Evolution and Prospects of Hydrothermal Carbonization

Abstract

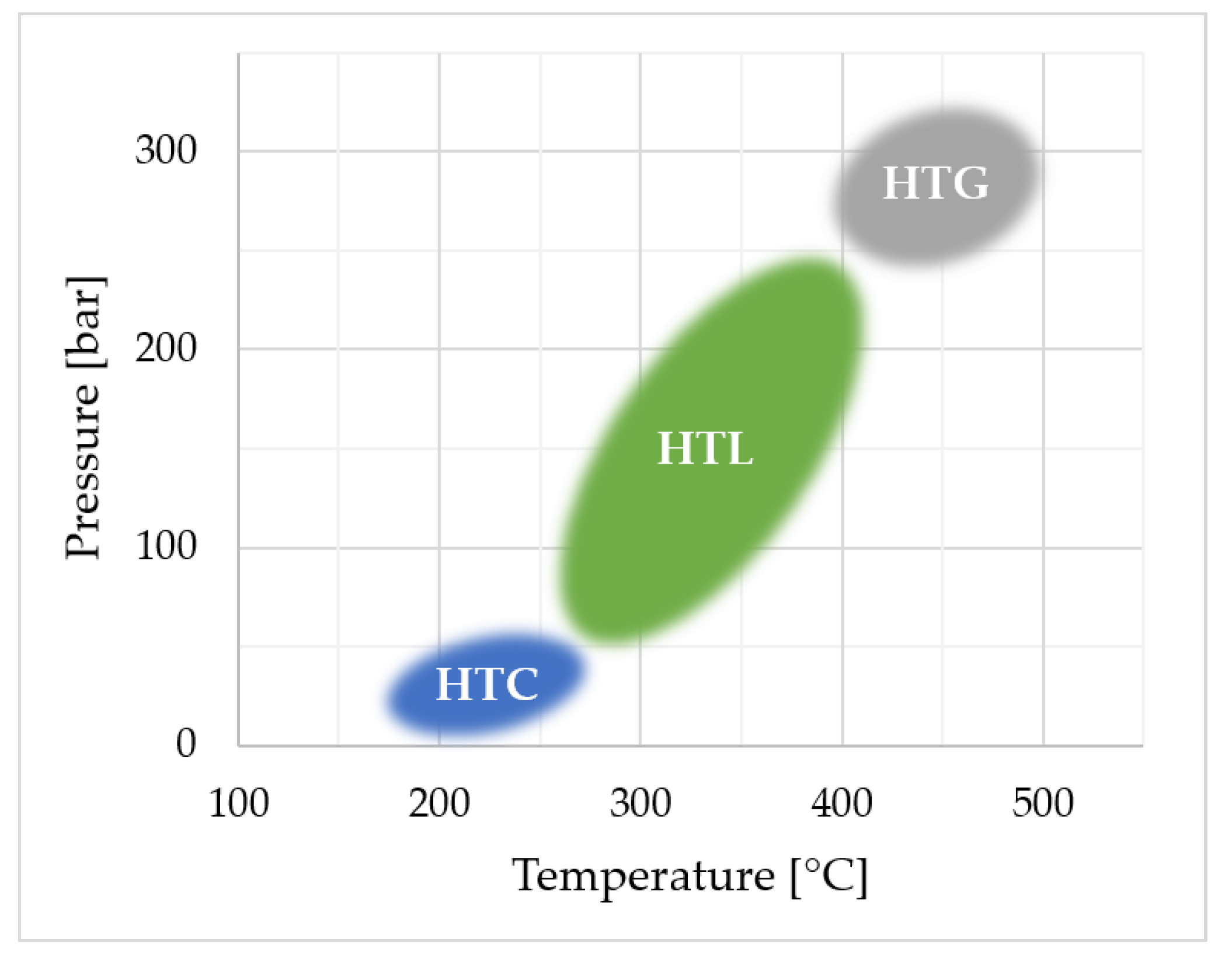

1. Hydrothermal Carbonization Technology

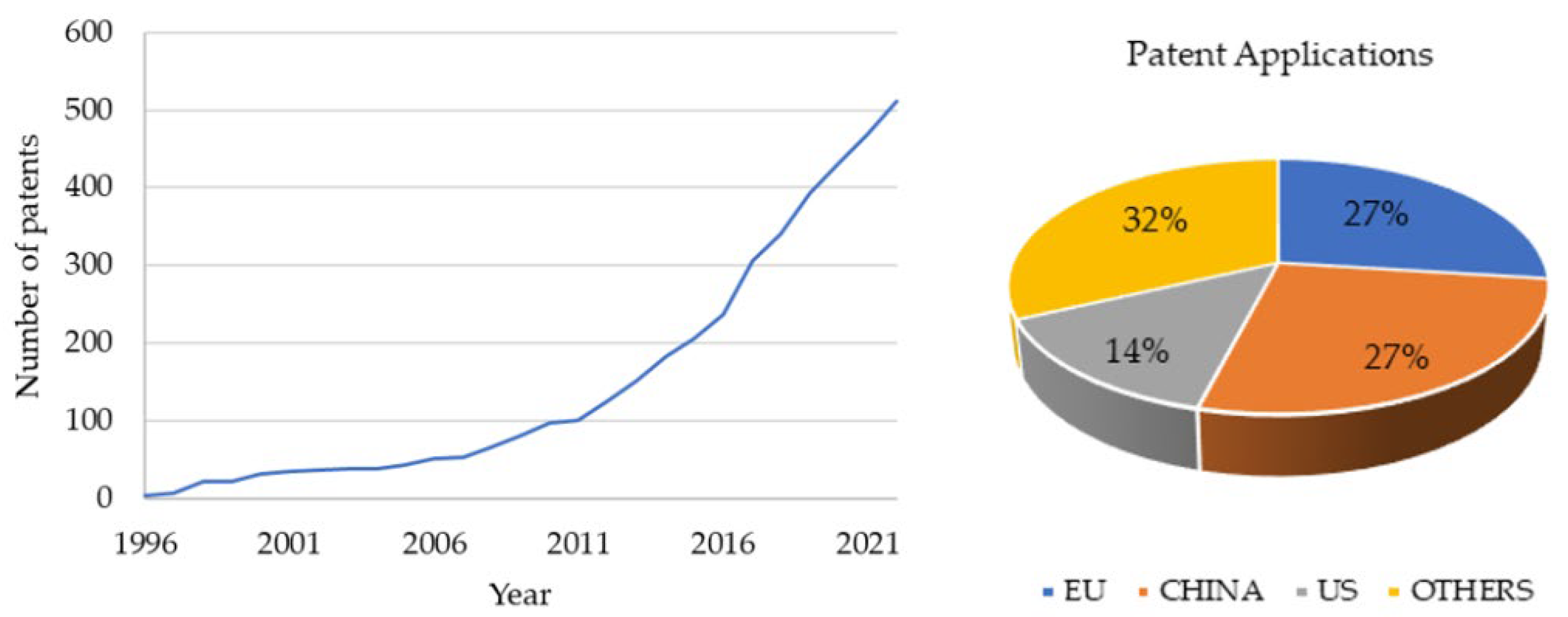

2. Evolution

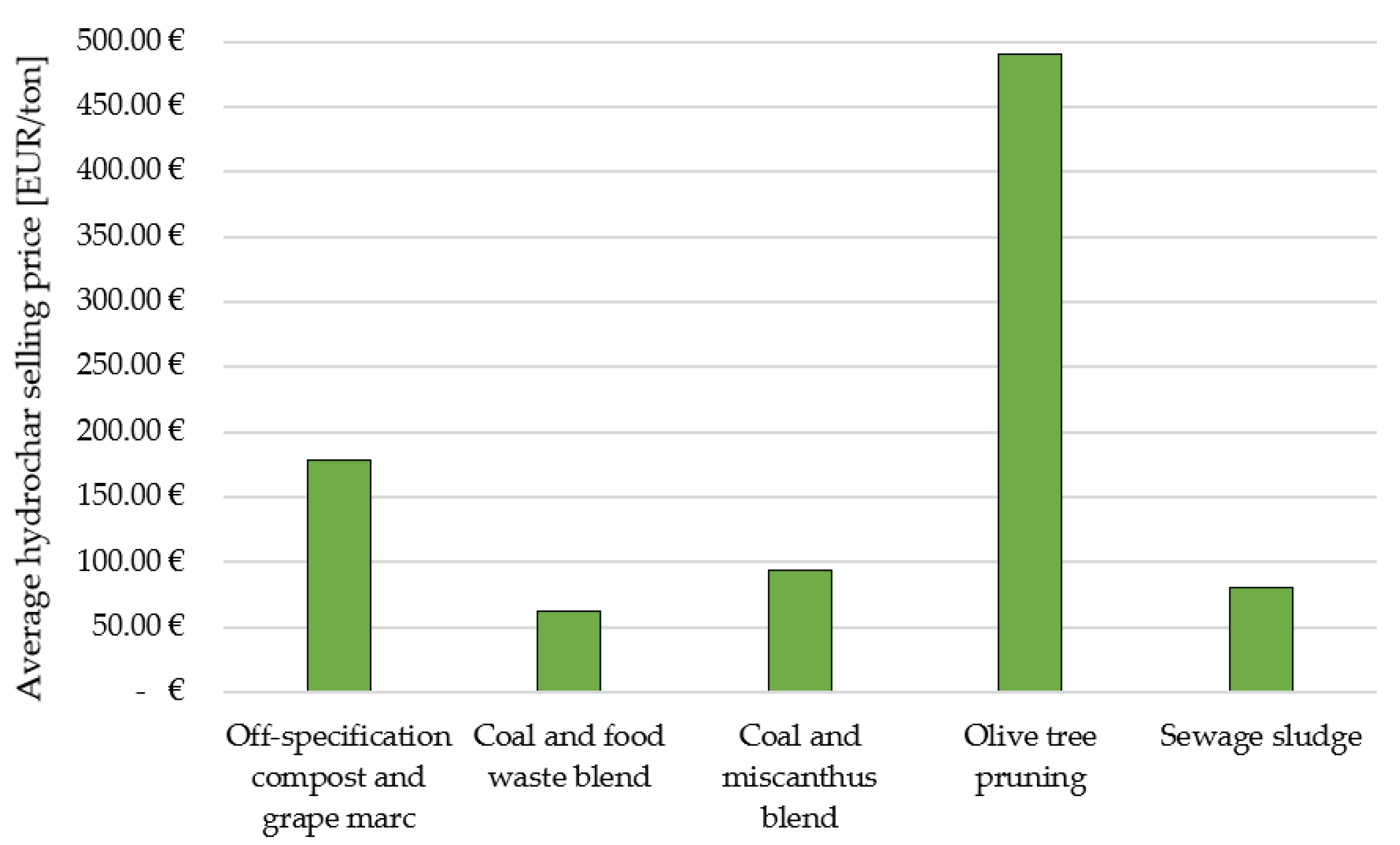

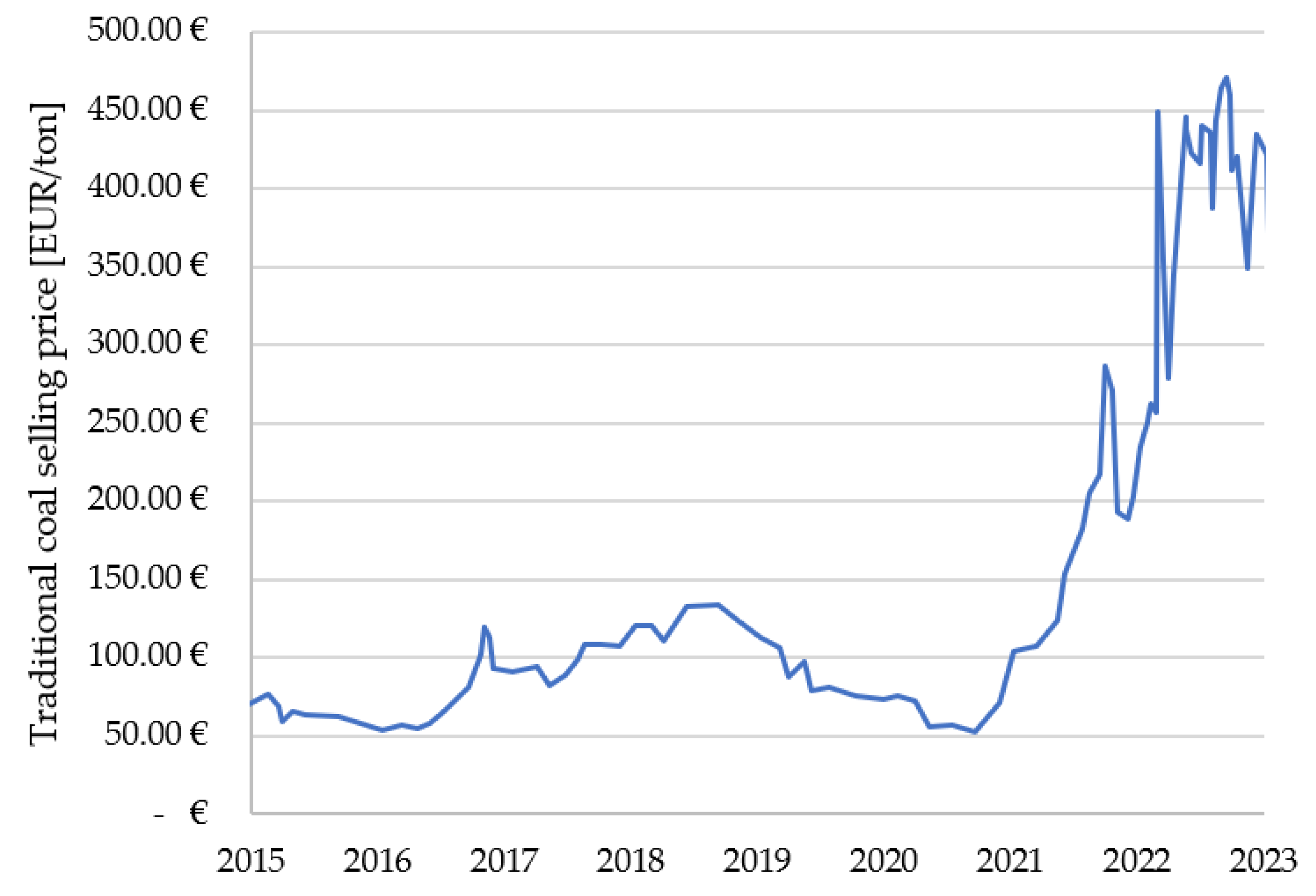

3. Prospects

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- DBFZ Hydrothermal Processes. Available online: https://www.dbfz.de/en/hydrothermal-processes (accessed on 15 January 2023).

- Di Giacomo, G.; Romano, P. Evolution of the Olive Oil Industry along the Entire Production Chain and Related Waste Management. Energies 2022, 15, 465. [Google Scholar] [CrossRef]

- Di Giacomo, G.; Romano, P. Evolution and Prospects in Managing Sewage Sludge Resulting from Municipal Wastewater Purification. Energies 2022, 15, 5633. [Google Scholar] [CrossRef]

- Teribele, T.; Costa, M.E.G.; Da Silva, C.D.M.S.; Pereira, L.M.; Bernar, L.P.; De Castro, D.A.R.; Assunção, F.P.D.C.; Santos, M.C.; Brandão, I.W.D.S.; Fonseca, C.J.N.; et al. Effect of Process Conditions on Hydro-Char Characteristics and Chemical Composition of Aqueous and Gaseous Products by Hydrothermal Processing of Corn Stover with Hot Compressed H2O: Structural Evolution of Hydro-Char and Kinetics of Corn Stover Decomposition. Preprints 2022, 2022110402. [Google Scholar] [CrossRef]

