure 8.

The effect of change in evaporation temperature of the ORC on the exergy efficiency and UCOP of the two configurations.

3.3. The Best Performance Points of the Systems

The parametric analysis conducted in Section 3.2 reveals that the optimal thermo-economic performance of the configurations was attained when the input parameters were set at the values presented in Table 9. According to Formulas (58), (59) and (63), there was an opposite correlation between exergy efficiency and UCOP, and this is shown in Figure 5, Figure 6, Figure 7 and Figure 8. The main reason is that the exergy of a product is the numerator of the exergy efficiency formula and the denominator of the UCOP formula. However, given that the high value of exergy efficiency and the low value of UCOP are favorable factors, the mentioned opposite correlation does not appear as a conflict in multi-objective optimization. Hence, the values were selected based on the highest and the lowest UCOP. The direct search method in EES software was used for obtaining the best points. As and UCOP did not have any conflict in the parametric study, the best points for them were exactly the same. Hence, they were obtained using the direct search method in EES. As can be seen from Table 9, of SOFC-GT was 69.41% at the best performance point. It increased by 2.56% and 2.86% in Configurations 1 and 2, respectively. In addition, the UCOP of SOFC-GT was obtained as USD 26.53/GJ. It rose by 0.45% and 12.25% in Configurations 1 and 2, respectively. Here, Configuration 1 had an acceptable performance, with a 2.56% increase in and only a 0.45% increase in UCOP. But, in Configuration 2, a considerable increase in UCOP has occurred, mostly because of the high investment cost of RODU. In the best case, RODU made up 50.93% of . So, in Configuration 2, there was a trade-off between producing freshwater and the high investment cost of RODU.

Table 9.

The best performance points of configurations.

Table 10 gives the contribution of each subsystem to the energy destruction and cost rate of Configuration 2 in the optimal performance mode for a more precise evaluation of the subsystem’s performance in that configuration. As a result, the SOFC subsystem contributed most to and, consequently, to . The SOFC subsystem also comprised the second-highest proportion of . Regarding , in addition to the SOFC subsystem, only GT had a share of more than 5%, and other subsystems contributed less than 5% to . As far as is concerned, RODU had the highest contribution percentage. As mentioned, this was the main reason for the weak economic performance of Configuration 2. When it comes to , the SOFC subsystem had the highest proportion. After the SOFC subsystem, two subsystems, namely GT and ORC+TEG, contributed to this cost rate with a share of more than 5%.

Table 10.

Configuration 2′s energy destruction and cost rates for every subsystem.

At the end of the Results section, a comparison between the output indicators of Configuration 2 of the present study and some tri-generation multi-generation systems in the literature is illustrated in Table 11. As it can be seen, despite the complexity of Configuration 2 and its high investment cost, it had the highest value of exergy efficiency among the considered studies. On the other hand, the high cost associated with RODU was the main reason for the high unit cost of Configuration 2 in comparison with the previous studies.

Table 11.

Comparing the current study with a few SOFC-based systems.

4. Conclusions

Previous studies have mostly used GT+ORC for the high-temperature waste energy recovery of SOFC. This coupled SOFC-GT-ORC was known as Configuration 1 in the present study. However, there was a significant quantity of waste energy in this combined system, which was recovered in Configuration 2 by a TEG and an HWU. A RODU and a PEME were equipped with the TEG’s power output in order to produce freshwater and hydrogen, respectively, in order to meet human needs. The base case, the parametric study, and the optimal performance mode were used to compare the 4E performance of the suggested configurations. Among the significant findings of this study are the following:

- #

- In the base case mode and in Configurations 1 and 2, the power of SOFC sub, GT, and ORC was 500 kW, 392.3 kW, and 25.85 kW. The waste energy recovery of Configuration 1 resulted in an extra 1.77 kW of power in the TEG and 42.67 kW of heating in the HWU.

- #

- The exergy fuel was equal to 1314 kW in both layouts. The product exergy was 2 kW and 921.2 kW in Configurations 1 and 2. Because of the waste heat recovery in Configuration 2, in this configuration was lower than in Configuration 1, leading to lower in Configuration 2 and higher exergy efficiency.

