Impact of the Short-Circuit Current Value on the Operation of Overhead Connections in High-Voltage Power Stations

Abstract

1. Introduction

- Three-phase short circuits;

- Two-phase short circuits;

- Two-phase short circuits with earth;

- Single-phase short circuits.

- Strong heating of power system components;

- Fire;

- The generation of large dynamic forces, the impact of which may lead to deformation or damage to, for example, buses, support insulators, equipment or support structures;

- Exceeding the permissible values of touch and step voltages;

- The formation of electromagnetic interference;

- The possibility of a loss of stability of the power system.

- Increasing the short-circuit impedance by introducing additional elements into the network or by shaping the network accordingly;

- Rapid switching off of the short circuit;

- Limiting the duration of a short circuit by means of power automation.

- Correcting the normative calculations (IEC 60865-1:2012 standard) and taking into account the two-point attachment of the haul-off chains;

- Enhancement and impact on the method of calculating electrodynamic forces in flexible wires on high voltage lines were obtained;

- Enhancement and impact on the calculations of mechanical stresses in supporting structures and poles of the highest voltage lines were obtained;

- Scalability of the calculations for lower voltage lines, if it is possible to use two-point fastening of the haul-off chains.

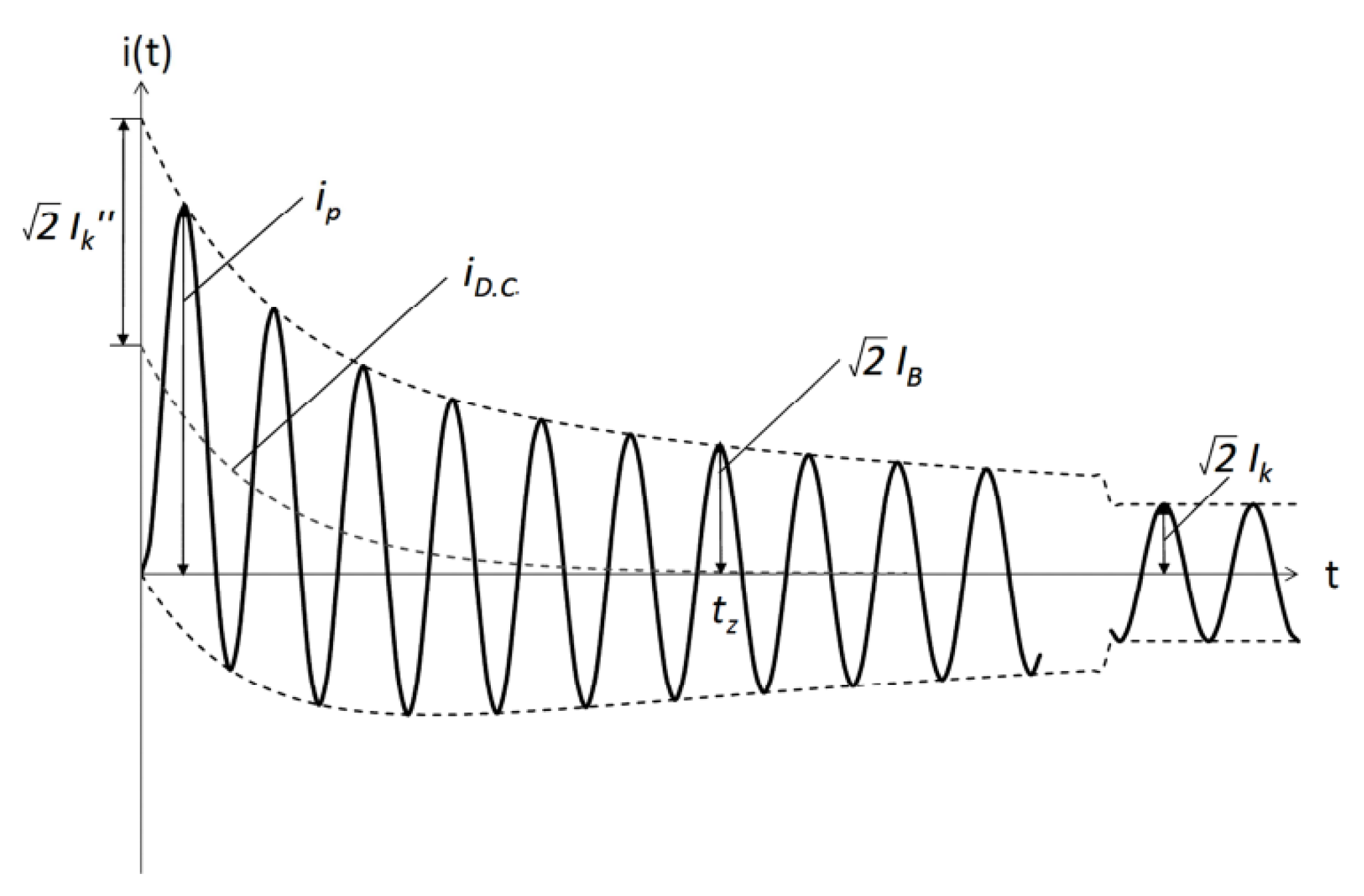

2. The Effect of the Short-Circuit Current on Individual Elements of High Voltage System

- −

- Short-circuit current parameters:

- The value of the initial short-circuit current;

- The time constant of the short circuit depending on the R/X ratio;

- The surge factor, which depends on the R/X ratio.

- −

- Span parameters:

- The wire cross section;

- The conductor mass;

- The cable length;

- The elasticity of the conductor;

- The static tension of the conductors;

- The distance between axes of supports;

- The length of the chains;

- The distance between phases;

- The number of wires in a bundle;

- The distance between conductors in a bundle;

- The number of spacers;

- The type of spacers.

- −

- Parameters of support structures:

- The rigidity of support structures.

