1. Introduction

Wind power generation is widely recognized as an eco-friendly and sustainable energy source, necessitating extensive research and development in this critical field. While wind turbines can function individually, they are often arranged in large-scale wind farms, consisting of multiple turbines. Wake flow generated by upstream turbines within a wind farm produces turbulent flow, leading to structural loads on turbines and reduced overall power production [

1,

2,

3]. Wake flow control in wind farms is typically achieved by predicting the entire wind farm’s flow and adjusting the position and angle of turbines to minimize wake flow effects. However, due to the physical complexity and uncertain flow characteristics of wake flow, it is challenging to control [

4]. As a result, continuous research and development in wake flow control utilizing numerical modeling and control theory is essential to optimize wind power generation performance and extend turbine lifespan [

5,

6,

7,

8,

9,

10]. Moreover, accurately modeling the dynamics of wind turbines and wind farms is crucial for applying control algorithms and constructing control systems.

Wind farm simulators, which model the dynamics of a wind farm, can be categorized into low-fidelity, medium-fidelity, and high-fidelity models based on the accuracy of their mathematical wake models [

11]. High-fidelity models capture wake characteristics with high precision, but their computational requirements and time are substantial, making them less suitable for control purposes. These models are typically employed for research purposes, aiding in understanding and improving the wake’s physical characteristics. In contrast, medium-fidelity and low-fidelity models have lower computational demands and time requirements, making them more appropriate for control purposes and practical wind farm control applications. However, their reduced accuracy may result in prediction errors under actual operating conditions. When modeling a wind farm’s wake, a simulator should select a suitable model tailored to specific objectives and situations. These models are utilized in wind farm design and operational simulations to anticipate and address potential issues in real-world settings and facilitate the development of optimized operational strategies.

In this paper, our objective is to deepen the understanding of wind farm simulators by comparing and discussing well-established low-fidelity and medium-fidelity models. We focus on open-source simulation models that are commonly employed by control researchers, such as FLORIS, FLORIDyn, and WFSim. Through this comparison and analysis, we aim to evaluate the effects of wake flow in wind farms, ultimately contributing to a more comprehensive knowledge of wind farm simulators and their underlying models.

FLORIS is a low-fidelity wind farm simulator developed by the National Renewable Energy Laboratory (NREL), and it is an open-source based on Python. The model aims to predict time-averaged flow fields and time-averaged power capture for each turbine within a wind farm at a very low computational cost. Additionally, FLORIS includes several types of wake deficit and wake steering models, which allow for the modeling of interaction between wind turbines. This simulator is particularly used for real-time online wind farm analysis, control, and layout optimization, and it has scalability for designing and operating wind turbines and wind farms, thereby improving their efficiency and economic viability. As FLORIS is developed as an open-source based on Python, users can easily modify or extend the model, which is very useful for supporting the optimal design and operation of wind farm, considering various scenarios that are actually applied in the wind power industry [

12,

13,

14].

FLORIDyn is a low-fidelity wind farm model that enables the dynamic real-time control of a wind farm with multiple turbines. The model implements a 3D Gaussian FLORIS model and introduces a new method for generating observation points in the wake under varying and heterogeneous flow conditions. This simulator is specialized for a real-time wind farm analysis and control, particularly for dynamic control. Since FLORIDyn is based on the FLORIS model, it is classified as a low-fidelity model similar to FLORIS. Therefore, for applications that require high accuracy, a medium-fidelity model should be used. However, FLORIDyn is suitable for large-scale wind farm design and operation simulations due to its low computational cost [

15,

16].

WFSim is a 2D medium-fidelity wind farm model grounded in the Navier–Stokes equations and developed with a control-oriented approach. To reduce computational costs, it simplifies the 3D flow equations by assuming negligible effects of flow in the z-direction. This enables fast and efficient wind farm simulations. With a limited number of tunable parameters, WFSim can achieve control objectives with high performance, making it well-suited for wind farm control and optimization analysis [

17,

18].

FLORIS is a steady-state wake model, while FLORIDyn and WFSim are dynamic wake models. In essence, FLORIS calculates wakes using a constant wind speed as input, while FLORIDyn and WFSim model wind conditions over time and compute wakes accordingly. Due to this distinction, when comparing the three simulators, the dynamic wind farm models should only be compared with the steady-state wind farm model under steady-state wind conditions. Thus, to compare simulation outcomes, the outputs of FLORIS, FLORIDyn, and WFSim should be evaluated under the same wind conditions and steady-state circumstances.

This paper is organized as follows:

Section 2 offers an overview of the wind farm simulator, encompassing its coordinate representation and wake models.

Section 3 details the turbine model, power calculations, and parameter tuning required for the experiments.

Section 4 showcases and compares the simulation results from various experiments. Lastly, the conclusion is provided in

Section 5.

2. Wind Farm Simulator

The characteristics of the three simulators—FLORIS, FLORIDyn, and WFSim—are summarized in

Table 1. Detailed descriptions of each simulator can be found in their respective subsections.