- #

- Because there were more components in Configuration 2, its was considerably higher than that of Configuration 1, bringing about a higher and UCOP for Configuration 2. Furthermore, the fuel cost and environmental cost rate of the two configurations were the same at USD 55.24/h and USD 6.06/h, respectively.

- #

- In the parametric study, a rise in TSOFC,out and PR of the SOFC subsystem improved the performance of both systems, while a climb in current density and Teva,ORC negatively impacted the overall performance of the systems.

- #

- In the best performance mode, increased from 69.41% in SOFC-GT to 71.19% in Configuration 1 and 71.4% in Configuration 2, and UCOP increased from USD 26.53/GJ to USD 26.56/GJ in Configuration 1 and USD 29.78/GJ in Configuration 2. The economic performance of Configuration 1 was justifiable, while in Configuration 2, the high of RODU made a trade-off between the production of potable water and economic indicators.

- #

- In comparison with the previous studies, of Configuration 2 was competitive, but its UCOP was not good enough because of the high investment cost of some components of the system.

Finally, the limitations and future work suggestions of the present study are as follows:

Limitations:

- #

- High investment cost: Configuration 2 involved a significant initial investment, particularly due to the cost of integrating the RODU, which affected its economic competitiveness.

- #

- System complexity: The inclusion of additional components such as the TEG, HWU, PEME, and RODU increased the system’s complexity, potentially leading to higher maintenance and operational challenges.

- #

- Simulation-based data: The study’s findings are primarily based on simulation data, which may not fully capture real-world operational conditions and variances.

Future Work:

- #

- Experimental validation: Conduct real-world experiments and pilot studies to validate the simulated performance and economic assessments of the proposed configurations.

- #

- Cost optimization: Explore strategies to reduce the capital and operational costs of Configuration 2, particularly focusing on the cost-effective integration and operation of the RODU and PEME.

- #

- System optimization: Further optimize system parameters, such as the placement and operating conditions of the TEG and HWU, to enhance overall efficiency and economic performance.

Author Contributions

Methodology, M.Z.; Software, M.Z.; Validation, M.Z.; Formal analysis, M.Z.; Investigation, M.Z.; Writing—original draft, M.Z.; Writing—review & editing, N.H., S.G. and A.Z.; Supervision, N.H., S.G. and A.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Boretti, A. The Perspective of Fuel Cell High-Speed Powerboats. Energy Technol. 2023, 11, 2300442. [Google Scholar] [CrossRef]

- Zhao, F.; Mu, Z.; Hao, H.; Liu, Z.; He, X.; Victor Przesmitzki, S.; Ahmad Amer, A. Hydrogen fuel cell vehicle development in China: An industry chain perspective. Energy Technol. 2020, 8, 2000179. [Google Scholar] [CrossRef]

- Inci, M. Technoeconomic Analysis of Fuel Cell Vehicle-to-Grid (FCV2G) System Supported by Photovoltaic Energy. Energy Technol. 2023, 11, 2201162. [Google Scholar] [CrossRef]

- Elharati, M.A.; Dewa, M.; Bkour, Q.; Mohammed Hussain, A.; Miura, Y.; Dong, S.; Fukuyama, Y.; Dale, N.; Marin-Flores, O.G.; Ha, S. Internal reforming solid oxide fuel cell system operating under direct ethanol feed condition. Energy Technol. 2020, 8, 2000350. [Google Scholar] [CrossRef]

- Guan, X.; Jiang, J.; Lattimer, J.; Tsuchiya, M.; Friend, C.M.; Ramanathan, S. Hydride-Based Solid Oxide Fuel Cell–Battery Hybrid Electrochemical System. Energy Technol. 2017, 5, 616–622. [Google Scholar] [CrossRef]

- Lo Faro, M.; Oliveira, V.L.; Reis, R.M.; Saglietti, G.G.A.; Zignani, S.C.; Trocino, S.; Ticianelli, E.A.; Aricò, A.S. Solid Oxide Fuel Cell fed directly with dry glycerol. Energy Technol. 2019, 7, 45–47. [Google Scholar] [CrossRef]

- Wang, S.; Ma, J.; Li, W.; Khayatnezhad, M.; Rouyendegh, B.D. An optimal configuration for hybrid SOFC, gas turbine, and Proton Exchange Membrane Electrolyzer using a developed Aquila Optimizer. Int. J. Hydrogen Energy 2022, 47, 8943–8955. [Google Scholar] [CrossRef]

