Life Cycle Assessment of a 150 kW Electronic Power Inverter

Abstract

1. Introduction

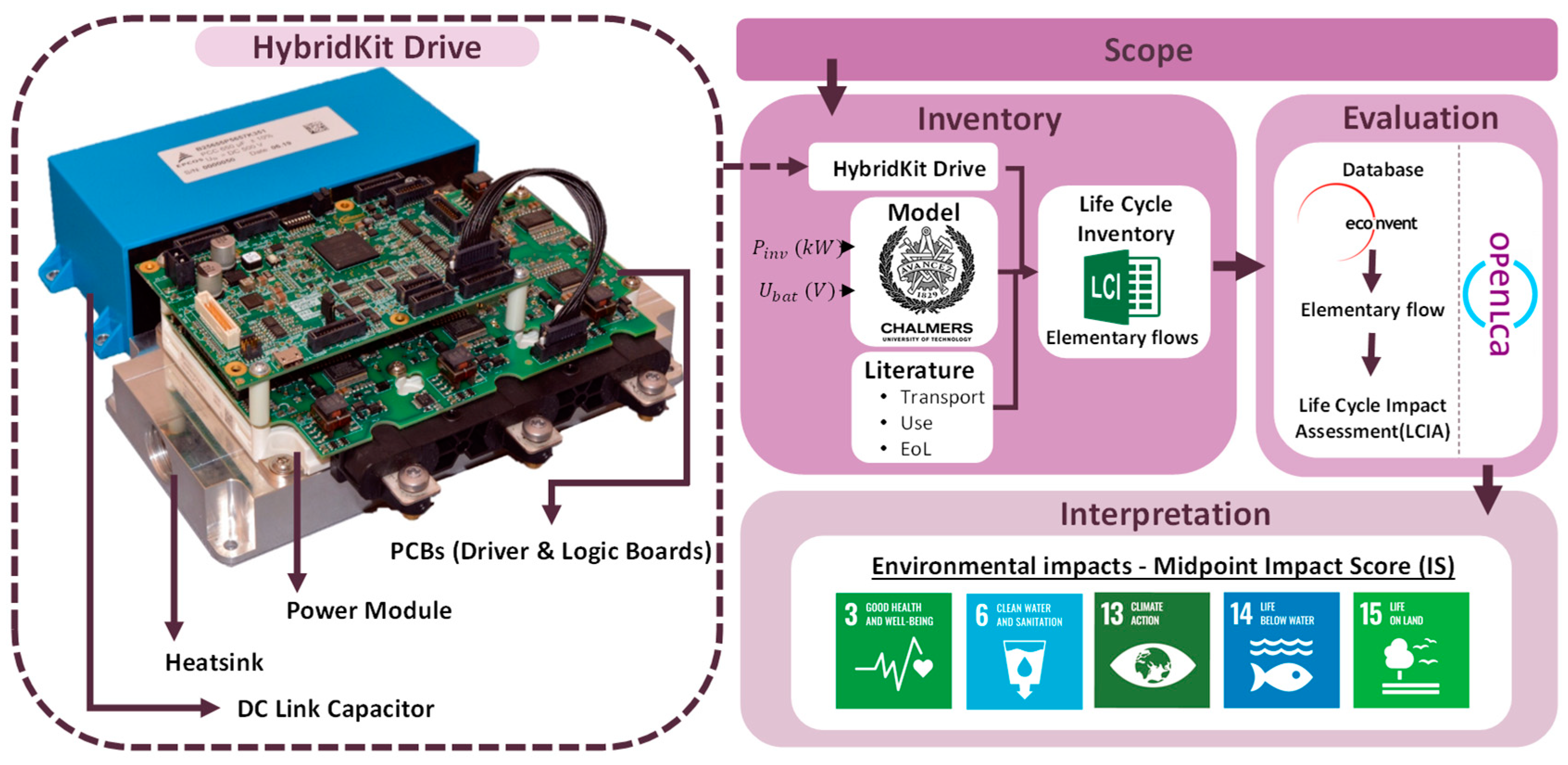

2. Materials and Methods—LCA

2.1. First Step: Scope

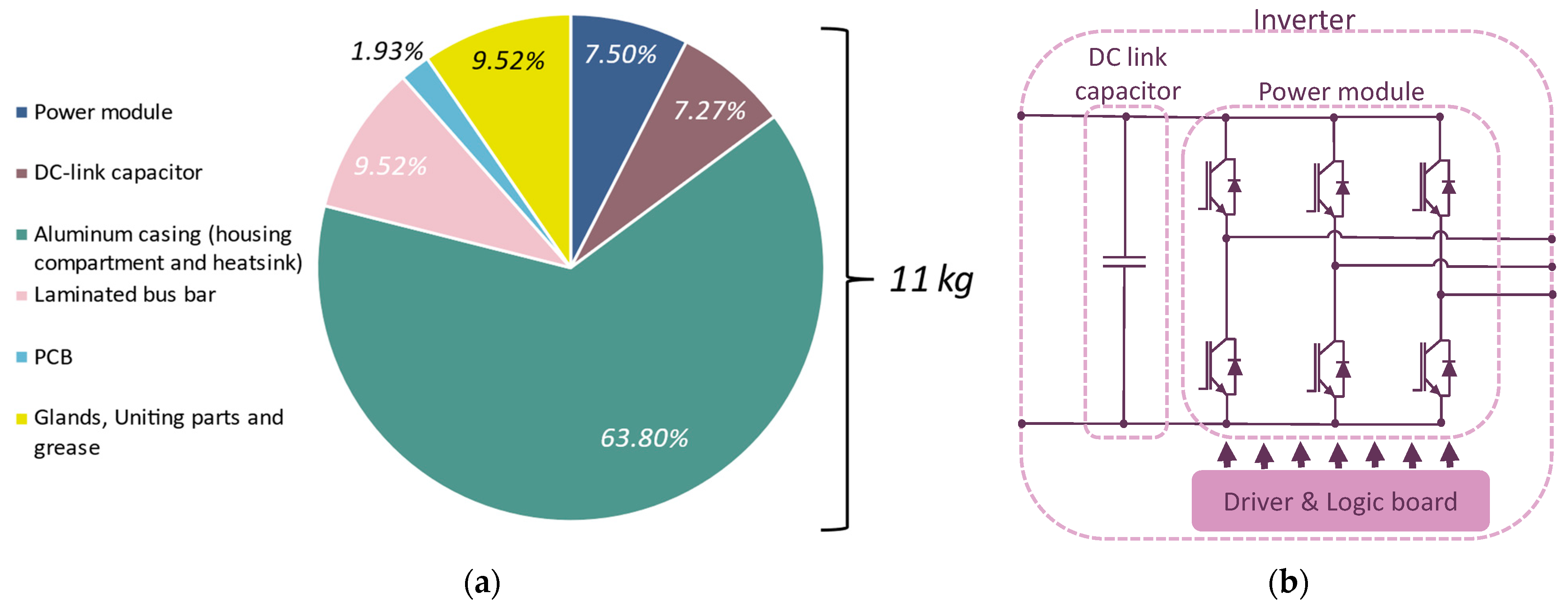

2.2. Second Step: Inventory

3. Analysis of the Uncertain Nature of the LCA

3.1. Context

3.2. Methods

4. Results

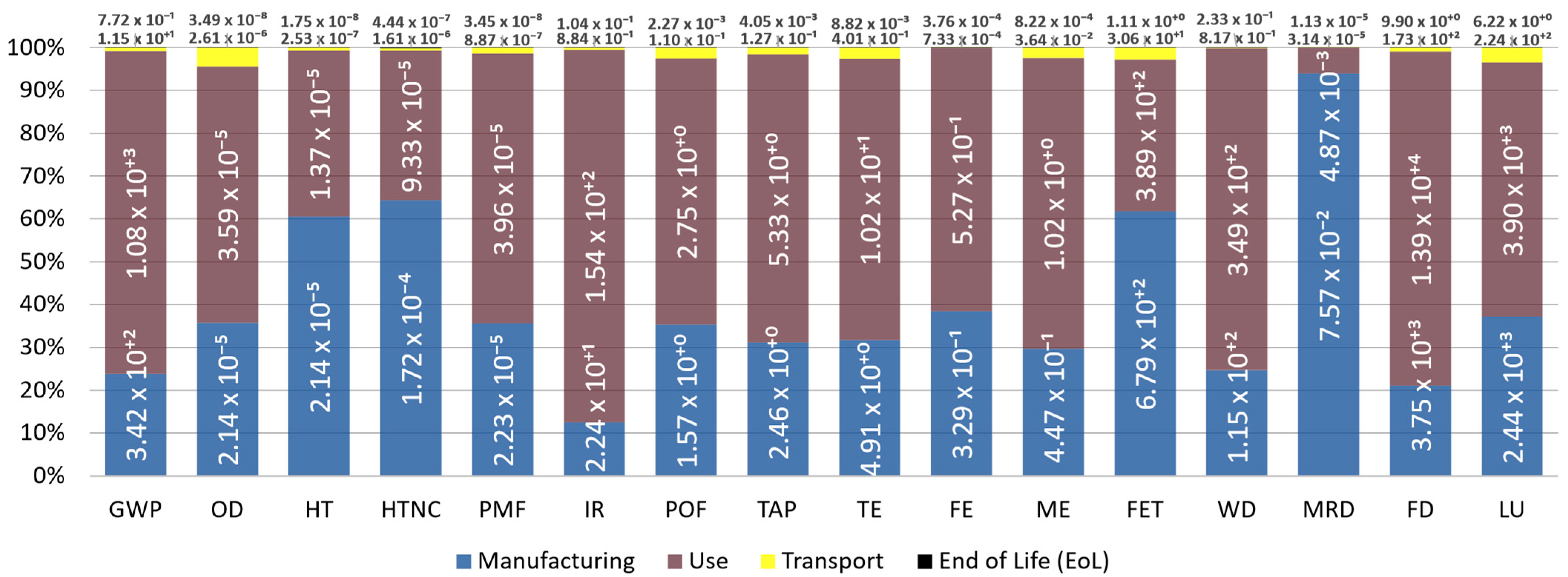

4.1. LCA of a Power Inverter

4.2. Hierarchy/Communication of Results

4.3. “Gate-to-Gate” Inverter Environmental Impacts

4.4. “Gate-to-Gate” Power Module Environmental Impacts

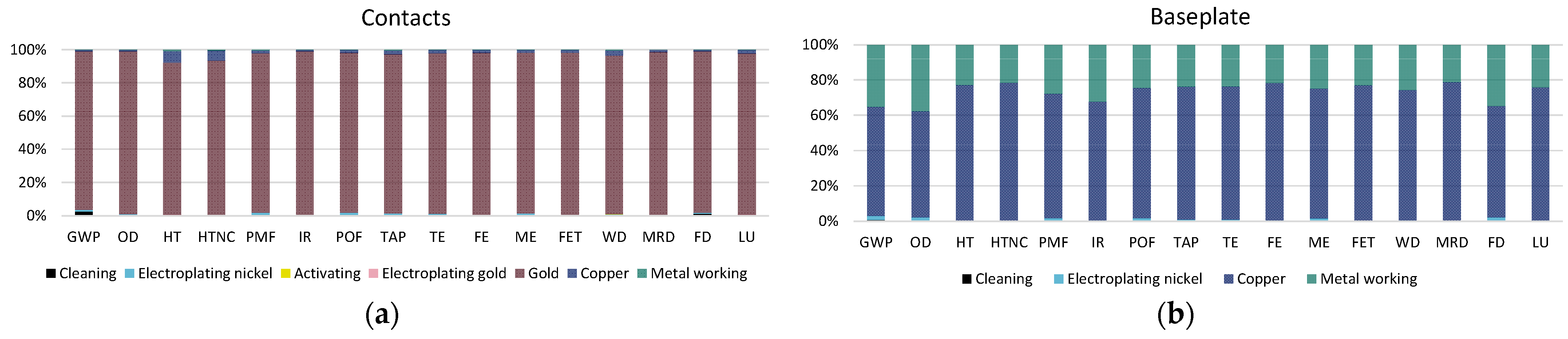

