1. Introduction

In recent years, wireless power transfer (WPT) has gained popularity as a technology because it offers mobile and stationary devices a practical and effective way to receive electrical energy [

1]. Dynamic wireless power transfer (DWPT), which involves the continuous supply of electricity to a moving device or vehicle, is one particular area of WPT that has drawn a lot of interest [

2,

3,

4]. This technology offers a wide range of possible uses, such as industrial applications [

5], mobile devices [

6] and charging for electric vehicles [

7]. Thus, DWPT is a rapidly developing technology with several potential uses in a variety of industries. In the upcoming years, it is expected that new and creative applications of DWPT will emerge as research in this area continues to improve.

Various initiatives throughout the world have previously tackled the topic of inductive power transmission for EVs while driving. These projects are related to various use cases and a wide range of system topologies, illustrating the enormous potential of DWPT charging technology in a wide range of applications. DWPT has the ability to interfere with both long and short ranges, which means highway intercity connectivity as well as inner-city mobility of both light- and heavy-duty EVs. Although such a vision is to be expected based on earlier proofs of concept, widespread implementation is still a long way off.

Table 1 summarizes the technical design of yet accomplished system implementations by listing a selection of the most significant accomplishments in DWPT technology.

One primary goal is to maximize the uptime of electrically driven vehicles while reducing the size of its battery. In this context, the primary and secondary coil configuration and form are very important to the system’s power continuity and control approach. The authors of [

8] provide a summary of potential coil types for DWPT applications. Circular coils [

2,

9], DD (double D) coils [

3] or line cables [

10] have been utilized frequently.

When only one secondary coil is employed and the pickup moves over the joints, systems with end-to-end concatenated circular primary coils experience a large power loss. The authors of [

9] illustrate a solution to this issue, but they greatly elevate the system’s complexity. Alternative methods to maintain a constant power flow include either matching the size of primary and secondary coils [

11] or using control algorithms [

12]. Several pickup modules must be used in parallel when utilizing DD coils horizontally to avoid zero levels of transferred power [

13]. Conversely, DD coils that are vertically oriented [

14] are more prone to lateral displacement.

Table 1.

Milestones in DWPT history of total system implementation.

Table 1.

Milestones in DWPT history of total system implementation.

| Project | Vehicle Type | Road Design | Power

in kW | Eff.

in % | Fequ.

in kHz | Ref. |

|---|

Bombardier

PRIMOVE | Tram, E-Bus | Multiphase

Rail-Based | 200kW | 85 | 20 | [15,16] |

KAIST

OLEV 4G | E-Bus | Singlephase

Rail-Based | 4 × 25 | 80 | 20 | [15,17,18] |

Qualcomm

FABRIC | EVs | DD Pad-Based | 20 | 85 | 85 | [3,13,15] |

| ORNL | Trucks,

E-Bus, EVs | Long DD Pad-Based | 200 | >90 | 85 | [14,19] |

| Electreon | Trucks,

E-Bus, EVs | DD Pad-Based | 70 | | 85 | [4] |

| Toyota | EVs, E-Bus | Circular | 10 | 85 | 85 | [2] |

The following work provides a new method for DWPT systems that enables a smooth power flow using circular coils. It only requires one pickup coil and a fairly straightforward control scheme. Additionally, the size of the secondary coil allows for a simple adjustment of the design power level. In the beginning of this article, the basics of the analytical design of the system are presented. A system based on a LCC-LCC compensation is designed. Afterward, both hardware and software implementations are explained in more detail. Especially, the primary sided inverters and the communication between them, as well as the software-implemented state machine to control the system, are further described. Subsequently, the transmittable power as well as the influence of the primary coils on each other are examined on the basis of a final design. Finally, the results and especially the primary couplings among each other are critically analyzed, and the results are summarized.

This article is an extended version of paper [

20] presented at the 2022 Wireless Power Week from 5 to 8 July 2022 in Bordeaux, France.

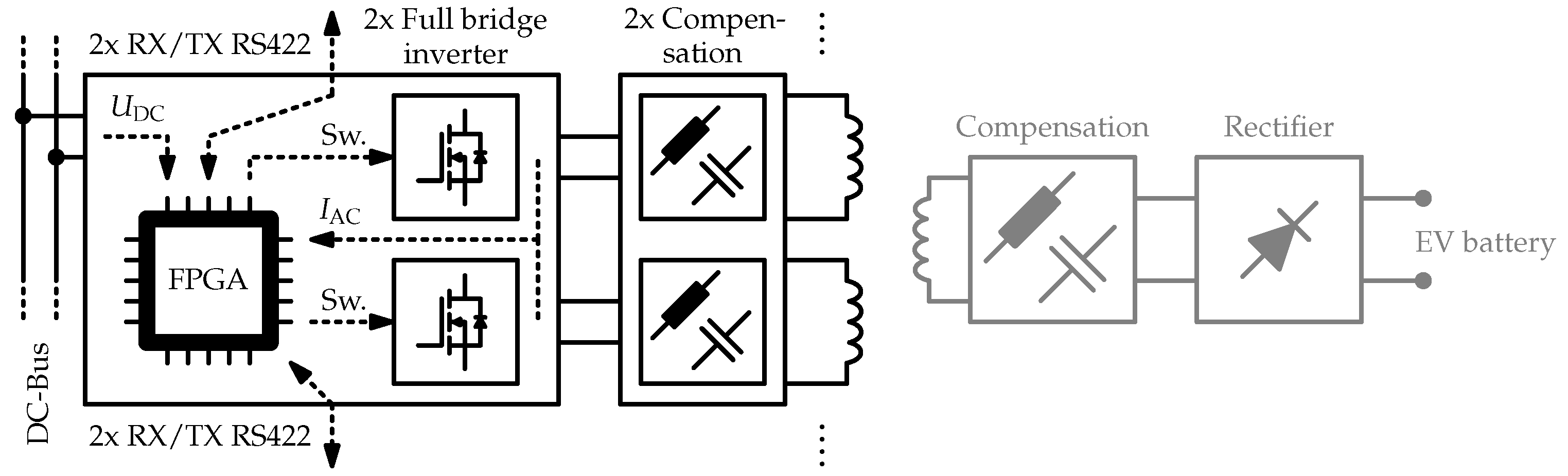

2. Fundamentals of LCC-LCC Systems

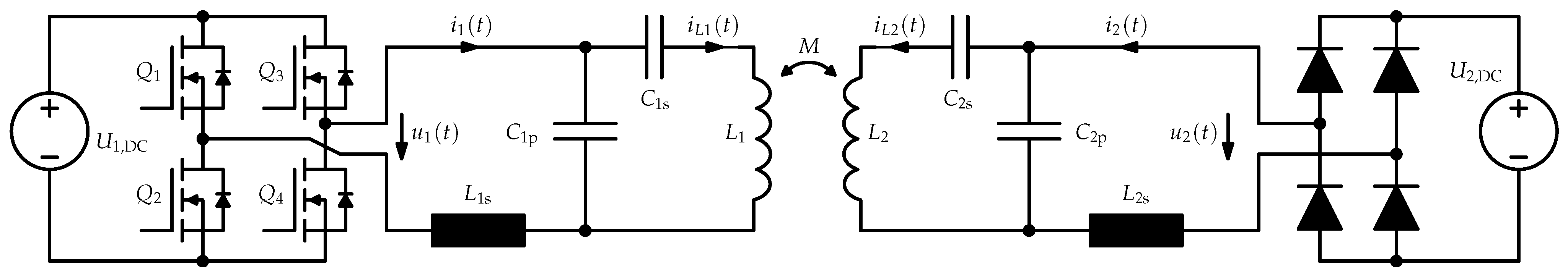

In this section, the fundamentals of inductive power transfer systems with LCC-LCC compensation are explained in more detail. First, systems with one primary coil are considered. The proposed dynamic wireless power transfer (DWPT) system uses an LCC-LCC-compensated wireless power transfer path. An electric circuit of a conventional one-to-one system is shown in

Figure 1. The coupled coils are illustrated in an abstracted manner. Basic principles for the magnetic and electrical modeling of coupled coils are outlined in [

21,

22,

23].