- Lim, T.H.; Song, R.H.; Shin, D.R.; Yang, J.I.; Jung, H.; Vinke, I.C.; Yang, S.S. Operating characteristics of a 5 kW class anode-supported planar SOFC stack for a fuel cell/gas turbine hybrid system. Int. J. Hydrogen Energy 2008, 33, 1076–1083. [Google Scholar]

- Behzadi, A.; Habibollahzade, A.; Arabkoohsar, A.; Shabani, B.; Fakhari, I.; Vojdani, M. 4E analysis of efficient waste heat recovery from SOFC using APC: An effort to reach maximum efficiency and minimum emission through an application of grey wolf optimization. Int. J. Hydrogen Energy 2021, 46, 23879–23897. [Google Scholar] [CrossRef]

- Hai, T.; El-Shafay, A.S.; Alizadeh, A.A.; Almojil, S.F.; Almohana, A.I.; Alali, A.F. Employing a booster/ejector-assisted organic flash cycle to heat recovery of SOFC system; Exergy-and economic-based optimization. Int. J. Hydrogen Energy 2023, 48, 18433–18453. [Google Scholar] [CrossRef]

- Yan, Z.; Zhao, P.; Wang, J.; Dai, Y. Thermodynamic analysis of an SOFC–GT–ORC integrated power system with liquefied natural gas as heat sink. Int. J. Hydrogen Energy 2013, 38, 3352–3363. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Moradpoor, I. Combined solid oxide fuel cell, micro-gas turbine and organic Rankine cycle for power generation (SOFC–MGT–ORC). Energy Convers. Manag. 2016, 116, 120–133. [Google Scholar] [CrossRef]

- Ghaffarpour, Z.; Mahmoudi, M.; Mosaffa, A.H.; Farshi, L.G. Thermoeconomic assessment of a novel integrated biomass based power generation system including gas turbine cycle, solid oxide fuel cell and Rankine cycle. Energy Convers. Manag. 2018, 161, 1–12. [Google Scholar] [CrossRef]

- Singh, R.; Singh, O. Comparative study of combined solid oxide fuel cell-gas turbine-Organic Rankine cycle for different working fluid in bottoming cycle. Energy Convers. Manag. 2018, 171, 659–670. [Google Scholar] [CrossRef]

- Karimi, M.H.; Chitgar, N.; Emadi, M.A.; Ahmadi, P.; Rosen, M.A. Performance assessment and optimization of a biomass-based solid oxide fuel cell and micro gas turbine system integrated with an organic Rankine cycle. Int. J. Hydrogen Energy 2020, 45, 6262–6277. [Google Scholar] [CrossRef]

- Emadi, M.A.; Chitgar, N.; Oyewunmi, O.A.; Markides, C.N. Working-fluid selection and thermoeconomic optimisation of a combined cycle cogeneration dual-loop organic Rankine cycle (ORC) system for solid oxide fuel cell (SOFC) waste-heat recovery. Appl. Energy 2020, 261, 114384. [Google Scholar] [CrossRef]

- Cheng, C.; Cherian, J.; Sial, M.S.; Zaman, U.; Niroumandi, H. Performance assessment of a novel biomass-based solid oxide fuel cell power generation cycle; Economic analysis and optimization. Energy 2021, 224, 120134. [Google Scholar] [CrossRef]

- Gholamian, E.; Zare, V. A comparative thermodynamic investigation with environmental analysis of SOFC waste heat to power conversion employing Kalina and Organic Rankine Cycles. Energy Convers. Manag. 2016, 117, 150–161. [Google Scholar] [CrossRef]

- Ouyang, T.; Zhao, Z.; Su, Z.; Lu, J.; Wang, Z.; Huang, H. An integrated solution to harvest the waste heat from a large marine solid oxide fuel cell. Energy Convers. Manag. 2020, 223, 113318. [Google Scholar] [CrossRef]

- Pirkandi, J.; Penhani, H.; Maroufi, A. Thermodynamic analysis of the performance of a hybrid system consisting of steam turbine, gas turbine and solid oxide fuel cell (SOFC-GT-ST). Energy Convers. Manag. 2020, 213, 112816. [Google Scholar] [CrossRef]

