Enhanced Performance of Combined Photovoltaic–Thermoelectric Generator and Heat Sink Panels with a Dual-Axis Tracking System

Abstract

1. Introduction

2. Theoretical Consideration

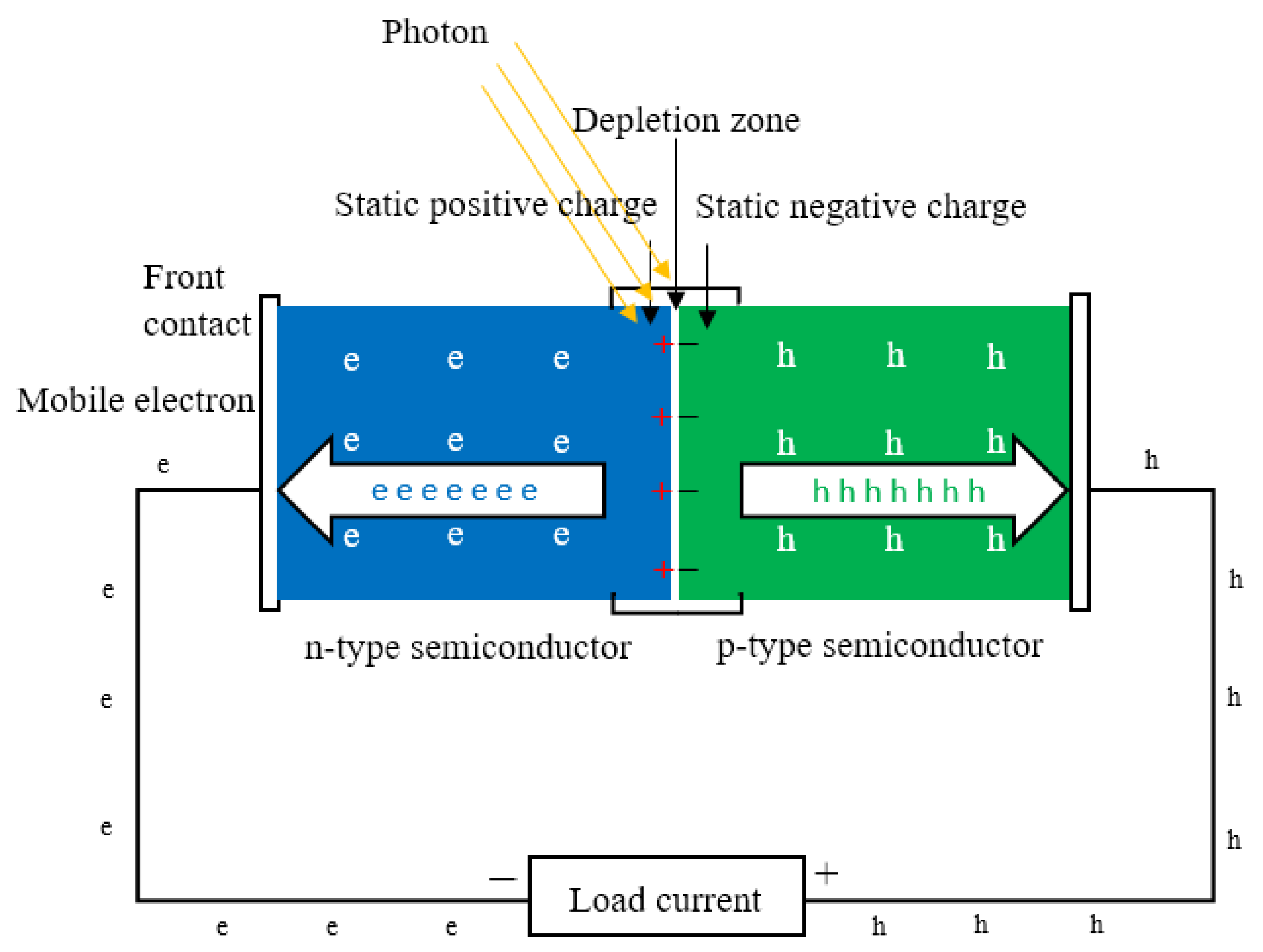

