1. Introduction

The search for alternative energy sources is essential to each country’s economy. Events such as the COVID-19 pandemic and Russia’s invasion of Ukraine in 2022 have shown how important it is to have an energy buffer in the form of oil or natural gas storage facilities. Energy blackmail from exporting countries may occur more and more often. Therefore, alternative sources of energy resources should be available [

1]. The search for alternative energy sources should entail support for energy sectors and industries with high technological development [

2]. These entities have solutions and can make a real contribution to creating a new, independent fuel [

3]. The advantages of low-emission solutions have a tangible impact on the development of urban infrastructure and also allow for a significant reduction in pollution and exhaust fumes. The electricity demand is met mainly by power plants burning natural coal or lignite, which will be replaced with natural gas and renewable energy sources over time [

4].

The work aimed to present solutions that could replace conventional vehicle power sources and would also be able to provide an energy buffer in industry and the economy [

5]. Alternative power sources for vehicles will help to reduce the demand of the energy sector, which, in the long run, will make it possible to separate the transport energy sector from the industrial energy sector [

6]. Slow changes in the transport sector may bring satisfactory results when the number of vehicles with a conventional power supply decreases over time. The main direction of changes aims to be the hydrogen fuel convention, which, thanks to its properties, can fully replace and meet transport requirements. Hydrogen, in appropriate conditions, allows for long-term storage, during which it does not lose its physical and chemical properties compared to electricity. The high-pressure tanks used for this purpose are among the most effective forms of energy storage. Storage is followed by hydrogen transport, which is developed in every mode of transportation, from pipeline transport to transit on large LNG ships [

7].

The conveyance of people and entities, being a socioeconomic measure, must use clean energy and the directive has continued advancing with modernisation. Accordingly, generating a fuel with more unassailable, efficient, economical, and environmentally pleasant features is critical to fulfilling such requests. Hydrogen is an excellent manufactured power conveyance due to its low weight, undivided quantity, and environmentally benign oxidation result (water). Nevertheless, the warehouse remains a significant challenge [

8].

The expression ‘Hydrogen Economy’ is not a contemporary vision. John Bockris introduced it in 1976 when hydrogen was identified as a pure fuel conveyance. In a Hydrogen Economy, the most delicate gases must be processed as any other market entity. Hydrogen is to be assembled, packaged, transported, stowed, and transmitted to the end-user, where it can be transformed into electricity using fuel cells or other transformation machines [

9].

Decarbonisation is essential in future energy strategies to reduce conservatory gas emissions and establish a zero-carbon community. Hydrogen is an encouraging secondary energy basis (energy conveyance) that can be converted, stowed, and utilised efficiently, directing a broad spectrum of opportunities for future applications. Moreover, hydrogen and electricity are mutually converted, constructing high-energy protection and vast monetary opportunities for increased energy solidity. Hydrogen can be stored in varied conditions, including condensed gas, fluid hydrogen, hydrides, adsorbed hydrogen, and reformed fuels. Among these, liquid hydrogen has benefits including increased gravimetric and volumetric hydrogen viscosity and hydrogen purity. Nevertheless, liquid hydrogen is garnering augmenting awareness owing to the demand for comprehensive depository times, long transportation lengths, and economic arrangements [

10].

The extensive use of fossil fuels has caused significant environmental pollution, climate change, and energy crises. The considerable advantages of hydrogen, such as purity, high efficiency, and a wide range of sources, make it quite promising. Hydrogen is susceptible to material damage, which can lead to leaks. High-pressure leaking hydrogen is highly sensitive to spontaneous combustion due to its combustion characteristics, which can result in jet fire or explosive accidents resulting in severe casualties and property damage. Details regarding the review of the progress of research on diffusion characteristics of hydrogen leakage, mechanisms of leakage self-ignition, and means of hydrogen destruction of materials from the perspective of theoretical analysis, experiments, and numerical simulations are presented in the article [

11]. This review indicates that although many research results on the safety characteristics of hydrogen have been obtained, there are still some gaps and limitations. The self-ignition of the leak in the open space, the development of hydrogen jet fuel bidirectional action, and crack growth under the influence of high-pressure jet fuel on the material may require further research. With advancing global energy needs, searching for environmentally friendly energy is necessary. Hydrogen is an energy source that is energy-efficient and pure and is regarded by multiple as the perfect fuel. The issue occurs when it comes to protection. It could have had a better reputation because of some tragic casualties in history [

12].