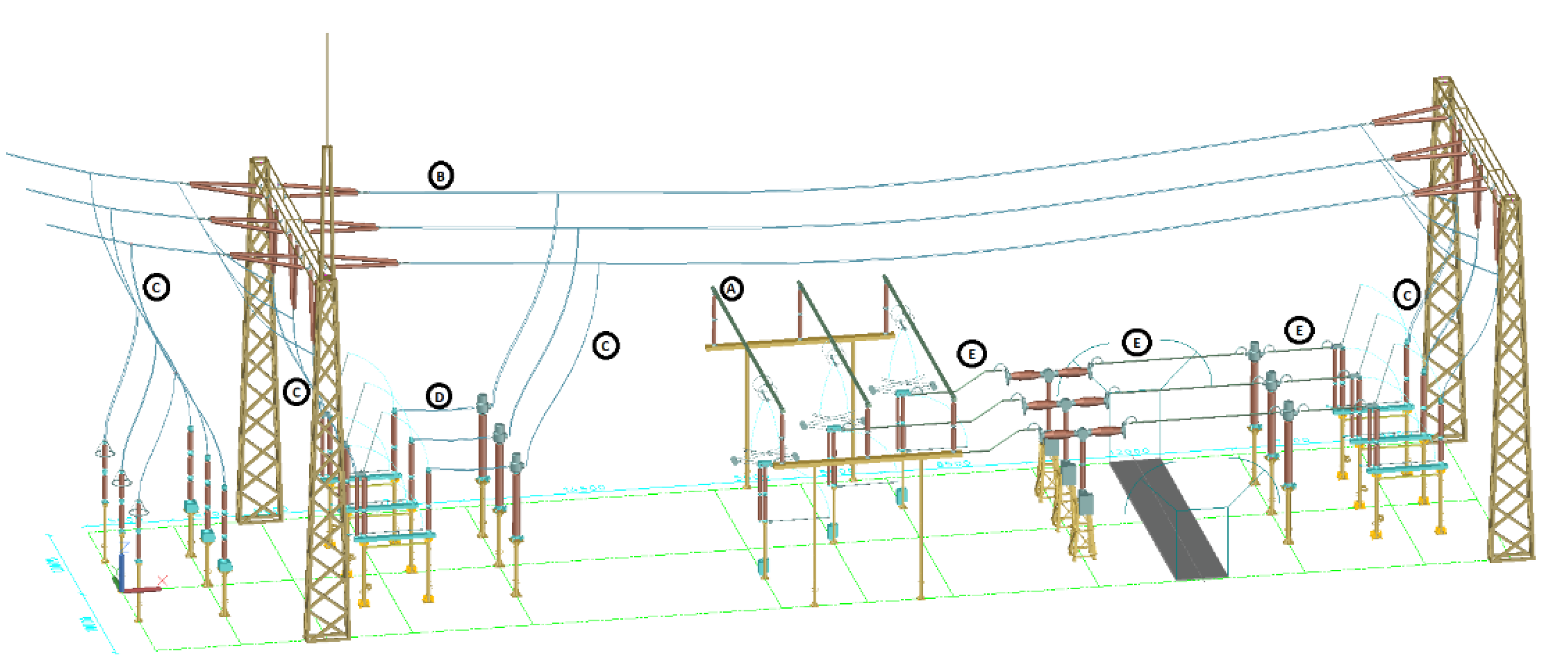

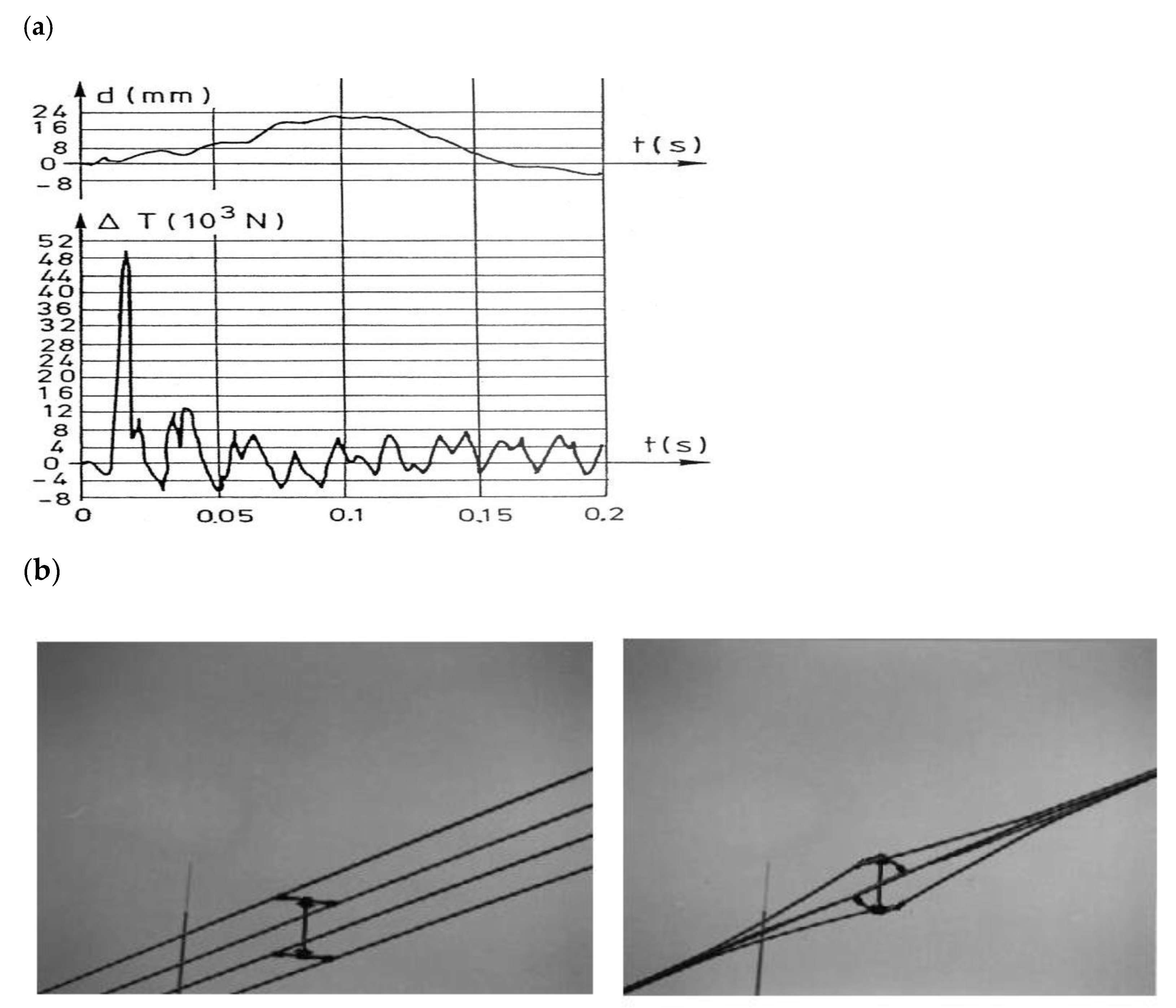

2.1. Mechanical Impact of Short-Circuit Current

- The busbar system made with rigid conductors with a tubular profile (A);

- The top rail of the switchgear made with a bundle of flexible conductors (B);

- Discharge wires (C);

- Connections between apparatuses made with flexible conductors (D);

- Connections between apparatuses made with rigid conductors (E).

