An Overview of Geological CO2 Sequestration in Oil and Gas Reservoirs

Abstract

1. Introduction

2. Reservoir Screening and Experimental Investigations for CO2 Sequestration

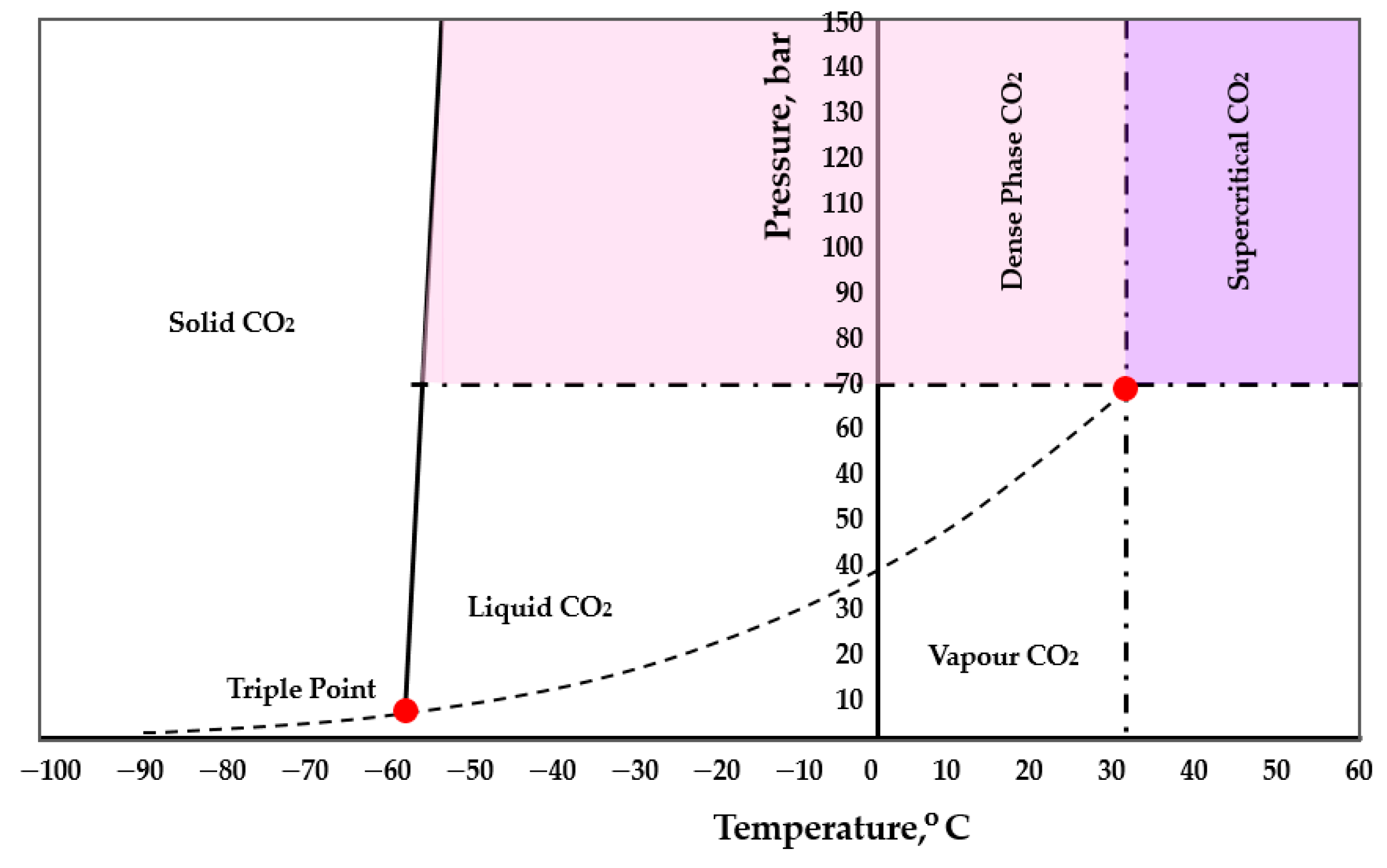

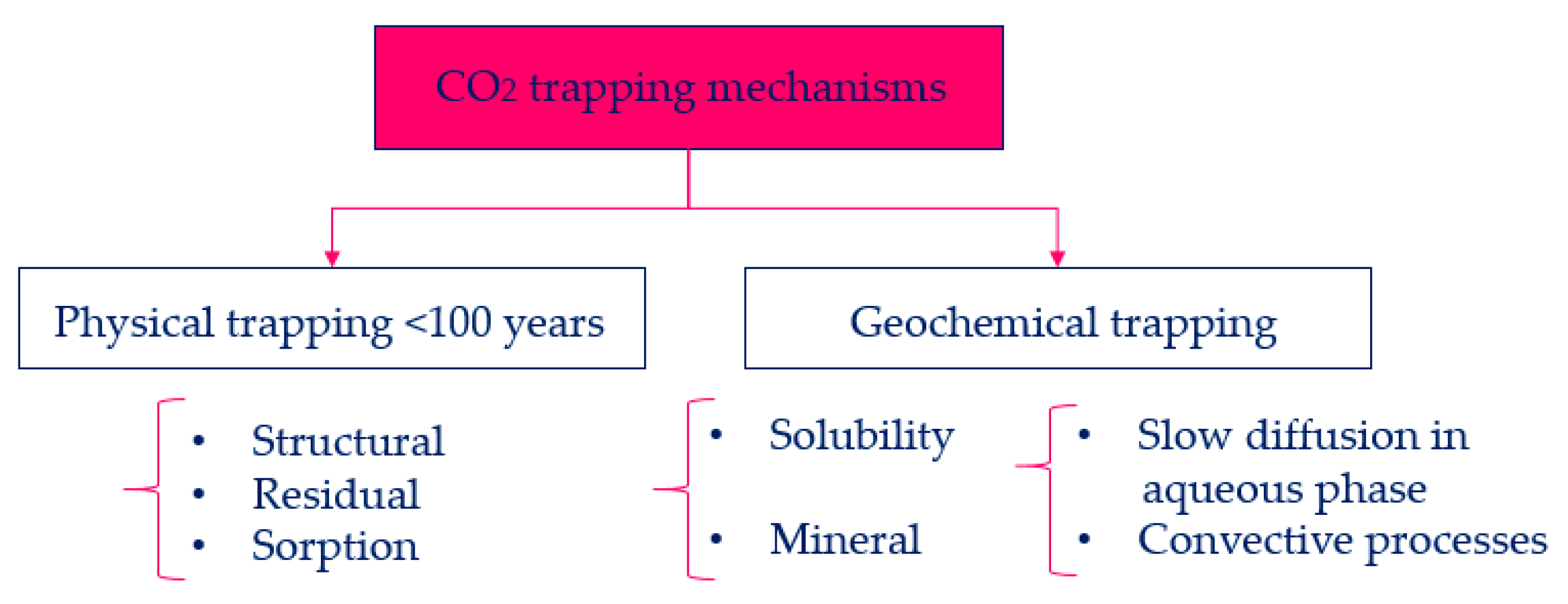

2.1. Preliminary Field Evaluation, Trapping Mechanisms and Control Parameters

- physical/stratigraphical applicability (presence of seal cap rock, logging data, and overall conditions);

- mechanical conditions of the target formations;

- the economic status of the field (calculated potential of storage), infrastructural (logistics and financial), reservoir properties;

- physicochemical interactions for the CO2-rock-fluid system at each step of the CSS process.

- Oil formation

- Gas formationwhere is a recovery factor, is an injected gas fraction, P and T are reservoir pressure and temperature, respectively, while and are injected and produced volumes of water. In case the geometry of the targeted formation should be considered, the authors provide an alternative model:

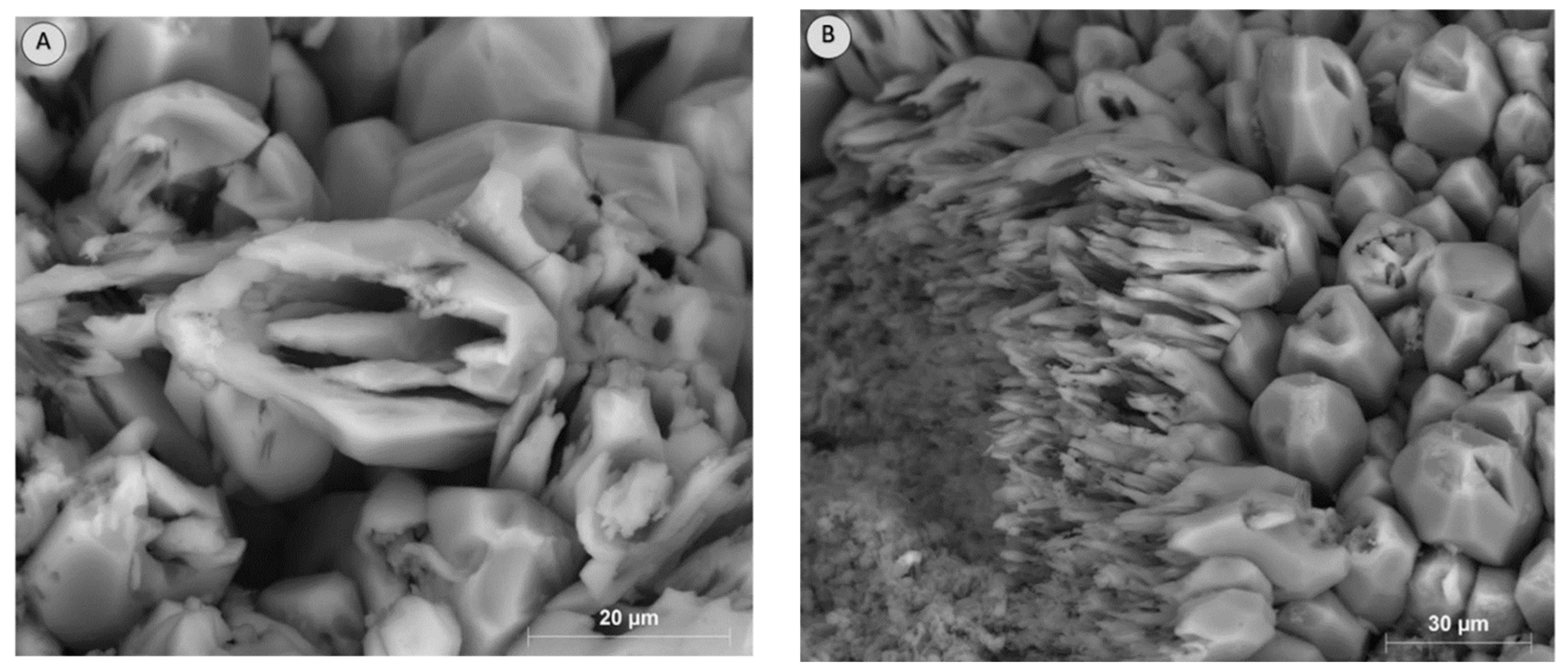

2.2. Physicochemical Interactions in Rock–Fluid–CO2 Systems

2.3. Advanced Laboratory Studies of CO2 Sequestration and Storage in Reservoir

2.4. Risks and Leakage Control

- Geomechanical leakages (caused by reservoir over-pressurization with the formation of cracks in the cap rock or out-of-zone hydraulic fracture or activation of pre-existing faults and fractures);

- Well integrity leakages (annular leak, cement degradation, casing degradation);

- Surface facilities leakages and leakages due to the induced seismicity.