2.1. FLORIS

FLORIS (FLOw Redirection In Steady-state), developed by the National Renewable Energy Laboratory (NREL), is a low-fidelity steady-state wind farm model written in Python. FLORIS is a steady-state control-oriented modeling tool widely used in research on wind farm control and layout optimization as wind farm modeling software. The aim of FLORIS is to accurately predict the time-averaged flow field and time-averaged power capture of each turbine in a wind farm at a very low computational cost. In this paper, we use FLORIS version 3.2 (v3.2), which was released in October 2022 [

12].

This simulator provides three tools: Visualization, Optimization, and Analysis. The input file required for the simulation consists of three basic sections: Farm, Flow field, and Wake. The Farm section sets the coordinates of the turbine layout in the wind farm and the type of turbine to be used in the simulation. The turbine model is represented by a simple actuator disk model, and the power coefficient and thrust coefficient are composed of a lookup table. The Flow field section includes parameters for the overall atmospheric state. In this section, parameters such as air density, wind speed, wind direction, wind shear, wind veer, turbulence intensity, and reference wind height are set. The Wake section includes the wake model used in the simulation and the corresponding parameters. The wake model of a turbine should reflect wind characteristics such as turbulence conditions in natural states, as well as wind turbine characteristics. The FLORIS model assumes a uniform wind direction across the wind farm, regardless of the wake effect, the yaw angle of the turbine, and the intensity of the atmospheric turbulence. Various mathematical models have been developed to predict the wake effect of wind turbines, and the wake velocity deficit, deflection, and turbulence models implemented in the FLORIS framework include Jensen, Multi-zone, Gaussian, Gauss-Curl Hybrid, Jimenez, Curled, and TurbOPark. In particular, most wake models use a combination of additional turbulence models.

For future research, the FLORIS model can be used to create a dynamic environment for wind farm control. Since it is crucial to accurately design wake models, turbulence models, and turbine models in wind farm models for controller verification, utilizing a model within FLORIS is highly effective in terms of accuracy.

2.1.1. Coordinate Representation

In FLORIS, the coordinate system of the wind direction is set clockwise relative to the north, and the initial yaw

of the turbine is set to face the input wind direction; at this time, the yaw angle is 0 degrees. The yaw angle

of the turbine has a positive value when moved counter-clockwise based on the initial yaw angle and a negative value when moved clockwise.

Figure 1 shows the top view of the wind turbine, and the angles shown outline the wind direction and the yaw angle of the turbine relative to the global coordinate system of FLORIS.

is the wind speed at the rotor and

means the direction of the wind based on the north.

2.1.2. Wake Model

The wind turbine wake model is used to characterize the velocity deficit behind the turbine during normal operation in a wind farm. This paper performs a simulation using the Gauss–Curl Hybrid model among the wake models provided by FLORIS. The Gauss–Curl Hybrid model proposed in this paper is based on the Gaussian model, which includes asymmetric and secondary wake steering effects. The velocity deficit of the wake is calculated by assuming a Gaussian wake, which is based on the theory of self-similarity and frequently used in free shear flows. The analytical representation of the three-dimensional velocity,

, behind the turbine is calculated as follows:

where

C is the velocity deficit at the center of the wake,

is the free stream velocity,

is the wake deflection,

is the height of the hub of the turbine,

defines the wake width in the y-direction, and

defines the wake width in the z-direction. Each of these parameters is defined for each turbine. The subscript “0” means the initial value at the start of the far wake, which depends on the ambient turbulence intensity,

, and the thrust coefficient,

. The velocity distributions

and

are defined as:

where

D is the rotor diameter,

is the velocity at the rotor,

is the velocity at the start of the far wake,

defines the wake expansion in the lateral direction, and

defines the wake expansion in the longitudinal direction [

14,

19].

The Gauss–Curl Hybrid model has a velocity distribution that forms a curl wake shape by adding a counter-rotating vortex distribution when obtaining a flow field solution. Therefore, the use of the Gauss–Curl Hybrid model is expected to result in a slow recovery of the wake compared to using only the Gaussian wake model, which can ultimately affect the power output.

2.2. FLORIDyn

FLORIDyn (FLOw Redirection and Induction Dynamics), developed by the Delft Center for Systems and Control at Delft University of Technology, is a dynamic implementation simulation application of the FLORIS model that considers changes in wind velocity and wind direction over time. It is written in MATLAB. One notable feature of this simulator is that it aims to create Observation Points (OPs) on the plane of the rotor where turbine-related characteristics are observed, and to calculate the effective wind speed at each observation point. The distribution of the chains determines the movement of the OPs in the plane of the rotor, and each OP interacts with others via wake modeling. The simulator also takes into account the time it takes for the wake to reach the downstream wind turbine [

15].

FLORIDyn simulations can be run using the FLORIDyn App or the main script. The main script provides convenience by allowing you to run all the required simulation conditions in one file. There are five simulation settings provided by the main script: controller type, turbine layout, wind field, observation point setting, and visualization. First of all, in the controller type setting, you can set control types such as greedy control, pitch and TSR control, yaw control, and model predictive control. Additionally, new user-defined control types can be created and used. These can use data to control wind turbines by obtaining from high-fidelity simulators such as SOWFA and PALM or lookup tables constructed in advance. Then, the turbine layout setting includes not only the turbine’s specifications, such as its location, diameter, and hub height, but also information on observation points. Next, the wind field setting contains all the necessary atmospheric data, such as wind speed, wind direction, turbulence intensity, and air density. Therefore, you can modify the input wind condition through this setting. After that, the observation point setting generates a shape and speed deficit of the wake according to the set distribution. Finally, the dynamic wake effect of the wind farm is visualized according to the values set so far.