2. Different Forms of Vehicle Power Supply

For centuries, people have been looking for a way to automate activities and treatments to make them easier or faster. They create machines that fulfil their tasks using the right power source. The appropriate fuel type must be provided depending on the device’s complexity and design.

Natural resources, otherwise known as fossil fuels, are most often used due to their apparent ease of availability, which include: hard coal, lignite, crude oil, and natural gas [

13].

The substances that make up the fuel can be obtained in various ways. Fossil fuels such as hard coal and lignite are mined by opencast and underground mining. The disadvantages of coal mining by these methods are the high pollution and degradation of the natural environment. Open-pit mines usually extract coal located relatively shallowly in the earth’s surface, and excavators uncover individual top layers of soil to dig into the deposits of the raw material [

14].

The processing of coal to obtain fuels is carried out using various methods; the main ones are:

Gasification (Thermal decomposition forming producer gas. Producer gas has become a starting additive for internal combustion engines; it is not used as the primary combustion fuel).

Extraction (extraction of coal and additives results in bituminous fuels).

Hydration (fragmented mixture of coal, catalysts, and heavy oils subjected to high pressure produces synthetic gasoline).

Coking (the process of heating coal at high temperatures without access to air).

The fuels mentioned above result from complex and energy-intensive procedures in steelworks, refineries, or installations close to mines.

Any chemical processing of active substances produces pollutants, which then get into the atmosphere to return in the form of smog, acid rain, or other forms of pollution, so all obtained substances should be used most effectively.

Crude oil is the most popular and calorific substance from which fuel is produced. It is an essential element of the petrochemical industry, where it is processed to create, e.g., kerosene, gasoline, oils, greases, asphalts, and many synthetic materials. Black gold deposits are found in the Middle East, Iraq, Iran, Saudi Arabia, Kuwait, and the United Arab Emirates. We count them among the key exporters of this raw material. Rich deposits are also found in North and South America and Asia. Crude oil is transported depending on the profitability and the distance the raw material must be moved. However, we can distinguish two primary means of transport: pipeline transport and sea transport [

15]. Pipeline transport is more economical on land than on road or air transport [

16]. Pipelines are made where possible on the surface of steel pipes, and the transmission is possible thanks to unique stations equipped with pumps. Despite the possibility of building pipelines underwater, it is a complicated, time-consuming, environmentally unfriendly, and expensive process. A better option is loading onto special FPSO (Floating Production, Storage, and Offloading) vessels/platforms adapted for this type, which are unloaded at oil terminals. Natural gas is another example of non-renewable fuel that we use to power vehicles and machines. Deposits of blue energy form in cracks in the Earth’s crust under high pressure. They are often accompanied by oil or coal deposits. Depending on the place of extraction, the chemical composition of natural gas changes; however, the primary substance remains as methane, which consists of 90% natural gas, and the other components are propane, butane, and ethane [

17].

Fossil fuels are finished energy products used in many countries to convert them into electricity [

18]. For this purpose, they undergo combustion and chemical treatment processes. The fuels that power most vehicles are products of the processing of these fossil fuels. Liquid fuels that power land vehicles such as cars, motorcycles, tractors, and all devices with an internal combustion engine include gasoline and diesel fuel [

19].

Gasoline is a product of crude oil rectification, the composition of which depends on its final use. It is enriched with unique ingredients that support the combustion process and is combined with oxygen from the air. The rapid combustion of the air–gasoline mixture in the engine’s pistons gives the engine the energy to keep the vehicle moving. The consequence of fuel combustion is the emission of small lead elements that harm the environment. To prevent lead release, platinum catalysts are used, which oxidise or neutralise undesirable compounds depending on the engine type.

Diesel fuel is produced when crude oil is distilled; the final product is a distillate with a high sulphur content, which is removed by the hydrotreatment process. Diesel oil is used in cars with diesel engines [

20]. Despite the high degree of complexity, the construction allows for achieving higher revolutions than gasoline-powered machines. The operation of internal combustion engines is based on using crude oil’s flammable and explosive properties. Gaseous substances also have similar properties [

21].

Hydrogen power is a fundamentally new issue, the market is practically nonexistent, and most solutions are in the testing phase. To produce hydrogen from water and electricity, electrolytes are required, which are very expensive because they contain gold and platinum. Several production methods are used worldwide, but all on a small scale, which has advantages because the demand is also high. Order must be created to discuss revolutionary changes, which supply will meet. The use of hydrogen is mainly counted on by renewable energy source (RES) producers and supporters of nuclear power plants. The widespread use of electrolysers and fuel cells could solve the production problem of not matching demand.