4.5. Contact and Baseplate Process

4.6. Uncertainty Analysis

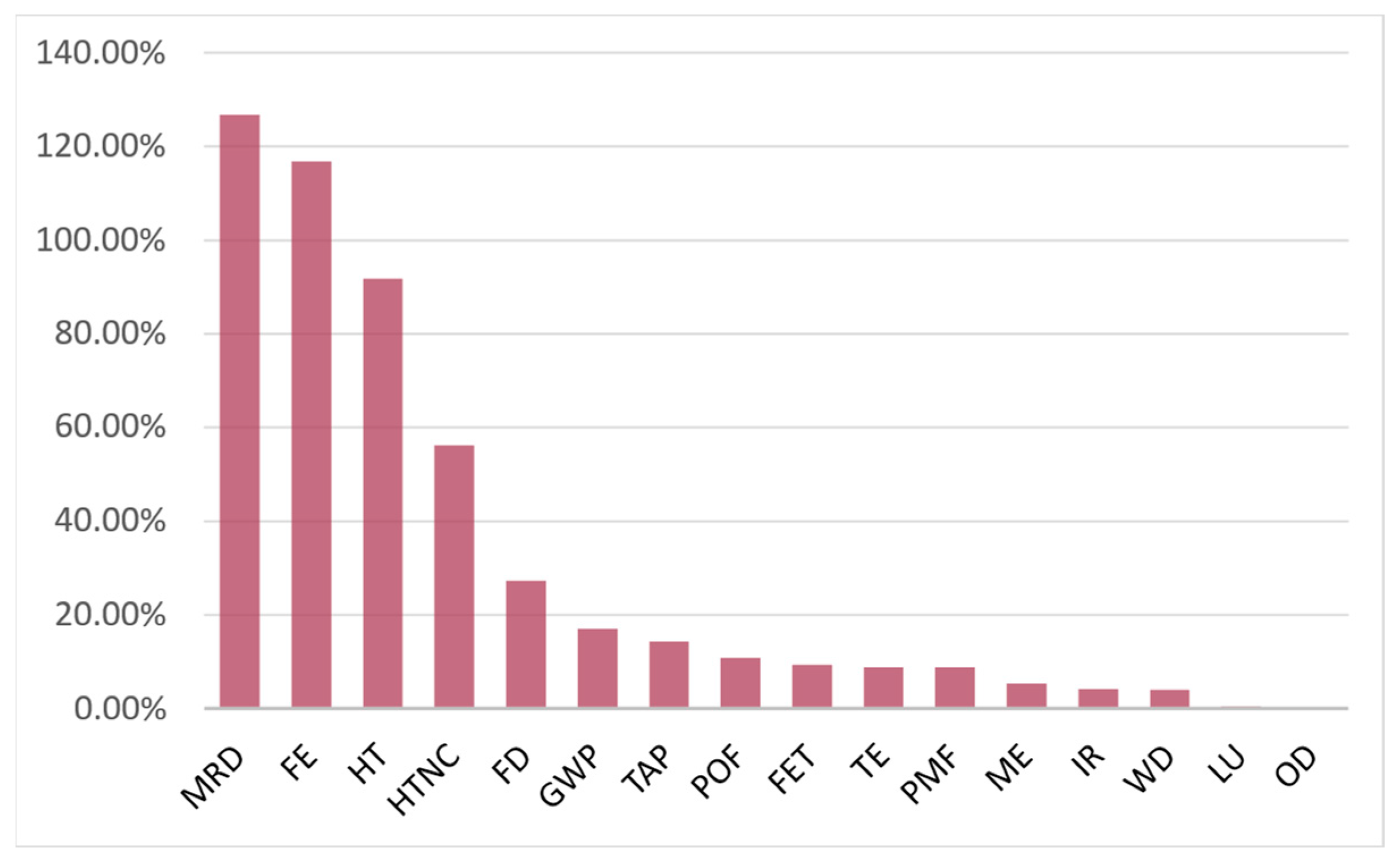

4.7. “OAT” Sensitivity Analysis of Input Values

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PE | Power electronics |

| LCA | Life cycle assessment |

| LCI | Life cycle inventory |

| IGBT | Insulated gate bipolar transistor |

| PCB | Printed circuit board |

| DCB | Direct copper bond |

Appendix A

| Substance | Scaled Mass (Grams) |

|---|---|

| Aluminum oxide | 10.5 |

| Copper | 554.8 |

| Diantimony trioxide | 0 |

| Glass fiber | 34.9 |

