Technical Implications of the Use of Biofuels in Agricultural and Industrial Compression-Ignition Engines with a Special Focus on the Interactions with (Bio)lubricants

Abstract

1. Introduction

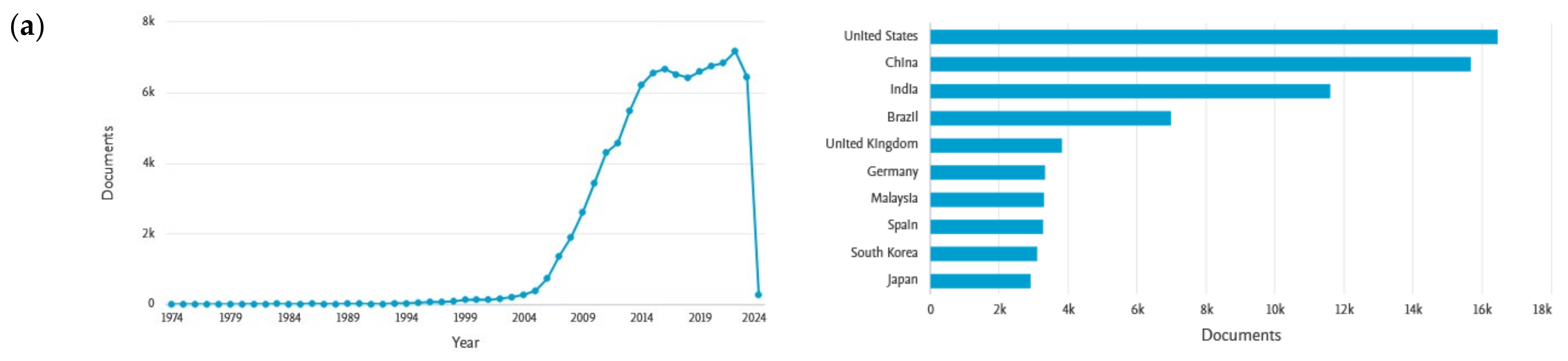

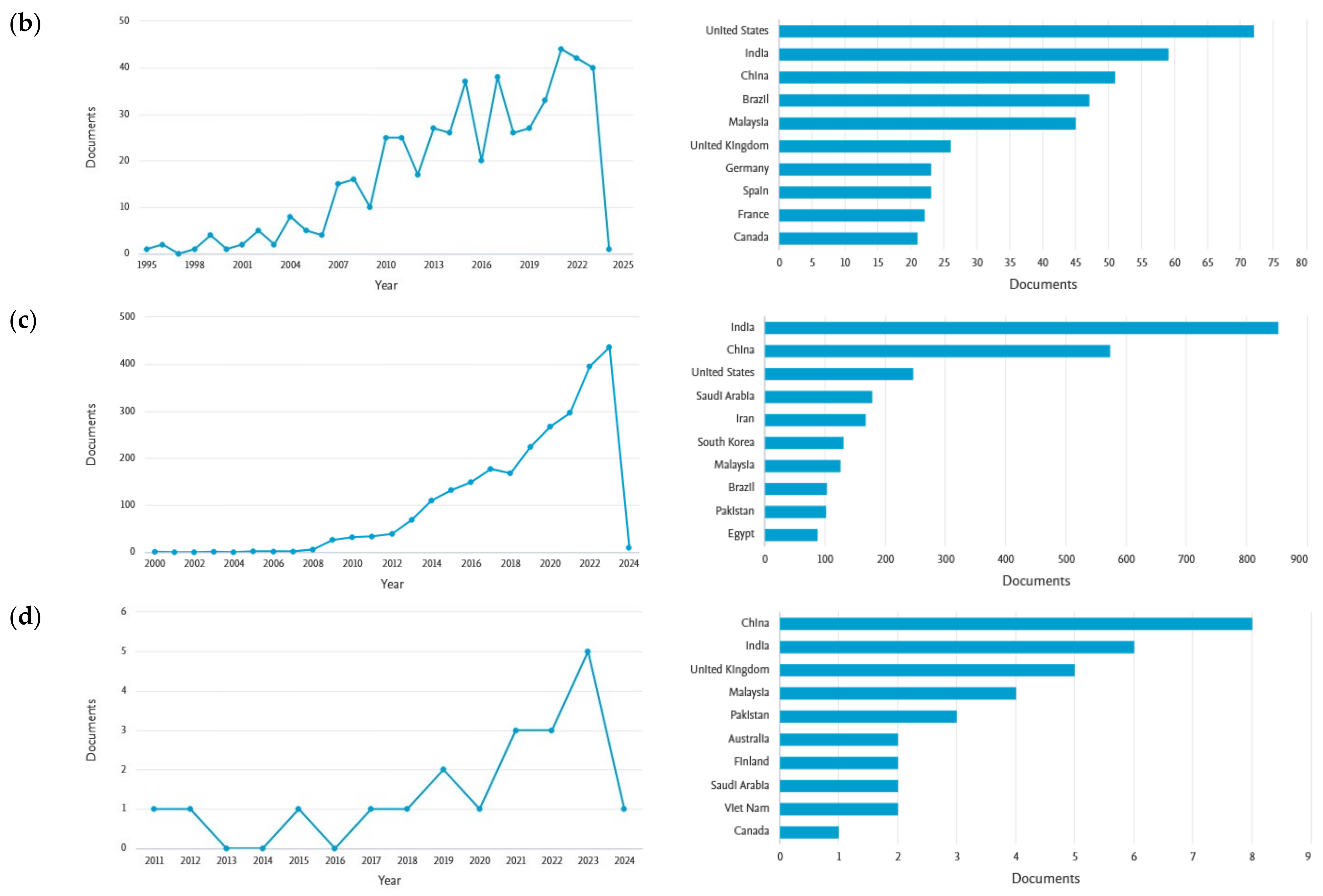

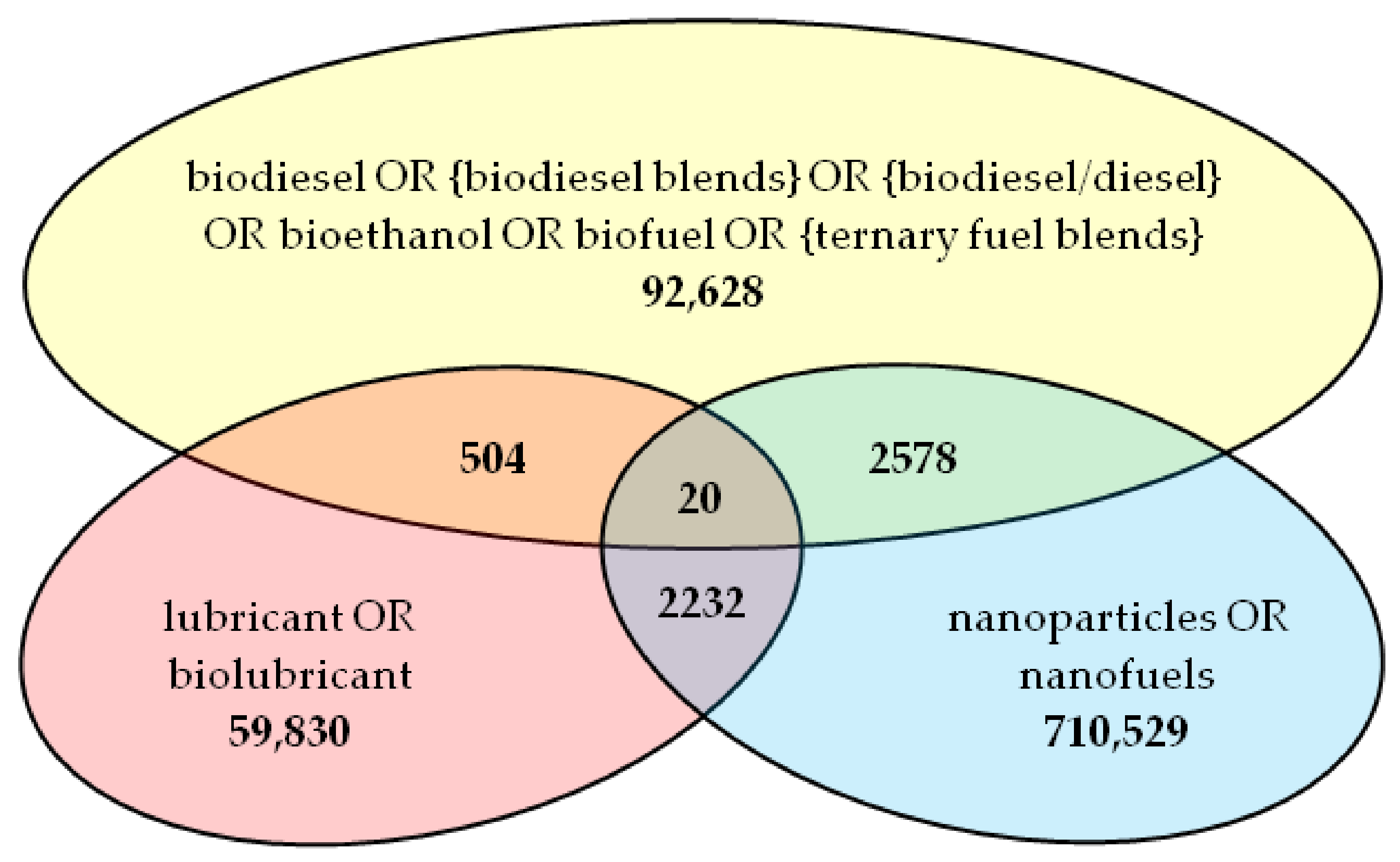

2. Global Trends in Scientific Publications on Biofuels

- (a)

- biodiesel OR {biodiesel blends} OR {biodiesel/diesel} OR bioethanol OR biofuel OR {ternary fuel blends}, obtaining 92,628 articles in the period 1974–2024 (i.e., 51 years);

- (b)

- (lubricant OR biolubricant) AND (biodiesel OR {biodiesel blends} OR {biodiesel/diesel} OR bioethanol OR biofuel OR {ternary fuel blends}), obtaining 504 articles in the period 1995–2024 (i.e., 30 years);

- (c)

- (nanoparticles OR nanofuels) AND (biodiesel OR {biodiesel blends} OR {biodiesel/diesel} OR bioethanol OR biofuel OR {ternary fuel blends}), obtaining 2578 articles in the period 2000–2024 (i.e., 25 years);

- (d)

- (lubricant OR biolubricant) AND (nanoparticles OR nanofuels) AND (biodiesel OR {biodiesel blends} OR {biodiesel/diesel} OR bioethanol OR biofuel OR {ternary fuel blends}), obtaining 20 articles in the period 2011–2024 (i.e., 14 years).

3. Why Biofuels Are Used in Agricultural and Industrial Heavy-Duty Engines

- By employing more renewable fuels produced locally, concerns about the dependency on fossil fuels may be allayed [17].

- It is possible to enhance the energy and environmental performance of the ICE, due to some superior physical and chemical characteristics of alternative fuels as compared to fossil fuels [1,18,19]. Notwithstanding some fossil fuels (e.g., diesel fuel) have a higher lower heating value than biodiesel and vegetable oil, this metric alone does not capture the full advantages brought by biofuels to engine performance and environmental impact. Biofuels, such as biodiesel, indeed, offer several advantages, including renewability, biodegradability, and lower emissions of greenhouse gases during combustion. These attributes contribute to a reduced environmental footprint and increased energy security, which are critical considerations in the transition towards sustainable energy sources.

- Biodiesel and alcohols have higher oxygen content compared to diesel fuel. This characteristic ensures the promotion of complete combustion [20]. Unfortunately, this characteristic can also result in the faster degradation of some properties of lubricant and materials coming into contact with biofuels, due to an increased solvency characteristic of higher blending rates. The search for a trade-off highlights the need for ongoing research to optimize biofuel formulations and engine designs to mitigate these effects.

- The maximum heat release rate (HRR) is kind of lower for biodiesel–diesel–ethanol blends and rises with the ethanol proportion in diesel–ethanol blends [1]. In diesel–ethanol blends, the ignition delay rises as the ethanol proportion rises, while it falls marginally in biodiesel–diesel–ethanol blends or when a cetane number (CN) improver is added [21,22,23]. In blends of diesel fuel and ethanol, cylinder pressure rises with increasing ethanol content, whereas it either slightly falls or remains similar in blends of biodiesel and diesel with ethanol [24,25].

- In terms of engine performance, when compared to the use of fossil (diesel) fuel, the brake-specific fuel consumption is greater in all the investigated circumstances; the brake thermal efficiency increases or is comparable; and the expressed power is very similar to or slightly lower. Some changes in exhaust gas temperatures were noted; the indicated mean effective pressure also shows minor variations or decreases when fuel blends contain more than 35% ethanol [1,4,23,24,25].

- Due to the increased demand for diesel fuel, renewable biodiesel from affordable sources, which can supply the need, is required. Realistically, the use of sustainable biodiesel in large quantities may immediately enhance engine performance and emission characteristics [26].

- The use of biodiesel in diesel engines reduces GHG emissions, and more reductions are possible with the anticipated growth in biodiesel production and fuel consumption [27].

3.1. Classification of Liquid Biofuels Used in Agricultural and Industrial Heavy-Duty Engines

3.1.1. Biodiesel, First-Generation Biofuels

3.1.2. Alcohols Methanol, Ethanol, Butanol

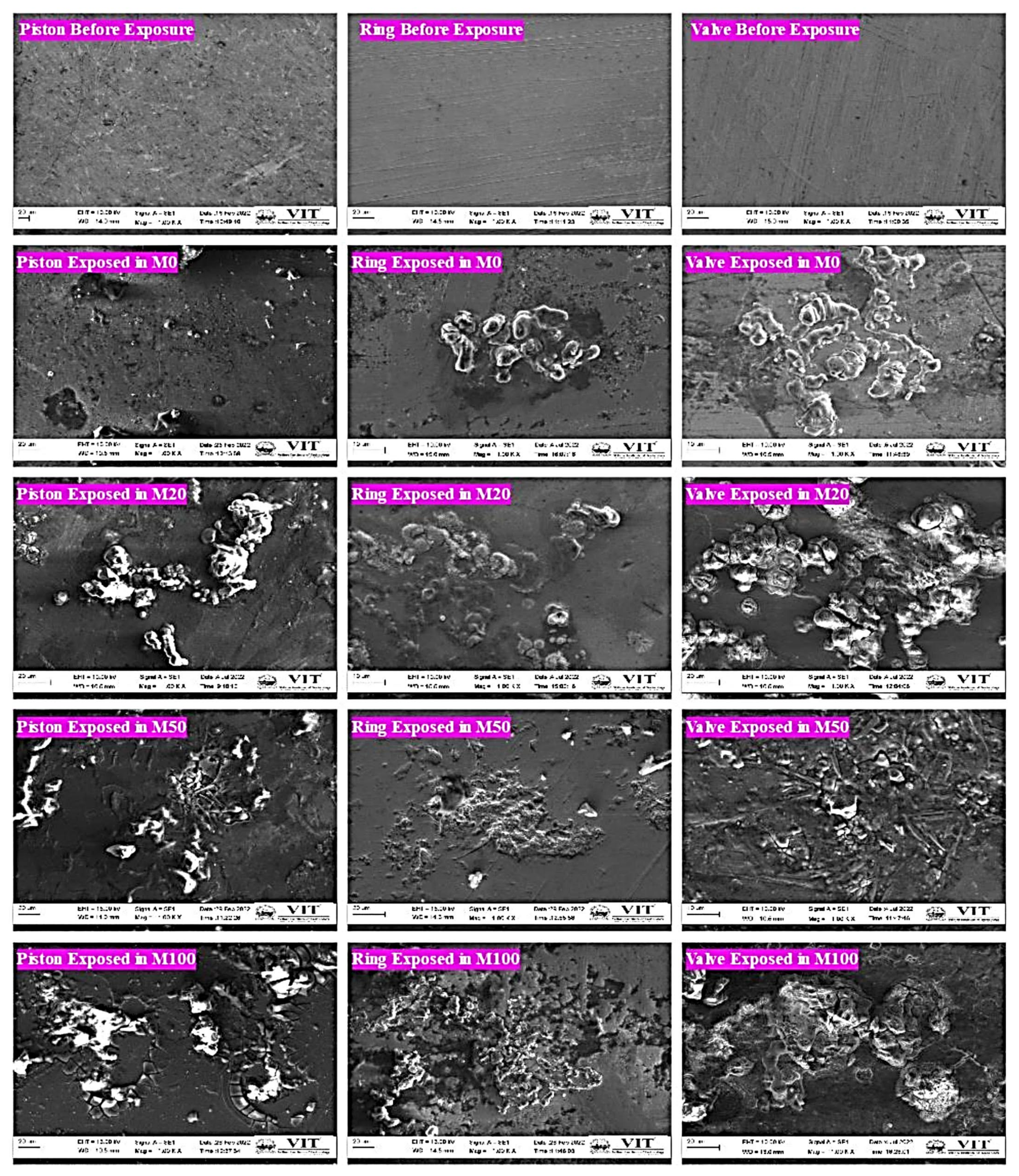

- Strong corrosive effect on metal parts: Figure 4 summarizes the scanning electron microscopy (SEM) images taken of the engine components’ surfaces before and after they were exposed to fuel samples for 180 days. The photographs demonstrate that the polished surface of the pistons has less corrosion damage than the surface exposed to fuel samples [57].