2.2. Electrical Connections

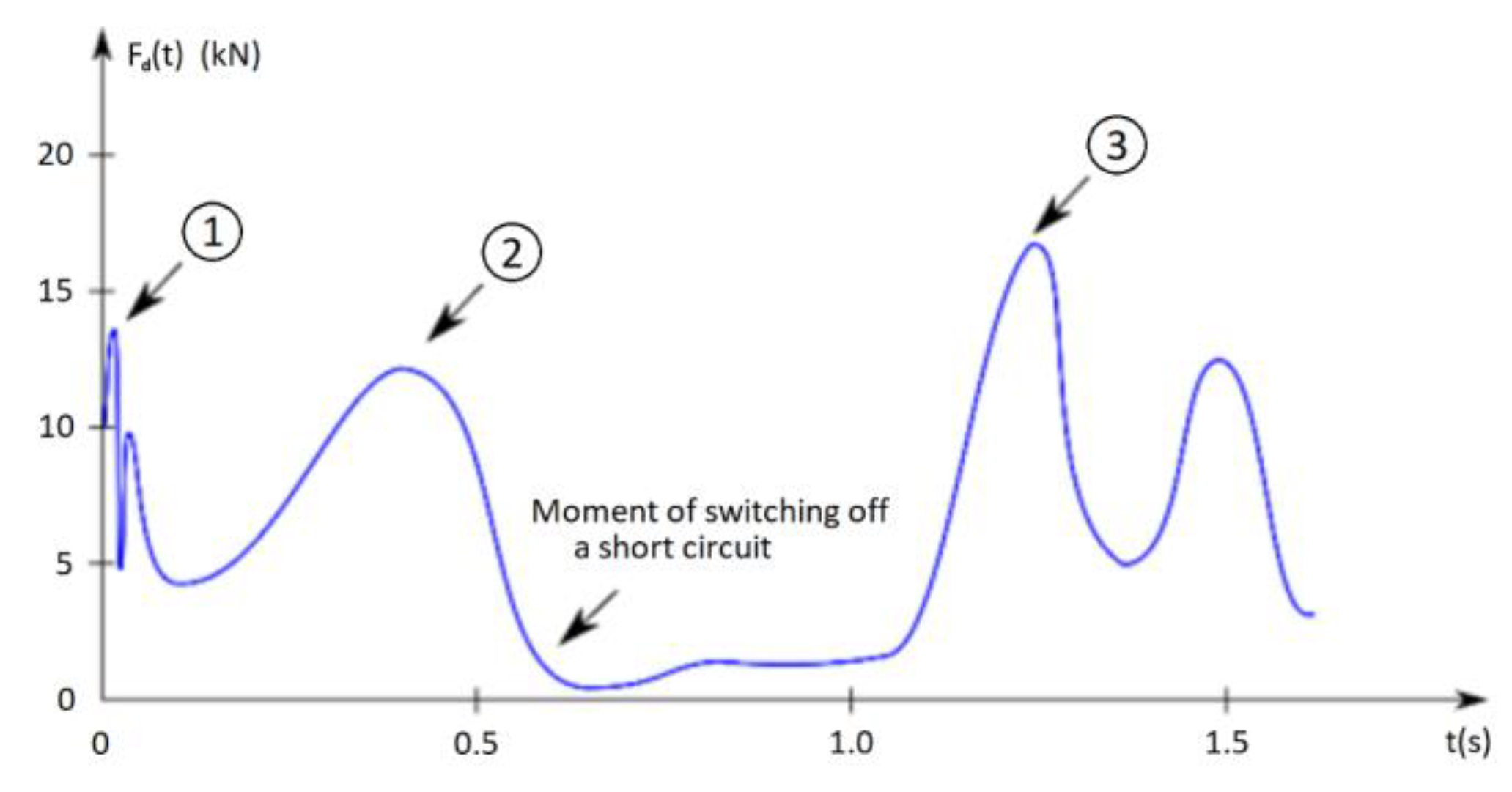

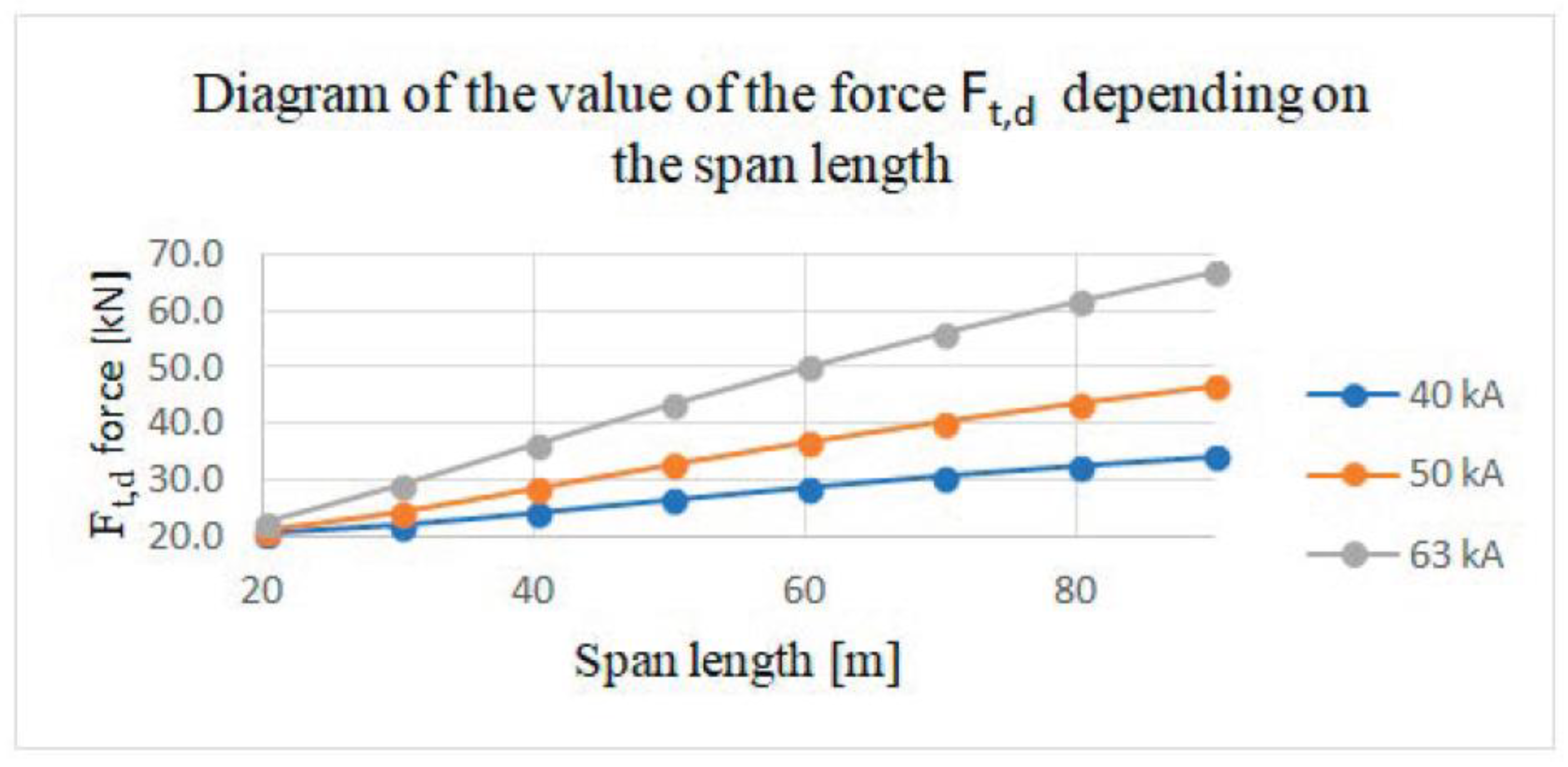

- The force associated with the deflection of the cable during the short circuit, denoted as Ft,d and arising from interfacial interaction;

