Performance Assessment of the Heat Recovery System of a 12 MW SOFC-Based Generator on Board a Cruise Ship through a 0D Model

Abstract

1. Introduction

2. Materials and Methods

2.1. SOFC Model

2.2. Model Validation

2.3. Heat Recovery System

2.4. Case Study

3. Results and Discussion

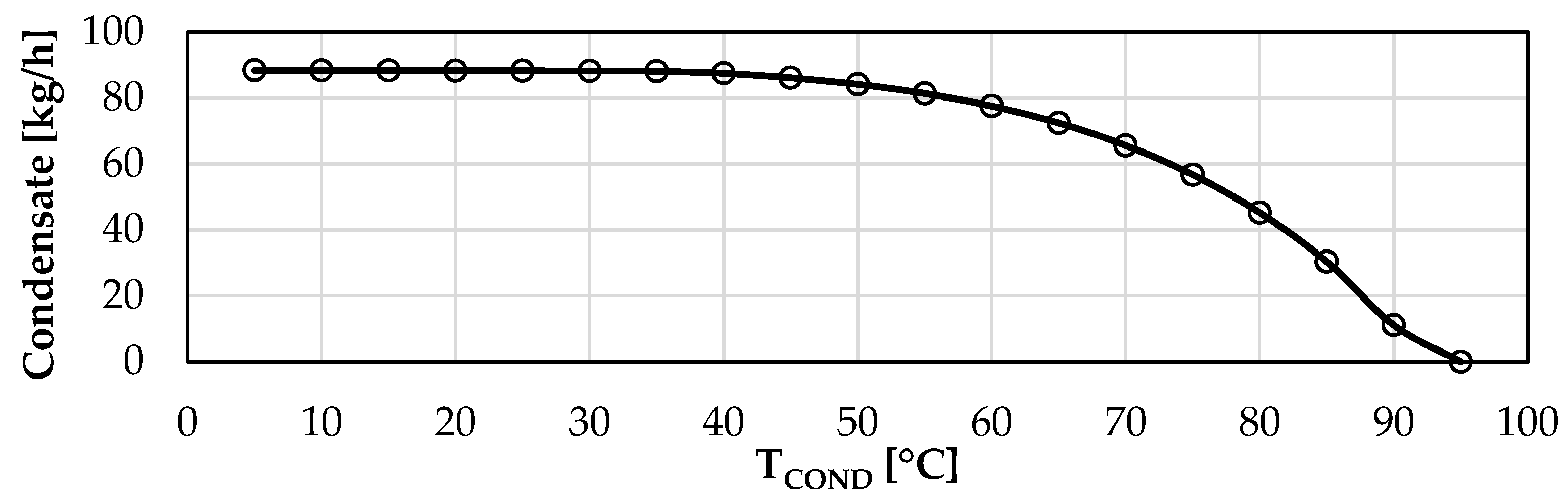

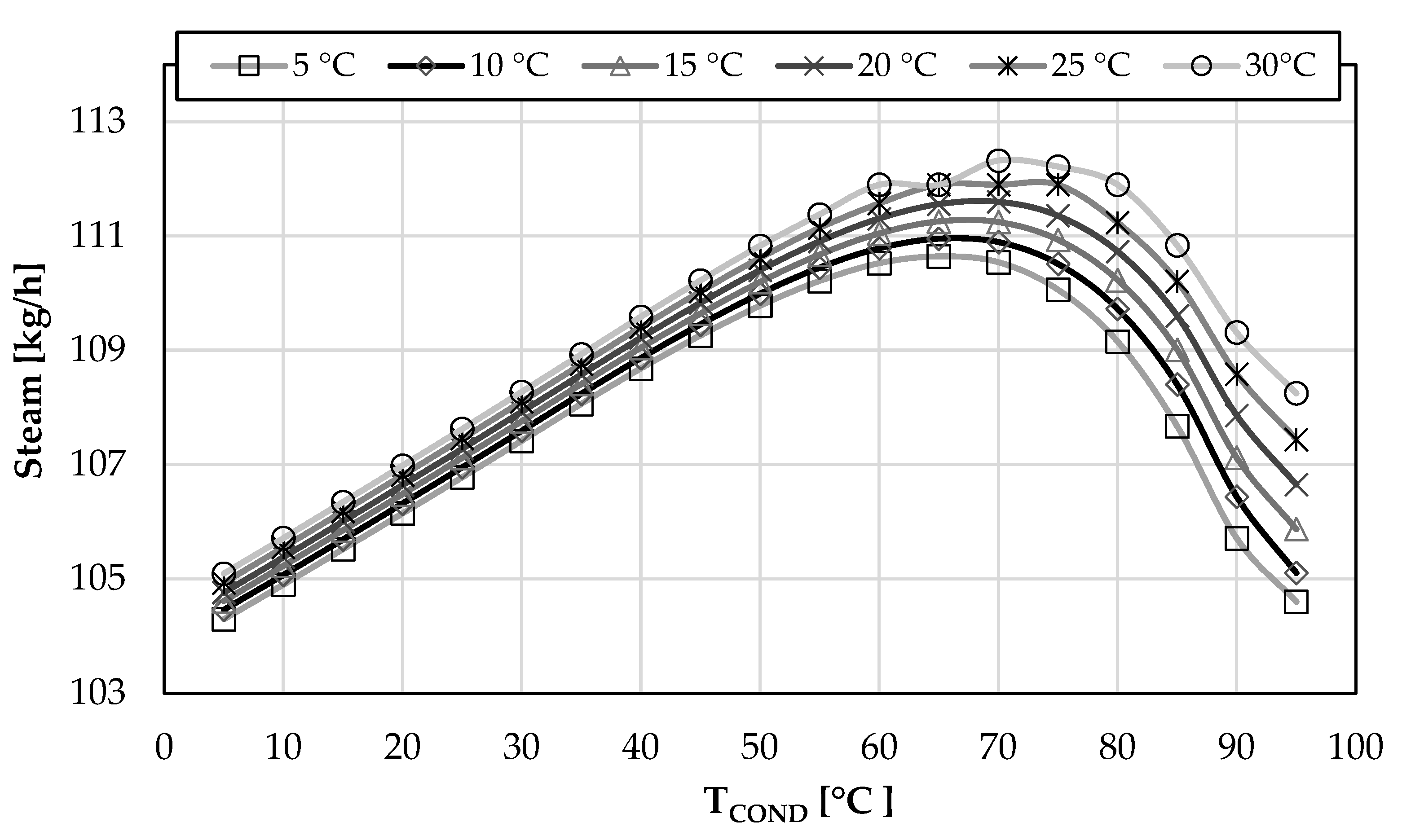

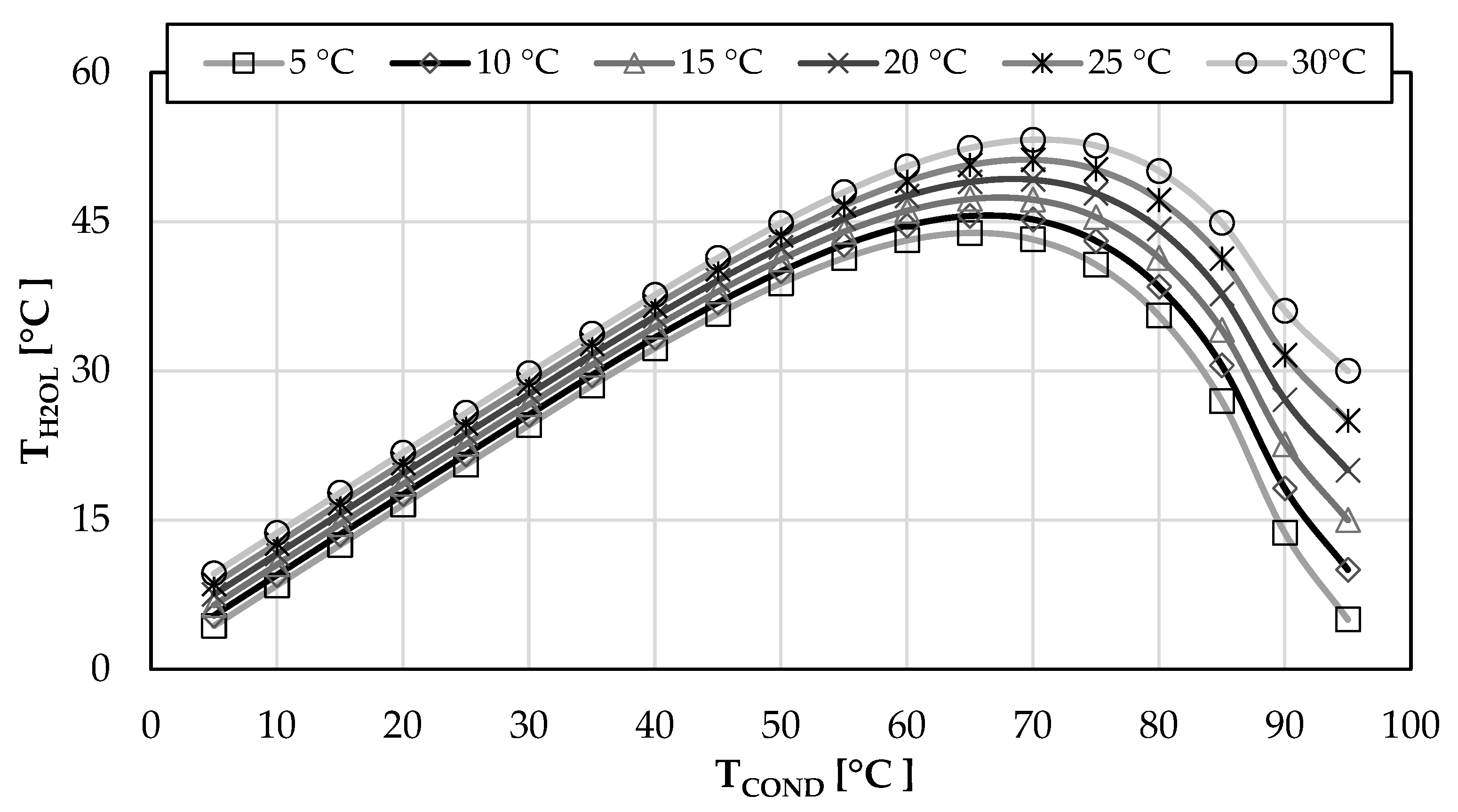

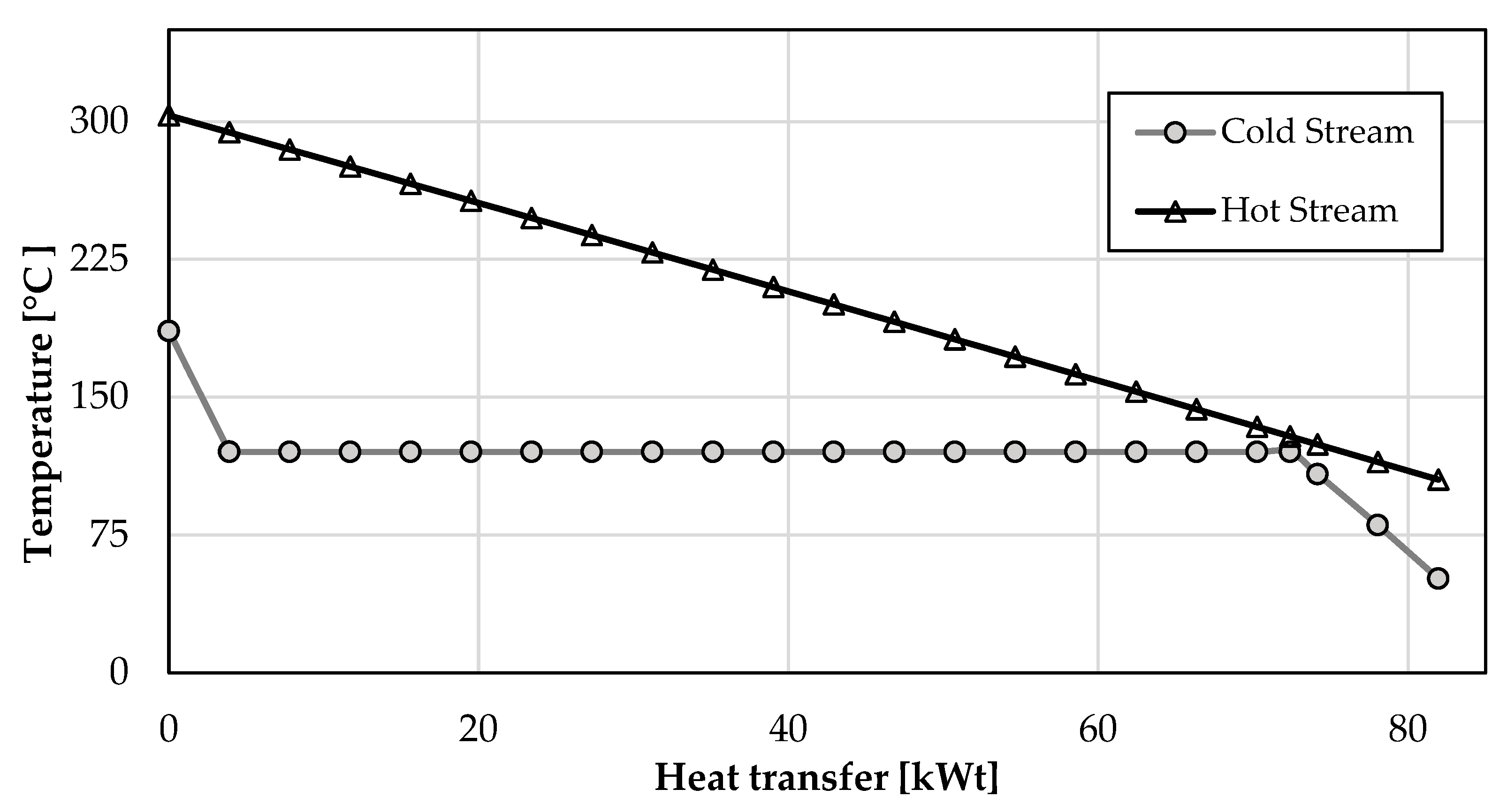

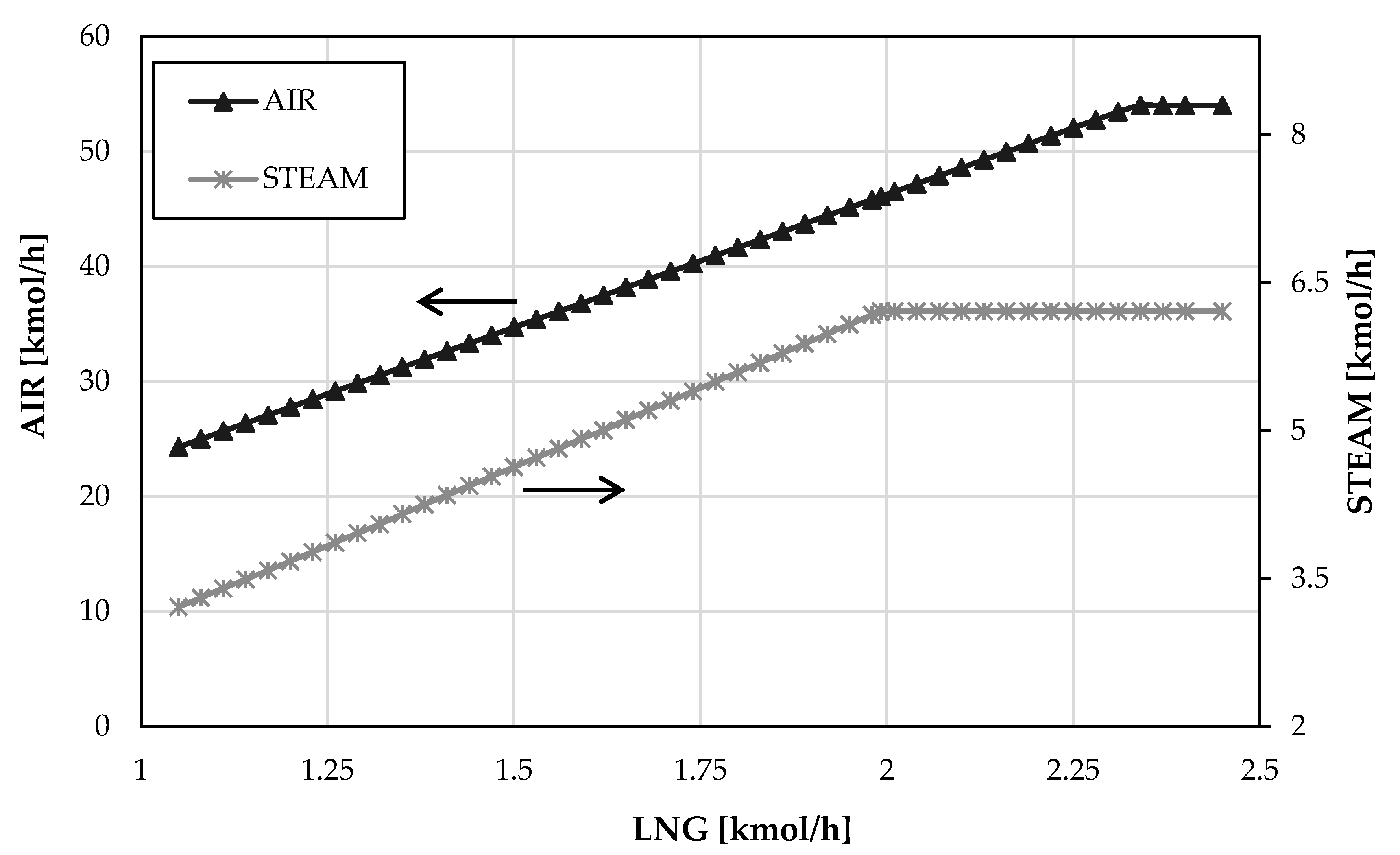

3.1. Heat Recovery System

3.2. Application of HRS to the Case Study

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Joung, T.H.; Kang, S.G.; Lee, J.K.; Ahn, J. The IMO Initial Strategy for Reducing Greenhouse Gas(GHG) Emissions, and Its Follow-up Actions towards 2050. J. Int. Marit. Saf. Environ. Aff. Shipp. 2020, 4, 1–7. [Google Scholar] [CrossRef]

