1. Introduction

Most power utilities firms and industrial establishments have significant underground (UG) electric distribution systems, the majority of which are near the end of service life and operate under an unknown condition. The typical design life of an UG power cable (UGPC) is 30 to 40 years. However, they tend to be in service for more than 40 years. The overall cost of replacing service-aged UGPCs is extremely high. Consequently, asset owners require an asset management approach to manage the fleet of UGPC systems, including the cable, termination, splice (joint), cable grounding, and cable monitoring system.

Medium voltage (MV) UGPC construction, including components such as insulation, semicon, jacket, and barrier, has undergone significant changes over the past five decades, experiencing nine cable design generations, as shown in [

1]. Improvements made to the overall cable construction have increased the life expectancy of UGPCs significantly.

However, based on the authors’ experience, since the 1970s several utilities have found it challenging to deal with complete cable replacements, resulting in high failure rates and significant customer interruptions.

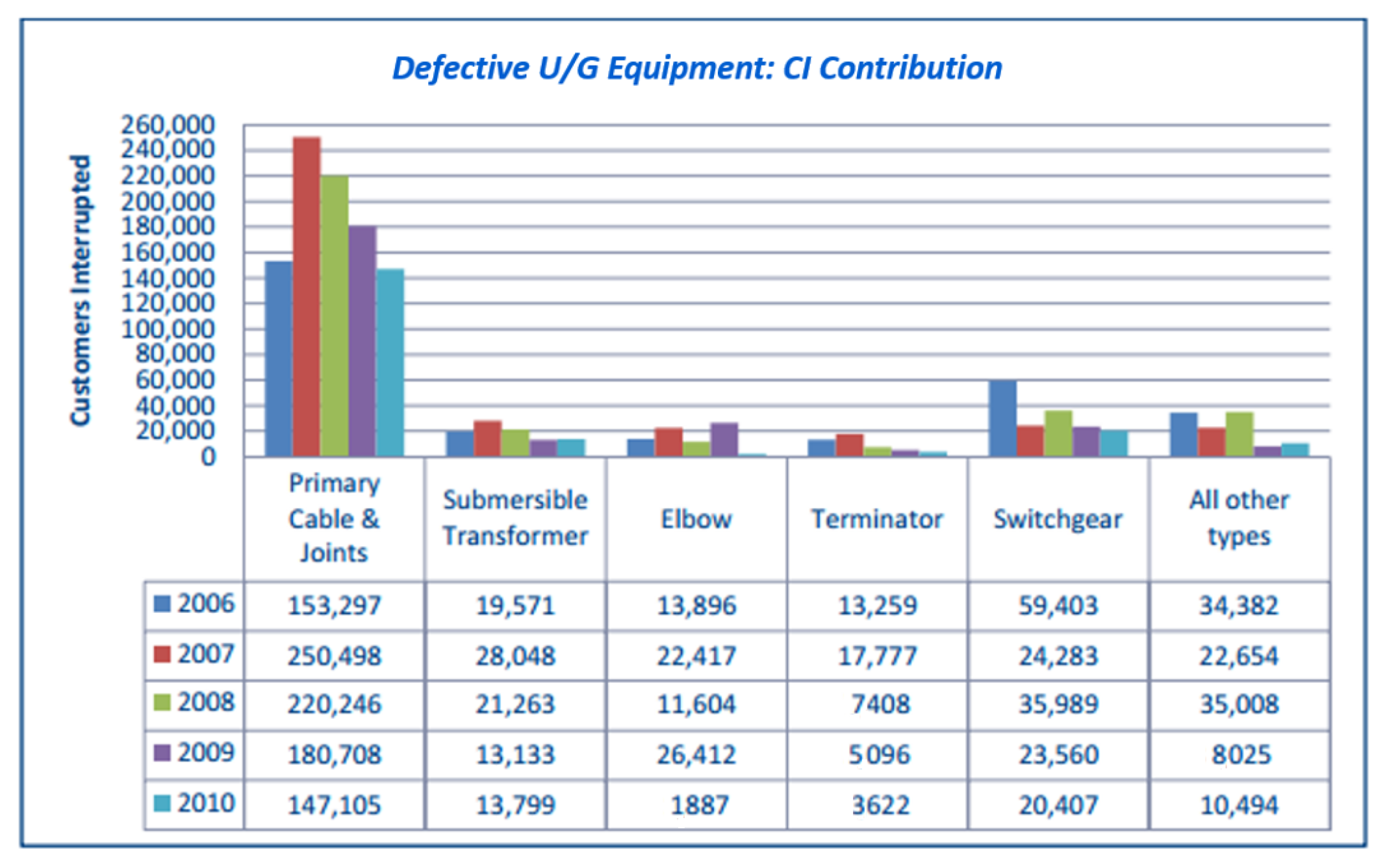

Figure 1 shows a study conducted by authors working for a Canadian power utility firm, which demonstrate the consequences of customer interruption due to no proactive maintenance management for primary cables and joints.

Currently, many in-service cables have also reached their end-of-life point, necessitating a cable fleet management program driven by diagnostic testing. UG cable testing has gone through a significant evolution since the early 1900s.

Figure 2 shows the evolution of testing and diagnostics techniques specific to UGPCs, based on the field experience of the authors.

UGPC testing has evolved from basic Go/No-Go tests, such as insulation resistance, DC and AC, to withstand more advanced diagnostic tests, such as VLF Tan-delta, partial discharge (PD), time domain reflectometry (TDR), and variable frequency resonant test sets (RTS), for performing Hipot and PD.

3. Best Practices for UGPC Condition Assessment

The failure of a UGPC can be best represented through a bathtub curve, using the mathematical aspects outlined by Montanari et al. [

5]. The three main sections of such a bathtub curve are infantile mortality, random failures, and aging.

With the uncertainty in predicting the condition of underground cable installations, cable diagnostic testing is critical to reducing premature failures (infantile morality section) and predicting the extent of degradation (aging section). Accordingly, commissioning testing, also known as SAT, serves as a quality control procedure to avoid unexpected early failures of new UGPCs, while maintenance testing helps detect the extent of degradation of in-service UGPC installations.