- Reduction in HC and CO exhaust, while NOx emission and formaldehyde formation increase 5 times (when using M85 fuel) [44].

- Because of its propensity to react with water and separate from petrol, it results in a heterogeneous combination.

- Higher cetane number;

- Lower corrosion;

- Lower ignition temperature;

- Lower evaporation enthalpy [61].

3.2. The Main Fluid Dynamic and Thermodynamic Properties of Fuels for ICEs

4. Lubrication and Complications of Interaction of Biofuels with Lubricants

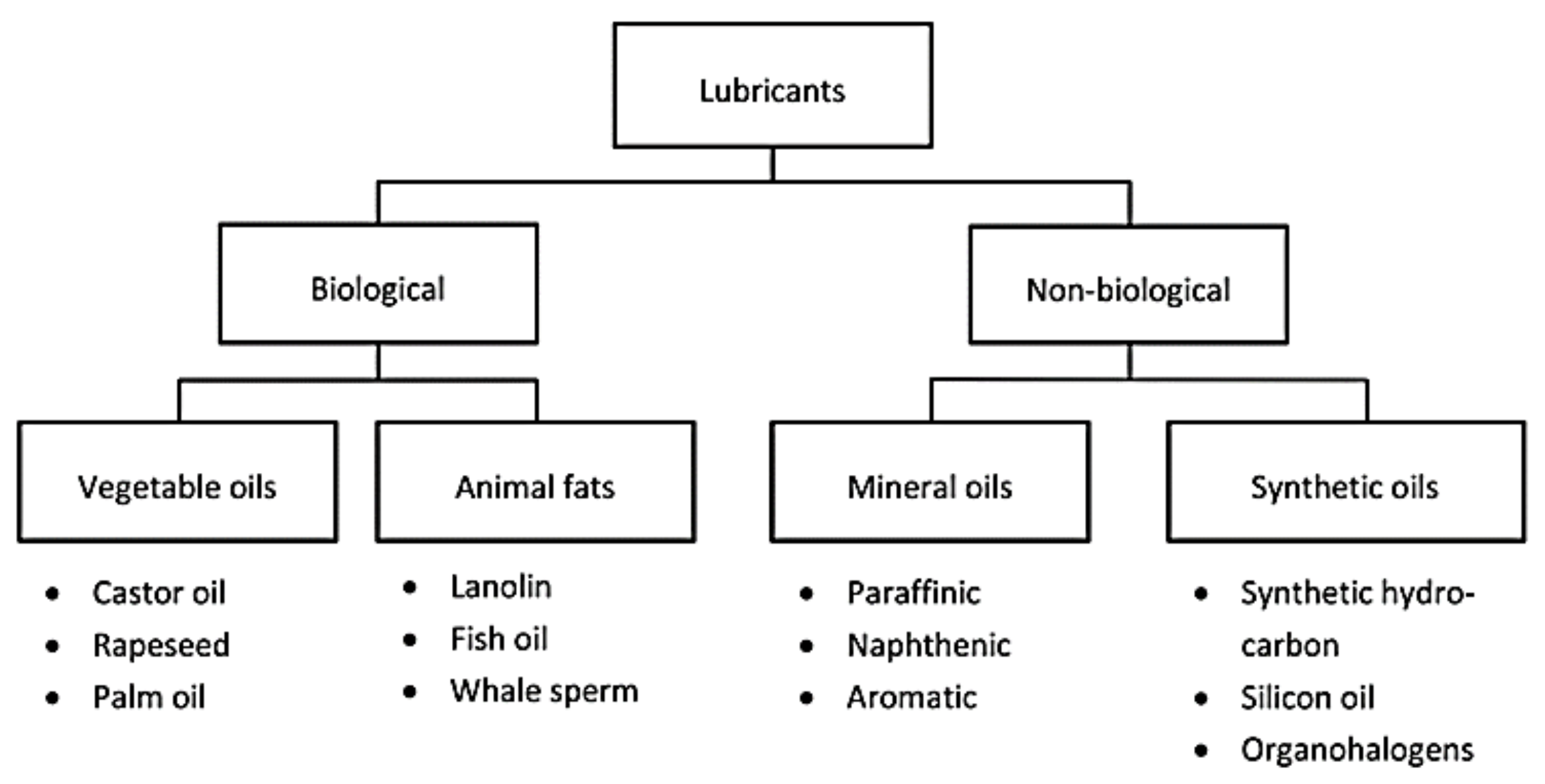

4.1. Non-Biological Lubricants

4.2. Biological Lubricants

4.3. Important Properties for Lubricating Oil Performance

- Viscosity. The most important characteristic of lubricants, which is measured as the fluid resistance to flow, directly related to the minimization of friction losses, is viscosity. The viscosity of the lubricating oil in an engine can decrease or increase due to the dilution operated by the fuel and according to the type of fuel used (diesel fuel causes it to decrease and heavy diesel fuel causes it to increase) [98]. Another factor that increases viscosity is oil aging due to progressive oxidation and thermal degradation [99]. One of the effects of too-high viscosity is an excessive resistance to flow, and one of the effects of too-low viscosity is the excessive wear of moving organs due to the lubricant film not being preserved between the moving surfaces [98,100]. In general, increasing the temperature of the lubricant leads to a decrease in viscosity [101], but, if the viscosity index is high (above 200), that lubricant has an outstanding advantage because, in this case, the viscosity will not be affected by temperature [102].

- Thermal stability. Thermal stability is another essential lubricant property, especially when vegetable oil is used as a lubricant under high-temperature conditions. The onset temperature, which can be defined as the temperature at which lubricant begins to decompose, determines thermal stability. Thermal stability is primarily determined by the chemical composition and fatty acid composition (FAC) of a hydrocarbon [103,104].

- Oxidation resistance. Oxidation is a chemical reaction that occurs when oil is exposed to oxygen and heat, resulting in thickening of the oil, sediment formation, and acidity. To preserve its efficacy and prevent engine or machinery damage, lubricating oil should have a high oxidation resistance [105].

- Wear protection. Strong film-forming lubricants can efficiently separate contact surfaces, resulting in minimal wear of interacting surfaces and low friction in mixed and boundary lubrication regimes. Therefore, the indicators of wear and friction are necessary to comprehend a lubricant’s efficacy [106].

- Foam resistance. One of the most fundamental physical properties of lubricants is their resistance to foam formation. In the formulation of a lubricant, detergent and anti-oxidation additives may contribute to the formation of foam. Foaming results in discontinuous lubrication, and the addition of anti-foaming agents prevents the formation of stable foam in oil. Antifoaming agents reduce the surface tension of air bubbles by breaking them into smaller bubbles or eliminating them on the surface, thereby promoting the rapid decomposition of foam [109].

- Compatibility with seals and materials. It is essential that lubricating oil is compatible with the seals and materials of the machinery. It should not cause seals, gaskets, or other components to expand, contract, or deteriorate [110].

- Water content. The presence of water [111] in the lubricant will cause many complications. It worsens the rheological properties, reduces the ability of lubrication and insulation, reduces the possibility of bearing load transfer, speeds up the oxidation process of the oil, rinses out the improvers, increases the amount of sediment, and causes corrosion [112]. According to the manufacturers’ regulations, the source should be investigated for the limit of 0.2% [111], while remedial measures are necessary at 0.5%. Also, the presence of Na and Mg in the lubricant indicates contamination with salt water [98], which is another condition to be avoided.

- Flash point. The flash point is the lowest temperature at which a liquid may generate sufficient vapor to combine with air to ignite. Commercial products must comply with specific flash points to guarantee safe handling, transit, and use because this can pose a major fire risk. The precise flash point specifications, which might change depending on the product and how it will be used, are frequently set by supervisory authorities or organizations that develop industry standards [98,113,114].

- Content of metal particles. Metals, non-metals, and chemicals can belong to one of the main categories of wear metals, oil elements, pollutants, and additives. The limits of chemical components accepted in the industry for diesel engines are summarized according to Table 6. Due to the wear and tear of engine components, metal particles are discharged into the lubricant during engine operation. In addition to dust, dirt, and combustion by-products, lubricants can contain other contaminants. As a guide for monitoring the metal particle content of the lubricating oil, the limits presented in Table 6 are used. They represent the permissible maximum levels of each metal component in the lubricant, which can indicate abnormal engine wear or other problems. By frequently monitoring the metal particle content in the lubricant and comparing it to the limits presented in Table 6, engine operators can determine if the engine is experiencing abnormal degradation or other issues that may necessitate maintenance [100,115].

- Total Base Number (TBN). TBN refers to a lubricant’s capacity to neutralize acids, measured by the quantity of potassium hydroxide (KOH) needed to neutralize one gram of the lubricant sample, expressed in milligrams. TBN is a crucial parameter in petroleum products, and its value fluctuates based on the specific use case [116,117].

- Total Acid Number (TAN). TAN is a crucial parameter for evaluating the overall acidity of a substance, determined by the quantity of potassium hydroxide required to neutralize the acids present in one gram of lubricant. TAN testing plays a vital role in assessing additive depletion, acidic contamination, and oxidation in lubricants, contributing to the proactive preservation of equipment. This measurement encompasses both low-pH organic acids and high-pH inorganic acids within the lubricant. An increase in TAN indicates lubricant oxidation, which may result from factors such as time or operational temperature [118,119].

5. Possible Problems in Using Biofuels in Internal Combustion Engines

- In comparison to conventional fuels, biofuels often include more water [1] and oxygen [120], which can cause, for example, fuel system components to corrode [1]. Older engines that might not have been built to manage the increasing levels of water and oxygen of actual fuels may find this to be especially problematic. Fuel leaks and other issues brought on by corrosion can cause serious damage to an engine [121]. The high temperature of combustion leads to an increase in the acidity of biodiesel and the chemical reaction between biodiesel and the surface of the injection nozzle, and these processes of oxidation and corrosion increase the level of wear [122].

- Compared to traditional fuels, biofuels have a larger potential for pollutant build-up, including dust, debris, and other impurities [123]. Due to chemical differences, biodiesel has a higher boiling point and a more limited range compared to diesel, which leads to accumulation in crankshaft oil [124]. These impurities may block diesel fuel filters [125,126] and injectors, thus reducing engine output and energy efficiency [127]. Biofuels may also be more susceptible to clogs and other issues with the fuel system [128,129,130,131].

- If exposed to cold temperatures, biofuels could be more likely to gel or form wax, which might lead to fuel system clogging and engine stalling. In colder areas where winter temperatures can drop dramatically this can be very hazardous [137].

- In comparison to traditional fuels, biofuels have the potential to minimize greenhouse gas emissions while maintaining equal engine power output; however, the actual emissions profile can vary greatly depending on the kind of biofuel, the method of production, and the engine technology. For instance, some types of biofuels may increase emissions of specific pollutants including nitrogen oxides (NOx) [23,138,139] or particulate matter (PM) [140], which may be harmful to the environment and the general public health.

- The ignition and combustion characteristics of biofuels may differ from those of conventional fuels, which can impact engine performance and emissions. Some biofuels, for instance, may have lower volatility [30,141,142] or higher boiling points [143] than conventional fuels. This can result in issues such as misfires [144], decreased power output, and even, paradoxically, increased NOx emissions [145,146]. Pure biodiesel’s enhanced viscosity and density have an adverse effect on fuel atomization, air-fuel mixing, and the combustion process in a diesel engine that has not been adjusted to use such fuels [147].