- Eyring, V.; Köhler, H.W.; Lauer, A.; Lemper, B. Emissions from International Shipping: 2. Impact of Future Technologies on Scenarios until 2050. J. Geophys. Res. Atmos. 2005, 110, 183–200. [Google Scholar] [CrossRef]

- Altosole, M.; Figari, M.; Altosole, M.; Buglioni, G.; Figari, M. Alternative Propulsion Technologies for Fishing Vessels: A Case Study. Int. Rev. Mech. Eng. 2016, 8, 296–301. [Google Scholar]

- Altosole, M.; Benvenuto, G.; Campora, U.; Laviola, M.; Altosole, M.; Laviola, M.; Trucco, A.; SpA, F. Waste Heat Recovery Systems from Marine Diesel Engines: Comparison between New Design and Retrofitting Solutions. Energies 2015, 10, 718. [Google Scholar] [CrossRef]

- Mazzoccoli, M.; Altosole, M.; Vigna, V.; Bosio, B.; Arato, E. Marine Pollution Mitigation by Waste Oils Recycling Onboard Ships: Technical Feasibility and Need for New Policy and Regulations. Front. Mar. Sci. 2020, 7, 566363. [Google Scholar] [CrossRef]

- Altosole, M.; Campora, U.; Mocerino, L.; Zaccone, R. An Innovative Variable Layout Steam Plant for Waste Heat Recovery from Marine Dual-Fuel Engines. Ships Offshore Struct. 2022, 18, 429–437. [Google Scholar] [CrossRef]

- Altosole, M.; Balsamo, F.; Campora, U.; Mocerino, L. Marine Dual-Fuel Engines Power Smart Management by Hybrid Turbocharging Systems. J. Mar. Sci. Eng. 2021, 9, 663. [Google Scholar] [CrossRef]

- Altosole, M.; Benvenuto, G.; Campora, U.; Silvestro, F.; Terlizzi, G. Efficiency Improvement of a Natural Gas Marine Engine Using a Hybrid Turbocharger. Energies 2018, 11, 1924. [Google Scholar] [CrossRef]

- Qin, T.; Yuan, S. Research Progress of Catalysts for Catalytic Steam Reforming of High Temperature Tar: A Review. Fuel 2023, 331, 125790. [Google Scholar] [CrossRef]

- van Biert, L.; Godjevac, M.; Visser, K.; Aravind, P.V. A Review of Fuel Cell Systems for Maritime Applications. J. Power Sources 2016, 327, 345–364. [Google Scholar] [CrossRef]