3. Numerical Simulation

3.1. Primary Approaches

3.1.1. Numerical Models Differentiated by Scale

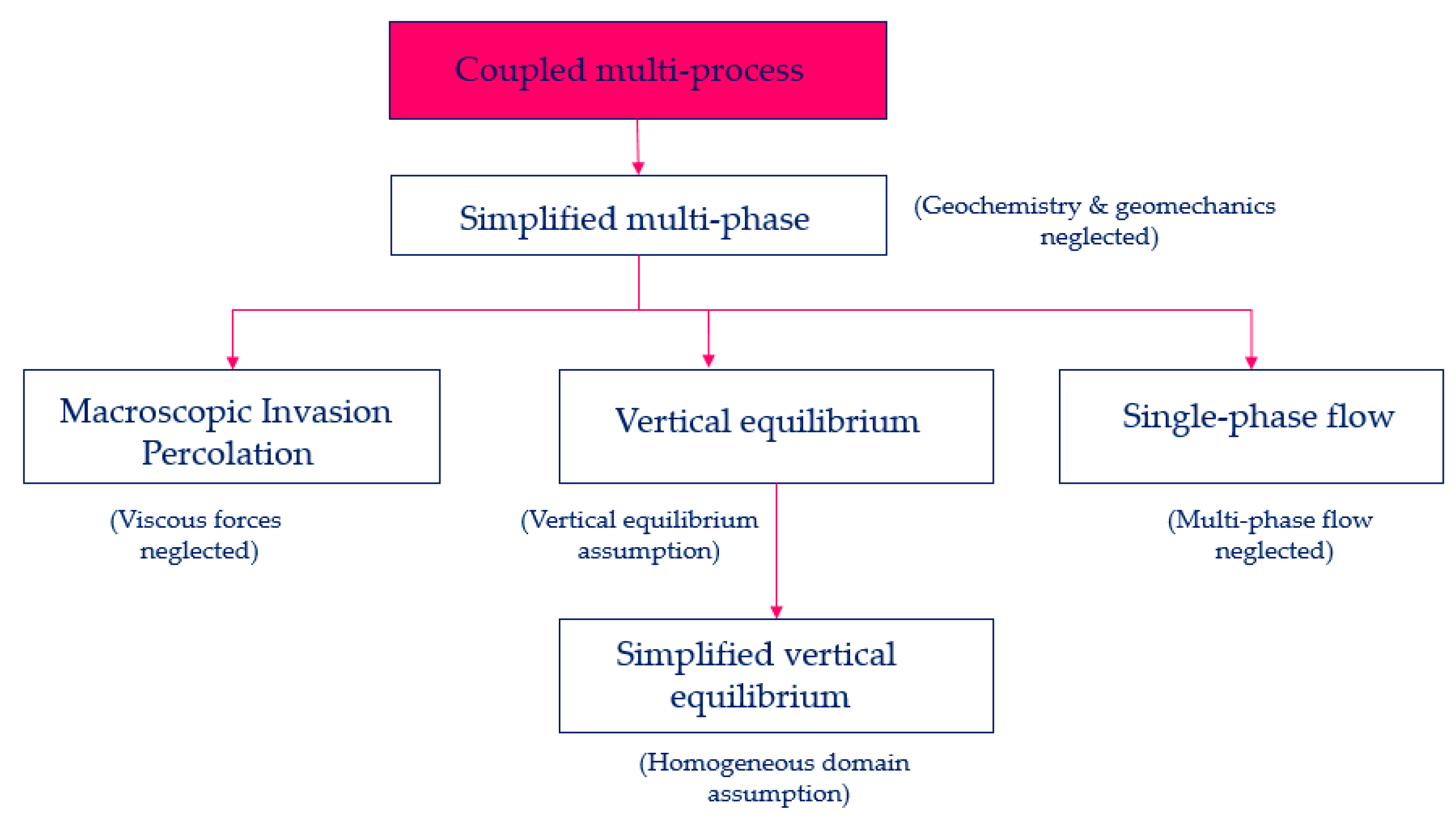

3.1.2. Numerical Models Differentiated by Complexity

3.2. Existing Simulators

3.3. Model Design Considerations and Application Examples

4. Field Projects: Application of Laboratory and Computational Experiments

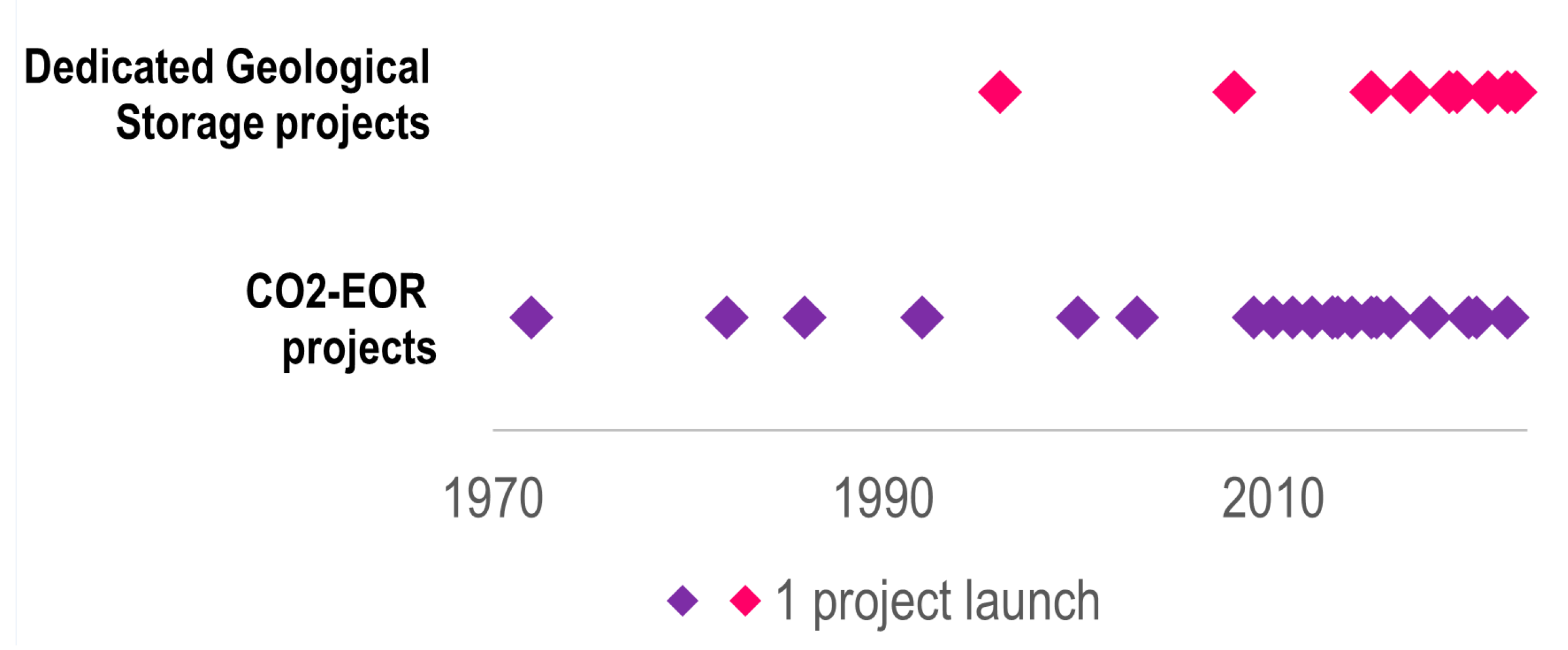

4.1. Potential of Geological CCS and Its History

- the reservoir depth preferably over 1 km;

- cap rock integrity confirmed by retention of hydrocarbons;

- injectivity and capacity of 25–50% more than required by preliminary calculations;

- low heterogeneity of the reservoir;

- low residual water saturation;

- the presence of a nearby/underlying aquifer;

- the presence of active and relatively new infrastructure, well-recorded exploration and production data for the reservoir.

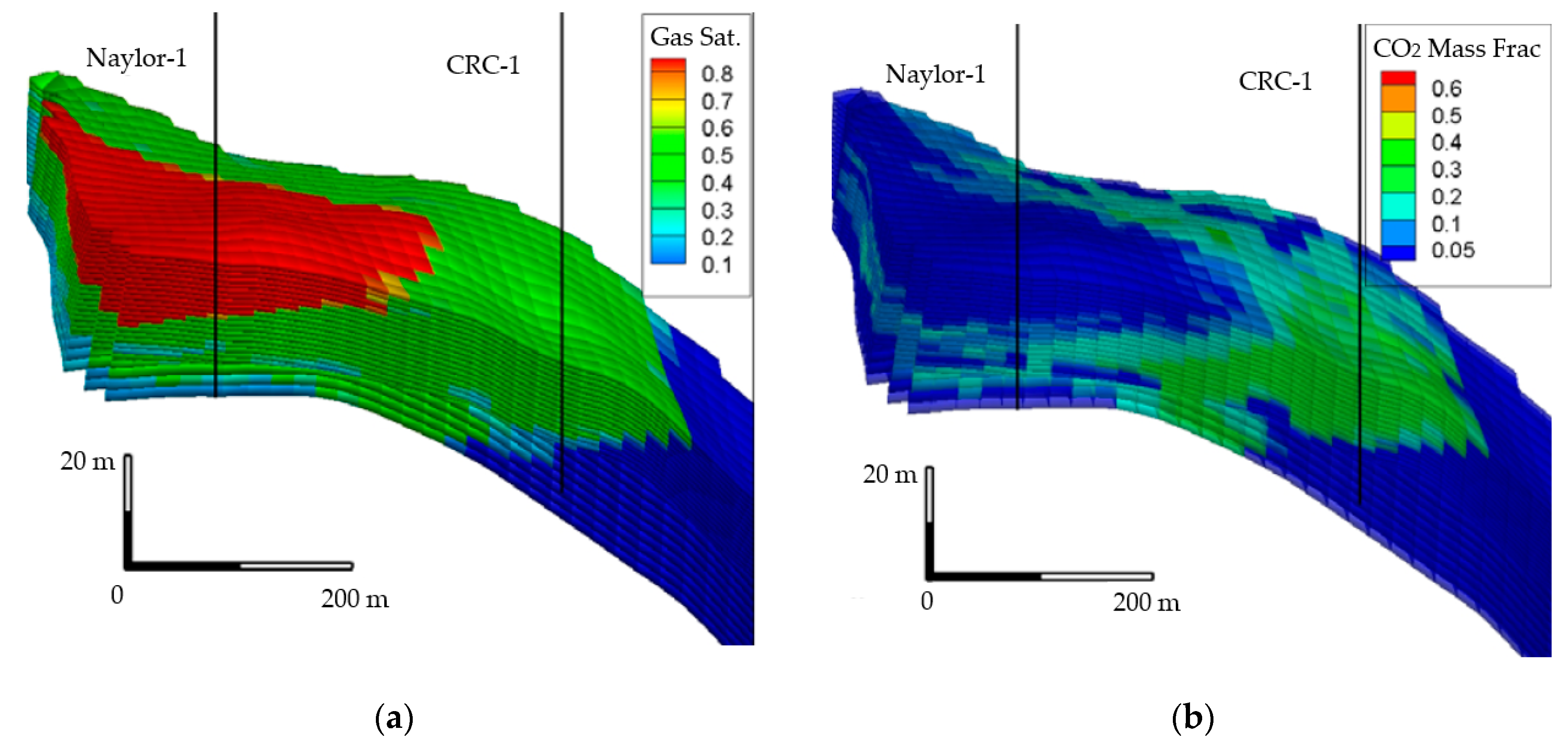

4.2. Selected CCS Field Projects

- CO2 storage capacity of 71 Mt was evaluated;

- most of the CO2 should be maintained at a supercritical state and trapped structurally (>60%);

- the remaining volume was predicted to be dissolved in brine and oil;

- CO2 plumes were likely to be unevenly distributed within the reservoir due to reservoir heterogeneity;

- reservoir and bottom-hole pressures were identified as key parameters in controlling the CO2 flooding performance, channeling, and breakthroughs;

- the near-miscible flooding mode was found to be preferable for storage measures due to the better sweep efficiency;

- the higher injection pressure was associated with increased risk for re-opening of the pre-existing natural fractures in the reservoir, which could lead to changes in the CO2 flow pattern and leakages;

- gas absorption in high permeable zones was found to be greater than in low permeable zones, which could have adverse effects on the sweeping efficiency and the distribution of remaining oil and gas.

5. Summary

- Simulation of field-scale projects in DOGR has several advantages, since these models feature the storage-site characteristics with greater accuracy and have a development history. The history-matching method can increase prediction accuracy and confidence [139].