UGPC circuit components include the actual cable, terminations, joints (splices), and grounding. The cable itself has various components, such as the core conductor, conductor shield, insulation (TRXLPE, XLPE, or EPR), insulation shield, metallic shield, and jacket. Any condition assessment should consider all cable components.

3.1. Commissioning Testing

Between factory production and installation in the field, a UGPC experiences multiple stages of transportation and handling. This increases the likelihood of the introduction of a defect in such cable systems, especially those related to cable pulling and laying on-site and the installation of cable accessories (terminations and joints).

Industry data points to the fact that over half of cable system failures, such as poor workmanship or manufacturing issues, can be avoided through proper commissioning testing. Commissioning testing involves a series of tests conducted on-site prior to the energization of cable systems. A common best industry practice of commissioning testing typically involves three main tests to assess different components of a cable system: voltage withstand test, PD measurement, and metallic shield and jacket integrity test.

3.1.1. Voltage Withstand Test

Voltage withstand test, also known as a high-potential (Hipot) test, involves applying a voltage higher than the rated level for a defined duration to overstress the insulation to evaluate its integrity. The test is considered a “PASS” if no breakdown is observed at the completion of the defined test period. This test is well defined in the IEEE Std. 400. Various frequencies and waveshapes can be used to perform this test, with each having its merits and demerits [

6].

The use of the power frequency (50/60 Hz) AC voltage to perform a voltage withstand test simulates the actual operating condition of an UGPC. However, there are practical limitations to testing longer cable lengths due to the size and capacity of such power supplies to supply the required cable charging current.

Given the challenge of using a power frequency AC voltage to test long cables, a modular variable frequency resonance test set (VFRTS) can be used. A VFRTS typically includes a fixed inductance module to strike a resonance with the cable under test, thereby reducing the input power requirement. The resonant frequency range typically lies between 20 Hz and 300 Hz and depends on the cable capacitance.

