Characteristics of Porosity Distribution and Gas Migration in Different Layers of Comprehensive Working Face Goaf

Abstract

1. Introduction

2. Mathematical Model of Gas Migration and Storage in Goaf

2.1. Porosity and Permeability of Different Layers of Gob

2.2. Governing Equations of Gas Flow

2.2.1. Continuity Equation of Gas

2.2.2. Equation of Momentum Conservation

2.3. Re-Normalisation Group (RNG) K-ε Model of Gas Transport

2.4. Mass Conservation Equation of Gas Components

2.5. Fluid Equation of State

3. Numerical Simulation of Gas Migration and Reservoir Characteristics in Goaf

3.1. Overview of Test Working Face

3.1.1. Lithologic Parameters of Overlying Strata on the Working Face

3.1.2. Gas Emission from the Working Face

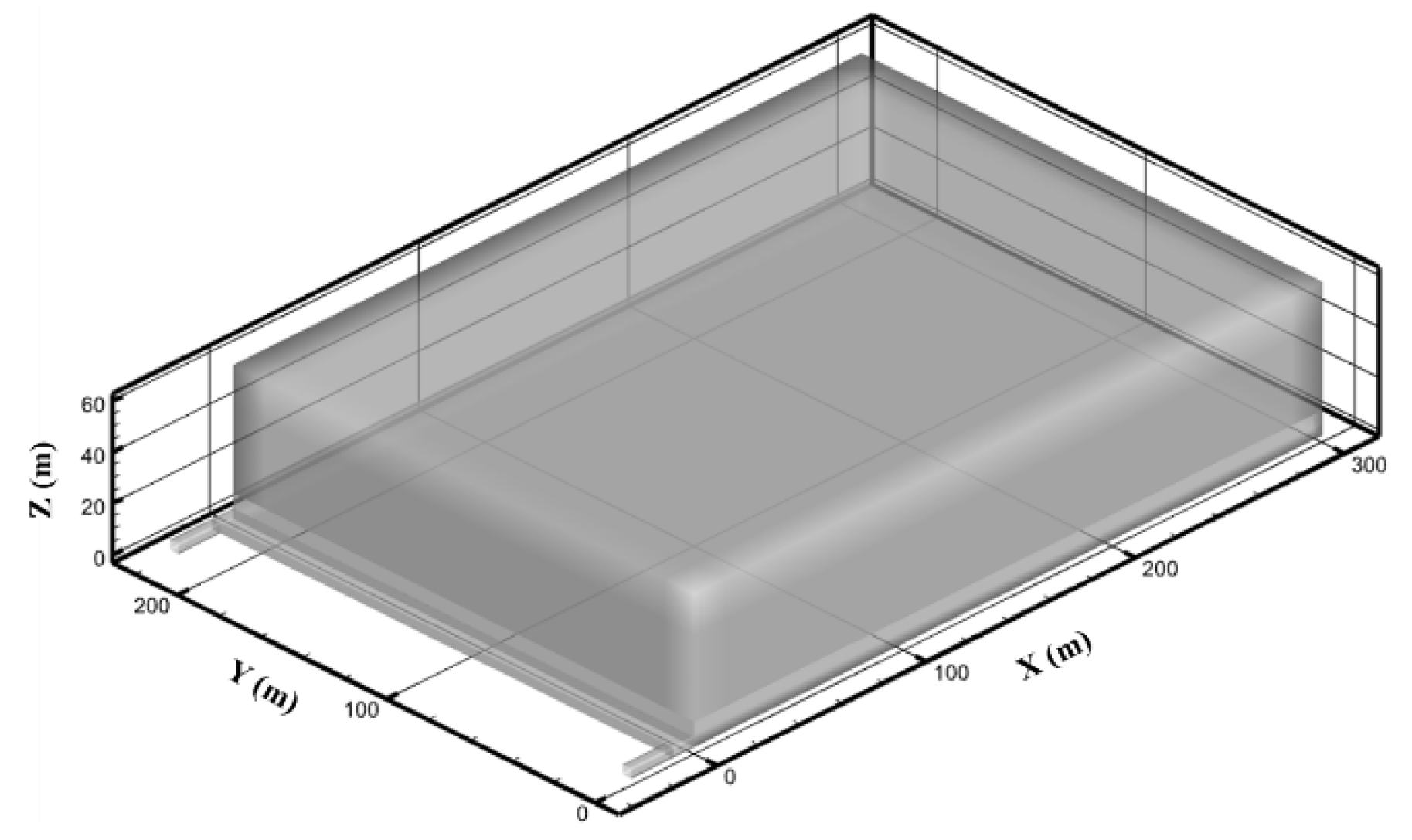

3.2. Establishment of Geometric Model

3.3. Mesh Generation and Test System Setup

4. Test Results and Analysis

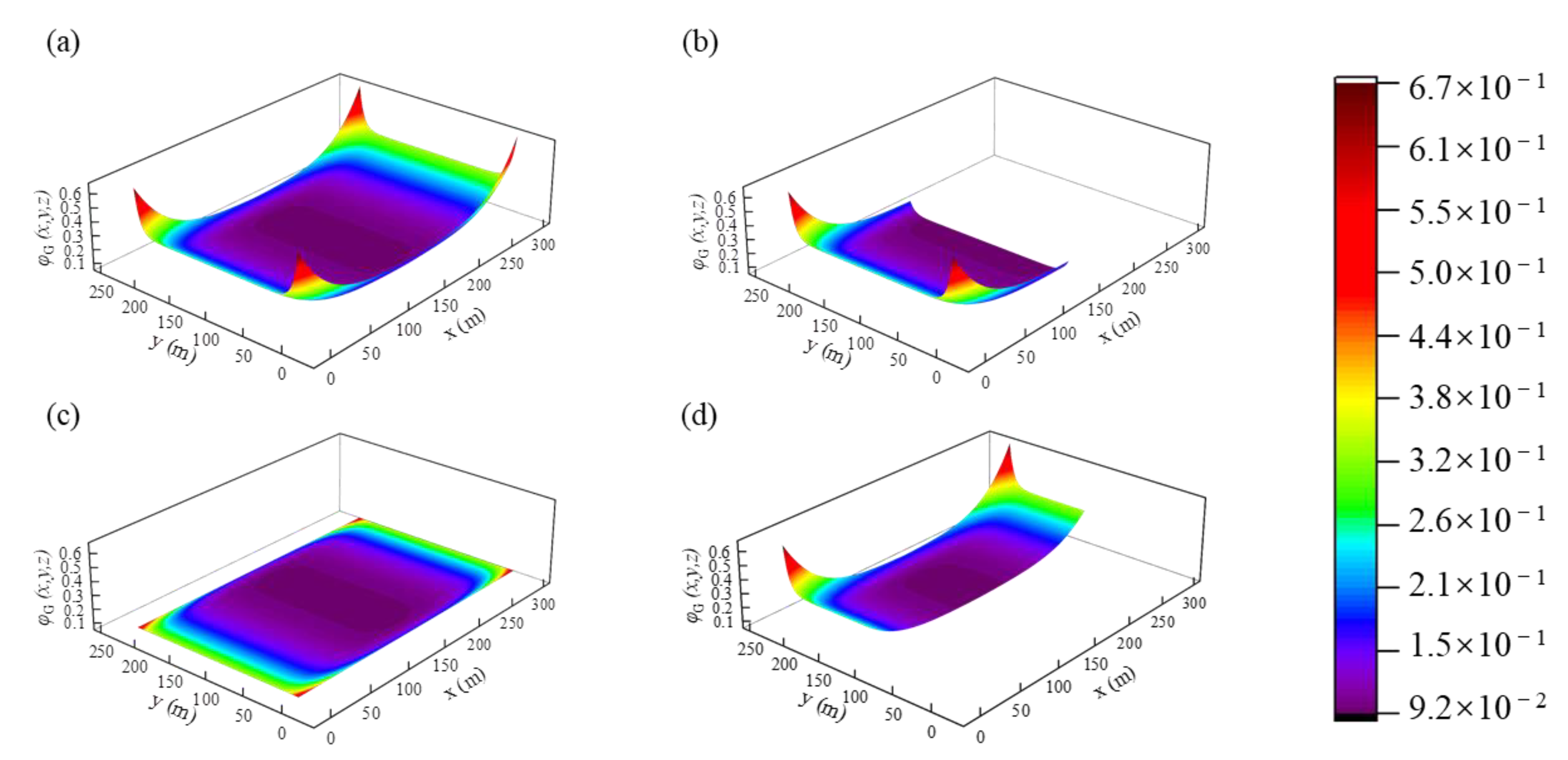

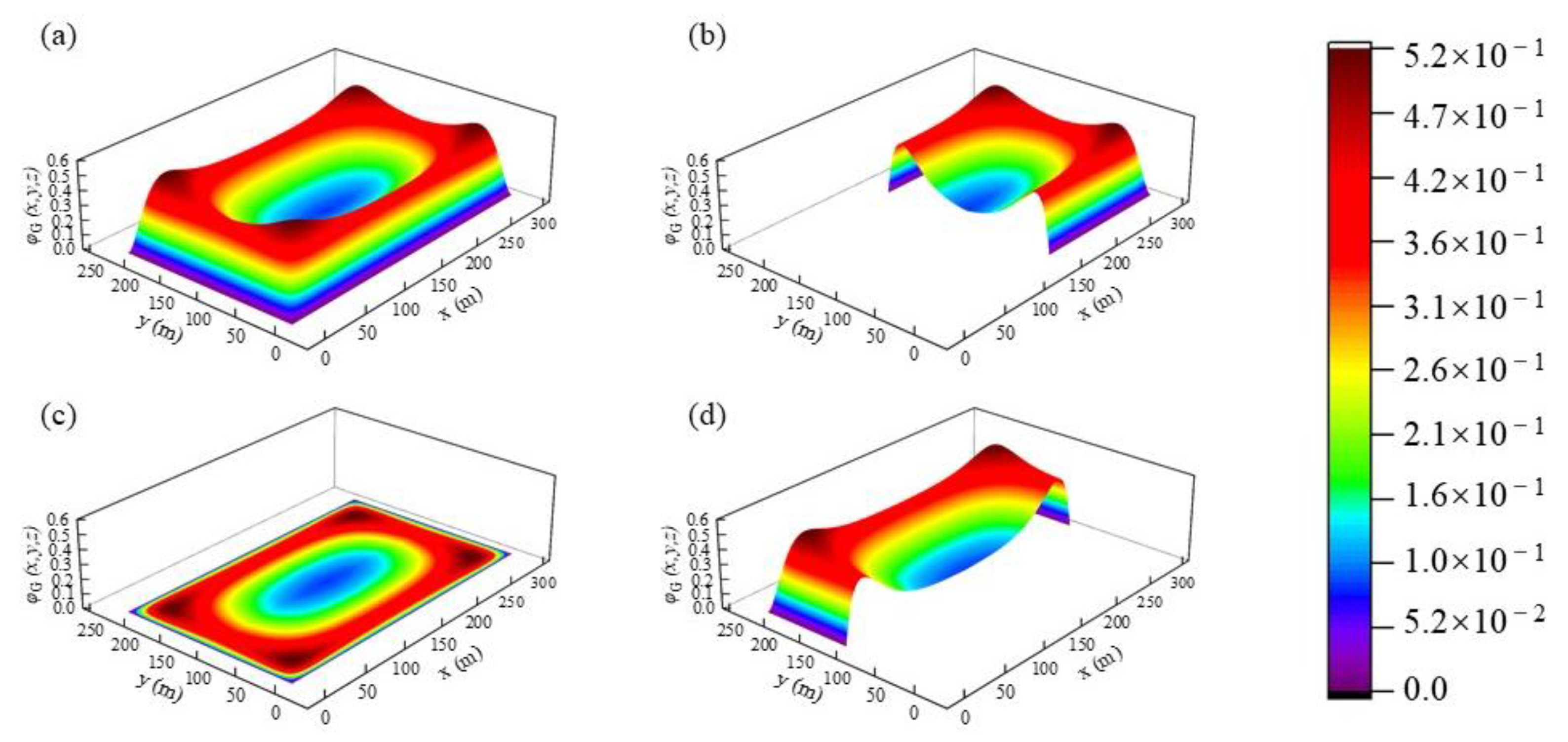

4.1. Distribution Characteristics of Porosity in Caving Zone and Fracture Zone

4.2. Characteristics of Gas Migration and Accumulation

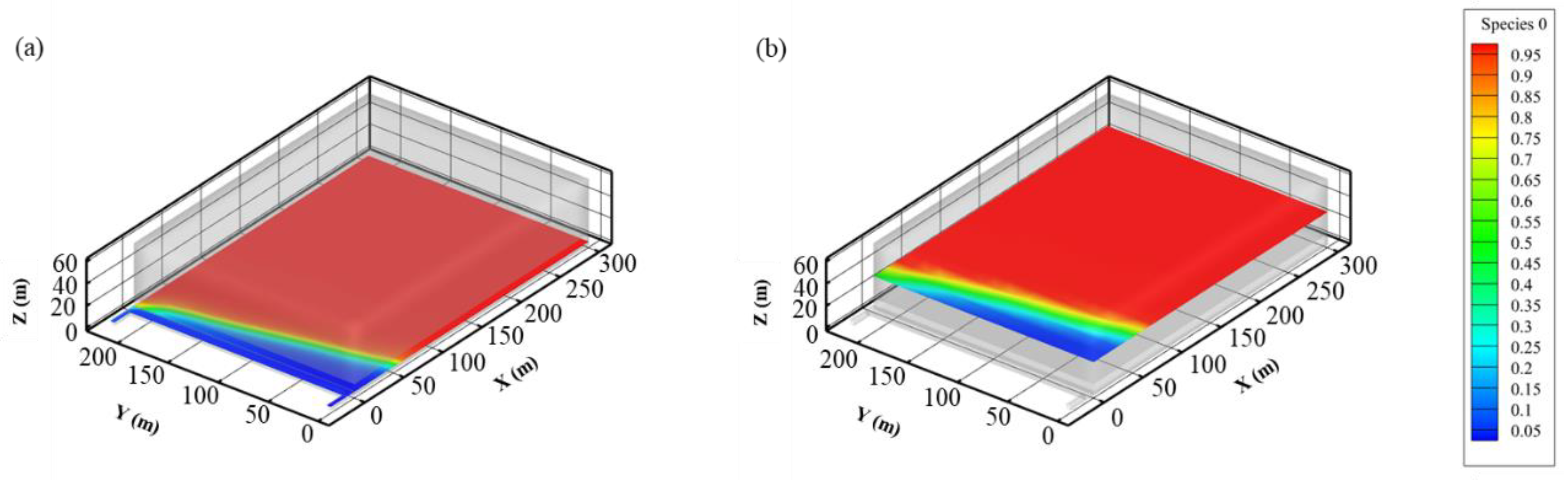

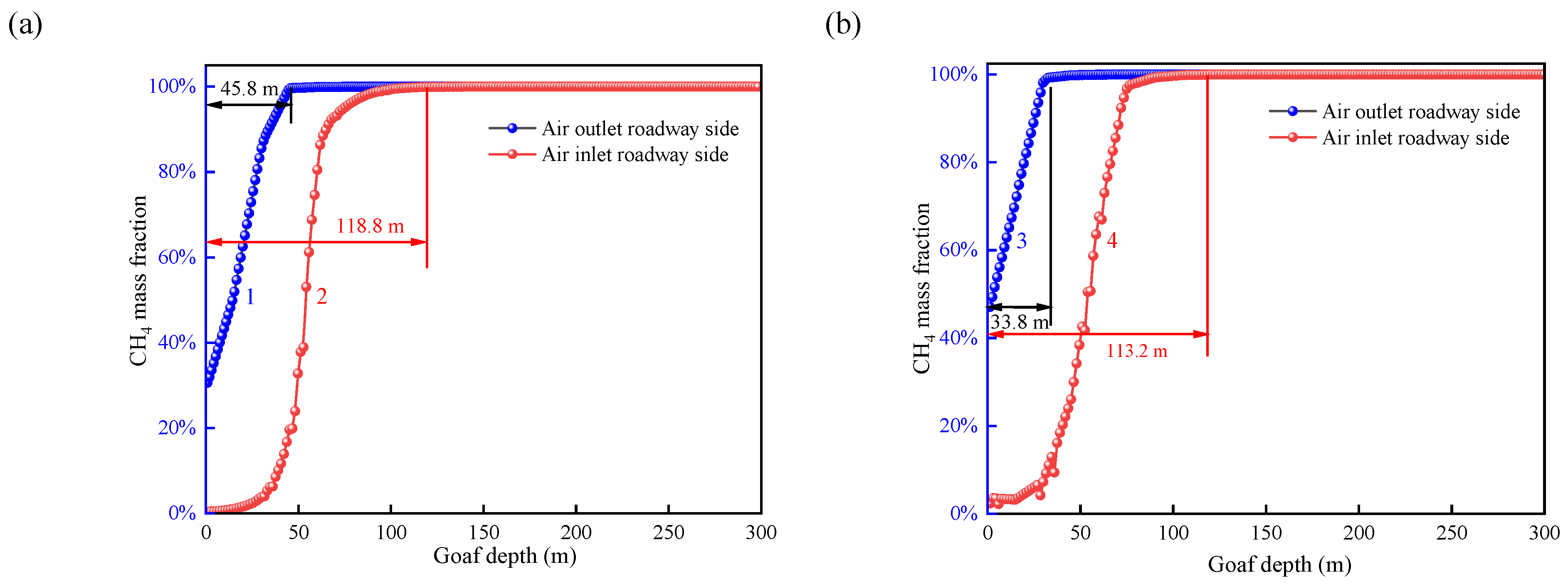

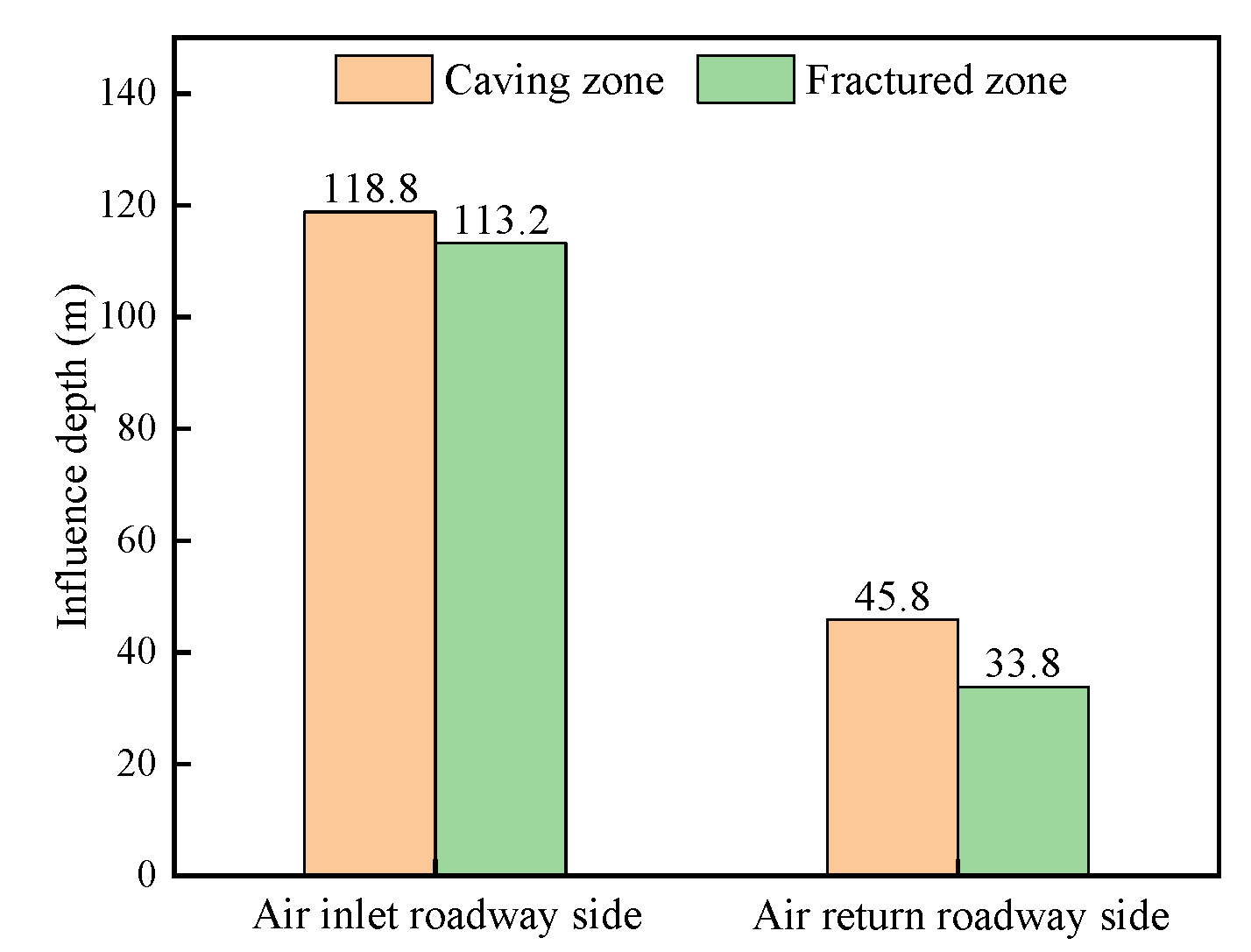

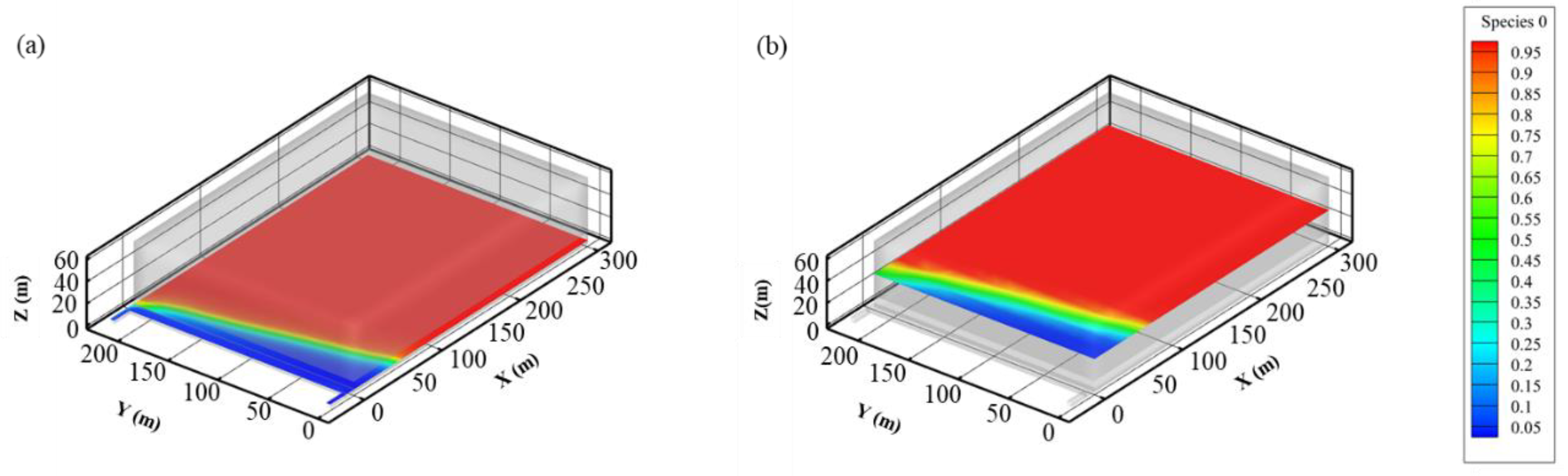

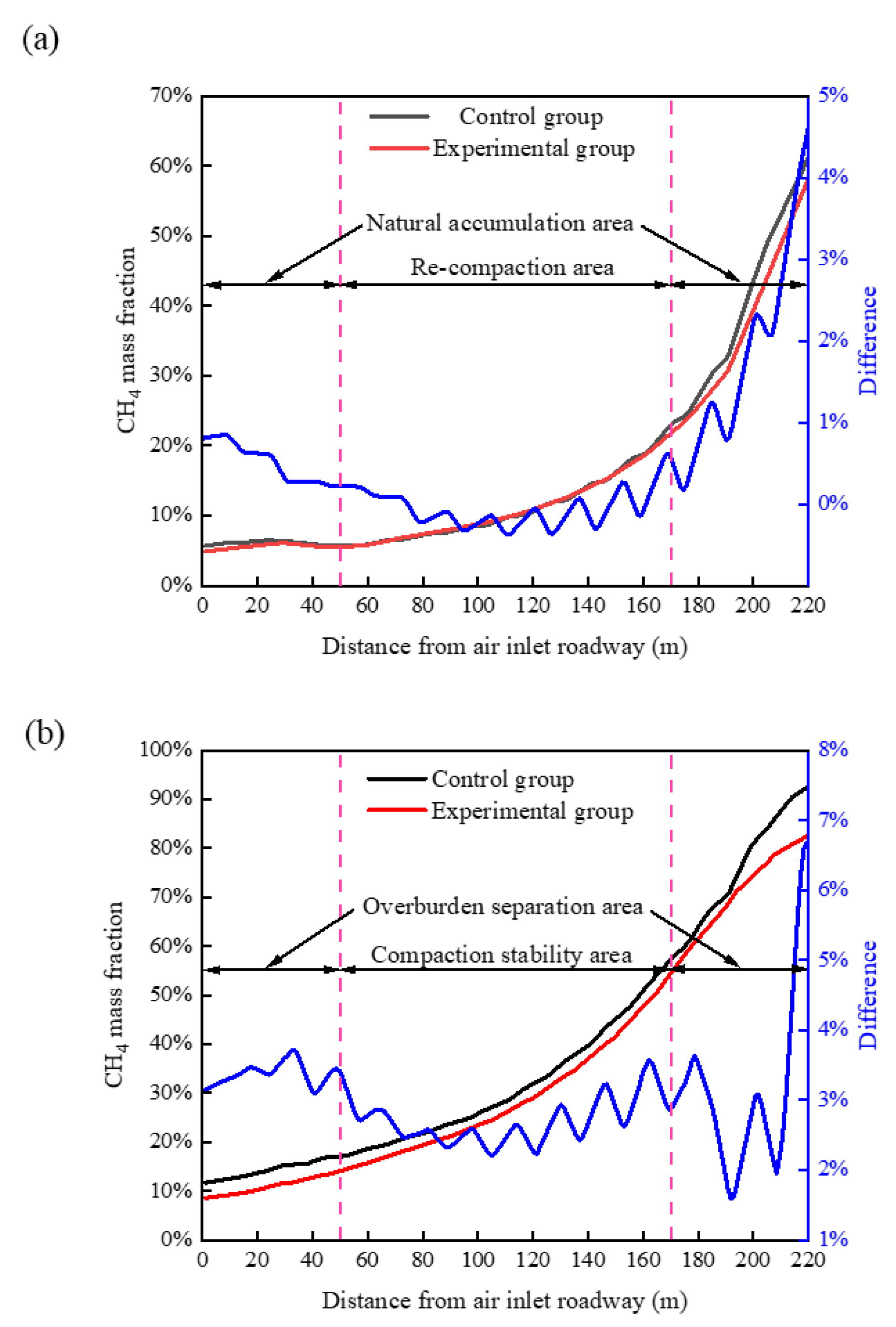

4.2.1. Characteristics of Gas Migration and Accumulation in the Strike Direction

4.2.2. Characteristics of Gas Migration and Accumulation in the Inclination Direction

