A Comparison of a Transparent Thermal Insulation System Filled with Refrigerants and a Pig-Fat Based PCM

Abstract

:1. Introduction

- The Trombe wall and PCM will reduce the amount of energy consumed in the building, as the ventilated facade significantly improves the thermal behaviour of the exterior wall. During the day, the exterior wall is heated by solar radiation and the PCM melts; then at night, when the outdoor temperature falls below the phase change temperature, the heat stored by the PCM is released and the air inside the building heats up.

- The effective technology used on the façade exposed to solar radiation, such as natural ventilation, Prisma solar glass and shading devices, prevents overheating of the air inside of the building in summer and conserves the heat from the combined TTI-PCM and Trombe wall in winter [14].

- The TTI-PCM and Trombe wall combination can be used as a passive heating system because the TTI can be filled with refrigerant 134a, which has similar thermal conductivity to noble gases such as krypton. (Krypton: 0.0094 W/m K at 25 °C and pressure 0.1 MPa. R134a: 0.01409 W/m K at 29.85 °C and pressure 0.122 MPa.) [15,16].

- The transparent sheet used must be of a material such as acrylic, as the refrigerant expands when exposed to solar radiation. The sheet must be sufficiently flexible to withstand the increase in the volume of the refrigerant as its temperature rises. Many other works have found disadvantages of TTI-PCM systems, including:

- The highest fluxes occur in the pure liquid state of the PCM, which for PCM depends on the solar radiation, the size of the glazed area and the dimensions of ventilated façade [9].

- In a cold climate, the optimum area of the TTI-PCM wall must be increased, to allow more of the incident solar radiation to heat it [17].

- With more incident solar radiation, and a Trombe wall in the TTI-PCM, the building will overheat in summer. This can also occur when a large of amount of refrigerant is used, such as transparent thermal material [14].

2. Materials and Methods

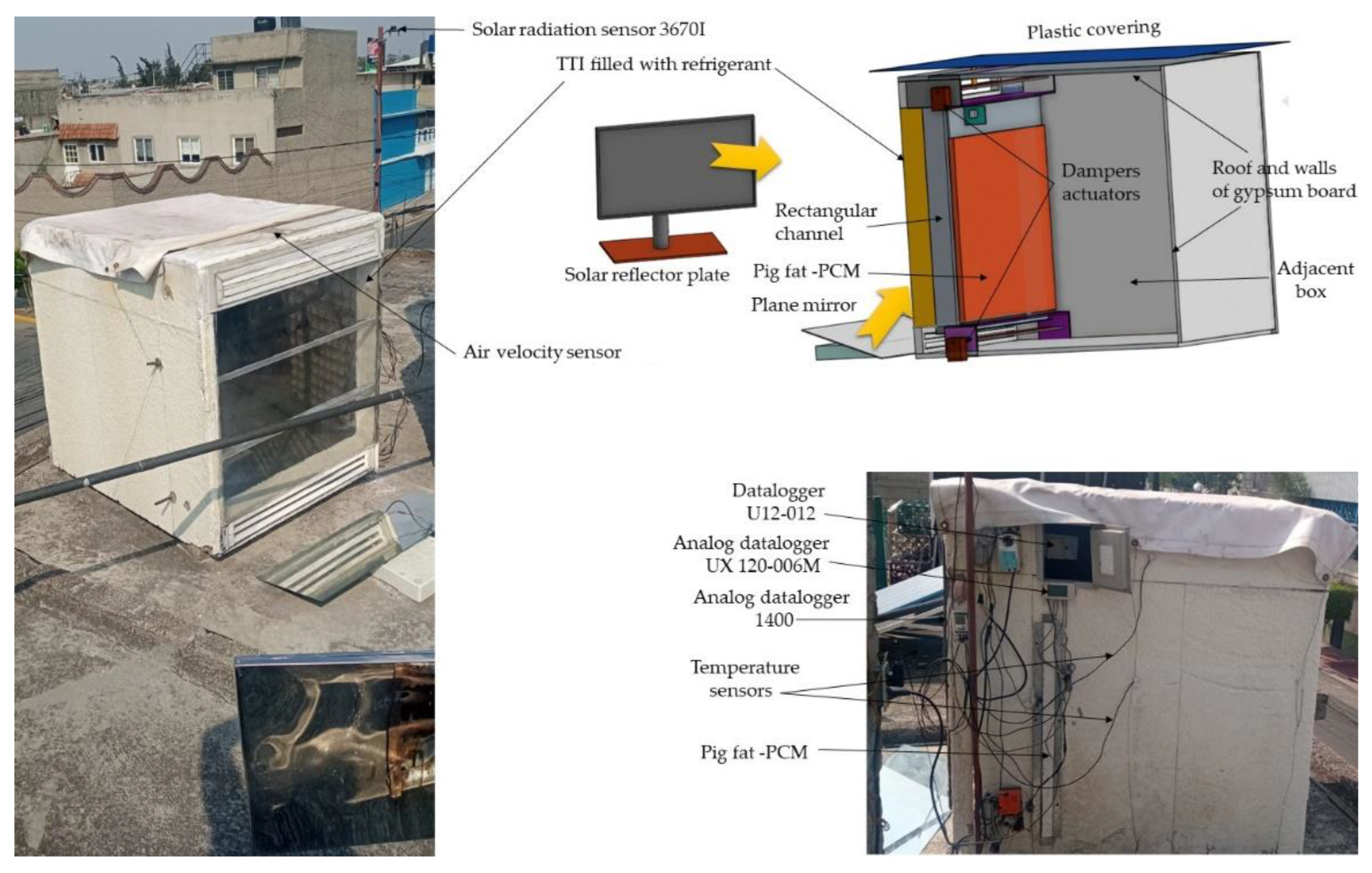

2.1. Building the HACS

2.2. Recording the Behaviour of the TTIs

Refrigerants R134a and R1233zd Used as Filler Gases in the TTI System

2.3. Removing Air and Moisture from the TTI

- The yellow hose of the vacuum pump manifold was connected to the inlet coupling and the blue hose to the inlet of the TTI valve. The vacuum pump power switch was turned on and the low-pressure valve was opened until the pressure gauge read 0.35 bar.

- 10 min elapsed to hold the vacuum between 0 and 0.35 bar.

- The vacuum pump was replaced by a gas cylinder and the low-pressure valve of the manifold was opened.

- The refrigerant was charged until the low-pressure gauge read 0.35 bar and the mass of the refrigerant container weighed 25 g.

- The low-pressure valve was closed, and thermal expansion was observed in the acrylic coating.