Figure 3 shows a 70 kV VFRTS used by the authors for MV UGPC voltage withstand testing.

AC very low frequency (VLF) at 0.1 Hz/lower or damped AC (DAC) are more convenient options when testing as power frequency is not necessarily required. This is primarily because they allow for modular test sets and can typically be applied for non-critical installations or locations with access issues. However, VLF withstand testing results in longer test times because of the low-frequency test range. On the other hand, the short-duration excitation and decaying nature of the DAC cause varied breakdown field strengths as compared to continuous AC application [

7].

3.1.2. Partial Discharge Measurement

A PD measurement helps identify and localize defects within insulation systems, both in cables and accessories. These defect types, such as voids, contaminants, surface impurities, or imperfections, become weak spots that can lead to the breakdown of cable systems.

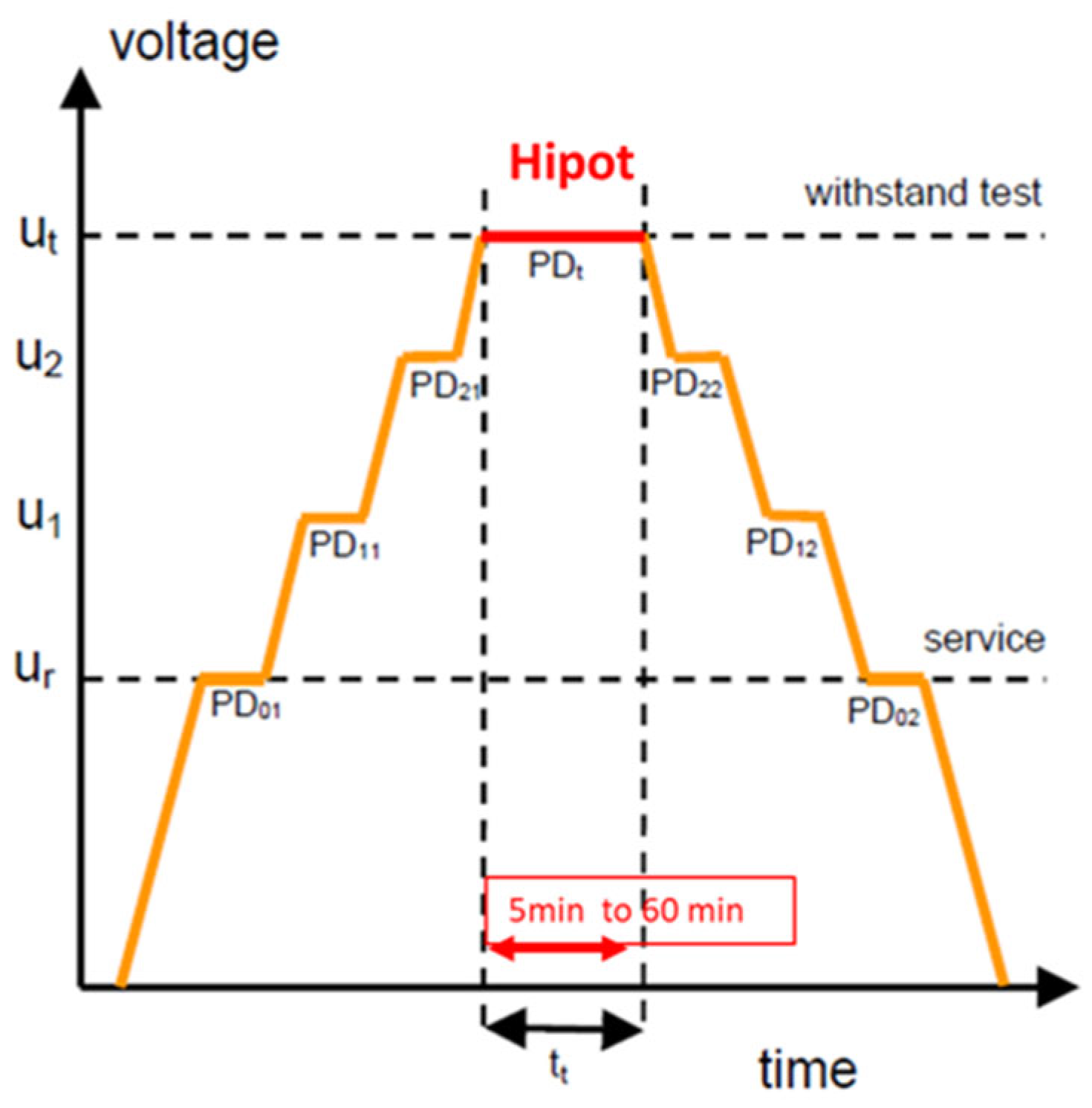

During commissioning, a PD measurement system can be set up in parallel to a voltage withstand test, as depicted in

Figure 4. During a PD measurement, various PD characteristics that help to determine the type and the severity of the PD sources must be recorded and reported: PD inception voltage (PDIV), PD extinction voltage (PDEV), PD magnitude, phase-resolved PD (PRPD) pattern, and localization of the PD source (if a PD defect is found).

The IEEE Std 400.3 [

9] is the industry guide for PD measurement in power cables. Due to the sophistication of this test procedure and the differences between lab and field conditions (specific to background noise), there is no generic guidance on the interpretation of test results. The latest revision of the IEEE Std, 400.3 has provided a dance, based on PDIV and PDEV values.

3.1.3. Metallic Shield & Jacket Integrity Test

The cable metallic shield must have continuity and low resistance. For longer cables with splices, the low-ohm resistance test is conducted on individual sections. Poor workmanship is a significant failure mode in cable systems. Jacket imperfections and cuts during cable pulling and installation can introduce defects in the jacket, resulting in moisture ingress and premature failures. A jacket integrity test involves the insulation resistance measurement of the jacket with respect to the ground. A defined DC voltage is applied and held for a fixed duration (e.g., 1 min). Moreover, temperature correction for the measured insulation resistance value needs to be performed. The NETA ATS [

10] provides adequate guidance for selecting the relevant test voltage and the expected threshold for the corresponding jacket insulation resistance value recorded.