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| CCS | Carbon capture and storage |

| CO2 | Carbon dioxide |

| CCUS | Carbon capture, use and storage |

| DOGR | Depleted oil and gas reservoirs |

| CCU | Carbon capture and utilization |

| IEA | International Energy Agency |

| EOR | Enhanced oil recovery |

| CMG | Computer modelling group |

| GEM | General equation model |

| EGR | Enhanced gas recovery |

| OOIP | Original oil in place |

| OGIP | Original gas in place |

| DOE | USA Department of Energy |

| CSLF | Carbon Dioxide Sequestration Leadership Forum |

| SEM | Scanning electron microscopy |

| TGA | Thermo-gravimetric analysis |

| XRD | X-ray diffraction |

| HP | High pressure |

| Micro-CT | Micro computed tomography |

| HPHT | High pressure & high temperature |

| EDS | Energy dispersive spectroscopy |

| NMR | Nuclear magnetic resonance |

| LF-NMR | Low-field nuclear magnetic resonance |

| UCS | Unconfined compressive strength |

| AE | Acoustic emission |

| PVT | Pressure, volume, temperature |

| DEM | Discrete element method |

| FEP | Free energy perturbation |

| PENS | Predictive engineering natural systems |

| CFD | Computed fluid dynamics |

| GHG | Greenhouse gas |

| ISC | In situ combustion |

| PDE | Partial differential equation |

| EOS | Equations of state |

References

- Zou, C.; Zhao, Q.; Zhang, G.; Xiong, B. Energy Revolution: From a Fossil Energy Era to a New Energy Era. Nat. Gas Ind. B 2016, 3, 1–11. [Google Scholar] [CrossRef]

- Wang, F.; Harindintwali, J.D.; Yuan, Z.; Wang, M.; Wang, F.; Li, S.; Yin, Z.; Huang, L.; Fu, Y.; Li, L.; et al. Technologies and Perspectives for Achieving Carbon Neutrality. Innovation 2021, 2, 100180. [Google Scholar] [CrossRef] [PubMed]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Sustainable Energy Transition for Renewable and Low Carbon Grid Electricity Generation and Supply. Front. Energy Res. 2022, 9, 1032. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2022; IEA: Paris, France, 2022. [Google Scholar]

- Zhang, S.; Chen, W. Assessing the Energy Transition in China towards Carbon Neutrality with a Probabilistic Framework. Nat. Commun. 2022, 13, 87. [Google Scholar] [CrossRef]

- Meckling, J.; Lipscy, P.Y.; Finnegan, J.J.; Metz, F. Why Nations Lead or Lag in Energy Transitions. Science 2022, 378, 31–33. [Google Scholar] [CrossRef]

- Babayomi, O.O.; Dahoro, D.A.; Zhang, Z. Affordable Clean Energy Transition in Developing Countries: Pathways and Technologies. iScience 2022, 25, 104178. [Google Scholar] [CrossRef] [PubMed]

- Turner, J.M. The Matter of a Clean Energy Future. Science 2022, 376, 1361. [Google Scholar] [CrossRef]

- Shin, L. Renewable Energy: The Clean Facts; NRDC: New York, NY, USA, 2018; pp. 1–2. [Google Scholar]

- Mitrova, T.; Melnikov, Y.; Chugunov, D.; Glagoleva, A. Hydrogen Economy—Path to the Low-Carbon Development; Skolkovo: Moscow, Russia, 2019. [Google Scholar]

- IEA. The Future of Fuel: The Future of Hydrogen; IEA: Paris, France, 2019. [Google Scholar]

- Iskhakov, R. High-Resolution Numerical Simulation of CO2 Sequestration in Saline Aquifers. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 2013. [Google Scholar]

- Jiang, X. A Review of Physical Modelling and Numerical Simulation of Long-Term Geological Storage of 2. Appl. Energy 2011, 88, 3557–3566. [Google Scholar] [CrossRef]

- Zhao, B.; MacMinn, C.W.; Juanes, R. Residual Trapping, Solubility Trapping and Capillary Pinning Complement Each Other to Limit CO2 Migration in Deep Saline Aquifers. Energy Procedia 2014, 63, 3833–3839. [Google Scholar] [CrossRef]

- Akai, T.; Kuriyama, T.; Kato, S.; Okabe, H. Numerical Modelling of Long-Term CO2 Storage Mechanisms in Saline Aquifers Using the Sleipner Benchmark Dataset. Int. J. Greenh. Gas Control 2021, 110, 103405. [Google Scholar] [CrossRef]

- Kano, Y.; Ishido, T. Numerical Simulation on the Long-Term Behavior of CO2 Injected into a Deep Saline Aquifer Composed of Alternating Layers. Energy Procedia 2011, 4, 4339–4346. [Google Scholar] [CrossRef]

- Celia, M.A.; Bachu, S.; Nordbotten, J.M.; Bandilla, K.W. Status of CO2 Storage in Deep Saline Aquifers with Emphasis on Modeling Approaches and Practical Simulations. Water Resour. Res. 2015, 51, 6846–6892. [Google Scholar] [CrossRef]

- Rackley, S.A. 14—Geochemical and Biogeochemical Features, Events, and Processes, 2nd ed.; Rackley, S.A., Ed.; Butterworth-Heinemann: Boston, MA, USA, 2017; pp. 365–386. ISBN 978-0-12-812041-5. [Google Scholar]

- Hamza, A.; Hussein, I.A.; Al-Marri, M.J.; Mahmoud, M.; Shawabkeh, R.; Aparicio, S. CO2 Enhanced Gas Recovery and Sequestration in Depleted Gas Reservoirs: A Review. J. Pet. Sci. Eng. 2021, 196, 107685. [Google Scholar] [CrossRef]

- Van Der Meer, B. Carbon Dioxide Storage in Natural Gas Reservoir. Oil Gas Sci. Technol. 2005, 60, 527–536. [Google Scholar] [CrossRef]

- Hawkes, C.D.; McLellan, P.J.; Zimmer, U.; Bachu, S. Geomechanical Factors Affecting Geological Storage of CO2 in Depleted Oil and Gas Reservoirs. In Proceedings of the 2004 Canadian International Petroleum Conference, Calgary, AB, Canada, 7–9 June 2004. PETSOC-2004-258. [Google Scholar]

- Sun, Q.; Ampomah, W.; Junior, E.; Appold, M.; Adu-gyamfi, B.; Dai, Z.; Reza, M. Assessment of CO2 Trapping Mechanisms in Partially Depleted Oil-Bearing Sands. Fuel 2020, 278, 118356. [Google Scholar] [CrossRef]

- Shukla, R.; Ranjith, P.; Haque, A.; Choi, X. A Review of Studies on CO2 Sequestration and Caprock Integrity. Fuel 2010, 89, 2651–2664. [Google Scholar] [CrossRef]

- Ajayi, T.; Salgado, J.; Achinta, G. A Review of CO2 Storage in Geological Formations Emphasizing Modeling, Monitoring and Capacity Estimation Approaches. Pet. Sci. 2019, 16, 1028–1063. [Google Scholar] [CrossRef]

- Ali, M.; Kumar, N.; Pal, N.; Keshavarz, A.; Hoteit, H. Recent Advances in Carbon Dioxide Geological Storage, Experimental Procedures, Influencing Parameters, and Future Outlook. Earth-Sci. Rev. 2022, 225, 103895. [Google Scholar] [CrossRef]

- Li, L.; Zhang, X.; Liu, J.; Xie, Q.; Zhou, X.; Zheng, J.; Su, Y. Research Progress and Prospect of Carbon Dioxide Utilization and Storage Based on Unconventional Oil and Gas Development. Energies 2022, 15, 9383. [Google Scholar] [CrossRef]

- Raza, A.; Gholami, R.; Rezaee, R.; Bing, C.H.; Nagarajan, R.; Hamid, M.A. Preliminary Assessment of CO2 Injectivity in Carbonate Storage Sites. Petroleum 2017, 3, 144–154. [Google Scholar] [CrossRef]

- Raza, A.; Gholami, R.; Rezaee, R.; Bing, C.H.; Nagarajan, R.; Hamid, M.A. CO2 Storage in Depleted Gas Reservoirs: A Study on the Effect of Residual Gas Saturation. Petroleum 2018, 4, 95–107. [Google Scholar] [CrossRef]

- Ranganathan, P.; Van Hemert, P.; Rudolph, E.S.J.; Zitha, P.Z.J. Numerical Modeling of CO2 Mineralisation during Storage in Deep Saline Aquifers. Energy Procedia 2011, 4, 4538–4545. [Google Scholar] [CrossRef]

- Al Hameli, F.; Belhaj, H.; Dhuhoori, M. Al CO2 Sequestration Overview in Geological Formations: Trapping Mechanisms Matrix Assessment. Energies 2022, 15, 7805. [Google Scholar] [CrossRef]

- Kalantari-Dahaghi, A. Numerical Simulation and Modeling of Enhanced Gas Recovery and CO2 Sequestration in Shale Gas Reservoirs: A Feasibility Study. In Proceedings of the SPE International Conference on CO2 Capture, Storage, and Utilization, New Orleans, LA, USA, 10–12 November 2010; pp. 533–550. [Google Scholar] [CrossRef]

- Pruess, K.; Nordbotten, J.M. Numerical Simulation Studies of the Long-Term Evolution of a CO2 Plume in a Saline Aquifer with a Sloping Caprock. Transp. Porous Media 2011, 90, 135–151. [Google Scholar] [CrossRef]

- Xu, T.; Pruess, K. Multiphase Fluid Flow and Subsequent Geochemical Transport in Variably Saturated Fractured Rocks: 1. Approaches; University of California: Berkeley, CA, USA, 1998. [Google Scholar]

- Pruess, K.; Xu, T.; Apps, J.A.; Garcia, J.E. Numerical Modeling of Aquifer Disposal of CO2. SPE J. 2001, 8, 49–60. [Google Scholar] [CrossRef]

- Sun, Y.; Lin, R.; Pan, Y.; Sun, L.; Tang, Y. Experimental Analysis and Numerical Simulation of the Stability of Geological Storage of CO2: A Case Study of Transforming a Depleted Gas Reservoir into a Carbon Sink Carrier. ACS Omega 2021, 6, 34832–34841. [Google Scholar] [CrossRef]

- Li, G. Numerical Investigation of CO2 Storage in Hydrocarbon Field Using a Geomechanical-Fluid Coupling Model. Petroleum 2016, 2, 252–257. [Google Scholar] [CrossRef]

- Sharma, P.; Ghosh, S.; Tandon, A. Study of CO2 Injection in a Depleted Oil Reservoir Using Geomechanically Coupled and Non-Coupled Simulation Models. Mater. Today Proc. 2022, 57, 1805–1812. [Google Scholar] [CrossRef]

- Raza, A.; Gholami, R.; Rezaee, R.; Rasouli, V.; Bhatti, A.A.; Bing, C.H. Suitability of Depleted Gas Reservoirs for Geological CO2 Storage: A Simulation Study. Greenh. Gases Sci. Technol. 2018, 8, 876–897. [Google Scholar] [CrossRef]

- Kopp, A.; Binning, P.J.; Johannsen, K.; Helmig, R.; Class, H. A Contribution to Risk Analysis for Leakage through Abandoned Wells in Geological CO2 Storage. Adv. Water Resour. 2010, 33, 867–879. [Google Scholar] [CrossRef]

- Akai, T.; Saito, N.; Hiyama, M.; Okabe, H. Numerical Modelling on CO2 Storage Capacity in Depleted Gas Reservoirs. Energies 2021, 14, 3978. [Google Scholar] [CrossRef]

- Lei, H.; Zhang, Q.; Li, X. Preliminary Numerical Modeling of CO2 Geological Storage in the Huangcaoxia Gas Reservoir in the Eastern Sichuan Basin, China. Geofluids 2019, 2019, 9545723. [Google Scholar] [CrossRef]

- Ren, B.; Ren, S.; Zhang, L.; Chen, G.; Zhang, H. Monitoring on CO2 Migration in a Tight Oil Reservoir during CCS-EOR in Jilin Oilfield China. Energy 2016, 98, 108–121. [Google Scholar] [CrossRef]

- Spence, B.; Horan, D.; Tucker, O. The Peterhead-Goldeneye Gas Post-Combustion CCS Project. Energy Procedia 2014, 63, 6258–6266. [Google Scholar] [CrossRef]

- Hannis, S.; Lu, J.; Chadwick, A.; Hovorka, S.; Kirk, K.; Pearce, J. CO2 Storage in Depleted or Depleting Oil and Gas Fields: What Can We Learn from Existing Projects? Energy Procedia 2017, 114, 5680–5690. [Google Scholar] [CrossRef]

- IEAGHG. Criteria for Depleted Reservoirs to Be Developed for CO2 Storage; IEAGHG: Cheltenham, UK, 2022. [Google Scholar]

- The Global CCS Institute. Global Status of CCS 2022; Global CCS Institute: Melbourne, VIC, Australia, 2022. [Google Scholar]