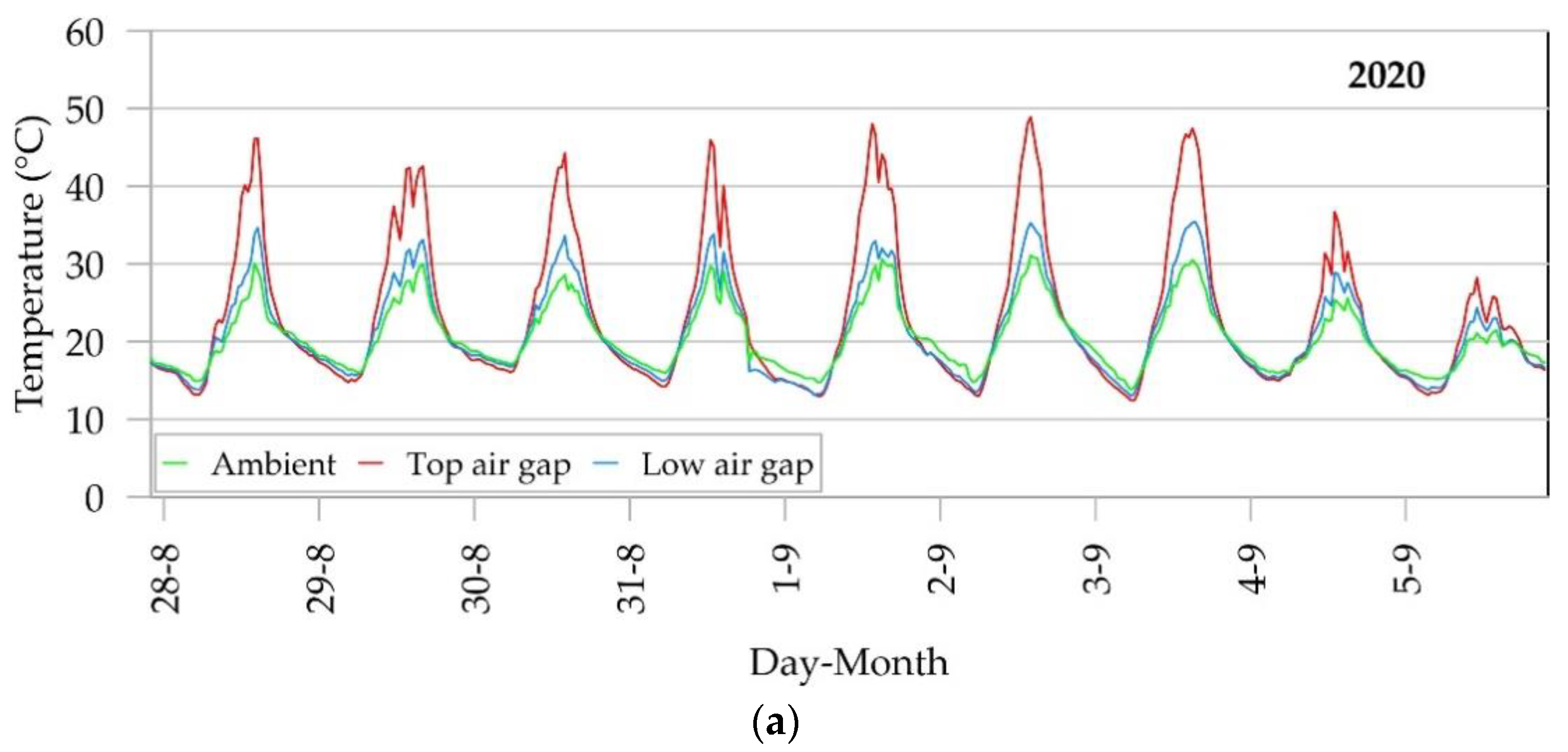

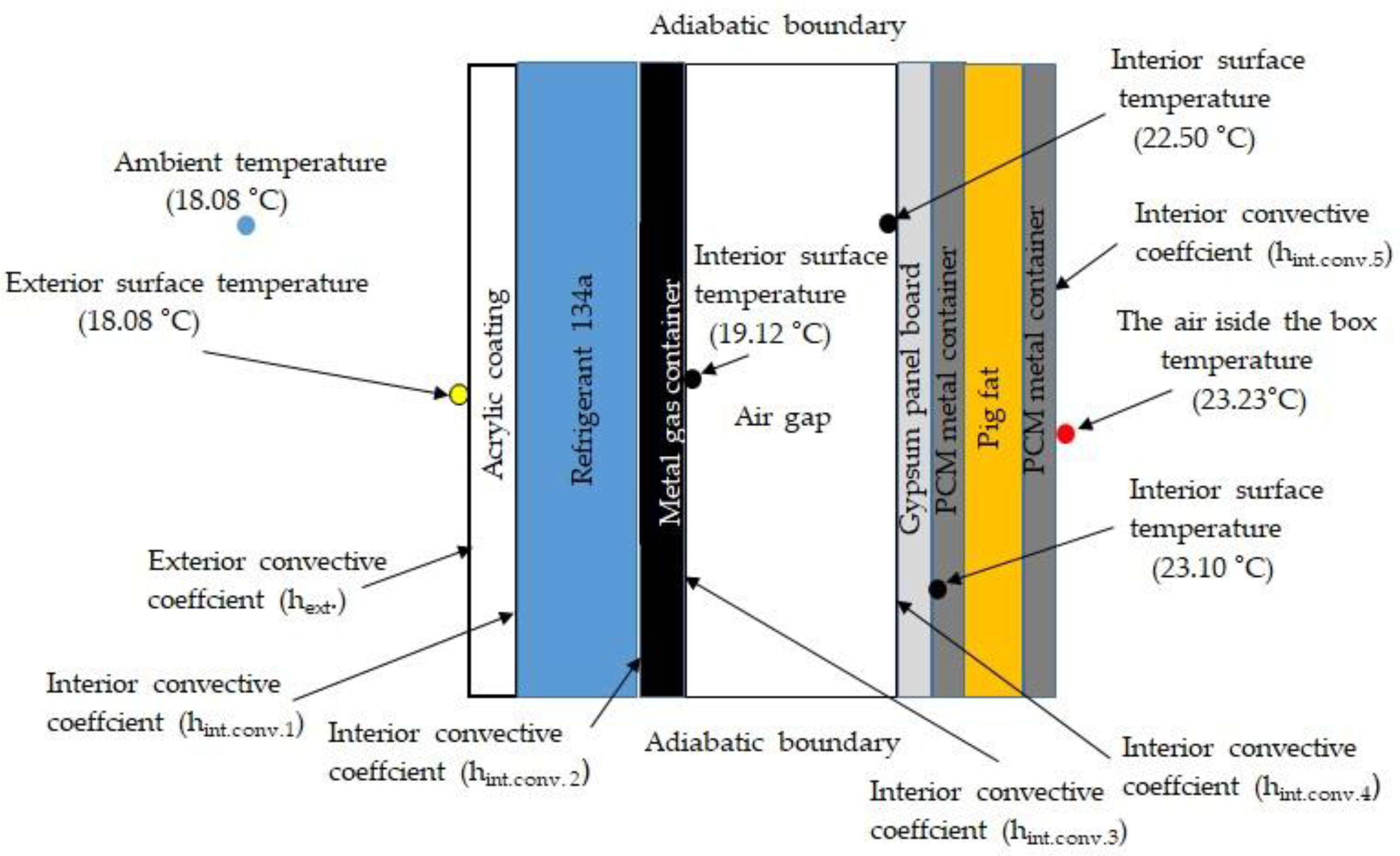

2.4. Measuring the Air Gap Temperature

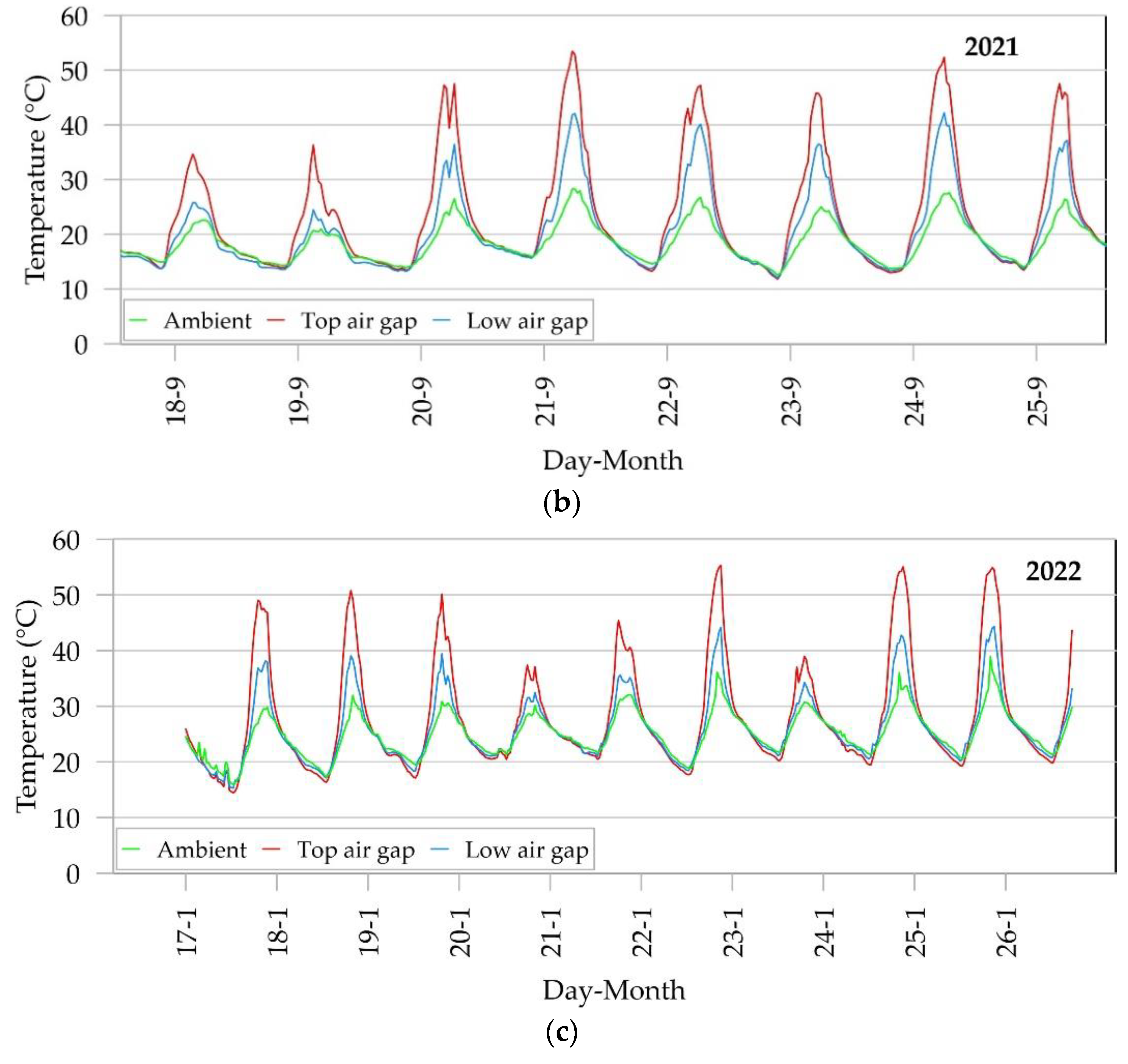

2.5. Measuring Temperature and Relative Humidity of the Air Inside the Box

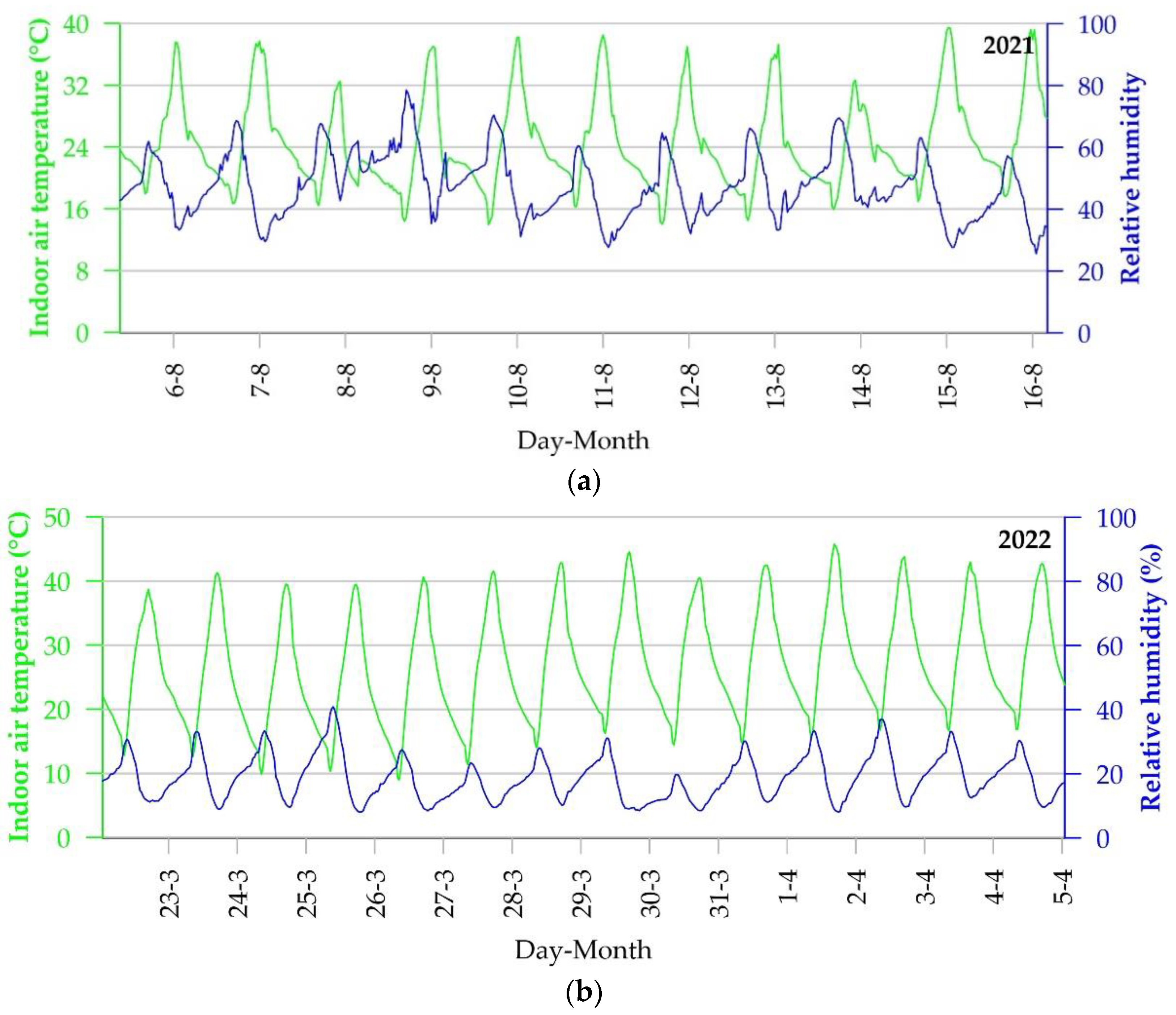

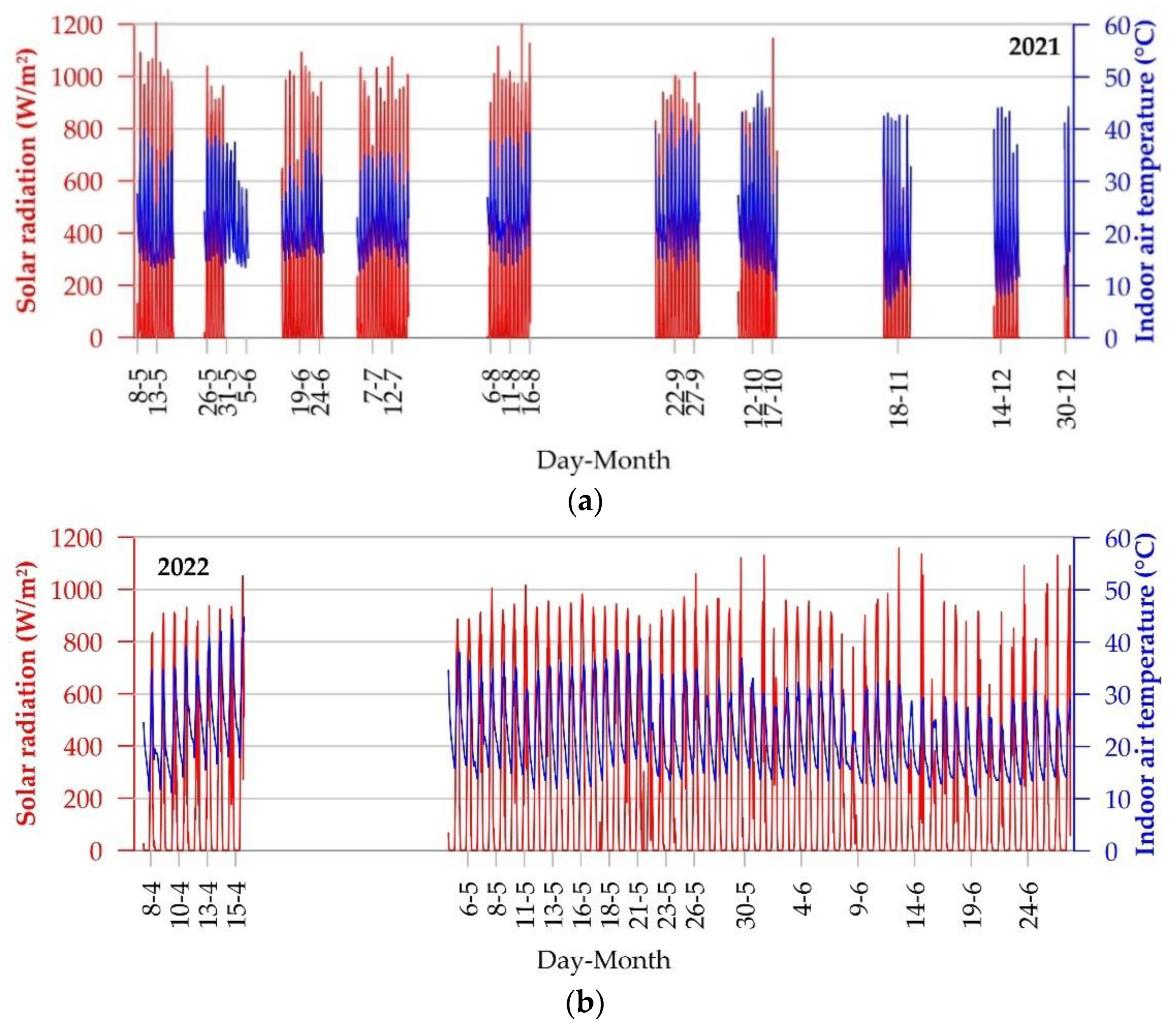

2.6. Recording Solar Radiation

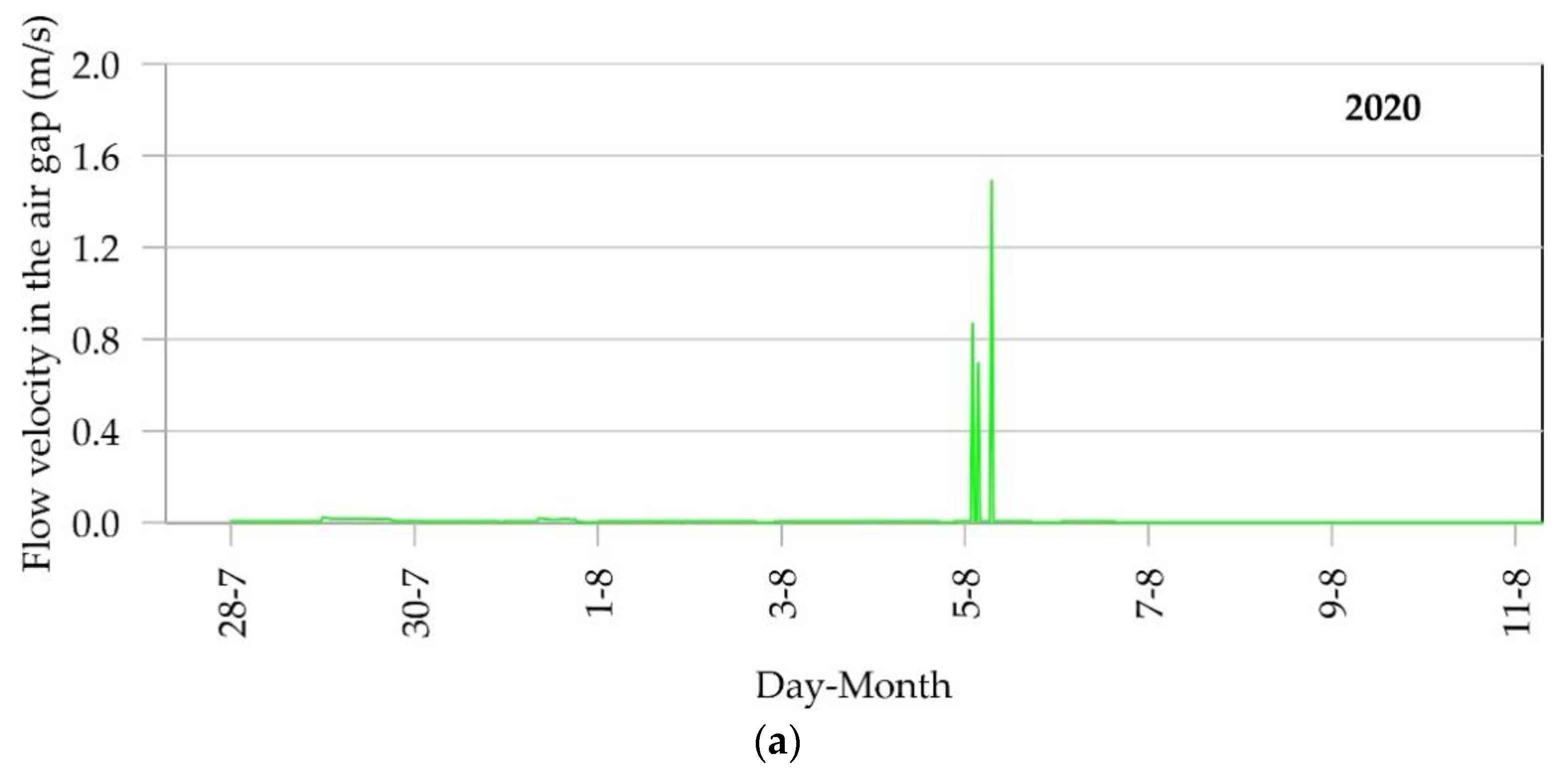

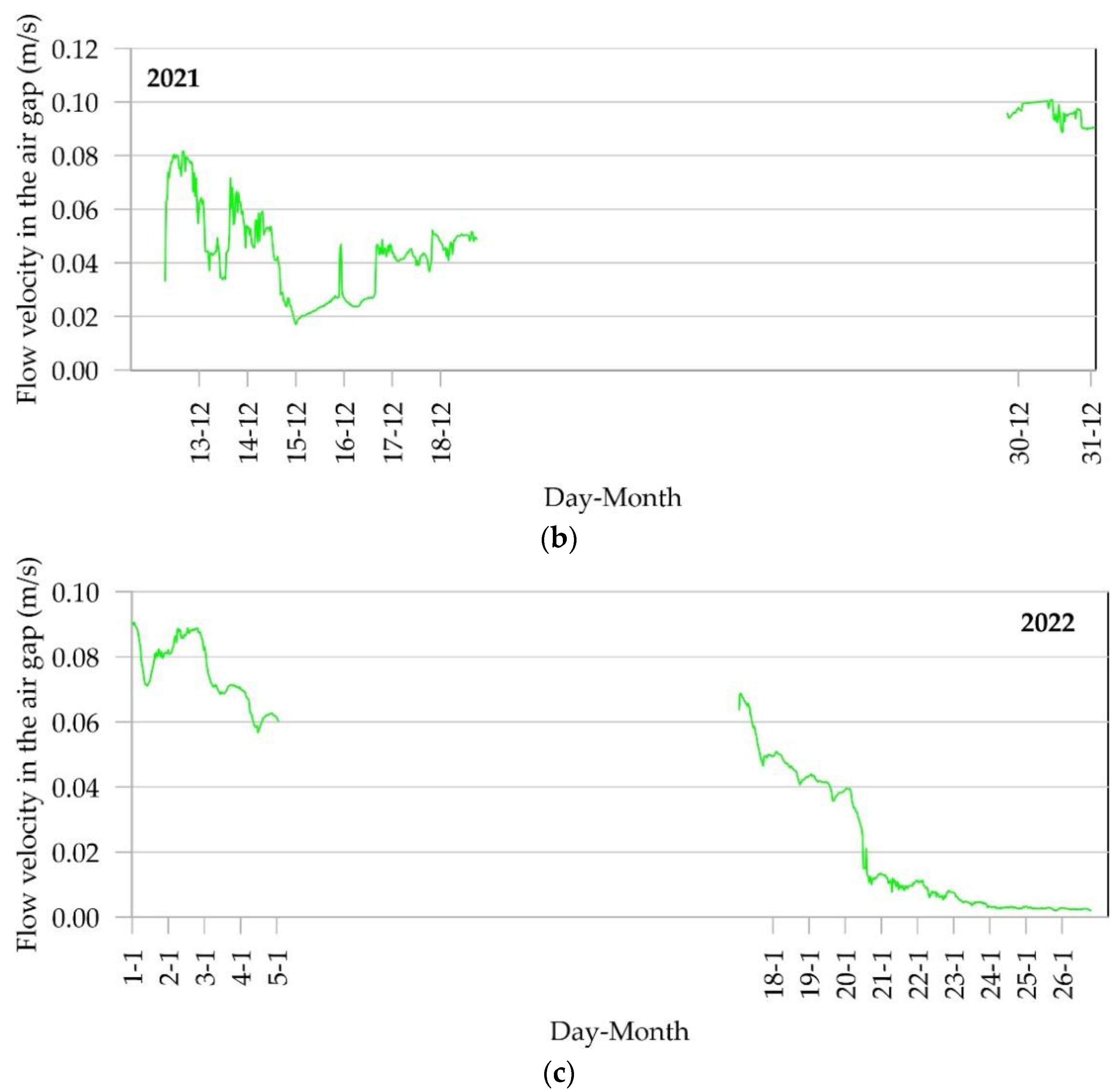

2.7. Velocity of Air-Flow at the Air Gap

2.8. Wind Velocity and Air-Flow in the Small Window

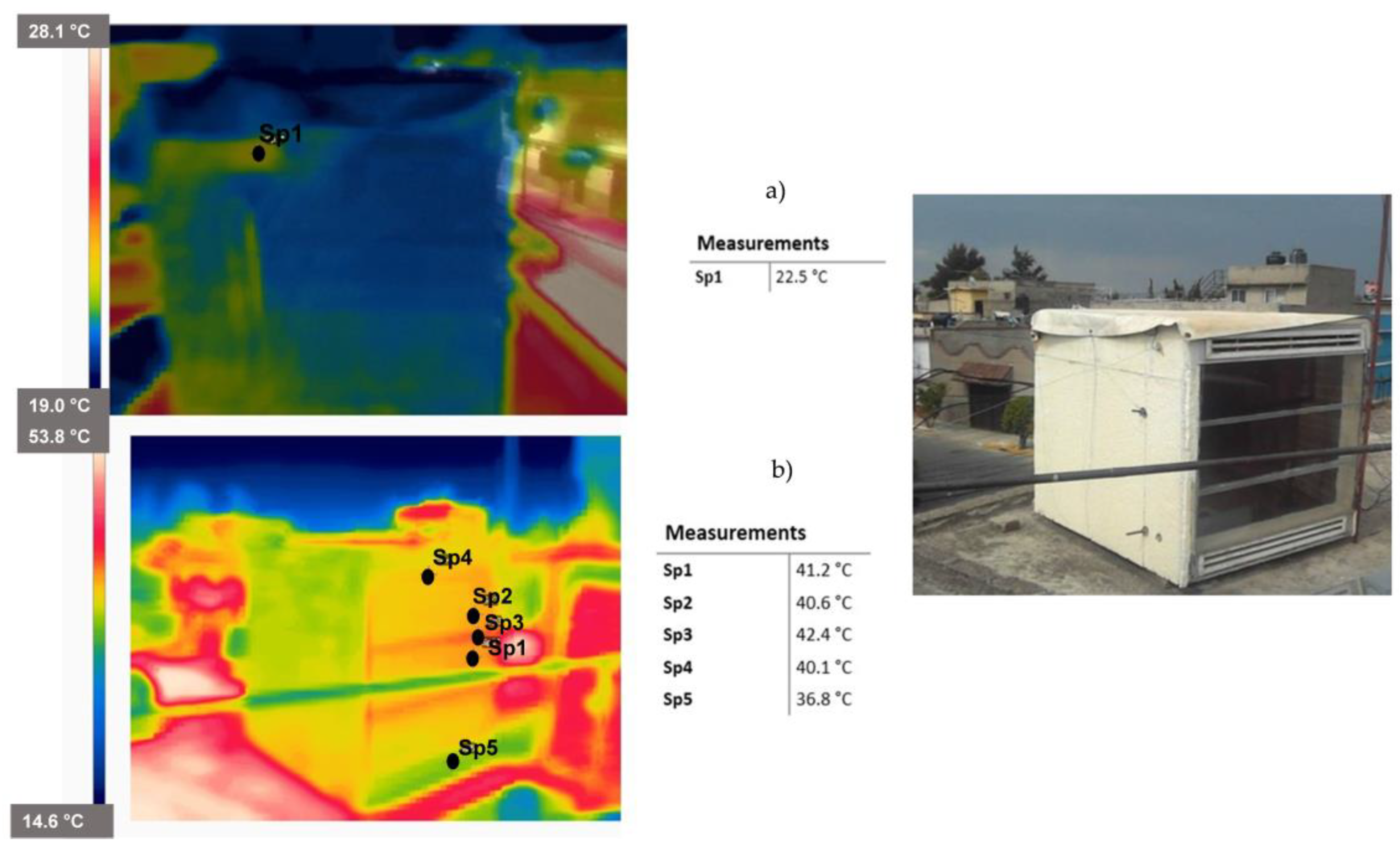

2.9. Thermographic Monitoring

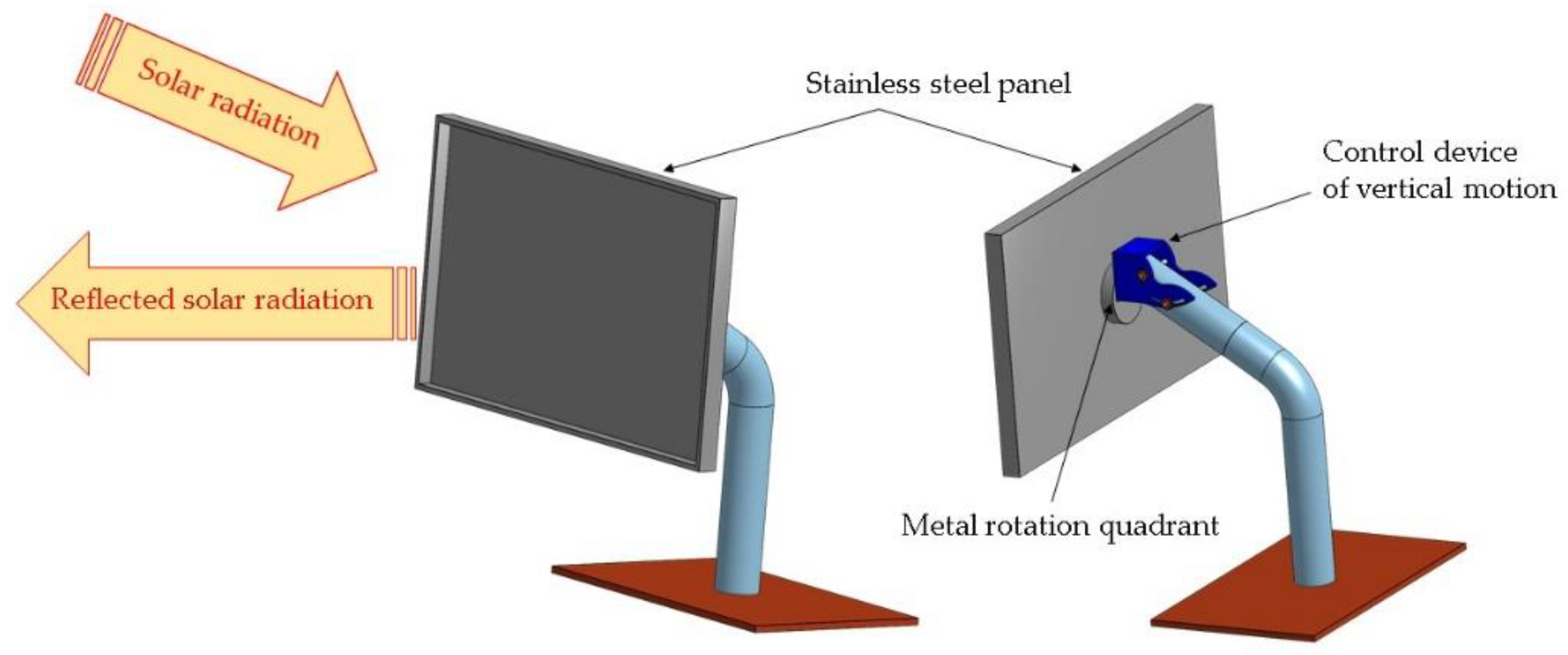

2.10. Design of Three TTI Models

2.11. Comparison of Two TTI Systems

3. Results and Discussion

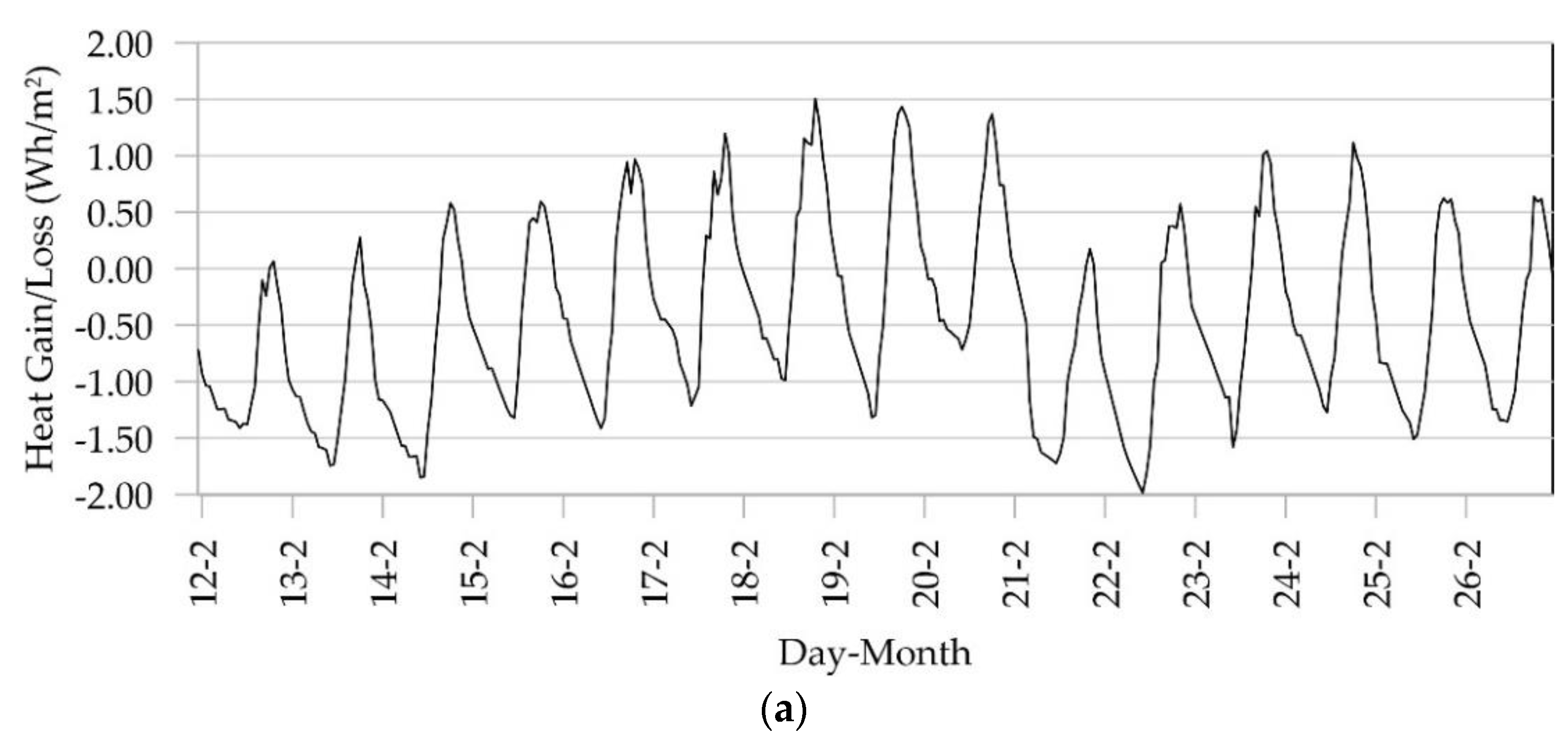

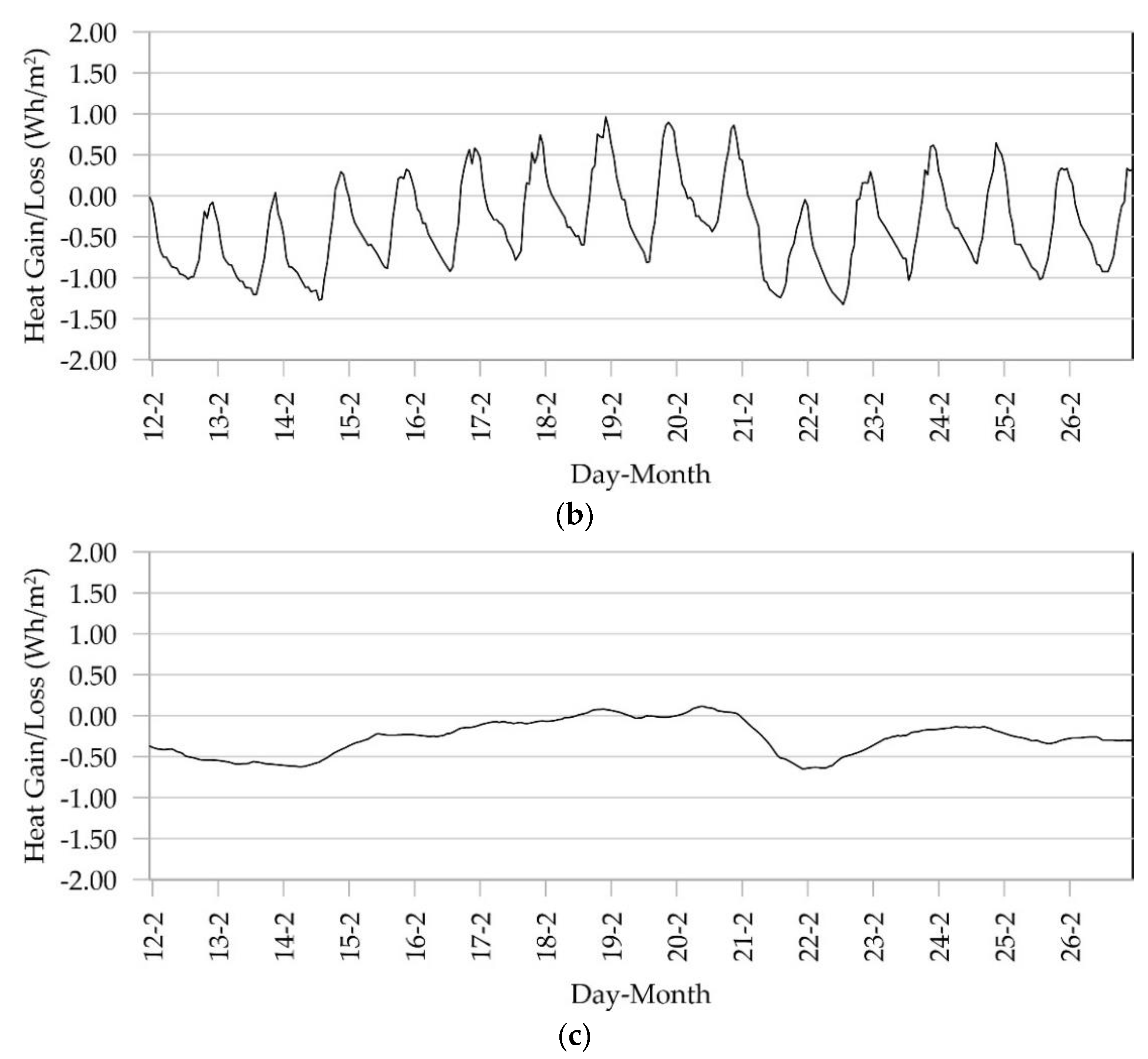

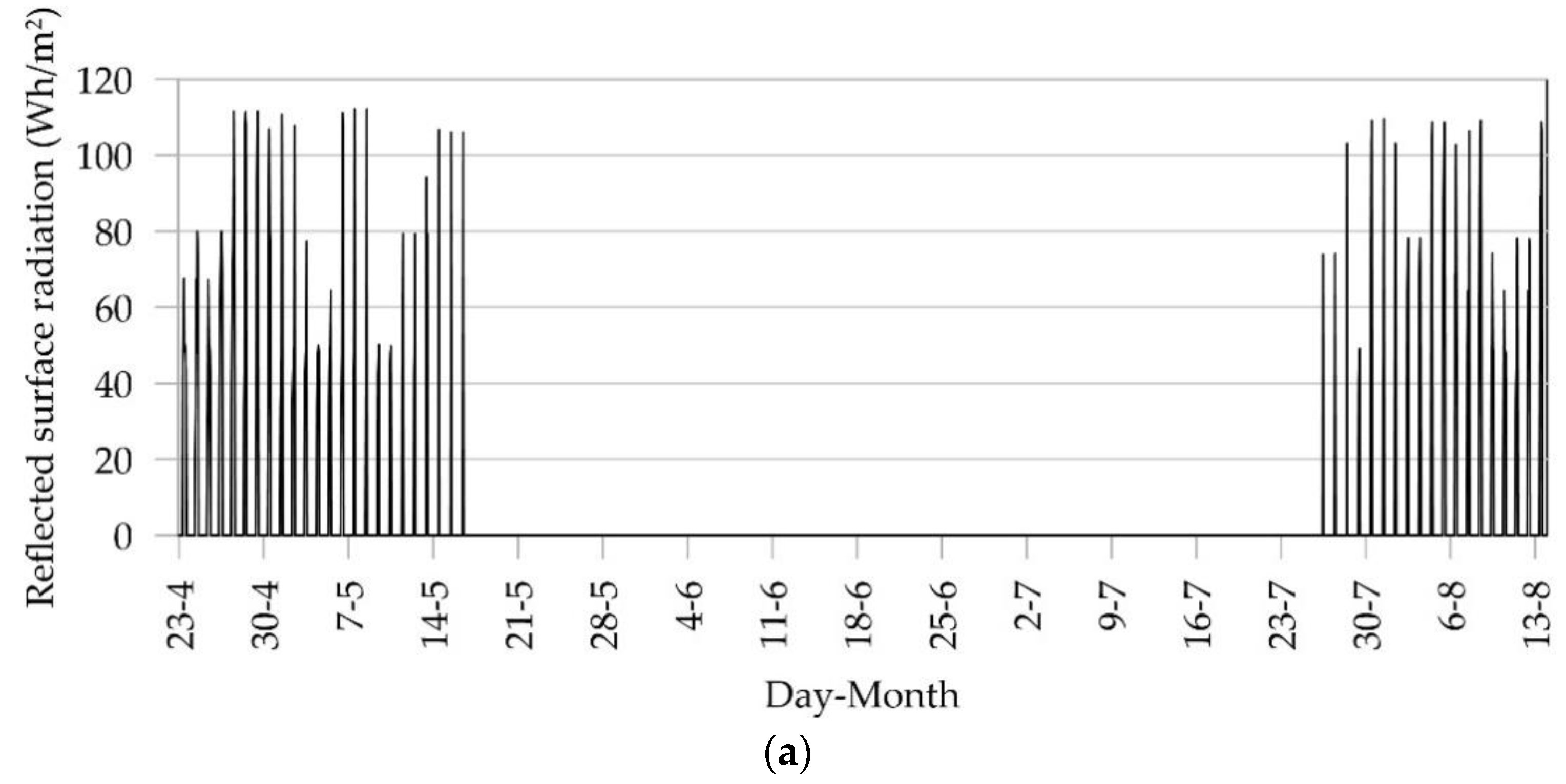

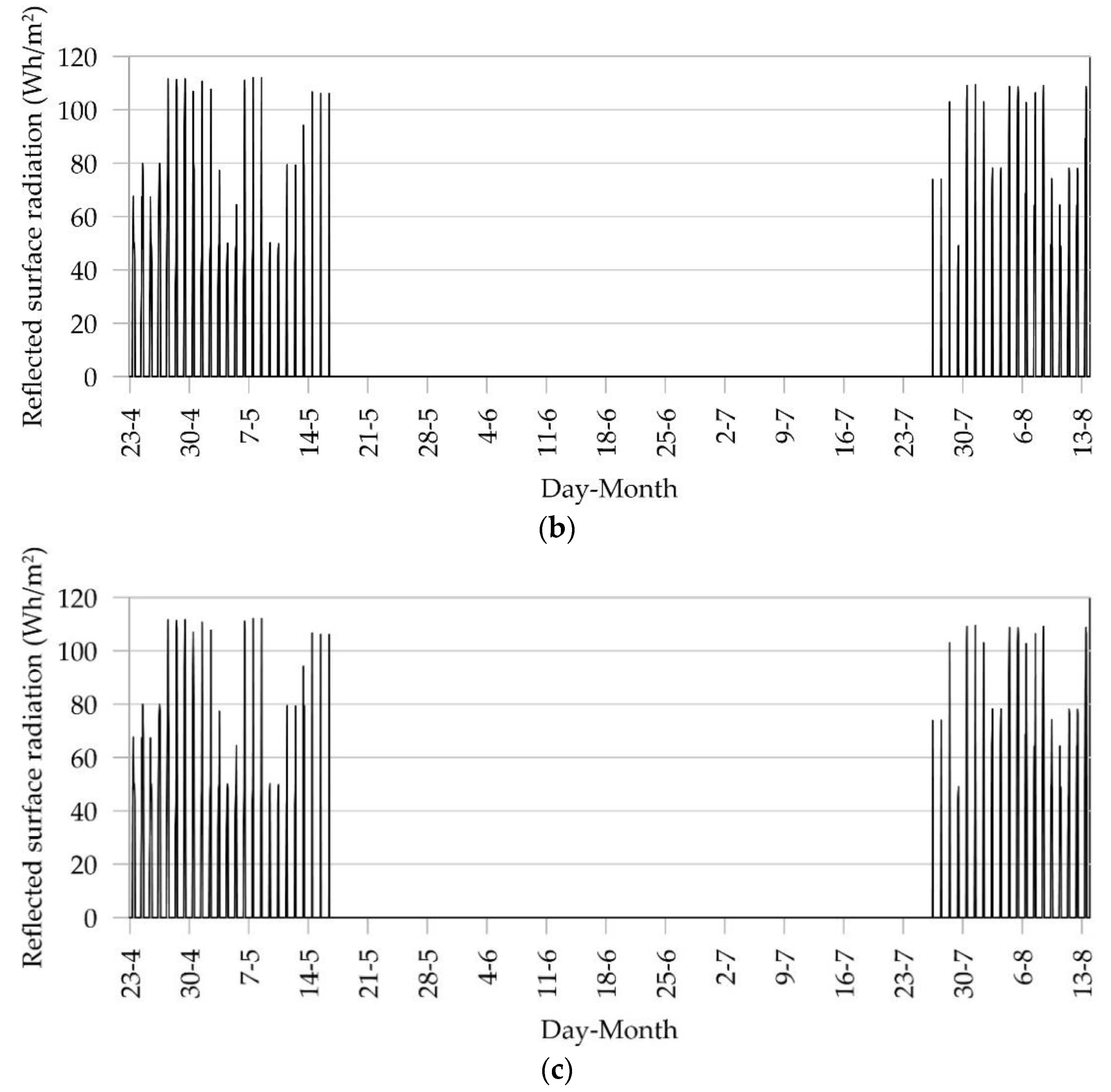

3.1. Results of Simulations with the Opaque 3 Program

3.2. Comparison of Simulations and Measured Data

3.3. CFD Simulations

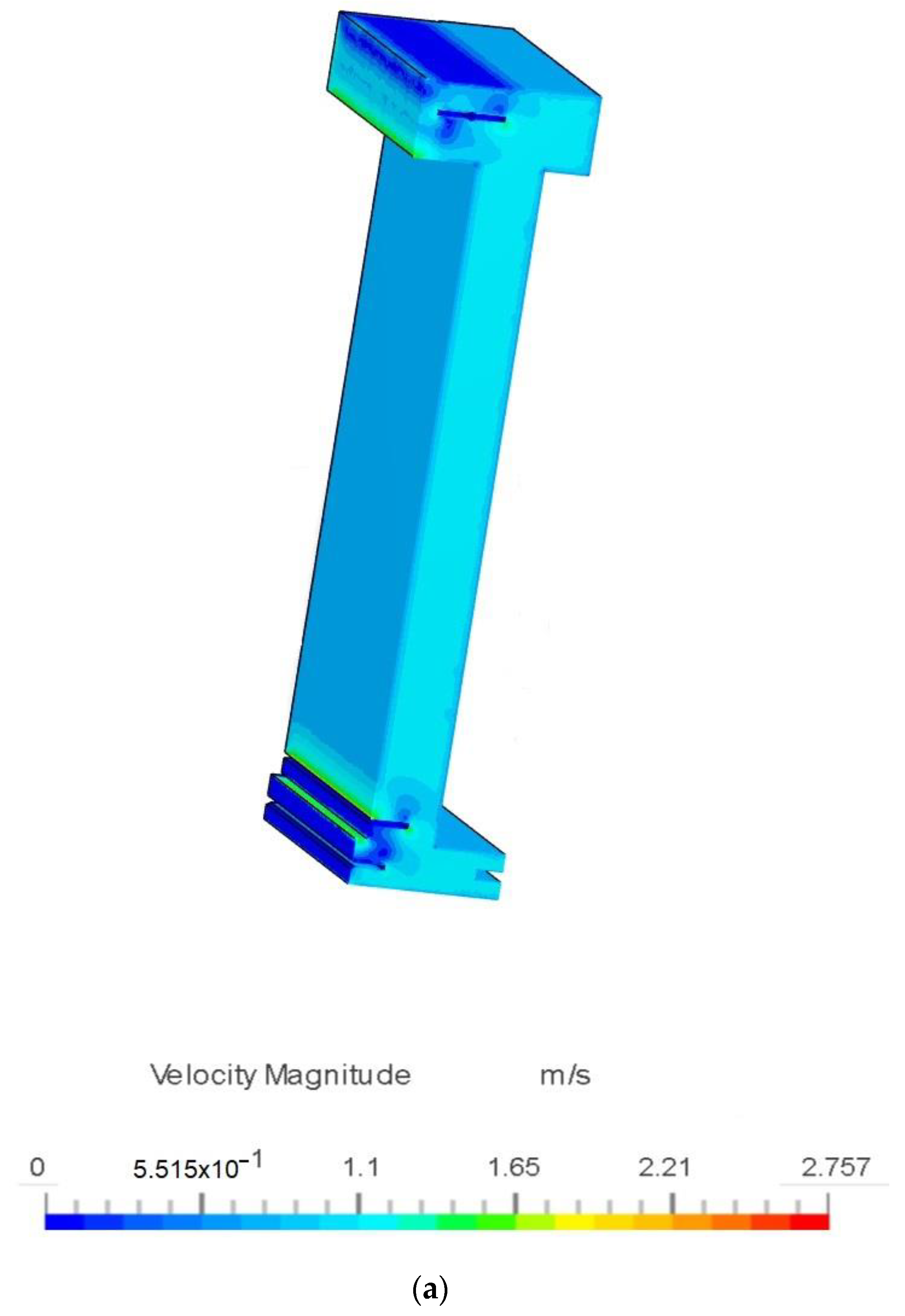