- Islam, M.T.; Sultana, A.I.; Chambers, C.; Saha, S.; Saha, N.; Kirtania, K.; Reza, M.T. Recent Progress on Emerging Applications of Hydrochar. Energies 2022, 15, 9340. [Google Scholar] [CrossRef]

- Román, S.; Libra, J.; Berge, N.; Sabio, E.; Ro, K.; Li, L.; Ledesma, B.; Alvarez, A.; Bae, S. Hydrothermal carbonization: Modeling, final properties design and applications: A review. Energies 2018, 11, 216. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Mubarak, N.M.; Tiripathi, M.; Jayakumar, N.S.; Sahu, J.N.; Ganesan, P. Chemical, dielectric and structural characterization of optimized hydrochar produced from hydrothermal carbonization of palm shell. Fuel 2016, 163, 88–97. [Google Scholar] [CrossRef]

- Masoumi, S.; Borugadda, V.B.; Nanda, S.; Dalai, A.K. Hydrochar: A review on its production technologies and applications. Catalysts 2021, 11, 939. [Google Scholar] [CrossRef]

- Mendoza Martinez, C.L.; Sermyagina, E.; Saari, J.; Silva de Jesus, M.; Cardoso, M.; Matheus de Almeida, G.; Vakkilainen, E. Hydrothermal carbonization of lignocellulosic agro-forest based biomass residues. Biomass Bioenergy 2021, 147, 106004. [Google Scholar] [CrossRef]

- Magdziarz, A.; Wilk, M.; Wądrzyk, M. Pyrolysis of hydrochar derived from biomass—Experimental investigation. Fuel 2020, 267, 117246. [Google Scholar] [CrossRef]

- Sabio, E.; Álvarez-Murillo, A.; Román, S.; Ledesma, B. Conversion of tomato-peel waste into solid fuel by hydrothermal carbonization: Influence of the processing variables. Waste Manag. 2016, 47, 122–132. [Google Scholar] [CrossRef]

- Basso, D.; Patuzzi, F.; Castello, D.; Baratieri, M.; Rada, E.C.; Weiss-Hortala, E.; Fiori, L. Agro-industrial waste to solid biofuel through hydrothermal carbonization. Waste Manag. 2016, 47, 114–121. [Google Scholar] [CrossRef]

- Lucian, M.; Volpe, M.; Gao, L.; Piro, G.; Goldfarb, J.L.; Fiori, L. Impact of hydrothermal carbonization conditions on the formation of hydrochars and secondary chars from the organic fraction of municipal solid waste. Fuel 2018, 233, 257–268. [Google Scholar] [CrossRef]

- Toufiq Reza, M.; Freitas, A.; Yang, X.; Hiibel, S.; Lin, H.; Coronella, C.J. Hydrothermal carbonization (HTC) of cow manure: Carbon and nitrogen distributions in HTC products. Environ. Prog. Sustain. Energy 2016, 35, 1002–1011. [Google Scholar] [CrossRef]

- Bardhan, M.; Novera, T.M.; Tabassum, M.; Islam, M.A.; Islam, M.A.; Hameed, B.H. Co-hydrothermal carbonization of different feedstocks to hydrochar as potential energy for the future world: A review. J. Clean. Prod. 2021, 298, 126734. [Google Scholar] [CrossRef]

- Yoganandham, S.T.; Sathyamoorthy, G.; Renuka, R.R. Emerging extraction techniques: Hydrothermal processing. In Sustainable Seaweed Technologies: Cultivation, Biorefinery, and Applications; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Méndez, A.; Gascó, G.; Ruiz, B.; Fuente, E. Hydrochars from industrial macroalgae “Gelidium Sesquipedale” biomass wastes. Bioresour. Technol. 2019, 275, 386–393. [Google Scholar] [CrossRef]

- Kirtania, K. Thermochemical Conversion Processes for Waste Biorefinery; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780444639929. [Google Scholar]

- Hu, B.; Yu, S.H.; Wang, K.; Liu, L.; Xu, X.W. Functional carbonaceous materials from hydrothermal carbonization of biomass: An effective chemical process. Dalt. Trans. 2008, 40, 5414–5423. [Google Scholar] [CrossRef]

- Sivaprasad, S.; Manandhar, A.; Shah, A. Hydrothermal Carbonization: Upgrading Waste Biomass to Char. Available online: https://ohioline.osu.edu/factsheet/fabe-6622 (accessed on 10 February 2023).