Major benefits include the constant current behavior at the load side and its immunity to a decoupling of the coil system (

). Furthermore, this compensation configuration provides a rather steady efficiency for misaligned coils [

24]. This makes LCC-LCC-compensated systems well suited for dynamic charging of electrical vehicles. A detailed derivation of the system’s behavior is given in [

25,

26]. Usually, the primary and secondary resonant tanks are designed to match the system’s design resonant frequency

In case of automotive application, the frequency is normally in the range of 85 kHz. The remaining design criteria for the transfer path’s components are given in (

2) and (

3).

The scaling factors

and

can be freely selected in the range

. For the following studies, a factor of 0.38 was chosen. The wireless power transfer path behaves like a band pass filter matched to

. Hence, for excitation only, the fundamental of the inverter output voltage

and the rectifier input voltage

has to be considered. The factor

D with

represents the relative pulse when using a symmetric PWM on the primary side. Both currents

in the coupled coils are proportional to the corresponding voltage levels

or

. Additionally, there is a constant phase relation between voltage and current that is utilized and is very important for the DWPT system’s concept. With the inverter output and rectifier input current

and the fundamental voltage levels (

4) or (

5), the transferred power

can be calculated.

3. Systems with Multiple Primary Coils

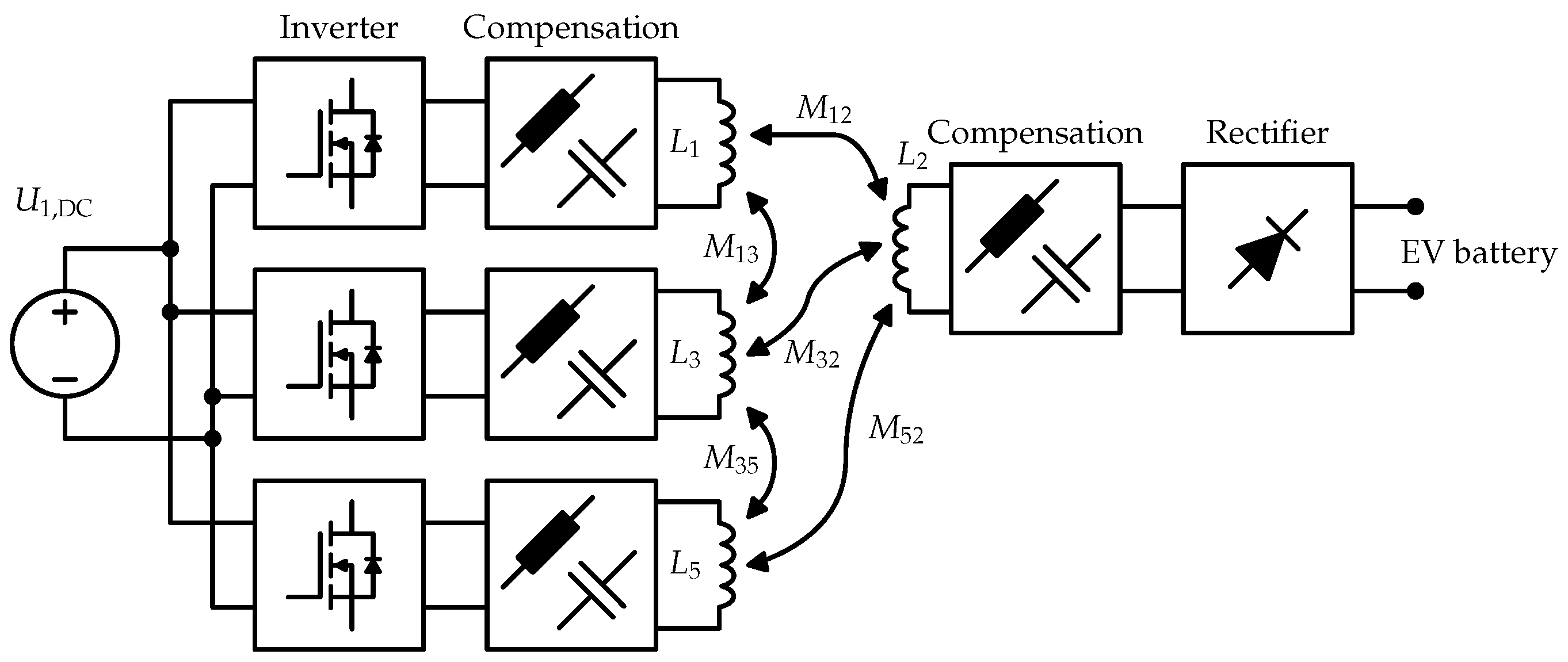

In the following section, the model is extended for use with multiple primary coils. In addition, the arrangement of the coils and the control of the inverters are explained. The proposed DWPT systems consist of numerous straight arranged primary segments outlined in

Figure 1. A simplified block diagram with three primary coils and a picture of the resulting system are shown in

Figure 2.

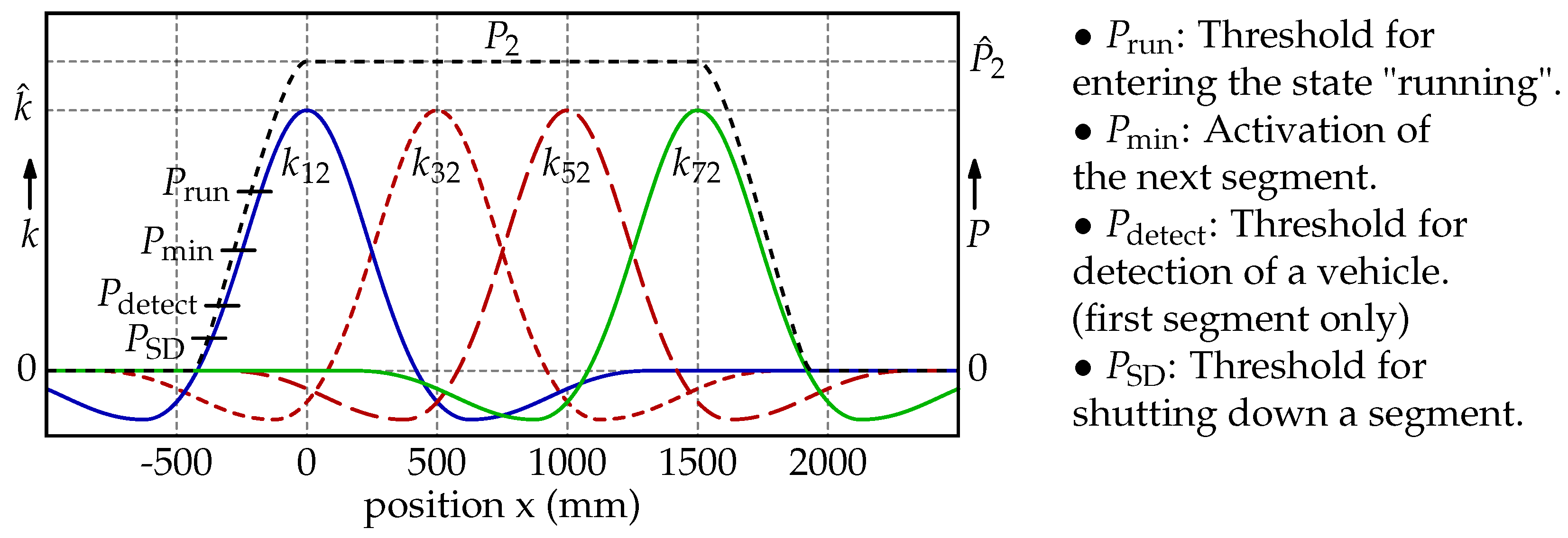

Driving the inverters synchronously results in phase primary coil currents according to (