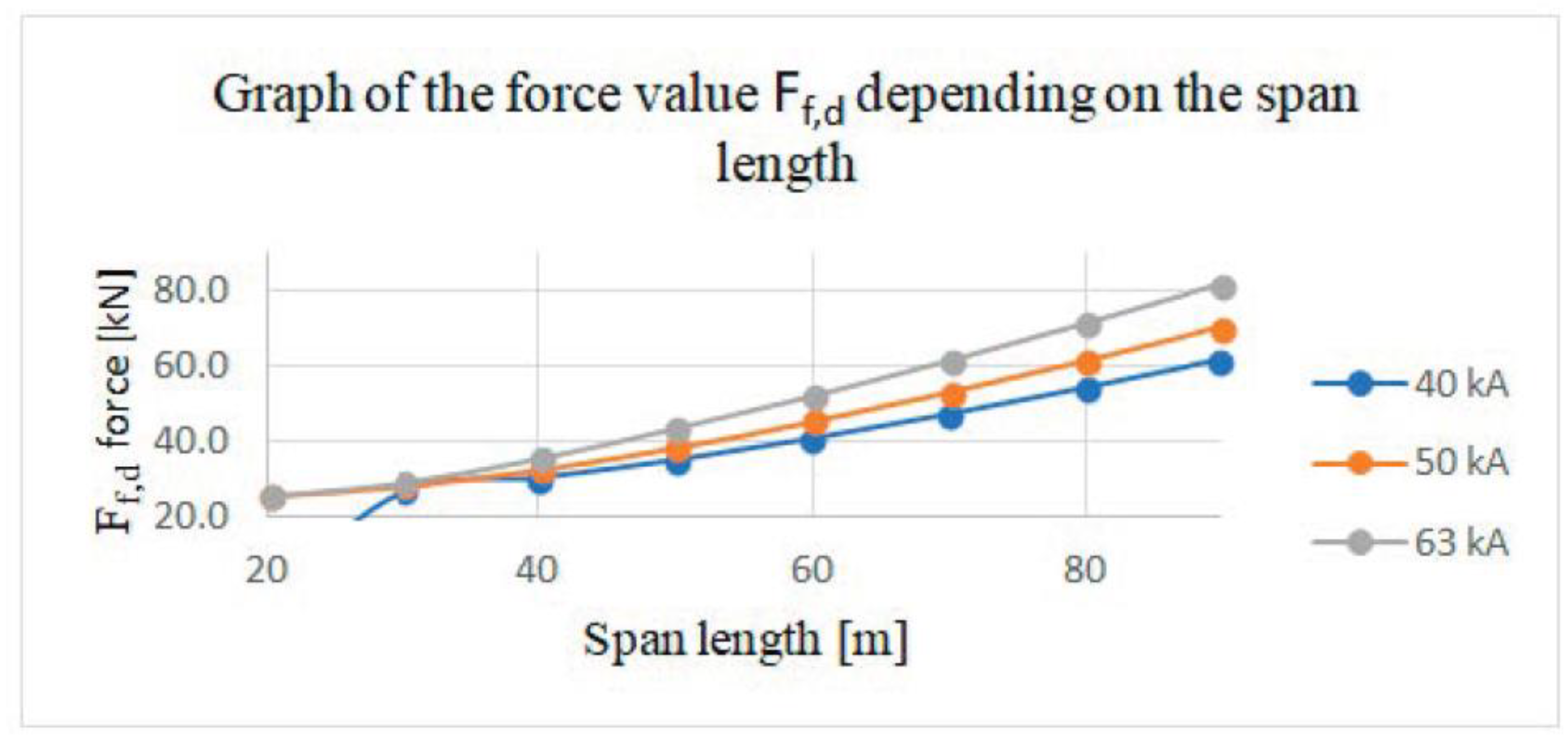

- The force associated with the descent of the wire after the short circuit has disappeared, denoted as Ff,d and arising from interfacial interaction;

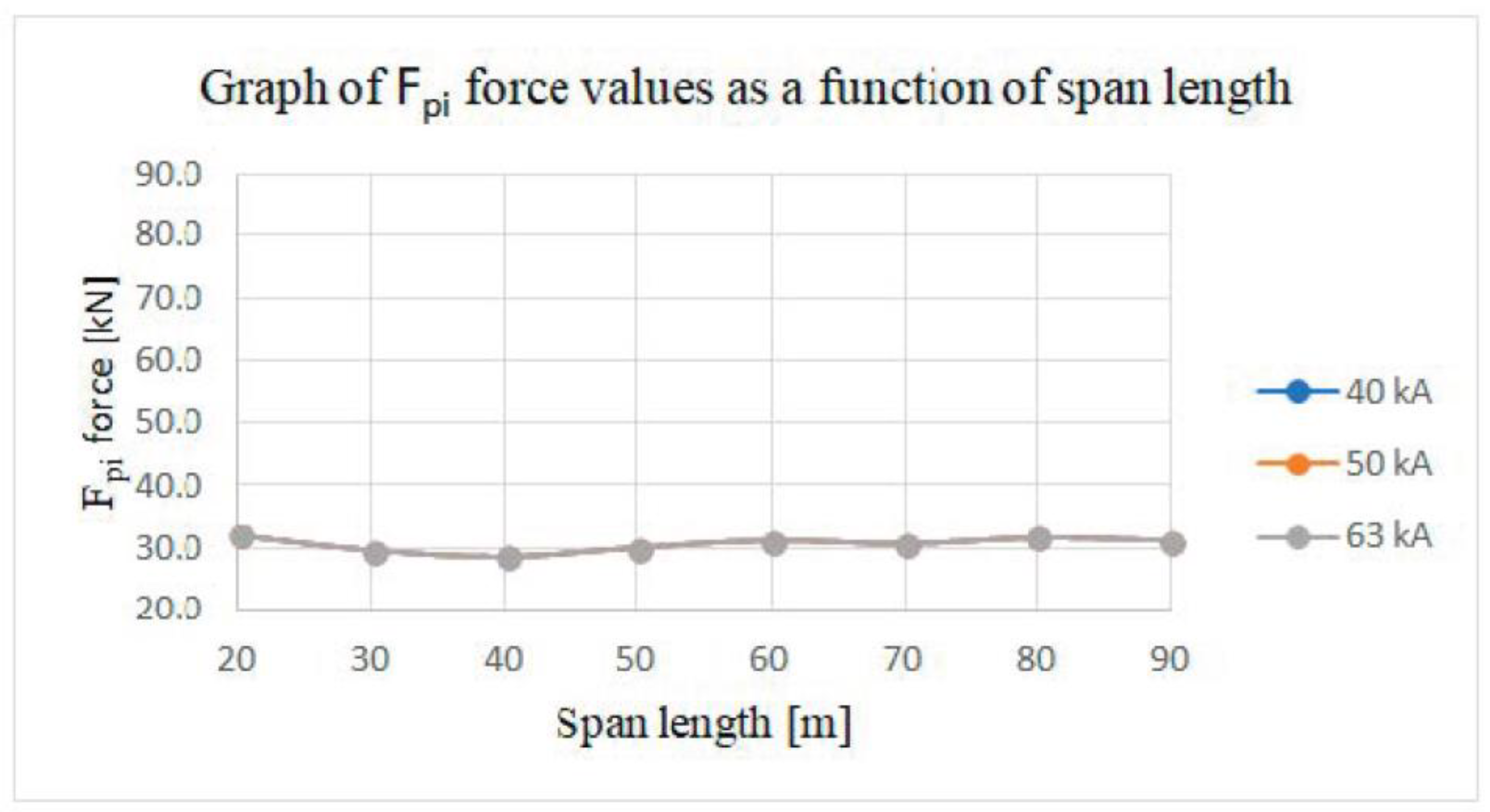

- The force associated with bringing the wires together in the bundle, denoted as Fpi and resulting from intra-bundle interaction.