- Xu, Z.; Bai, X. Microplastic Degradation in Sewage Sludge by Hydrothermal Carbonization: Efficiency and Mechanisms. Chemosphere 2022, 297, 134203. [Google Scholar] [CrossRef]

- Alipour, M.; Asadi, H.; Chen, C.; Besalatpour, A.A. Fate of organic pollutants in sewage sludge during thermal treatments: Elimination of PCBs, PAHs, and PPCPs. Fuel 2022, 319, 123864. [Google Scholar] [CrossRef]

- Bergius, F. Die Anwendung Hoher Drucke bei Chemischen Vorgängen und Die Nachbildung des Entstehungsprozesses der Steinkohle; Knapp: Braeside, VIC, Australia, 1913. [Google Scholar]

- Espacenet—Patent Search. Available online: https://worldwide.espacenet.com/ (accessed on 10 January 2023).

- De Mena Pardo, B.; Doyle, L.; Renz, M.; Salimbeni, A. Industrial Scale Hydrothermal Carbonization: New Applications for Wet Biomass Waste; Ttz Bremerhaven: Bremerhaven, Germany, 2016; ISBN 9783000529504. [Google Scholar]

- SwissWater. Available online: https://www.swisswater.ch/en/references/china/jining (accessed on 24 March 2023).

- Buttmann, M. Industrial Scale Plant for Sewage Sludge Treatment by Hydrothermal Carbonization in Jining/China and Phosphate Recovery by Terranova® Ultra Htc Process. Available online: https://conferences.aquaenviro.co.uk/wp-content/uploads/sites/7/2018/04/Marc-Buttmann-final.doc.pdf (accessed on 24 March 2023).

- Proceso Planta de Carbonización Hidrotermal. Available online: https://www.youtube.com/watch?v=CSfytiNxpPg&t=135s (accessed on 23 March 2023).

- Phoenixville’s Wastewater Treatment Plant to Get a First-of-Its-Kind Upgrade. Available online: https://whyy.org/articles/phoenixvilles-wastewater-treatment-plant-to-get-a-first-of-its-kind-upgrade/ (accessed on 24 March 2023).

- Solutions, I.-D.I. Converts Wet Sludge into Clean Bio-Coal. Available online: https://www.innoenergy.com/discover-innovative-solutions/online-marketplace-for-energy-innovations/oxypower-htc/ (accessed on 21 January 2023).

- HTCycle. Available online: https://htcycle.ag/en (accessed on 1 February 2023).

- Ingelia Italia Valencia. Available online: http://www.ingelia.it/portfolio/valencia/ (accessed on 1 February 2023).

- CPL Industries HTC—Hydrothermal Carbonisation. Turning Organic Waste into Renewable Fuels. Available online: https://cplindustries.co.uk/htc-hydrothermal-carbonisation/ (accessed on 5 February 2023).

- Ingelia Italia Piombino. Available online: http://www.ingelia.it/portfolio/piombino/ (accessed on 2 February 2023).

- Ingelia Italia Chiusi. Available online: http://www.ingelia.it/portfolio/chiusi/ (accessed on 1 February 2023).