- Thibeau, S.; Chiquet, P.; Prinet, C.; Lescanne, M. Lacq-Rousse CO2 Capture and Storage Demonstration Pilot: Lessons Learnt from Reservoir Modelling Studies. Energy Procedia 2013, 37, 6306–6316. [Google Scholar] [CrossRef]

- IEAGHG. Case Studies of CO2 Storage in Depleted Oil and Gas Fields; IEAGHG: Cheltenham, UK, 2017. [Google Scholar]

- Total. Carbon Capture and Storage: The Lacq Pilot. Project and Injection Period 2006–2013; Global CCS Institute: Melbourne, VIC, Australia, 2015. [Google Scholar]

- Bachu, S. Identification of Oil Reservoirs Suitable for CO2-EOR and CO2 Storage (CCUS) Using Reserves Databases, with Application to Alberta, Canada. Int. J. Greenh. Gas Control 2016, 44, 152–165. [Google Scholar] [CrossRef]

- Bachu, S.; Bonijoly, D.; Bradshaw, J.; Burruss, R.; Holloway, S.; Christensen, N.P.; Mathiassen, O.M. CO2 Storage Capacity Estimation: Methodology and Gaps. Int. J. Greenh. Gas Control 2007, 1, 430–443. [Google Scholar] [CrossRef]

- Jiang, J.; Rui, Z.; Hazlett, R.; Lu, J. An Integrated Technical-Economic Model for Evaluating CO2 Enhanced Oil Recovery Development. Appl. Energy 2019, 247, 190–211. [Google Scholar] [CrossRef]

- Afanasev, P.; Popov, E.; Cheremisin, A.; Berenblyum, R.; Mikitin, E.; Sorokin, E.; Borisenko, A.; Darishchev, V.; Shchekoldin, K.; Slavkina, O. An Experimental Study of the Possibility of In Situ Hydrogen Generation within Gas Reservoirs. Energies 2021, 14, 5121. [Google Scholar] [CrossRef]

- Kapadia, P.R.; Kallos, M.S.; Leskiw, C.; Gates, I.D. Potential for Hydrogen Generation during In Situ Combustion of Bitumen; SPE 122028. In Proceedings of the SPE EUROPEC/EAGE Annual Conference and Exhibition, Amsterdam, The Netherlands, 8–11 June 2009; pp. 1–14. [Google Scholar]

- Rui, Y.; Zhu, B.; Tang, Q.; Yang, C.; Wang, D.; Pu, W.; Tang, X. Experimental Study of the Feasibility of In Situ Hydrogen Generation from Gas Reservoir. Energies 2022, 15, 8185. [Google Scholar] [CrossRef]

- Askarova, A.; Afanasev, P.; Popov, E.; Mikitin, E.; Darishchev, V. Application of Oil in Situ Combustion for the Catalytic Methane Conversion in the Porous Medium of the Gas Reservoir. J. Pet. Sci. Eng. 2023, 220, 111256. [Google Scholar] [CrossRef]

- Bachu, S. Screening and Ranking of Sedimentary Basins for Sequestration of CO2 in Geological Media in Response to Climate Change. Environ. Geol. 2003, 44, 277–289. [Google Scholar] [CrossRef]

- Thibeau, S.; Mucha, V. Have We Overestimated Saline Aquifer CO2 Storage Capacities? Oil Gas Sci. Technol.–Rev. IFP Energ. Nouv. 2011, 66, 81–92. [Google Scholar] [CrossRef]

- Gholami, R.; Raza, A.; Iglauer, S. Leakage Risk Assessment of a CO2 Storage Site: A Review. Earth-Sci. Rev. 2021, 223, 103849. [Google Scholar] [CrossRef]

- Liebscher, A.; Möller, F.; Bannach, A.; Köhler, S.; Wiebach, J.; Schmidt-Hattenberger, C.; Weiner, M.; Pretschner, C.; Ebert, K.; Zemke, J. Injection Operation and Operational Pressure–Temperature Monitoring at the CO2 Storage Pilot Site Ketzin, Germany—Design, Results, Recommendations. Int. J. Greenh. Gas Control 2013, 15, 163–173. [Google Scholar] [CrossRef]

- Asghari, K.; Al-Dliwe, A.; Mahinpey, N. Effect of Operational Parameters on Carbon Dioxide Storage Capacity in a Heterogeneous Oil Reservoir: A Case Study. Ind. Eng. Chem. Res. 2006, 45, 2452–2456. [Google Scholar] [CrossRef]

- Goodman, A.; Hakala, A.; Bromhal, G.; Deel, D.; Rodosta, T.; Frailey, S.; Small, M.; Allen, D.; Romanov, V.; Fazio, J.; et al. U.S. DOE Methodology for the Development of Geologic Storage Potential for Carbon Dioxide at the National and Regional Scale. Int. J. Greenh. Gas Control 2011, 5, 952–965. [Google Scholar] [CrossRef]

- El-Suleiman, A.; Anosike, N.B.; Pilidis, P. A Preliminary Assessment of the Initial Compression Power Requirement in CO2 Pipeline “Carbon Capture and Storage (CCS) Technologies. Technologies 2016, 4, 15. [Google Scholar] [CrossRef]

- Raza, A.; Rezaee, R.; Gholami, R.; Han, C.; Nagarajan, R.; Ali, M. A Screening Criterion for Selection of Suitable CO2 Storage Sites. J. Nat. Gas Sci. Eng. 2016, 28, 317–327. [Google Scholar] [CrossRef]

- Rani, S.; Padmanabhan, E.; Prusty, B.K. Review of Gas Adsorption in Shales for Enhanced Methane Recovery and CO2 Storage. J. Pet. Sci. Eng. 2019, 175, 634–643. [Google Scholar] [CrossRef]

- Ding, S.; Xi, Y.; Jiang, H.; Liu, G. CO2 Storage Capacity Estimation in Oil Reservoirs by Solubility and Mineral Trapping. Appl. Geochem. 2018, 89, 121–128. [Google Scholar] [CrossRef]

- Yekeen, N.; Padmanabhan, E.; Sevoo, T.A.L.; Kanesen, K.A.L.; Adenike, O. Wettability of Rock/CO2/Brine Systems: A Critical Review of Influencing Parameters and Recent Advances. J. Ind. Eng. Chem. 2020, 88, 1–28. [Google Scholar] [CrossRef]

- Busch, A.; Gensterblum, Y. CBM and CO2-ECBM Related Sorption Processes in Coal: A Review. Int. J. Coal Geol. 2011, 87, 49–71. [Google Scholar] [CrossRef]

- Li, F.; Diao, H.; Li, W. Mineral Trapping of CO2: Hydrothermal Experimental System and Thermodynamic Simulation on Interaction between CO2–H2O–Dawsonite Bearing Sandstone with the PH of 4–9, Temperature of 80–140 °C, and Increasing pCO2. Mar. Pet. Geol. 2020, 111, 588–602. [Google Scholar] [CrossRef]

- Liu, Q.; Maroto-valer, M.M. Investigation of the PH Effect of a Typical Host Rock and Buffer Solution on CO2 Sequestration in Synthetic Brines. Fuel Process. Technol. 2010, 91, 1321–1329. [Google Scholar] [CrossRef]

- Prakash, R.; Kana Nguene, P.; Seers, T.D.; Noshadravan, A.; Abedi, S. Chemo-Mechanical Investigation of CO2-Fluid-Rock Interaction in CO2 Storage and CO2-EOR Processes in Unconventional Reservoirs. In Proceedings of the 53rd US Rock Mechanics/Geomechanics Symposium (ARMA-2019-1983), New York, NY, USA, 23–26 June 2019. [Google Scholar]

- Herrera, C.A.C.; Stevens, G.W.; Haese, R.R. Review of CO2 Leakage Mitigation and Remediation Technologies. In Geological Carbon Storage: Subsurface Seals and Caprock Integrity, 1st ed.; Vialle, S., AjoFranklin, J., Carey, J., Eds.; Wiley Online Library: New York, NY, USA, 2019; pp. 327–337. [Google Scholar]

- Zemke, K.; Liebscher, A. Petrophysical Characterization of in Situ Cores after CO2 Injection and Comparison with Batch Experiments of the German Ketzin Pilot Site. Energy Procedia 2017, 114, 2871–2879. [Google Scholar] [CrossRef]

- Shao, Q.; Boon, M.; Youssef, A.; Kurtev, K.; Benson, S.M.; Matthai, K. Modelling CO2 Plume Spreading in Highly Heterogeneous Rocks with Anisotropic, Rate-Dependent Saturation Functions: A Field-Data Based Numeric Simulation Study of Otway. Int. J. Greenh. Gas Control 2022, 119, 103699. [Google Scholar] [CrossRef]

- Pourmalek, A.; Newell, A.; Shariatipour, S.M.; Wood, A. The Impact of Heterogeneous Mixed Siliciclastic–Carbonate Systems on CO2 Geological Storage. Pet. Geosci. Geol. Soc. 2022, 28, petgeo2020-086. [Google Scholar] [CrossRef]

- Hovorka, S.D.; Doughty, C.; Benson, S.; Pruess, K.; Knox, R. The Impact of Geological Heterogeneity on CO2 Storage in Brine Formations: A Case Study from the Texas Gulf Coast. Geol. Storage Carbon Dioxide. Geol. Soc. London Spec. Publ. 2004, 233, 147–163. [Google Scholar] [CrossRef]

- Ambrose, W.; Lakshminarasimhan, S.; Holtz, M.; Nunez-Lopez, V.; Hovorka, S.D.; Duncan, I. Geologic Factors Controlling CO2 Storage Capacity and Permanence: Case Studies Based on Experience with Heterogeneity in Oil and Gas Reservoirs Applied to CO2 Storage. Environ. Geol. 2008, 54, 1619–1633. [Google Scholar] [CrossRef]

- Yin, H.; Zhou, J.; Xian, X.; Jiang, Y.; Lu, Z.; Tan, J.; Liu, G. Experimental Study of the Effects of Sub- and Super-Critical CO2 Saturation on the Mechanical Characteristics of Organic-Rich Shales. Energy 2017, 132, 84–95. [Google Scholar] [CrossRef]

- Harvey, O.R.; Qafoku, N.P.; Cantrell, K.J.; Lee, G.; Amonette, J.E.; Brown, C.F. Geochemical Implications of Gas Leakage Associated with Geologic CO2 Storage—A Qualitative Review. Environ. Sci. Technol. 2013, 47, 23–36. [Google Scholar] [CrossRef] [PubMed]

- Seyyedi, M.; Khaled, H.; Mahmud, B.; Verrall, M.; Giwelli, A.; Esteban, L.; Ghasemiziarani, M.; Clennell, B. Pore Structure Changes Occur During CO2 Injection into Carbonate Reservoirs. Sci. Rep. 2020, 10, 3624. [Google Scholar] [CrossRef]

- Hughes, T.J.; Honari, A.; Graham, B.F.; Chauhan, A.S.; Johns, M.L.; May, E.F. CO2 Sequestration for Enhanced Gas Recovery: New Measurements of Supercritical CO2-CH4 Dispersion in Porous Media and a Review of Recent Research. Int. J. Greenh. Gas Control 2012, 9, 457–468. [Google Scholar] [CrossRef]

- Hui, D.; Pan, Y.; Luo, P.; Zhang, Y.; Sun, L.; Lin, C. Effect of Supercritical CO2 Exposure on the High-Pressure CO2 Adsorption Performance of Shales. Fuel 2019, 247, 57–66. [Google Scholar] [CrossRef]

- Mansour, E.M.I. Carbon Dioxide-Oil Minimum Miscibility Pressure Methods Overview; Morsi, B.I., Baled, H.O., Eds.; IntechOpen: Rijeka, Croatia, 2022; p. 2. ISBN 978-1-80355-826-4. [Google Scholar]

- Chiquet, P.; Broseta, D.; Thibeau, S. Wettability Alteration of Caprock Minerals by Carbon Dioxide. Geofluids 2007, 7, 112–122. [Google Scholar] [CrossRef]

- Rezaee, R.; Saeedi, A.; Iglauer, S.; Evans, B. Shale Alteration after Exposure to Supercritical CO2. Int. J. Greenh. Gas Control 2017, 62, 91–99. [Google Scholar] [CrossRef]

- Lu, Y.; Ao, X.; Tang, J.; Jia, Y.; Zhang, X.; Chen, Y. Swelling of Shale in Supercritical Carbon Dioxide. J. Nat. Gas Sci. Eng. 2016, 30, 268–275. [Google Scholar] [CrossRef]