| Polyphenylene sulfide (PPS) | 81.5 |

| Silicone gel | 28 |

| Entity/subpart | Scaled area (cm2) |

| Baseplate area for system soldering | 86.8 |

| Entity/subpart | Value |

| Alumina substrate thickness (m) | 0.00032 |

| DCB substrate, area (cm2) | 86.8 |

| DCB foils, thickness (m) | 0.00056 |

| Copper in DCB (g) | 43.5 |

| Copper in baseplate (g) | 500 |

| Copper in wires (g) | 3.78 |

| Copper in terminals and conductors (g) | 11.3 |

| Total chip area (cm2) | 9.00 |

| Substance | Fixed Mass Share | Scaled Mass (Grams) |

|---|---|---|

| Capacitor | 100% | 8.00 × 102 |

| Aluminum | 0.10% | 8.00 × 10−1 |

| Copper | 0.10% | 8.00 × 10−1 |

| Polypropylene | 29.20% | 2.34 × 102 |

| Tin | 3.10% | 2.48 × 101 |

| Zinc | 7.10% | 5.68 × 101 |

| Polyethylene terephthalate (PET) | 19.00% | 1.52 × 102 |

| Polycarbonate | 0.90% | 7.20 × 100 |

| Polyurethane resin | 14.40% | 1.15 × 102 |

| Brass (64% copper, 36% zinc) | 0.40% | 3.20 × 100 |

| Copper | 25.10% | 2.01 × 102 |

| Tin | 0.60% | 4.80 × 100 |

References

- Ministère de la Transition Écologique (MTE). Chiffres Clés du Climat—France, Europe et Monde; Ministère de la Transition Écologique (MTE): Paris, France, 2020.