2.2.1. Coordinate Representation

FLORIDyn uses an angle of wind direction that is set counter-clockwise based on the west, where the west has a value of 0 degree. In this case, the yaw angle of the turbine, such as in FLORIS, has a positive value if it moves counter-clockwise and a negative value when moving clockwise. A schematic representation of the coordinate system in FLORIDyn for the turbine is shown in

Figure 2.

To set the coordinate system of FLORIS and FLORIDyn the same, you can use the relational expression below to set the coordinate system of the two simulators equally.

where

is the angle of wind direction in FLORIS, and

is the angle of wind direction in FLORIDyn.

2.2.2. Wake Model

The Gaussian FLORIDyn model is based on the Gaussian model of FLORIS and the Zone FLORIDyn framework. The core of the Gaussian FLORIS model used in this model is based on the work of Bastankhah and Porté-Agel (2016) [

20]. The Zone FLORIDyn model, as published by Gebraad and van Wingerden, approximates the wake shape into three zones: the near field, far field, and mixing zone. A velocity component recovery formula is implemented in all zones, and observation points (OPs) are generated in the rotor plane at each time step, which is used as an indicator of wake characteristics. The OPs move over time by the area of the wake zone, and their speed is equal to the effective wind speed. If there is a change in the wake of the upstream turbine, while the previous OP moves according to the previous trend, a new OP is created by inheriting the changed trend. Finally, this model is designed by reconstructing the computation of the effective wind speed in the rotor plane through the design phase for the appropriate distribution of OPs in a three-dimensional flow field [

21].

2.3. WFSim

WFSim (Wind Farm Simulator) was developed by Doekemeijer and Boersma from the Delft University of Technology. It is a medium-fidelity, dynamic control-oriented wind farm model based on the two-dimensional Navier–Stokes equations, written in MATLAB. The model simplifies three-dimensional flow equations by assuming that the effect of flow in the z-direction at hub height is negligible. By employing a 2D model, the flow in a wind farm can be approximated in an acceptable computational time, enabling the dynamic wind farm control. At each grid point, the 2D Navier–Stokes equations are spatially and temporally discretized. The Navier–Stokes equations for each point on this grid are solved to determine the local wind speed in the x- and y-directions, as well as the local pressure. In WFSim, the rotor of the turbine is modeled using a classical non-rotating Actuator Disk Model (ADM). In this method, each wind turbine is represented by a uniformly distributed force acting at the grid points where the rotor disk is located. The disk-based thrust coefficient

and yaw angle

are considered control variables and can be used to adjust the performance of the wake and wind farm [

17,

20].

where

is the axial induction factor of the

n-th turbine,

defines the classical thrust coefficient of the

n-th turbine, and

defines the disk-based thrust coefficient of the

n-th turbine.

The overall framework of WFSim is described by several steps for simulation condition setting and running the simulation. Specifically, the simulation condition setting step involves wind farm layout settings, wind field scenario settings, control input settings, and simulation solver settings. The function of wind farm layout settings includes all simulation settings related to the wind farm, such as turbine inputs, atmospheric characteristics, etc. To achieve this, a grid is generated for the number of cells in the x- and y-axis-direction based on the domain size of the flow field. The x and y-axis components of the velocity, u and v, can be calculated for each grid. The control input is designed using a predefined series of control inputs provided by the simulator, which is derived from high-fidelity simulation data from PALM and SOWFA. The selection of the model solver option completes the simulation condition setting step. The model settings of the solver include options such as whether to solve the WFSim by projecting away from the continuity equation, calculating the linear system matrix, and calculating the pressure field. The convergence settings of the solver include options for printing the convergence value at each time step, as well as settings for the convergence threshold and maximum number of iterations.

2.3.1. Coordinate Representation

The WFSim employs the same coordinate system as described in the previous section for FLORIDyn, with the wind direction set in a counter-clockwise direction and the west side at 0 degrees. As with the other two simulators, when the turbine’s heading rotates counter-clockwise, it corresponds to a positive yaw angle, and when it rotates clockwise, it corresponds to a negative yaw angle.

2.3.2. Wake Model

WFSim constructs a flow field model based on the Navier–Stokes equations. To improve the computational speed, it simplifies the 3D flow equation, assuming that the effect of flow in a z-direction at hub height can be ignored. In addition, WFSim focuses on implementing dynamic control by considering the dynamic effect of the wind field as well as changing atmospheric conditions in constructing the wake model. Therefore, it is possible to implement an online dynamic controller for the power optimization of a wind farm. The Navier–Stokes equations consist of two equations of momentum in the x-direction and the y-direction and the mass conservation equation, as follows [

17].

where

u and

v are the velocities in the x-direction and the y-direction, respectively,

p is the air pressure, and

is the air density. The external forces

and

are forces applied on the flow by the turbines in the wind farm. Equations (

9)–(

11) does not include a dynamic term, but instead, the variable

is introduced and used as a tuning variable for implementing wake recovery.