7). Consequently, the cumulative transferred power

can be expressed as a superposition of all transfer paths. However, an activated primary segment does not necessarily lead to an increased power flow even when it is magnetically coupled to the pickup coil. A negatively coupled and activated primary segment results in a negative power flow from the secondary to the primary side. This effect was verified with measurements. The qualitative illustration of the underlying coupling factor courses is shown afterward. Segments without any magnetic coupling to a pickup should be turned off to reduce losses. This must be performed by shorting the related inverter output. An abstracted schematic of the the coil arrangement and control strategy is shown in

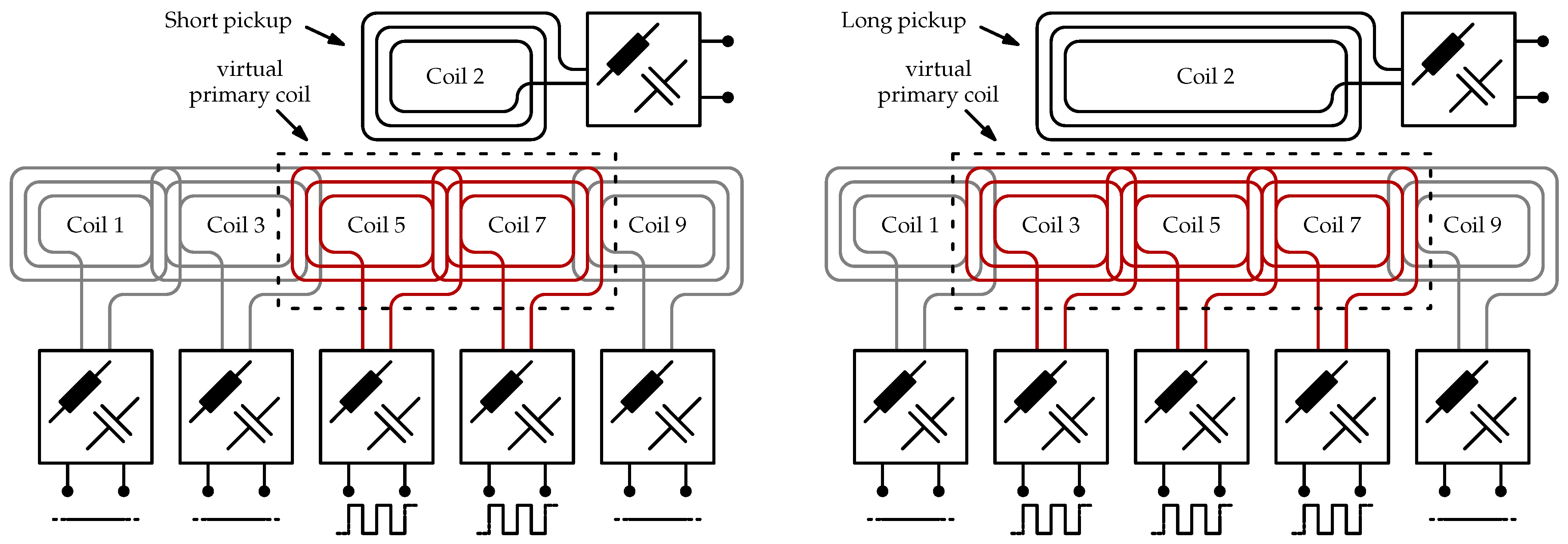

Figure 3.

The difference between the left and right configuration illustrates the scalability of the proposed approach. Depending on the pickup length, more or less primary segments are in an active state. Since the coil currents are in phase, the magnetic flux at the coil joints is eliminated, and a longer primary coil is formed. The transferred power can be easily scaled with the pickup coil length.