- Xing, H.; Stuart, C.; Spence, S.; Chen, H. Fuel Cell Power Systems for Maritime Applications: Progress and Perspectives. Sustainability 2021, 13, 1213. [Google Scholar] [CrossRef]

- Coraddu, A.; Gil, A.; Akhmetov, B.; Yang, L.; Romagnoli, A.; Ritari, A.; Huotari, J.; Tammi, K. Energy Storage on Ships. In Sustainable Energy Systems on Ships; Elsevier: Amsterdam, The Netherlands, 2022; pp. 197–232. [Google Scholar] [CrossRef]

- Okubo, M.; Kuwahara, T. Prospects for Marine Diesel Engine Emission Control. In New Technologies for Emission Control in Marine Diesel Engines; Elsevier: Amsterdam, The Netherlands, 2020; pp. 211–266. [Google Scholar] [CrossRef]

- IMO’s Work to Cut GHG Emissions from Ships. Available online: https://www.imo.org/en/MediaCentre/HotTopics/Pages/Cutting-GHG-emissions.aspx (accessed on 28 April 2022).

- IMO Cutting GHG Emissions from Shipping—10 Years of Mandatory Rules. Available online: https://gmn.imo.org/cutting-ghg-emission-from-shipping-10-years-of-mandatory-rules/ (accessed on 28 April 2022).