- IEA. Global EV Outlook 2021; IEA: Paris, France, 2021. Available online: https://www.iea.org/reports/global-ev-outlook-2021 (accessed on 1 April 2022).

- Rte. Futurs Énergétiques 2050, Principaux Résultats; Rte: Paris, France, 2021. [Google Scholar]

- negaWatt. (2022) Association négaWatt, La Transition Énergétique au Cœur D’une Transition Sociétale, Synthèse du Scénario négaWatt 2022. Available online: https://negawatt.org/Scenario-negaWatt-2022 (accessed on 1 November 2022).

- Forti, V.; Baldé, C.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020—Quantities, Flows, and the Circular Economy Potential; International Solid Waste Association: Rotterdam, The Netherlands, 2020; ISBN 978-92-808-9114-0. [Google Scholar]

- Smart Grid + Power Electronics Consortium Singapore (SPECS). Advanced Power Electronics: Enabler for Energy Transition & Efficiency; SPECS: Singapore, 2020. [Google Scholar]

- Blaabjerg, F. Villum Investigator. Power Electronics for Renewable Energy Systems—Wingrid; Aalborg University: Aalborg, Denmark, 2021. [Google Scholar]

- Adlkofer, H. Vice President, Bernstein Conference on EVs and Energy Storage; Infineon: Neubiberg, Germany, 2017. [Google Scholar]

- Saber, C. Analysis and Optimization of the Conducted Emissions of an On-Board Charger for Electric Vehicles—Electric Power; Université Paris Saclay: Paris, France, 2017. [Google Scholar]

- European Commission. Critical Materials for Strategic Technologies and Sectors in the EU—A Foresight Study; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Volke, A. IGBT Modules: Technologies, Driver and Application; Infineon: Neubiberg, Germany, 2012. [Google Scholar]

- Samsu Koroma, M.; Costa, D.; Philippot, M.; Cardellini, G.; Hosen, M.S.; Coosemans, T.; Messagie, M. Life cycle assessment of battery electric vehicles: Implications of future electricity mix and different battery end-of-life management. Sci. Total Environ. 2022, 831, 154859. [Google Scholar] [CrossRef] [PubMed]

- Boeglin, N.; Veuillet, D. Introduction à l’Analyse de Cycle de Vie (ACV); Note de Synthese Externe; ADEME: Angers, France, 2005. [Google Scholar]

- ILCD. International Reference Life Cycle Data System (ILCD) Handbook—General Guide for Life Cycle Assessment—Provisions and Action Steps; EUR 24378 EN; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Li, J.; Wang, C.; Zhang, B. Life Cycle Assessment of Typical Electric Vehicle IGBT Module. Mater. Sci. Forum 2016, 847, 398–402. [Google Scholar] [CrossRef]

- Valkama, J.; Keskinen, M. Comparison of simplified LCA variations for three LCA cases of electronic products from the ecodesign point of view. In Proceedings of the 2008 IEEE International Symposium on Electronics and the Environment, San Francisco, CA, USA, 19–22 May 2008; pp. 1–6. [Google Scholar] [CrossRef]

- Tschümperlin, L.; Stolz, P.; Frischknecht, R. Life Cycle Assessment of Low Power Solar Inverters (2.5 to 20 kW); treeze: Uster, Switzerland, 2016. [Google Scholar]

- Schellscheidt, B.; Richter, J.; Licht, T. Life-Cycle Assessment for Power Electronics Module Manufacturing. In Proceedings of the 22nd European Microelectronics and Packaging Conference & Exhibition (EMPC), Pisa, Italy, 16–19 September 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Temporelli, A.; Carvalho, M.L.; Girardi, P. Life Cycle Assessment of Electric Vehicle Batteries: An Overview of Recent Literature. Energies 2020, 13, 2864. [Google Scholar] [CrossRef]

- Tintelecan, A.; Dobra, A.C.; Martis, C.S. Literature Review—Electric Vehicles Life Cycle Assessment. In Proceedings of the 2020 ELEKTRO, Taormina, Italy, 25–28 May 2020; pp. 1–6. [Google Scholar]

- Nordelöf, A.; Messagie, M.; Tillman, A.M.; Söderman, M.L.; Van Mierlo, J. Environmental impacts of hybrid, plug-in hybrid, and battery electric vehicles—What can we learn from life cycle assessment? Int. J. Life Cycle Assess. 2014, 19, 1866–1890. [Google Scholar] [CrossRef]