Storing hydrogen is more accessible than storing electricity; existing natural gas tanks can be used in addition to storing hydrogen. Such a solution would make it possible to supply power to many places far away from power stations. Many believe that hydrogen will be the primary source of network flexibility in the future due to its energy properties, ease of transport, and storage.

3. Electric Drive as an Alternative to Fossil Fuels

The previously mentioned alternative energy sources are just a part of the hybrid drives under study, prepared to replace the limited supplies of crude oil and natural gas worldwide. Power supplies of other energy sources include electric batteries, hydrogen cells, fuel cells, supercapacitors, and photovoltaic cells and are adapted to power vehicles.

The possibilities of combining the above renewable energy sources can be used in hybrid electric vehicles (HEVs) and plug-in hybrid electric vehicles (PHEVs) for the next generation of cars. Batteries have been used to power vehicles for over a century, especially the advances over the last 30 years in lithium-ion (Li-Ion) batteries. Thanks to them, the market gains new possibilities for storing electricity in batteries of electric vehicles. The main barriers to the further development of work on batteries are the cost of materials, system lifetime, capacity, and heat dissipation.

Creating a high-energy and reversible electrochemical system is a challenge constructors face; the issue is very complicated because there are no similar solutions in other chemistry and energy sectors. The material costs can be reduced by using cathode materials other than those currently used, e.g., sulphur; the interchangeability of materials is a crucial cost consideration.

The continuous improvement in the abilities and solutions of materials in the desired results, as well as the use of information and collected data to create new structures and their properties, allow the development of a better understanding and improvement of energy systems. Electrochemical batteries store electrical energy through chemical reactions in the electrolyte and between the electrode and the electrolyte. Unlike batteries, which operate on renewable cycles, electric cells are not rechargeable.

Batteries can work in two modes:

Work during which the battery releases electricity while being gradually discharged.

Charging: the battery stores energy by converting it into chemical energy.

Basic working parameters of the battery:

Capacity is given in Ah (ampere-hours).

Rated operating voltage, 12 V or 24 V.

Batteries, due to their structure and principle of operation, can be further divided into lead-acid, lithium-polymer, nickel-cadmium, nickel-metal hydride, and Li-Ion.

The transport industry remains in first place in terms of demand for fossil fuels. The intensive development of civilisation is associated with increased demand for electricity. It is estimated that coal deposits will be exhausted around 2200, oil by 2050, and natural gas by 2060, so it is essential to partially and then completely abandon non-renewable energy sources. The exact cost of electricity production using renewable energy is at a similar level as conventional energy; the problem is the more considerable initial capital that must be paid at the beginning of the production process.

Comparing the types of power plants, one can notice the overwhelming advantage of unit costs in nuclear power plants, whose fuel (usually uranium) enables the production of vast amounts of electricity. Conventional power plants generate electricity using heat energy obtained during the combustion of primary fuel, e.g., natural coal. This is an essential aspect because the basic assumptions of this process are very similar to the principles of operation of the first steam engines. The boiling water produces steam, which increases its volume in the tank over time, transforming it into gas, which in turn causes the turbines to rotate. The mechanical energy obtained in this way is then converted into electrical power [

22].

The map in

Figure 1 shows EU countries’ share of renewable energy. According to it, the EU’s central states have the lowest percentages of RESs and show where changes still need to be made. Due to the terrain and natural upland areas, Scandinavian countries have the largest share.

According to the EU directive and communication from 2011, the other policy and the main target is the share of renewable energy to 55% by 2050 at the latest. This is an increase of about 40% compared to the 2021 level. The plan assumes a significant increase in the role of electricity at present. The electricity demand will increase by almost twice, from 36% to 39%. To achieve this, EU countries must contribute to decarbonising transport, industry, and energy [

23].

4. The Use of Hydrogen as a Low-Emission Fuel in Transport

By the concept set out in the Paris Agreement, the EU requires member states to present targets toward zero carbon dioxide emissions [

24].

One of the options available to decarbonise the environment is hydrogen fuel cell technology. Fuel cells are, in a nutshell, energy converters that generate electricity through an electrochemical reaction. The first recorded hydrogen production occurred in 1520 due to the reaction of acetic acid and iron. The official discoverer of hydrogen, Henry Cavendish, 1766, described hydrogen as “combustible air” resulting from the dissolution of metals in dilute acids. Hydrogen and oxygen are more explosive than when combined with air, which helped identify and classify it as an element in 1783. Hundreds of years of research have allowed the estimation and examination of the properties of hydrogen as a fuel.