- Aakko-Saksa, P.T.; Lehtoranta, K.; Kuittinen, N.; Järvinen, A.; Jalkanen, J.P.; Johnson, K.; Jung, H.; Ntziachristos, L.; Gagné, S.; Takahashi, C.; et al. Reduction in Greenhouse Gas and Other Emissions from Ship Engines: Current Trends and Future Options. Prog. Energy Combust. Sci. 2023, 94, 101055. [Google Scholar] [CrossRef]

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-Art Technologies, Measures, and Potential for Reducing GHG Emissions from Shipping—A Review. Transp. Res. Part D Transp. Environ. 2017, 52, 408–421. [Google Scholar] [CrossRef]

- Coralli, A.; Sarruf, B.J.M.; De Miranda, P.E.V.; Osmieri, L.; Specchia, S.; Minh, N.Q. Fuel Cells. In Science and Engineering of Hydrogen-Based Energy Technologies: Hydrogen Production and Practical Applications in Energy Generation; Academic Press: Cambridge, MA, USA, 2019; pp. 39–122. [Google Scholar] [CrossRef]

- Breeze, P.; Breeze, P. Chapter 7—Fuel Cells. In Power Generation Technologies; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Dicks, A.L.; Rand, D.A.J. Fuel Cell Systems Explained; John Wiley & Sons Ltd.: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Fuel Cell Industry Review. 2021. Available online: https://www.e4tech.com/resources/249-fuel-cell-industry-review-2021.php (accessed on 19 November 2022).

- Tronstad, T.; Høgmoen, Å.H.; Haugom, G.P.; Langfeldt, L. Study on the Use of Fuel Cells in Shipping. Study Commissioned by European Maritime Safety Agency (EMSA); EMSA European Maritime Safety Agency: Lisboa, Portugal, 2017. [Google Scholar]

- Coppola, T.; Micoli, L.; Turco, M. State of the Art of High Temperature Fuel Cells in Maritime Applications. In Proceedings of the 2020 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Sorrento, Italy, 24–26 June 2020; pp. 430–435. [Google Scholar] [CrossRef]

- Singla, M.K.; Nijhawan, P.; Oberoi, A.S. Hydrogen Fuel and Fuel Cell Technology for Cleaner Future: A Review. Environ. Sci. Pollut. Res. 2021, 28, 15607–15626. [Google Scholar] [CrossRef] [PubMed]

- Rosli, R.E.; Sulong, A.B.; Daud, W.R.W.; Zulkifley, M.A.; Husaini, T.; Rosli, M.I.; Majlan, E.H.; Haque, M.A. A Review of High-Temperature Proton Exchange Membrane Fuel Cell (HT-PEMFC) System. Int. J. Hydrogen Energy 2017, 42, 9293–9314. [Google Scholar] [CrossRef]

- Raza, T.; Yang, J.; Wang, R.; Xia, C.; Raza, R.; Zhu, B.; Yun, S. Recent Advance in Physical Description and Material Development for Single Component SOFC: A Mini-Review. Chem. Eng. J. 2022, 444, 136533. [Google Scholar] [CrossRef]

- McPhail, S.J.; Conti, B.; Kiviaho, J. The Yellow Pages of SOFC Technology—International Status of SOFC Deployment 2017; International Energy Agency: Paris, France, 2017; ISBN 978-88-8286-290-9. [Google Scholar]

- Paściak, G.; Chmielowiec, J.; Bujło, P. New Ceramic Superionic Materials for IT-SOFC Applications. Mater. Sci.-Pol. 2005, 23, 209–219. [Google Scholar]

- Liu, Y.; Shao, Z.; Mori, T.; Jiang, S.P. Development of Nickel Based Cermet Anode Materials in Solid Oxide Fuel Cells—Now and Future. Mater. Rep. Energy 2021, 1, 100003. [Google Scholar] [CrossRef]

- Ma, M.; Yang, X.; Qiao, J.; Sun, W.; Wang, Z.; Sun, K. Progress and Challenges of Carbon-Fueled Solid Oxide Fuel Cells Anode. J. Energy Chem. 2021, 56, 209–222. [Google Scholar] [CrossRef]

- Solovyev, A.A.; Shipilova, A.V.; Rabotkin, S.V.; Bogdanovich, N.M.; Pikalova, E.Y. Study of the Efficiency of Composite LaNi0.6Fe0.4O3-Based Cathodes in Intermediate-Temperature Anode-Supported SOFCs. Int. J. Hydrogen Energy 2023, in press. [Google Scholar] [CrossRef]

- Tahir, N.N.M.; Baharuddin, N.A.; Samat, A.A.; Osman, N.; Somalu, M.R. A Review on Cathode Materials for Conventional and Proton-Conducting Solid Oxide Fuel Cells. J. Alloys Compd. 2022, 894, 162458. [Google Scholar] [CrossRef]

- Sazali, N.; Salleh, W.N.W.; Jamaludin, A.S.; Razali, M.N.M. New Perspectives on Fuel Cell Technology: A Brief Review. Membranes 2020, 10, 99. [Google Scholar] [CrossRef]

- Braun, R.J.; Kazempoor, P. Application of SOFCs in Combined Heat, Cooling and Power Systems. In Solid Oxide Fuel Cells; Royal Society of Chemistry: London, UK, 2013. [Google Scholar]

- Ellamla, H.R.; Staffell, I.; Bujlo, P.; Pollet, B.G.; Pasupathi, S. Current Status of Fuel Cell Based Combined Heat and Power Systems for Residential Sector. J. Power Sources 2015, 293, 312–328. [Google Scholar] [CrossRef]

- Baldi, F.; Moret, S.; Tammi, K.; Maréchal, F. The Role of Solid Oxide Fuel Cells in Future Ship Energy Systems. Energy 2020, 194, 116811. [Google Scholar] [CrossRef]