- Roy, D.; Samanta, S.; Ghosh, S. Techno-economic and environmental analyses of a biomass based system employing solid oxide fuel cell, externally fired gas turbine and organic Rankine cycle. J. Clean. Prod. 2019, 225, 36–57. [Google Scholar] [CrossRef]

- Pan, M.; Zhang, K.; Li, X. Optimization of supercritical carbon dioxide based combined cycles for solid oxide fuel cell-gas turbine system: Energy, exergy, environmental and economic analyses. Energy Convers. Manag. 2021, 248, 114774. [Google Scholar] [CrossRef]

- Ran, P.; Zhou, X.; Wang, Y.; Fan, Q.; Xin, D.; Li, Z. Thermodynamic and exergetic analysis of a novel multi-generation system based on SOFC, micro-gas turbine, s-CO2 and lithium bromide absorption refrigerator. Appl. Therm. Eng. 2023, 219, 119585. [Google Scholar] [CrossRef]

- Liu, Y.; Han, J.; You, H. Exergoeconomic analysis and multi-objective optimization of a CCHP system based on SOFC/GT and transcritical CO2 power/refrigeration cycles. Appl. Therm. Eng. 2023, 230, 120686. [Google Scholar] [CrossRef]

- Al-Sulaiman, F.A.; Dincer, I.; Hamdullahpur, F. Energy analysis of a trigeneration plant based on solid oxide fuel cell and organic Rankine cycle. Int. J. Hydrogen Energy 2010, 35, 5104–5113. [Google Scholar] [CrossRef]

- Hou, R.; Zhang, N.; Gao, W.; Chen, K.; Liu, Y. Thermodynamic, environmental, and exergoeconomic feasibility analyses and optimization of biomass gasifier-solid oxide fuel cell boosting a doable-flash binary geothermal cycle; a novel trigeneration plant. Energy 2023, 265, 126316. [Google Scholar] [CrossRef]

- Balali, A.; Asadabadi, M.J.R.; Moghimi, M. 4E assessment and neural network optimization of a solid oxide fuel cell-based plant with anode and cathode recycling for electricity, freshwater, and hydrogen production. Process Saf. Environ. Prot. 2023, 177, 95–117. [Google Scholar] [CrossRef]

- You, H.; Xiao, Y.; Han, J.; Lysyakov, A.; Chen, D. Thermodynamic, exergoeconomic and exergoenvironmental analyses and optimization of a solid oxide fuel cell-based trigeneration system. Int. J. Hydrogen Energy 2023, 48, 25918–25938. [Google Scholar] [CrossRef]

- Vojdani, M.; Fakhari, I.; Ahmadi, P. A novel triple pressure HRSG integrated with MED/SOFC/GT for cogeneration of electricity and freshwater: Techno-economic-environmental assessment, and multi-objective optimization. Energy Convers. Manag. 2021, 233, 113876. [Google Scholar] [CrossRef]

- Ogorure, O.J.; Oko, C.O.C.; Diemuodeke, E.O.; Owebor, K. Energy, exergy, environmental and economic analysis of an agricultural waste-to-energy integrated multigeneration thermal power plant. Energy Convers. Manag. 2018, 171, 222–240. [Google Scholar] [CrossRef]

- Liang, W.; Yu, Z.; Bai, S.; Li, G.; Wang, D. Study on a near-zero emission SOFC-based multi-generation system combined with organic Rankine cycle and transcritical CO2 cycle for LNG cold energy recovery. Energy Convers. Manag. 2022, 253, 115188. [Google Scholar] [CrossRef]

- Zhong, L.; Yao, E.; Zou, H.; Xi, G. Thermo-economic-environmental analysis of an innovative combined cooling and power system integrating Solid Oxide Fuel Cell, Supercritical CO2 cycle, and ejector refrigeration cycle. Sustain. Energy Technol. Assess. 2021, 47, 101517. [Google Scholar] [CrossRef]