Hydrogen exhibition, repository, and conveyance are the critical points to be addressed to realise a pure and endurable hydrogen economy. Different exhibition techniques, warehouse procedures, and hydrogen transportation have been listed in publications, along with their restrictions. Therefore, this review presents a detailed discussion on hydrogen production, storage, and transportation to summarise the condition of these suggested technologies. In addition, these methods’ recent advancements include hydrogen exhibition, repository, and conveyance on their kinetics, cyclic demeanour, toxicity, pressure, thermal reaction, and cost-effectiveness. Moreover, the latest methods, such as ball milling, ultrasonic irradiation, ultrasonication, alloying, additives, cold rolling, alloying, and plasma metal reactions, have been highlighted to address those drawbacks [

25].

An essential feature of hydrogen is its low density, which allows for a quick transition from a liquid to gaseous state, facilitating storage and transport. The explosiveness of hydrogen is directly related to its thermal conductivity and its specific heat of 120 MJ/kg, which makes it 2.5 times higher than that of gasoline and almost five times higher than that of coal. The first laboratory production of hydrogen occurred in 1800 during an electrolysis reaction. Hydrogen and oxygen react with a potassium hydroxide solution, in which, thanks to ionic conduction, the current flows through the receiver connected to the fuel cell.

The high energy demand is growing yearly, and the growing degradation of the natural environment and the uncertainty of energy security force the search for new, highly efficient, and ecological energy technologies. A highly probable direction of development, offering a wide range of possibilities, is hydrogen. Hydrogen can be found everywhere; it is one of the most common elements on Earth and in the universe, but it is infrequent in the free state in the Earth’s atmosphere. Hence, its production requires the use of processing technology.

It is different from water, which contains a lot of hydrogen. In the long term, the forecast of replacing all fossil fuels with hydrogen fuel would make it possible to eliminate the emission of harmful substances into the atmosphere, negatively affecting the progressing heating of the atmosphere.

Hydrogen energy faces three main challenges that must be met to achieve the intended goal: energy-sustainable transport. The real challenges are:

Increased efficiency of fuel and energy production.

Reducing the emission of harmful substances into the atmosphere.

Satisfying the demand for ecological electricity and liquid and gaseous fuels.

“Hydrogen energy” means technological processes that include all stages of hydrogen processing (production, storage, transport, conversion, and consumption). Hydrogen is obtained through processing and subjecting to various processing processes, e.g., crude oil; it is not drawn directly from natural resources. The conversion results in obtaining electrical energy, which is to be converted into mechanical energy.

Studying the above processes is essential to achieve ever greater technical and economic efficiency, particularly important for the energy, technology, economics, and environmental performance sectors.

The main goals of hydrogen energy are:

Production of high-efficiency fuel cells.

Hydrogen is the primary source of power for means of transport.

Production of hydrogen from various fossil energy carriers (coal, natural gas, crude oil, nuclear energy, hydrocarbon fuel derivatives).

Development of prototype technologies for producing hydrogen from mainly RESs (photovoltaic panels, hybrid thermochemical decomposition processes, thermolysis).

The impact of hydrogen on the technological and industrial structure, energy integration of various infrastructure systems powered by hydrogen.

Total reduction in environmental pollution emissions.

The goals presented above clearly define the direction of development of hydrogen technologies; it is also clear that all branches of the economy should be developed, not only transport. Integrated industrial systems will help decarbonise the economy and relieve non-renewable energy sources. Investments in research programs are required, which would be the basis for all new developments and solutions. However, these processes take very little time. Hydrogen and natural gas can play a fundamental role in the energy transition, replacing fossil fuels. Following the previously mentioned EU energy changes, by 2050, hydrogen will play a critical role as a distributor of renewable energy in many sectors, a decarboniser of transport and industry, a substance reducing emissivity, and an energy reserve in times of transformation and a lack of primary raw material.

According to the forecasts, the most significant energy transformations will occur in 2040–2050; in this decade, hydrogen production and related infrastructure dynamics will increase several times, from 2222.4 TWh to 21,668.4 TWh. Such values clearly show how much technological potential lies in hydrogen. The EU scenario is optimistic but requires many years of research and testing. Currently, producing hydrogen using low-emission fuels is very expensive, and the elements the hydrogen system is to consist of are also costly. To reduce the cost of switching to hydrogen propulsion, electricity from RESs should be used, the prices of which are to be reduced. Another obstacle is the need for a properly developed infrastructure; development could be faster, which is not conducive to the willingness of consumers to invest in this industry; in addition, hydrogen prices remain high due to the shortage of refuelling stations.