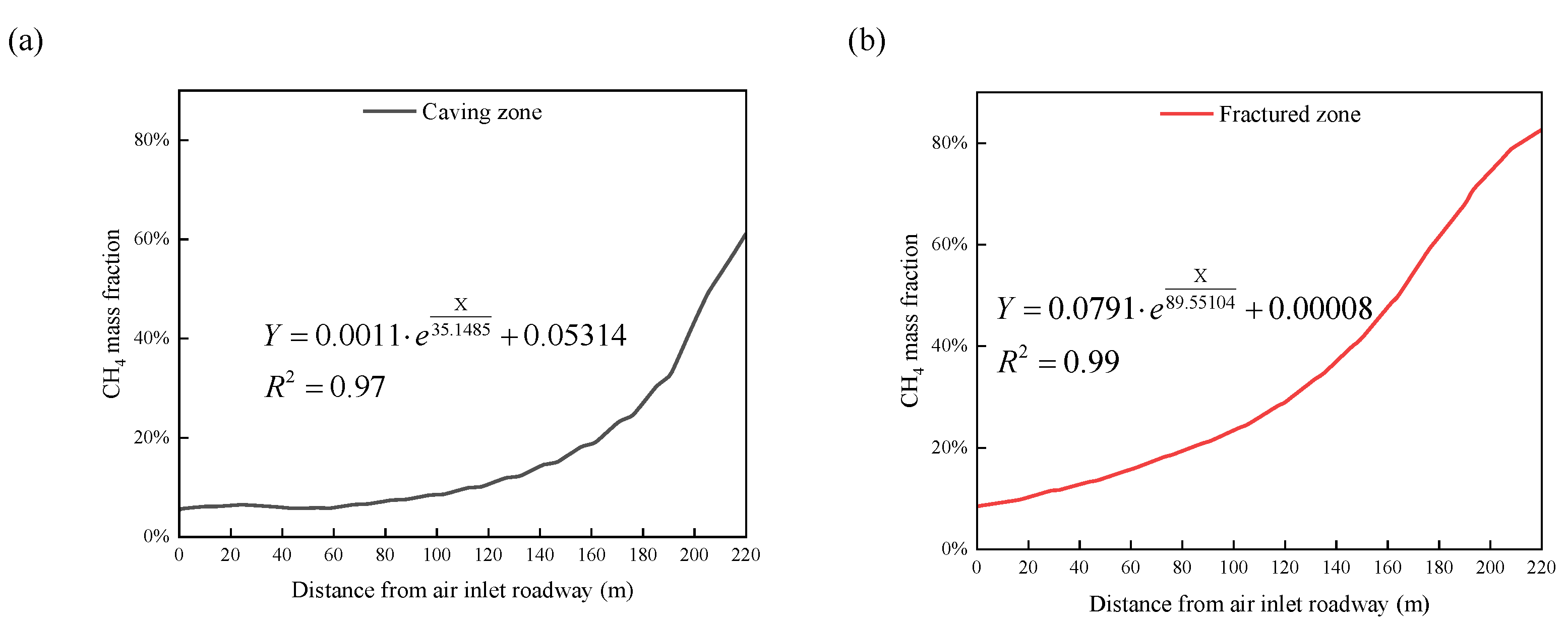

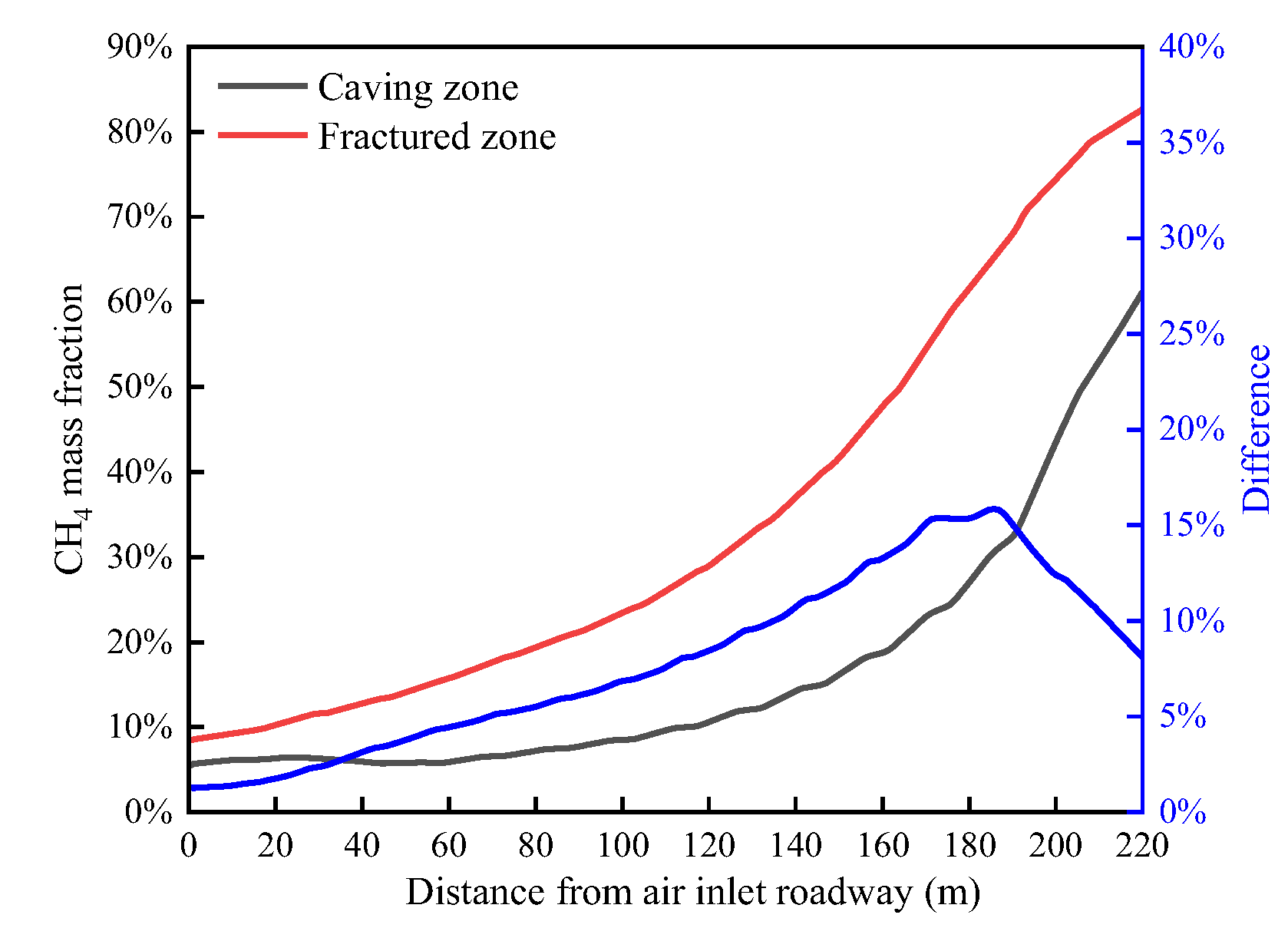

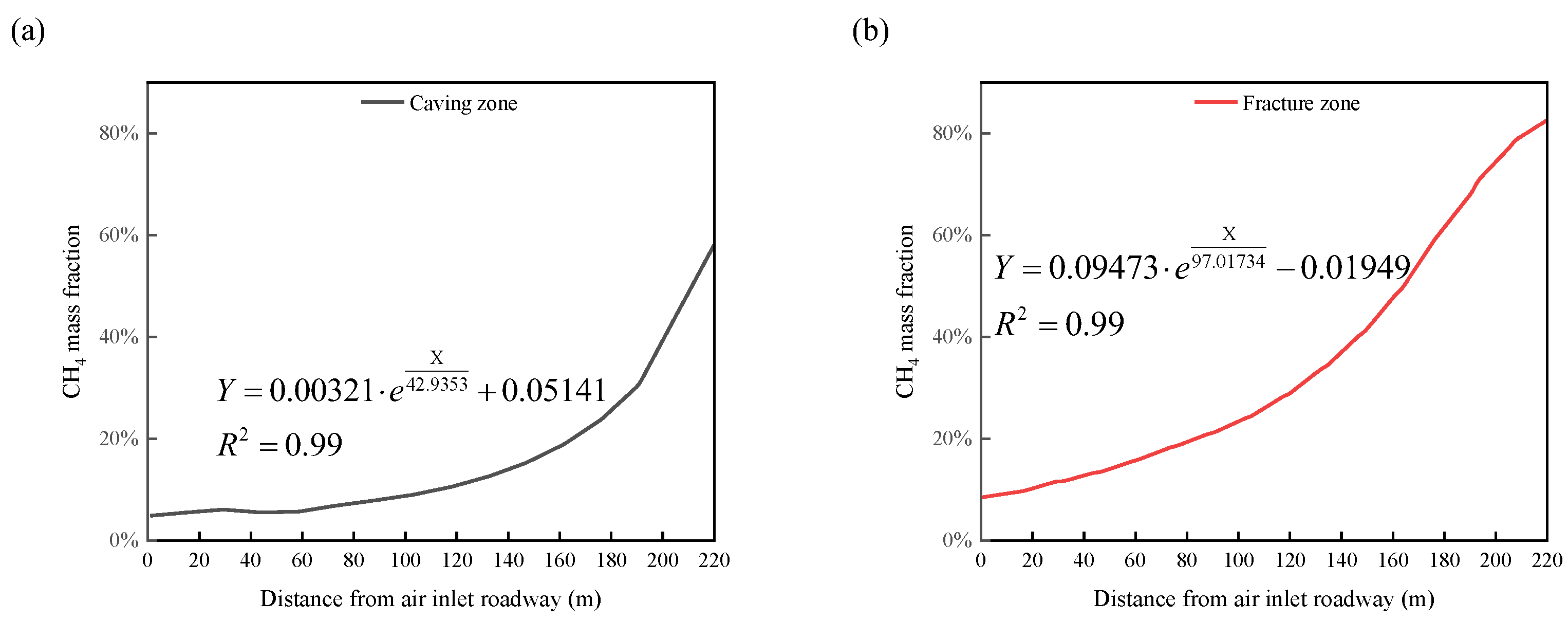

4.2.3. Characteristics of Gas Migration and Storage in Different Layers of Goaf

4.3. Influencing Factors of Gas Migration and Reservoir Characteristics

5. Results and Discussion

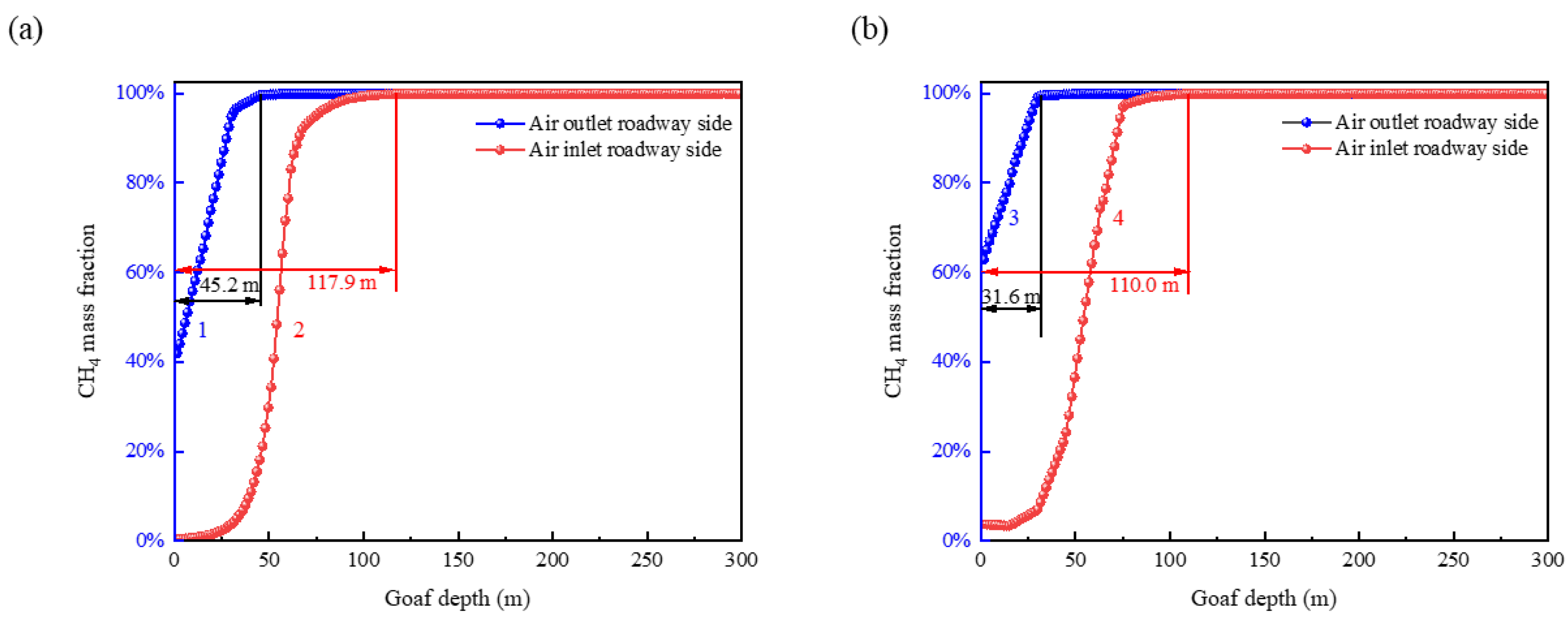

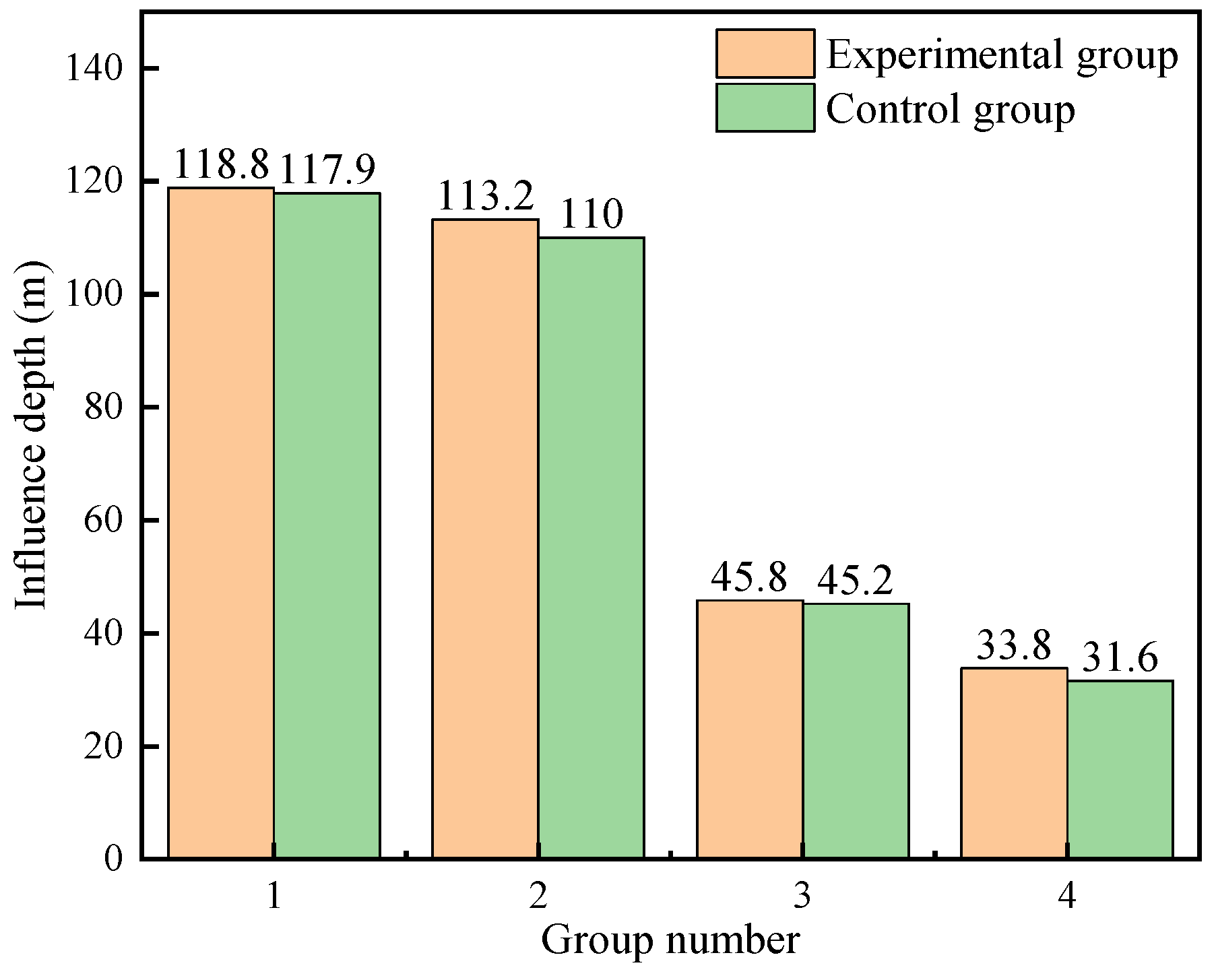

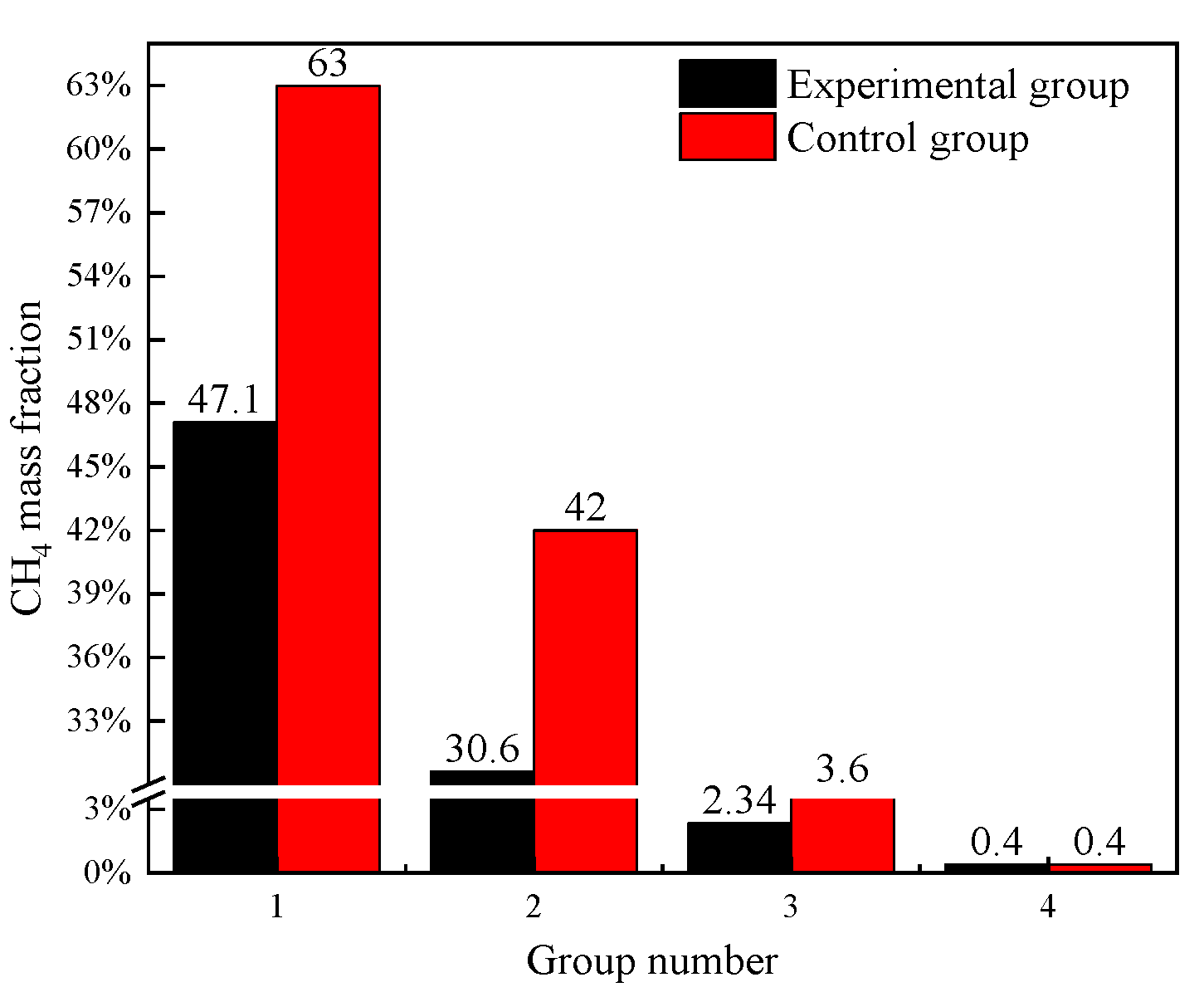

5.1. Comparison of Gas Reservoir Characteristics in Goaf Strike Direction

5.2. Comparison of Gas Reservoir Characteristics in Goaf Inclination Direction

5.3. Comparison of Gas Migration and Reservoir Characteristics in Different Layers of Goaf