2.4. Comparison

In summary, the three simulators offer the capability to implement wind farm models as open-source tools with low computational costs. Common features shared by the three simulators include the ability to customize turbine types and layouts, as well as the capacity to design various yaw angles as control input values to optimize power output. The main differences between the three simulators are concisely presented in

Table 2.

4. Experiments

The presented simulations compare and contrast different wind farm simulators based on their power performance under various scenarios. The simulations are conducted in four main categories: (1) spacing, (2) yaw angle, (3) wind speed, and (4) other factors.

The goal is to analyze the computational methods used by each simulator and provide insights into their potential applications for wind farm research. By identifying the strengths and limitations of each simulator, researchers can select the most suitable one for their research needs. The simulation results also provide valuable insights into the accuracy and reliability of the models, which can inform future developments in wind farm simulation technology.

The spacing case examines how simulators perform in terms of power output when the distance between wind turbines is changed. The yaw angle case evaluates how simulators handle wind turbine yaw misalignment. The wind speed case explores how simulators deal with changes in wind speed. Finally, the other factor’s category considers additional variables that could impact the simulators’ performance.

This section provides a comprehensive analysis of different wind farm simulators, highlighting their potential applications in wind energy research and development. By examining the performance of each simulator under different scenarios, we can identify areas for improvement in computational methods, leading to more precise and efficient simulations.

4.1. Spacing

In this section, we aim to investigate the effect of turbine spacing on the output of wind farm. The study compares different simulators to provide valuable insights into the impact of turbine spacing on power output. Optimizing wind farm layouts to achieve maximum output in the future requires a better understanding of the relationship between turbine spacing and power output. Therefore, the presented experiments compare simulators and provide simulation results on how turbine speed and power vary with turbine spacing in each simulator.

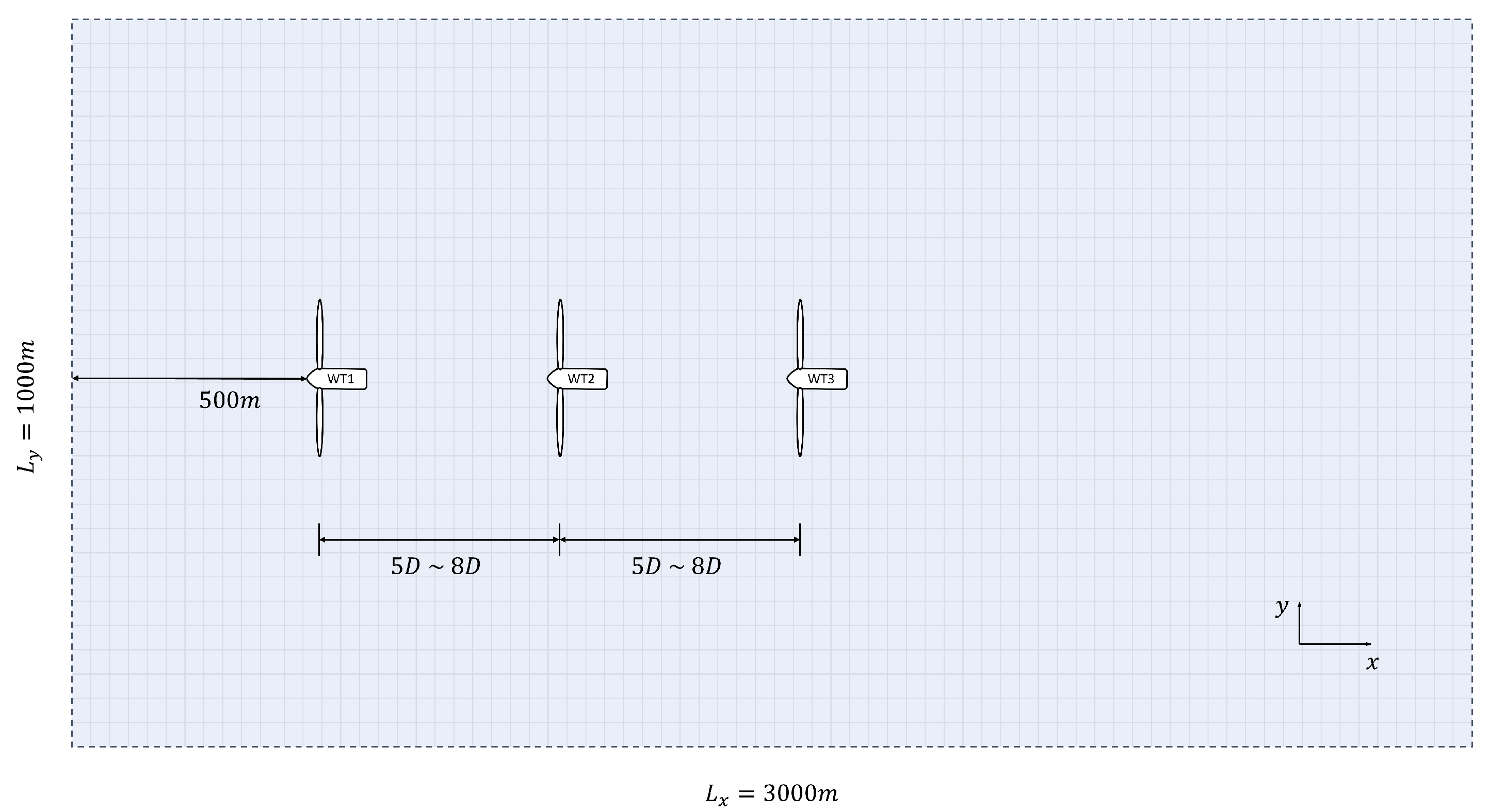

In the experiment, a basic 1 × 3 turbine configuration was utilized, as depicted in

Figure 4. This figure serves as a schematic representation rather than a scaled illustration. Four scenarios were examined, with the spacing between turbines incrementally increasing from 5D to 8D at 1D intervals. The turbines operated under greedy control, and the wind input condition was a wind speed of 8 m/s from the west.