- Micoli, L.; Coppola, T.; Turco, M. A Case Study of a Solid Oxide Fuel Cell Plant on Board a Cruise Ship. J. Mar. Sci. Appl. 2021, 20, 524–533. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Jovanović, I.; Koričan, M. Application of Fuel Cells with Zero-Carbon Fuels in Short-Sea Shipping. Appl. Energy 2022, 309, 118463. [Google Scholar] [CrossRef]

- Singh, D.V.; Pedersen, E. A Review of Waste Heat Recovery Technologies for Maritime Applications. Energy Convers. Manag. 2016, 111, 315–328. [Google Scholar] [CrossRef]

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste Heat Recovery Technologies and Applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Shu, G.; Liang, Y.; Wei, H.; Tian, H.; Zhao, J.; Liu, L. A Review of Waste Heat Recovery on Two-Stroke IC Engine Aboard Ships. Renew. Sustain. Energy Rev. 2013, 19, 385–401. [Google Scholar] [CrossRef]

- Shu, G.; Liu, P.; Tian, H.; Wang, X.; Jing, D. Operational Profile Based Thermal-Economic Analysis on an Organic Rankine Cycle Using for Harvesting Marine Engine’s Exhaust Waste Heat. Energy Convers. Manag. 2017, 146, 107–123. [Google Scholar] [CrossRef]

- Ouyang, T.; Wang, Z.; Zhao, Z.; Lu, J.; Zhang, M. An Advanced Marine Engine Waste Heat Utilization Scheme: Electricity-Cooling Cogeneration System Integrated with Heat Storage Device. Energy Convers. Manag. 2021, 235, 113955. [Google Scholar] [CrossRef]

- Alirahmi, S.M.; Gundersen, T.; Yu, H. A Comprehensive Study and Tri-Objective Optimization for an Efficient Waste Heat Recovery from Solid Oxide Fuel Cell. Int. J. Hydrogen Energy 2023, in press. [CrossRef]

- Ouyang, T.; Zhao, Z.; Su, Z.; Lu, J.; Wang, Z.; Huang, H. An Integrated Solution to Harvest the Waste Heat from a Large Marine Solid Oxide Fuel Cell. Energy Convers. Manag. 2020, 223, 113318. [Google Scholar] [CrossRef]

- Zhang, H.; Kong, W.; Dong, F.; Xu, H.; Chen, B.; Ni, M. Application of Cascading Thermoelectric Generator and Cooler for Waste Heat Recovery from Solid Oxide Fuel Cells. Energy Convers. Manag. 2017, 148, 1382–1390. [Google Scholar] [CrossRef]

- Doherty, W.; Reynolds, A.; Kennedy, D. Process Simulation of Biomass Gasification Integrated with a Solid Oxide Fuel Cell Stack. J. Power Sources 2015, 277, 292–303. [Google Scholar] [CrossRef]

- Doherty, W.; Reynolds, A.; Kennedy, D. Computer Simulation of a Biomass Gasification-Solid Oxide Fuel Cell Power System Using Aspen Plus. Energy 2010, 35, 4545–4555. [Google Scholar] [CrossRef]

- Corigliano, O.; Pagnotta, L.; Fragiacomo, P. On the Technology of Solid Oxide Fuel Cell (SOFC) Energy Systems for Stationary Power Generation: A Review. Sustainability 2022, 14, 15276. [Google Scholar] [CrossRef]

- Wain-Martin, A.; Campana, R.; Morán-Ruiz, A.; Larrañaga, A.; Arriortua, M.I. Synthesis and Processing of SOFC Components for the Fabrication and Characterization of Anode Supported Cells. Boletín Soc. Española Cerámica Vidr. 2022, 61, 264–274. [Google Scholar] [CrossRef]

- Zamudio-García, J.; Caizán-Juanarena, L.; Porras-Vázquez, J.M.; Losilla, E.R.; Marrero-López, D. A Review on Recent Advances and Trends in Symmetrical Electrodes for Solid Oxide Cells. J. Power Sources 2022, 520, 230852. [Google Scholar] [CrossRef]

- Cigolotti, V.; Genovese, M.; Fragiacomo, P. Comprehensive Review on Fuel Cell Technology for Stationary Applications as Sustainable and Efficient Poly-Generation Energy Systems. Energies 2021, 14, 4963. [Google Scholar] [CrossRef]

- Bove, R.; Ubertini, S. Modeling Solid Oxide Fuel Cell Operation: Approaches, Techniques and Results. J. Power Sources 2006, 159, 543–559. [Google Scholar] [CrossRef]

- Huang, K.; Goodenough, J.B. Solid Oxide Fuel Cell Technology: Principles, Performance and Operations. In Solid Oxide Fuel Cell Technology: Principles, Performance and Operations; Elsevier: Amsterdam, The Netherlands, 2009; pp. 1–328. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. An Overview of Fuel Cell Technology: Fundamentals and Applications. Renew. Sustain. Energy Rev. 2014, 32, 810–853. [Google Scholar] [CrossRef]

- Koh, J.; Yoo, Y.; Park, J.; Ionics, H.L.-S.S. Carbon Deposition and Cell Performance of Ni-YSZ Anode Support SOFC with Methane Fuel. Solid State Ion. 2002, 149, 157–166. [Google Scholar] [CrossRef]

- Ke, K.; Gunji, A.; Mori, H.; Tsuchida, S.; Takahashi, H.; Ionics, K.U.-S.S. Effect of Oxide on Carbon Deposition Behavior of CH4 Fuel on Ni/ScSZ Cermet Anode in High Temperature SOFCs. Solid State Ion. 2006, 177, 541–547. [Google Scholar] [CrossRef]

- Lee, W.Y.; Hanna, J.; Ghoniem, A.F. On the Predictions of Carbon Deposition on the Nickel Anode of a SOFC and Its Impact on Open-Circuit Conditions. J. Electrochem. Soc. 2013, 160, F94–F105. [Google Scholar] [CrossRef]