3.3.1. Simulations of Air Velocity

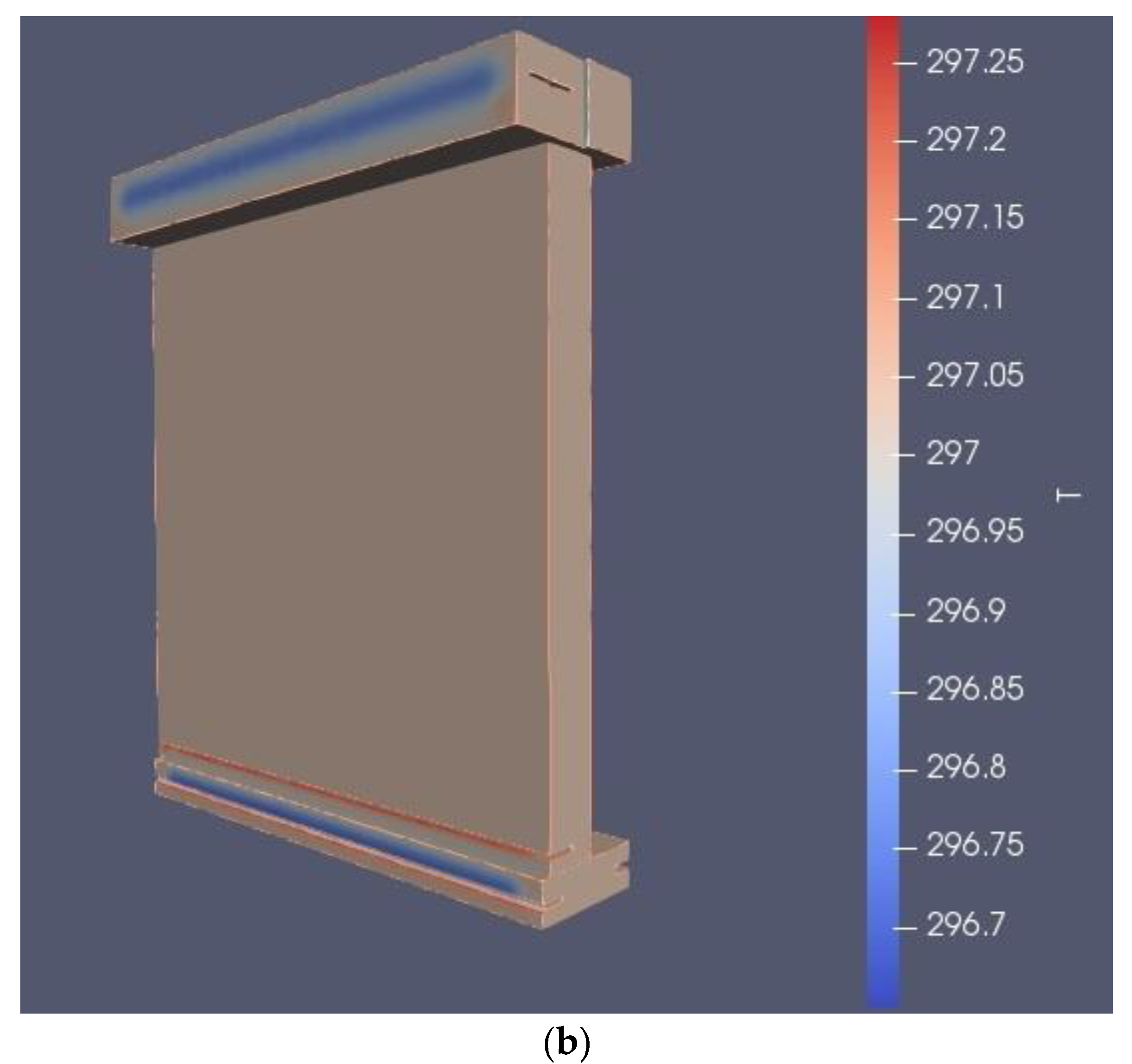

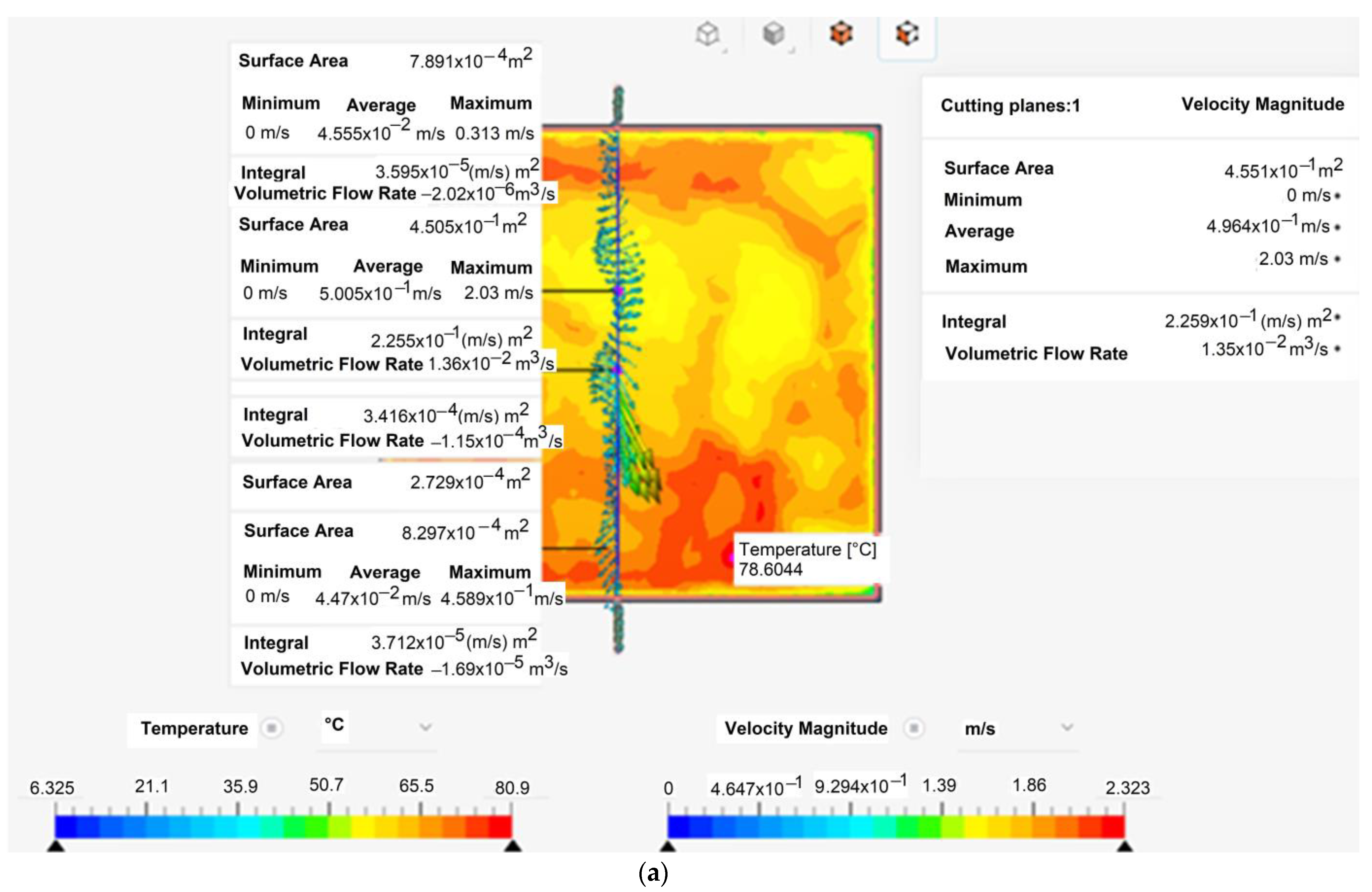

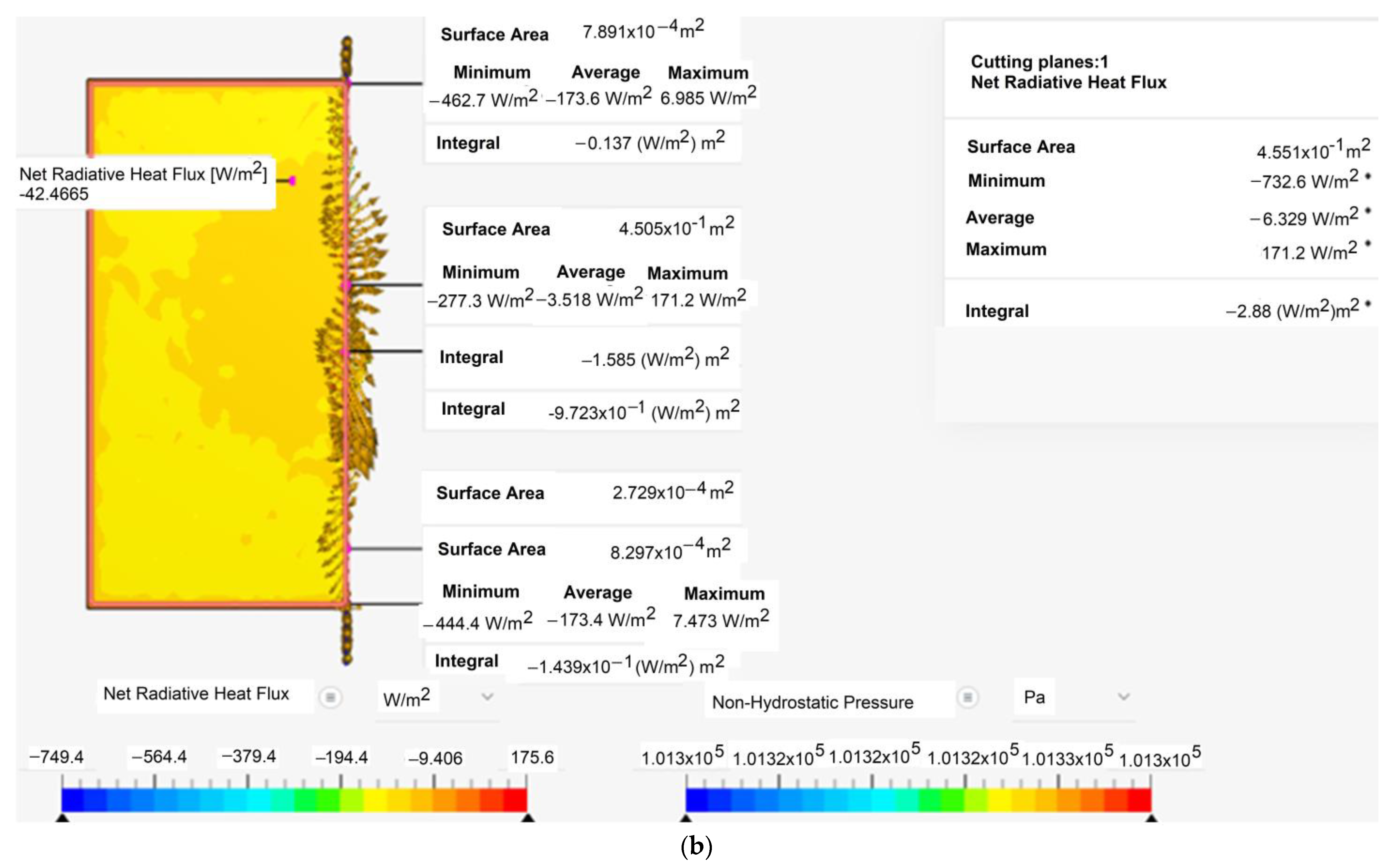

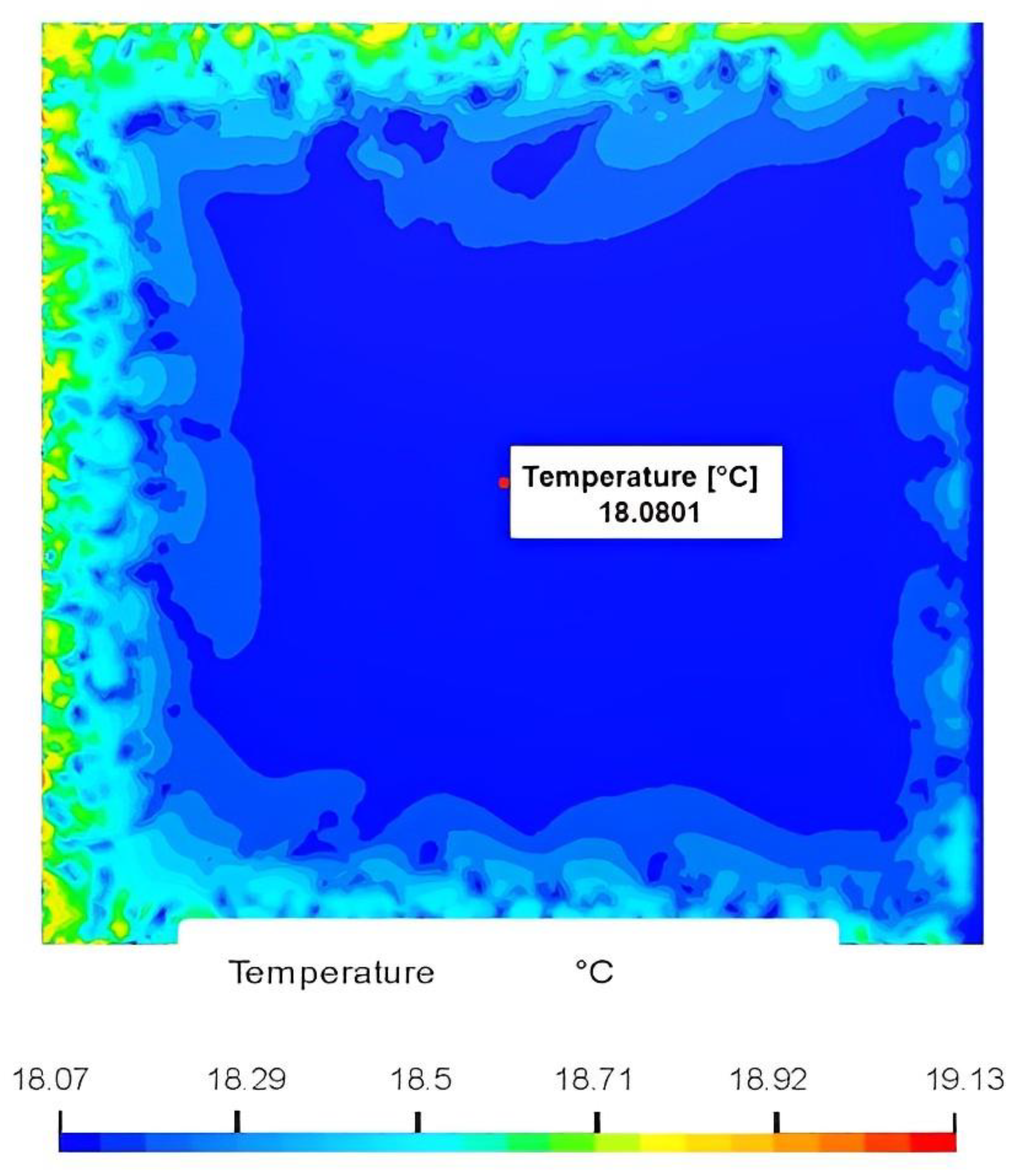

3.3.2. Simulations of Heat Transfer of TTI

Heat Transfer Simulations of the Black Metal Absorber

Heat-Transfer Simulations of the PCM

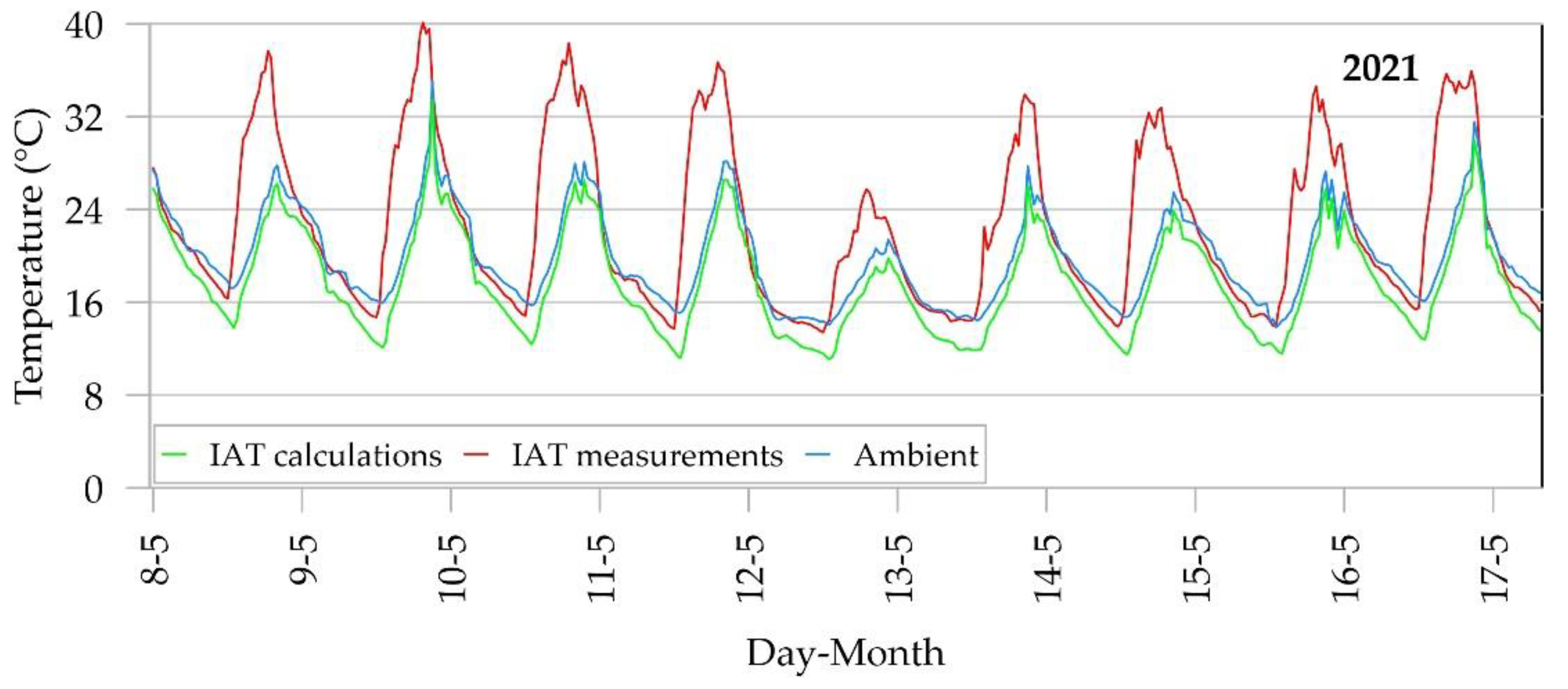

Comparative Analysis between Experimental and Simulated IAT

3.4. Comparative Analysis

3.4.1. Analysis of the Results of the Simulations and the Heat Transfer of the TTI Systems

3.4.2. The Thermal Behaviour Analysis of the HACS

3.4.3. Convergence Criterion for CFD Simulations

4. Conclusions

- Currently, refrigerants are used in the mechanical circuits of refrigeration and air-conditioning systems, but have not been used in TTI applications. Refrigerants are sought for these systems with low thermal conductivity and low global warming potential. Under real conditions, in Nezahualcoyotl City, these transparent thermal materials have similar thermal behaviour to noble gases, and TTI filled with a combination of R134A or R1233zd and pig fat were found to be non-flammable.