Unlike HV cables, MV cable jackets do not have conductive paint and, therefore, the jacket integrity test result is only limited to a very small portion of the cable close to the terminations, which reduces the efficiency of this test.

3.2. Maintenance Testing

The proper condition assessment of service-aged cable systems is important for fleet management of underground cable installations. Diagnostic testing, performed as a maintenance procedure, provides the means to accurately determine the condition of in-service UGPCs and detect the type and extent of aging or degradation mechanisms involved. The best practice for cable maintenance testing includes performing a VLF tan-delta (TD) test, PD measurement, and time-domain reflectometry (TDR). Contrary to certain beliefs in the industry, these maintenance tests are non-destructive as the maximum applied test voltage is always within the cable-rated voltage.

3.2.1. VLF Tan-Delta Test

The VLF TD test is a popular offline diagnostic test that is used to estimate the amount of loss in a cable system based on the measurement of tan δ, which assesses the level of global insulation aging. This test is typically performed at three voltage steps up to 1.5 times the system phase-to-ground voltage (U

0) at 0.1 Hz. The IEEE Std. 400.2 is the industry guide for testing shielded power cables at lower frequencies. This guide provides the condition assessment criteria for interpreting VLF TD results based on three diagnostic parameters: mean TD (at U

0), differential TD (between 1.5 U

0 and 0.5 U

0), and TD stability (at U

0) [

11].

3.2.2. Partial Discharge Measurement

Similar to performing PD measurement as a commissioning test, it can also be used for relevant condition assessment of service-aged UGPCs to localize defects in the cable insulation or accessories. The key PD factors that should be considered during PD test are: PD magnitude (pC), PD inception voltage (PDIV), PD extinction voltage (PDEV), and the phase-resolved pattern (PRPD) [

12]. The identification of the relevant PD defect type, based on the PD diagnostic parameters and subsequent localization of the PD source, is valuable from a condition assessment perspective. Through relevant PD localization and establishment of the PD severity level, cost-effective remediation or intervention strategies can be planned, alongside the recommended timeline for implementation, e.g., replacement of a cable elbow or splice as opposed to the entire cable system. Three critical elements for any PD test are: 1—Magnetude (pC or mV), 2—defect type confirmed by PRPD, 3—PDEV.