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chang, Y.; Shu, C.; You, M. Explosion prevention and weighting analysis on the inerting effect of methane via grey entropy model. J. Loss Prev. Process. Ind. 2021, 71, 104385. [Google Scholar] [CrossRef]

- Linghu, J.; Zhao, W.; Zhou, J.; Yan, Z.; Wang, K.; Xu, C. Influence of deep magma-induced thermal effects on the regional gas outburst risk of coal seams. Int. J. Coal Sci. Technol. 2021, 8, 1411–1422. [Google Scholar] [CrossRef]

- Du, X.; Xue, J.; Ma, Q.; Chen, Z.; Zhan, K. Energy evolution characteristics of coal–rock composite bodies based on unidirectional load. Nat. Resour. Res. 2022, 31, 1647–1663. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, Y.; Chen, X.; Zhang, Y.; Rui, L.; Guo, R. Numerical simulation on response characteristics of coal ignition under the disturbance of fluctuating heat. Combust. Flame 2022, 237, 111870. [Google Scholar] [CrossRef]

- Valiulin, S.V.; Onischuk, A.A.; Baklanov, A.M.; Bazhina, A.A.; Paleev, D.Y.; Zamashchikov, V.V. Effect of coal mine organic aerosol on the methane/air lower explosive limit. Int. J. Coal Sci. Technol. 2020, 7, 778–786. [Google Scholar] [CrossRef]

- Gao, K.; Huang, P.; Liu, Z.G.; Liu, J.; Wang, F.; Shu, C.M. Pressure relief by blasting roof cutting in close seam group mining under thick sandstone to enhance gas extraction for mining safety. Processes 2021, 9, 603. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, M.; Xue, J.; Li, M.; Li, J. Repetitive mining stress and pore pressure effects