- Mojaver, P.; Abbasalizadeh, M.; Khalilarya, S.; Chitsaz, A. Co-generation of electricity and heating using a SOFC-ScCO2 Brayton cycle-ORC integrated plant: Investigation and multi-objective optimization. Int. J. Hydrogen Energy 2020, 45, 27713–27729. [Google Scholar] [CrossRef]

- Habibollahzade, A.; Gholamian, E.; Houshfar, E.; Behzadi, A. Multi-objective optimization of biomass-based solid oxide fuel cell integrated with Stirling engine and electrolyzer. Energy Convers. Manag. 2018, 171, 1116–1133. [Google Scholar] [CrossRef]

- Behzadi, A.; Habibollahzade, A.; Zare, V.; Ashjaee, M. Multi-objective optimization of a hybrid biomass-based SOFC/GT/double effect absorption chiller/RO desalination system with CO2 recycle. Energy Convers. Manag. 2019, 181, 302–318. [Google Scholar] [CrossRef]

- Cao, Y.; Zoghi, M.; Habibi, H.; Raise, A. Waste heat recovery of a combined solid oxide fuel cell-gas turbine system for multi-generation purposes. Appl. Therm. Eng. 2021, 198, 117463. [Google Scholar] [CrossRef]

- Sadat, S.M.S.; Ghaebi, H.; Lavasani, A.M. 4E analyses of an innovative polygeneration system based on SOFC. Renew. Energy 2020, 156, 986–1007. [Google Scholar] [CrossRef]

- Liu, C.; Han, J.; Liang, W.; Ge, Y.; Zhu, W.; Yang, J.; Mou, C.; Lv, W. Performance analysis and multi-objective optimization of a novel poly-generation system integrating SOFC/GT with SCO2/HDH/ERC. Appl. Therm. Eng. 2024, 238, 122075. [Google Scholar] [CrossRef]

- Chitsaz, A.; Mahmoudi, S.M.S.; Rosen, M.A. Greenhouse gas emission and exergy analyses of an integrated trigeneration system driven by a solid oxide fuel cell. Appl. Therm. Eng. 2015, 86, 81–90. [Google Scholar] [CrossRef]

- Khan, M.N.; Zoghi, M.; Habibi, H.; Zanj, A.; Anqi, A.E. Waste heat recovery of two solar-driven supercritical CO2 Brayton cycles: Exergoeconomic analysis, comparative study, and monthly performance. Appl. Therm. Eng. 2022, 214, 118837. [Google Scholar] [CrossRef]

- Chen, Y.; Feng, L.; Li, X.; Zoghi, M.; Javaherdeh, K. Exergy-economic analysis and multi-objective optimization of a multi-generation system based on efficient waste heat recovery of combined wind turbine and compressed CO2 energy storage system. Sustain. Cities Soc. 2023, 96, 104714. [Google Scholar] [CrossRef]

- Yousuf, M.U.; Abbasi, M.A.; Kashif, M.; Umair, M. Energy, exergy, economic, environmental, energoeconomic, exergoeconomic, and enviroeconomic (7E) analyses of wind farms: A case study of Pakistan. Environ. Sci. Pollut. Res. 2022, 29, 67301–67324. [Google Scholar] [CrossRef] [PubMed]

- Hai, T.; Zoghi, M.; Abed, H.; Chauhan, B.S.; Ahmed, A.N. Exergy-economic study and multi-objective optimization of a geothermal-based combined organic flash cycle and PEMFC for poly-generation purpose. Energy 2023, 268, 126607. [Google Scholar] [CrossRef]

- Hai, T.; Zoghi, M.; Javaherdeh, K. 4E analysis and optimization of a biomass-fired waste-to-energy plant integrated with a compressed air energy storage system for the multi-generation purpose. Fuel 2023, 348, 128457. [Google Scholar] [CrossRef]

- Zoghi, M.; Habibi, H.; Chitsaz, A.; Holagh, S.G. Multi-criteria analysis of a novel biomass-driven multi-generation system including combined cycle power plant integrated with a modified Kalina-LNG subsystem employing thermoelectric generator and PEM electrolyzer. Therm. Sci. Eng. Prog. 2021, 26, 101092. [Google Scholar] [CrossRef]