Figure 5 shows the power at each turbine as a function of the turbine spacing. The figure illustrates that the upstream turbine T1 generates nearly constant power, while the power output of downstream turbines T2 and T3 is influenced by the spacing between turbines. As the distance between turbines increases, the wake effect on downstream turbines is mitigated. Furthermore, the power output of the turbines varies with wind speed, and as the wind speed increases, the power output also increases. Although the numerical values are not identical, it was verified that all three simulators exhibited the same trend. The discrepancy in numerical values is likely due to differences in wake model calculations.

Evaluating the decrease in downstream wind speed, or in other words, the extent to which the downstream turbine is influenced by the upstream turbine, is crucial for effective wind farm control. To accomplish this, we compared the free stream speed with the local wind speed at the turbine by employing Equation (

12) to calculate the rate of the wind speed reduction.

Table 5 presents the defined rates of the wind speed decrease for FLORIS, FLORIDyn, and WFSim. It was noted that the wind speed measured by the upstream turbine T1 demonstrated a minimal deviation from the free stream speed in both FLORIS and FLORIDyn. Conversely, WFSim revealed a wind speed reduction of around 26% in comparison to the free stream speed. This difference can likely be attributed to variations in the wake models or calculation techniques utilized by the three simulators.

Upon further examination, it was found that FLORIS documented a 20% to 30% decrease in downstream turbine speed compared to the free stream speed. Meanwhile, FLORIDyn exhibited a substantial recovery in turbine speed towards the end, particularly when the turbine spacing was 7D and 8D, which may stem from discrepancies in wake models. WFSim produced significantly different results in comparison to the other two simulators.

4.2. Yaw Angle

The objective of this experiment was to examine the influence of adjusting the yaw angle of upstream turbines on downstream turbines within wind farms. The wake generated by upstream turbines can impact downstream turbines, leading to decreased local wind speed. By controlling the yaw angle of the upstream turbine, it is possible to alleviate the wake effect and increase the power output of downstream turbines, ultimately enhancing the total power production of the wind farm.

The experiment involved simulations of 11 cases, testing yaw angles ranging from −25 degree to +25 degree at 5 degree intervals. The input wind conditions were set to a wind speed of 8 m/s blowing from the west. In this experiment, the yaw angle of upstream turbines was adjusted to examine how the output changes throughout the wind farm, and the results from three simulators were compared. The experimental condition is shown in