- Infineon. HybridKit Drive Quickstart Manual Quick Start Guide for HYBRIDKIT DRIVE; Infineon: Neubiberg, Germany, 2020. [Google Scholar]

- Nordelöf, A.; Alatalo, M. A Scalable Life Cycle Inventory of an Automotive Power Electronic Inverter Unit; Chalmers University of Technology: Gothenburg, Sweden, 2017. [Google Scholar]

- ISO 14040; DIN EN ISO 14040: Environmental Management—Life Cycle Assessment—Principles and Framework. European Committee for Standardization: Brussels, Belgium, 2006.

- ISO 14044; DIN EN ISO 14044: Environmental Management—Life Cycle Assessment—Requirements and Guidelines. European Com-mittee for Standardization: Brussels, Belgium, 2006.

- Wang, H.; Liserre, M.; Blaabjerg, F.; de Place Rimmen, P.; Jacobsen, J.B.; Kvisgaard, T.; Landkildehus, J. Transitioning to Physics-of-Failure as a Reliability Driver in Power Electronics. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 97–114. [Google Scholar] [CrossRef]

- Zampori, L.; Pant, R. Méthode De l’Empreinte Environnementale de Produit (PEF), EUR 29682 FR; Office des Publications de l’Union Européenne: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Althaus, H.-J.; Doka, G.; Dones, R.; Heck, T.; Hellweg, S.; Hischier, R.; Nemecek, T.; Rebitzer, G.; Spielmann, M.; Wernet, G. Overview and Methodology Data v2.0, Ecoinvent Report No. 1; Frischknecht, R., Jungbluth, N., Eds.; ecoinvent: Dübendorf, Switzerland, 2007. [Google Scholar]

- System Plus Consulting. Infineon FS820R08A6P2B HybridPACK Drive 750V IGBT Module Power Semiconductor Report by Elena Barbarini November 2017—Version 2; SEMI: Nantes, France, 2017. [Google Scholar]

- EPCOS. Product Brief 2016 Film Capacitors PCC Power Capacitors for HybridPACK™ IGBT Modules; EPCOS: Munich, Germany, 2017. [Google Scholar]

- Winfried, B.; Schüler, D.; Sellin, G.; Elwert, T.; Schmid, D.; Goldmann, D.; Buchert, M.; Kammer, U. Electric vehicle recycling 2020: Key component power electronics. Waste Manag. Res. 2018, 36, 311–320. [Google Scholar] [CrossRef]

- Kersten, A.; Kuder, M.; Grunditz, E.; Geng, Z.; Wikner, E.; Thiringer, T.; Weyh, T.; Eckerle, R. Inverter and Battery Drive Cycle Efficiency Comparisons of CHB and MMSP Traction Inverters for Electric Vehicles. In Proceedings of the 2019 21st European Conference on Power Electronics and Applications (EPE ’19 ECCE Europe), Genova, Italy, 3–5 September 2019. [Google Scholar] [CrossRef]

- ID3 Volkswagen (2021) ID.3 100% électrique, Tarifs au 20 juillet 2021—Mise à jour au 5 octobre 2021 Année-modèle 2022.

- Lloyd, S.M.; Ries, R. Characterizing, Propagating, and Analyzing Uncertainty in Life-Cycle Assessment: A Survey of Quantitative Approaches. J. Ind. Ecol. 2007, 11, 161–179. [Google Scholar] [CrossRef]

- Leroy, Y.; Froelich, D. A qualitative, quantitative or mixed approach to deal with uncertainty in Life Cycle Assessment of complex systems: Towards a selective integration of uncertainty according to LCA objectives. Int. J. Des. Eng. IJDE 2010, 3, 151–171. [Google Scholar] [CrossRef]

- Huijbregts, M. Application of uncertainty and variability in LCA. Int. J. LCA 1998, 3, 273. [Google Scholar] [CrossRef]

- Sonnemann, G.W.; Schuhmacher, M.; Castells, F. Uncertainty assessment by a Monte Carlo simulation in a life cycle inventory of electricity produced by a waste incinerator. J. Clean. Prod. 2003, 11, 279–292. [Google Scholar] [CrossRef]

- Pannier, M.-L.; Schalbart, P.; Peuportier, B. Comprehensive assessment of sensitivity analysis methods for the identification of influential factors in building life cycle assessment. J. Clean. Prod. 2018, 199, 466–480. [Google Scholar] [CrossRef]