Impact of Biofuels on Engine Lubricant: Performance, Dilution, and Degradation

6. Technical Solutions Proposed So Far to Handle Biofuels in ICEs

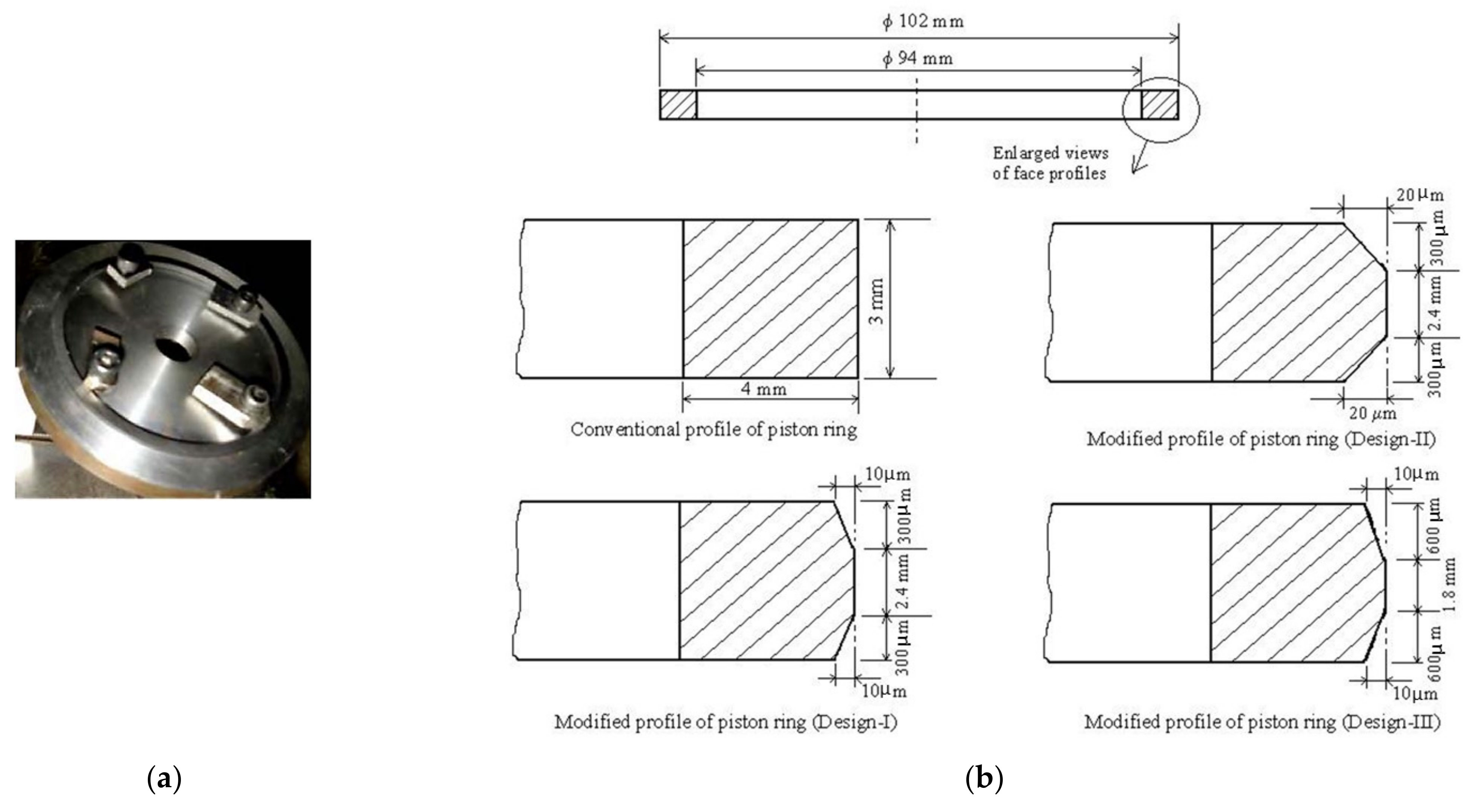

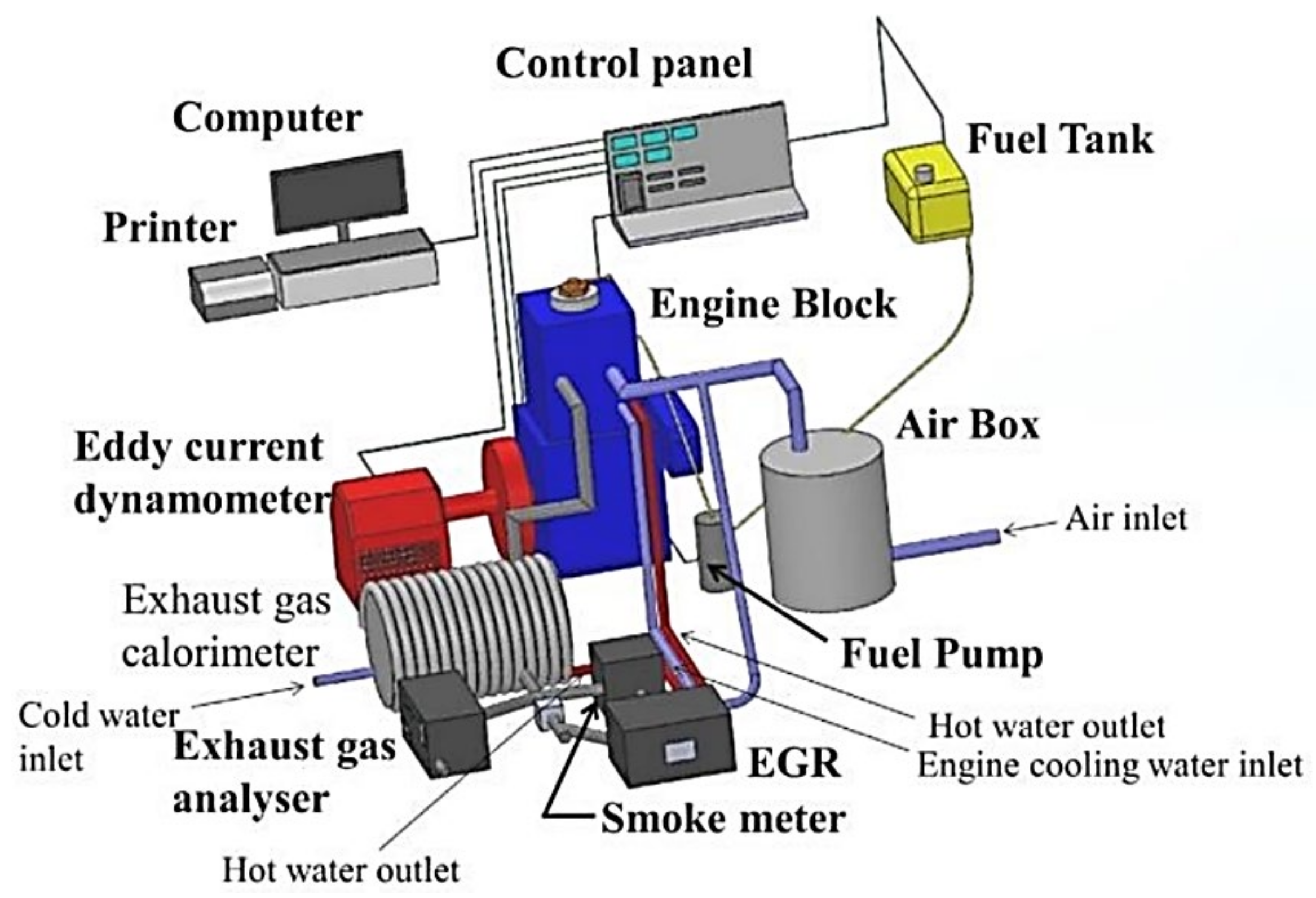

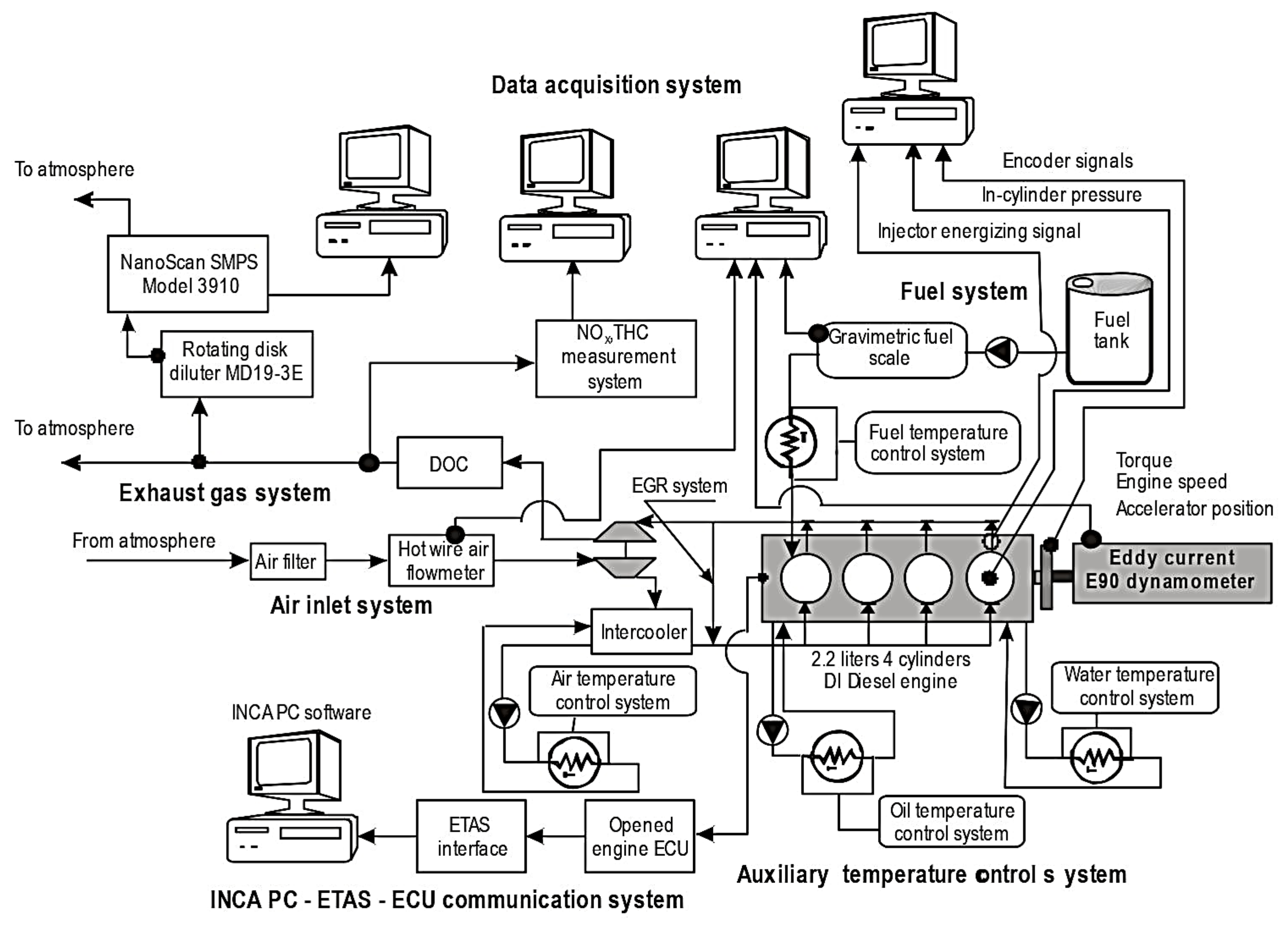

6.1. Modification of the Engine Design

6.2. Advanced Fuel Injection Technologies

6.3. Alternative Combustion Strategies

6.4. Implementing Exhaust Gas After-Treatment Systems

6.5. Using Fuel Preheating Systems

6.6. Using Advanced Sensors and Control Systems

6.7. Using Biofuel-Specific Engine Calibration

6.8. Developing New and Innovative Biofuel Blends

6.9. Using Nanoparticles to Empower Additives

6.10. Blending Biofuels with Traditional Diesel Fuel

- The duration of combustion is diminished due to the difference in combustion characteristics compared to diesel fuels [1]. By raising the fraction of ethanol in the diesel-ethanol blends, the maximum rate of heat release increases, while it decreases slightly for biodiesel–diesel–ethanol blends [23]. In diesel–ethanol blends, the ignition delay increases [23] as the ethanol proportion rises, although it decreases marginally in biodiesel–diesel–ethanol blends when an improver is added. In diesel-ethanol blends, cylinder pressure increases [24] with increasing ethanol proportion, but it decreases somewhat or stays constant in biodiesel–diesel–ethanol blends.

- Engine performance is modified when using blends of biofuels; in these cases, the specific fuel consumption is higher [4,25,238] compared to diesel fuel, and the brake-specific thermal efficiency increases [239] comparably, while the expressed power is slightly less or significantly comparable. The temperature of the exhaust gases shows small and minor changes. The mean effective pressure also showed minor changes [1].

6.11. Emulsified Biofuels

6.12. Improving the Quality and Consistency of Biofuels (Alternative Feedstocks)

6.13. Developing Advanced Lubricants

7. Conclusions and Recommendations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Niculescu, R.; Clenci, A.; Iorga-Siman, V. Review on the Use of Diesel–Biodiesel–Alcohol Blends in Compression Ignition Engines. Energies 2019, 12, 1194. [Google Scholar] [CrossRef]

- Ishaq, M.; Ghouse, G.; Fernández-González, R.; Puime-Guillén, F.; Tandir, N.; de Oliveira, H.M.S. From Fossil Energy to Renewable Energy: Why is Circular Economy Needed in the Energy Transition? Front. Environ. Sci. 2022, 10, 941791. [Google Scholar] [CrossRef]

- Storch, M.; Erdenkäufer, S.; Wensing, M.; Will, S.; Zigan, L. The Effect of Ethanol Blending on Combustion and Soot Formation in an Optical DISI Engine Using High-speed Imaging. In Physics Procedia; Elsevier B.V.: Amsterdam, The Netherlands, 2015; pp. 77–80. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Papagiannakis, R.G.; Kyritsis, D.C. Influence of properties of various common bio-fuels on the combustion and emission characteristics of high-speed DI (direct injection) diesel engine: Vegetable oil, bio-diesel, ethanol, n-butanol, diethyl ether. Energy 2014, 73, 354–366. [Google Scholar] [CrossRef]

- Wagner, L.E.; Clark, S.J.; Schrock, M.D. Effects of Soybean Oil Esters on the Performance, Lubricating Oil, and Water of Diesel Engines; SAE International: Warrendale, PA, USA, 1984. [Google Scholar]

- Balat, M.; Balat, H. Progress in biodiesel processing. Appl. Energy 2010, 87, 1815–1835. [Google Scholar] [CrossRef]

- Blackburn, J.H.; Pinchin, R.; Nobre, J.I.T.; Crichton, B.A.L.; Cruse, H.W. Performance of Lubricating Oils in Vegetable Oil Ester-Fuelled Diesel Engines; SAE Transactions: New York, NY, USA, 1983. [Google Scholar]

- Chybowski, L. The Initial Boiling Point of Lubricating Oil as an Indicator for the Assessment of the Possible Contamination of Lubricating Oil with Diesel Oil. Energies 2022, 15, 7927. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.; Varman, M.; Kalam, M.; Zulkifli, N.; Mufti, R.; Liaquat, A.; Zahid, R.; Arslan, A. Effects of biodiesel blends on lubricating oil degradation and piston assembly energy losses. Energy 2016, 111, 713–721. [Google Scholar] [CrossRef]

- BIODIESEL MARKET. 2021. Available online: https://www.mordorintelligence.com/industry-reports/biodiesel-market (accessed on 16 November 2022).

- Clenci, A.; Niculescu, R.; Danlos, A.; Iorga-Simăn, V.; Trică, A. Impact of Biodiesel Blends and Di-Ethyl-Ether on the Cold Starting Performance of a Compression Ignition Engine. Energies 2016, 9, 284. [Google Scholar] [CrossRef]

- Kovač, O.; Šikuljak, D.; Evđić, T.; Vujica, J. The influence of biodiesel on engine oil properties when conducting high-temperature engine test. Fuels Lubr. J. Tribol. Lubr. Appl. Liq. Gaseous Fuels Combust. Eng. 2015, 54, 8–19. [Google Scholar]

- Khan, A.A.; Kamal, T.A. Biofuel Second Generation and Energy Security: An Overview. Int. J. Sci. Eng. Res. 2016, 7, 1306–1320. Available online: http://www.ijser.org (accessed on 20 November 2022).

- World Energy Council. World Energy Trilemma Index. 2019. Available online: https://www.worldenergy.org/transition-toolkit/world-energy-trilemma-index (accessed on 20 November 2022).