2.1. Photovoltaic Panels

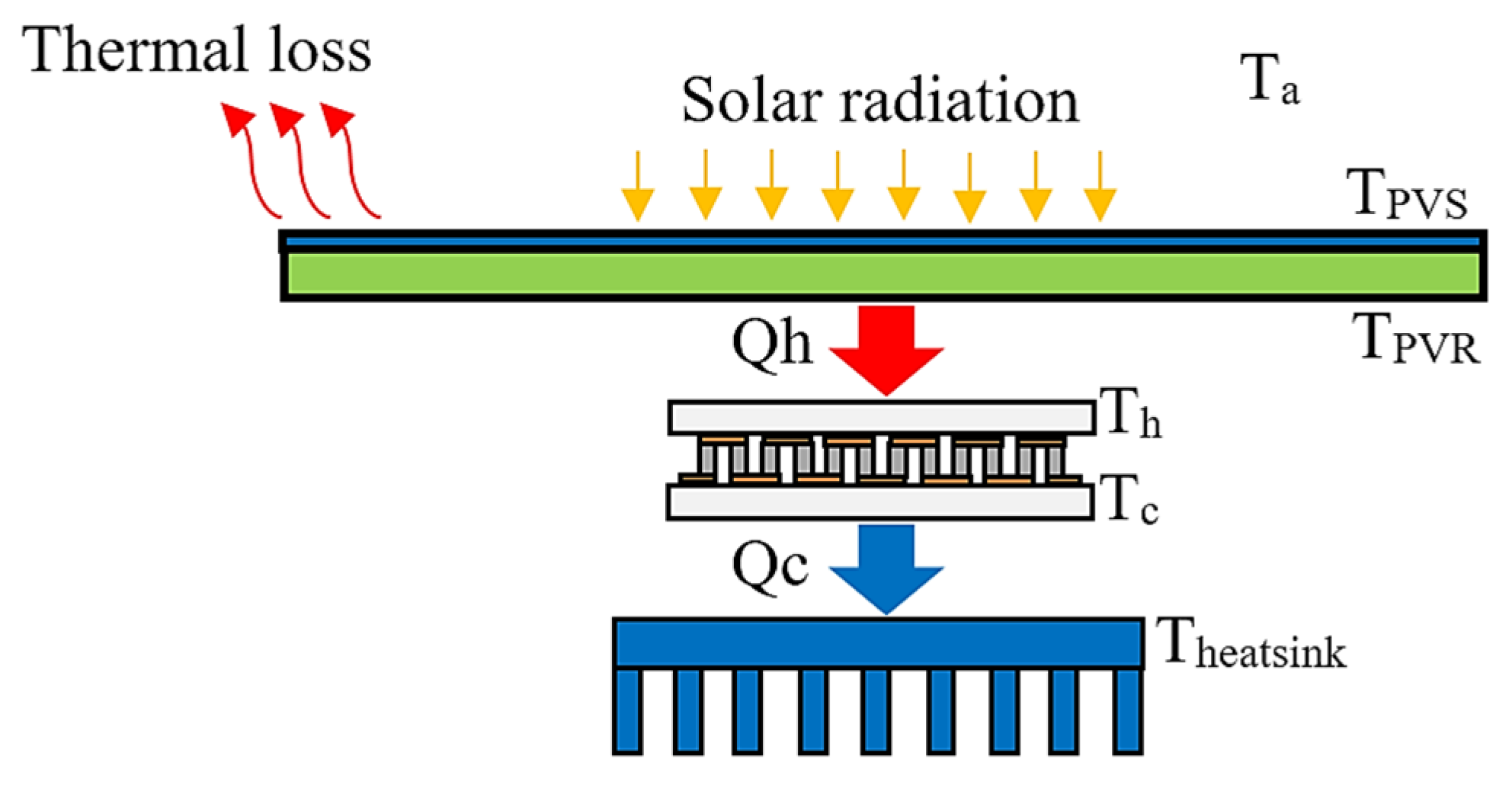

2.2. Combined Photovoltaic/Thermoelectric Generator Panels

3. Experimental Methods

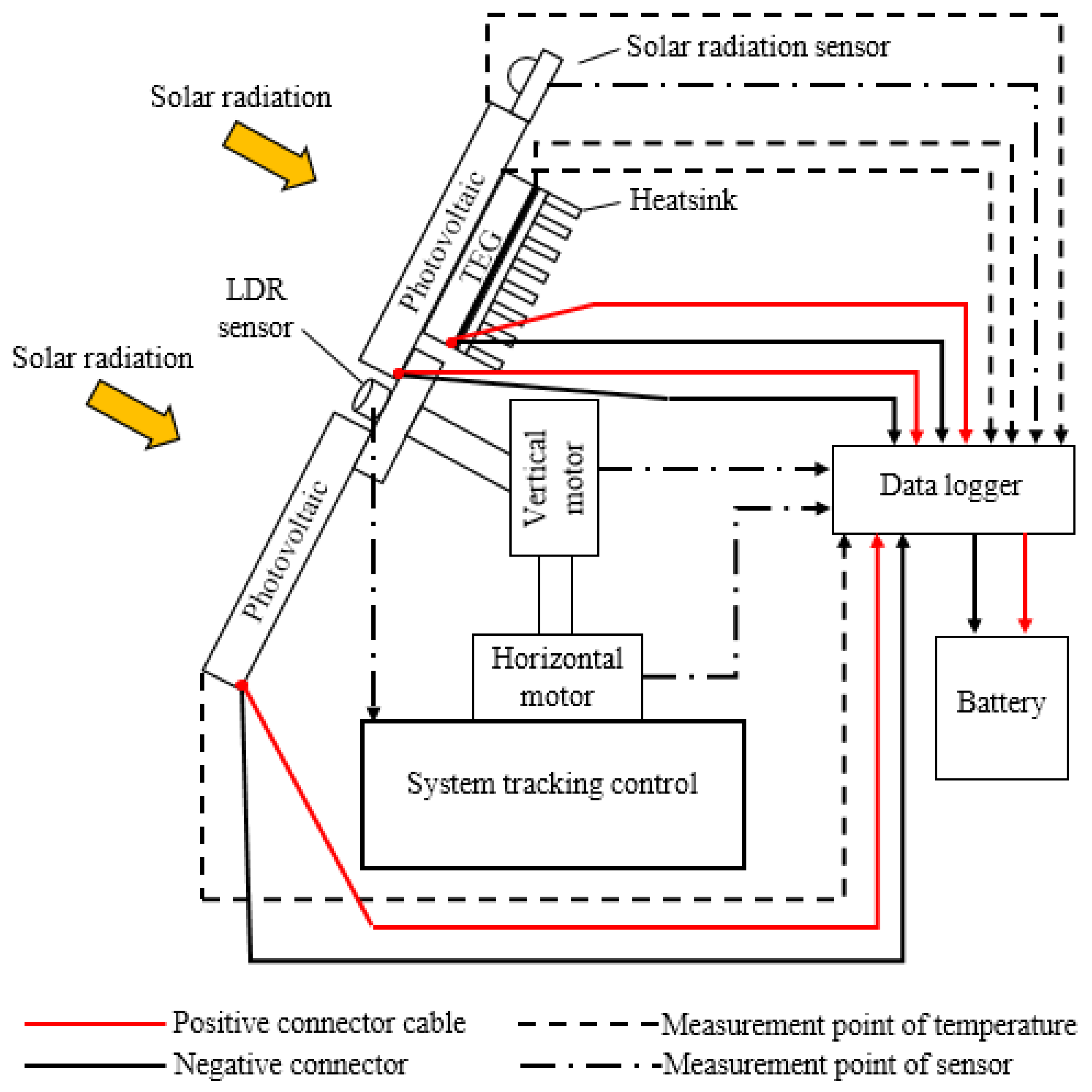