- Safe gases that do not destroy the ozone layer can be a viable, sustainable option for heating buildings with a solar radiation of over 800 W/m2.

- The TTI of an HACS can be charged with different refrigerants that are not dependent on the use of a noble gas such as krypton. In these experiments, pig fat was shown to be a non-flammable organic material that could be used in the passive system of a building.

- Overheating in the air gap can be controlled using Ni-Ti actuators, as these materials change their physical dimensions at 23 °C cooling temperature and 70 °C heating temperature. The Ni-Ti actuators will open the dampers at 23 °C and close them completely at 51 °C in the cooling mode.

- The air gap can increase the airflow velocity from the adjacent box by means of a fan, which could be powered with a 5 W solar panel plate and installed on the roof of the HACS.

- The use of phase-change interior thermal materials will be more common in passive heating systems of buildings.

- In this study digital twin solutions that combine data streams from individual devices and implement new simulations, and that can optimise their performance and thus decrease their impact on the environment, were sought for bioclimatic architecture by means of an HACS.

- In the future, CFD simulations should be run with measured data, transient heat-transfer and turbulence models to improve the accuracy of the simulation results and the thermal behaviour of HACS in different meteorological conditions, and to improve HACS design.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Building the HACS

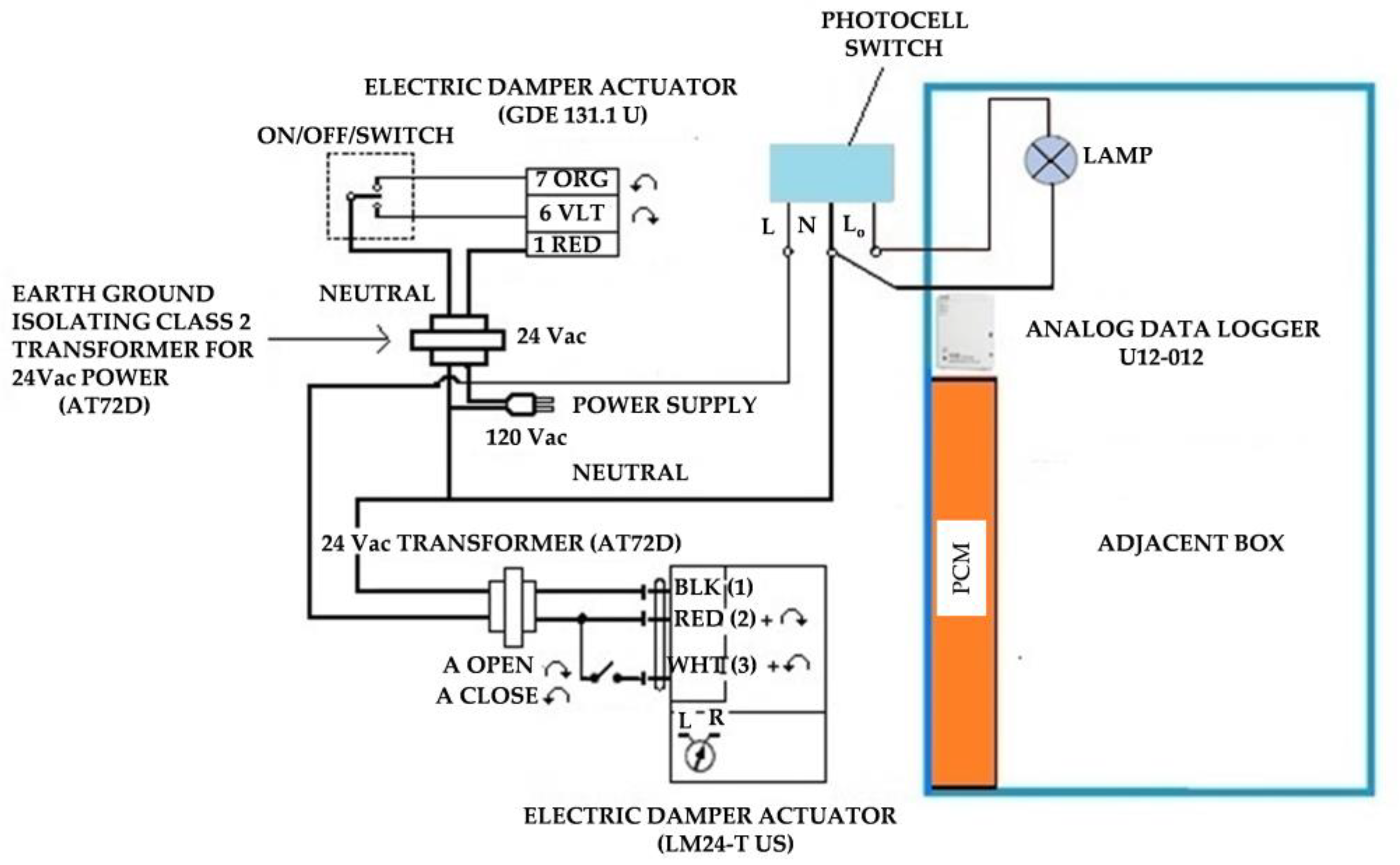

Appendix B. Technical Data of Actuators

| Bottom Actuator | Top Actuator | |

|---|---|---|

| Model | LM24-T US | GDE 131.1U |

| Power supply | 24 VAC ± 20% 50/60 Hz 24 VDC ± 10% | 24 Vac +20%, −15%, 50/60 Hz |

| Power consumption | 2 W | |

| Transformer | 3 VA (Class 2 power source) | 2.3 VA |

| Electrical connection | 3 ft, 18 GA, UL CL2P plenum cable | 3 ft, 18 GA, UL CL2P plenum cable |

| Control | On-Off | On-Off |