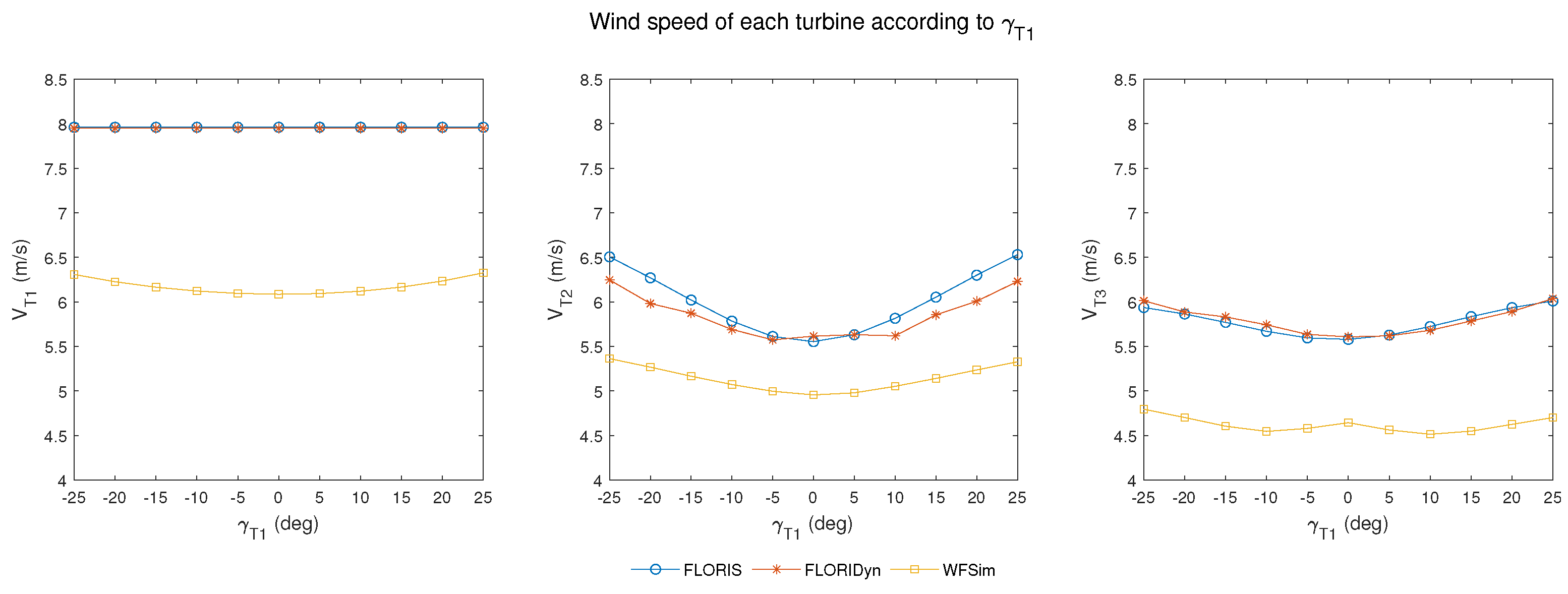

Figure 6.

Figure 7 illustrates that the wind speed and output values of the three simulators tend to be almost identical. It can be observed that yawing the preceding turbine T1 increases the wind speed of the T2 and T3 turbines, and consequently enhances the output. FLORIS and WFSim demonstrate that the change in the speed at the rotor of the turbine is symmetrical, and therefore, the power in the wind farm increases symmetrically based on the yaw angle. On the other hand, FLORIDyn demonstrates asymmetric results in positive and negative yawing. The figure indicates an increase in power output from the wind farm when the yaw angle is applied to the upstream turbine, depending on the yaw angle. FLORIDyn displayed similar trends to the other two simulators when the yaw angle had a positive value but showed different results when the yaw angle had a negative value.

The experimental results imply that the speed of the downstream turbine is affected when upstream turbine yawing occurs, which adds credibility to the study that upstream turbine yawing can affect the power production of the downstream turbine. It can also be concluded that adjusting the yaw angle of the turbine to control the wake can increase the overall power of the wind farm. Please refer to

Table 4 for the equations used to calculate the power of each simulator.

The equation

was introduced to confirm the effect of the yaw angle change of two turbines on the power production of the wind farm. Equation (

13) is an indicator of how much power production increases when the yaw angle is changed compared to the power produced through the greedy control of each simulator.

For the numerical comparison among each simulator, the ROI for each is presented in

Table 6. Both FLORIS and WFSim demonstrated a symmetrical power increase with altering yaw angles based on the greedy control. Conversely, FLORIDyn exhibited a minor increase in power production when yawing was applied, but the difference was not substantial compared to the greedy control. Given these outcomes, it appears essential to establish and utilize parameters tailored to the user environment when implementing a yawing control with FLORIDyn.

Upon applying a yaw angle to the upstream turbine in all three simulators, the power output experienced an increase. The simulation outcomes indicate that managing yaw angles in wind farms positively impacts power generation. This finding lends credibility and importance to yaw angle control in wind farms.

4.3. Wind Speed

This experiment investigates the correlation between wind speed and power through simulations under three wind speed conditions: 6, 8, and 10 m/s.

Table 7 shows the rate of reduction in the wind speed for each turbine compared to the free stream speed computed from Equation (

14).

is an abbreviation for the rate of the decrease in wind speed and the following equation.

As shown in

Table 7, when evaluating the rate of the speed reduction for each turbine in relation to the free stream velocity, it is evident that the speed reduction rate for each turbine in WFSim remains consistent across all simulation conditions. In contrast, the reduction rates for FLORIS and FLORIDyn vary depending on the conditions. Specifically, FLORIS exhibits a constant reduction ratio for T1 under all conditions, while the ratios for T2 and T3 differ. FLORIDyn, however, presents distinct reduction ratios for each turbine as conditions change. Ultimately, the reduction ratios for each turbine are contingent upon the wake models employed in each simulator. Nevertheless, the reduction trend of speed for turbines T1 to T3 is confirmed to be consistent.

WFSim displays the lowest wind speed at the rotor of the first turbine when compared to FLORIS and FLORIDyn, signifying that WFSim exhibits the greatest speed reduction for the free stream velocity. In all wind conditions, WFSim demonstrates a speed reduction rate of over 20% compared to the other two simulators, which can be attributed to the differences in the composition of velocity components within WFSim. Conversely, it was determined that the speed reduction rate at the rotors of the second and third turbines is the smallest in FLORIDyn.

Figure 8 displays the local wind speeds and power outputs for each turbine, from T1 to T3, for each simulator under different wind speed conditions. As shown in the figure, the speed component of T3 has increased compared to T2. This result demonstrates that the speed of T3 is higher than the speed of T2 in FLORIS, which can be interpreted as a decrease in the wake effect of the first turbine on the third turbine. Similarly, FLORIDyn also shows a similar trend under a wind speed of 6 m/s. It is also noticeable that the trends in turbine speed components and the power output are the same. Theses results indicate that each simulator considers the interaction between turbines and produces the output of each turbine based on this information.