Currently, the total production of hydrogen comes from coal and natural gas; despite their advanced processing technology, it releases carbon dioxide emissions, so the process should be switched to renewable energy or less harmful processing processes.

Due to the lack of standardisation and international safety standards, international regulations are required to regulate transportation, storage of large amounts of hydrogen, and environmental impact.

The developed standards and arrangements must define the role of hydrogen in long-term energy strategies. National and international policies should define short-term and long-term goals for companies wishing to engage in manufacturing or re-industry.

The most sensitive sectors are:

Management Board of the hydrogen economy.

Metallurgy (steel, iron, precious metals).

Chemistry (refineries, industrial chemistry).

Transport (safe and standardised, integrated with storage and infrastructure).

Storage (tanks integrated with transport).

Infrastructure (buildings).

By creating the supply, one should also stimulate the demand for H2, the costs of which are currently very high and unprofitable for consumers. Market balance, sustainable supply, and the possibility of using hydrogen in commercial vehicles are essential elements of the implementation phase.

Strengthening hydrogen with programs and investments will speed up the implementation process, and the next stage may be displacing hydrogen production with fossil fuels to finally receive cheaper, cleaner hydrogen. Supporting distributors, suppliers, and customers financially, whether in direct payments or financial relief, broadens market opportunities and encourages conversion [

26]. Staying on the economic issue, it is also worth securing potential investors in H

2 by regulating loans, granting guarantees, and suggesting assistance programs for companies that have already implemented hydrogen technology solutions. The companies, already established on the hydrogen market, providing academic and technological assistance, operate in research and science, perfecting the already developed schemes as an entity at a higher level of advancement.

Such action is crucial and aims to find cheaper substitutes, thus reducing the prices of components and applied solutions. The new cells, the heart of any system converting and creating hydrogen, are also their most expensive element. Hydrogen, with its potential, can meet the energy needs of industries such as transport, industry, and energy. The dissemination of hydrogen in transportation will be possible when the cost of its production and disposal is lower than the other available options. Understanding the production and use of hydrogen is essential for future consumers. Educated staff, knowing the opportunities and challenges facing the hydrogen transformation, will be able to deal with them. In hydrogen transport, one of the essential issues is hydrogen cells installed in each hydrogen vehicle; their cost is a factor inhibiting the development of this propulsion solution. The competitiveness of hydrogen cells in transport depends mainly on the components used in them, construction solutions, and charging station infrastructure. By reducing the costs of hydrogen production, cells, and the hydrogen storage system, hydrogen-powered vehicles have a better chance of development and widespread use.

Table 1 presents a list of selected modes of transport in which hydrogen is used. There is a clear advantage of road vehicles, which are responsible for most environmental pollution. It is also the most significant transport branch in terms of users and vehicles, which is why the introduction of hydrogen begins with land vehicles. Land transport and railways have the best chance of quickly converting their propulsion sources to hydrogen. Currently, little interest is recorded in the sea and air transport sectors due to the need for development paths and a clear plan presented. Prototypes are used to promote clean hydrogen energy and as outlines for scientific papers. Airplanes and ships require the most significant amount of power, and the currently used engines powered by compressed hydrogen cannot meet their requirements. Due to its specificity, passenger shipping can appear in the hydrogen economy faster than transport ships [

27].

Hydrogen is widely used in transport, energy, and industry. There is a widespread belief that the hydrogen drive is the future of the automotive industry. There are two types of propulsion, electric and combustion, which differ despite using the same hydrogen fuel. Hydrogen vehicles eliminate the disadvantages of the internal combustion engine, which are exhaust fumes, and the electric motor, whose battery is only sometimes easy to dispose of.

The internal combustion engine can run on hydrogen fuel. Officially, several companies worldwide, including Toyota, have created the first vehicles with a spark-ignition internal combustion engine that runs on hydrogen fuel. Hydrogen, stored under high pressure in the tank chamber, is sucked into the engine compartment, where an explosion occurs, which, in the process of expansion, pushes the piston, which turns the crankshaft, creating a rotational motion that drives the wheels. Toyota has stated that their first tests of the 1.6 L engine as a result of the combustion of hydrogen are just as practical and run quieter. Still, the most significant advantage is the eco-friendliness of such a solution. As in the case of LPG, hydrogen does not produce such large amounts of exhaust gases, especially CO2; according to research, the result of hydrogen combustion is only water and steam.