on permeability and pore pressure sensitivity of bituminous coal. Nat. Resour. Res. 2021, 30, 4457–4476. [Google Scholar] [CrossRef]

- Xiang, Z.; Si, G.; Wang, Y.; Belle, B.; Webb, D. Goaf gas drainage and its impact on coal oxidation behaviour: A conceptual model. Int. J. Coal Geol. 2021, 248, 103878. [Google Scholar] [CrossRef]

- Qin, J.; Qu, Q.; Guo, H. CFD simulations for longwall gas drainage design optimisation. Int. J. Min. Sci. Technol. 2017, 27, 777–782. [Google Scholar] [CrossRef]

- Wei, P.; Li, X.; Hu, Q.; Peng, S.; Liu, S. A Trapezoidal three-dimensional model for gas extraction based on shapes of caved overlying strata and numerical calculation. Nat. Resour. Res. 2020, 29, 4031–4051. [Google Scholar] [CrossRef]

- Si, G.; Belle, B. Performance analysis of vertical goaf gas drainage holes using gas indicators in Australian coal mines. Int. J. Coal Geol. 2019, 216, 103301. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, K.; Zhang, R.; Dong, H.; Lou, Z.; An, F. Influence of combination forms of intact sub-layer and tectonically deformed sub-layer of coal on the gas drainage performance of boreholes: A numerical study. Int. J. Coal Sci. Technol. 2020, 7, 571–580. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, M.; Li, M.; Lu, S.; Yuan, X.; Li, J. Experimental study on evolution of fracture network and permeability characteristics of bituminous coal under repeated mining effect. Nat. Resour. Res. 2022, 31, 463–486. [Google Scholar] [CrossRef]