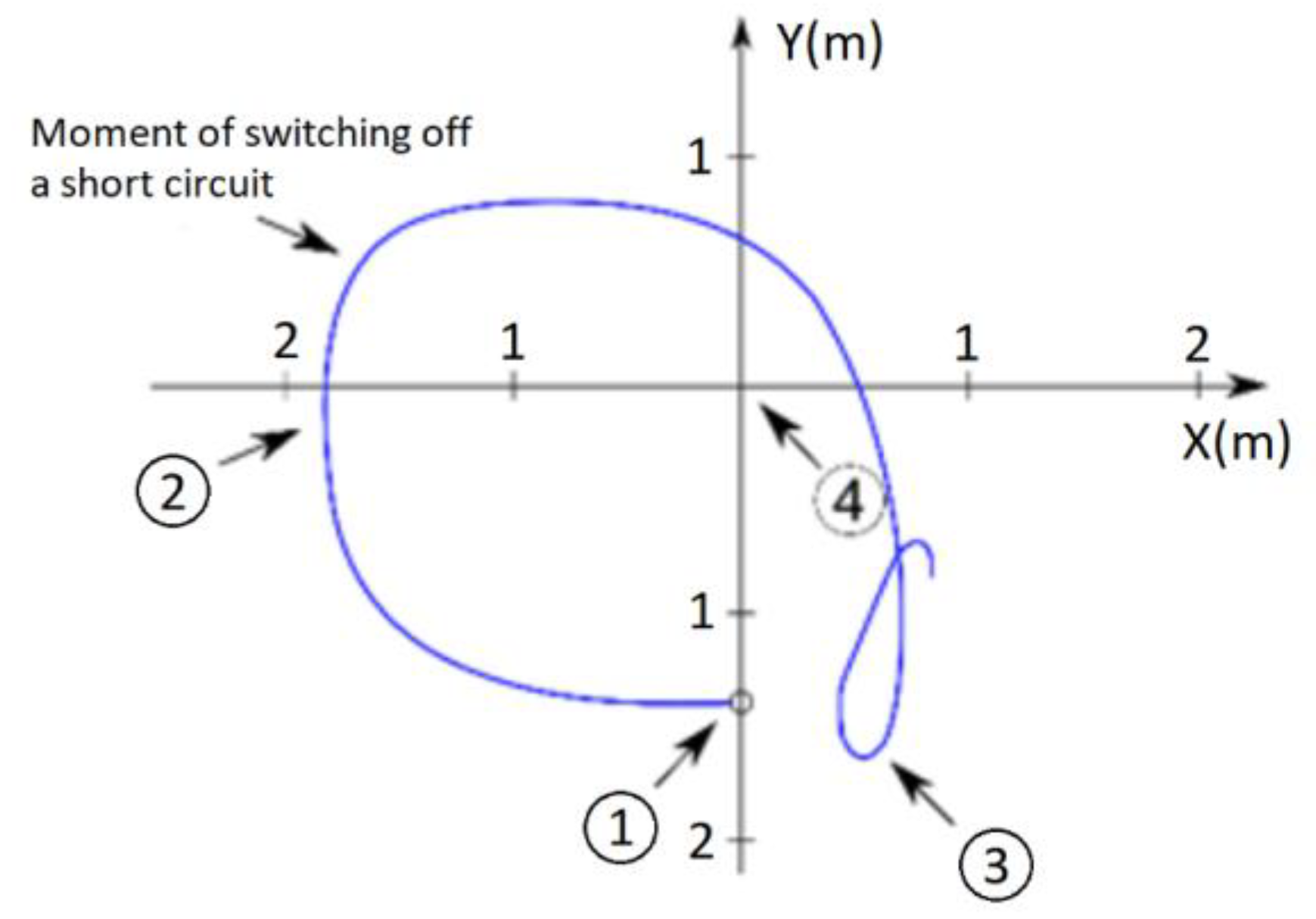

3. Analysis of the Dynamic Effects of Short-Circuit Current

3.1. Connections Made with Flexible Wires

- The value of the initial three-phase short-circuit current;

- The time Tpi;

- The type of short circuit;

- The static tension force of the wire harness;

- The rigidity of the structure;

- The method of attachment of the lashing chains.

3.2. Input Data for Analytical Calculations

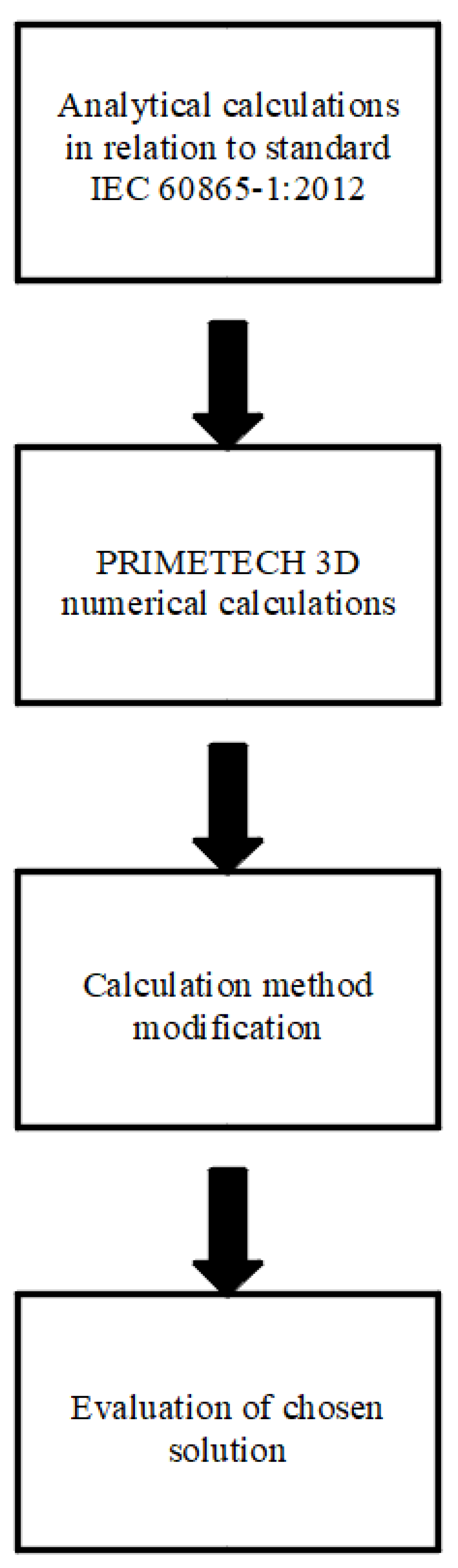

3.3. Analytical Calculations According to Normative Recommendations

- The value of r is greater than 0.6;

- The angle δmax is greater than or equal to 70°;

- The determined value of the angle δ in the span, in which there are discharge wires, is greater than 60°—this does not apply to the mentioned case.