- Lucian, M.; Fiori, L. Hydrothermal carbonization of waste biomass: Process design, modeling, energy efficiency and cost analysis. Energies 2017, 10, 211. [Google Scholar] [CrossRef]

- Mazumder, S.; Saha, P.; McGaughy, K.; Saba, A.; Reza, M.T. Technoeconomic analysis of co-hydrothermal carbonization of coal waste and food waste. Biomass Convers. Biorefinery 2022, 12, 39–49. [Google Scholar] [CrossRef]

- Saba, A.; McGaughy, K.; Toufiq Reza, M. Techno-economic assessment of co-hydrothermal carbonization of a coal-Miscanthus blend. Energies 2019, 12, 630. [Google Scholar] [CrossRef]

- González-Arias, J.; Baena-Moreno, F.M.; Sánchez, M.E.; Cara-Jiménez, J. Optimizing hydrothermal carbonization of olive tree pruning: A techno-economic analysis based on experimental results. Sci. Total Environ. 2021, 784, 147169. [Google Scholar] [CrossRef]

- Medina-Martos, E.; Istrate, I.R.; Villamil, J.A.; Gálvez-Martos, J.L.; Dufour, J.; Mohedano, Á.F. Techno-economic and life cycle assessment of an integrated hydrothermal carbonization system for sewage sludge. J. Clean. Prod. 2020, 277, 122930. [Google Scholar] [CrossRef]

- González-Arias, J.; Baena-Moreno, F.M.; Gonzalez-Castaño, M.; Arellano-García, H.; Lichtfouse, E.; Zhang, Z. Unprofitability of small biogas plants without subsidies in the Brandenburg region. Environ. Chem. Lett. 2021, 19, 1823–1829. [Google Scholar] [CrossRef]

- González-Arias, J.; Sánchez, M.E.; Cara-Jiménez, J.; Baena-Moreno, F.M.; Zhang, Z. Hydrothermal carbonization of biomass and waste: A review. Environ. Chem. Lett. 2022, 20, 211–221. [Google Scholar] [CrossRef]

- González-Arias, J.; Carnicero, A.; Sánchez, M.E.; Martínez, E.J.; López, R.; Cara-Jiménez, J. Management of off-specification compost by using co-hydrothermal carbonization with olive tree pruning. Assessing energy potential of hydrochar. Waste Manag. 2021, 124, 224–234. [Google Scholar] [CrossRef]

- Trading Economics. Available online: https://tradingeconomics.com/commodity/coal (accessed on 10 February 2023).

- Ciceri, G.; Hernandez Latorre, M.; Kumar Mediboyina, M.; Murphy, F. Hydrothermal Carbonization (HTC): Valorisation of Organic Waste and Sludges for Hydrochar Production of Biofertilizers; Mar Edo, F., Hoffman, B., Johansson, I., Roberts, D., Eds.; IEA: Paris, France, 2021; Available online: https://www.ieabioenergy.com/wp-content/uploads/2021/10/HTC-Valorisation-of-organic-wastes-and-sludges-for-hydrochar-production-and-biofertilizers-Full-Report.pdf (accessed on 10 March 2023).

- Rodriguez, J.J.; Ipiales, R.P.; de la Rubia, M.A.; Diaz, E.; Mohedano, A.F. Integration of hydrothermal carbonization and anaerobic digestion for energy recovery of biomass waste: An overview. Energy Fuels 2021, 35, 17032–17050. [Google Scholar]

- Aragón-Briceño, C.I.; Ross, A.B.; Camargo-Valero, M.A. Mass and energy integration study of hydrothermal carbonization with anaerobic digestion of sewage sludge. Renew. Energy 2021, 167, 473–483. [Google Scholar] [CrossRef]

- Parmar, K.R.; Ross, A.B. Integration of hydrothermal carbonisation with anaerobic digestion; Opportunities for valorisation of digestate. Energies 2019, 12, 1586. [Google Scholar] [CrossRef]

- Ferrentino, R.; Merzari, F.; Fiori, L.; Andreottola, G. Coupling hydrothermal carbonization with anaerobic digestion for sewage sludge treatment: Influence of HTC liquor and hydrochar on biomethane production. Energies 2020, 13, 6262. [Google Scholar] [CrossRef]

- Oliveira, A.S.; Sarrión, A.; Baeza, J.A.; Diaz, E.; Calvo, L.; Mohedano, A.F.; Gilarranz, M.A. Integration of hydrothermal carbonization and aqueous phase reforming for energy recovery from sewage sludge. Chem. Eng. J. 2022, 442, 136301. [Google Scholar] [CrossRef]