3.1. Photovoltaic/Thermoelectric Generator Panels

3.2. Experimental Procedures

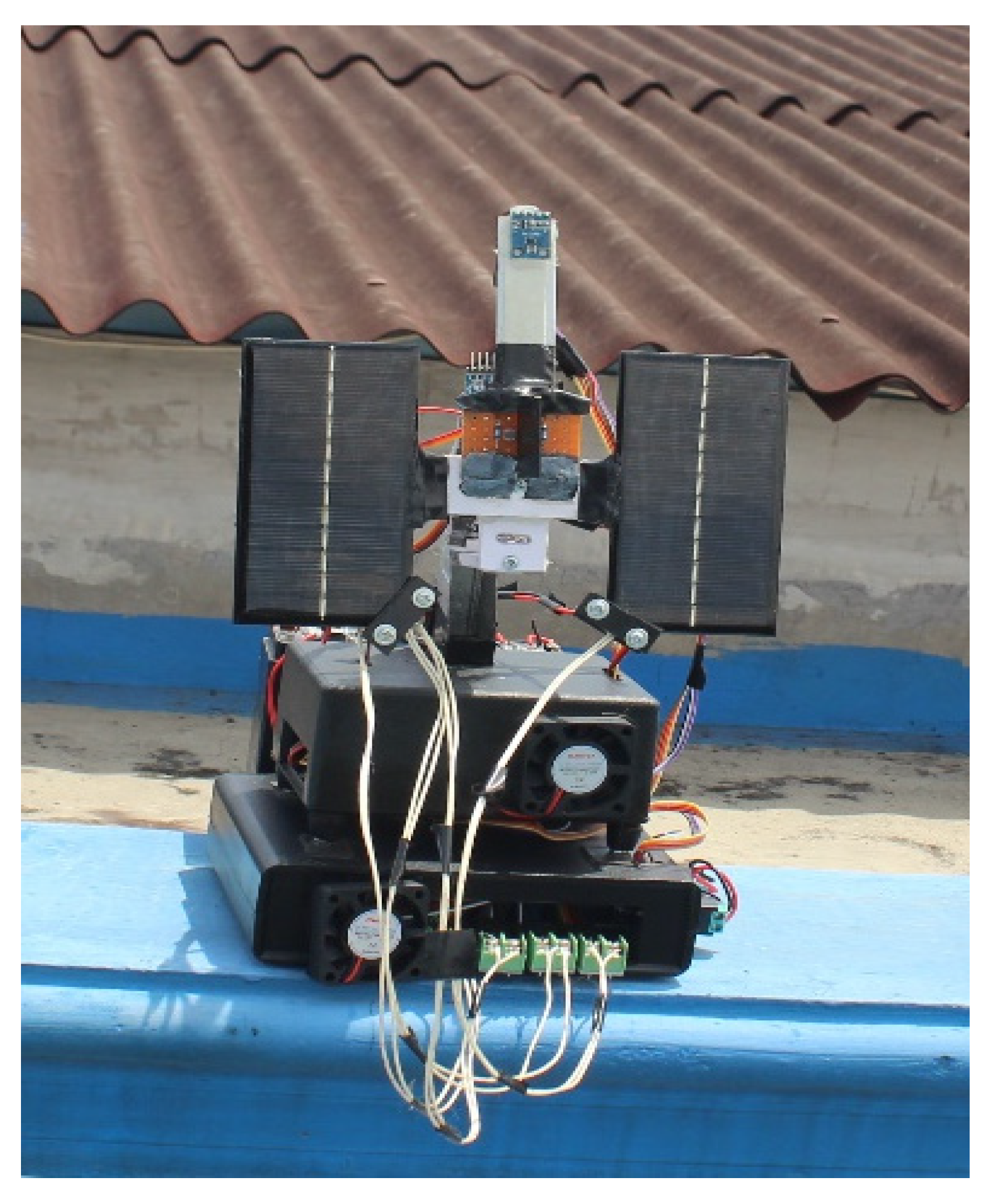

3.3. Solar Tracking Mechanism

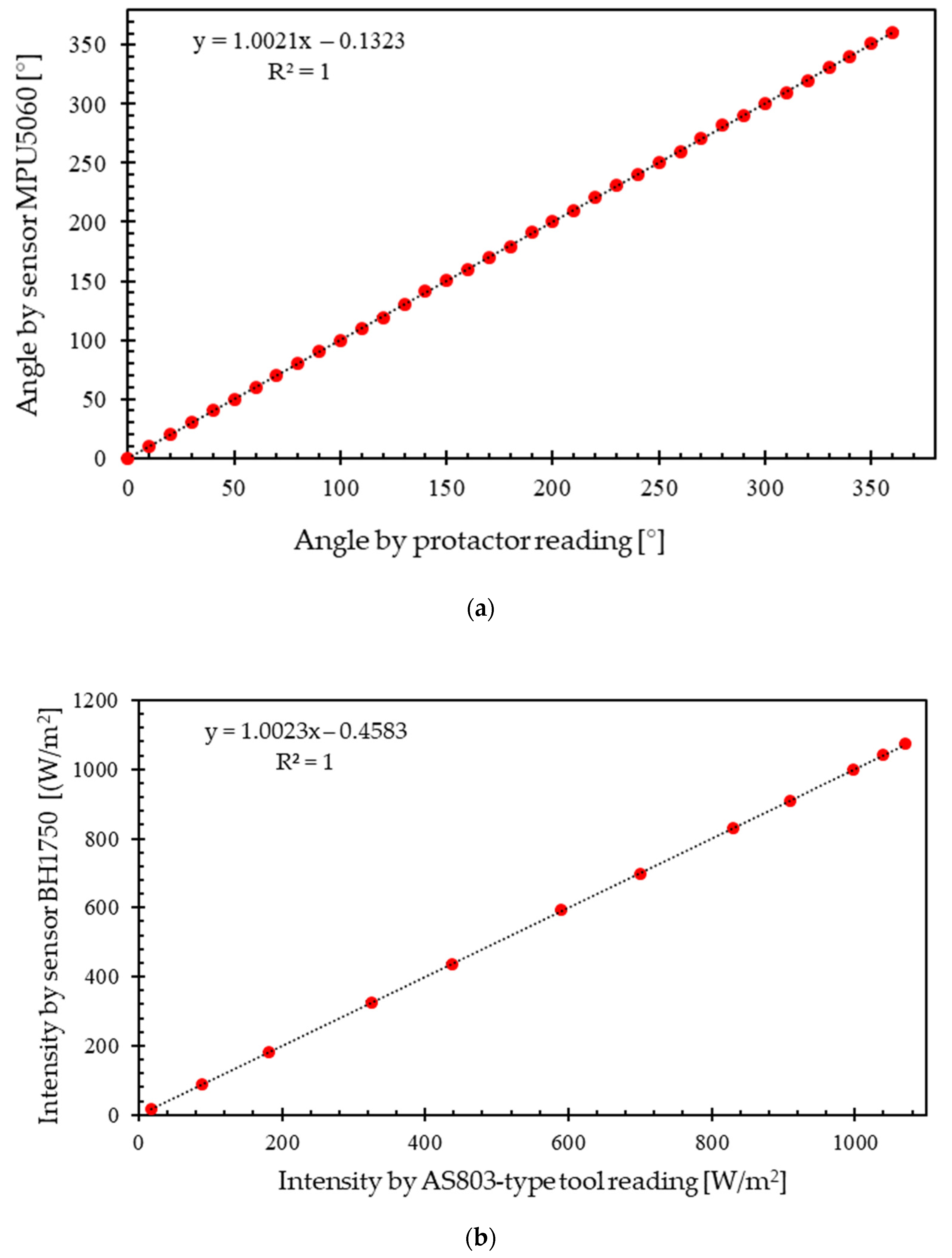

3.4. Tool Calibration