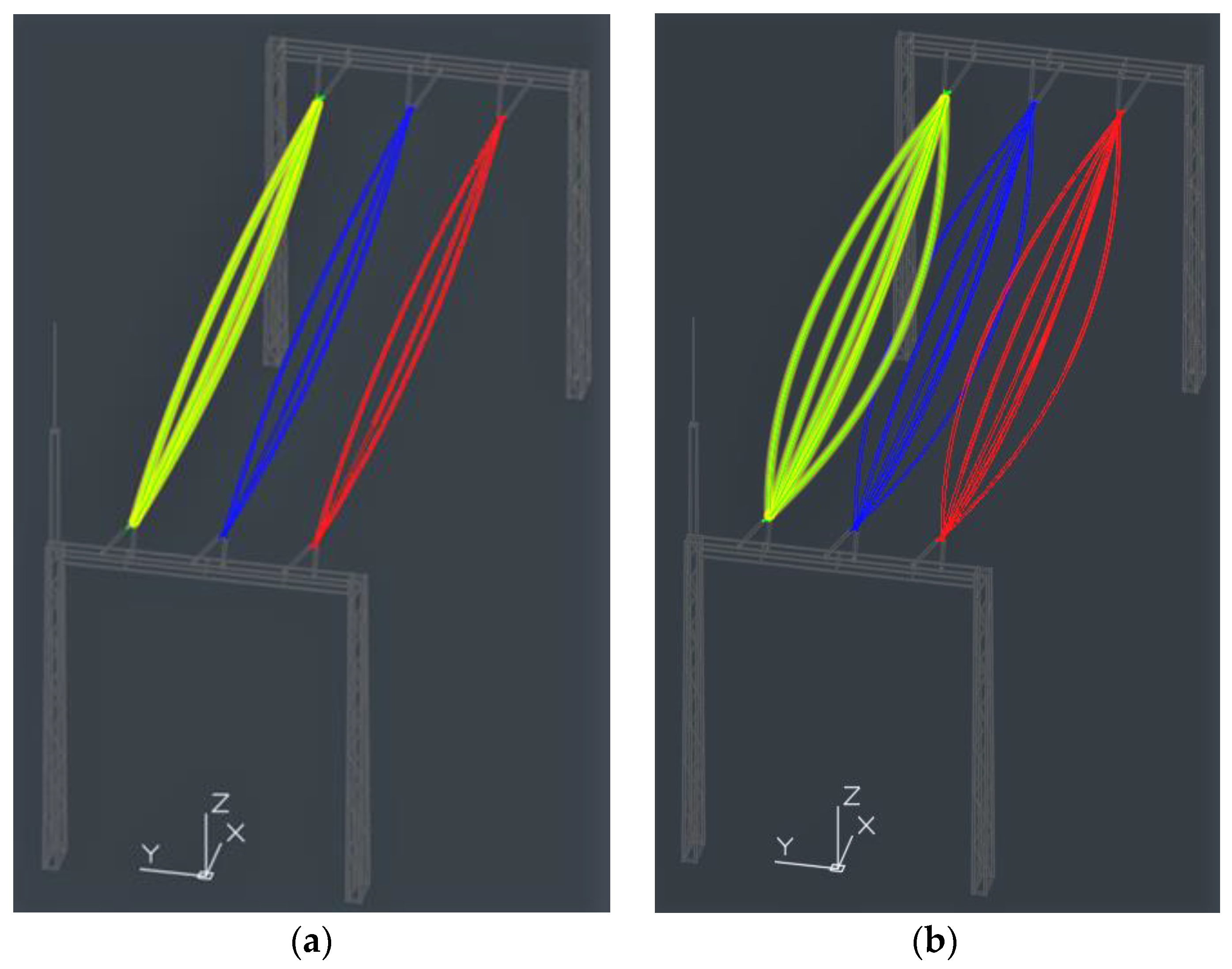

3.4. PRIMTECH 3D Program Numerical Calculations

4. Analysis Summary

- The value of the initial three-phase short-circuit current: 40 kA, 50 kA or 63 kA;

- The type of short circuit: three-phase or two-phase;

- The type of conductor pipe: AR120 × 12 or AR250 × 8;

- Consideration of the presence of protection automation: YES or NO;

- Consideration of natural frequency of conductors: YES or NO;

- The method of attachment of conductors: FLEXIBLE or COMBINED.

- The value of the initial three-phase short-circuit current: 40 kA, 50 kA or 63 kA;

- The Tpi time: 10 ms, 12 ms or 50 ms;

- The type of short circuit: three-phase or two-phase;

- The static tension force of the wire harness: 10 kN or 20 kN;

- The construction stiffness: 440⋅103 N/m, 880⋅103 N/m or 1320⋅103 N/m;

- The attachment method of the lashing chains: SINGLE-POINT or TWO-POINT.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bun, R.; Krzyszkowski, A. Mathematical models of electrodynamic influences on an example of the flat inductor. In Proceedings of the Modern Problems of Radio Engineering, Telecommunications and Computer Science (IEEE Cat. No.02EX542), Lviv-Slavsko, Ukraine, 18–23 February 2002; pp. 24–25. [Google Scholar]

- Triantafyllidis, D.G.; Dokopoulos, P.S.; Labridis, D.P. Parametric short-circuit force analysis of three-phase busbars-a fully automated finite element approach. IEEE Trans. Power Deliv. 2003, 18, 531–537. [Google Scholar] [CrossRef]

- Shen, B.; Zhang, X.; Zhou, D. Analysis and calculation of short-circuit electro-dynamic forces on rectangular bus bars. In Proceedings of the 2009 IEEE 6th International Power Electronics and Motion Control Conference, Wuhan, China, 17–20 May 2009; pp. 2618–2621. [Google Scholar]

- Yusop, F.M.; Jamil, M.K.M.; Ishak, D.; Masri, S. Study on the electromagnetic force affected by short-circuit current in vertical and horizontal arrangement of busbar system. In Proceedings of the International Conference on Electrical, Control and Computer Engineering 2011 (InECCE), Kuantan, Malaysia, 21–22 June 2011; pp. 196–200. [Google Scholar]

- Mouhamad, M.; Elleau, C.; Mazaleyrat, F.; Guillaume, C.; Jarry, B. Short-Circuit Withstand Tests of Metglas 2605SA1-Based Amorphous Distribution Transformers. IEEE Trans. Magn. 2011, 47, 4489–4492. [Google Scholar] [CrossRef]

- Komurgoz, G.; Gundogdu, T. Effect of the tap winding configurations on the electromagnetic forces acting on the concentric transformer coils. In Proceedings of the 2013 3rd International Conference on Electric Power and Energy Conversion Systems, Istanbul, Turkey, 2–4 October 2013; pp. 1–6. [Google Scholar]

- Vilhena, N.; Taillacq, A.; Pronto, A.; Murta-Pina, J.; Álvarez, A. Analysis of Electromagnetic Forces in Superconducting Fault-Current Limiters Under Short-Circuit Condition. IEEE Trans. Appl. Supercond. 2016, 26, 5601704. [Google Scholar] [CrossRef]

- Popa, I.A.; Dolan, D.I. Numerical modeling of three-phase busbar systems: Calculation of the thermal field and electrodynamic forces. In Proceedings of the 2016 International Conference on Applied and Theoretical Electricity (ICATE), Craiova, Romania, 6–8 October 2016; pp. 1–9. [Google Scholar]