- Bietresato, M.; Caligiuri, C.; Bolla, A.; Renzi, M.; Mazzetto, F. Proposal of a Predictive Mixed Experimental- Numerical Approach for Assessing the Performance of Farm Tractor Engines Fuelled with Diesel- Biodiesel-Bioethanol Blends. Energies 2019, 12, 2287. [Google Scholar] [CrossRef]

- Guo, M.; Song, W.; Buhain, J. Bioenergy and biofuels: History, status, and perspective. Renew. Sustain. Energy Rev. 2015, 42, 712–725. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Sustainable Energy Transition for Renewable and Low Carbon Grid Electricity Generation and Supply. Front. Energy Res. 2022, 9, 1032. [Google Scholar] [CrossRef]

- Yasin, M.H.M.; Ali, M.A.; Mamat, R.; Yusop, A.F.; Ali, M.H. Physical properties and chemical composition of biofuels. In Second and Third Generation of Feedstocks: The Evolution of Biofuels; Elsevier: Amsterdam, The Netherlands, 2019; pp. 291–320. [Google Scholar] [CrossRef]

- MHafiz; Hafizil, M.; Yasin, M.; Salleh, M.R.; Ali, M.H.; Mamat, R. Characterization of Physical Properties for Diesel-alcohol and Biodiesel-alcohol Blends Fuel, Mixture Formation and Combustion Process Characterization of Physical Properties for Diesel-alcohol and Biodiesel-alcohol Blends. Fuel Mix. Form. Combust. Process 2022, 4, 1–5. Available online: www.fazpublishing.com/fmc (accessed on 20 November 2022).

- Khan, M.; Sharma, R.; Kadian, A.K.; Hasnain, S.M.M. An assessment of alcohol inclusion in various combinations of biodiesel-diesel on the performance and exhaust emission of modern-day compression ignition engines—A review. Mater. Sci. Energy Technol. 2022, 5, 81–98. [Google Scholar] [CrossRef]

- Li, W.; Ren, Y.; Wang, X.-B.; Miao, H.; Jiang, D.-M.; Huang, Z.-H. Combustion characteristics of a compression ignition engine fuelled with diesel—Ethanol blends. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2008, 222, 265–274. [Google Scholar] [CrossRef]

- Wang, L.-J.; Song, R.-Z.; Zou, H.-B.; Liu, S.-H.; Zhou, L.-B. Study on combustion characteristics of a methanol—Diesel dual-fuel compression ignition engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2008, 222, 619–627. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Pyrc, M.; Sobiepański, M. Investigation on combustion process and emissions characteristic in direct injection diesel engine powered by wet ethanol using blend mode. Fuel Process. Technol. 2016, 149, 86–95. [Google Scholar] [CrossRef]

- Hansdah, D.; Murugan, S.; Das, L. Experimental studies on a DI diesel engine fueled with bioethanol-diesel emulsions. Alex. Eng. J. 2013, 52, 267–276. [Google Scholar] [CrossRef]

- Yasin, M.H.M.; Mamat, R.; Yusop, A.F.; Aziz, A.; Najafi, G. Comparative Study on Biodiesel-methanol-diesel Low Proportion Blends Operating with a Diesel Engine. Energy Procedia 2015, 75, 10–16. [Google Scholar] [CrossRef]

- Yalini, V.; Kannan, T.; Wilson, D.H. Optimization of Engine Performance through different piston shapes by Taguchi Method. Int. J. Innov. Technol. Explor. Eng. 2020, 9, 333–337. [Google Scholar] [CrossRef]

- Ogunkunle, O.; Ahmed, N.A. A review of global current scenario of biodiesel adoption and combustion in vehicular diesel engines. Energy Rep. 2019, 5, 1560–1579. [Google Scholar] [CrossRef]

- Magda, R.; Szlovák, S.; Tóth, J. The role of using bioalcohol fuels in sustainable development. In Bio-Economy and Agri-Production; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar] [CrossRef]

- Roberts, L.G.; Patterson, T.J. Biofuels. In Encyclopedia of Toxicology: Third Edition; Elsevier: Amsterdam, The Netherlands, 2014; pp. 469–475. [Google Scholar] [CrossRef]

- Malode, S.J.; Prabhu, K.K.; Mascarenhas, R.J.; Shetti, N.P.; Aminabhavi, T.M. Recent advances and viability in biofuel production. Energy Convers. Manag. X 2020, 10, 100070. [Google Scholar] [CrossRef]

- Hannah, L. Climate Change Biology, 3rd ed.; Academic Press: Cambridge, MA, USA, 2022. [Google Scholar]

- Sharma, S.; Kundu, A.; Basu, S.; Shetti, N.P.; Aminabhavi, T.M. Sustainable environmental management and related biofuel technologies. J. Environ. Manag. 2020, 273, 111096. [Google Scholar] [CrossRef] [PubMed]

- Awogbemi, O.; Von Kallon, D.V.; Onuh, E.I.; Aigbodion, V.S. An Overview of the Classification, Production and Utilization of Biofuels for Internal Combustion Engine Applications. Energies 2021, 14, 5687. [Google Scholar] [CrossRef]

- Bhuiya, M.M.K.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N.; Azad, A.K. Prospects of 2nd generation biodiesel as a sustainable fuel—Part: 1 selection of feedstocks, oil extraction techniques and conversion technologies. Renew. Sustain. Energy Rev. 2016, 55, 1109–1128. [Google Scholar] [CrossRef]

- Hemp as a Renewable Energy Source: Biomass, Ethanol, Biodiesel. Available online: www.bottegadellacanapa.it (accessed on 20 November 2022).

- Northrop, W.F. Particulate and Gas Phase Hydrocarbon Emissions from Partially Premixed Low Temperature Compression Ignition Combustion of Biodiesel. Automotive Emissions View Project Cloud Connected Delivery Vehicles: Boosting Fuel Economy Using Physics-Aware Spatiotemporal Data Analytics and Realtime Powertrain Control View Project. Available online: https://www.researchgate.net/publication/265047147 (accessed on 20 November 2022).

- Hoekman, S.K.; Broch, A.; Robbins, C.; Ceniceros, E.; Natarajan, M. Review of biodiesel composition, properties, and specifications. Renew. Sustain. Energy Rev. 2012, 16, 143–169. [Google Scholar] [CrossRef]

- Deviren, H.; Aydın, H. Production and physicochemical properties of safflower seed oil extracted using different methods and its conversion to biodiesel. Fuel 2023, 343, 128001. [Google Scholar] [CrossRef]

- Veljković, V.B.; Biberdžić, M.O.; Banković-Ilić, I.B.; Djalović, I.G.; Tasić, M.B.; Nježić, Z.B.; Stamenković, O.S. Biodiesel production from corn oil: A review. Renew. Sustain. Energy Rev. 2018, 91, 531–548. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.; Sharma, S.; Kumari, D. Chemical compositions, properties, and standards for different generation biodiesels: A review. Fuel 2019, 253, 60–71. [Google Scholar] [CrossRef]

- Bacha, J.; Freel, J.; Gibbs, A.; Gibbs, L.; Hemighaus, G.; Hoekman, K.; Horn, J.; Ingham, M.; Jossens, L.; Kohler, D.; et al. Diesel Fuels Technical Review. 2007. [Google Scholar]

- Read the Specifications for EN 590 Diesel and EN 590 Gas Oil. Available online: https://www.crownoil.co.uk/fuel-specifications/en-590/ (accessed on 20 November 2022).

- Demirbas, A.; Baluabaid, M.A.; Kabli, M.; Ahmad, W. Diesel Fuel from Waste Lubricating Oil by Pyrolitic Distillation. Pet. Sci. Technol. 2014, 33, 129–138. [Google Scholar] [CrossRef]

- Kumar, A.; Hardikk, A.; Editors, V. Energy, Environment, and Sustainability Series Editor: Avinash Kumar Agarwal Potential and Challenges of Low Carbon Fuels for Sustainable Transport. 2022. Available online: https://link.springer.com/bookseries/15901 (accessed on 20 November 2022).

- Vancoillie, J.; Sileghem, L.; Verhelst, S. Development and validation of a quasi-dimensional model for methanol and ethanol fueled SI engines. Appl. Energy 2014, 132, 412–425. [Google Scholar] [CrossRef]

- Yates, A.; Bell, A.; Swarts, A. Insights relating to the autoignition characteristics of alcohol fuels. Fuel 2010, 89, 83–93. [Google Scholar] [CrossRef]

- Jangi, M.; Li, C.; Shamun, S.; Tuner, M.; Bai, X. Modelling of Methanol Combustion in a Direct Injection Compression Ignition Engine using an Accelerated Stochastic Fields Method. Energy Procedia 2017, 105, 1326–1331. [Google Scholar] [CrossRef]

- Obergruber, M.; Hönig, V.; Procházka, P.; Kučerová, V.; Kotek, M.; Bouček, J.; Mařík, J. Physicochemical Properties of Biobutanol as an Advanced Biofuel. Materials 2021, 14, 914. [Google Scholar] [CrossRef] [PubMed]

- Zhen, X.; Wang, Y.; Liu, D. Bio-butanol as a new generation of clean alternative fuel for SI (spark ignition) and CI (compression ignition) engines. Renew. Energy 2020, 147, 2494–2521. [Google Scholar] [CrossRef]

- Li, R.; Teng, W.; Li, Y.; Liu, E. Liquefaction of Sewage Sludge To Produce Bio-oil in Different Organic Solvents with In Situ Hydrogenation. Energy Fuels 2019, 33, 7415–7423. [Google Scholar] [CrossRef]

- Liu, H.; Lee, C.F.; Liu, Y.; Huo, M.; Yao, M. Spray and combustion characteristics of n-butanol in a constant volume combustion chamber at different oxygen concentrations. In Proceedings of the SAE 2011 World Congress and Exhibition, Detroit, MI, USA, 12–14 April 2011. [Google Scholar] [CrossRef]

- Jin, C.; Yao, M.; Liu, H.; Lee, C.-F.L.; Ji, J. Progress in the production and application of n-butanol as a biofuel. Renew. Sustain. Energy Rev. 2011, 15, 4080–4106. [Google Scholar] [CrossRef]

- Yusri, I.; Mamat, R.; Najafi, G.; Razman, A.; Awad, O.I.; Azmi, W.; Ishak, W.; Shaiful, A. Alcohol based automotive fuels from first four alcohol family in compression and spark ignition engine: A review on engine performance and exhaust emissions. Renew. Sustain. Energy Rev. 2017, 77, 169–181. [Google Scholar] [CrossRef]

- The Emergency Response Safety and Health Database: Methanol. Available online: https://www.cdc.gov/niosh/ershdb/EmergencyResponseCard_29750029.html (accessed on 20 November 2022).

- Verhelst, S.; Turner, J.W.; Sileghem, L.; Vancoillie, J. Methanol as a fuel for internal combustion engines. Prog. Energy Combust. Sci. 2019, 70, 43–88. [Google Scholar] [CrossRef]

- Pandey, S. A critical review: Application of methanol as a fuel for internal combustion engines and effects of blending methanol with diesel/biodiesel/ethanol on performance, emission, and combustion characteristics of engines. Heat Transf. 2022, 51, 3334–3352. [Google Scholar] [CrossRef]

- Kumar, T.S.; Ashok, B. Material compatibility of SI engine components towards corrosive effects on methanol-gasoline blends for flex fuel applications. Mater. Chem. Phys. 2023, 296, 127344. [Google Scholar] [CrossRef]

- Choi, B.; Jiang, X.; Kim, Y.K.; Jung, G.; Lee, C.; Choi, I.; Song, C.S. Effect of diesel fuel blend with n-butanol on the emission of a turbocharged common rail direct injection diesel engine. Appl. Energy 2015, 146, 20–28. [Google Scholar] [CrossRef]

- Ethanol. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/ethanol (accessed on 17 November 2022).

- Atsumi, S.; Hanai, T.; Liao, J.C. Non-fermentative pathways for synthesis of branched-chain higher alcohols as biofuels. Nature 2008, 451, 86–89. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Kumar, A.; Ashutosh, A.; Ram, J.; Upadhyay, K. Energy, Environment, and Sustainability Series Editor: Avinash Kumar Agarwal Advances in Engine Tribology. Available online: https://link.springer.com/bookseries/15901 (accessed on 20 November 2022).

- Niculescu, R.; Clenci, A. Diesel Fuels. Physico-Chemical Properties. Development of a Test Method for Distillation of Diesel-Biodiesel-Alcohols Mixtures at Reduced Pressure Cold Starting of Biodiesel Fuelled Compression Ignition Engines View Project Variable Compression Ratio View Project. 2018. Available online: https://www.researchgate.net/publication/323538581 (accessed on 20 November 2022).

- Pan, J.; Yang, W.; Chou, S.; Li, D.; Xue, H.; Zhao, J.; Tang, A. Spray and combustion visualization of bio-diesel in a direct injection diesel engine. Therm. Sci. 2013, 17, 279–289. [Google Scholar] [CrossRef]

- WWFC_19_gasoline_diesel. Available online: https://www.acea.auto/files/WWFC_19_gasoline_diesel.pdf (accessed on 20 November 2022).

- Tesfa, B.; Gu, F.; Mishra, R.; Ball, A. LHV Predication Models and LHV Effect on the Performance of CI Engine Running with Biodiesel Blends. 2013. Available online: http://eprints.hud.ac.uk/id/eprint/17195/http://eprints.hud.ac.uk/ (accessed on 20 November 2022).

- García, M.; Gonzalo, A.; Sánchez, J.L.; Arauzo, J.; Peña, J. Prediction of normalized biodiesel properties by simulation of multiple feedstock blends. Bioresour. Technol. 2010, 101, 4431–4439. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, H.L.; Fregolente, P.B.L.; Maciel, M.R.W.; Fregolente, L.V. Formulation of hydrogels for water removal from diesel and biodiesel. Sep. Sci. Technol. 2021, 56, 374–388. [Google Scholar] [CrossRef]

- Uppar, R.; Dinesha, P.; Kumar, S. A critical review on vegetable oil-based bio-lubricants: Preparation, characterization, and challenges. Environ. Dev. Sustain. 2022, 25, 9011–9046. [Google Scholar] [CrossRef]

- Singh, Y.; Farooq, A.; Raza, A.; Mahmood, M.A.; Jain, S. Sustainability of a non-edible vegetable oil based bio-lubricant for automotive applications: A review. Process Saf. Environ. Prot. 2017, 111, 701–713. [Google Scholar] [CrossRef]

- Neale, M.J. Chapter C1—Viscosity of Lubricants. In Lubrication and Reliability Handbook; Newnes: Oxford, UK, 2001; pp. 1–4. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batchelor, A.W. Chapter 2—Physical Properties of Lubricants. In Engineering Tribology Book, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2014; pp. 11–50. [Google Scholar] [CrossRef]

- Sander, D.E.; Knauder, C.; Allmaier, H.; Baleur, S.D.-L.; Mallet, P. Friction Reduction Tested for a Downsized Diesel Engine with Low-Viscosity Lubricants Including a Novel Polyalkylene Glycol. Lubricants 2017, 5, 9. [Google Scholar] [CrossRef]

- Parekh, K.; Radadiya, R.; Gaur, R.; Shahabuddin, S.; Ahmad, I. A cost-effective approach for decontamination of used lubricant oil: Enhanced recovery of base oil using different adsorbents. Int. J. Environ. Sci. Technol. 2022, 20, 12323–12342. [Google Scholar] [CrossRef]

- Yash, M. Re-refining of used lubricating oil. Int. J. Sci. Eng. Res. 2015, 6, 329–332. Available online: http://www.ijser.org (accessed on 20 November 2022). [CrossRef]