| Overload protection | Electronic throughout 0 to 95° rotation | Electronic throughout 0 to 95° rotation |

| Angle of rotation | Max. 95°, adjust. with mechanical stops | 0° to 90° with 5° intervals |

| Torque | Min 4 N-m | 5 N-m |

| Direction of rotation | Reverse wires terminals 2 and 3 | Reverse wires terminals Y1 and Y2 |

| Running time | 80 to 110 s for 0 to 35 in-lb | 90 s at 60 Hz (108 s at 50 Hz) |

| Manual override | External push button | External push button |

| Humidity | 5 to 95% RH, non-condensing | 95% RH |

| Ambient temperature | −30 °C to 50 °C | −32 °C to 54.44 °C |

| Storage temperature | −40 °C to 80 °C | −40 °C to 70 °C |

| Housing type | NEMA type 2 (-T models NEMA 1) | Class 2 according to UL, CSA |

| Electrical connection | Screw terminal (for 26 to 14 GA wire) | Class III per EN60730 |

| Housing material rating | UL94-5V | Screw terminal (18 GA wire) |

| Noise level | Less than 35 dB (A) | NEMA Type 2 IP54 according to EN 60 529 |

| Servicing | Maintenance free | - |

| Quality standard | ISO 9001 | Maintenance free |