- Kadkhodaei, G.; Sheshyekani, K.; Hamzeh, M. Coupled electric– magnetic–thermal–mechanical modelling of busbars nder shortcircuit conditions. IET Gener. Transm. Distrib. 2016, 10, 955–963. [Google Scholar] [CrossRef]

- Aprahamian, B.; Marinova, M.; Dimova, T. Assessment of the Influence of Magnetron Sputtered Coatings on the Electrodynamic Forces of Current-Carrying Busbars. In Proceedings of the 2018 20th International Symposium on Electrical Apparatus and Technologies (SIELA), Bourgas, Bulgaria, 3–6 June 2018; pp. 1–4. [Google Scholar]

- Popov, I.V.; Evdokunin, G.A.; Syutkin, A.V. Computation Modelling of Electrodynamic Forces in Transformers and Reactors. In Proceedings of the 2020 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), St. Petersburg and Moscow, Russia, 27–30 January 2020. [Google Scholar]

- Popov, I.V.; Evdokunin, G.A.; Popov, V.V. Influence of Transformer’s Operating Mode for Value of Electrodynamic Force. In Proceedings of the 2020 Ural Smart Energy Conference (USEC), Ekaterinburg, Russia, 13–15 November 2020; pp. 88–92. [Google Scholar]

- Piechocki, P.; Frackowiak, R.; Dombek, G.; Chmielewska, I. Estimation of Short Circuit Duration for the Assessment of Dynamic Effects in Distribution Substations with Flexible Conductors. Energies 2020, 13, 970. [Google Scholar] [CrossRef]

- Borkowski, P.; Bartosik, M.; Rodak, M.; Siemko, A. Ultra-Fast, Redundant and Unpolarized DC Energy Extraction Systems for the Protection of Superconducting Magnet Circuits. IEEE Trans. Ind. Electron. 2020, 69, 9895–9904. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Y.; Hu, D.; Wu, B.; Che, B.; Li, J. Transient electromagnetic force analysis of GIS bus based on FEM. In Proceedings of the International Conference on Condition Monitoring and Diagnosis (CMD), Xi’an, China, 25–28 September 2016; pp. 554–557. [Google Scholar]

- Szulborski, M.; Łapczyński, S.; Kolimas, Ł.; Tyryk, M. Electrodynamic Forces in a High Voltage Circuit Breakers With Tulip Contact System—FEM Simulations. IEEE Access 2022, 10, 99299–99320. [Google Scholar] [CrossRef]

- Jiaxin, Y.; Ruichao, W.; Huimin, L.; Longqing, B.; Hongjian, W. Research on the calculation methods of enclosed isolated phase busbar in short-circuit condition. In Proceedings of the IEEE 62nd Holm Conference on Electrical Contacts (Holm), Clearwater Beach, FL, USA, 9–12 October 2016; pp. 111–114. [Google Scholar]

- Park, S.W.; Cho, H. A practical study on electrical contact resistance and temperature rise at at the connections of the copper busbars in switchgears. In Proceedings of the IEEE 60th Holm Conference on Electrical Contacts (Holm), New Orleans, LA, USA, 12–15 October 2014; pp. 1–7. [Google Scholar]

- Gatherer, J.; Jackson, R.L. A multi-variable parametric study on the performance of bolted busbar contacts. In Proceedings of the IEEE 61st Holm Conference on Electrical Contacts (Holm), San Diego, CA, USA, 11–14 October 2015; pp. 124–131. [Google Scholar]

- Guan, X.; Shu, N. Electromagnetic field and force analysis of three-phase enclosure type GIS bus capsule. In Proceedings of the IEEE PES T&D Conference and Exposition, Chicago, IL, USA, 14–17 April 2014; pp. 1–4. [Google Scholar]

- Kulas, S. Current Paths and Contact System; OWPW: Warsaw, Poland, 2008; ISBN 978-83-7207-774-5. [Google Scholar]

- Zhong, J.Y.; Wu, S.J.; Wang, Z.; Guo, Y.J.; Qin, X.Y. A 3-D steady-state analysis of thermal behavior in EHV GIS busbar. J. Electr. Eng. Technol. 2016, 11, 781–789. [Google Scholar]

- Khademi-Zahedi, R.; Alimouri, P. Finite element analysis to the effect of thermo-mechanical loads on stress distribution in buried polyethylene gas pipes jointed by electrofusion sockets, repaired by PE patches. Energies 2018, 11, 2818. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Y.; Yang, W.; Jiang, Z.; Song, Y.; Jiang, S.; Luo, Q.; Liu, D. Finite element simulation of multi-scale bedding fractures in tight sandstone oil reservoir. Energies 2020, 13, 131. [Google Scholar] [CrossRef]

- IEC 60609—Short Circuit Current Standard. Available online: https://pdf.wecabrio.com/iec-60609.pdf (accessed on 15 May 2022).

- Premkumar, M.; Jangir, P.; Kumar, B.S.; Sowmya, R.; Alhelou, H.H.; Abualigah, L.; Yildiz, R.A.; Mirjalili, S. A new arithmetic optimization algorithm for solving real-world multiobjective CEC-2021 constrained optimization problems: Diversity analysis and validations. IEEE Access 2021, 9, 84263–84295. [Google Scholar] [CrossRef]

- Premkumar, M.; Jangir, P.; Sowmya, R.; Alhelou, H.H.; Heidari, A.; Chen, H. MOSMA: Multi-objective slime mould algorithm based on elitist non-dominated sorting. IEEE Access 2020, 9, 3229–3248. [Google Scholar] [CrossRef]