- Pirro, D.M.; Webster, M.; Daschner, E. Lubrication Fundamentals, Revised and Expanded, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Shafi, W.K.; Raina, A.; Haq, M.I.U. Friction and wear characteristics of vegetable oils using nanoparticles for sustainable lubrication. Tribol. Mater. Surfaces Interfaces 2018, 12, 27–43. [Google Scholar] [CrossRef]

- Kadirgama, G.; Kamarulzaman, M.K.; Ramasamy, D.; Kadirgama, K.; Hisham, S. Classification of Lubricants Base Oils for Nanolubricants Applications—A Review. In Lecture Notes in Mechanical Engineering; Springer Science and Business Media: Berlin/Heidelberg, Germany, 2023; pp. 205–213. [Google Scholar] [CrossRef]

- Sadriwala, M.; Singh, Y.; Sharma, A.; Singla, A.; Mishra, S. Friction and wear behavior of jojoba oil based biolubricant-Taguchi method approach. Mater. Today Proc. 2019, 25, 704–709. [Google Scholar] [CrossRef]

- Afifah, A.; Syahrullail, S.; Azlee, N.I.W.; Sidik, N.A.C.; Yahya, W.; Rahim, E.A. Biolubricant production from palm stearin through enzymatic transesterification method. Biochem. Eng. J. 2019, 148, 178–184. [Google Scholar] [CrossRef]

- do Valle, C.P.; Rodrigues, J.S.; Fechine, L.M.U.D.; Cunha, A.P.; Malveira, J.Q.; Luna, F.M.T.; Ricardo, N.M.P.S. Chemical modification of Tilapia oil for biolubricant applications. J. Clean. Prod. 2018, 191, 158–166. [Google Scholar] [CrossRef]

- Cavalcanti, E.D.; Aguieiras, C.; da Silva, P.R.; Duarte, J.G.; Cipolatti, E.P.; Fernandez-Lafuente, R.; da Silva, J.A.C.; Freire, D.M. Improved production of biolubricants from soybean oil and different polyols via esterification reaction catalyzed by immobilized lipase from Candida rugosa. Fuel 2018, 215, 705–713. [Google Scholar] [CrossRef]

- Salimon, J.; Salih, N.; Yousif, E. Biolubricants: Raw materials, chemical modifications and environmental benefits. Eur. J. Lipid Sci. Technol. 2010, 112, 519–530. [Google Scholar] [CrossRef]

- Panchal, T.M.; Patel, A.; Chauhan, D.; Thomas, M.; Patel, J.V. A methodological review on bio-lubricants from vegetable oil based resources. Renew. Sustain. Energy Rev. 2017, 70, 65–70. [Google Scholar] [CrossRef]

- Liew Yun Hsien, W. Utilization of Vegetable Oil as Bio-lubricant and Additive. In Towards Green Lubrication in Machining. Springer Briefs in Molecular Science; Springer: Singapore, 2015; pp. 7–17. [Google Scholar] [CrossRef]

- Shashidhara, Y.; Jayaram, S. Vegetable oils as a potential cutting fluid—An evolution. Tribol. Int. 2010, 43, 1073–1081. [Google Scholar] [CrossRef]

- Alves, S.M.; Barros, B.S.; Trajano, M.F.; Ribeiro, K.S.B.; Moura, E. Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions. Tribol. Int. 2013, 65, 28–36. [Google Scholar] [CrossRef]

- Mobarak, H.; Mohamad, E.N.; Masjuki, H.; Kalam, M.; Al Mahmud, K.; Habibullah, M.; Ashraful, A. The prospects of biolubricants as alternatives in automotive applications. Renew. Sustain. Energy Rev. 2014, 33, 34–43. [Google Scholar] [CrossRef]

- Singh, Y.; Garg, R.; Kumar, S. Aspects of Non-edible Vegetable Oil-Based Bio-lubricants in the Automotive Sector. Green 2015, 5, 59–72. [Google Scholar] [CrossRef]

- Syahir, A.Z.; Zulkifli, N.W.M.; Masjuki, H.H.; Kalam, M.A.; Alabdulkarem, A.; Gulzar, M.; Khuong, L.S.; Harith, M.H. A review on bio-based lubricants and their applications. J. Clean. Prod. 2017, 168, 997–1016. [Google Scholar] [CrossRef]

- Chan, C.-H.; Tang, S.W.; Mohd, N.K.; Lim, W.H.; Yeong, S.K.; Idris, Z. Tribological behavior of biolubricant base stocks and additives. Renew. Sustain. Energy Rev. 2018, 93, 145–157. [Google Scholar] [CrossRef]

- Shah, R.; Woydt, M.; Zhang, S. The Economic and Environmental Significance of Sustainable Lubricants. Lubricants 2021, 9, 21. [Google Scholar] [CrossRef]

- Arumugam, S.; Sriram, G. Effect of Bio-Lubricant and Biodiesel-Contaminated Lubricant on Tribological Behavior of Cylinder Liner–Piston Ring Combination. Tribol. Trans. 2012, 55, 438–445. [Google Scholar] [CrossRef]

- Salih, N.; Salimon, J.; Yousif, E. Synthetic biolubricant basestocks based on environmentally friendly raw materials. J. King Saud Univ. Sci. 2012, 24, 221–226. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.; Kalam, M.; Shahabuddin, M.; Hazrat, M.; Liaquat, A. Palm Oil Methyl Ester and Its Emulsions Effect on Lubricant Performance and Engine Components Wear. Energy Procedia 2012, 14, 1748–1753. [Google Scholar] [CrossRef]

- Nagendramma, P.; Kaul, S. Development of ecofriendly/biodegradable lubricants: An overview. Renew. Sustain. Energy Rev. 2012, 16, 764–774. [Google Scholar] [CrossRef]

- Quinchia, L.A.; Delgado, M.A.; Valencia, C.; Franco, J.M.; Gallegos, C. Viscosity Modification of High-Oleic Sunflower Oil with Polymeric Additives for the Design of New Biolubricant Formulations. Environ. Sci. Technol. 2009, 43, 2060–2065. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Masjuki, H.; Kalam, M.; Bhuiya, M.; Mehat, H. Comparative tribological investigation of bio-lubricant formulated from a non-edible oil source (Jatropha oil). Ind. Crop. Prod. 2013, 47, 323–330. [Google Scholar] [CrossRef]

- Kaminski, P. Experimental Investigation into the Effects of Fuel Dilution on the Change in Chemical Properties of Lubricating Oil Used in Fuel Injection Pump of Pielstick PA4 V185 Marine Diesel Engine. Lubricants 2022, 10, 162. [Google Scholar] [CrossRef]

- Santos, J.C.O.; Santos, I.M.G.; Souza, A.G. Thermal degradation of synthetic lubricating oils: Part II—Rheological study. Pet. Sci. Technol. 2017, 35, 535–539. [Google Scholar] [CrossRef]

- Fernández-Feal, M.; Sánchez-Fernández, L.R.; Pérez-Prado, J.R. Study of Metal Concentration in Lubricating Oil with Predictive Purposes. Curr. J. Appl. Sci. Technol. 2018, 27, 1–12. [Google Scholar] [CrossRef]

- Ting, C.-C.; Chen, C.-C. Viscosity and working efficiency analysis of soybean oil based bio-lubricants. Measurement 2011, 44, 1337–1341. [Google Scholar] [CrossRef]

- Rodrigues, J.d.A.; Cardoso, F.d.P.; Lachter, E.R.; Estevão, L.R.M.; Lima, E.; Nascimento, R.S.V. Correlating chemical structure and physical properties of vegetable oil esters. J. Am. Oil Chem. Soc. 2006, 83, 353–357. [Google Scholar] [CrossRef]

- Kalam, M.; Masjuki, H.; Cho, H.M.; Mosarof, M.; Mahmud, I.; Chowdhury, M.A.; Zulkifli, N. Influences of thermal stability, and lubrication performance of biodegradable oil as an engine oil for improving the efficiency of heavy duty diesel engine. Fuel 2017, 196, 36–46. [Google Scholar] [CrossRef]

- Santos, J.C.O.; Lima, L.N.; Santos, I.M.G.; Souza, A.G. Thermal, Spectroscopic and Rheological Study of Mineral Base Lubricating Oils. J. Therm. Anal. Calorim. 2007, 87, 639–643. [Google Scholar] [CrossRef]

- Von, G.H.; Diamond, H. Oxidation Characteristics of Lubricating Oils Relation between Stability and Chemical Composition. Available online: https://pubs.acs.org/sharingguidelines (accessed on 20 November 2022).

- Yilmaz, N.; Ileri, E.; Atmanli, A. Performance of biodiesel/higher alcohols blends in a diesel engine. Int. J. Energy Res. 2016, 40, 1134–1143. [Google Scholar] [CrossRef]

- Wilson, R.W.; Lyon, S.B. Corrosion in lubricants/fuels. In Shreir’s Corrosion; Elsevier: Amsterdam, The Netherlands, 2010; pp. 1299–1307. [Google Scholar] [CrossRef]

- Wang, J.; Hu, W.; Li, J. Lubrication and Anti-Rust Properties of Jeffamine-Triazole Derivative as Water-Based Lubricant Additive. Coatings 2021, 11, 679. [Google Scholar] [CrossRef]

- Prolić, T.Ć.; Lepušić, A. Effect of foaming on the antiwear properties of lubricating oils. Goriva Maz. 2012, 51, 38. [Google Scholar]

- Mang, T.; Noll, S.; Bartels, T. Lubricants, 1. Fundamentals of Lubricants and Lubrication. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2011. [Google Scholar] [CrossRef]

- Markova, L.; Myshkin, N.; Makarenko, V.M.; Semenyuk, M.S.; Kong, H.; Han, H.; Yun, E.S. The Dry Sliding of Ceramics View Project Ceramic Wear View Project Monitoring of Water Content in Oil as a Method of Tribodiagnostics. 2004. Available online: https://www.researchgate.net/publication/294544148 (accessed on 20 November 2022).

- Li, J.; Tian, H.X.; Sun, Y.L.; Ming, T.F.; Sheng, C.X. Application of FTIR Spectrum in Quantitatively Monitoring Oil Contaminants. Spectrosc. Spectr. Anal. 2019, 39, 3459–3464. [Google Scholar] [CrossRef]

- Abu-Elella, R.; Ossman, M.E.; Farouq, R.; Abd-Elfatah, M. Used Motor Oil Treatment: Turning Waste Oil into Valuable Products. Int. J. Chem. Biochem. Sci. 2015, 7, 57–67. [Google Scholar]

- Fu, J. Flash points measurements and prediction of biofuels and biofuel blends with aromatic fluids. Fuel 2018, 241, 892–900. [Google Scholar] [CrossRef]

- Inthawatkul, I.; Sriratana, W.; Satthamsakul, S. Measurement of Metal Particles in Oil Lubricant using Hall Effect Sensor Under Temperature Conditions. In Proceedings of the 2017 56th Annual Conference of the Society of Instrument and Control Engineers of Japan (SICE), Kanazawa, Japan, 19–22 September 2017. [Google Scholar] [CrossRef]

- Total Base Number. Available online: https://en.wikipedia.org/wiki/Total_base_number (accessed on 20 November 2022).

- Dong, J.; van de Voort, F.R.; Yaylayan, V.; Ismail, A.A.; Pinchuk, D.; Taghizadeh, A. Determination of total base number (tbn) in lubricating oils by mid-ftir spectroscopy. Lubr. Eng. 2001, 57, 24–30. [Google Scholar]

- Malik, M.A.I.; Usman, M.; Hayat, N.; Zubair, S.W.H.; Bashir, R.; Ahmed, E. Experimental evaluation of methanol-gasoline fuel blend on performance, emissions and lubricant oil deterioration in SI engine. Adv. Mech. Eng. 2021, 13, 1–17. [Google Scholar] [CrossRef]

- Acid Number: A Comprehensive Guide. Available online: https://www.machinerylubrication.com/Read/1052/acid-number-test (accessed on 20 November 2022).

- Demirbas, A. Biofuels sources, biofuel policy, biofuel economy and global biofuel projections. Energy Convers. Manag. 2008, 49, 2106–2116. [Google Scholar] [CrossRef]

- Hoang, A.T.; Tabatabaei, M.; Aghbashlo, M. A review of the effect of biodiesel on the corrosion behavior of metals/alloys in diesel engines. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 42, 2923–2943. [Google Scholar] [CrossRef]

- Celik, I.; Aydin, O. Effects of B100 Biodiesel on Injector and Pump Piston. Tribol. Trans. 2011, 54, 424–431. [Google Scholar] [CrossRef]

- Velasco, R. Application of Biofuel Impurities and Effect on the Hot Corrosion of Yttria-Stabilized Zirconia Thermal Barrier Coatings. Surf. Coat. Technol. 2018, 358, 340–346. [Google Scholar] [CrossRef]

- Morcos, M.; Parsons, G.; Lauterwasser, F.; Boons, M.; Hartgers, W. Detection methods for accurate measurements of the fame biodiesel content in used crankcase engine oil. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Jayaseelan, G.A.C.; Anderson, A.; Manigandan, S.; Elfasakhany, A.; Dhinakaran, V. Effect of engine parameters, combustion and emission characteristics of diesel engine with dual fuel operation. Fuel 2021, 302, 121152. [Google Scholar] [CrossRef]

- Pranoto, H.; Wahab, A.; Arifin, Z.; Siswanto, I. Fuel filter condition monitoring (ffcm) devices innovation on truck diesel engine to prevent filter blocking due to use of bio diesel: b10-b20-b30. J. Phys. Conf. Ser. 2020, 1700, 012099. [Google Scholar] [CrossRef]

- Canha, N.; Felizardo, P.; Correia, M.J.N. Controlling the oxidative stability of biodiesel using oils or biodiesel blending or antioxidants addition. Environ. Prog. Sustain. Energy 2018, 37, 1031–1040. [Google Scholar] [CrossRef]

- Wang, S.; Sun, X.; Yuan, Q. Strategies for enhancing microbial tolerance to inhibitors for biofuel production: A review. Bioresour. Technol. 2018, 258, 302–309. [Google Scholar] [CrossRef]

- Cazarolli, J.C.; de Quadros, P.D.; Bücker, F.; Santiago, M.R.F.; Piatnicki, C.M.S.; Peralba, M.D.C.R.; Cavalcanti, E.H.d.S.; Bento, F.M. Microbial growth in Acrocomia aculeata pulp oil, Jatropha curcas oil, and their respective biodiesels under simulated storage conditions. Biofuel Res. J. 2016, 3, 514–520. [Google Scholar] [CrossRef][Green Version]

- Longinos, S.N.; Zannikos, F. The effect of microbial growth on physicochemical properties of biodiesel–diesel mixtures. Braz. J. Chem. Eng. 2022, 39, 345–360. [Google Scholar] [CrossRef]

- Komariah, L.N.; Arita, S.; Rendana, M.; Ramayanti, C.; Suriani, N.L.; Erisna, D. Microbial contamination of diesel-biodiesel blends in storage tank: An analysis of colony morphology. Heliyon 2022, 8, e09264. [Google Scholar] [CrossRef]

- Abdullah, A.Z.; Razali, N.; Mootabadi, H.; Salamatinia, B. Critical technical areas for future improvement in biodiesel technologies. Environ. Res. Lett. 2007, 2, 034001. [Google Scholar] [CrossRef]

- Jeyaseelan, T.; Chacko, N.; Pushyanth, N.; Alexander, J.; Porpatham, E. Partial hydrogenation and hydrogen induction: A comparative study with B20 operation in a turbocharged CRDI diesel engine. Int. J. Hydrogen Energy 2021, 46, 22659–22669. [Google Scholar] [CrossRef]