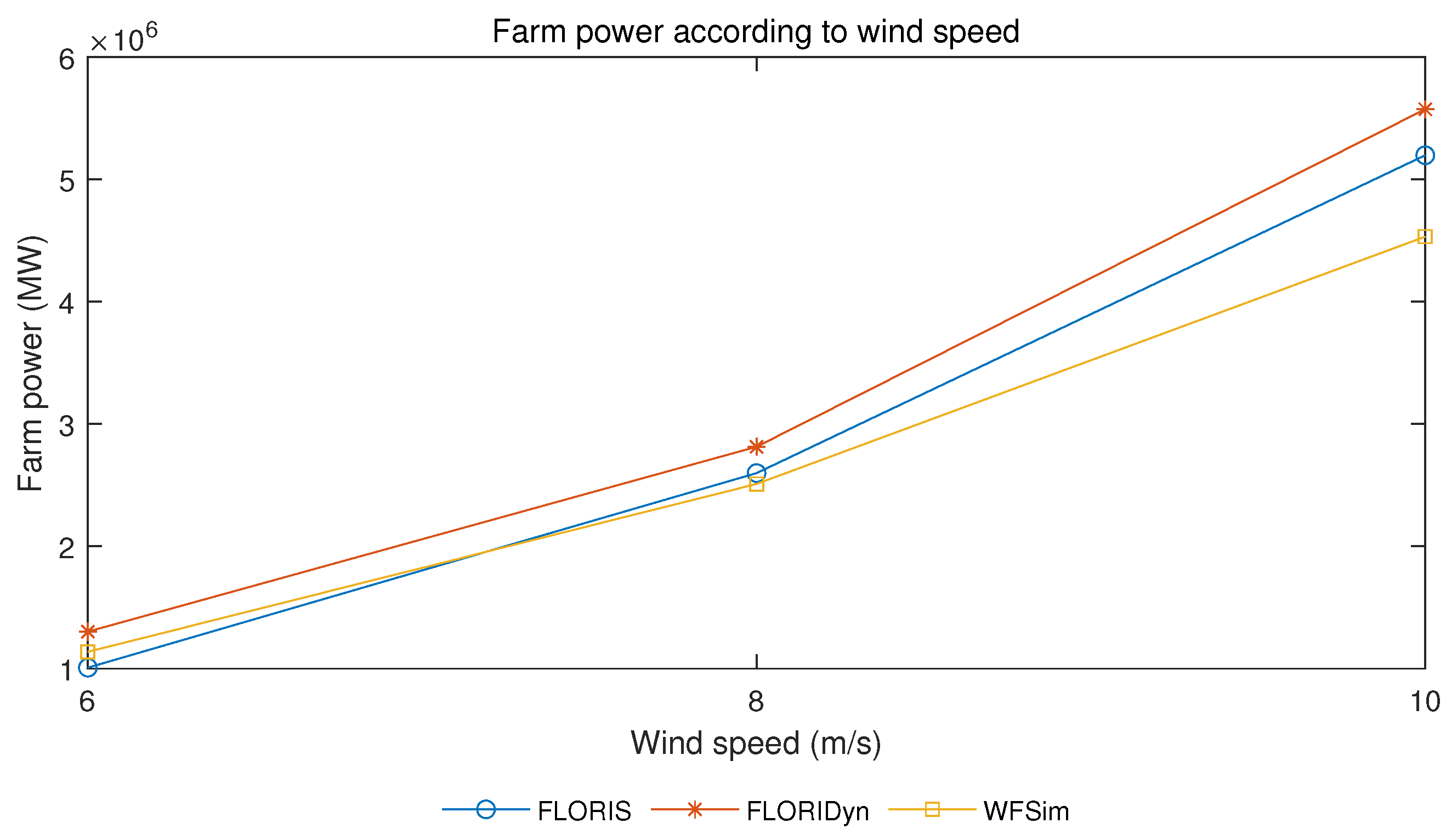

As the free stream wind speed increases, the power output of the wind farm increases in

Figure 9, with all three simulators exhibiting the same tendency. This is because the amount of power that can be extracted from the wind is proportional to the cube of the wind speed.

4.4. Others

In addition to the conditions experimented above, various parameters can be set for each simulator. Since each simulator has different parameters that can be set and differ in how they operate, it is necessary to clearly distinguish the difference. This section lists the commonalities and differences among simulators based on the results obtained from the simulations.

Firstly, according to the results derived from FLORIS, the domain size and the number of grids do not have a significant impact on the power output of the FLORIS model. This conclusion is drawn because FLORIS models the interaction between wind turbines using a wake model that considers various wake effects throughout the entire domain. Additionally, the wind speed at the rotor of the turbine is not affected by the domain size. Therefore, even if the domain size and grid spacing used for modeling differ, the output of the wind farm is not significantly affected because the wake model is accurately applied.

Next, in FLORIDyn, the wake model is computed based on the number and distribution of the Observation Points (OPs), which are used as simulation setup variables. Unlike other simulators, the FLORIDyn model does not generate grid points with uniform spacing. Instead, the distribution of OPs is determined based on the shape of the wake, depending on the chain structure designed on rotor plane of each turbine. For example, OP structures can be set up to distribute OPs evenly throughout the entire rotor plane or to distribute them within a specific range of the horizontal plane based on the hub height. Some experimental results have shown that the configuration of OPs does not significantly affect the power output. This because the speed at the rotor of the turbine and wake models are the same regardless of the configuration of the OP, under the same input conditions. However, the sine ofthe wake from the upstream turbine needs to reach the downstream turbine, and this can vary depending on the specifications and distance between turbines. This paper designed each turbine’s chain to have 200 OPs to ensure that the wake from the upstream turbine sufficiently affects the downstream turbine.