Electric vehicles, considered the most ecological of the known drives, have the following main disadvantage: the battery and recycling. Disassembling and disposing of a used battery is very expensive and very heavy. The cost of production and installation alone directly affects the price of an electric vehicle. The charging process is long, and the substances used in the construction of the battery may pose a fire hazard.

Batteries can be replaced by fuel cells, where hydrogen is highly efficient. The advantages include the low weight of the hydrogen fuel tank: a 120 L tank of compressed hydrogen weighs about 5 kg (depending on the applied pressure).

The disadvantages include the operating temperature, which, in low-temperature cells, ranges from 10 °C to 250 °C. Each time the vehicle is started, the cell and the engine must be warmed up for at least a few seconds to move off safely. Such problems are faced by the first hydrogen models, the cells of which are outdated, despite hydrogen technology developing dynamically for only 15 years.

In 2018, the German company MEMBRASENZ developed a composite membrane, which, combined with non-precious catalysts (steel), can significantly reduce the price, and the cell itself greatly accelerates the alkaline electrolysis of water, producing hydrogen.

The latest prototypes can start from the spot, thanks to which they do not restrict road traffic. The infrastructural obstacle faced by hydrogen vehicles is the need for refuelling stations, of which there are about 11 in Poland, and most of them are used to service public transport vehicles. This causes a lack of demand for hydrogen vehicles because their combustion equivalents are significantly cheaper, and the infrastructure is more extensive.

Toyota was one of the first to start working on hydrogen vehicles in 1992, and four years later, they produced their first hydrogen-powered vehicle.

In 2002, Toyota began serial production of vehicles in the USA and Japan; thanks to 2008, the hydrogen vehicle model FCHV-ADV reached a range of 1100 km. Toyota strives to bring the highest-energy-efficiency hydrogen fuel cells to the market. Toyota Hydrogen Society works in Europe to change the face of transport by promoting and inspiring hydrogen solutions. An example of a commercially available hydrogen car is the Toyota Mirai FCEV 182 hp e-CVT. Technical details are below.

Based on the data in

Table 2, it can be concluded that the Toyota Mirai performs very similar to or even better than a combustion or electric vehicle. The range of 650 km allows for safe operation while expanding the hydrogen infrastructure, including charging stations. Currently, the price of a kilogram of hydrogen in Germany, where hydrogen stations are more widespread, costs around 10 euros, so in theory, the Mirai can drive 100 km for 10 euros.

5. Construction and Test of a Hydrogen Cell

The construction of a simple hydrogen-producing cell at home is straightforward [

28], and the components for its construction are in every household. The design of the oxygen cell differs depending on the hydrogen production method used; we distinguish the following:

The production of hydrogen takes place in the same way, and the same reactions occur in the cell, but they differ in the location of the electrolyte. In dry cells, the cells are arranged in series and separated from each other by a non-conductive material, such as hardened rubber or caoutchouc. The electrolyte is applied and distributed between the cell plates. In contrast to the wet cell, the cells arranged in series are immersed in the electrolyte and tightly closed, supplying current from the outside.