- Hall, D.J.; Colclaser, R.G. Transient Modeling and Simulation of a Tubular Solid Oxide Fuel Cell. IEEE Trans. Energy Convers. 1999, 14, 749–753. [Google Scholar] [CrossRef]

- Hofmann, P.; Panopoulos, K.D.; Fryda, L.E.; Kakaras, E. Comparison between Two Methane Reforming Models Applied to a Quasi-Two-Dimensional Planar Solid Oxide Fuel Cell Model. Energy 2009, 34, 2151–2157. [Google Scholar] [CrossRef]

- Panopoulos, K.D.; Fryda, L.; Karl, J.; Poulou, S.; Kakaras, E. High Temperature Solid Oxide Fuel Cell Integrated with Novel Allothermal Biomass Gasification: Part II: Exergy Analysis. J. Power Sources 2006, 159, 586–594. [Google Scholar] [CrossRef]

- Yi, J.H.; Kim, T.S. Effects of Fuel Utilization on Performance of SOFC/Gas Turbine Combined Power Generation Systems. J. Mech. Sci. Technol. 2017, 31, 3091–3100. [Google Scholar] [CrossRef]

- Bolonkin, A.A.; Neumann, S.; Friedlander, J.J. A Novel Macro-Engineering Approach to Seawater Desalination. Environ. Sci. Eng. 2011, 1, 675–689. [Google Scholar] [CrossRef]

- Mocerino, L.; Soares, C.G.; Rizzuto, E.; Balsamo, F.; Quaranta, F. Validation of an Emission Model for a Marine Diesel Engine with Data from Sea Operations. J. Mar. Sci. Appl. 2021, 20, 534–545. [Google Scholar] [CrossRef]

- Nguyen, T.V. Water Management by Material Design and Engineering for PEM Fuel Cells. ECS Trans. 2006, 3, 1171–1180. [Google Scholar] [CrossRef]

- Patel, M. Shipboard Electrical Power Systems; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Men, Y.; Liu, X.; Zhang, T. Performance Comparison of Different Total Heat Exchangers Applied for Waste Heat Recovery. Appl. Therm. Eng. 2021, 182, 115715. [Google Scholar] [CrossRef]

- Itoh, J.; Shiroko, K.; Umeda, T. Extensive Applications of the T-Q Diagram to Heat Integrated System Synthesis. Comput. Chem. Eng. 1986, 10, 59–66. [Google Scholar] [CrossRef]

- Min, G.; Park, Y.J.; Hong, J. Thermodynamic Analysis of a Solid Oxide Co-Electrolysis Cell System for Its Optimal Thermal Integration with External Heat Supply. Energy Convers. Manag. 2020, 225, 113381. [Google Scholar] [CrossRef]

| Block ID | Aspen Plus Unit Block | Description |

|---|---|---|

| NG-TCON | Heater | Sets the fuel inlet temperature |

| MIXER | Mixer | Mixes the recycled unconverted fuel with fresh fuel |

| T-CON | Heater | Preheats the inlet stream to the reformer reactor up to 850 °C |

| PREREFOR | RGibbs (Gibbs free energy reactor) | Simulates steam reforming of CH4 of lighter hydrocarbons and the shifting of CO to H2 (Water–Gas Shift reaction) |

| ANODE | RGibbs (Gibbs free energy reactor) | Simulates the reforming and electrochemical reactions occurring at the anode |

| ANSEP | FSplit (Splitter) | Splits the anode outlet into a recycle stream and a stream sent to the afterburner |

| AFTERBUR | RStoic (Stoichiometric reactor) | Simulates the complete combustion of the remaining fuel with the depleted oxidant |

| AFT-TCON | Heater | Manages the overall heat balance |

| HEATER | Heater | Sets the cathode temperature at 900 °C |

| CATHODE | Sep (Separator) | Simulates the cathode and the electrolyte ion flow separating the O2 required by the electrochemical reactions from the air inlet stream |

| HEATEX | HeatX (Heat exchanger) | Preheats the inlet air using the hot gases from the afterburner |

| AIR-TCON | Heater | Sets the air inlet temperature |

| Input | Value |

|---|---|

| LNG composition [% vol] | CH4: 90; C2H6: 8; C3H8: 2 |

| Air composition [% vol] | N2: 78.5; O2: 20; H2O: 1.5 |

| SOFC-operating temperature [°C] | 900 |

| SOFC-operating pressure [bar] | 2 |

| SOFC efficiency [%] | 60 |

| DC stack power [kW] | 75 |

| Anodic recycle ratio [%] | 85 |

| Fuel-utilization factor [%] | 67 |

| Reformer-operating temperature [°C] | 850 |

| Thermal losses [%] | 3 |

| Block/Stream ID | Aspen Plus Unit Block/Stream | Description |

|---|---|---|

| EXCH | HeateX (Heat exchanger) | Simulates a Heat Recovery Steam Generator (HRSG). |

| MIX-H2O | Mixer | Mixes the condensed and freshwater streams |

| COND | Heater | Simulates a condenser |

| EX300 | Stream | Exhaust stream from the SOFC plant (at an average temperature of about 300 °C) |

| STEAM | Stream | Steam, produced at 186 °C and 2 bar |

| H2OL | Stream | Water stream to be vaporized |

| EXOUT | Stream | Cooled exhaust stream from the HRSG |

| H2OF | Stream | Freshwater stream at 25 °C |

| H2OC | Stream | Condensed water from the exhaust stream |

| EXHOUT2 | Stream | Water-depleted exhaust stream |

| Phase ID | Duration [h] | Speed [kn] | Propulsion Power at MSB * [kWe] | Non-Prop. Electric Power [kWe] | Total Electric Power at MSB * [kWe] | Heat Demand [kWt] | Heat Recovered [kWt] | Heat Demand (Net) [kWt] | EGB Steam Production [kWt] |