3.5. Uncertainty Analysis

4. Results and Discussion

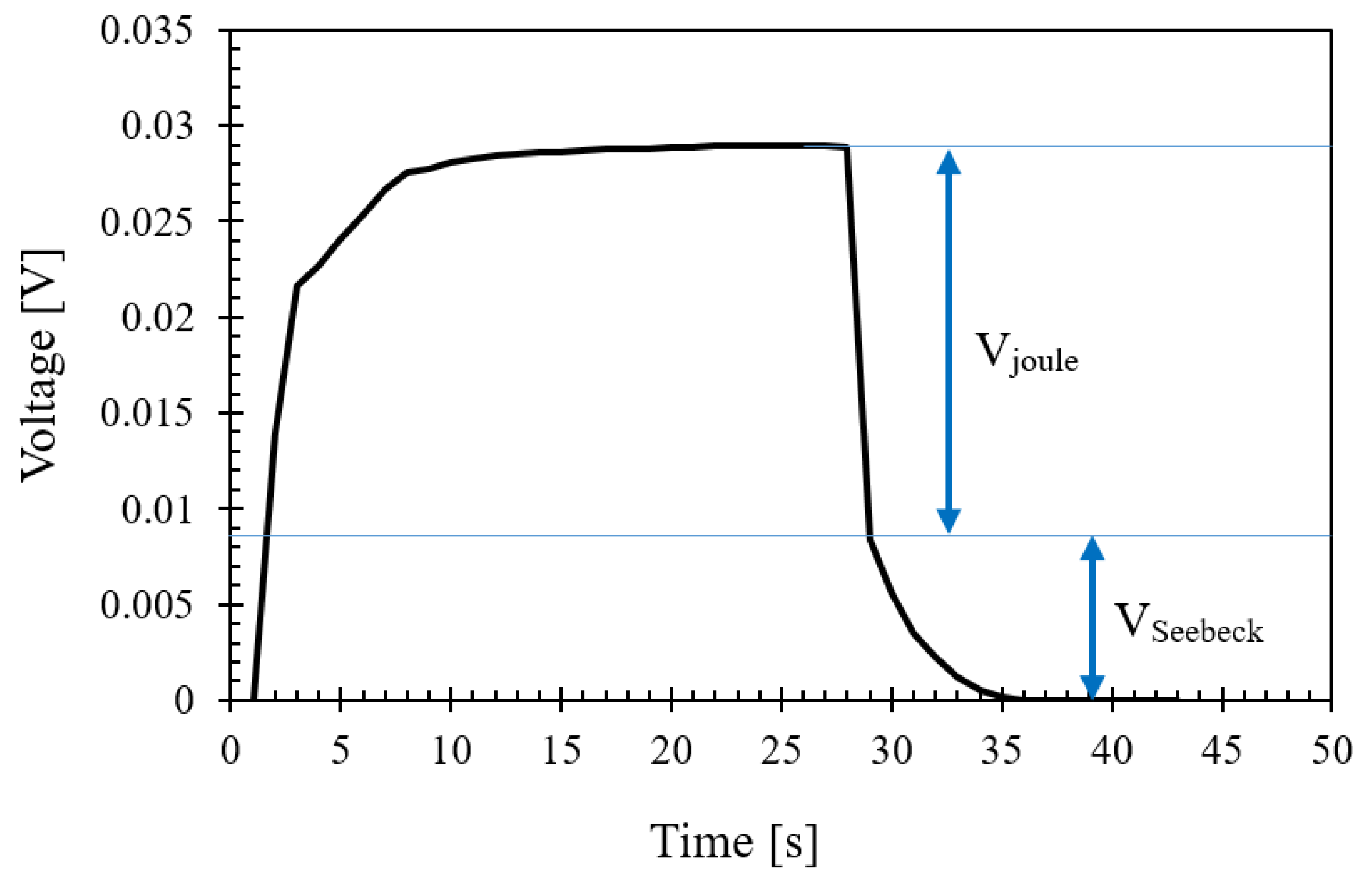

4.1. Harman Methods

4.2. Solar Angles

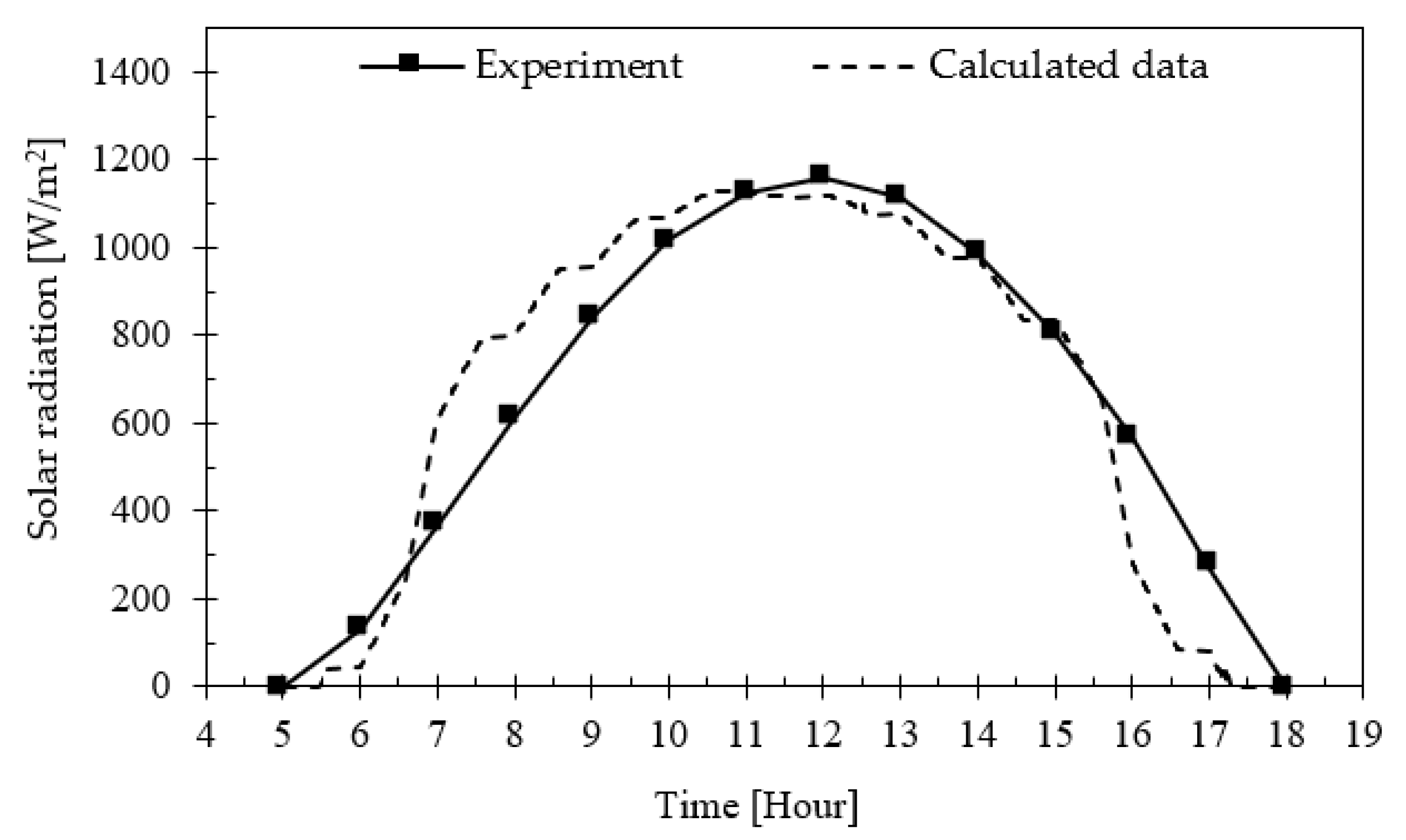

4.3. Solar Irradiation

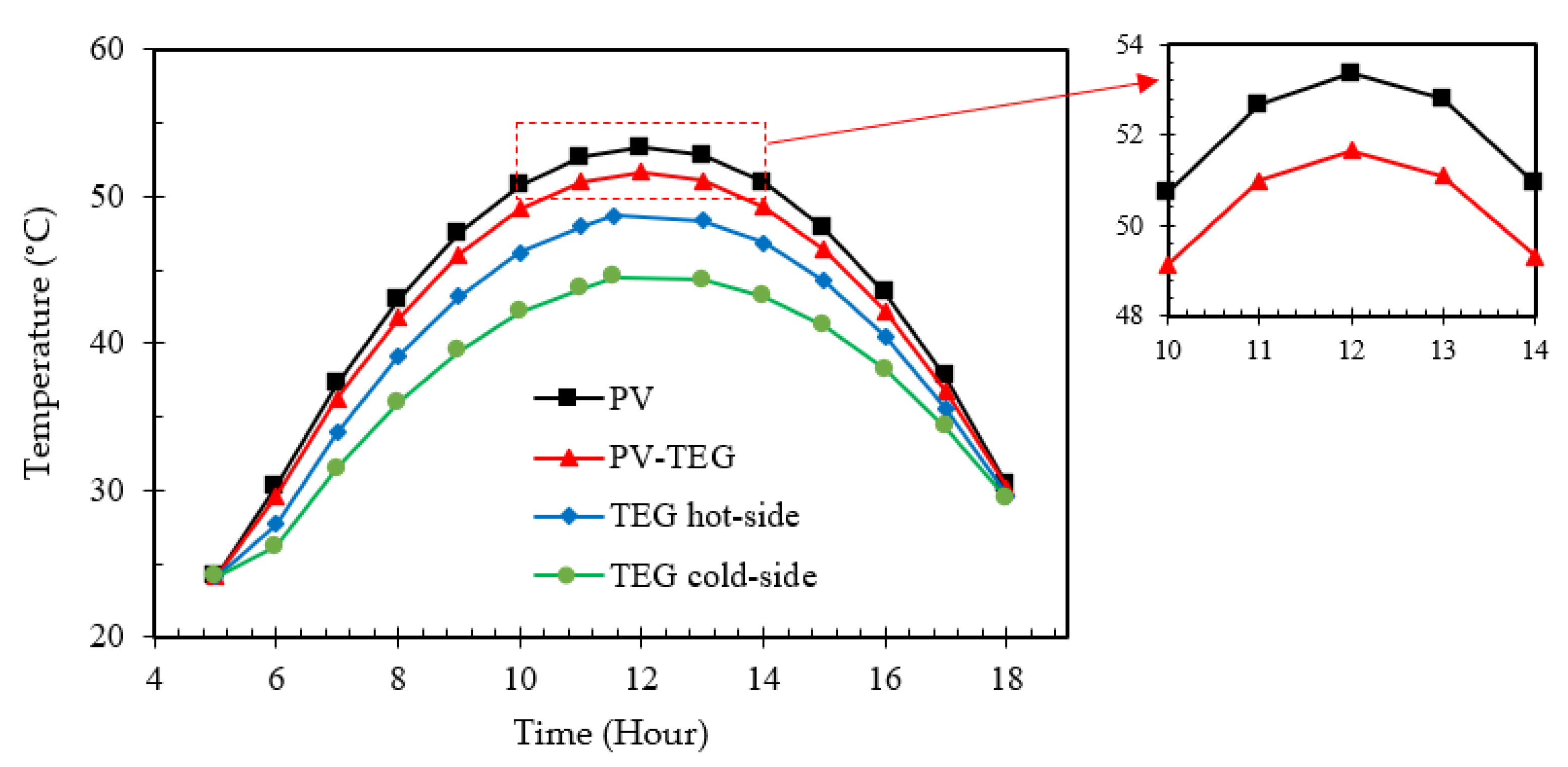