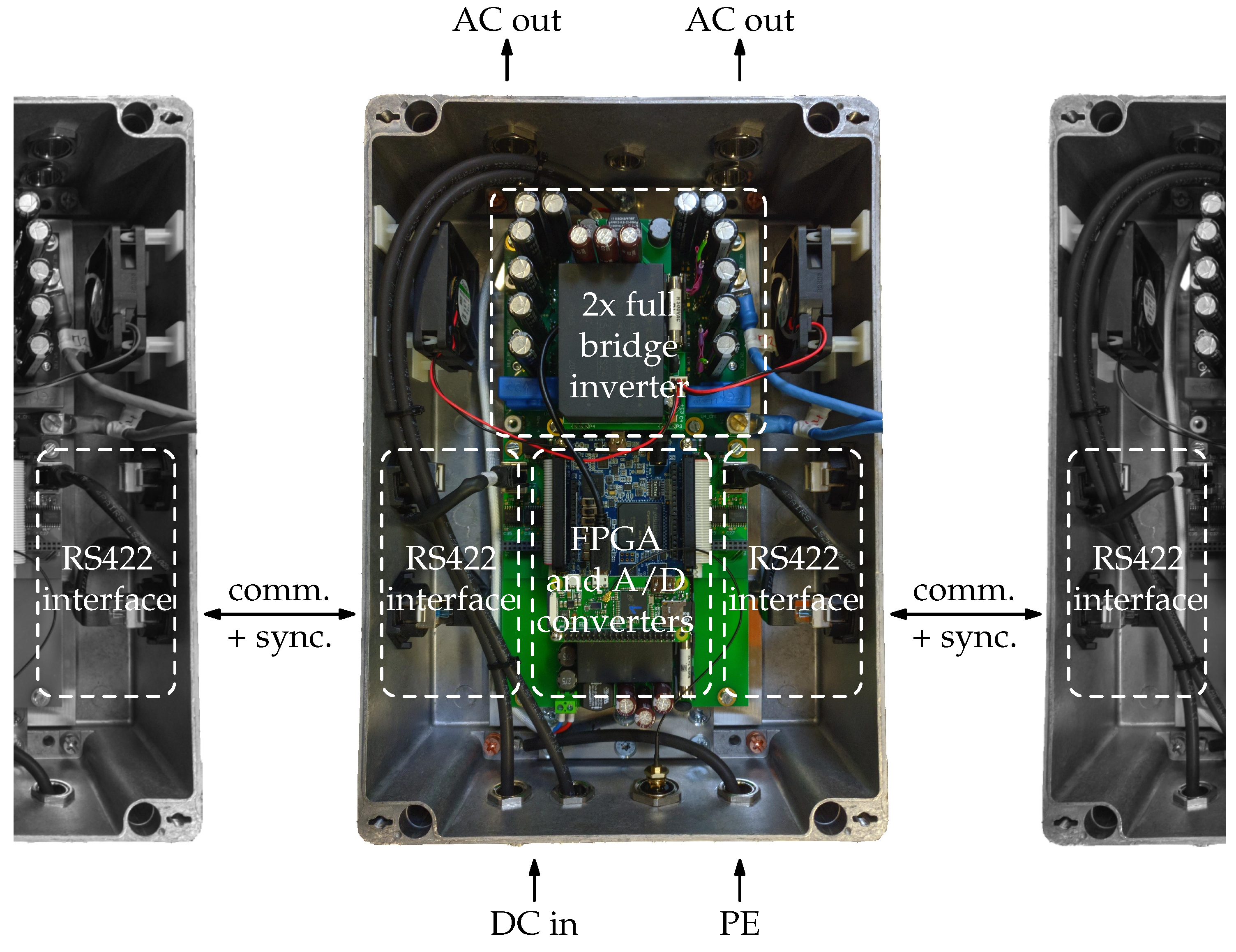

4. Realization of the DWPT System and Measurement Setup

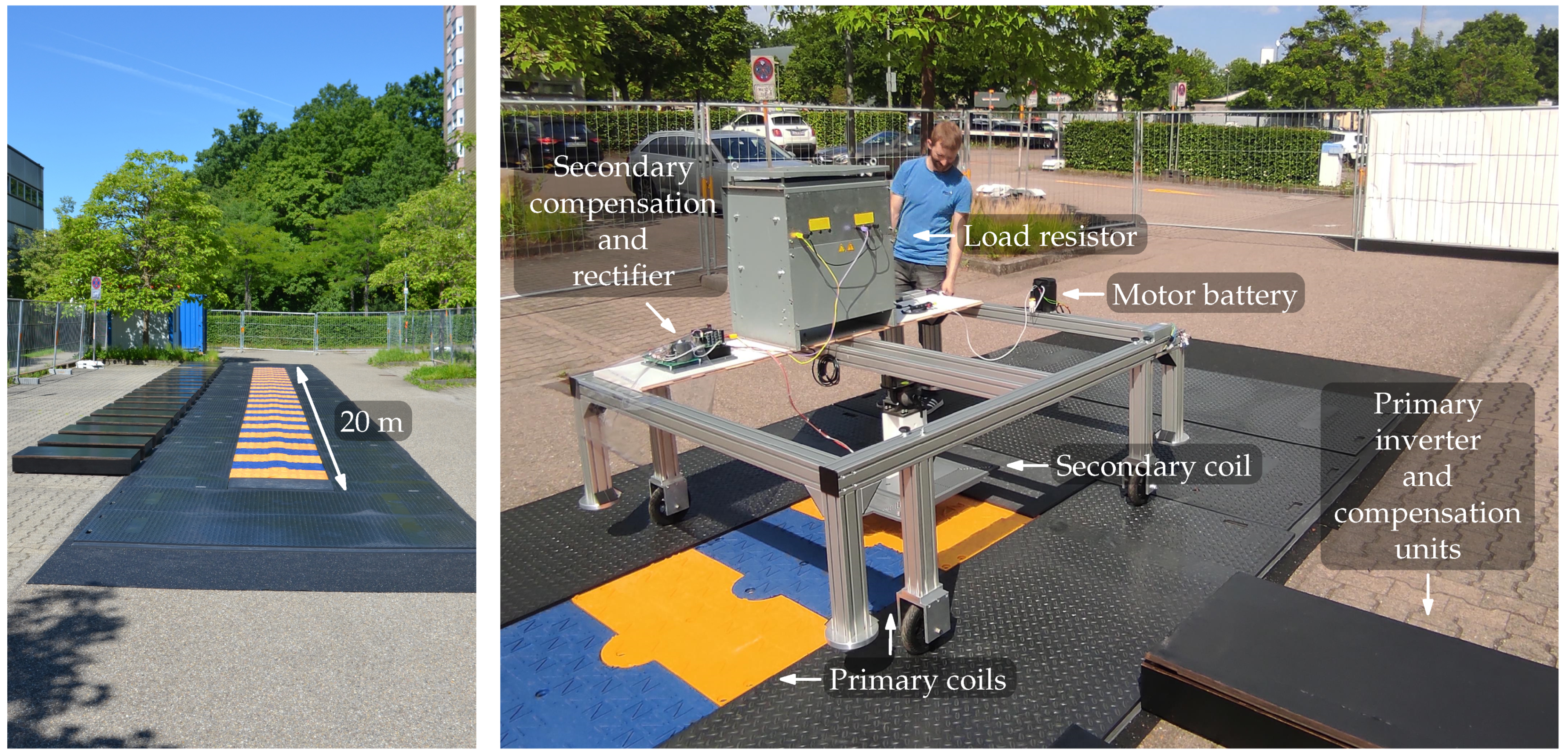

This section describes the design of the DWPT test system. It includes the hardware architecture as well as the functionality of the software used in the inverter units. According to the principle outlined in the previous section, a DWPT test track was built up. An overview of the realized system is given in

Figure 4.

To keep the vehicle on the track, a plastic rail (not depicted in

Figure 4) on one side of the lane was mounted. This rail guided both left side wheels of the vehicle. For safety reasons and for sufficient clearance between the person and the coil system, the vehicle was electrically driven and remote controlled. The drive motors were supplied by a 36 V battery. A summary of the system’s boundary conditions for the measurements in the following section are given in

Table 2. The 20 m long test track consists of 40 primary segments connected to 20 inverter and compensation units. Each inverter unit is connected to a compensation unit and supplies two primary segments. A block diagram is depicted in

Figure 5.

Any unit is controlled by an FPGA board (Terasic DE0-Nano-SoC), contains two full bridge inverters (8x GeneSiC G3R30MT12K in total) and is supplied by a general DC bus. Both inverter output currents and the DC link voltage are available measurement quantities to the FPGA. Currents are measured with a sampling rate of 10 MSps and 12 bit resolution (2x Analog Devices LTC1420 in total). Since the DC link voltage changes very slowly, it is sampled with 100 kSps but with a higher 16 bit resolution (Analog Devices AD7684). The inverter output voltages

are not acquired but can be reconstructed by means of the DC link voltage and the full bridge switching commands according to (

10). Subsequently, the active output power

for both full bridge inverters can be calculated two times per full wave. Each inverter unit is equipped with two RS422 communication interfaces used for synchronization and high-level communication to the direct adjacent units. One interface consists of two bidirectional channels. The first channel is used for high-level data transmission such as segment power or state. The other channel is utilized for PWM synchronization in a low level way. A detailed picture of the developed inverter unit is shown in

Figure 6.