- Bôas, R.N.V.; Mendes, M.F. A review of biodiesel production from non-edible raw materials using the transesterification process with a focus on influence of feedstock composition and free fatty acids. J. Chil. Chem. Soc. 2022, 67, 5433–5444. [Google Scholar] [CrossRef]

- Schumacher, L.; Borgelt, S.C.; Hires, W.G.; Wetherell, W.; Nevils, A. 100,000 Miles of Fueling 5.9L Cummins Engines with 100% Biodiesel. J. Fuels Lubr. 1996, 105, 2332–2339. [Google Scholar]

- Mahmudul, H.; Hagos, F.; Mamat, R.; Adam, A.A.; Ishak, W.; Alenezi, R. Production, characterization and performance of biodiesel as an alternative fuel in diesel engines—A review. Renew. Sustain. Energy Rev. 2017, 72, 497–509. [Google Scholar] [CrossRef]

- Hazrat, M.A.; Rasul, M.G.; Mofijur, M.; Khan, M.M.K.; Djavanroodi, F.; Azad, A.K.; Bhuiya, M.M.K.; Silitonga, A. A Mini Review on the Cold Flow Properties of Biodiesel and its Blends. Front. Energy Res. 2020, 8, 598651. [Google Scholar] [CrossRef]

- Kowalewicz, A.; Wojtyniak, M. Alternative fuels and their application to combustion engines. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2005, 219, 103–125. [Google Scholar] [CrossRef]

- Ghadikolaei, M.A. Effect of alcohol blend and fumigation on regulated and unregulated emissions of IC engines—A review. Renew. Sustain. Energy Rev. 2016, 57, 1440–1495. [Google Scholar] [CrossRef]

- Jindra, P.; Kotek, M.; Mařík, J.; Vojtíšek, M. Effect of different biofuels to particulate matters production. Agron. Res. 2016, 14, 783–789. [Google Scholar]

- Aziz, M. Integrated supercritical water gasification and a combined cycle for microalgal utilization. Energy Convers. Manag. 2015, 91, 140–148. [Google Scholar] [CrossRef]

- Chakravarthy, K.; Mcfarlane, J.; Daw, S.; Ra, Y.; Reitz, R.; Griffin, J. Physical Properties of Bio-Diesel and Implications for Use of Bio-Diesel in Diesel Engines. J. Fuels Lubr. 2007, 116, 885–895. [Google Scholar]

- Enagi, I.I.; Al-Attab, K.A.; Alauddin, Z.A.Z. Combustion Stability Analysis of Liquid Biofuels using Acoustic Signals. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 76, 145–155. [Google Scholar] [CrossRef]

- Bello, U.; Agu, C.M.; Ajiya, D.A.; Mahmoud, A.A.; Udopia, L.; Lawal, N.M.; Abubakar, A.A.; Muhammad, M. Biodiesel, In a Quest For Sustainable Renewable Energy: A Review on Its Potentials and Production Strategies. J. Chem. Rev. 2022, 4, 272–287. [Google Scholar] [CrossRef]

- Freitas, S.V.D.; Oliveira, M.B.; Lima, S.; Coutinho, J.A.P. Measurement and Prediction of Biodiesel Volatility. Energy Fuels 2012, 26, 3048–3053. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Gupta, J.G.; Dhar, A. Potential and challenges for large-scale application of biodiesel in automotive sector. Prog. Energy Combust. Sci. 2017, 61, 113–149. [Google Scholar] [CrossRef]

- No, S.-Y. Inedible vegetable oils and their derivatives for alternative diesel fuels in CI engines: A review. Renew. Sustain. Energy Rev. 2011, 15, 131–149. [Google Scholar] [CrossRef]

- Mahapatra, S.; Kumar, D.; Singh, B.; Sachan, P.K. Biofuels and their sources of production: A review on cleaner sustainable alternative against conventional fuel, in the framework of the food and energy nexus. Energy Nexus 2021, 4, 100036. [Google Scholar] [CrossRef]

- Devlin, C.C.; Passut, C.A.; Campbell, R.L.; Jao, T.-C. Biodiesel Fuel Effect on Diesel Engine Lubrication. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2008. [Google Scholar]

- Bietresato, M.; Friso, D. Durability test on an agricultural tractor engine fuelled with pure biodiesel (B100). Turk. J. Agric. For. 2014, 38, 214–223. [Google Scholar] [CrossRef]

- Taylor, R.I. Fuel-Lubricant Interactions: Critical Review of Recent Work. Lubricants 2021, 9, 92. [Google Scholar] [CrossRef]

- Maji, N.C.; Rastogi, P.; Krishnasamy, A.; Aidhen, I.S.; Kaisare, N.S.; Basavaraj, M.G. Storage and Temperature Stability of Emulsified Biodiesel–Diesel Blends. ACS Omega 2022, 7, 44762–44771. [Google Scholar] [CrossRef]

- Fang, H.L.; Whitacre, S.D.; Yamaguchi, E.S.; Boons, M. Biodiesel Impact on Wear Protection of Engine Oils. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Sentanuhady, J.; Majid, A.I.; Prasidha, W.; Saputro, W.; Gunawan, N.P.; Raditya, T.Y.; Muflikhun, M.A. Analisis Pengaruh Biodiesel B20 Dan B100 Terhadap Degradasi Viskositas Dan Total Base Number Minyak Pelumas Pada Mesin Diesel Yang Beroperasi Dalam Jangka Panjang Dengan Metode ASTM D2896 Dan ASTM D445-06. TEKNIK 2020, 41, 269–274. [Google Scholar] [CrossRef]

- Cuerva, M.P.; Gonçalves, A.C.; Albuquerque, M.d.C.F.d.; Chavarette, F.R.; Outa, R.; de Almeida, E.F. Analysis of the Influence of Contamination in Lubricant by Biodiesel in a Pin-On-Disk Equipment. Mater. Res. 2022, 25, e20210375. [Google Scholar] [CrossRef]

- Dandu, M.S.R.; Nanthagopal, K. Tribological aspects of biofuels—A review. Fuel 2019, 258, 116066. [Google Scholar] [CrossRef]

- Kannan, G.; Anand, R. Effect of injection pressure and injection timing on DI diesel engine fuelled with biodiesel from waste cooking oil. Biomass-Bioenergy 2012, 46, 343–352. [Google Scholar] [CrossRef]

- Al-Abboodi, N.K.F.; Al-Waaly, A.A.Y. Combined effect of multi-injection scheme, injector nozzle bore, and biodiesel blends on combustion and performance characteristics of diesel engine. Heat Transf. 2023, 52, 3168–3186. [Google Scholar] [CrossRef]

- Park, S.H.; Yoon, S.H.; Lee, C.S. Effects of multiple-injection strategies on overall spray behavior, combustion, and emissions reduction characteristics of biodiesel fuel. Appl. Energy 2011, 88, 88–98. [Google Scholar] [CrossRef]

- Yehliu, K.; Boehman, A.L.; Armas, O. Emissions from different alternative diesel fuels operating with single and split fuel injection. Fuel 2010, 89, 423–437. [Google Scholar] [CrossRef]

- Fang, T.; Lee, C.-F.F. Bio-diesel effects on combustion processes in an HSDI diesel engine using advanced injection strategies. Proc. Combust. Inst. 2009, 32, 2785–2792. [Google Scholar] [CrossRef]

- Singh, R.C.; Chaudhary, R.; Maji, S. Experimental Studies for the Role of Piston Rings’ Face Profiles on Performance of a Diesel Engine Fueled with Diesel and Jatropha Based Biodiesel. Available online: https://www.researchgate.net/publication/268331191 (accessed on 20 November 2022).

- Blumreiter, J. Refueling the Engine. Available online: https://www.asme.org/topics-resources/content/refueling-the-engine (accessed on 1 June 2023).

- EdwinGeo, V.; Fol, G.; Aloui, F.; Thiyagarajan, S.; Stanley, M.J.; Sonthalia, A.; Brindhadevi, K.; Saravanan, C. Experimental analysis to reduce CO2 and other emissions of CRDI CI engine using low viscous biofuels. Fuel 2021, 283, 118829. [Google Scholar] [CrossRef]

- Saiteja, P.; Ashok, B. A critical insight review on homogeneous charge compression ignition engine characteristics powered by biofuels. Fuel 2021, 285, 119202. [Google Scholar] [CrossRef]

- Komninos, N.; Rakopoulos, C. Modeling HCCI combustion of biofuels: A review. Renew. Sustain. Energy Rev. 2012, 16, 1588–1610. [Google Scholar] [CrossRef]

- Chaudhari, V.; Deshmukh, D. Challenges in charge preparation and combustion in homogeneous charge compression ignition engines with biodiesel: A review. Energy Rep. 2019, 5, 960–968. [Google Scholar] [CrossRef]

- Riyadi, T.W.; Spraggon, M.; Herawan, S.; Idris, M.; Paristiawan, P.; Putra, N.; Faizullizam, R.M.; Silambarasan, R.; Veza, I. Biodiesel for HCCI engine: Prospects and challenges of sustainability biodiesel for energy transition. Results Eng. 2023, 17, 100916. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, J.; Hernández, J.J.; Sánchez-Valdepeñas, J. Effect of oxygenated and paraffinic alternative diesel fuels on soot reactivity and implications on DPF regeneration. Fuel 2016, 185, 460–467. [Google Scholar] [CrossRef]

- Liati, A.; Spiteri, A.; Eggenschwiler, P.D.; Vogel-Schäuble, N. Microscopic investigation of soot and ash particulate matter derived from biofuel and diesel: Implications for the reactivity of soot. J. Nanoparticle Res. 2012, 14, 1224. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, J.; Lapuerta, M.; Sánchez-Valdepeñas, J. Regeneration of diesel particulate filters: Effect of renewable fuels. Renew. Energy 2017, 104, 30–39. [Google Scholar] [CrossRef]

- Heeb, N.V.; Rey, M.D.; Zennegg, M.; Haag, R.; Wichser, A.; Schmid, P.; Seiler, C.; Honegger, P.; Zeyer, K.; Mohn, J.; et al. Biofuel-Promoted Polychlorinated Dibenzodioxin/furan Formation in an Iron-Catalyzed Diesel Particle Filter. Environ. Sci. Technol. 2015, 49, 9273–9279. [Google Scholar] [CrossRef] [PubMed]

- Carucci, J.H.; Kurman, A.; Karhu, H.; Arve, K.; Eränen, K.; Wärnå, J.; Salmi, T.; Murzin, D. Kinetics of the biofuels-assisted SCR of NOx over Ag/alumina-coated microchannels. Chem. Eng. J. 2009, 154, 34–44. [Google Scholar] [CrossRef]

- Cheng, X.; Bi, X.T. A review of recent advances in selective catalytic NOx reduction reactor technologies. Particuology 2014, 16, 1–18. [Google Scholar] [CrossRef]

- Vallinayagam, R.; Vedharaj, S.; Yang, W.; Saravanan, C.; Lee, P.; Chua, K.; Chou, S. Emission reduction from a diesel engine fueled by pine oil biofuel using SCR and catalytic converter. Atmospheric Environ. 2013, 80, 190–197. [Google Scholar] [CrossRef]

- Calle-Asensio, A.; Hernández, J.; Rodríguez-Fernández, J.; Lapuerta, M.; Ramos, A.; Barba, J. Effect of advanced biofuels on WLTC emissions of a Euro 6 diesel vehicle with SCR under different climatic conditions. Int. J. Engine Res. 2021, 22, 3433–3446. [Google Scholar] [CrossRef]

- Santhosh, K.; Kumar, G.N.; Shahapur, S. The effect of tri-fuel blends on engine characteristics of a direct injection diesel engine with exhaust gas recirculation. Energy Sour. Part A Recover. Util. Environ. Eff. 2022, 44, 1227–1249. [Google Scholar] [CrossRef]

- Rajasekar, V.; Geo, V.E.; Martin, L.J.; Nagalingam, B. The combined effect of low viscous biofuel and EGR on NO-smoke tradeoff in a biodiesel engine—An experimental study. Environ. Sci. Pollut. Res. 2020, 27, 17468–17480. [Google Scholar] [CrossRef]

- van Niekerk, A.; Drew, B.; Larsen, N.; Kay, P. Impact of low NOx strategies on holistic emission reduction from a CI engine over transient conditions. Int. J. Engine Res. 2020, 22, 3286–3299. [Google Scholar] [CrossRef]

- Vinayagam, N.K.; Hoang, A.T.; Solomon, J.M.; Subramaniam, M.; Balasubramanian, D.; El-Seesy, A.I.; Nguyen, X.P. Smart control strategy for effective hydrocarbon and carbon monoxide emission reduction on a conventional diesel engine using the pooled impact of pre-and post-combustion techniques. J. Clean. Prod. 2021, 306, 127310. [Google Scholar] [CrossRef]

- Dubey, A.; Prasad, R.S.; Singh, J.K.; Nayyar, A. Combined effects of biodiesel—ULSD blends and EGR on performance and emissions of diesel engine using Response surface methodology (RSM). Energy Nexus 2022, 7, 100136. [Google Scholar] [CrossRef]

- Desmira, N.; Kitagawa, K.; Gupta, A.K. Hydroxyl and Nitric Oxide Distribution in Waste Rice Bran Biofuel-Octanol Flames. J. Energy Resour. Technol. 2014, 136, 014501. [Google Scholar] [CrossRef]

- Ashok, B.; Gopal, K.N.; Rajagopal, T.K.R.; Alagiasingam, S.; Appu, S.; Murugan, A. Design and Analysis of a Fuel Preheating Device for Evaluation of Ethanol Based Biofuel Blends in a Diesel Engine Application. SAE Int. J. Engines 2017, 10, 39–45. [Google Scholar] [CrossRef]

- Bietresato, M.; Bolla, A.; Caligiuri, C.; Renzi, M.; Mazzetto, F. The kinematic viscosity of conventional and bio-based fuel blends as a key parameter to indirectly estimate the performance of compression-ignition engines for agricultural purposes. Fuel 2021, 298, 120817. [Google Scholar] [CrossRef]

- Pham, V.V. An optimal research for diesel engine using biofuels fuel when considering the effects of the change of parameters on ECU. In AIP Conference Proceedings; American Institute of Physics Inc.: College Park, MD, USA, 2020. [Google Scholar] [CrossRef]

- Guido, C.; Beatrice, C.; Napolitano, P. Application of bioethanol/RME/diesel blend in a Euro5 automotive diesel engine: Potentiality of closed loop combustion control technology. Appl. Energy 2013, 102, 13–23. [Google Scholar] [CrossRef]

- Soriano, J.A.; García-Contreras, R.; Leiva-Candia, D.; Soto, F.; Eacute, J.; Soriano, A. Influence on Performance and Emissions of an Automotive Diesel Engine Fueled with Biodiesel and Paraffinic Fuels: GTL and Biojet Fuel Farnesane. Energy Fuels 2018, 32, 5125–5133. [Google Scholar] [CrossRef]

- Vignesh, R.; Ashok, B. Deep neural network model-based global calibration scheme for split injection control map to enhance the characteristics of biofuel powered engine. Energy Convers. Manag. 2021, 249, 114875. [Google Scholar] [CrossRef]