4.4. Temperature Profile

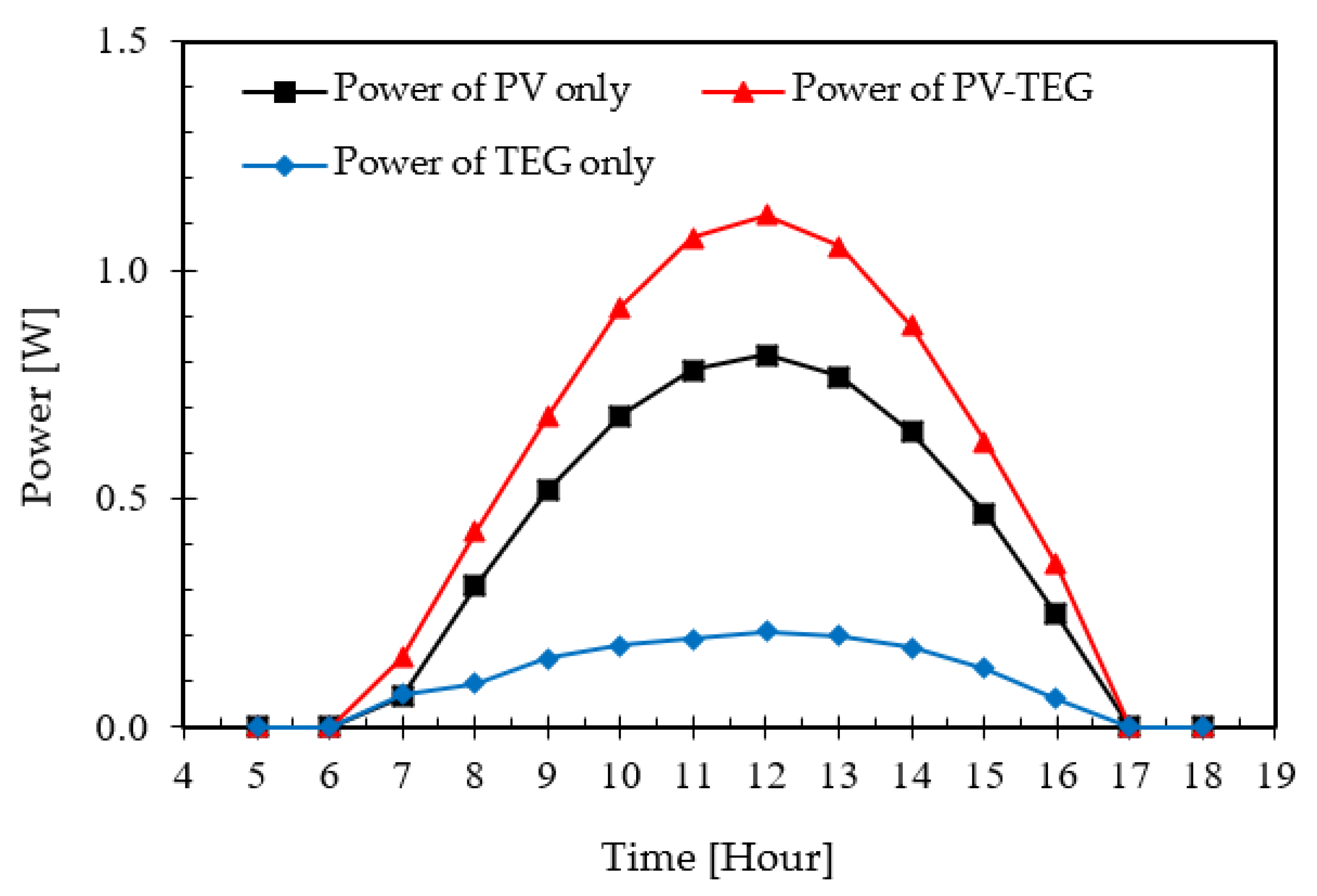

4.5. Power Output

4.6. Efficiency

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ATE | Cross-section of TEG element [m2] |