| Weight | 0.55 kg | 0.48 kg |

Appendix C. GWP Index and Physical Properties of Commonly Used Refrigerants

| Refrigerant | GWP Index | Liq. Temp. (°C) | Liq. Pressure (kPa) | Liq. Therm. Conductivity (mW/m-K) | Vapor Therm. Conductivity (mW/m-K) | ASHRAE Flammable Classification |

|---|---|---|---|---|---|---|

| R1233zd | 5 | 46.85 | 266.80 | 72.10 | 12.22 | A1 |

| R1234yf | 0 | 46.85 | 1207.20 | 62.94 | 16.44 | A2L |

| R1234ze | 1 | 46.85 | 919.60 | 71.69 | 15.66 | A2L |

| R11 | 4660 | 46.85 | 215.10 | 80.67 | 9.42 | A1 |

| R134a | 1300 | 46.85 | 1216.60 | 71.78 | 16.30 | A1 |

| R12 | 10,200 | 46.85 | 1130.50 | 59.64 | 11.94 | A1 |

| R123 | 79 | 46.85 | 192.60 | 70.59 | 10.50 | B1 |

| R141b | 782 | 46.85 | 165.80 | 80.63 | 11.46 | A1 |

| R22 | 1760 | 46.85 | 1806.10 | 73.40 | 13.77 | A1 |

| R410A | 1130 | 46.85 | 1362.20 | 72.64 | 14.36 | A1 |

| CO2 | 1 | 28.85 | 7062.80 | 84.45 | 71.01 | A1 |

Appendix D. Simulations

References

- International Energy Agency. Word Energy Outlook 2022; IEA: Paris, France, 2022; pp. 288–289. [Google Scholar]