- Han, D.; Hu, S.; Zhang, A.; Hao, G.; Hu, L. Study on voidage distribution regulation and formation mechanism of crushed rock mass in gob. Coal Sci. Technol. 2020, 48, 113–120. (In Chinese) [Google Scholar]

- Zhang, C.; Tu, S.; Zhang, L. Field measurements of compaction seepage characteristics in longwall mining goaf. Nat. Resour. Res. 2020, 29, 905–917. [Google Scholar] [CrossRef]

- Yi, M.; Wang, L.; Hao, C.; Liu, Q.; Wang, Z. Method for designing the optimal sealing depth in methane drainage boreholes to realize efficient drainage. Int. J. Coal Sci. Technol. 2021, 8, 1400–1410. [Google Scholar] [CrossRef]

- Shi, H.; Zhang, Y.; Tang, L. Physical test of fracture development in the overburden strata above the goaf and diffusion process of permeable grout slurry. Bull. Eng. Geol. Environ. 2021, 80, 4791–4802. [Google Scholar] [CrossRef]

- Xu, C.; Li, X.; Chen, Q.; Cao, M.; Shen, L. Optimization of precise extraction parameters in high-drainage roadway based on nonlinear permeability model. Coal Sci. Technol. 2021, 49, 100–109. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y. Three-dimensional spatial dynamic distribution model on porosity and permeability characteristics of porous media in goaf. J. Saf. Sci. Technol. 2020, 16, 40–46. (In Chinese) [Google Scholar] [CrossRef]

- Poulsen, B.A.; Adhikary, D.; Guo, H. Simulating mining-induced strata permeability changes. Eng. Geol. 2018, 237, 208–216. [Google Scholar] [CrossRef]

- Guo, D.; Lv, P.; Zhao, J.; Zhang, C. Research progress on permeability improvement mechanisms and technologies of coalbed deep-hole cumulative blasting. Int. J. Coal Sci. Technol. 2020, 7, 329–336. [Google Scholar] [CrossRef]

- Adhikary, D.P.; Guo, H. Modelling of longwall mining-induced strata permeability change. Rock Mech. Rock Eng. 2015, 48, 345–359. [Google Scholar] [CrossRef]

- Fan, L.; Liu, S. A conceptual model to characterize and model compaction behavior and permeability evolution of broken rock mass in coal mine gobs. Int. J. Coal Geol. 2017, 172, 60–70. [Google Scholar] [CrossRef]

- Song, J.; Deng, J.; Zhao, J.; Zhang, Y.; Wang, C.; Shu, C. Critical particle size analysis of gas emission under high-temperature oxidation of weathered coal. Energy 2021, 214, 118995. [Google Scholar] [CrossRef]

- Qu, Q.; Xu, J.; Wu, R.; Qin, W.; Hu, G. Three-zone characterisation of coupled strata and gas behaviour in multi-seam mining. Int. J. Rock Mech. Min. 2015, 78, 91–98. [Google Scholar] [CrossRef]

- Hu, B.; Wang, J.G.; Wu, D.; Wang, H. Impacts of zone fractal properties on shale gas productivity of a multiple fractured horizontal well. Fractals 2019, 27, 1950006. [Google Scholar] [CrossRef]

- Zhang, Y.; Niu, K.; Du, W.; Zhang, J.; Wang, H.; Zhang, J. A method to identify coal spontaneous combustion-prone regions based on goaf flow field under dynamic porosity. Fuel 2021, 288, 119690. [Google Scholar] [CrossRef]

- Liu, Q.; Lin, B.; Zhou, Y.; Li, Y. Porosity model of the goaf based on overlying strata movement and deformation. Environ. Earth Sci. 2022, 81, 214. [Google Scholar] [CrossRef]

- Bear, J. Dynamics of fluids in porous media. Soil Sci. 1975, 120, 162–163. [Google Scholar] [CrossRef]

- Ergun, S. Fluid flow through packed columns. J. Mater. Sci. Chem. Eng. 1952, 48, 89–94. [Google Scholar]

- Liu, Y.; Hinrichsen, O. Study on CFD–PBM turbulence closures based on k–ε and Reynolds stress models for heterogeneous bubble column flows. Comput. Fluids 2014, 105, 91–100. [Google Scholar] [CrossRef]

- Selma, B.; Bannari, R.; Proulx, P. A full integration of a dispersion and interface closures in the standard k–ε model of turbulence. Chem. Eng. Sci. 2010, 65, 5417–5428. [Google Scholar] [CrossRef]

- Jin, L.; Yao, W.; Zhang, J. CFD simulation of gas seepage regularity in goaf. J. China Coal Soc. 2010, 35, 1476–1480. (In Chinese) [Google Scholar] [CrossRef]

- Iqbal, N.; Rauh, C. Coupling of discrete element model (DEM) with computational fluid mechanics (CFD): A validation study. Appl. Math. Comput. 2016, 277, 154–163. [Google Scholar] [CrossRef]

- Gui, X.; Xue, H.; Zhan, X.; Hu, Z.; Song, X. Measurement and numerical simulation of coal spontaneous combustion in goaf under y-type ventilation mode. ACS Omega 2022, 7, 9406–9421. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Lin, B.; Fu, X.; Liu, A. Mechanical criterion for coal and gas outburst: A perspective from multiphysics coupling. Int. J. Coal Sci. Technol. 2021, 8, 1423–1435. [Google Scholar] [CrossRef]

- Qian, M.; Xu, J. Study on the “O shape” circle distribution characteristics of mining induced fractures in the overlaying strata. J. China Coal Soc. 1998, 23, 466–469. (In Chinese) [Google Scholar]

- Qin, Z.; Yuan, L.; Guo, H.; Qu, Q. Investigation of longwall goaf gas flows and borehole drainage performance by CFD simulation. Int. J. Coal Geol. 2015, 150, 51–63. [Google Scholar] [CrossRef]

| Number of Overlying Strata | Height of Strata from Floor (m) | Thickness of Strata (m) | Maximum Subsidence of Rock Strata (m) | Average Length of Broken Rock (MPa) |

|---|---|---|---|---|

| 1 | 10 | 4 | 2.95 | 8 |

| 2 | 19 | 9 | 2.867 | 11 |

| 3 | 40 | 21 | 2.52 | 12 |

| 4 | 63 | 23 | 1.488 | 15 |

| Group Number | Fitting Equation | Coefficient of Determinant (R2) |

|---|---|---|

| 1 | 0.98 | |

| 2 | 0.99 | |

| 3 | 0.99 | |

| 4 | 0.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Q.; Xue, J.; Shi, Y.; Zeng, X. Characteristics of Porosity Distribution and Gas Migration in Different Layers of Comprehensive Working Face Goaf. Energies 2023, 16, 2325. https://doi.org/10.3390/en16052325

Ma Q, Xue J, Shi Y, Zeng X. Characteristics of Porosity Distribution and Gas Migration in Different Layers of Comprehensive Working Face Goaf. Energies. 2023; 16(5):2325. https://doi.org/10.3390/en16052325

Chicago/Turabian StyleMa, Qian, Junhua Xue, Yu Shi, and Xiangzhen Zeng. 2023. "Characteristics of Porosity Distribution and Gas Migration in Different Layers of Comprehensive Working Face Goaf" Energies 16, no. 5: 2325. https://doi.org/10.3390/en16052325

APA StyleMa, Q., Xue, J., Shi, Y., & Zeng, X. (2023). Characteristics of Porosity Distribution and Gas Migration in Different Layers of Comprehensive Working Face Goaf. Energies, 16(5), 2325. https://doi.org/10.3390/en16052325