- Lu, G.; Liu, Y.; Jiang, L.; Ying, T.; Song, Y.; Wu, B. Study of Density Driven Convection in a Hele-Shaw Cell with Application to the Carbon Sequestration in Aquifers. Energy Procedia 2017, 114, 4303–4312. [Google Scholar] [CrossRef]

- Zhang, Y.; Lebedev, M.; Sarmadivaleh, M.; Barifcani, A.; Iglauer, S. Change in Geomechanical Properties of Limestone Due to Supercritical CO2 Injection. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Perth, WA, Australia, 25–27 October 2016; Volume 2. [Google Scholar] [CrossRef]

- Li, S.; Zhang, S.; Xing, H.; Zou, Y. CO2-Brine-Rock Interactions Altering the Mineralogical, Physical, and Mechanical Properties of Carbonate-Rich Shale Oil Reservoirs. Energy 2022, 256, 124608. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Arif, M.; Lebedev, M.; Busch, A.; Sarmadivaleh, M.; Iglauer, S. Carbonate Rock Mechanical Response to CO2 Flooding Evaluated by a Combined X-Ray Computed Tomography—DEM Method. J. Nat. Gas Sci. Eng. 2020, 84, 103675. [Google Scholar] [CrossRef]

- Park, J.; Griffiths, L.; Iranpour, K.; Bj, T.I.; Haque, N.; Sauvin, G.; Sarout, J.; Soldal, M.; Oye, V.; Dewhurst, D.N.; et al. Induced-Seismicity Geomechanics for Controlled CO2 Storage in the North Sea (IGCCS). Int. J. Greenh. Gas Control 2022, 115, 103614. [Google Scholar] [CrossRef]

- Lin, R.; Yu, Z.; Zhao, J.; Dai, C.; Sun, Y.; Ren, L.; Xie, M. Experimental Evaluation of Tight Sandstones Reservoir Flow Characteristics under CO2–Brine–Rock Multiphase Interactions: A Case Study in the Chang 6 Layer, Ordos Basin, China. Fuel 2022, 309, 122167. [Google Scholar] [CrossRef]

- Kitamura, K.; Honda, H.; Nishizawa, O.; Mitani, Y. Impacts of CO2 Injection Speed on Two-Phase Flow and Physical Parameters in Porous Sandstone. Int. J. Greenh. Gas Control 2021, 107, 103228. [Google Scholar] [CrossRef]

- Amarasinghe, W.; Fjelde, I.; Rydland, J.Å.; Guo, Y. Effects of Permeability on CO2 Dissolution and Convection at Reservoir Temperature and Pressure Conditions: A Visualization Study. Int. J. Greenh. Gas Control 2020, 99, 103082. [Google Scholar] [CrossRef]

- Agartan, E.; Trevisan, L.; Cihan, A.; Birkholzer, J.; Zhou, Q.; Illangasekare, T. Experimental Study on Effects of Geologic Heterogeneity in Enhancing Dissolution Trapping of Supercritical CO2. J. Am. Water Resour. Assoc. 2015, 5, 2. [Google Scholar] [CrossRef]

- Baban, A.; Keshavarz, A.; Amin, R.; Iglauer, S. Residual Trapping of CO2 and Enhanced Oil Recovery in Oil-Wet Sandstone Core—A Three-Phase Pore-Scale Analysis Using NMR. Fuel 2023, 332, 126000. [Google Scholar] [CrossRef]

- Fauziah, C.A.; Al-yaseri, A.; Al-khdheeawi, E.; Jha, N.K.; Abid, R.; Iglauer, S.; Lagat, C.; Barifcani, A. Effect of CO2 Flooding on the Wettability Evolution of Sand-Stone. Energies 2021, 14, 5542. [Google Scholar] [CrossRef]

- Farokhpoor, R.; Bjørkvik, B.J.A.; Lindeberg, E.; Torsæter, O. International Journal of Greenhouse Gas Control Wettability Behaviour of CO2 at Storage Conditions. Int. J. Greenh. Gas Control 2013, 12, 18–25. [Google Scholar] [CrossRef]

- Baban, A.; Al-yaseri, A.; Keshavarz, A.; Amin, R.; Iglauer, S. CO2–Brine–Sandstone Wettability Evaluation at Reservoir Conditions via Nuclear Magnetic Resonance Measurements. Int. J. Greenh. Gas Control 2021, 111, 103435. [Google Scholar] [CrossRef]

- Cui, X.; Zheng, L.; Liu, Z.; Cui, P.; Du, D. Determination of the Minimum Miscibility Pressure of the CO2/Oil System Based on Quantification of the Oil Droplet Volume Reduction Behavior. Colloids Surfaces A Physicochem. Eng. Asp. 2022, 653, 130058. [Google Scholar] [CrossRef]

- Wang, F.; Ping, S.; Yuan, Y.; Sun, Z.; Tian, H.; Yang, Z. Effects of the Mechanical Response of Low-Permeability Sandstone Reservoirs on CO2 Geological Storage Based on Laboratory Experiments and Numerical Simulations. Sci. Total Environ. 2021, 796, 149066. [Google Scholar] [CrossRef] [PubMed]

- Nordbotten, J.M.; Celia, M.A.; Bachu, S. Injection and Storage of CO2 in Deep Saline Aquifers: Analytical Solution for CO2 Plume Evolution During Injection. Transp. Porous Media 2005, 58, 339–360. [Google Scholar] [CrossRef]

- Taheri, A.; Torsæter, O.; Lindeberg, E.; Hadia, N.J.; Wessel-Berg, D. Effect of Convective Mixing Process on Storage of CO2 in Saline Aquifers with Layered Permeability. Adv. Chem. Res. 2021, 3, 1–21. [Google Scholar] [CrossRef]

- Amarasinghe, W.; Fjelde, I.; Guo, Y. CO2 Dissolution and Convection in Oil at Realistic Reservoir Conditions: A Visualization Study. J. Nat. Gas Sci. Eng. 2021, 95, 104113. [Google Scholar] [CrossRef]

- Faisal, T.F.; Chevalier, S.; Sassi, M. Experimental and Numerical Studies of Density Driven Natural Convection in Saturated Porous Media with Application to CO2 Geological Storage. Energy Procedia 2013, 37, 5323–5330. [Google Scholar] [CrossRef]

- Tang, Y.; Li, Z.; Wang, R.; Cui, M.; Wang, X.; Lun, Z.; Lu, Y. Experimental Study on the Density-Driven Carbon Dioxide Convective Diffusion in Formation Water at Reservoir Conditions. ACS Omega 2019, 4, 11082–11092. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, S.; Liu, D.; Zhang, W.; Lu, G.; Liu, Y.; Zhao, J. Change in Convection Mixing Properties with Salinity and Temperature: CO2 Storage Application. Polymers 2020, 12, 2084. [Google Scholar] [CrossRef]

- Gan, M.; Zhang, L.; Miao, X.; Oladyshkin, S.; Cheng, X. Application of Computed Tomography (CT) in Geologic CO2 Utilization and Storage Research: A Critical Review. J. Nat. Gas Sci. Eng. 2020, 83, 103591. [Google Scholar] [CrossRef]

- Math2Market GmbH. GeoDict Simulation Software Release 2023; Math2Market GmbH: Kaiserslautern, Germany, 2023. [Google Scholar]

- Wang, Y.; Arns, C.H.; Arns, S.S.R.J. Porous Structure Reconstruction Using Convolutional Neural Networks. Math. Geosci. 2018, 50, 781–799. [Google Scholar] [CrossRef]

- Othman, F.; Wang, Y.; Le-Hussain, F. The Effect of Fines Migration During CO2 Injection Using Pore-Scale Characterization. SPE J. 2019, 24, 2804–2821. [Google Scholar] [CrossRef]

- Yue, P.; Liu, F.; Yang, K.; Han, C.; Ren, C.; Zhou, J.; Wang, X.; Fang, Q.; Li, X.; Dou, L. Micro-Displacement and Storage Mechanism of CO2 in Tight Sandstone Reservoirs Based on CT Scanning. Energies 2022, 15, 6201. [Google Scholar] [CrossRef]

- Yonebayashi, H.; Iwama, H.; Takabayashi, K.; Miyagawa, Y.; Watanabe, T. Uneven Distribution of Asphaltene Deposits in CO2 Flooding Path: Interpretation by Combining Thermodynamic and Micro-CT 3D Geological Porous Models. Energy Fuels 2021, 35, 329–340. [Google Scholar] [CrossRef]

- Garcia-Rios, M.; Luquot, L.; Soler, J.M.; Cama, J. Influence of the Flow Rate on Dissolution and Precipitation Features during Percolation of CO2-Rich Sulfate Solutions through Fractured Limestone Samples. Chem. Geol. 2015, 414, 95–108. [Google Scholar] [CrossRef]

- Fuchs, S.J.; Espinoza, D.N.; Lopano, C.L.; Akono, A.-T.; Werth, C.J. Geochemical and Geomechanical Alteration of Siliciclastic Reservoir Rock by Supercritical CO2-Saturated Brine Formed during Geological Carbon Sequestration. Int. J. Greenh. Gas Control 2019, 88, 251–260. [Google Scholar] [CrossRef]

- Zhang, Y.; Lebedev, M.; Jing, Y.; Yu, H.; Iglauer, S. In-Situ X-Ray Micro-Computed Tomography Imaging of the Microstructural Changes in Water-Bearing Medium Rank Coal by Supercritical CO2 Flooding. Int. J. Coal Geol. 2019, 203, 28–35. [Google Scholar] [CrossRef]

- Al Shafloot, T.; Kim, T.W.; Kovscek, A.R. Investigating Fracture Propagation Characteristics in Shale Using Sc-CO2 and Water with the Aid of X-Ray Computed Tomography. J. Nat. Gas Sci. Eng. 2021, 92, 103736. [Google Scholar] [CrossRef]

- Solomon, S. Carbon Dioxide Storage: Geological Security and Environmental Issues-Case Study on the Sleipner Gas Field in Norway. Bellona Rep. 2007, 1986, 128. [Google Scholar]

- Li, Q.; Liu, G. Risk Assessment of the Geological Storage of CO2: A Review. In Geologic Carbon Sequestration; Springer: Cham, Switzerland, 2016; pp. 249–284. ISBN 9783319270197. [Google Scholar]

- Tanaka, A.; Sakamoto, Y.; Komai, T. Development of Risk Assessment Tool for CO2 Geological Storage. Energy Procedia 2011, 4, 4178–4184. [Google Scholar] [CrossRef]

- Loizzo, M.; Lecampion, B.; Bérard, T.; Harichandran, A.; Jammes, L. Reusing O&G-Depleted Reservoirs for CO2 Storage: Pros and Cons. SPE Proj. Facil. Constr. 2010, 5, 166–172. [Google Scholar] [CrossRef]

- Espinoza, D.N.; Kim, S.H.; Santamarina, J.C. CO2 Geological Storage—Geotechnical Implications. KSCE J. Civ. Eng. 2011, 15, 707–719. [Google Scholar] [CrossRef]

- Zulqarnain, M.; Zeidouni, M.; Hughes, R.G. Risk Based Approach to Identify the Leakage Potential of Wells in Depleted Oil and Gas Fields for CO2 Geological Sequestration. In Proceedings of the Carbon Management Technology Conference, Huston, TX, USA, 17–20 July 2017; Volume 1, pp. 221–236. [Google Scholar] [CrossRef]

- Patil, P.A.; Chidambaram, P.; Bin, M.S.; Amir, E.; Tiwari, P.K.; Das, D.P. FEP Based Model Development for Assessing Well Integrity Risk Related to CO2 Storage in Central Luconia Gas Fields in Sarawak Challenges with CO2 Storage in Central Luconia. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 21–23 February 2021. [Google Scholar]

- Cui, Y.; Bai, J.; Liao, S.; Cao, S.; Liu, F. Suggestions on the Development of Environmental Monitoring Technology of CO2 Geological Storage and Leakage under the Background of China’s “ Double-Carbon ” Strategy. Atmosphere 2022, 14, 51. [Google Scholar] [CrossRef]

- Li, Q.; Liu, G.; Cai, B.; Ma, J.; Cao, L.; Zhou, Y. Principle and Methodology of Determining the Spatial Range of Environmental Risk Assessment of Carbon Dioxide Geological Storage. Environ. Eng. 2018, 36, 27–32. [Google Scholar]

- Teletzke, G.F.; Lu, P. Guidelines for Reservoir Modeling of Geologic CO2 Storage. Energy Procedia 2013, 37, 3936–3944. [Google Scholar] [CrossRef]

- Class, H.; Ebigbo, A.; Helmig, R.; Dahle, H.K.; Nordbotten, J.M.; Celia, M.A.; Audigane, P.; Darcis, M.; Ennis-King, J.; Fan, Y.; et al. A Benchmark Study on Problems Related to CO2 Storage in Geologic Formations: Summary and Discussion of the Results. Comput. Geosci. 2009, 13, 409–434. [Google Scholar] [CrossRef]

- Zhan, J.; Niu, Z.; Li, M.; Zhang, Y.; Ma, X.; Fan, C.; Wang, R. Numerical Simulation and Modeling on CO2 Sequestration Coupled with Enhanced Gas Recovery in Shale Gas Reservoirs. Geofluids 2021, 2021, 9975296. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.; Coninck, H.; Loos, M.; Meyer, L. Carbon Dioxide Capture and Storage; U.S. Department of Energy: Washington, DC, USA, 2005.