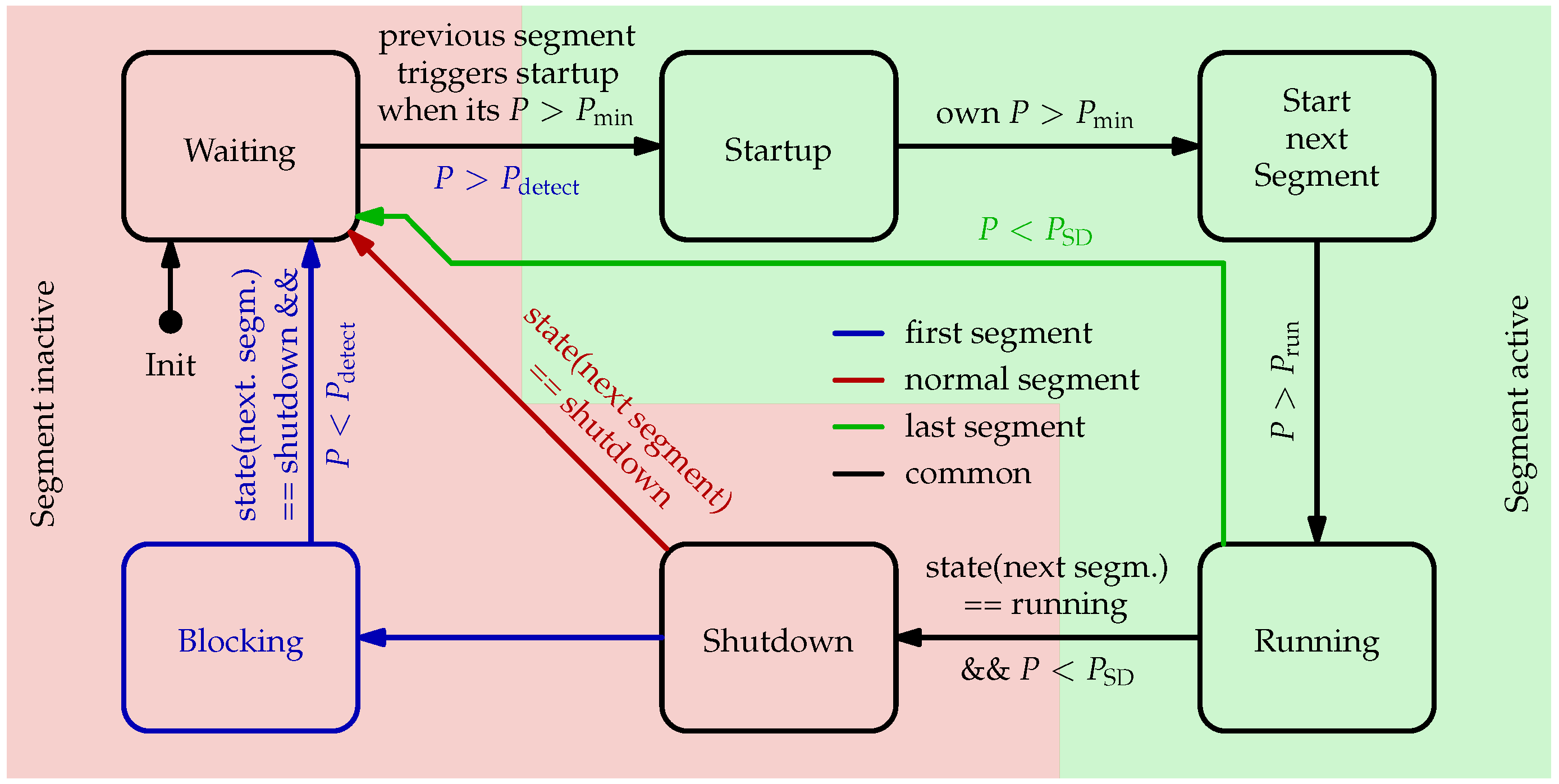

Segment activation and shutdown are controlled by one state machine per segment. A state flow diagram of the underlying state machine is shown in

Figure 7. A qualitative illustration of the related power levels besides the courses of the coupling factors and the transferred power is depicted in

Figure 8.

Depending on the segment type, the state flow varies at certain points. There are three different types: one first segment at the track’s starting point, followed by several normal segments, and finally one last segment at the track’s tail end. A startup of a normal segment is triggered by the preceding one when its transferred power reaches the level

. As the first segment has no precursor, it normally runs in an idle state with reduced PWM duty cycle and starts itself when

is exceeded. As soon as a segment’s transferred power reaches

, its state changes to the running state. Subsequently, the coupling factor and transferred power of the regarding segment reach and cross their maximum, and the transferred power decreases afterward (see

Figure 8). If the following segment is in the running state and the power drops below

, a segment enters the shutdown state. Because the last segment has no successor, only the power condition (

) is sufficient to re-enter the waiting state. Normal segments just reach the waiting state when the following one is shut down. The first segment is additionally blocked after a shutdown in order to avoid an instant reactivation by itself. This mode can only be left if the following segment is shut down and its own transferred power is below

.

5. Measurement Results

Following, the measurements obtained with the test system are presented. In addition to the transmitted power and efficiency, the interference between the primary segments and its effect on the inverter currents are considered. To acquire the following results, the pickup vehicle (see

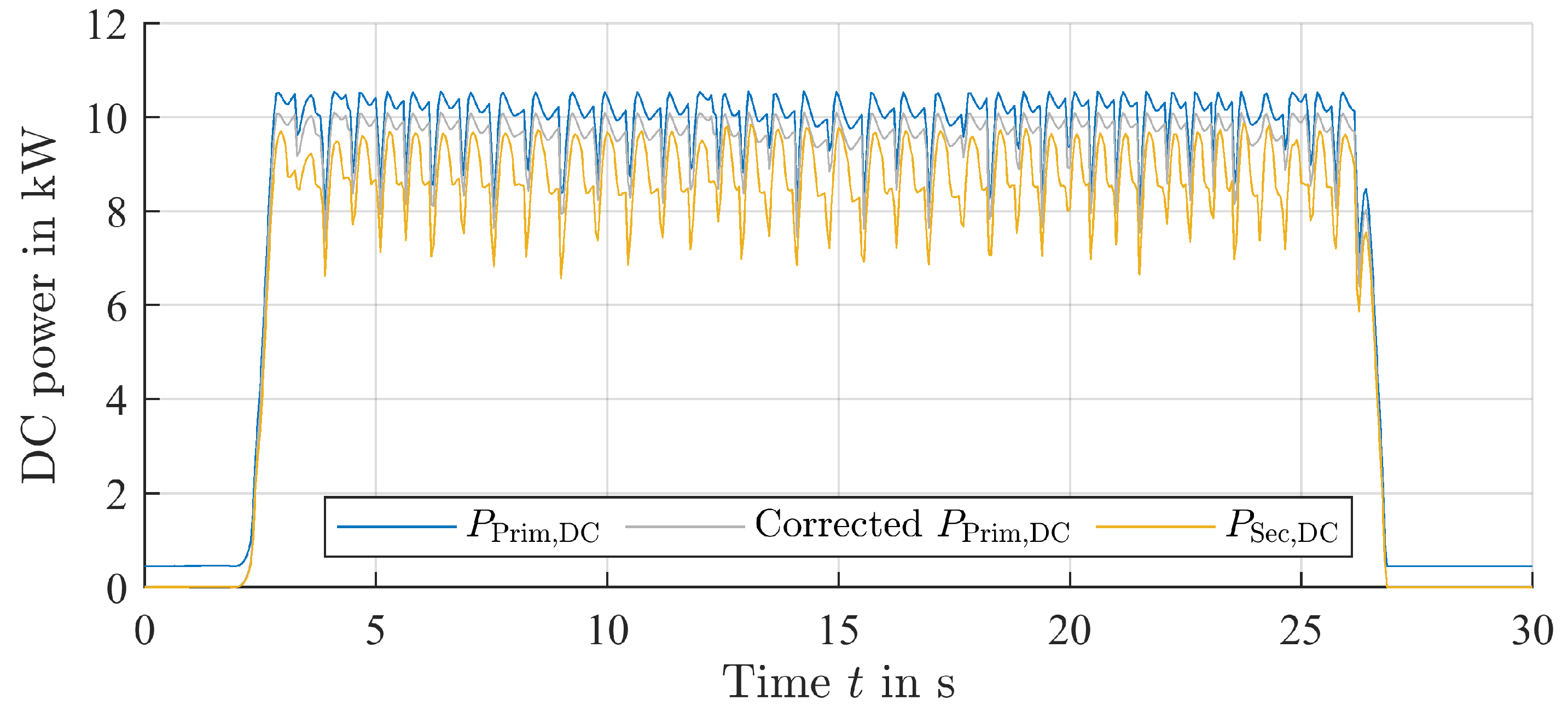

Figure 4) was moved over the test track with moderate velocity. The power and efficiency measurements in

Figure 9 and

Figure 10 were performed with a pickup speed of approximately

. Both primary and secondary power were recorded with a Yokogawa WT1800-E power analyzer. Since only one power meter was used, the secondary DC voltage and current were measured with the aid of a trailing cable. All remaining evaluations were made on the basis of oscilloscope recordings and an elevated pickup speed of about

. Here, an Yokogawa DLM4038 eight channel oscilloscope, current clamps and differential voltage probes were utilized. An overview of the system’s parameters is shown in

Table 2.

Figure 9 shows the primary and secondary DC power

and

while the pickup moves over the entire test track. The system’s overall idle power is fairly high by reason of the modular research friendly design and the idling first segment. Both reasons have little practical relevance. The pickup approximation detection should later be realized with dedicated high-frequency coils. Additionally, a monolithic controller and power electronics design allow for massively reduced idle power consumption. Thus, a corrected primary power

that neglects the idle consumption was derived. Primary inverter, rectifier, compensation and coil losses are nevertheless included in the corrected power.