| Input Data | |||

|---|---|---|---|

| Parameter | Designation | Value | Measuring Unit |

| Physical constants | |||

| Magnetic permeability in a vacuum | [H/m] | ||

| Earth acceleration | 9.81 | [] | |

| Electrical parameters | |||

| R/X ratio | R/X | 0.07 | [Ω] |

| Frequency of network | f | 50 | [Hz] |

| Impact factor | k | 1.81 | [-] |

| Initial value of three-phase short circuit current | 40 | [kA] | |

| Short circuit duration | 1 | [s] | |

| Time to beam force | 50 | [ms] | |

| Wire parameters | |||

| Unit weight of AFL-8 525 cable | 1.939 | [kg/m] | |

| Young’s modulus | E | [] | |

| Outer diameter of the conduit | d | 32.2 | [mm] |

| Cross section of aluminum in the conduit | 525.89 | [] | |

| Cross section of steel in the conduit | 64.39 | [] | |

| Span parameters | |||

| Span parameters | S | 440103 | [N/m] |

| Static tension of the wire harness | 20 | [kN] | |

| Distance between axes of supports | l | 67 | [m] |

| Insulator length | 5.15 | [m] | |

| The length of the cable in the span | 56,7 | [m] | |

| Inter-phase distance | a | 6 | [m] |

| Number of wires in the harness | 2 | [pcs] | |

| Spacing between wires in the harness | 0.2 | [m] | |

| Number of spacers | 3 | [pcs] | |

| Distance between spacers | 14.18 | [m] | |

| Calculation criteria | |||

| Type of short circuit | Three-Phase | ||

| Method of fixing support insulators | Single | ||

| Calculation Results | |||

|---|---|---|---|

| Parameter | Designation | Value | Measuring Unit |

| Intermediate results | |||

| Unit electromagnetic force | 34 | [N/m] | |

| Ratio of electromagnetic force to gravitational force | r | 0.89 | [-] |

| Angular direction of force | 41.8 | ||

| Static cable sag in the middle of the span | 1.06 | [m] | |

| Free vibration period of the wire | T | 1.85 | [s] |

| Period of vibration of the wire during a short circuit | 1.65 | [s] | |

| Short circuit duration used in calculations | 0.74 | [s] | |

| Actual Young’s modulus | ] | ||

| Norm stiffness | N | [1/N] | |

| Tension coefficient of the cable | 0.61 | [-] | |

| Coefficient Χ | Χ | 0.12 | [-] |

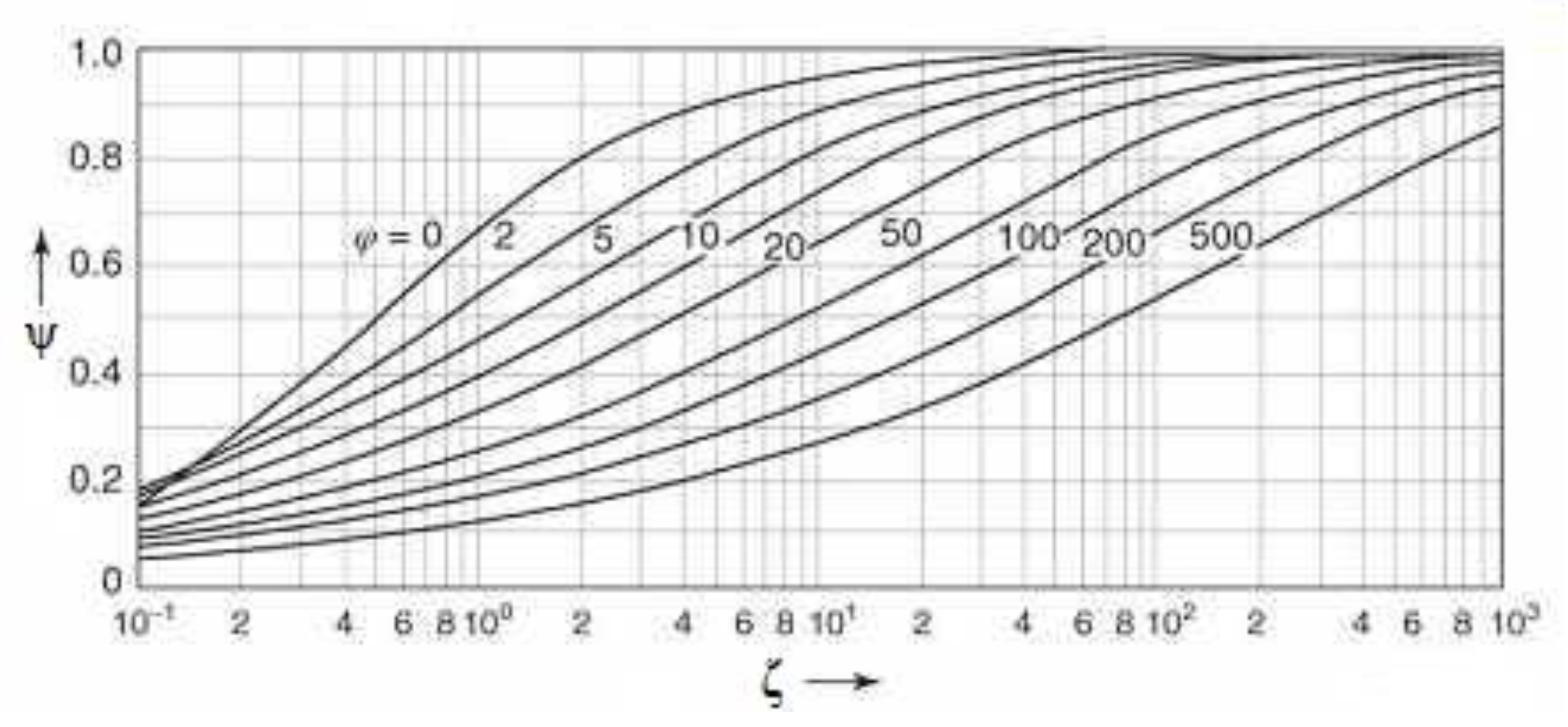

| Coefficient Φ | Φ | 1.02 | [-] |

| Coefficient Ψ | Ψ | 0.49 | [-] |

| Elastic expansion | [-] | ||

| Dilatation factor | CD | 1.42 | [-] |

| Form factor | CF | 1.06 | [-] |

| Deformation coefficients of conductors related to force | 11.76 1144.52 | [-] [-] | |

| Parameter that determines the configuration of the wire harness | j | 9.47 | [-] |

| Coefficient ζ | ζ | 7.67 | [-] |

| Force between bundle wires | 46,089.65 | [N] | |

| 1.43 | [-] | ||

| 2.58 | [-] | ||

| 0.32 | [-] | ||

| 5.21 | [-] | ||

| 1.58 | [-] | ||

| Final results | |||

| Final angle of cable swing | 81.38 | ||

| Maximum angle of cable deflection | 93.34 | ||

| Dynamic cable overhang in the middle of the span | 1.59 | [m] | |

| Maximum horizontal displacement of the cable | 1.06 | [m] | |

| Minimum insulation distance | 3.87 | [m] | |

| The force due to deflection of the cable | 30,008.56 | [N] | |

| The force caused by the descent of the cable | 45,102.48 | [N] | |

| The force of the pinch effect | 40,622.87 | [N] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozarek, Ł.; Cichecki, H.; Bogacki, M.; Tyryk, M.; Szulborski, M.; Łapczyński, S.; Kolimas, Ł.; Rasolomampionona, D.; Lange, A.; Berowski, P.; et al. Impact of the Short-Circuit Current Value on the Operation of Overhead Connections in High-Voltage Power Stations. Energies 2023, 16, 3462. https://doi.org/10.3390/en16083462

Kozarek Ł, Cichecki H, Bogacki M, Tyryk M, Szulborski M, Łapczyński S, Kolimas Ł, Rasolomampionona D, Lange A, Berowski P, et al. Impact of the Short-Circuit Current Value on the Operation of Overhead Connections in High-Voltage Power Stations. Energies. 2023; 16(8):3462. https://doi.org/10.3390/en16083462

Chicago/Turabian StyleKozarek, Łukasz, Hubert Cichecki, Mateusz Bogacki, Mykhailo Tyryk, Michał Szulborski, Sebastian Łapczyński, Łukasz Kolimas, Desire Rasolomampionona, Andrzej Lange, Przemysław Berowski, and et al. 2023. "Impact of the Short-Circuit Current Value on the Operation of Overhead Connections in High-Voltage Power Stations" Energies 16, no. 8: 3462. https://doi.org/10.3390/en16083462

APA StyleKozarek, Ł., Cichecki, H., Bogacki, M., Tyryk, M., Szulborski, M., Łapczyński, S., Kolimas, Ł., Rasolomampionona, D., Lange, A., Berowski, P., Sul, P., & Owsiński, M. (2023). Impact of the Short-Circuit Current Value on the Operation of Overhead Connections in High-Voltage Power Stations. Energies, 16(8), 3462. https://doi.org/10.3390/en16083462