- Cao, Y.; Habibi, H.; Zoghi, M.; Raise, A. Waste heat recovery of a combined regenerative gas turbine-recompression supercritical CO2 Brayton cycle driven by a hybrid solar-biomass heat source for multi-generation purpose: 4E analysis and parametric study. Energy 2021, 236, 121432. [Google Scholar] [CrossRef]

- Hai, T.; El-Shafay, A.S.; Alizadeh, A.A.; Chauhan, B.S.; Almojil, S.F.; Almohana, A.I.; Alali, A.F. Combination of a geothermal-driven double-flash cycle and a Kalina cycle to devise a polygeneration system: Environmental assessment and optimization. Appl. Therm. Eng. 2023, 228, 120437. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, H.; Zoghi, M.; Habibi, H. Comparison between biogas and pure methane as the fuel of a polygeneration system including a regenerative gas turbine cycle and partial cooling supercritical CO2 Brayton cycle: 4E analysis and tri-objective optimization. Energy 2022, 257, 124695. [Google Scholar] [CrossRef]

- Hassan, H.; Yousef, M.S.; Fathy, M. Productivity, exergy, exergoeconomic, and enviroeconomic assessment of hybrid solar distiller using direct salty water heating. Environ. Sci. Pollut. Res. 2021, 28, 5482–5494. [Google Scholar] [CrossRef]

- Azari, P.; Mirabdolah Lavasani, A.; Rahbar, N.; Eftekhari Yazdi, M. Performance enhancement of a solar still using a V-groove solar air collector—Experimental study with energy, exergy, enviroeconomic, and exergoeconomic analysis. Environ. Sci. Pollut. Res. 2021, 28, 65525–65548. [Google Scholar] [CrossRef]

- Mehr, A.S.; Mahmoudi, S.M.S.; Yari, M.; Chitsaz, A. Thermodynamic and exergoeconomic analysis of biogas fed solid oxide fuel cell power plants emphasizing on anode and cathode recycling: A comparative study. Energy Convers. Manag. 2015, 105, 596–606. [Google Scholar] [CrossRef]

- Zoghi, M.; Habibi, H.; Chitsaz, A.; Ayazpour, M. Multi-criteria performance comparison between a novel and two conventional configurations of natural gas–driven combined cycle power plant based on a hybrid multi-objective optimization. Therm. Sci. Eng. Prog. 2020, 19, 100597. [Google Scholar] [CrossRef]

- Sadeghi, M.; Chitsaz, A.; Mahmoudi, S.M.S.; Rosen, M.A. Thermoeconomic optimization using an evolutionary algorithm of a trigeneration system driven by a solid oxide fuel cell. Energy 2015, 89, 191–204. [Google Scholar] [CrossRef]

- Zoghi, M.; Habibi, H.; Chitsaz, A.; Ayazpour, M.; Mojaver, P. Thermo-economic assessment of a novel trigeneration system based on coupling of organic Rankine cycle and absorption-compression cooling and power system for waste heat recovery. Energy Convers. Manag. 2019, 196, 567–580. [Google Scholar] [CrossRef]

- Zhou, J.; Hai, T.; Ali, M.A.; Shamseldin, M.A.; Almojil, S.F.; Almohana, A.I.; Alali, A.F. Waste heat recovery of a wind turbine for poly-generation purpose: Feasibility analysis, environmental impact assessment, and parametric optimization. Energy 2023, 263, 125891. [Google Scholar] [CrossRef]

- Zhou, Z.; Cao, Y.; Anqi, A.E.; Zoghi, M.; Habibi, H.; Rajhi, A.A.; Alamri, S. Converting a geothermal-driven steam flash cycle into a high-performance polygeneration system by waste heat recovery: 3E analysis and Genetic-Fgoalattain optimization. Renew. Energy 2022, 186, 609–627. [Google Scholar] [CrossRef]

- Wang, D.; Dhahad, H.A.; Ali, M.A.; Almojil, S.F.; Almohana, A.I.; Alali, A.F.; Alyousuf, F.Q.A.; Almoalimi, K.T. Environmental/Economic assessment and multi-aspect optimization of a poly-generation system based on waste heat recovery of PEM fuel cells. Appl. Therm. Eng. 2023, 223, 119946. [Google Scholar] [CrossRef]