The DC to DC efficiency rests on the corrected primary and secondary DC powers, which are shown in

Figure 10. For a better readability, the course was additionally smoothed with a moving average filter. Over the relevant range, an efficiency of approximately 91 to 92% was achieved. The high variation in the efficiency is presumably caused by the large distributed DC link capacitance. Energy stored in the inverter-integrated capacitors is not recognized immediately, because the power meter is connected to the DC bus entry point. Fast power demand changes of the inverters are initially evened out by the distributed DC link capacitors, which leads to a lag in the primary power recordings, whereas the transferred power on the secondary side is recorded with no or neglectable delay.

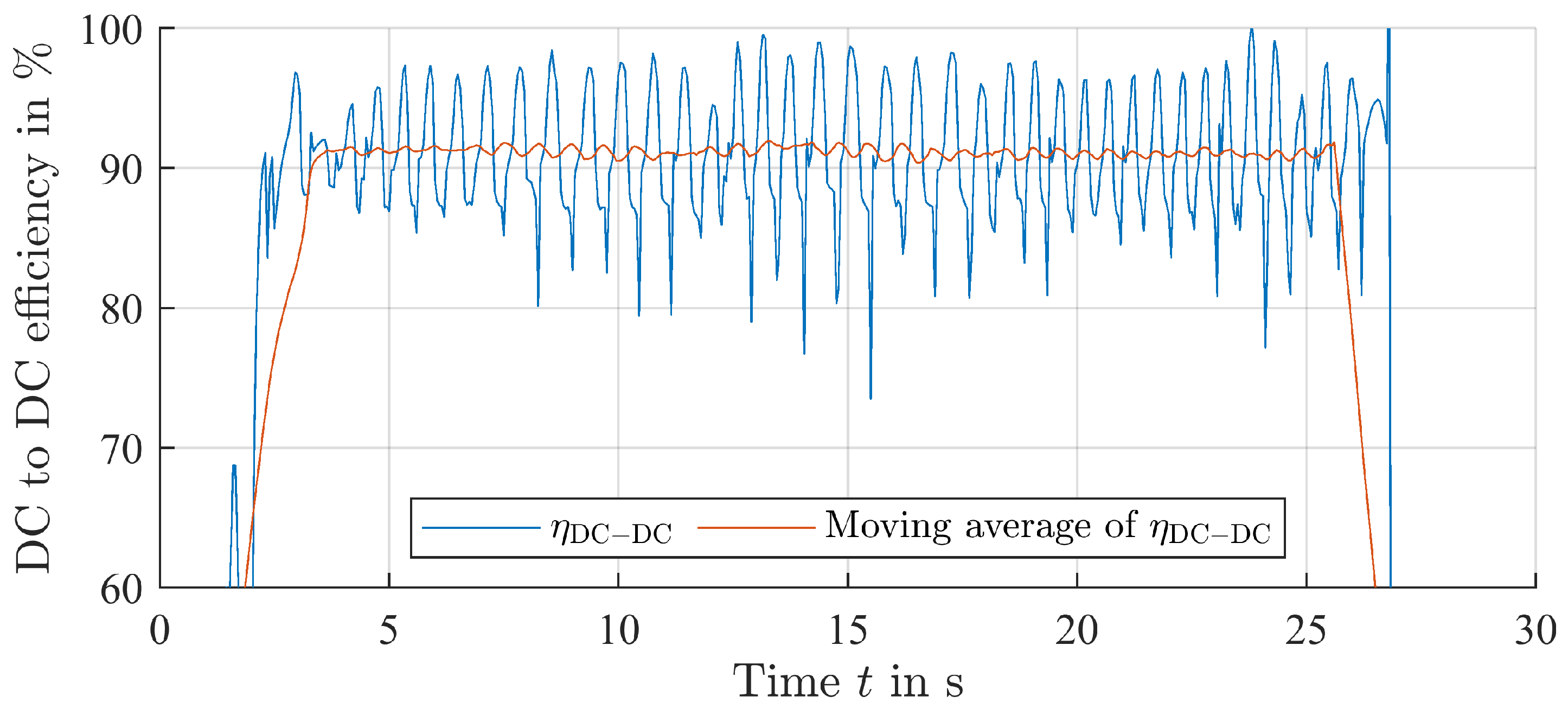

Due to a 20 Hz acquisition rate limitation of the Yokogawa WT1800-E power analyzer, the above shown results are very course. To obtain a power course with a more precise time resolution, additional surveys based on oscilloscope recordings were performed. In this case, a sample rate of 12.5 MSps was chosen, which allowed for a 2 s logging time for all eight channels. Two segments in the middle region of the test track were surveyed with an elevated pickup speed of

. The measured quantities were the primary DC voltage and current, both inverter output voltages and currents, and both primary coil currents. All following results are derived from the mentioned quantities.

Figure 11 shows the DC input power

and AC output powers

and

of one inverter unit.

For better insight, the courses of the two following segments

,

and

were reconstructed from the original measurements and are marked light gray. The total drawn and drain power is marked in dark gray. Startups and shutdowns of segments are flagged with dotted green and red lines. The pickup power fluctuation is approximately 25% with on average 2.37 activated segments. If a more constant power flow is required, the transmitted power can be regulated by an additional DC-DC converter or active rectifier on the secondary side. However, since the traction battery will be used as an energy buffer in battery electric vehicles, a constant power flow is not necessary in this use case. The current algorithm (see

Figure 7) of a segment’s startup is comparatively early in the range of a negative coupling factor. Later startups should have no negative effect on the power flow. However, a higher trigger threshold

leads to a less robust system behavior in case of pickup misalignments.

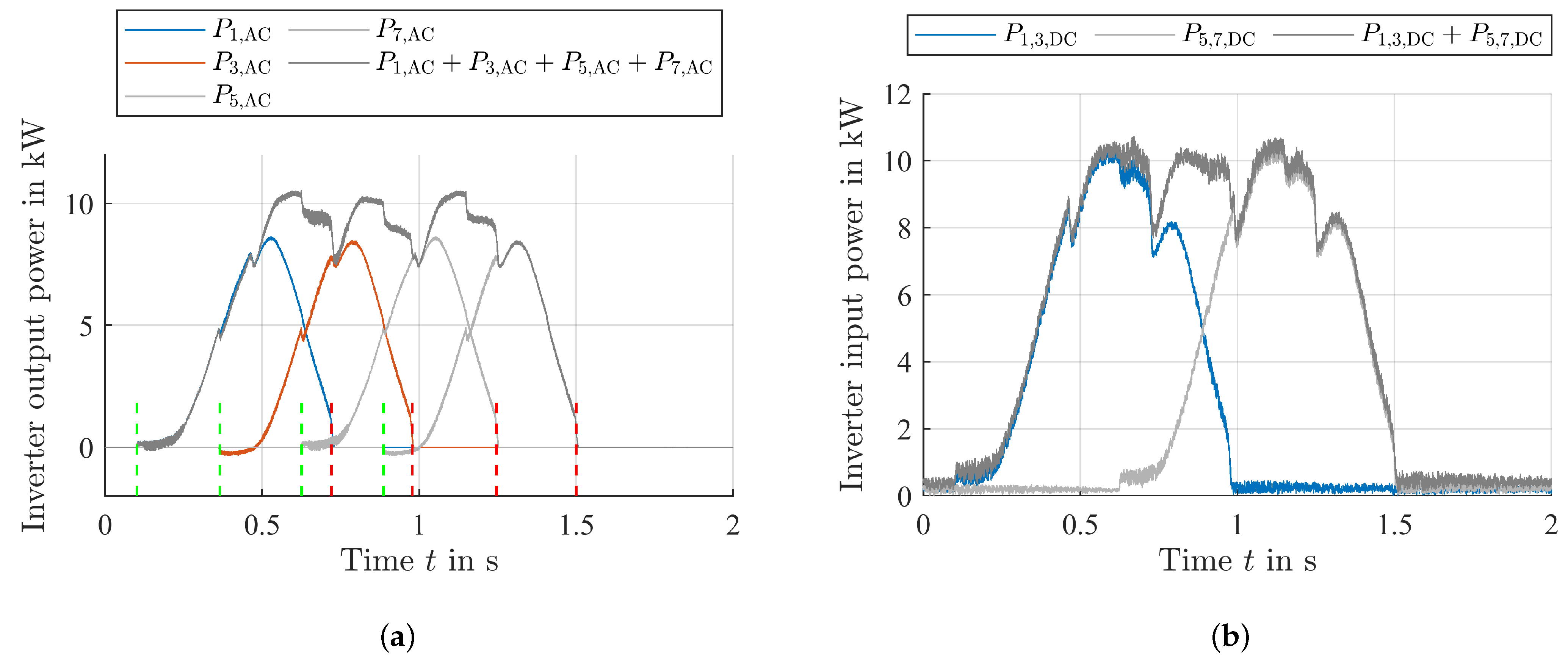

The following section focuses on the inverter output quantities. For best presentability, currents and voltages were transformed from the time domain into the frequency domain via fast Fourier transform (FFT). FFT was applied block-wise for ten WPT system periods.