Figure 5 shows a 3-D illustration of PD severity based on these 3 factors.

The IEEE Std. 400.3 is the industry guide for PD measurement as a maintenance test procedure. This guide was recently revised to include the latest interpretation of PD test results [

9].

PD measurement as a maintenance test can be performed either offline or online. Offline PD measurement requires switching and cable isolation but is more sensitive and informative than an online evaluation. Online PD measurement involves either an ultrasonic scanning of the cable terminations/elbows or temporary/permanent PD monitoring, which occurs through the installation of high-frequency current transformers (HFCTs) around the concentric neutral.

Simultaneous VLF Tan-Delta and PD measurement performed by the authors, as shown in

Figure 6, is a common practice for the onsite maintenance testing of UGPCs.

3.2.3. Time-Domain Reflectometry

TDR is a useful diagnostic procedure for determining/verifying the overall cable length, locating the presence of splices, and identifying any signs of water ingress/neutral corrosion in the concentric neutral of the cable. TDR is conducted offline by injecting a pulse with a fast rise time, observing the nature of the reflected pulse, and looking for any specific impedance changes. Each unique TDR trace or reflection represents the corresponding defect or cable system characteristic. The IEEE Std. 1617 is the industry guide for TDR and suggests comparing the size of reflection due to corrosion to joint reflection and end-of-cable reflection to assess the condition of the concentric neutral [

13]. The NEETRAC guide on TDR measurement provides a detailed practical best practice of TDR measurement on power cables to determine the neutral corrosion and other modes of failure [

14].

5. Recommended Best Practice of UGPC Fleet Management

The latest industry practice for UGPC fleet management is based on developing a risked-based work frame (

Section 4.4), which considers the total impact cost and risk cost (

Section 4.4). The probability of failure used to calculate the risk is HI condition-based, not aged-based (

Section 4.3). A typical HI formulation used by several Canadian power utilities firms is shown in

Table 2.

The HI for each asset is used to calculate failure probability based on available industry data. The failure probability is then compared to the hazard rates on the Weibull curves presented in

Figure 11 to find the condition-suggested age, which is known as effective age. The hazard rate is the probability that the asset will fail in the following year, given the current age of the cable. From this, the asset age is adjusted to find the effective age. Failure probability distribution depends on cable insulation, cable construction, operating and environment condition, loading, and maintenance practices. An example of difference between XLPE and TRXLPE PDF is shown in

Figure 12.

An effective asset management program requires accurate asset data. The degree of accuracy and the extent of such data varies widely across the industry [

22]. Data availability represents the single most important element that can influence the degree to which AM decision making relies on objective factors. Asset owners often either do not have readily available data or the data format is not suitable for ACA analysis.