- Santibanez-Borda, E.; Govindan, R.; Elahi, N.; Korre, A.; Durucan, S. Maximising the Dynamic CO2 Storage Capacity through the Optimisation of CO2 Injection and Brine Production Rates. Int. J. Greenh. Gas Control 2019, 80, 76–95. [Google Scholar] [CrossRef]

- Nordbotten, J.M.; Flemisch, B.; Gasda, S.E.; Nilsen, H.M.; Fan, Y.; Pickup, G.E.; Wiese, B.; Celia, M.A.; Dahle, H.K.; Eigestad, G.T.; et al. Uncertainties in Practical Simulation of CO2 Storage. Int. J. Greenh. Gas Control 2012, 9, 234–242. [Google Scholar] [CrossRef]

- Raynaud, X.; Pizzolato, A.; Johansson, A.; Caresani, F.; Ferrari, A.; Møyner, O.; Nilsen, H.M.; Cominelli, A.; Lie, K.-A. Toward Accurate Reservoir Simulations on Unstructured Grids: Design of Simple Error Estimators and Critical Benchmarking of Consistent Discretization Methods for Practical Implementation. SPE J. 2021, 26, 4109–4127. [Google Scholar] [CrossRef]

- Nilsen, H.M.; Herrera, P.A.; Ashraf, M.; Ligaarden, I.; Iding, M.; Hermanrud, C.; Lie, K.A.; Nordbotten, J.M.; Dahle, H.K.; Keilegavlen, E. Field-Case Simulation of CO2-Plume Migration Using Vertical-Equilibrium Models. Energy Procedia 2011, 4, 3801–3808. [Google Scholar] [CrossRef]

- Raza, A.; Gholami, R.; Sarmadivaleh, M.; Tarom, N.; Rezaee, R.; Bing, C.H.; Nagarajan, R.; Hamid, M.A.; Elochukwu, H. Integrity Analysis of CO2 Storage Sites Concerning Geochemical-Geomechanical Interactions in Saline Aquifers. J. Nat. Gas Sci. Eng. 2016, 36, 224–240. [Google Scholar] [CrossRef]

- Pomar-Castromonte, R.; Ingol-Blanco, E.; Santos, J.; Santa-Cruz, S. Analytical and Numerical Modeling for the Assessment of CO2 Storage in the Pariñas Geological Formation—Talara, Peru. Int. J. Greenh. Gas Control 2021, 110, 103446. [Google Scholar] [CrossRef]

- Preisig, M.; Prévost, J.H. Coupled Multi-Phase Thermo-Poromechanical Effects. Case Study: CO2 Injection at In Salah, Algeria. Int. J. Greenh. Gas Control 2011, 5, 1055–1064. [Google Scholar] [CrossRef]

- Oldenburg, C.M. Joule-Thomson Cooling Due to CO2 Injection into Natural Gas Reservoirs. Energy Convers. Manag. 2007, 48, 1808–1815. [Google Scholar] [CrossRef]

- Ennis-King, J.; Dance, T.; Xu, J.; Boreham, C.; Freifeld, B.; Jenkins, C.; Paterson, L.; Sharma, S.; Stalker, L.; Underschultz, J. The Role of Heterogeneity in CO2 Storage in a Depleted Gas Field: History Matching of Simulation Models to Field Data for the CO2CRC Otway Project, Australia. Energy Procedia 2011, 4, 3494–3501. [Google Scholar] [CrossRef]

- Kano, Y.; Sato, T.; Kita, J.; Hirabayashi, S.; Tabeta, S. Multi-Scale Modeling of CO2 Dispersion Leaked from Seafloor off the Japanese Coast. Mar. Pollut. Bull. 2010, 60, 215–224. [Google Scholar] [CrossRef]

- Niessner, J.; Helmig, R. Multi-scale Modelling of Two-phase–Two-component Processes in Heterogeneous Porous Media. Numer. Linear Algebr. Appl. 2006, 13, 699–715. [Google Scholar] [CrossRef]

- Efendiev, Y.; Durlofsky, L.; Lee, S. Modeling of Subgrid Effects in Coarse-Scale Simulations of Transport in Heterogeneous Porous Media. Water Resour. Res. 2000, 36, 2031–2041. [Google Scholar] [CrossRef]

- Flemisch, B.; Darcis, M.; Erbertseder, K.; Faigle, B.; Lauser, A.; Mosthaf, K.; Nuske, P.; Tatomir, A.; Wolff, M.; Helmig, R. DuMu X: DUNE for Multi-Phase, Component, Scale, Physics, Flow and Transport in Porous Media. Adv. Water Resour. 2011, 34, 1102–1112. [Google Scholar] [CrossRef]

- Bandilla, K.; Celia, M.; Birkholzer, J.; Cihan, A.; Leister, E. Multiphase Modeling of Geologic Carbon Sequestration in Saline Aquifers. Ground Water 2015, 53, 362–377. [Google Scholar] [CrossRef]

- Helmig, R.; Flemisch, B.; Wolff, M.; Ebigbo, A.; Class, H. Model Coupling for Multiphase Flow in Porous Media. Adv. Water Resour. 2013, 51, 52–66. [Google Scholar] [CrossRef]

- Audigane, P.; Gaus, I.; Czernichowski-Lauriol, I.; Pruess, K.; Xu, T. Two-Dimensional Reactive Transport Modeling of CO2 Injection in a Saline Aquifer at the Sleipner Site, North Sea. Am. J. Sci. 2007, 307, 974–1008. [Google Scholar] [CrossRef]

- Brooks, R.H.; Corey, A.T. Hydraulic Properties of Porous Media and Their Relation to Drainage Design. Trans. ASABE 1964, 7, 26–28. [Google Scholar]

- Press, W.H.; Teukolsky, S.A.; Vetterling, W.T.; Flannery, B.P. Numerical Recipes Source Code CD-ROM, 3rd ed.; Cambridge University Press: Cambridge, UK, 2007; ISBN 978-0-521-70685-8. [Google Scholar]

- Li, Q.; Li, S.; Ding, S.; Yin, Z.; Liu, L.; Li, S. Numerical Simulation of Gas Production and Reservoir Stability during CO2 Exchange in Natural Gas Hydrate Reservoir. Energies 2022, 15, 8968. [Google Scholar] [CrossRef]

- Nghiem, L.; Sammon, P.; Grabenstetter, J.; Ohkuma, H. Modeling CO2 Storage in Aquifers with a Fully-Coupled Geochemical EOS Compositional Simulator. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 17–21 April 2004. [Google Scholar] [CrossRef]

- Gupta, N.; Sass, B.M.; Sminchak, J.R.; Naymik, T.G.; Bergman, P. Hydrodynamics of CO2 Disposal in a Deep Saline Formation in the Midwestern United States. In Greenhouse Gas Control Technologies; Elsevier: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Johnson, J.W.; Oelkers, E.H.; Helgeson, H.C. SUPCRT92: A Software Package for Calculating the Standard Molal Thermodynamic Properties of Minerals, Gases, Aqueous Species, and Reactions from 1 to 5000 Bar and 0 to 1000 °C. Comput. Geosci. 1991, 18, 899–947. [Google Scholar] [CrossRef]

- Holt, T.; Jensen, J.-I.; Lindeberg, E. Underground Storage of CO2 in Aquifers and Oil Reservoirs. Energy Convers. Manag. 1995, 36, 535–538. [Google Scholar] [CrossRef]

- Krumhansl, J.; Pawar, R.; Grigg, R.; Westrich, H.; Warpinski, N.; Zhang, D.; Jove-Colon, C.; Lichtner, P.; Lorenz, J.; Svec, R.; et al. Geological Sequestration of Carbon Dioxide in a Depleted Oil Reservoir. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 17–20 April 2002; pp. 1144–1151. [Google Scholar] [CrossRef]

- Izgec, O. Experimental and Numerical Investigation of Carbon Dioxide Sequestration in Deep Saline Aquifers. Master’s Thesis, Middle East Technical University, Ankara, Turkey, 2005. [Google Scholar]

- Ahmadi, M.A.; Pouladi, B.; Barghi, T. Numerical Modeling of CO2 Injection Scenarios in Petroleum Reservoirs: Application to CO2 Sequestration and EOR. J. Nat. Gas Sci. Eng. 2016, 30, 38–49. [Google Scholar] [CrossRef]

- Ghomian, Y.; Pope, G.A.; Sepehrnoori, K. Economical Co-Optimization of CO2 Sequestration and Enhanced Oil Recovery. In Proceedings of the Sixth Annual Conference on Carbon Capture & Sequestration, Pittsburgh, PA, USA, 7–10 May 2007. [Google Scholar]

- Kovscek, A.R. Screening Criteria for CO2 Storage in Oil Reservoirs. Pet. Sci. Technol. 2002, 20, 841–866. [Google Scholar] [CrossRef]

- IEA. Putting CO2 to Use. Creating Value from Emissions; IEA: Paris, France, 2019. [Google Scholar]

- Kamkeng, A.D.N.; Wang, M.; Hu, J.; Du, W.; Qian, F. Transformation Technologies for CO2 Utilisation: Current Status, Challenges and Future Prospects. Chem. Eng. J. 2021, 409, 128138. [Google Scholar] [CrossRef]

- Marbun, B.T.H.; Santoso, D.; Kadir, W.G.A.; Wibowo, A.; Suardana, P.; Prabowo, H.; Susilo, D.; Sasongko, D.; Sinaga, S.Z.; Purbantanu, B.A.; et al. Improvement of Borehole and Casing Assessment of CO2-EOR/CCUS Injection and Production Well Candidates in Sukowati Field, Indonesia in a Well-Based Scale. Energy Rep. 2021, 7, 1598–1615. [Google Scholar] [CrossRef]

- Yuan, S.; Ma, D.; Li, J.; Zhou, T.; Ji, Z.; Han, H. Progress and Prospects of Carbon Dioxide Capture, EOR-Utilization and Storage Industrialization. Pet. Explor. Dev. 2022, 49, 955–962. [Google Scholar] [CrossRef]

- Peres, C.B.; Resende, P.M.R.; Nunes, L.J.R.; Morais, L.C. de Advances in Carbon Capture and Use (CCU) Technologies: A Comprehensive Review and CO2 Mitigation Potential Analysis. Clean Technol. 2022, 4, 1193–1207. [Google Scholar] [CrossRef]

- Chehrazi, M.; Moghadas, B.K. A Review on CO2 Capture with Chilled Ammonia and CO2 Utilization in Urea Plant. J. CO2 Util. 2022, 61, 102030. [Google Scholar] [CrossRef]

- Hepburn, C.; Adlen, E.; Beddington, J.; Carter, E.A.; Fuss, S.; Mac Dowell, N.; Minx, J.C.; Smith, P.; Williams, C.K. The Technological and Economic Prospects for CO2 Utilization and Removal. Nature 2019, 575, 87–97. [Google Scholar] [CrossRef]

- Rosental, M.; Fröhlich, T.; Liebich, A. Life Cycle Assessment of Carbon Capture and Utilization for the Production of Large Volume Organic Chemicals. Front. Clim. 2020, 2, 586199. [Google Scholar] [CrossRef]

- Desport, L.; Selosse, S. An Overview of CO2 Capture and Utilization in Energy Models. Resour. Conserv. Recycl. 2022, 180, 106150. [Google Scholar] [CrossRef]