Figure 12 shows the amplitude spectrum of the inverter output currents of two adjacent segments.

The frequency range is 500 kHz in order to visualize the current up to the fifth harmonic. Segment startups and shutdowns are flagged as green and red, respectively. Marks related to the regarded segment are solid. Dotted and dashed lines relate to directly adjoining segments and segments with a distance of at least two. A segment’s current fundamental is heavily influenced by directly adjoining segments due to a high primary-to-primary coupling (

). An activated adjacent segment leads to a significant current amplitude increase (best visibility in

Figure 12b). Harmonics in the currents are generated by their own inverter.

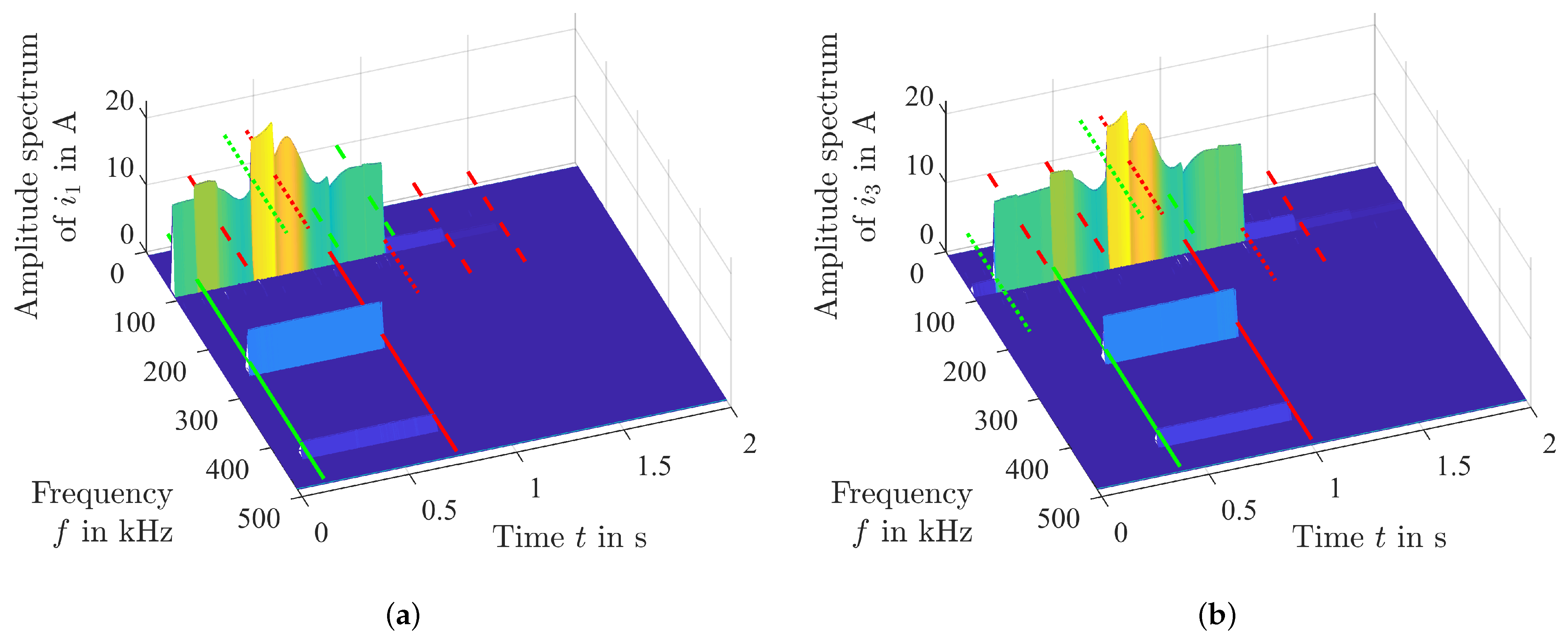

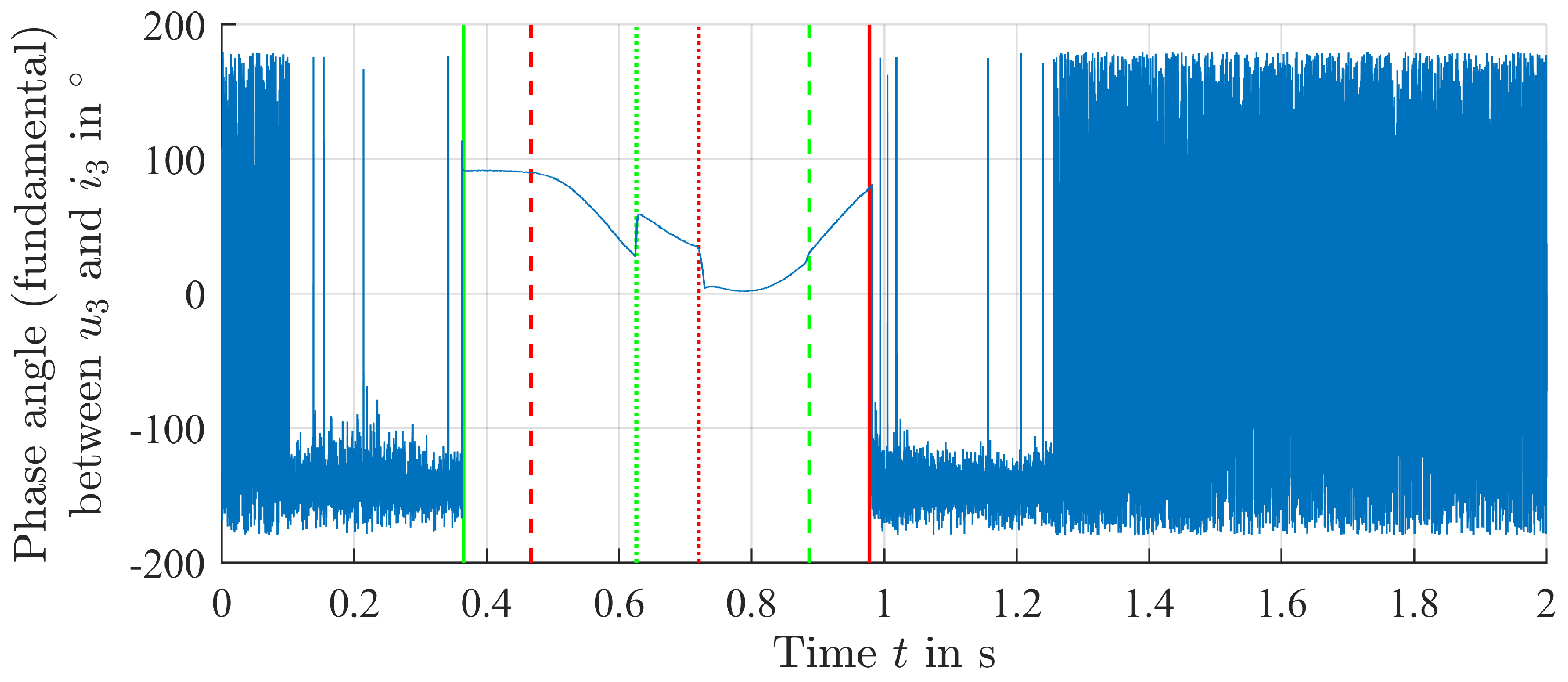

Figure 13 depicts the phase angle between the inverter output voltage and current fundamentals of the second examined segment.