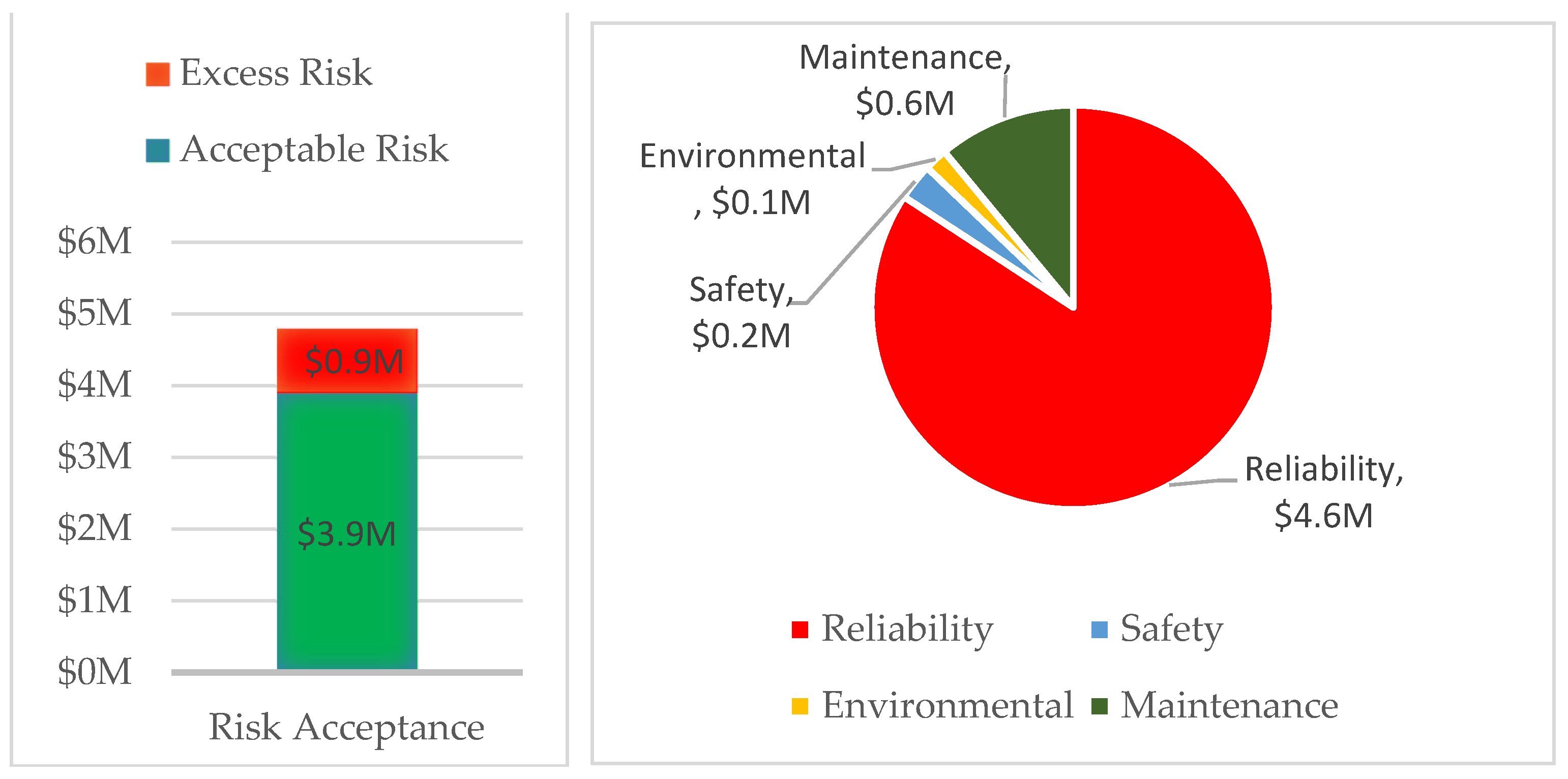

Following a comprehensive HI analysis, the risk is calculated for each cable segment by incorporating the UGPC HI values, failure curves, failure modes, and impacts of failure described in

Section 4.4.

Figure 13 provides a summary of risked-based best practices for UGPC fleet management.

The steps toward the proposed fleet management methodology are:

Based on

Table 2 parameters, collect the data and verify the data quality, validity, and accuracy;

Calculate HI (see

Table 2) and determine the condition of cable. If required, apply the intervention recommendation given in

Table 1;

It is recommended that each utility establishes its own PF% curves for different types of cables. In the absence of available data, a generic formulation based on thousands of data points collected in the past several years in Canada and USA can be used: ;

Calculate the impact costs: Total Impact Cost = Reliability Impact + Financial Impact + Environmental Damage Impact + Safety Impact Cost;

Calculate the risk cost. Risk Cost = PF% × Total Impact Cost;

Prioritize replacement based on the risk cost for the UGPC Fleet.