|---|---|---|---|---|---|---|---|---|---|

| P1 | 7 | 13.0 | 12,427 | 11,810 | 24,237 | 15,448 | 6651 | 8797 | 8804 |

| P2 | 3 | 16.0 | 17,246 | 11,810 | 29,056 | 17,417 | 8424 | 8993 | 9309 |

| P3 | 1 | 18.3 | 23,572 | 11,810 | 35,382 | 20,897 | 9118 | 11,779 | 12,207 |

| P4 | 0.5 | 20.5 | 33,193 | 11,810 | 45,003 | 24,989 | 12,021 | 12,968 | 14,256 |

| P5 | 0.5 | 21.5 | 38,274 | 11,810 | 51,449 | 24,931 | 12,360 | 12,571 | 16,434 |

| P6 | 12 | 0 | - | 8485 | 8485 | 10,920 | 2882 | 8038 | 0 |

| Power | Specific LNG Consumption |

|---|---|

| [kWe] | [kg/h] |

| 11,328 | 1828 |

| 8485 | 1362 |

| 8085 | 1296 |

| Stream ID | |||

|---|---|---|---|

| AIR | NG | EX300 | |

| Mass Flow by Component [kg/h] | |||

| O2 | 294.9 | 0 | 156 |

| N2 | 1013.3 | 0 | 1013.3 |

| H2O | 12.5 | 0 | 88.5 |

| CH4 | 0 | 28.8 | 0 |

| C2H6 | 0 | 4.8 | 0 |

| C3H8 | 0 | 1.8 | 0 |

| CO2 | 0 | 0 | 98.2 |

| Total mass flow [kg/h] | 1320.7 | 35.3 | 1356 |

| Total mole flow [kmol/h] | 46.1 | 2 | 48.2 |

| Total volume flow [m3/h] | 561.6 | 24.3 | 1154.9 |

| Temperature [°C] | 20 | 20 | 303.3 |

| EX300 | EXHOUT2 | EXOUT | H2OC | H2OF | H2OL | STEAM | |

|---|---|---|---|---|---|---|---|

| Mass Flow by Component [kg/h] | |||||||

| O2 | 156 | 156 | 156 | 0 | 0 | 0 | 0 |

| N2 | 1013.3 | 1013.3 | 1013.3 | 0 | 0 | 0 | 0 |

| H2O | 88.5 | 22.8 | 88.5 | 65.7 | 46.2 | 111.9 | 111.9 |

| CO2 | 98.2 | 98.2 | 98.2 | 0 | 0 | 0 | 0 |

| Total mass flow [kg/h] | 1356 | 1290.3 | 1356 | 65.7 | 46.2 | 111.9 | 111.9 |

| Total mole flow [kmol/h] | 48.2 | 44.5 | 48.2 | 3.7 | 2.6 | 6.2 | 6.2 |

| Total volume flow [m3/h] | 1154.9 | 635.4 | 757.8 | 0.067 | 0.048 | 0.12 | 118.6 |

| Temperature [°C] | 303.3 | 70 | 105.1 | 70 | 25 | 51.2 | 186 |

| Phase ID | HRS Steam Production | Net Steam | Boiler Steam Production |

|---|---|---|---|

| [kWt] | [kWt] | [kWt] | |

| P1 | 3280 | 3287 | - |

| P2 | 3280 | 3596 | - |

| P3 | 3280 | 3708 | - |

| P4 | 3280 | 4568 | - |

| P5 | 3280 | 7143 | - |

| P6 | 2441 | −5597 | 5597 |

| Phase ID | LNG Consumption [kg] | ||||

|---|---|---|---|---|---|

| DF + EGB | SOFC + HRS | BOILER | |||

| W/out SOFC | With SOFC | W/out SOFC | With SOFC | ||

| P1 | 28,081 | 14,873 | 9392 | - | - |

| P2 | 14,427 | 8767 | 4025 | - | - |

| P3 | 5856 | 3969 | 1342 | - | - |

| P4 | 3724 | 2781 | 671 | - | - |

| P5 | 4269 | 3323 | 671 | - | - |

| P6 | 16,741 | 0 | 11,984 | 7150 | 6905 |

| Total P [1,2,3,4,5,6] | 73,099 | 33,713 | 28,086 | 7150 | 6905 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Micoli, L.; Russo, R.; Coppola, T.; Pietra, A. Performance Assessment of the Heat Recovery System of a 12 MW SOFC-Based Generator on Board a Cruise Ship through a 0D Model. Energies 2023, 16, 3334. https://doi.org/10.3390/en16083334

Micoli L, Russo R, Coppola T, Pietra A. Performance Assessment of the Heat Recovery System of a 12 MW SOFC-Based Generator on Board a Cruise Ship through a 0D Model. Energies. 2023; 16(8):3334. https://doi.org/10.3390/en16083334

Chicago/Turabian StyleMicoli, Luca, Roberta Russo, Tommaso Coppola, and Andrea Pietra. 2023. "Performance Assessment of the Heat Recovery System of a 12 MW SOFC-Based Generator on Board a Cruise Ship through a 0D Model" Energies 16, no. 8: 3334. https://doi.org/10.3390/en16083334

APA StyleMicoli, L., Russo, R., Coppola, T., & Pietra, A. (2023). Performance Assessment of the Heat Recovery System of a 12 MW SOFC-Based Generator on Board a Cruise Ship through a 0D Model. Energies, 16(8), 3334. https://doi.org/10.3390/en16083334