| LDR | Light dependent resistor [-] |

| P | Power [W] |

| PV | Photovoltaic [-] |

| PPV | Output power of PV [W] |

| PPV-TEG | Combined power of PV and TEG [W] |

| PTEG | Output power of TEG [W] |

| Rc | Thermal resistance at the cold side of TEG [K] |

| Re | Electrical resistance of TEG element [Ω] |

| Rte | Thermal resistance of TEG element [K/W] |

| Ta | Ambient temperature [K] |

| Tc | Temperature at the TEG cold side [K] |

| Th | Temperature at the TEG hot side [K] |

| Theat sink | Temperature at the heat sink [K] |

| TPVS | Temperature at the PV surface [K] |

| TPVR | Temperature at the PV rear [K] |

| TEG | Thermoelectric generator [-] |

| Q | Input energy per area unit of PV [W] |

| Qh | Heat flux at the TEG hot side [K] |

| Qc | Heat flux at the TEG cold side [K] |

| Ns | Number of semiconductor pairs |

| VJ | Voltage due to Joule effect [V] |

| VS | Voltage due to Seebeck effect [V] |

| PV | Photovoltaic panel |

| TEG | Thermoelectric generator |

| Transmittance | |

| α | Seebeck coefficient |

| as | Absorbance |

| Thermal emittance | |

| Efficiency of PV-TEG [%] | |

| Efficiency of TEG [%] | |

| Electrical resistivity | |

| λ | Thermal conductivity |

| ∆T | Temperature gradient |

| N | Number of measurement |

| Mean of value | |

| SD | Standard of deviation |

| Uncertainty of mean | |

| Bi2Te3 | Bismuth telluride |

References

- Foteinis, S.; Savvakis, N.; Tsoutsos, T. Energy and Environmental Performance of Photovoltaic Cooling Using Phase Change Materials under the Mediterranean Climate. Energy 2023, 265, 126355. [Google Scholar] [CrossRef]

- Wang, L.; Xu, S.; Gong, Y.; Ning, J.; Zhang, X.; Zhao, Y. High Resolution Photovoltaic Power Generation Potential Assessments of Rooftop in China. Energy Rep. 2022, 8, 14545–14553. [Google Scholar] [CrossRef]

- Zhang, F.; Han, C.; Wu, M.; Hou, X.; Wang, X.; Li, B. Global Sensitivity Analysis of Photovoltaic Cell Parameters Based on Credibility Variance. Energy Rep. 2022, 8, 7582–7588. [Google Scholar] [CrossRef]

- Shoaib, M.; Kakati, P.; Dandotiya, D.; Ramesh, C.S. A Comprehensive Review on Various Cooling Techniques to Decrease an Operating Temperature of Solar Photovoltaic Panels. Energy Nexus 2022, 8, 100161. [Google Scholar] [CrossRef]

- Ali, M.; Cebula, A.; Su, M. A Cooling Design for Photovoltaic Panels e Water-Based PV/T System. Energy 2022, 256, 124654. [Google Scholar] [CrossRef]

- Khorrami, N.; Rajabi, M.; Dehghan, M. A Novel Spectrally Selective Radiation Shield for Cooling a Photovoltaic Module. Sustain. Energy Technol. Assess. 2021, 46, 101269. [Google Scholar] [CrossRef]

- Zhao, Y.; Gong, S.; Zhang, C.; Ge, M.; Xie, L. Case Studies in Thermal Engineering Performance Analysis of a Solar Photovoltaic Power Generation System with Spray Cooling. Case Stud. Therm. Eng. 2022, 29, 101723. [Google Scholar] [CrossRef]

- Mahmood, D.M.N.; Aljubury, I.M.A. Results in Engineering Experimental Investigation of a Hybrid Photovoltaic Evaporative Cooling (PV/EC) System Performance under Arid Conditions. Results Eng. 2022, 15, 100618. [Google Scholar] [CrossRef]

- Sripadmanabhan, S.; Aravind, C.; Chong, K.; Saidur, R.; Faizal, M.; Abubakar, S.; Paiman, S. A Review on Various Configurations of Hybrid Concentrator Photovoltaic and Thermoelectric Generator System. Sol. Energy 2020, 201, 122–148. [Google Scholar] [CrossRef]

- Awasthi, A.; Shukla, A.K.; Murali Manohar, S.R.; Dondariya, C.; Shukla, K.N.; Porwal, D.; Richhariya, G. Review on Sun Tracking Technology in Solar PV System. Energy Rep. 2020, 6, 392–405. [Google Scholar] [CrossRef]

- Fathabadi, H. Novel High Ef Fi Cient of Fl Ine Sensorless Dual-Axis Solar Tracker for Using in Photovoltaic Systems and Solar Concentrators. Renew. Energy 2016, 95, 485–494. [Google Scholar] [CrossRef]

- Shittu, S.; Li, G.; Tang, X.; Zhao, X.; Ma, X.; Badiei, A. Analysis of Thermoelectric Geometry in a Concentrated Photovoltaic- Thermoelectric under Varying Weather Conditions. Energy 2020, 202, 117742. [Google Scholar] [CrossRef]

- Soltani, S.; Kasaeian, A.; Lavajoo, A.; Loni, R.; Naja, G. Exergetic and Enviromental Assessment of a Photovoltaic Thermal- Thermoelectric System Using Nano Fl Uids: Indoor Experimental Tests. Energy Convers. Manag. 2020, 218, 112907. [Google Scholar] [CrossRef]

- Widodo, T.; Riyadi, B.; Radiant, B.; Effendy, M.; Tri, A.; Al-kayiem, H.H. International Journal of Thermal Sciences Effect of Thermal Cycling with Various Heating Rates on the Performance of Thermoelectric Modules. Int. J. Therm. Sci. 2022, 178, 107601. [Google Scholar] [CrossRef]

- Bjørk, R.; Nielsen, K.K. The Performance of a Combined Solar Photovoltaic (PV) and Thermoelectric Generator (TEG) System. Sol. Energy 2015, 120, 187–194. [Google Scholar] [CrossRef]

- Shittu, S.; Li, G.; Zhao, X.; Ma, X.; Golizadeh, Y.; Fan, Y. Comprehensive Study and Optimization of Concentrated Photovoltaic- Thermoelectric Considering All Contact Resistances. Energy Convers. Manag. 2020, 205, 112422. [Google Scholar] [CrossRef]

- Van Sark, W.G.J.H.M. Feasibility of Photovoltaic—Thermoelectric Hybrid Modules. Appl. Energy 2011, 88, 2785–2790. [Google Scholar] [CrossRef]