- Heijungs, R.; Huijbregts, M. A Review of Approaches to Treat Uncertainty in LCA, IEMs. In Proceedings of the 2nd International Congress on Environmental Modelling and Software, Osnabrück, Germany, 14–17 June 2004. [Google Scholar]

- Chouquet, J. Development of a Method for Building Life Cycle Analysis at an Early Design Phase—Implementation in a Tool—Sensitivity and Uncertainty of Such a Method in Comparison to Detailed LCA Software; KIT: Karlsruhe, Germany, 2007. [Google Scholar]

- Andrianandraina, A. Approche D’éco-Conception Basée sur la Combinaison de l’Analyse de Cycle de Vie et de l’Analyse de Sensibilité: Cas d’Application sur le Cycle de vie du Matériau d’Isolation Thermique Biosourcé, le Béton de Chanvre; Eco-conception; Ecole Centrale de Nantes (ECN): Nantes, France, 2014. [Google Scholar]

- Saltelli, A.; Tarantola, S.; Campolongo, F.; Ratto, M. Sensitivity Analysis in Practice: A Guide to Assessing Scientific Models; Wiley: New York, NY, USA, 2004. [Google Scholar]

- Igos, E.; Benetto, E.; Meyer, R.; Baustert, P.; Othoniel, B. How to treat uncertainties in life cycle assessment studies? Int. J. Life Cycle Assess. 2019, 24, 794–807. [Google Scholar] [CrossRef]

- Pedersen, W.B.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.; Wernet, G. Overview and Methodology: Data Quality Guideline for the Ecoinvent Database Version 3; Aalborg University: Aalborg, Denmark, 2013. [Google Scholar]

- United Nations Economic Commission for Europe. Life Cycle Assessment of Electricity Generation Options; UNECE: Geneva, Switzerland, 2022. [Google Scholar]

- Zhang, X.; Bauer, C. Life Cycle Assessment (LCA) of Nuclear Power in Switzerland—Final Report; PSI: Würenlingen, Switzerland, 2018. [Google Scholar]

- Gérard, A.; Descos, I. Apprehender l’Ordre de Grandeur Des Résultats d’Impacts Environnementaux—Les Apports et Les Limites de Normation; Guide à l’Intention des Praticiens et Lecteurs d’ACV. (Rapport de recherche); HAL: Lyon, France, 2013; 92p, pp. 92. [Google Scholar]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S., III; Lambin, E.F.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schnellnhuber, H.J.; et al. A safe operating space for humanity. Nature 2009, 461, 472–475. [Google Scholar] [CrossRef] [PubMed]

- Sala, S.; Crenna, E.; Secchi, M.; Pant, R. Global Normalisation Factors for the Environmental Footprint and Life Cycle Assessment; EUR (28984); Publications Office of the European Union: Luxembourg, 2017; ISBN 978-92-79-77213-9. [Google Scholar] [CrossRef]

- Yang, Y.; Dorn-Gomba, L.; Rodriguez, R.; Mak, C.; Emadi, A. Automotive Power Module Packaging: Current Status and Future Trends. IEEE Access 2020, 8, 160126–160144. [Google Scholar] [CrossRef]

- Lipppert, M. Key Account Manager at Starpower Europe, Power modules for E-vehicles—Available solutions and future challenges. 2018. [Google Scholar]

- Rahmani, B.; Rio, M.; Lembeye, Y.; Andreta, A.; Crebier, J.-C. Opportunités de la Modularité Pour l’Écoconception de Convertisseurs de Puissance. In Proceedings of the 4th Symposium de Genie Electrique (SGE 2021), Nantes, France, 6–8 July 2021. [Google Scholar]

| Climate change | GWP | Ecotoxicity, freshwater | FET |

| Ozone depletion | OD | Water use | WD |

| Resource use, fossil fuels | FD | Eutrophication, freshwater | FE |

| Human toxicity, cancer | HT | Eutrophication, marine | ME |

| Human toxicity, non-cancer | HTNC | Acidification | TAP |

| Particulate matter | PM | Eutrophication, terrestrial | TE |

| Ionizing radiation | IR | Resource use, minerals, and metals | MRD |

| Photochemical ozone formation | POF | Land use | LU |

| Subpart | Scaling and Information | Source |

|---|---|---|

| Casing | Aluminum housing, protected by a varnish. Geometrically modeled to consider all other subparts. The cooler represents the lower part of the housing. | [23] |