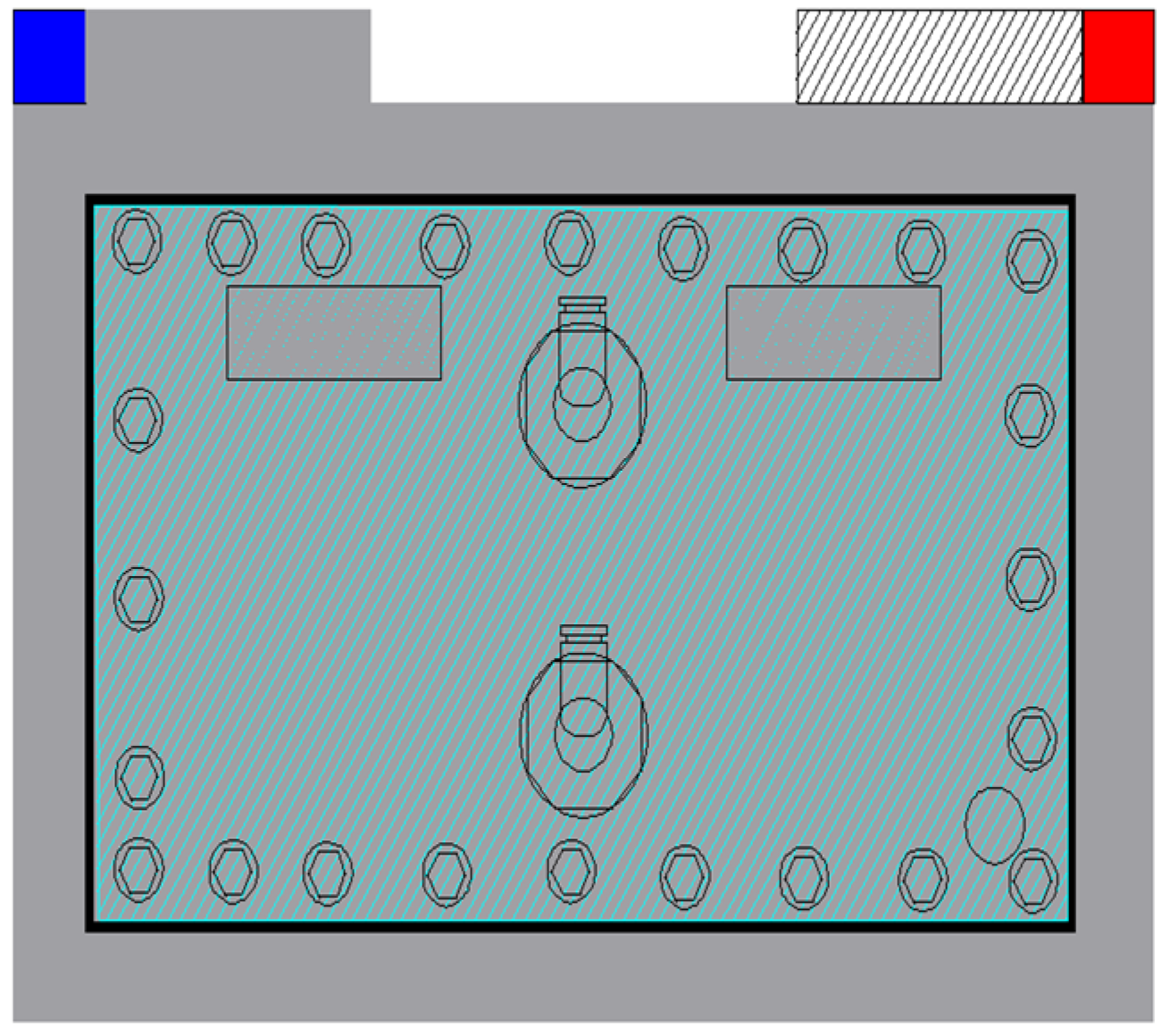

According to

Figure 2, in the wet cell, the cells are immersed in the electrolyte; in the dry cell, the electrolyte is between the elements of the cell. Dry cells are safer due to the location of the electrolyte between the cell plates. However, wet cells can produce more hydrogen by being wholly immersed in hydrogen.

The cell’s operation principle consists of hydrogen production from the electrolyser, and a water and potassium hydroxide solution accelerating and improving the reaction. The electrolyte used in the cell inspected consists of 230 mL of water (H2O) and 10 g of potassium hydroxide (KOH), giving the compound KOH (water fully dissolves potassium hydroxide).

The cell connected to a laboratory power supply with a voltage of 12 V causes the KOH electrolyte to react, in which water molecules adhere to the positively charged electrode (anode). The oxidation process breaks down the electrons in the water, splitting oxygen and positive hydrogen molecules.

Free electrons flow through the power source, and positive hydrogen passes through a membrane of 5 neutral plates. The positive hydrogen passes through and reacts with the membrane. Part of the oxygen passes through the membrane or remains circulating in the cell without undergoing a reaction.

The hydrogen leaving the membrane re-reacts due to the electrons on the cathode, forming hydrogen and oxygen. Part of the water remains in the cell and re-circulates; too much water not combined with KOH may result in faster cell corrosion. Compressed or stored in a free state, accumulated hydrogen can power the selected device. The accumulated hydrogen is delivered to the cell with a demand for electric current. Hydrogen, passing through the negative electrode, removes the electrons that flow through the connected device, powering it. Positively charged hydrogen passes through the membrane.