- Fokaides, P.A.; Kalogirou, S.A. Application of infrared thermography for the determination of the overall heat transfer coefficient (U-Value) in building envelopes. Appl. Energy 2011, 88, 4358–4365. [Google Scholar] [CrossRef]

- Lucchi, E. Applications of the infrared thermography in the energy audit of buildings: A review. Renew. Sustain. Energy Rev. 2018, 82, 3077–3090. [Google Scholar] [CrossRef]

- Youcef, M.L.; Feuillet, V.; Ibos, L.; Candau, Y.; Balcon, P.; Filloux, A. In situ quantitative diagnosis of insulated building walls using passive infrared thermography. In Proceedings of the 11th International Conference on Quantitative InfraRed Thermography, Naples, Italy, 11–14 June 2012. [Google Scholar] [CrossRef]

- Barbi, S.; Barbieri, F.; Marinelli, S.; Rimini, B.; Merchiori, S.; Bottarelli, M.; Montorsi, M. Phase Change Material Evolution in Thermal Energy Storage Systems for the Building Sector, with a Focus on Ground-Coupled Heat Pumps. Polymers 2022, 14, 620. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Wilson, R.; Wu, Y. A Review of Transparent Insulation Material (TIM) for building energy saving and daylight comfort. Appl. Energy 2018, 226, 713–729. [Google Scholar] [CrossRef]

- Paneri, A.; Wong, I.L.; Burek, S. Transparent insulation materials: An overview on past, present and future developments. Sol. Energy 2019, 184, 59–83. [Google Scholar] [CrossRef]

- Bao, Y.; Guo, R.; Kang, Q.; Liu, C.; Zhang, W.; Zhu, Q. Transparent, thermal insulation and UV-shielding coating for energy efficient glass window. Ceram. Int. 2021, 47, 24597–24606. [Google Scholar] [CrossRef]

- Manz, H.; Egolf, P.W.; Suter, P.; Goetzberger, A. TIM–PCM external wall system for solar space heating and daylighting. Sol. Energy 1997, 61, 6, 369–379. [Google Scholar] [CrossRef]

- Kalnæs, S.E.; Jelle, B.P. Phase change materials and products for building applications: A state-of-the-art review and future research opportunities. Energy Build. 2015, 94, 150–176. [Google Scholar] [CrossRef]

- Li, D.; Zhang, C.; Li, Q.; Liu, C.; Arıcı, M.; Wu, Y. Thermal performance evaluation of glass window combining silica aerogels and phase change materials for cold climate of China. Appl. Therm. Eng. 2019, 165, 114547. [Google Scholar] [CrossRef]

- Torres-Rodríguez, A.; Morillón-Gálvez, D.; Aldama-Ávalos, D.; Hernández-Gómez, V.H.; Kerdan, I.G. Thermal performance evaluation of a passive building wall with CO2-filled transparent thermal insulation and paraffin-based PCM. Sol. Energy 2020, 205, 1–11. [Google Scholar] [CrossRef]

- Rangel, C.G.; Rivera-Solorio, C.; Gijón-Rivera, M.; Mousavi, S. The effect on thermal comfort and heat transfer in naturally ventilated. Energy Build. 2022, 274, 112453. [Google Scholar] [CrossRef]

- Souayfane, F.; Biwole, P.H.; Fardoun, F. Thermal behavior of a translucent superinsulated latent heat energy storage wall in summertime. Appl. Energy 2018, 217, 390–408. [Google Scholar] [CrossRef]

- Le Neindre, B.; Garrabos, Y.; Tufeu, R. Thermal conductivity of dense noble gases. Phys. A Stat. Mech. Its Appl. 1989, 156, 512–521. [Google Scholar] [CrossRef]

- Laesecke, A.; Perkins, R.; de Castro, C.N. Thermal conductivity of R134a. Fluid Phase Equilibria 1992, 80, 263–274. [Google Scholar] [CrossRef]

- Souayfane, F.; Biwole, P.H.; Fardoun, F.; Achard, P. Energy performance and economic analysis of a TIM-PCM wall under different climates. Energy 2019, 169, 1274–1291. [Google Scholar] [CrossRef]

- Okochi, G.S.; Yao, Y. A review of recent developments and technological advancements of variable-air-volume (VAV) air-conditioning systems. Renew. Sustain. Energy Rev. 2016, 59, 784–817. [Google Scholar] [CrossRef]

- Envirotrolsgroup. LM24(-T) US BELIMO. Available online: https://r.search.yahoo.com/_ylt=AwrFBFddIXxjizsCy11U04lQ;_ylu=Y29sbwNiZjEEcG9zAzEEdnRpZAMEc2VjA3Ny/RV=2/RE=1669108189/RO=10/RU=http%3a%2f%2fwww.envirotrolsgroup.com%2fBelimo%2fGeneralDamperActuators%2fLMSeries%2fLM24-3-5P0-T_1_.1.pdf/RK=2/RS=5JezmoXFfRxb2msexXeybcYp7Fc (accessed on 21 November 2022).

- Siemens Industry. GDE 131.1U. Available online: https://www.kele.com/product/actuators-and-dampers/non-spring-return/siemens-industry/gde131.1u (accessed on 21 November 2022).

- Ali, A.H.; Ibrahim, S.I.; Jawad, Q.A.; Jawad, R.S.; Chaichan, M.T. Effect of nanomaterial addition on the thermophysical properties of Iraqi paraffin wax. Case Stud. Therm. Eng. 2019, 15, 100537. [Google Scholar] [CrossRef]

- Nižetić, S.; Arıcı, M.; Bilgin, F.; Grubišić-Čabo, F. Investigation of pork fat as potential novel phase change material for passive cooling applications in photovoltaics. J. Clean. Prod. 2018, 170, 1006. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K. Enhanced thermophysical properties of organic PCM through shape stabilization for thermal energy storage in buildings: A state of the art review. Energy Build. 2021, 236, 110799. [Google Scholar] [CrossRef]

- Honeywell. Genetron Properties Suite v 1.4.1. Available online: https://www.honeywell-refrigerants.com/europe/genetron-properties-suite/ (accessed on 21 November 2022).

- ANSI/ASHRAE Standard 34-2019. Designation and Safety Classification of Refrigerants. Available online: https://ashrae.iwrapper.com/ASHRAE_PREVIEW_ONLY_STANDARDS/STD_34_2019 (accessed on 28 November 2022).

- OPAQUE 3. Available online: https://www.sbse.org/resources/opaque (accessed on 18 December 2022).

- Churchill, S.W.; Chu, H.H. Correlating equations for laminar and turbulent free convection from a horizontal cylinder. Int. J. Heat Mass Transf. 1975, 18, 1049–1053. [Google Scholar] [CrossRef]

- Soltis, D.; Jackson, J.E. Physical Properties of Materials. In ASHRAE Handbook-Fundamentals; Kennedy, H.E., Ed.; ASHRAE Research: Peachtree Corners, GA, USA, 2021; pp. 33.1–33.4. [Google Scholar]

- Soltis, D.; Jackson, J.E. Thermal properties of foods. In ASHRAE Refrigeration; Kennedy, H.E., Ed.; ASHRAE Research: Peachtree Corners, GA, USA, 2018; pp. 19.1–19.31. [Google Scholar]

- Propiedades del Acrílico. Available online: http://plasco.com.mx/upload/productos/6_318.pdf (accessed on 22 December 2022).

- Cengel, Y.A. Transferencia de Calor, 2nd ed.; Mc Graw Hill: Distrito Federal, México, 2004; p. 736. [Google Scholar]

- OnshapeI Product Development Platform. Available online: https://www.onshape.com/en/ (accessed on 10 February 2022).

- Simulation Softwarei Engineering in the CloudI SimScale. Available online: https://www.simscale.com/ (accessed on 2 April 2022).

- ParaView 5.6.2. Available online: https://www.paraview.org/ (accessed on 20 April 2022).

- Calculation of Thermal Mass according to EN ISO 13786. Available online: https://www.htflux.com/en/free calculation tool for-thermal mass of building components iso 13786/ (accessed on 4 April 2023).

| PCM | Units | Iraqi Paraffin | Paraffin Wax | Lauric Acid | Stearic Acid | Pig Fat |

|---|---|---|---|---|---|---|

| Melting temp. | °C | 43 | 0–90 | 44 | 54 | 36–45 |

| Liquid state density | kg/m3 | 850 | - | - | - | 986 |

| Solid state density | kg/m3 | 950 | 880–950 | 66 | 940 | 910 |

| Latent heat of fusion | kJ/kg | 195 | 150–250 | 212 | 157 | 155–180 |

| Thermal conditions | W/m °C | 0.20 | 0.20 | 0.20 | 0.29 | 0.32–0.41 |

| Liquid state specific heat | kJ/kg °C | 2.10 | - | - | - | 2.05 |

| Solid state specific heat | kJ/kg °C | 2.20 | - | - | - | 2.03 |

| TTI Filled with R134a | TTI Filled with R1233zd | TTI Filled with Krypton |

|---|---|---|

| Inside air film | Inside air film | Inside air film |

| Galvanized steel sheet | Galvanized steel sheet | Galvanized steel sheet |

| Pig fat | Pig fat | Micro-Phase Change Material 24D |

| Galvanized steel sheet | Galvanized steel sheet | Galvanized steel sheet |

| Plaster board | Plaster board | Plaster board |

| Air space (wall) | Air space (wall) | Air space (wall) |

| Steel sheet with black paint | Steel sheet with black paint | Steel sheet with black paint |

| Refrigerant 134a | Refrigerant 1233zd | Krypton gas |

| Acrylic sheet | Acrylic sheet | Acrylic sheet |

| Outside air film | Outside air film | Outside air film |

| Total R Value = 6.62 m2-K/W | Total R Value = 8.67 m2-K/W | Total R Value = 10.01 m2-K/W |

| Total U-Value = 0.15 W/m2-K | Total U-Value = 0.12 W/m2-K | Total U-Value 0.10 W/m2-K |

| Parameter | R134a | R1233zd | Unit |

|---|---|---|---|

| Ambient temperature | 18.08 | 38.05 | °C |

| Relative humidity | 39.05 | 14.112 | % |

| Solar radiation | 0 | 630 | W/m2 |

| Exterior gypsum panel board temperature | 23.10 | 44.90 | °C |

| Interior surface temperature of metal refrigerant container | 19.12 | 48.78 | °C |

| Interior surface temperature in gypsum panel board | 22.50 | 45.90 | °C |

| Indoor air temperature | 23.23 | 43.47 | °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torres Rodríguez, A.; Morillón Gálvez, D.; García Kerdan, I.; Silva Casarín, R. A Comparison of a Transparent Thermal Insulation System Filled with Refrigerants and a Pig-Fat Based PCM. Energies 2023, 16, 3630. https://doi.org/10.3390/en16093630

Torres Rodríguez A, Morillón Gálvez D, García Kerdan I, Silva Casarín R. A Comparison of a Transparent Thermal Insulation System Filled with Refrigerants and a Pig-Fat Based PCM. Energies. 2023; 16(9):3630. https://doi.org/10.3390/en16093630

Chicago/Turabian StyleTorres Rodríguez, Agustín, David Morillón Gálvez, Iván García Kerdan, and Rodolfo Silva Casarín. 2023. "A Comparison of a Transparent Thermal Insulation System Filled with Refrigerants and a Pig-Fat Based PCM" Energies 16, no. 9: 3630. https://doi.org/10.3390/en16093630

APA StyleTorres Rodríguez, A., Morillón Gálvez, D., García Kerdan, I., & Silva Casarín, R. (2023). A Comparison of a Transparent Thermal Insulation System Filled with Refrigerants and a Pig-Fat Based PCM. Energies, 16(9), 3630. https://doi.org/10.3390/en16093630