- Lapuerta, M.; Ramos, Á.; Rubio, S.; Estévez, C. Optimization of a diesel engine calibration for operating with a residual glycerol-derived biofuel. Int. J. Engine Res. 2021, 22, 1273–1284. [Google Scholar] [CrossRef]

- Wong, K.I.; Wong, P.K. Optimal calibration of variable biofuel blend dual-injection engines using sparse Bayesian extreme learning machine and metaheuristic optimization. Energy Convers. Manag. 2017, 148, 1170–1178. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Zhang, Z.; Chen, J.; Pham, M.; Zhao, X.; Peng, Q.; Zuo, W.; Yin, Z. Performance and emission evaluation of a marine diesel engine fueled by water biodiesel-diesel emulsion blends with a fuel additive of a cerium oxide nanoparticle. Energy Convers. Manag. 2018, 169, 194–205. [Google Scholar] [CrossRef]

- Kannan, G.; Karvembu, R.; Anand, R. Effect of metal based additive on performance emission and combustion characteristics of diesel engine fuelled with biodiesel. Appl. Energy 2011, 88, 3694–3703. [Google Scholar] [CrossRef]

- Musthafa, M.M. Development of performance and emission characteristics on coated diesel engine fuelled by biodiesel with cetane number enhancing additive. Energy 2017, 134, 234–239. [Google Scholar] [CrossRef]

- Costa, K.; Valle, S.D.; Dos Santos, T.; Rangel, E.; Pinto, A.; Suarez, P.; Rezende, M. Synthesis and Evaluation of Biocide and Cetane Number Improver Additives for Biodiesel from Chemical Changes in Triacylglycerides. J. Braz. Chem. Soc. 2018, 29, 2605–2615. [Google Scholar] [CrossRef]

- Chaluvadi, N.; Vijay, P.; Puli RV, R.; Dadi, Y.; Pavan, C.V.N. Diesel Engine Performance Improvement by Using Cetane Improver. Int. J. Eng. Innov. Technol. 2013, 2, 179–182. [Google Scholar]

- Ramalingam, S.; Rajendran, S.; Ganesan, P.; Govindasamy, M. Effect of operating parameters and antioxidant additives with biodiesels to improve the performance and reducing the emissions in a compression ignition engine—A review. Renew. Sustain. Energy Rev. 2018, 81, 775–788. [Google Scholar] [CrossRef]

- Jain, S.; Purohit, S.; Kumar, D.; Goud, V.V. Passion fruit seed extract as an antioxidant additive for biodiesel: Shelf life and consumption kinetics. Fuel 2021, 289, 119906. [Google Scholar] [CrossRef]

- Fernandes, D.M.; Sousa, R.M.; de Oliveira, A.; Morais, S.A.; Richter, E.M.; Muñoz, R.A. Moringa oleifera: A potential source for production of biodiesel and antioxidant additives. Fuel 2015, 146, 75–80. [Google Scholar] [CrossRef]

- Kumar, M.V.; Babu, A.V.; Kumar, P.R. The impacts on combustion, performance and emissions of biodiesel by using additives in direct injection diesel engine. Alex. Eng. J. 2018, 57, 509–516. [Google Scholar] [CrossRef]

- Anwar, M.; Rasul, M.G.; Ashwath, N. The synergistic effects of oxygenated additives on papaya biodiesel binary and ternary blends. Fuel 2019, 256, 115980. [Google Scholar] [CrossRef]

- Ganesan, S.; Sivasubramanian, R.; Sajin, J.B.; Subbiah, G.; Devarajan, Y. Performance and emission study on the effect of oxygenated additive in neat biodiesel fueled diesel engine. Energy Sources A Recovery Util. Environ. Eff. 2018, 41, 2017–2027. [Google Scholar] [CrossRef]

- Barrios, C.C.; Álvarez-Mateos, P.; Urueña, A.; Díez, D.; García-Martín, J.F. Experimental Investigation on Emissions Characteristics from Urban Bus Fueled with Diesel, Biodiesel and an Oxygenated Additive from Residual Glycerin from Biodiesel Production. Processes 2021, 9, 987. [Google Scholar] [CrossRef]

- Çetinkaya, M.; Ulusoy, Y.; Tekìn, Y.; Karaosmanoğlu, F. Engine and winter road test performances of used cooking oil originated biodiesel. Energy Convers. Manag. 2005, 46, 1279–1291. [Google Scholar] [CrossRef]

- Sezer, I. A review study on using diethyl ether in diesel engines: Effects on fuel properties, injection, and combustion characteristics. Energy Environ. 2019, 31, 179–214. [Google Scholar] [CrossRef]

- Vedharaj, S.; Vallinayagam, R.; Sarathy, S.M.; Dibble, R.W. Improving Vegetable Oil Fueled CI Engine Characteristics Through Diethyl Ether Blending. In Proceedings of the ASME 2016 Internal Combustion Engine Division Fall Technical Conference, Greenville, SC, USA, 9–12 October 2016; Available online: http://proceedings.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/conferences/asmep/90468/ (accessed on 20 November 2022).

- Venu, H.; Madhavan, V. Influence of diethyl ether (DEE) addition in ethanol-biodiesel-diesel (EBD) and methanol-biodiesel-diesel (MBD) blends in a diesel engine. Fuel 2017, 189, 377–390. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Aydin, M. Experimental investigation on the performance, combustion and exhaust emission characteristics of a compression-ignition engine fueled with cottonseed oil biodiesel/diethyl ether/diesel fuel blends. Energy Convers. Manag. 2019, 205, 112355. [Google Scholar] [CrossRef]

- Tamilvanan, A.; Balamurugan, K.; Ashok, B.; Selvakumar, P.; Dhamotharan, S.; Bharathiraja, M.; Karthickeyan, V. Effect of diethyl ether and ethanol as an oxygenated additive on Calophyllum inophyllum biodiesel in CI engine. Environ. Sci. Pollut. Res. 2020, 28, 33880–33898. [Google Scholar] [CrossRef]

- Sivasankaralingam, V.; Raman, V.; Ali, M.J.M.; Alfazazi, A.; Lu, T.; Im, H.; Sarathy, S.M.; Dibble, R. Experimental and Numerical Investigation of Ethanol/Diethyl Ether Mixtures in a CI Engine. In Proceedings of the SAE 2016 International Powertrains, Fuels & Lubricants Meeting, Baltimore, MD, USA, 24–26 October 2016. [Google Scholar] [CrossRef]

- Naik, B.D.; Meivelu, U.; Thangarasu, V.; Annamalai, S.; Sivasankaralingam, V. Experimental and empirical analysis of a diesel engine fuelled with ternary blends of diesel, waste cooking sunflower oil biodiesel and diethyl ether. Fuel 2022, 320, 123961. [Google Scholar] [CrossRef]

- Sangeetha, M.; Boomadevi, P.; Khalifa, A.S.; Brindhadevi, K.; Sekar, M. Vibration, acoustic and emission characteristics of the chlorella vulgaris microalgae oil in compression ignition engine to mitigate environmental pollution. Chemosphere 2022, 293, 133475. [Google Scholar] [CrossRef]

- Kumar, S.; Dinesha, P.; Bran, I. Influence of nanoparticles on the performance and emission characteristics of a biodiesel fuelled engine: An experimental analysis. Energy 2017, 140, 98–105. [Google Scholar] [CrossRef]

- Pulluri, G.K.; Padal, K.T.B.; Sagari, J. Vibration and noise assessment of a diesel engine fueled with Al2O3 nanoparticles dispersed Schleichera oleosa biodiesel. Int. J. Environ. Sci. Technol. 2022, 20, 12645–12658. [Google Scholar] [CrossRef]

- Kumar, O.M.C.; Simhadri, K. Effect of Al2O3 nanoparticle blended Mahua oil biodiesel combustion on performance and emission characteristics of CI engine. Nanotechnol. Environ. Eng. 2022, 7, 765–774. [Google Scholar] [CrossRef]

- Sateesh, K.A.; Yaliwal, V.S.; Soudagar, M.E.M.; Banapurmath, N.R.; Fayaz, H.; Safaei, M.R.; Elfasakhany, A.; El-Seesy, A.I. Utilization of biodiesel/Al2O3 nanoparticles for combustion behavior enhancement of a diesel engine operated on dual fuel mode. J. Therm. Anal. Calorim. 2021, 147, 5897–5911. [Google Scholar] [CrossRef]

- Jaikumar, S.; Srinivas, V.; Meher, R.S. Combustion Characteristics of Direct Injection Diesel Engine Fueled with Dispersant-mixed Al2O3 Nanoparticle-added Biodiesel Blend. Int. J. Thermophys. 2021, 42, 1–15. [Google Scholar] [CrossRef]

- Kaushik, Y.; Verma, V.; Saxena, K.K.; Prakash, C.; Gupta, L.R.; Dixit, S. Effect of Al2O3 Nanoparticles on Performance and Emission Characteristics of Diesel Engine Fuelled with Diesel–Neem Biodiesel Blends. Sustainability 2022, 14, 7913. [Google Scholar] [CrossRef]

- Venu, H.; Madhavan, V. Effect of Al2O3 nanoparticles in biodiesel-diesel-ethanol blends at various injection strategies: Performance, combustion and emission characteristics. Fuel 2016, 186, 176–189. [Google Scholar] [CrossRef]

- Pourhoseini, S.; Ghodrat, M. Experimental investigation of the effect of Al2O3 nanoparticles as additives to B20 blended biodiesel fuel: Flame characteristics, thermal performance and pollutant emissions. Case Stud. Therm. Eng. 2021, 27, 101292. [Google Scholar] [CrossRef]

- Channappagoudra, M. Influence of the aluminium oxide (Al2O3) nanoparticle additive with biodiesel on the modified diesel engine performance. Int. J. Ambient. Energy 2019, 42, 1776–1784. [Google Scholar] [CrossRef]

- Raju, V.D.; Kishore, P.; Nanthagopal, K.; Ashok, B. An experimental study on the effect of nanoparticles with novel tamarind seed methyl ester for diesel engine applications. Energy Convers. Manag. 2018, 164, 655–666. [Google Scholar] [CrossRef]

- Ganesh, D.; Gowrishankar, G. Effect of nano-fuel additive on emission reduction in a biodiesel fuelled CI engine. In Proceedings of the 2011 International Conference on Electrical and Control Engineering (ICECE), Yichang, China, 16–18 September 2011; pp. 3453–3459. [Google Scholar] [CrossRef]

- Gan, Y.; Qiao, L. Combustion characteristics of fuel droplets with addition of nano and micron-sized aluminum particles. Combust. Flame 2011, 158, 354–368. [Google Scholar] [CrossRef]

- Tyagi, H.; Phelan, P.E.; Prasher, R.; Peck, R.; Lee, T.; Pacheco, J.R.; Arentzen, P. Increased Hot-Plate Ignition Probability for Nanoparticle-Laden Diesel Fuel. Nano Lett. 2008, 8, 1410–1416. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Attia, A.M.; El-Batsh, H.M. The effect of Aluminum oxide nanoparticles addition with Jojoba methyl ester-diesel fuel blend on a diesel engine performance, combustion and emission characteristics. Fuel 2018, 224, 147–166. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Afzal, A.; Safaei, M.R.; Manokar, A.M.; El-Seesy, A.I.; Mujtaba, M.A.; Samuel, O.D.; Badruddin, I.A.; Ahmed, W.; Shahapurkar, K.; et al. Investigation on the effect of cottonseed oil blended with different percentages of octanol and suspended MWCNT nanoparticles on diesel engine characteristics. J. Therm. Anal. Calorim. 2020, 147, 525–542. [Google Scholar] [CrossRef]

- Lapuerta, M.; Rodríguez-Fernández, J.; Agudelo, J.R.; Boehman, A.L. Blending scenarios for soybean oil derived biofuels with conventional diesel. Biomass-Bioenergy 2013, 49, 74–85. [Google Scholar] [CrossRef]

- Veza, I.; Zainuddin, Z.; Tamaldin, N.; Idris, M.; Irianto, I.; Fattah, I.R. Effect of palm oil biodiesel blends (B10 and B20) on physical and mechanical properties of nitrile rubber elastomer. Results Eng. 2022, 16, 100787. [Google Scholar] [CrossRef]

- Lahane, S.; Subramanian, K. Effect of different percentages of biodiesel–diesel blends on injection, spray, combustion, performance, and emission characteristics of a diesel engine. Fuel 2015, 139, 537–545. [Google Scholar] [CrossRef]

- Palani, Y.; Devarajan, C.; Manickam, D.; Thanikodi, S. Performance and emission characteristics of biodiesel-blend in diesel engine: A review. Environ. Eng. Res. 2020, 27, 200338. [Google Scholar] [CrossRef]

- Mirhashemi, F.S.; Sadrnia, H. NOx emissions of compression ignition engines fueled with various biodiesel blends: A review. J. Energy Inst. 2019, 93, 129–151. [Google Scholar] [CrossRef]

- Sharp, C.A.; Ryan, T.W.; Knothe, G. Heavy-Duty Diesel Engine Emissions Tests Using Special Biodiesel Fuels; SAE International: Warrendale, PA, USA, 2018; pp. 1204–1212. [Google Scholar]

- Zdrodowski, R.; Gangopadhyay, A.; Anderson, J.E.; Ruona, W.C.; Uy, D.; Simko, S.J. Effect of Biodiesel (B20) on Vehicle-Aged Engine Oil; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Devarajan, Y. Experimental evaluation of combustion, emission and performance of research diesel engine fuelled di-methyl- carbonate and biodiesel blends. Atmospheric Pollut. Res. 2018, 10, 795–801. [Google Scholar] [CrossRef]

- Atmanli, A.; Ileri, E.; Yuksel, B.; Yilmaz, N. Extensive analyses of diesel–vegetable oil–n-butanol ternary blends in a diesel engine. Appl. Energy 2015, 145, 155–162. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A.; Vigil, F.M. Quaternary blends of diesel, biodiesel, higher alcohols and vegetable oil in a compression ignition engine. Fuel 2018, 212, 462–469. [Google Scholar] [CrossRef]

- Yilmaz, N.; Vigil, F.M. Potential use of a blend of diesel, biodiesel, alcohols and vegetable oil in compression ignition engines. Fuel 2014, 124, 168–172. [Google Scholar] [CrossRef]

- Sastry, G.; Deb, M.; Panda, J.K. Effect of Fuel Injection Pressure, Isobutanol and Ethanol Addition on Performance of Diesel-biodiesel Fuelled D.I. Diesel Engine. Energy Procedia 2015, 66, 81–84. [Google Scholar] [CrossRef]

- How, H.; Masjuki, H.; Kalam, M.; Teoh, Y. Engine Performance, Emission and Combustion Characteristics of a Common-rail Diesel Engine Fuelled with Bioethanol as a Fuel Additive in Coconut Oil Biodiesel Blends. Energy Procedia 2014, 61, 1655–1659. [Google Scholar] [CrossRef]

- CHasimoglu, C. Exhaust emission characteristics of a low-heat-rejection diesel engine fuelled with 10 per cent ethanol and 90 per cent diesel fuel mixture. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2008, 222, 93–100. [Google Scholar] [CrossRef]

- Subbaiah, G.V.V.; Gopal, K.R.R.; Hussain, S.A.A.; Prasad, B.D.D.; Reddy, K.T.T.; Pradesh, A. Rice Bran Oil Biodiesel as an Additive in Diesel-Ethanol Blends for Diesel Engines. Int. J. Recent Res. Appl. Stud. 2010, 3, 334–342. [Google Scholar]

- Ramalingam, K.; Kandasamy, A.; Subramani, L.; Balasubramanian, D.; Thadhani, J.P.J. An assessment of combustion, performance characteristics and emission control strategy by adding anti-oxidant additive in emulsified fuel. Atmospheric Pollut. Res. 2018, 9, 959–967. [Google Scholar] [CrossRef]

- Markov, V.A.; Sa, B.; Devyanin, S.N.; Zherdev, A.A.; Maldonado, P.R.V.; Zykov, S.A.; Denisov, A.D.; Ambawatte, H.C. Investigation of the Performances of a Diesel Engine Operating on Blended and Emulsified Biofuels from Rapeseed Oil. Energies 2021, 14, 6661. [Google Scholar] [CrossRef]

- Hamid, M.; Abdullah, M.; Idroas, M.; Alauddin, Z.Z.; Sharzali, C.; Naser, M.; Khimi, S. A study of performance of a diesel engine fueled with emulsified biofuel and its blends. J. Pshys. 2018, 1082, 012098. [Google Scholar] [CrossRef]

- Ikura, M.; Stanciulescu, M.; Hogan, E. Emulsiÿcation of Pyrolysis Derived Bio-Oil in Diesel Fuel. 2003. Available online: www.sciencedirect.com (accessed on 20 November 2022).