To build out a cable testing and condition assessment program, a pilot study is recommended to pick out unique service-aged cable segments from different regions of service of a utility or targeted locations of a commercial & industrial (C&I) establishment. Based on the results of the pilot study, an annual testing program can be put in place to test a mix of cables of different constructions, voltage classes, insulations (XLPE, TR-XLPE, EPR, PILC), vintages, rejuvenation conditions (injected versus non-injected), loading dimensions, and geographic locations. On top of offline cable testing, the cable termination and joint (splice) can be evaluated for any inherent hotspots or thermal anomalies using online infrared thermography. Major cable testing options (specifically for utilities firms) include:

Purchasing test equipment and using a third-party expert to train their field crew to perform field testing and assist with the interpretation of test results;

Involving a third-party expert to perform field testing and provide a relevant condition assessment.

The results from field testing can be fed into an asset management framework for relevant condition assessment and to decide on an intervention strategy based on a risk-based analysis. The environmental/cable laying conditions play a critical role in influencing the degradation mechanisms/factors affecting an UGPC in the field. With the advent of the Geographic Information System (GIS), the actual condition of UGPCs can be visually tracked to choose relevant cable segments for future editions of the annual testing program.

Based on the field test results updated in GIS, it is also important to identify the major degradation patterns (e.g., global cable insulation aging, PD, neutral corrosion, etc.) observed in the various regions tested and the corresponding condition of the cable segments. It is useful to correlate different geographic regions to the corresponding UGPC aging mechanisms to better inform future iterations of cable testing and condition assessment, trending of test results, developing specifications, and deciding on replacing a given cable segment.