The startup and shutdown marks are comparable to those in

Figure 12. The phase angle is only valuable while the regarded segment is activated due to an absence of voltage phase information when the inverter output is shorted. Directly neighbored activated segments lead to significantly increased phase shift between the fundamental’s voltage and current. Generally, a pretty large phase shift can be observed in the span of operation time, as there is at least one activated directly adjoining segment.

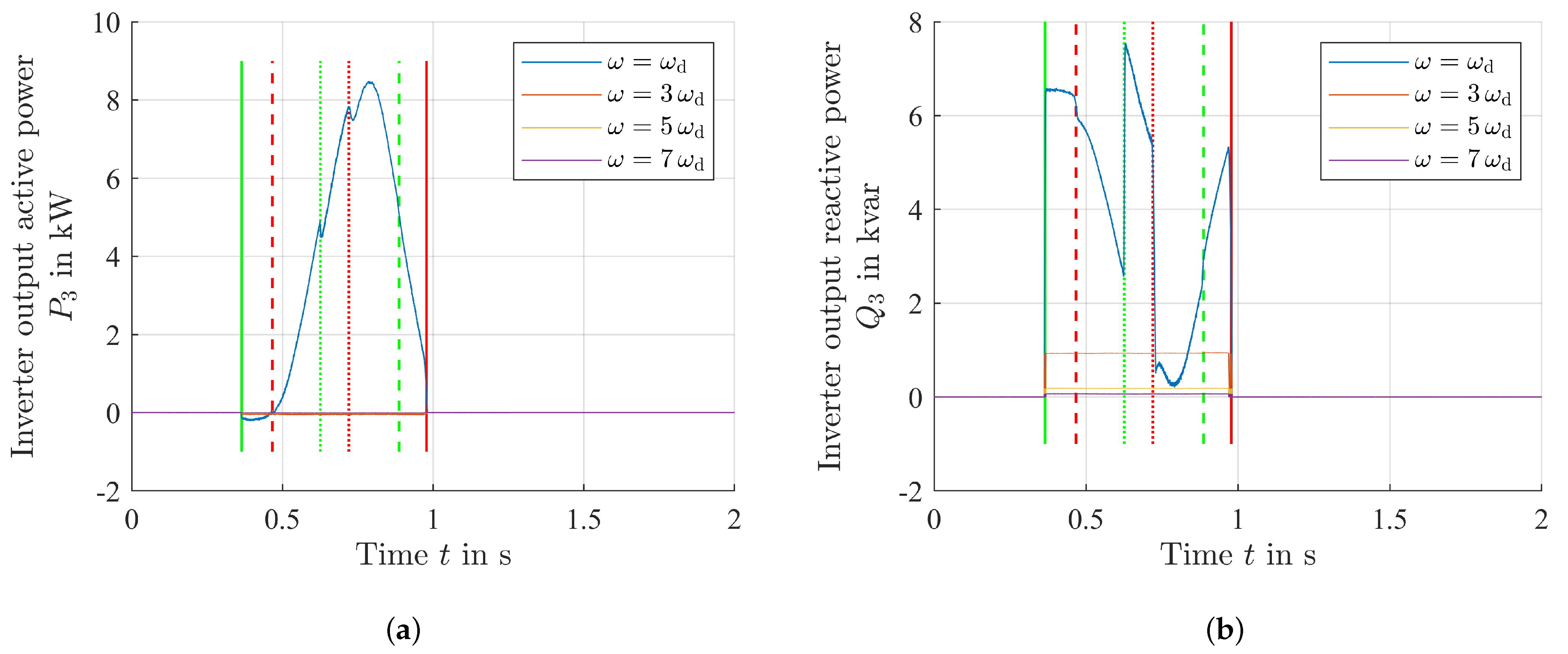

Figure 14b shows the inverter’s reactive output power from the fundamental to the seventh harmonic and clarifies this impact.

Multiple activated and coupled segments lead to an elevated reactive power requirement at the corresponding inverter outputs. However, the reactive powers in the harmonics are constant and negligible compared to the fundamental. The fundamental’s active power course derived from the FFT (see

Figure 14a) matches to that shown in

Figure 11a.

Due to the harmonics’ phase angle of approximately 90°, these are not involved in active power transfer.

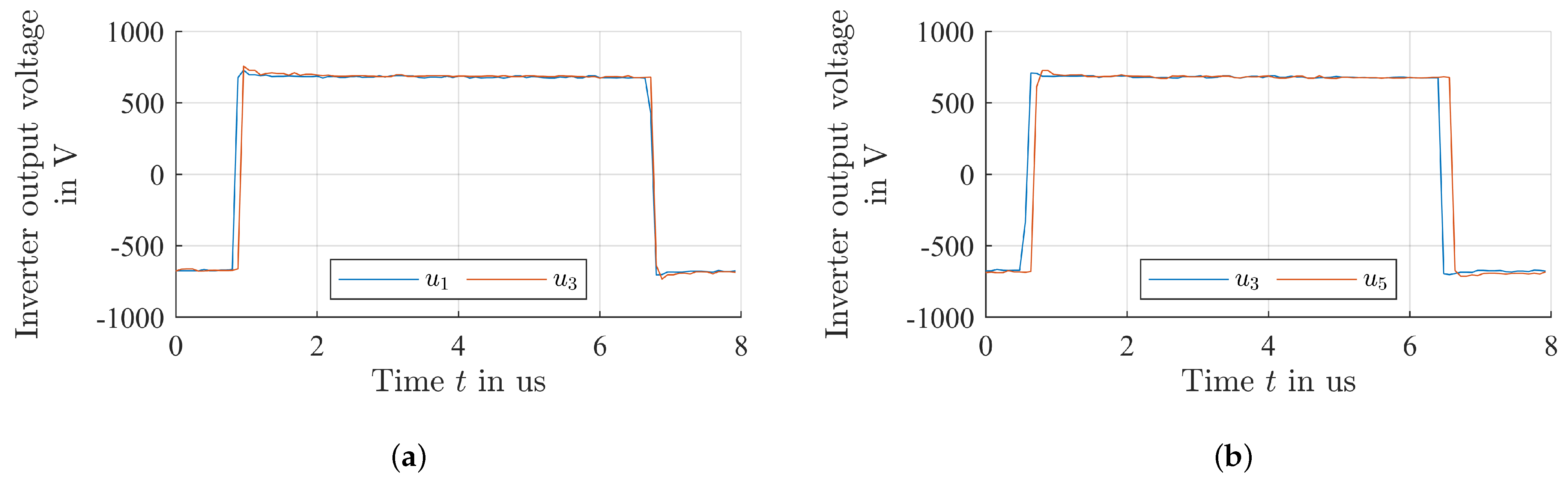

Finally, the voltage phase shift between two successive inverter outputs was evaluated. A good synchronization is important in case of larger pickups that cover multiple primary coils.

Figure 15a shows the voltage courses of both inverters within one unit for a half wave. A delay of 40 ns was measured that leads to a 1.22° phase shift.

Figure 15b depicts the same measurement for the delay between two inverter units. Between the second output of the first and the first output of the second evaluated inverter, a 140 ns delay or, respectively, 4.28° phase shift was measured. These phase shifts would not significantly affect the power transfer to larger pickup coils.