- Ahsan, M.; Khan, I.; Khan, M.I.; Kazim, A.H.; Shabir, A. An Experimental and Comparative Performance Evaluation of a Hybrid Photovoltaic-Thermoelectric System. Front. Energy Res. 2021, 9, 1–9. [Google Scholar] [CrossRef]

- Nabil, T.; Mansour, T.M. Results in Engineering Augmenting the Performance of Photovoltaic Panel by Decreasing Its Temperature Using Various Cooling Techniques. Results Eng. 2022, 15, 100564. [Google Scholar] [CrossRef]

- Kumar, N.; Gaur, M.K.; Malvi, C.S. Application of Phase Change Materials for Cooling of Solar Photovoltaic Panels: A Review. Mater. Today Proc. 2021, 47, 6759–6765. [Google Scholar] [CrossRef]

- Rabelo, M.; Yousuf, H.; Kim, J.; Dao, V.; Phong, D. Progressive Cooling Techniques for Photovoltaic Module Efficiency and Reliability: Comparative Evaluation and Optimization. Energy Rep. 2022, 8, 8534–8545. [Google Scholar] [CrossRef]

- Shittu, S.; Li, G.; Golizadeh, Y.; Ma, X.; Zhao, X.; Ayodele, E. Advancements in Thermoelectric Generators for Enhanced Hybrid Photovoltaic System Performance. Renew. Sustain. Energy Rev. 2019, 109, 24–54. [Google Scholar] [CrossRef]

- Omri, M.; Selimefendigil, F.; Smaoui, H.T.; Kolsi, L. Case Studies in Thermal Engineering Cooling System Design for Photovoltaic Thermal Management by Using Multiple Porous Deflectors and Nanofluid. Case Stud. Therm. Eng. 2022, 39, 102405. [Google Scholar] [CrossRef]

- Mahdavi, A.; Farhadi, M.; Gorji-bandpy, M.; Mahmoudi, A. A Review of Passive Cooling of Photovoltaic Devices. Clean. Eng. Technol. 2022, 11, 100579. [Google Scholar] [CrossRef]

- Ramkiran, B.; Sundarabalan, C.K.; Sudhakar, K. Sustainable Passive Cooling Strategy for PV Module: A Comparative Analysis. Case Stud. Therm. Eng. 2021, 27, 101317. [Google Scholar] [CrossRef]

- Sutanto, B.; Setyo, Y.; Tri, A.; Iacovides, H. International Journal of Thermal Sciences Enhancing the Performance of Floating Photovoltaic System by Using Thermosiphon Cooling Method: Numerical and Experimental Analyses. Int. J. Therm. Sci. 2022, 180, 107727. [Google Scholar] [CrossRef]

- Grubišić-Čabo, F.; Nižetić, S.; Marinić Kragić, I.; Čoko, D. Further Progress in the Research of Fin-Based Passive Cooling Technique for the Free-Standing Silicon Photovoltaic Panels. Int. J. Energy Res. 2019, 43, 3475–3495. [Google Scholar] [CrossRef]

- Kidegho, G.; Njoka, F.; Muriithi, C.; Kinyua, R. Evaluation of Thermal Interface Materials in Mediating PV Cell Temperature Mismatch in PV–TEG Power Generation. Energy Rep. 2021, 7, 1636–1650. [Google Scholar] [CrossRef]

- Al-Ezzi, A.S.; Ansari, M.N.M. Photovoltaic Solar Cells: A Review. Appl. Syst. Innov. 2022, 5, 67. [Google Scholar] [CrossRef]

- Lincot, D. The New Paradigm of Photovoltaics: From Powering Satellites to Powering Humanity. Comptes Rendus Phys. 2017, 18, 381–390. [Google Scholar] [CrossRef]

- Simya, O.K.; Radhakrishnan, P.; Ashok, A.; Kavitha, K.; Althaf, R. Engineered Nanomaterials for Energy Applications. Handb. Nanomater. Ind. Appl. 2018, 751–767. [Google Scholar] [CrossRef]

- Zhu, W.; Deng, Y.; Wang, Y.; Shen, S.; Gulfam, R. High-Performance Photovoltaic-Thermoelectric Hybrid Power Generation System with Optimized Thermal Management. Energy 2016, 100, 91–101. [Google Scholar] [CrossRef]

- Babu, C.; Ponnambalam, P. The Theoretical Performance Evaluation of Hybrid PV-TEG System. Energy Convers. Manag. 2018, 173, 450–460. [Google Scholar] [CrossRef]

- Tenorio, H.C.R.L.; Vieira, D.A.; De Souza, C.P.; De Macedo, E.C.T.; Freire, R.C.S. A Thermoelectric Module Thermal-Cycling Testing Platform with Automated Measurement Capabilities. In Proceedings of the 2016 IEEE International Instrumentation and Measurement Technology Conference Proceedings, Taipei, Taiwan, 23–26 May 2016. [Google Scholar] [CrossRef]

- Barako, M.T.; Park, W.; Marconnet, A.M.; Asheghi, M.; Goodson, K.E. A Reliability Study with Infrared Imaging of Thermoelectric Modules under Thermal Cycling. In Proceedings of the 13th InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, San Diego, CA, USA, 30 May–1 June 2012; pp. 86–92. [Google Scholar] [CrossRef]

- Hatzikraniotis, E.; Zorbas, K.T.; Samaras, I.; Kyratsi, T.; Paraskevopoulos, K.M. Efficiency Study of a Commercial Thermoelectric Power Generator (TEG) under Thermal Cycling. J. Electron. Mater. 2010, 39, 2112–2116. [Google Scholar] [CrossRef]

- Barako, M.T.; Park, W.; Marconnet, A.M.; Asheghi, M.; Goodson, K.E. Thermal Cycling, Mechanical Degradation, and the Effective Figure of Merit of a Thermoelectric Module. J. Electron. Mater. 2013, 42, 372–381. [Google Scholar] [CrossRef]

- Castillo, E.E.; Hapenciuc, C.L.; Borca-Tasciuc, T. Thermoelectric Characterization by Transient Harman Method under Nonideal Contact and Boundary Conditions. Rev. Sci. Instrum. 2010, 81, 044902. [Google Scholar] [CrossRef] [PubMed]

- Williams, N.P.; Power, J.; Trimble, D.; O’Shaughnessy, S.M. An Experimental Evaluation of Thermoelectric Generator Performance under Cyclic Heating Regimes. Heat Mass Transf. 2022. [Google Scholar] [CrossRef]

- Champier, D. Thermoelectric Generators: A Review of Applications. Energy Convers. Manag. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Kanagaraj, N. Photovoltaic and Thermoelectric Generator Combined Hybrid Energy System with an Enhanced Maximum Power Point Tracking Technique for Higher Energy Conversion Efficiency. Sustainability 2021, 13, 3144. [Google Scholar] [CrossRef]

- Nagaraj, N.N.A.M.; Kumar, L.S. Electrical Energy Harvesting Using Thermo Electric Generator for Rural Communities in India. Int. J. Energy Power Eng. 2019, 13, 663–667. [Google Scholar]

- Atmoko, N.T.; Veza, I.; Widodo, T.; Riyadi, B. Study on the Energy Conversion in the Thermoelectric Liquefied Petroleum Gas Cooking Stove with Different Cooling Methods. Int. J. Eng. Trends Technol. 2021, 69, 185–193. [Google Scholar] [CrossRef]

- Nouman, A.S.; Chokhachian, A.; Santucci, D.; Auer, T. Prototyping of Environmental Kit for Georeferenced Transient Outdoor Comfort Assessment. ISPRS Int. J. Geo-Inf. 2019, 8, 76. [Google Scholar] [CrossRef]

- Robert, J. Moffat Describing the Uncertainties in Experimental Results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Hoffman, T. Altitude and Azimuth Angle. Available online: https://www.suncalc.org/ (accessed on 11 November 2022).