- Pérez, C.; Boily, J.F.; Jansson, S.; Gustafsson, T.; Fick, J. Acid-Induced Phosphorus Release from Hydrothermally Carbonized Sewage Sludge. Waste Biomass Valorization 2021, 12, 6555–6568. [Google Scholar] [CrossRef]

- Liu, H.; Hu, G.; Basar, I.A.; Li, J.; Lyczko, N.; Nzihou, A.; Eskicioglu, C. Phosphorus recovery from municipal sludge-derived ash and hydrochar through wet-chemical technology: A review towards sustainable waste management. Chem. Eng. J. 2021, 417, 129300. [Google Scholar] [CrossRef]

- MacDermid-Watts, K.; Pradhan, R.; Dutta, A. Catalytic Hydrothermal Carbonization Treatment of Biomass for Enhanced Activated Carbon: A Review. Waste Biomass Valorization 2021, 12, 2171–2186. [Google Scholar] [CrossRef]

- Wirth, B.; Eberhardt, G.; Lotze-Campen, H.; Erlach, B.; Rolinski, S.; Rothe, P. Hydrothermal Carbonization: Influence of Plant Capacity, Feedstock Choice and Location on Product Costs. In Proceedings of the 19th European Biomass Conference & Exhibition, Berlin, Germany, 6–10 June 2011. [Google Scholar]

| Biomass Type | Operating Conditions | Higher Heating Value (MJ/kg) | Carbon Content (wt%) | Nitrogen Content (wt%) | Applications | Ref. |

|---|---|---|---|---|---|---|

| Agricultural residues | Temperature: 180–250 °C | 17–30 | 40–70 | 0.5–2.5 | Fertilizer, solid fuel, pollutant adsorbent | [7,8] |

| Pressure: 10–30 bar | ||||||

| Residence time: 0.5–2 h | ||||||

| Forest residues | Temperature: 180–240 °C | 17–30 | 45–55 | 0.2–1.5 | Solid fuel, activated carbon, pollutant adsorbent | [9,10] |

| Pressure: 10–30 bar | ||||||

| Residence time: 1–3 h | ||||||

| Agro-industrial residues | Temperature: 180–250 °C | 20–30 | 40–70 | 0.5–2.5 | Solid fuel, pollutant adsorbent, production of bio-oils and biogas | [11,12] |

| Pressure: 10–30 bar | ||||||

| Residence time: 0.5–10 h | ||||||

| Organic fraction of municipal solid waste | Temperature: 120–280 °C | 20–35 | 50–75 | 2–6 | Fertilizer, solid fuel, pollutant adsorbent | [13] |

| Pressure: 10–20 bar | ||||||

| Residence time: 0.5–6 h | ||||||

| Livestock waste (manure, digestate) | Temperature: 180–260 °C | 5–15 | 30–45 | 2–6 | Fertilizer, solid fuel, pollutant adsorbent | [14,15] |

| Pressure: 10–30 bar | ||||||

| Residence time: 0.5–1.5 h | ||||||

| Marine biomass (algae) | Temperature: 180–230 °C | 15–25 | 45–55 | 2–6 | Production of biogas, solid fuel, fertilizer | [16,17] |

| Pressure: 10–30 bar | ||||||

| Residence time: 2–16 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romano, P.; Stampone, N.; Di Giacomo, G. Evolution and Prospects of Hydrothermal Carbonization. Energies 2023, 16, 3125. https://doi.org/10.3390/en16073125

Romano P, Stampone N, Di Giacomo G. Evolution and Prospects of Hydrothermal Carbonization. Energies. 2023; 16(7):3125. https://doi.org/10.3390/en16073125

Chicago/Turabian StyleRomano, Pietro, Nicola Stampone, and Gabriele Di Giacomo. 2023. "Evolution and Prospects of Hydrothermal Carbonization" Energies 16, no. 7: 3125. https://doi.org/10.3390/en16073125

APA StyleRomano, P., Stampone, N., & Di Giacomo, G. (2023). Evolution and Prospects of Hydrothermal Carbonization. Energies, 16(7), 3125. https://doi.org/10.3390/en16073125