- Jacob, A.; Ashok, B.; Alagumalai, A.; Chyuan, O.H.; Le, P.T.K. Critical review on third generation micro algae biodiesel production and its feasibility as future bioenergy for IC engine applications. Energy Convers. Manag. 2020, 228, 113655. [Google Scholar] [CrossRef]

- Subramani, S.; Natarajan, K.; Rao, G.L.N. Optimization of injection timing and anti-oxidants for multiple responses of CI engine fuelled with algae biodiesel blend. Fuel 2020, 287, 119438. [Google Scholar] [CrossRef]

- Bošnjaković, M.; Sinaga, N. The Perspective of Large-Scale Production of Algae Biodiesel. Appl. Sci. 2020, 10, 8181. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A.; Hall, M.J.; Vigil, F.M. Determination of the Optimum Blend Ratio of Diesel, Waste Oil Derived Biodiesel and 1-Pentanol Using the Response Surface Method. Energies 2022, 15, 5144. [Google Scholar] [CrossRef]

- Chaudhary, V.; Gakkhar, R.P. Exergy analysis of small DI diesel engine fueled with waste cooking oil biodiesel. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 43, 201–215. [Google Scholar] [CrossRef]

- Thomas, J.J.; Sabu, V.; Nagarajan, G.; Kumar, S.; Basrin, G. Influence of waste vegetable oil biodiesel and hexanol on a reactivity controlled compression ignition engine combustion and emissions. Energy 2020, 206, 118199. [Google Scholar] [CrossRef]

- Khan, H.M.; Iqbal, T.; Yasin, S.; Irfan, M.; Kazmi, M.; Fayaz, H.; Mujtaba, M.; Ali, C.H.; Kalam, M.; Soudagar, M.E.M.; et al. Production and utilization aspects of waste cooking oil based biodiesel in Pakistan. Alex. Eng. J. 2021, 60, 5831–5849. [Google Scholar] [CrossRef]

- Hajjari, M.; Tabatabaei, M.; Aghbashlo, M.; Ghanavati, H. A review on the prospects of sustainable biodiesel production: A global scenario with an emphasis on waste-oil biodiesel utilization. Renew. Sustain. Energy Rev. 2017, 72, 445–464. [Google Scholar] [CrossRef]

- Abed, K.; El Morsi, A.; Sayed, M.; El Shaib, A.; Gad, M. Effect of waste cooking-oil biodiesel on performance and exhaust emissions of a diesel engine. Egypt. J. Pet. 2018, 27, 985–989. [Google Scholar] [CrossRef]

- Spikes, H. Friction Modifier Additives. Tribol. Lett. 2015, 60, 5. [Google Scholar] [CrossRef]

- Spikes, H. The History and Mechanisms of ZDDP. Tribol. Lett. 2004, 17, 469–489. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of nanoparticles in oil lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Choa, S.-H.; Ludema, K.C.; Potter, G.E.; DeKoven, B.M.; Morgan, T.A.; Kar, K.K. A Model for the Boundary Film Formation and Tribological Behavior of a Phosphazene Lubricant on Steel. Tribol. Trans. 1995, 38, 757–768. [Google Scholar] [CrossRef]

- Fein, R.S.; Kreuz, K.L. Chemistry of Boundary Lubrication of Steel by Hydrocarbons. ASLE Trans. 1965, 8, 29–38. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Luo, J. Superlubricity Achieved with Mixtures of Polyhydroxy Alcohols and Acids. Langmuir 2013, 29, 5239–5245. [Google Scholar] [CrossRef] [PubMed]

- Ge, X.; Li, J.; Zhang, C.; Luo, J. Liquid Superlubricity of Polyethylene Glycol Aqueous Solution Achieved with Boric Acid Additive. Langmuir 2018, 34, 3578–3587. [Google Scholar] [CrossRef]

- George, J.M.; Martin, J.M.; Mathia, T.; Kapsa, P.; Meille, G.; Montes, H. Mechanism of Boundary Lubrication with Zinc Dithiophosphate; Elsevier: Amsterdam, The Netherlands, 1979. [Google Scholar]

- Nygaard, E.M.; Oberright, E.A.; Woodbury, N.J. Lubricating Oil Containing Zinc Carboxylate-Coordenated Zinc Dthophos Phates. U.S. Patent No. 3,102,096, 27 August 1963. [Google Scholar]

- Wang, J.; He, T.; Song, C.; Li, X.; Chen, B. Engine Oil Degradation Induced by Biodiesel: Effect of Methyl Oleate on the Performance of Zinc Dialkyldithiophosphate. ACS Omega 2019, 4, 16166–16170. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. A review of current understanding in tribochemical reactions involving lubricant additives. Friction 2022, 11, 489–512. [Google Scholar] [CrossRef]

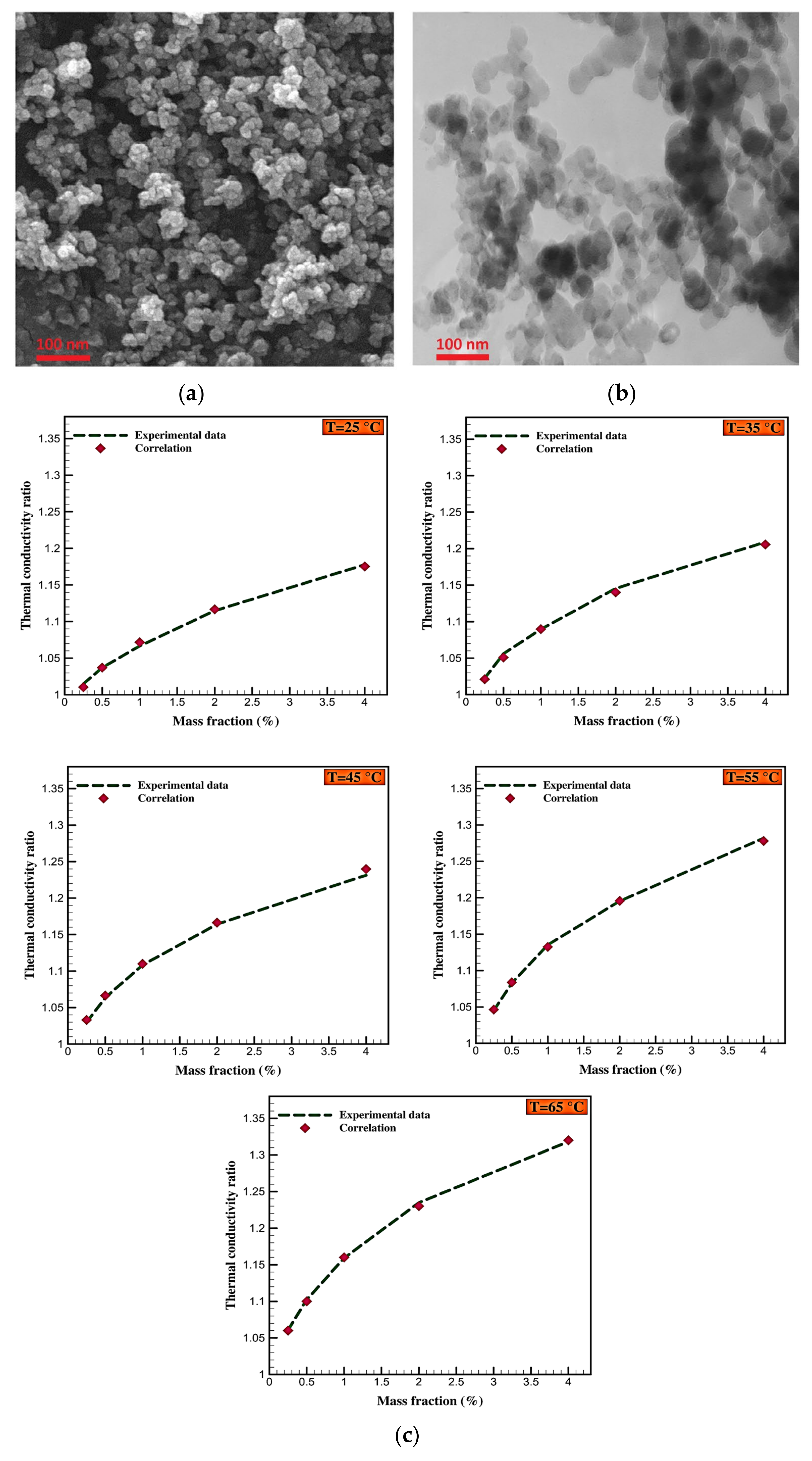

- Sulgani, M.T.; Karimipour, A. Improve the thermal conductivity of 10w40-engine oil at various temperature by addition of Al2O3/Fe2O3 nanoparticles. J. Mol. Liq. 2019, 283, 660–666. [Google Scholar] [CrossRef]

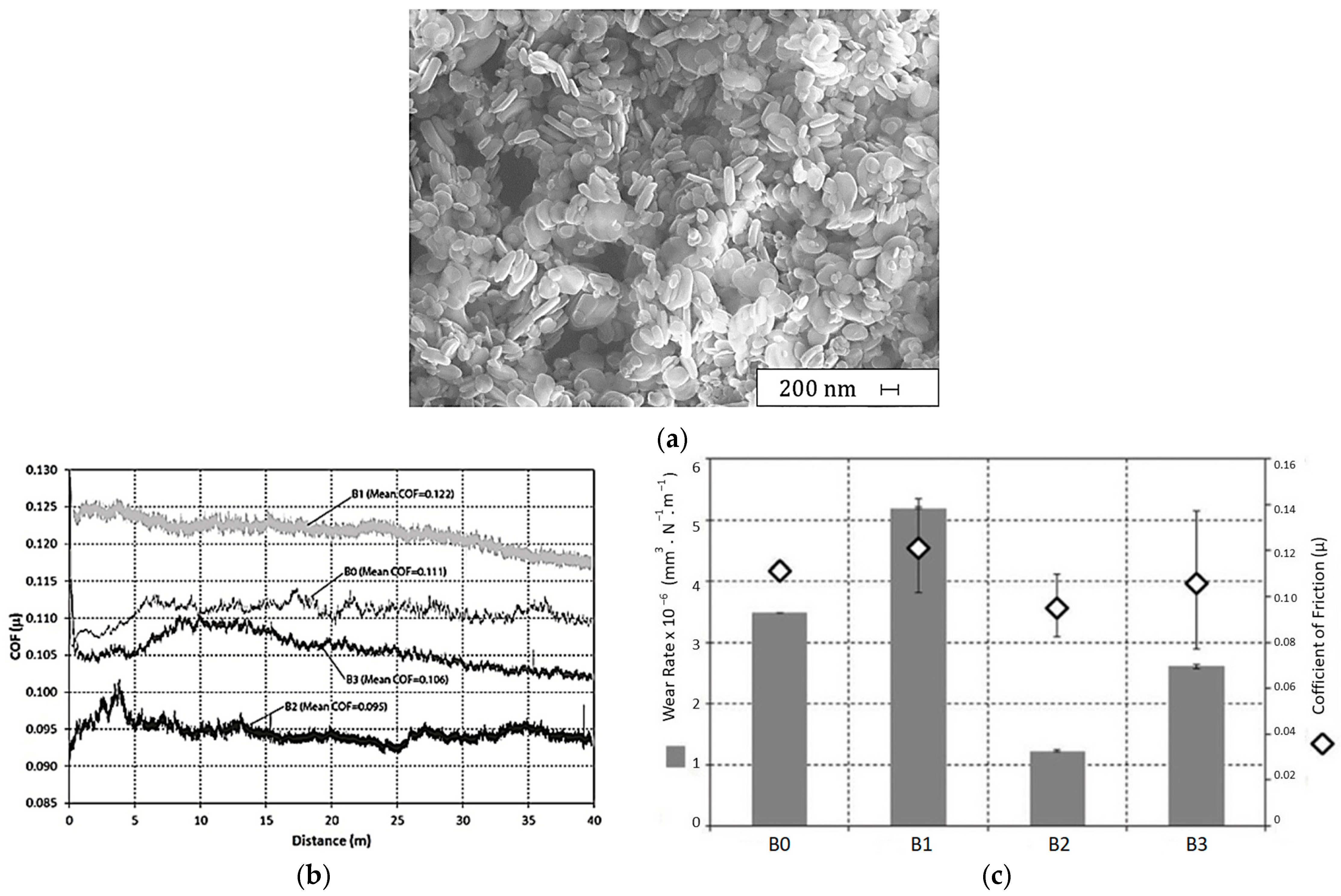

- Çelik, O.N.; Ay, N.; Göncü, Y. Effect of Nano Hexagonal Boron Nitride Lubricant Additives on the Friction and Wear Properties of AISI 4140 Steel. Part. Sci. Technol. 2013, 31, 501–506. [Google Scholar] [CrossRef]

- Kumar, V.; Jatti, S. Titanium Oxide Nano-Particles as Anti-Wear and Friction-Reduction Additives in Lubricating Oil. J. Chem. Pharm. Res. 2015, 7, 1049–1055. Available online: www.jocpr.com (accessed on 20 November 2022).

- Singh, Y.; Singla, A.; Upadhyay, A.K. Effect of SiO2 as an additive to Mongongo oil during friction and wear characterization. Mater. Today Proc. 2021, 46, 11165–11168. [Google Scholar] [CrossRef]

- Singh, A.; Chauhan, P.; Mamatha, T. A review on tribological performance of lubricants with nanoparticles additives. Mater. Today Proc. 2020, 25, 586–591. [Google Scholar] [CrossRef]

- Padgurskas, J.; Rukuiza, R.; Prosyčevas, I.; Kreivaitis, R. Tribological properties of lubricant additives of Fe, Cu and Co nanoparticles. Tribol. Int. 2013, 60, 224–232. [Google Scholar] [CrossRef]

- Wan, Q.; Jin, Y.; Sun, P.; Ding, Y. Tribological Behaviour of a Lubricant Oil Containing Boron Nitride Nanoparticles. Procedia Eng. 2015, 102, 1038–1045. [Google Scholar] [CrossRef]