- Kearns, J.; Teletzke, G.; Palmer, J.; Thomann, H.; Kheshgi, H.; Chen, Y.H.H.; Paltsev, S.; Herzog, H. Developing a Consistent Database for Regional Geologic CO2 Storage Capacity Worldwide. Energy Procedia 2017, 114, 4697–4709. [Google Scholar] [CrossRef]

- OGCI. Interactive CO2 Map Carbon Capture Utilisation and Storage; OGCI: Huston, TX, USA, 2022. [Google Scholar]

- The Global CCS Institute. The Global Status of CCS 2020: Vital to Achieve Net Zero; Global CCS Institute: Melbourne, VIC, Australia, 2020. [Google Scholar]

- Rystad Energy. Rystad Energy’s CCUSCube; Rystad Energy: Oslo, Norway, 2022. [Google Scholar]

- IEA. IEA Global Hydrogen Review 2022; IEA: Paris, France, 2022. [Google Scholar]

- Kapadia, P.R.; Kallos, M.S.; Gates, I.D. Potential for Hydrogen Generation from in Situ Combustion of Athabasca Bitumen. Fuel 2011, 90, 2254–2265. [Google Scholar] [CrossRef]

- Surguchev, L.; Berenblyum, B. In-Situ H2 Generation from Hydrocarbons and CO2 Storage in the Reservoir. In Proceedings of the Fourth EAGE CO2 Geological Storage Workshop; European Association of Geoscientists & Engineers, Stavanger, Norway, 22–24 April 2014. [Google Scholar]

- The Global CCS Institute. CCS Facilities Database; Global CCS Institute: Melbourne, VIC, Australia, 2022. [Google Scholar]

- Neades, S.; Haines, M.; Dixon, T. What Have We Learnt from Ccs Demonstrations—Phase 1b. Energy Procedia 2013, 37, 6295–6305. [Google Scholar] [CrossRef]

- Wang, F.; Liu, X.; Liu, C.; Zhang, Y. Fracture Diagnostics and Modeling Help to Understand the Performance of Horizontal Wells in the Jilin Oilfield, China. In Proceedings of the Asia Pacific Oil and Gas Conference & Exhibition (APOGCE 09), Jakarta, Indonesia, 4–6 August 2009; Volume 1, pp. 311–318. [Google Scholar] [CrossRef]

- Ren, B.; Zhang, L.; Huang, H.; Ren, S.; Chen, G.; Zhang, H. Performance Evaluation and Mechanisms Study of Near-Miscible CO2 Flooding in a Tight Oil Reservoir of Jilin Oilfield China. J. Nat. Gas Sci. Eng. 2015, 27, 1796–1805. [Google Scholar] [CrossRef]

- Ren, B.; Xu, Y.; Niu, B.; Ren, S.; Li, X.; Guo, P.; Song, X. Laboratory Assessment and Field Pilot of near Miscible CO2 Injection for IOR and Storage in a Tight Oil Reservoir of ShengLi Oilfield China. In Proceedings of the SPE Enhanced Oil Recovery Conference (EORC 2011), Kuala Lumpur, Malaysia, 19–21 July 2011; Volume 1, pp. 604–614. [Google Scholar] [CrossRef]

- Guo, X.; Du, Z.; Sun, L.; Fu, Y.; Huan, W.; Zhang, C. Optimization of Tertiary Water-Alternate-CO2 Flood in Jilin Oil Field of China: Laboratory and Simulation Studies. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 22–26 April 2006; Voluem 1, pp. 391–412. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Ren, B.; Cui, G.D.; Ren, S.R.; Chen, G.L. Preliminary Assessment of CO2 Storage Potential in the H-59 Block in Jilin Oilfield CCS Project. In Proceedings of the Carbon Management Technology Conference, Sugar Land, TX, USA, 17–19 November 2015; Volume 2, pp. 1082–1091. [Google Scholar] [CrossRef]

- Li, W.; Yu, H.; Yang, Z.; Li, J.; Chen, X.; Ma, L. Experimental Study on the Sweep Law of CO2 Miscible Flooding in Heterogeneous Reservoir in Jilin. Energies 2022, 15, 5755. [Google Scholar] [CrossRef]

- Dean, M.; Tucker, O. A Risk-Based Framework for Measurement, Monitoring and Verification (MMV) of the Goldeneye Storage Complex for the Peterhead CCS Project, UK. Int. J. Greenh. Gas Control 2017, 61, 1–15. [Google Scholar] [CrossRef]

- Shell, U.K. Peterhead CCS Project. Basic Design and Engineering Package; Shell U.K.: London, UK, 2015. [Google Scholar]

- Shell, U.K. Peterhead CCS Project. FEED Summary Report for Full CCS Chain; Shell U.K.: London, UK, 2016. [Google Scholar]

- Tucker, O.; Holley, M.; Metcalfe, R.; Hurst, S. Containment Risk Management for CO2 Storage in a Depleted Gas Field, UK North Sea. Energy Procedia 2013, 37, 4804–4817. [Google Scholar] [CrossRef]

- Shell, U.K. Peterhead CCS Project. Storage Development Plan; Shell U.K.: London, UK, 2015. [Google Scholar]

- Shell U.K. Goldeneye Decommissioning Programmes; Shell U.K.: London, UK, 2019. [Google Scholar]

- Shell, U.K. Goldeneye Comparative Assessment. Emerging Recommendations Report; Shell U.K.: London, UK, 2018. [Google Scholar]

- Mahmoud, R.M.A.; Dodds, P.E. A Technical Evaluation to Analyse of Potential Repurposing of Submarine Pipelines for Hydrogen and CCS Using Survival Analysis. Ocean Eng. 2022, 266, 112893. [Google Scholar] [CrossRef]

- Pawar, R.; Brunner, L.; van der Valk, K.; van Bijsterveldt, L.; Harp, D.; Chen, B.; Cangemi, L.; Dudu, A.; Guy, N.; Opedal, N.; et al. A Screening Tool for Assessing Feasibility of Re-Using Existing Oil and Gas Wells for CCUS Operations. In Proceedings of the 15th Greenhouse Gas Control Technologies Conference, 15–18 March 2021; pp. 1–12. Available online: https://ssrn.com/abstract=3819822 or http://dx.doi.org/10.2139/ssrn.3819822 (accessed on 8 February 2023).

- Girard, J.P.; Chiquet, P.; Thibeau, S.; Lescanne, M.; Prinet, C. Geochemical Assessment of the Injection of CO2 into Rousse Depleted Gas Reservoir, Part I: Initial Mineralogical and Geochemical Conditions in the Mano Reservoir. Energy Procedia 2013, 37, 6395–6401. [Google Scholar] [CrossRef]

- Chiquet, P.; Thibeau, S.; Lescanne, M.; Prinet, C. Geochemical Assessment of the Injection of CO2 into Rousse Depleted Gas Reservoir Part II: Geochemical Impact of the CO2 Injection. Energy Procedia 2013, 37, 6383–6394. [Google Scholar] [CrossRef]

- Pourtoy, D.; Onaisi, A.; Lescanne, M.; Thibeau, S.; Viaud, C. Seal Integrity of the Rousse Depleted Gas Field Impacted by CO2 Injection (Lacq Industrial CCS Reference Project France). Energy Procedia 2013, 37, 5480–5493. [Google Scholar] [CrossRef]

- Prinet, C.; Thibeau, S.; Lescanne, M.; Monne, J. Lacq-Rousse CO2 Capture and Storage Demonstration Pilot: Lessons Learnt from Two and a Half Years Monitoring. Energy Procedia 2013, 37, 3610–3620. [Google Scholar] [CrossRef]

- Bacanskas, L.; Karimjee, A.; Ritter, K. Toward Practical Application of the Vulnerability Evaluation Framework for Geological Sequestration of Carbon Dioxide. Energy Procedia 2009, 1, 2565–2572. [Google Scholar] [CrossRef]

- Wollenweber, J.; Busby, D.; Wessel-Berg, D.; Nepveu, M.; Codreanu, D.B.; Grimstad, A.-A.; Sijacic, D.; Maurand, N.; Lothe, A.; Wahl, F.; et al. Integrated Carbon Risk Assessment (ICARAS). Energy Procedia 2013, 37, 4825–4832. [Google Scholar] [CrossRef]

- Song, Y.; Jun, S.; Na, Y.; Kim, K.; Jang, Y.; Wang, J. Geomechanical Challenges during Geological CO2 Storage: A Review. Chem. Eng. J. 2023, 456, 140968. [Google Scholar] [CrossRef]

- Khan, S.; Khulief, Y.A. Mitigating Climate Change via CO2 Sequestration into Biyadh Reservoir: Geomechanical Modeling and Caprock Integrity. Mitig. Adapt. Strateg. Glob. Chang. 2018, 24, 23–52. [Google Scholar] [CrossRef]

- Khan, S.; Al, Y.A.; Al-Shuhai, A.A. Effects of Reservoir Size and Boundary Conditions on Pore-Pressure Buildup and Fault Reactivation during CO2 Injection in Deep Geological Reservoirs. Environ. Earth Sci. 2020, 79, 294. [Google Scholar] [CrossRef]

- Rahman, J.; Fawad, M.; Chan, J.; Haque, N. Effect of Overburden Spatial Variability on Field-Scale Geomechanical Modeling of Potential CO2 Storage Site Smeaheia, Offshore Norway. J. Nat. Gas Sci. Eng. 2022, 99, 104453. [Google Scholar] [CrossRef]

- Moghanloo, R.G.; Yan, X.; Law, G.; Roshani, S.; Babb, G.; Herron, W. Challenges Associated with CO2 Sequestration and Hydrocarbon Recovery. In Recent Advances in Carbon Capture and Storage; Yun, Y., Ed.; IntechOpen: Rijeka, Croatia, 2017. [Google Scholar]

- Moghanloo, R.G.; Yan, X.; Law, G.; Roshani, S.; Babb, G.; Herron, W. Challenges Associated with CO2 Sequestration and World’s Largest Science, Technology & Medicine Open Access Book Publisher. In Recent Advances in Carbon Capture and Storage; IntechOpen: Rijeka, Croatia, 2017. [Google Scholar] [CrossRef]

- Li, C.; Laloui, L. Impact of Material Properties on Caprock Stability in CO2 Geological Storage. Geomech. Energy Environ. 2017, 11, 28–41. [Google Scholar] [CrossRef]

- Harding, F.C.; James, A.T.; Robertson, H.E. The Engineering Challenges of CO2 Storage. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 232, 17–26. [Google Scholar] [CrossRef]

- Tang, Y.; Hu, S.; He, Y.; Wang, Y.; Wan, X.; Cui, S.; Long, K. Experiment on CO2-Brine-Rock Interaction during CO2 Injection and Storage in Gas Reservoirs with Aquifer. Chem. Eng. J. 2020, 413, 127567. [Google Scholar] [CrossRef]

| Study | Studied Parameters | Experiment Methods | P-T Conditions | Rock Type | Implications | |

|---|---|---|---|---|---|---|

| Geomechanical and Reservoir Properties | ||||||

| Zhang et al., 2016 [88] | Geomechanical changes of limestione due to the sc-CO2 injection | Young’s modulus, indentation modulus, porosity, permeability | HP core flooding, nanoindentation test, ultrasonic test, gas porosity, and permeability, XRD, X-ray micro-CT. | P: 10 MPa T: 50 °C | Savonnieres limestone | After sc-CO2 flooding Young’s modulus decreased while the indentation modulus varied, most likely due migration of fines. Permeability and porosity also increased. |

| Sihai Li et al., 2022 [89] | Interaction of CO2, rock and brine in carbonate rich shale systems | Mineral composition, dissolution, elastic modulus, hardness, tensile strength, porosity, permeability, and T2 relaxation time. | Microidentation, Brazilian split, three-point bending test, HPHT soaking in sc-CO2, XRD, SEM-EDS, gas porosity and permeability, 1D LF-NMR. | P: 35 MPa T: 90 °C | Limestone, dolomitic shale, silty dolomite | Carbonate samples’ hardness and tensile strength are in strong inverse proportion with a soaking period, while permeability and porosity are in direct proportion (notably along the bedding planes). Dissolution of calcite occurs much faster than K-feldspar and albite. |

| Zhang et al., 2020 [90] | Mechanical response of carbonates to CO2 flooding | Maximum compressive stress, Young’s modulus, porosity | HPHT core flooding, CT scanning, UCS test | P: 10 MPa T: 50 °C | Savonnieres limestone | Maximum compressive stress decreases, Young’s modulus decreases significantly after flooding with sc-CO2 and CO2-saturated brine, while porosity increases. |