Lastly, unlike the other two simulators, WFSim produces simulation results that vary depending on the number of grids. When the number of grids is increased or decreased for the same domain size and input conditions, the speed on the rotor plane of the turbine changes, and this results in changes in the power output as well. In the spacing experiment of

Section 4.1, a comparison of how the power output and turbine speed change with variations in the number of grids is shown in

Table 8 for the same simulation conditions as when using the 5D spacing condition. In WFSim, the speed at the rotor plane is calculated as the average speed, considering the velocity in the grid located in the rotor plane in the y-axis-direction based on a single x-axis. Therefore, this experiment only changes the number of grids in the y-axis-direction. The

represents the number of grids in the x-axis-direction, and

represents the number of grids in the y-axis-direction. From the experiment results, it can be observed that WFSim produces different results depending on the number of grids. In theory, a higher number of grids would allow for a more accurate calculation of the average velocity, but this would require more computational power.

5. Implications

In this section, we discuss three perspectives on the implications of this paper, based on the results of the experiments conducted in

Section 4. First, we evaluate the three simulators and present factors to consider when selecting an appropriate simulator for a given scenario. Second, we demonstrate the utility of simulators from a control perspective. Finally, we conduct a trend analysis to identify patterns related to the operation of wind farms. Through these discussions, we provide guidelines for selecting and utilizing simulators in the wind farm research field, which are expected to facilitate more accurate and efficient research endeavors.

5.1. Evaluation

When evaluating and selecting simulators, several factors should be taken into consideration, such as:

The suitability of the simulator’s characteristics to the scenario: FLORIS uses static modeling for faster computation, while FLORIDyn and WFSim use dynamic modeling for higher accuracy, but this may not be suitable for large-scale wind farm simulations due to slower computation compared to FLORIS.

The user’s purpose and requirements: For achieving control objectives in dynamic environments, simulators such as FLORIDyn and WFSim with dynamic modeling may be suitable. On the other hand, for design and optimization purposes, the static modeling simulator FLORIS may be more effective.

The complexity of the model and interpretation method of results: FLORIS considers the interactions between wind turbines and models the characteristics of turbines and wind farms using a static modeling approach. FLORIDyn generates the OPs based on the shape of the wake over time, while WFSim updates physical variable values at fixed points every time step.

Quality and accuracy of input data: When using simulators, it is important to carefully review the quality and accuracy of input data, model parameter settings, etc., to ensure reliable and accurate results.

5.2. Control

These simulators serve as valuable tools for control engineers in wind control systems, as they can be utilized to develop and test new control algorithms and enhance the performance of wind farms. Here are several ways to use simulators from a control perspective:

Develop control algorithms: Engineers can use wind farm simulators to model the behavior of wind turbines and wind farms under various conditions and test different control strategies to optimize the system performance.

Test control systems: By connecting the simulator to the control algorithm, engineers can simulate different scenarios and evaluate the performance of the control system. They can also adjust parameters to improve the system’s performance and thoroughly test the control system using the simulator before deploying it in a real-world environment.

Optimize system performance: Simulations can be run under various conditions to identify optimal set points for control parameters such as rotor speed, blade pitch, generator torque, and yaw angle. This helps engineers identify the best control strategies to optimize the system’s performance.

Overall, the wind farm simulators are valuable tools for engineers in wind systems, allowing them to optimize the system performance and ensure reliable and efficient operation.

5.3. Tendency

Based on the results of several experiments, it is possible to discern a series of data patterns and characteristics observed in a wind farm, which can provide insights into its operation and management. Trend analysis results based on data collected under various conditions, such as speed and power output, can be used to identify tendencies in the operation and power output changes of the wind farm.

The wind farm simulators introduced in this paper are low- and medium-fidelity simulators, which makes obtaining precise data for operating a wind farm challenging. As evidenced by the simulation results presented in

Section 4, the detailed numerical values of the simulators may differ slightly, but overall trends are consistent across all three simulators. If precise control is required in designing a wind farm control system or more data are desired, a more sophisticated simulator than those introduced in this paper is necessary. Such simulators include medium-fidelity options such as FAST.Farm, as well as high-fidelity options such as SOWFA, WAsP, and WindPRO. By utilizing these simulators effectively, they can aid in developing operating plans and prediction models for wind farms.

6. Conclusions

In this study, our primary objective was to conduct a comparative analysis of three wind farm simulators: FLORIS, FLORIDyn, and WFSim. We carried out three experiments focusing on various aspects of wind farm power production. The first experiment investigated the effects of turbine spacing on speed and power changes, demonstrating that wider spacing contributed to faster recovery speeds due to reduced wake effects. The second experiment showcased that by adjusting the yaw angle of upstream turbines, the downstream turbine’s wake effect could be mitigated, leading to enhanced overall power production within the wind farm. In the final experiment, we compared the turbine speed reduction rates based on wind speed, highlighting the differences among the simulators in terms of the speed component composition.

By modifying the settings used in each experiment, we delved into the unique characteristics of each simulator, providing a comprehensive understanding of their capabilities, limitations, and potential applications.