- Zoghi, M.; Habibi, H.; Chitsaz, A.; Shamsaiee, M. Exergoeconomic and environmental analyses of a novel trigeneration system based on combined gas turbine-air bottoming cycle with hybridization of solar power tower and natural gas combustion. Appl. Therm. Eng. 2021, 188, 116610. [Google Scholar] [CrossRef]

- Nemati, A.; Sadeghi, M.; Yari, M. Exergoeconomic analysis and multi-objective optimization of a marine engine waste heat driven RO desalination system integrated with an organic Rankine cycle using zeotropic working fluid. Desalination 2017, 422, 113–123. [Google Scholar] [CrossRef]

- Nafey, A.S.; Sharaf, M.A. Combined solar organic Rankine cycle with reverse osmosis desalination process: Energy, exergy, and cost evaluations. Renew. Energy 2010, 35, 2571–2580. [Google Scholar] [CrossRef]

- Ni, M.; Leung, M.K.H.; Leung, D.Y.C. Energy and exergy analysis of hydrogen production by a proton exchange membrane (PEM) electrolyzer plant. Energy Convers. Manag. 2008, 49, 2748–2756. [Google Scholar] [CrossRef]

- Habibi, H.; Zoghi, M.; Chitsaz, A.; Javaherdeh, K.; Ayazpour, M. Thermo-economic analysis and optimization of combined PERC-ORC-LNG power system for diesel engine waste heat recovery. Energy Convers. Manag. 2018, 173, 613–625. [Google Scholar] [CrossRef]

- Habibi, H.; Zoghi, M.; Chitsaz, A.; Javaherdeh, K.; Ayazpour, M. Thermo-economic performance comparison of two configurations of combined steam and organic Rankine cycle with steam Rankine cycle driven by Al2O3-therminol VP-1 based PTSC. Sol. Energy 2019, 180, 116–132. [Google Scholar] [CrossRef]

- Zare, V.; Palideh, V. Employing thermoelectric generator for power generation enhancement in a Kalina cycle driven by low-grade geothermal energy. Appl. Therm. Eng. 2018, 130, 418–428. [Google Scholar] [CrossRef]

- Tohidi, F.; Holagh, S.G.; Chitsaz, A. Thermoelectric Generators: A comprehensive review of characteristics and applications. Appl. Therm. Eng. 2022, 201, 117793. [Google Scholar] [CrossRef]

- Tukenmez, N.; Yilmaz, F.; Ozturk, M. Parametric analysis of a solar energy based multigeneration plant with SOFC for hydrogen generation. Int. J. Hydrogen Energy 2022, 47, 3266–3283. [Google Scholar] [CrossRef]

- Gholamian, E.; Zare, V.; Mousavi, S.M. Integration of biomass gasification with a solid oxide fuel cell in a combined cooling, heating and power system: A thermodynamic and environmental analysis. Int. J. Hydrogen Energy 2016, 41, 20396–20406. [Google Scholar] [CrossRef]

- Chitgar, N.; Emadi, M.A. Development and exergoeconomic evaluation of a SOFC-GT driven multi-generation system to supply residential demands: Electricity, fresh water and hydrogen. Int. J. Hydrogen Energy 2021, 46, 17932–17954. [Google Scholar] [CrossRef]

- Ghaebi, H.; Ahmadi, S. Energy and exergy evaluation of an innovative hybrid system coupled with HRSG and HDH desalination units. J. Clean. Prod. 2020, 252, 119821. [Google Scholar] [CrossRef]

- Chitgar, N.; Moghimi, M. Design and evaluation of a novel multi-generation system based on SOFC-GT for electricity, fresh water and hydrogen production. Energy 2020, 197, 117162. [Google Scholar] [CrossRef]

- You, H.; Han, J.; Liu, Y.; Chen, C.; Ge, Y. 4E analysis and multi-objective optimization of a micro poly-generation system based on SOFC/MGT/MED and organic steam ejector refrigerator. Energy 2020, 206, 118122. [Google Scholar] [CrossRef]

- Haghghi, M.A.; Holagh, S.G.; Chitsaz, A.; Parham, K. Thermodynamic assessment of a novel multi-generation solid oxide fuel cell-based system for production of electrical power, cooling, fresh water, and hydrogen. Energy Convers. Manag. 2019, 197, 111895. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).