| Park et al., 2022 [91] | Controlled CO2 injection in North Sea reservoir rocks—study on induced sesimicity | Induced seismicity (acoustic emission (AE), microseismic events), Young’s modulus, shear strength, and failure stress. | Uniaxial and triaxial loading and unloading tests, HPHT core flooding (sc-CO2, sc-CO2-brine, brine), ultrasonic velocity test. | P: 1–30 MPa T: 20–65 °C | Sandstone, siltstone, mudstone, shale | Experiments distributed by sample depth. A large temperature gradient between sc-CO2 and sandstone with increased stiffness rises the likelihood of failure (micro-seismicity). Rocks saturated with sc-CO2 show the highest strength and stiffness, and fracture reactivation pressure increases. Brine-sc-CO2 injection produces large numbers of low magnitude AEs, while pure sc-CO2 high magnitude AEs. The sc-CO2-saturated samples have a lower dominant frequency compared to the brine-saturated samples. The elasticity of the sandstone samples varies from inelastic to non-linearly elastic. Shale and mudstone exhibit aseismic behaviour. |

| CO2 solubility and alteration of flow parameters | ||||||

| Lin et al., 2022 [92] | CO2, rock and brine interactions and their influence on flow in porous media | Porosity, relative permeability, CO2 solubility, mineral composition, T2 relaxation time | HPHT core flooding, helium porosimetry, 1D LF-NMR, centrifuge test, relative permeability (by Darcy), XRD | P: 15–25 MPa T: 44–64 °C | Tight sandstone | Dissolution of calcite, dolomite, and K-feldspar. Pore size, pore throat size, and relative permeability increase over time, and irreducible water saturation decrease. The rise of pressure raises the CO2 solubility in water/brine, while the rise of temperature causes it to decrease. |

| Kitamura et al., 2020 [93] | CO2 injection speed influence on physical properties of sandstone and two-phase flow | Macroscopic capillary number, porosity, absolute permeability, CO2 saturation, P-wave velocity, electrical resistivity, and fluid capillary and viscous limit. | HP core flooding, X-ray micro-CT, mercury injection capillary pressure, complex impedance four-electrode test, pulse transmission P-wave velocity. | P: 10 MPa T: 40 °C | Berea sandstone | CO2 saturation in pores can be monitored using parameters such as macroscopic capillary number (Nc), P-wave velocity (Vp), and electrical resistivity (ρ). The flow rate or injection speed (represented by Nc) is directly related to CO2 saturation. However, when Nc is low, the derived CO2 saturation does not yield satisfactory monitoring accuracy, and resistivity measurements can be used instead. |

| Amarasinghe et al., 2020 [94] | Visualisation of CO2 convective mixing (viscous fingering) and dissolution—effects of various permeabilities | Convective mixing fingers, Rayleigh number (Ra), permeability, dimensionless time (τ), CO2 mixing rate | HPHT Hele-Shaw cell flooding (2D), digital and thermal imaging, synthetic sc-CO2-brine | P: 10 MPa T: 50 °C | Hydrophilic micro glass beads (synthetic core) | In media with φ = 100%, CO2 fingers and mixing occurs almost instantaneously seconds). The rate of CO2 mixing is proportional to permeability. Permeability dictates the CO2 dissolution pattern. For smaller permeabilities, fingering was not observed. |

| Agartan et al., 2015 [95] | Visualisation of CO2 convective mixing—effects of mixed sand permeabilities | Permeability, heterogeneity, Rayleigh number (Ra), permeability, dimensionless time (τ), CO2 mixing rate | 2D flooding cell, digital imaging, synthetic sc-CO2-brine | P: Ambient T: Ambient | Sand packs with varied heterogeneity | In homogenous sands with high permeability, convective mixing is more prevalent, whereas in low-permeable sections, diffusion mixing dominates. Heterogeneous permeability impacts the propagation of the brine- CO2 phase and mixing mechanism. Transition zones between low and high permeability lead to lateral spreading of the injected phase, resulting in increased surface area between phases and enhanced diffusive mixing, promoting CO2 dissolution in the long term. |

| Baban et al., 2023 [96] | Residual trapping evaluation of CO2 in three-phase system | Water, oil, CO2 saturations, recovery factors, wettability, oil displacement efficiency, spreading coefficient, T1 and T2 relaxation time | HPHT core flooding, wettability alteration (sample aging), 2D & 1D LF-NMR | P: 8 MPa T: 50 °C | San Sabo sandstone | CO2 flooding generally improves oil recovery. Wettability plays an essential role in the residual trapping of injected CO2: the oil-wet core had 12%, while the water-wet core had 20% residual CO2 saturation. In both cases, CO2 flooding yielded higher oil recovery than water flooding. |

| Wettability and interfacial tension | ||||||

| Fauziah et al., 2021 [97] | Effect of CO2 flooding on sandstone wetabillity alteration | Advancing and receding contact angles, mineral composition, permeability, porosity | HPHT core flooding, SEM, drop shape analysis (contact angle), gas porosity, gas permeability, XRD | P: 10, 15 MPa T: 50 °C | Berea sandstone, Bandera grey sandstone | Advancing and receding contact angle changes are directly proportional to pressure change. Exposure of sandstone to CO2 leads to wettability alteration to more hydrophobic (more CO2 philic). Such alteration reduces residual trapping capacity but increases solubility trapping capacity. |

| Farokhpoor et al., 2013 [98] | CO2 wettability alteration behaviour of reservoir rock minerals | Contact angle, CO2 compressibility | Drop shape analysis (captive-needle drop) | P: 0.1–40 MPa T: 36, 66 °C | Quartz, fledspar, calcite, muscovite mica | Hydrophilic, quartz, feldspar, and calcite, their contact angle is not significantly affected by pressure variation. Muscovite mica, with increased pressure, increases its contact angles (from strongly water-wet to intermediate water-wet). The maximum contact angle is observed near critical pressure at 36 °C for feldspar calcite and quartz. |

| Baban et al., 2021 [99] | Wettabilitty alteraton due to CO2, rock and brine interactions | Wettability indices, permeability, porosity, T1 time, T2 time, capillary pressure, capillary number | HPHT core flooding, gas permeability and porosity, 2D and 1D LF-NMR mapping | P: 8 MPa T: 60 °C | San Sabo sandstone | CO2 reduces the hydrophilicity of sandstone and lowers water wetness, likely caused by the protonation of surface silanol groups on quartz. NMR measurements show preferential water displacement in large pores following sc-CO2 flooding, with no change in smaller pores. |

| Cui et al., 2022 [100] | Determination of minimum miscibility pressure of CO2 into oil | Interfacial tension (ITF), minimum miscibility pressure (MMP) | HPHT oil droplet volume measurement (ODVM), visual inspection techinque (VIT), pendant drop | P: 1, 5, 9 MPa T: 27-80 °C | Without porous medium | Two types of CO2/oil phases were tested, with various molecular weights and densities. Newly propsed method MMP measurement method (ODVM) shows greater accuracy. MMP is heavily dependant from P-T conditions. Authors report MMPs in for specific P-T values. |

| Study | Studied Parameters | Software | Implications | |

|---|---|---|---|---|

| Li, 2016 [36] | CO2 storage simulation using geomechanical-fluid coupling model | Geomechanical (stress) and reservoir properties (porosity), operational parameters (pressure) | CMG 2012 |

|

| Sharma et al., 2022 [37] | Simulation of CO2 injection into DOGR using geomechanically coupled and non-coupled simulation models | Geomechanical properties (stress, Poisson’s ratio, and Young’s modulus) | CMG |

|

| Raza et al., 2018 [28] | Simulation of CO2 storage accounting the effect of residual gas saturation | Operational parameters (injection rate) and reservoir properties (residual saturation) | Eclipse (E300) |

|

| King et al., 2011 [139] | History matching of the CO2 storage simulation models accounting heterogeneity | Operational parameters (arrival time), downhole pressure | TOUGH2/EOS7C |

|

| Kopp et al., 2010 [39] | Implicit simulation of CO2 leakage risks through abandoned wells | Operational parameters (injection time, distances between wells) and reservoir properties (permeability anisotropy, geothermal gradient, relative permeability, irreducible water saturation) | MUFTE_UG |

|

| Raza et al., 2018 [38] | Numerical simulation of depleted reservoirs suitability for CO2 storage | Operational parameters (injection rate), reservoir properties (permeability) | Eclipse (E300) |

|

| Sun et al., 2021 [35] | Numerical study of the stability of CO2 storage | Operational parameters (injection rate, pressure, temperature) | CMG |

|

| Akai et al., 2021 [40] | Comparison of numerical simulation of CO2 storage and analytical solution | Reservoir properties (porosity, permeability, aquifer size, saturation, rock compressibility) | Eclipse (Version 2019.2) |

|

| Lei et al., 2019 [41] | Field scale numerical simulation of CO2 storage of four different gas fields | Operational parameters (injection rate, pressure, development scheme) and reservoir properties (permeability, depleted pressure) | TOUGH2/EOS7 |

|

| Reservoir Type | Challenges | Author, Year |

|---|---|---|

| Oil (sandstones) | Influence of heterogeneity of the reservoir porosity and permeability on the storage capacity | Akai et al., 2021 [40] |

| Estimation of the post injection pore pressure distribution and it’s influence on the storage integrity | Li et al., 2022 [26] | |

| Geomechanical modeling for storage integrity (cap-rock poroelastic behavior, cap-rock stability, reactivation of faults, formation of fractures), estimation of reversibility of rock compaction using different modeling approaches | Song et al., 2023 [198] | |

| Evaluation of the theoretical reservoir equilibrium conditions among several phases and reconstruction of physico-chemical variations of different phases at non-equilibrium conditions | Khan et al., 2018 [199] | |

| Influence of CO2 induced precipitation reactions on the pore space evolution and thus the physical properties and the need for the development of coupled flow, geochemical and geomechanical models | Khan et al., 2020 [200] | |

| Limited information on catalyzation and imbibition of CO2-rock interaction reactions | Rahman et al., 2022 [201] | |

| Shales, tight reservoirs | Limited information on available storage capacity, formation and reservoir data that specifies favorable sequestration settings, understanding long-term CO2 interaction in shale, and testing different strategies for CO2 injection and well patterns to achieve efficient carbon dioxide sequestration complications in the estimation of the storage capacity | Li et al., 2022 [26] |

| Alteration of the limestone and calcite matrix, which raises a question about the mechanical stability of rocks | Monghanloo et el., 2017 [202] | |

| Solubility trapping in carbonates that will dominate until mineral trapping occurs | Monghanloo et el., 2017 [203] | |

| Gas and gas condensate (sandstones) | Understanding and mitigating Joule Thomson effects to avoid the possible formation of ice and gas hydrates | Li& Laloui, 2017 [204] |

| Geomechanical modeling for storage integrity (cap-rock poroelastic behavior, cap-rock stability, reactivation of faults, formation of fractures), CO2–rock interaction that causes mineral dissolution | Harding et al., 2018 [205] | |

| Mechanism and effect of CO2-rock-brine interaction on reservoir properties in gas reservoirs with aquifers | Tang et al., 2020 [206] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Askarova, A.; Mukhametdinova, A.; Markovic, S.; Khayrullina, G.; Afanasev, P.; Popov, E.; Mukhina, E. An Overview of Geological CO2 Sequestration in Oil and Gas Reservoirs. Energies 2023, 16, 2821. https://doi.org/10.3390/en16062821

Askarova A, Mukhametdinova A, Markovic S, Khayrullina G, Afanasev P, Popov E, Mukhina E. An Overview of Geological CO2 Sequestration in Oil and Gas Reservoirs. Energies. 2023; 16(6):2821. https://doi.org/10.3390/en16062821

Chicago/Turabian StyleAskarova, Aysylu, Aliya Mukhametdinova, Strahinja Markovic, Galiya Khayrullina, Pavel Afanasev, Evgeny Popov, and Elena Mukhina. 2023. "An Overview of Geological CO2 Sequestration in Oil and Gas Reservoirs" Energies 16, no. 6: 2821. https://doi.org/10.3390/en16062821

APA StyleAskarova, A., Mukhametdinova, A., Markovic, S., Khayrullina, G., Afanasev, P., Popov, E., & Mukhina, E. (2023). An Overview of Geological CO2 Sequestration in Oil and Gas Reservoirs. Energies, 16(6), 2821. https://doi.org/10.3390/en16062821