- First Rays LLC. Solar Intensity Calculator. Available online: https://firstrays.com/natural-sunlight-intensity/ (accessed on 11 November 2022).

- Das, S. Materials Today: Proceedings Short Term Forecasting of Solar Radiation and Power Output of 89.6 kWp Solar PV Power Plant. Mater. Today Proc. 2021, 39, 1959–1969. [Google Scholar] [CrossRef]

- Mccormick, P.G.; Suehrcke, H. The e Ff Ect of Intermittent Solar Radiation on the Performance of PV Systems. Sol. Energy 2018, 171, 667–674. [Google Scholar] [CrossRef]

- Sharaf, M.; Yousef, M.S.; Huzayyin, A.S. Review of Cooling Techniques Used to Enhance the Efficiency of Photovoltaic Power Systems. Environ. Sci. Pollut. Res. 2022, 29, 26131–26159. [Google Scholar] [CrossRef]

- Idoko, L.; Anaya-Lara, O.; McDonald, A. Enhancing PV Modules Efficiency and Power Output Using Multi-Concept Cooling Technique. Energy Rep. 2018, 4, 357–369. [Google Scholar] [CrossRef]

- Dida, M.; Boughali, S.; Bechki, D.; Bouguettaia, H. Experimental Investigation of a Passive Cooling System for Photovoltaic Modules Efficiency Improvement in Hot and Arid Regions. Energy Convers. Manag. 2021, 243, 114328. [Google Scholar] [CrossRef]

- Adibpour, S.; Raisi, A.; Ghasemi, B.; Sajadi, A.R.; Rosengarten, G. Experimental Investigation of the Performance of a Sun Tracking Photovoltaic Panel with Phase Change Material. Renew. Energy 2021, 165, 321–333. [Google Scholar] [CrossRef]

| Author | Type PV | System Cooling | Power | Efficiency |

|---|---|---|---|---|

| Sark [17] | Not mentioned | TEG | Not mentioned | 8–23% |

| Ahsan et al. [18] | Polycrystalline | TEG | Increases by 19% | Increases by 2.4% |

| Sutanto et al. [26] | Polycrystalline | Floating and thermosiphon-floating | The floating PV increases by 4.52% from PV ground; thermosiphon-floating PV increases by 7.86% from PV. | The floating PV increases by 4.53% from PV ground; thermosiphon-floating PV increases by 7.76% from PV. |

| Grubišić-Čabo et al. [27] | Not mentioned | Fin and passive air-based cooler | Increases by 5% | Not mentioned |

| Kidegho et al. [28] | Polycrystalline | TEG combination air and water cooler | Air cooling increases by 19.7%; water cooling increases by 24.85%. | Not mentioned |

| Parameters | Unit | Value |

|---|---|---|

| Dimension | mm | 110 × 60 |

| Max. working voltage | V | 5 |

| Max. working current | mA | 200 |

| Parameters | Unit | Value |

|---|---|---|

| Dimension | mm | 40 × 40 × 3.9 |

| Operation temperature | °C | 0–150 |

| Seebeck coefficient | V/K | 0.054 |

| Working voltage at ΔT 100 °C | V | 6.4 |

| Working current at ΔT 100 °C | A | 0.969 |

| Parameters | Specification |

|---|---|

| Working voltage | 4.5 V |

| Operation temperature | 40–80 °C |

| Accuracy | +/− 20% |

| Sensor’s build | 16 bitAD |

| Chip | ROHM |

| Parameters | Uncertainty of Mean |

|---|---|

| Angle | ±0.176° |

| Solar radiation | ±0.759 W/m2 |

| Temperature | ±0.574 C |

| Voltage | ±0.043 V |

| Power | ±0.067 W |

| Efficiency | ±0.250% |

| Reference | Type PV | Cooling System | Temperature Reduction | Solar Tracker | Efficiency Increase |

|---|---|---|---|---|---|

| Čabo et al. [27] | Polycrystalline 520 Wp | Fin cooling | 2 °C | No | 0.40% |

| Babu and Ponnambalam [33] | Crystalline | TEG | Not mentioned | No | 6% |

| Dida et al. [52] | Polycrystalline 80 W | Evaporative water cooling | 17.1 °C | No | 1.46% |

| Adibpour et al. [53] | Monocrystalline 60 W | PV-PCM system | 9.1 °C | Yes | 6.80% |

| Khan et al. [18] | Polycrystalline | TEG | 3 °C | No | 1.40% |

| Sutanto et al. [26] | Polycrystalline 50 Wp | Floating and thermosiphon-floating | 1–4 °C | No | 7.76% |

| Present work | Monocrystalline 5 V | TEG and heat sink | 4.23 °C | Yes | 3.35% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Utomo, B.R.; Sulistyanto, A.; Riyadi, T.W.B.; Wijayanta, A.T. Enhanced Performance of Combined Photovoltaic–Thermoelectric Generator and Heat Sink Panels with a Dual-Axis Tracking System. Energies 2023, 16, 2658. https://doi.org/10.3390/en16062658

Utomo BR, Sulistyanto A, Riyadi TWB, Wijayanta AT. Enhanced Performance of Combined Photovoltaic–Thermoelectric Generator and Heat Sink Panels with a Dual-Axis Tracking System. Energies. 2023; 16(6):2658. https://doi.org/10.3390/en16062658

Chicago/Turabian StyleUtomo, Bagus Radiant, Amin Sulistyanto, Tri Widodo Besar Riyadi, and Agung Tri Wijayanta. 2023. "Enhanced Performance of Combined Photovoltaic–Thermoelectric Generator and Heat Sink Panels with a Dual-Axis Tracking System" Energies 16, no. 6: 2658. https://doi.org/10.3390/en16062658

APA StyleUtomo, B. R., Sulistyanto, A., Riyadi, T. W. B., & Wijayanta, A. T. (2023). Enhanced Performance of Combined Photovoltaic–Thermoelectric Generator and Heat Sink Panels with a Dual-Axis Tracking System. Energies, 16(6), 2658. https://doi.org/10.3390/en16062658