In

Figure 3, electrons that have flown through the device return to the cell system, where they meet positive hydrogen and the remaining oxygen at the anode. During the reaction at the positive electrode, water is produced. Each cycle causes the activity of the electrolyte to decrease, the water remains constant, but the KOH loses its chemical properties with each reaction.

The cell comprises 13 plates of 316 L stainless steel, where we distinguish two positive plates, one negative plate, and ten neutral plates. The plates are separated from each other with 0.3 cm wide acid-resistant rubber; from the outside, the link is closed with plex plastic with a width of 0.5 cm. The cell has three openings, supplying and discharging electrolytes and hydrogen. The amount of current provided to the cell is strictly defined, according to the principle of conduction of wind in the water of 1.24 V, but not exceeding 2 V per cell plate. The dimension of one plate is 15 cm × 10 cm; subtracting the rubber frame, we obtain a surface of 14 cm × 9 cm, which takes part in the reactions. The area of one cell plate is 126 cm2; this number should be divided into two sides, thanks to which we obtain the result of 63 cm2.

Figure 4 above shows a side view of a cell showing the holes through which the KOH and electrolyte pass. Rectangular holes pass directly through all plates, and a circular gap alternates on the right and left sides, allowing the electrolyte to spread more easily between the plates. An appropriate electrolyte distribution is crucial for good conductivity between the leaves; the complete arrangement is shown below in

Figure 5.

The cell test begins with filling the cell and the 200 mL electrolyte reservoir. Demineralised water is poured into the second tank. The electrolyte is a solution of demineralised water and potassium hydroxide (KOH) in a ratio of 1:20. As shown in

Figure 5, it offers the water levels and the power source, which is 0.00 in this phase. A laboratory power supply allows for connecting precise voltage and current. The power is gradually turned on after ensuring that the tanks are tight.

The cells produce hydrogen, and the white foam is formed after applying the voltage of 13.5 V, which is also the maximum voltage the power supply can deliver. White foam indicates the formation of hydrogen and water, which are discharged through the connection back to the electrolyte tank. Water by gravity remains in the tank, and hydrogen gets into the second tank, the so-called “bubbler”.

The bubbler allows for the safe removal of hydrogen, which can be directly fed to the burner. Thanks to the bubbler, the system has no risk of flame flooding.

The hydrogen produced from the cell can act as a burner; it is achieved by connecting the appropriate nozzle and igniting the gas.

The bubbler can also be hydrogen storage, as in the cell above. This way, you can determine how much hydrogen fills the tank and pushes the water out. To check the efficiency of the cell, an additional 1 L tank filled with demineralised water is used. The rate of filling a litre tank determines the efficiency of the cell.

The 1 L tank is filled in 58 s, a good result for the number of cells used. Cell construction is not a task requiring high technical or chemical skills. The construction of the cell shows that hydrogen production is theoretically a simple issue, and by using essential elements, we can produce hydrogen in significant quantities. This only offers the possibilities for technology companies whose financial and technological expenditure is much higher.

The amount of generated hydrogen and the parameters are shown in

Table 3 below.

A significant factor that does not allow for more excellent hydrogen production in the presented example is the need for a membrane isolating the produced hydrogen and oxygen. This is due to the technical limitations of the cell itself, as the solution is available but with the use of more sophisticated tools and components. The second problem encountered is the impossibility of compressing hydrogen to increase gas storage due to the need for a pump and a suitable tank capable of withstanding the higher pressure.

The experiment shows hydrogen production at a high level, which can be compared to the produced and available hydrogen cells installed by drivers in their cars. This is the closest possible comparison currently available. The cells mounted in the vehicles draw power from the battery, produce hydrogen, and deliver the hydrogen/air mixture to the air intake system needed by the engine to generate torque in the machine. According to estimates, the amount of fuel saved with this modification is based on the level of 7–8%. The comparison of the electricity consumed during hydrogen production does not reflect the result obtained; an unequal amount of hydrogen is brought to the electricity input. Complete recovery of electric energy is not possible, because the transformation process and the resistance of the plates cause significant losses during the electrolysis process, generating heat, which is why it is so essential to use RESs to produce hydrogen in the electrolysis process.

The hydrogen obtained in this way can be safely produced, for example, using photovoltaic panels; the time needed to fill the tank fully is relatively long; however, in the long-term forecast, the energy obtained is worth the investment and funds.

The development of hydrogen forms of transport power supply should aim to use the best elements from a given type of vehicle propulsion, drawing on proven solutions and implementing innovative solutions from RESs.