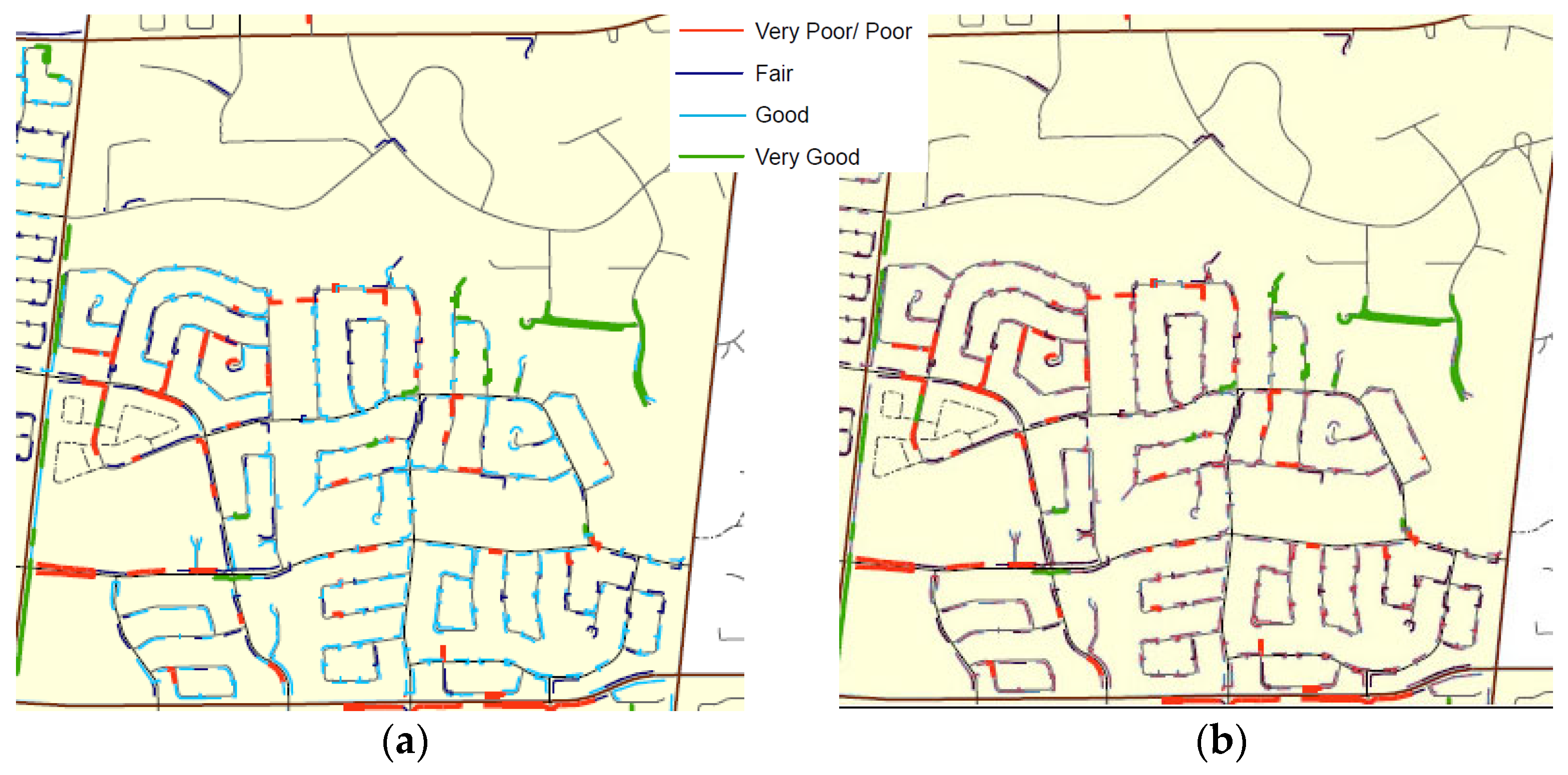

An example of GIS mapping showing the condition of a region of UGPCs (28 kV, TRXLPE/XLPE, 2/0, Al, direct buried, jacketed type) based on an age-based assessment and a condition-based assessment through testing, conducted by the authors, is illustrated in

Figure 14. A proper condition-based assessment, facilitated by advanced diagnostic testing, reveals the actual condition of the various cable segments, thereby supporting relevant intervention strategies for managing different cable segments of the same vintage. Such a visual map also helps with identifying region-based degradation patterns and performing relevant condition assessments.

With data from a few years of testing, utilities firms could use data science to identify sample populations to represent the entire fleet of UGPCs. Once these sample populations are tested, these results can be incorporated into a HI framework and extrapolated to the remaining fleet.

This way, utilities firms could test a fraction of their overall underground cable population and still find valuable information to decide on the relevant intervention strategy for the remaining in-service cable infrastructure. Based on the experience of the authors in testing cables for more than 30 power utilities firms, the minimum size of the sample population varies between 20% to 30% of the total cable circuit length. For a utility with 1000 km of in-service MV UGPCs, considering a 25% sample population, it is required to test 250 km of cables. If the utilities firm can test 50 km of cables a year, it will take five years to fulfill the minimum sample population size, enabling the firm to have a more precise model for their HI framework and extrapolate results to the remaining fleet at the end of year five.

The remediations for geographic regions with issues such as global insulation aging and neutral corrosion in UGPCs include the choice of better cable insulation, such as a TRXLPE type, and ensuring a durable outer jacket, such as a polyethylene type, once these cables are replaced. Improving the cable laying conditions, such as the building of duct banks, is recommended for critical cable runs. Having a proper commissioning testing program helps avoid all three major degradation issues (accelerated insulation aging/water treeing, neutral corrosion, and PD) and ensures that the cable system can perform reliably up to the end of its typical useful life. A risk-based condition assessment is useful to prioritize the relevant cables for replacement and ensures a levelized capital expenditure profile.

Another new approach to cable fleet management is testing retired cables before scrapping them out. Reels of extracted cable segments can be evaluated using VLF Tan-Delta, PD measurement, and TDR test procedures to identify degradation patterns based on factors such as geographic location, cable insulation type, voltage rating, vintage, etc. Moreover, a sufficient length of these cable reels can be subject to an evaluation in the laboratory by performing limited HV breakdown testing, cable wafering, dyeing, and microscopic examination. The outcome of such an assessment can be used to perform targeted testing in the field and better inform future iterations of cable specifications, procurement, and management.