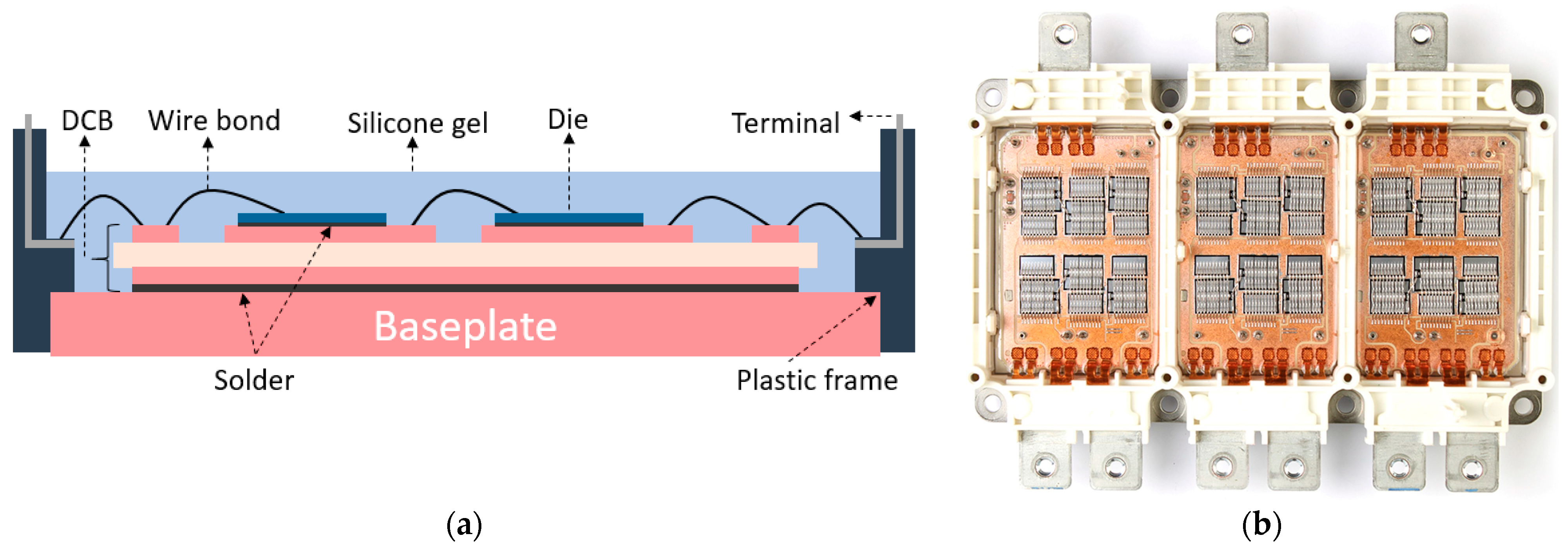

| Power module | IGBTs and diodes are used, FS820R08A6P2B HybridPACK Drive 750 V IGBT. The chips are soldered to the direct copper bond (DCB) and interconnected with wire bonds. DCB is soldered to the baseplate (copper). A plastic frame closes the entire assembly with accessible copper terminals. Silicone gel is deposited on the chips. The copper surfaces are nickel-plated, some connections are gold-plated (to reduce electrical resistance). The power terminals are made of galvanized steel for screw connections to external busbars. | [22,23,29] |

| DC link capacitor | TDK/Epcos Capacitor B25655P5507K, C = 500 µF, Vdc = 500 V, Imax = 120 A. A brick-shaped plastic film-type capacitance is selected. A superposition of plastic dielectric layer and electrodes (tin and zinc). The mass of the capacitor evolves with both the power and DC bus voltage. | [23,30] |

| Busbar | Copper layers, insulated by a polymer (PET). The busbar weight evolution follows a design rule for the cross-section; it allows for proper system functioning at specific power levels. Moreover, it is directly correlated with mass. The weight is also correlated with the length, as determined by the geometry of the inverter, and evolves with the power. | [23] |

| Printed circuit board (PCB), driver, and logic boards | Identified as standard, 6 layers, type FR-4. The components are of the SMD type (volume determined with a list of identified components), soldered with Sn95.5Ag3.9Cu0.6. A polyurethane layer is added on both sides. No correlation was found between the power of the inverter and the volume of the boards; hence, the mass of the driver and logic boards was identified as a constant vs. both power and DC bus voltage. | [22,23] |

| Connectors, spacers, glands, screws, and washers | Cable glands are made of brass and are nickel-plated. Inserts, seals, and O-rings are made of nylon and thermoset elastomers. The external communication connector is patterned (molded plastics, brass pin conductors, and gold-plated contacts). Screws and washers are made of low-alloy steel and galvanized for assembly. | [23] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baudais, B.; Ben Ahmed, H.; Jodin, G.; Degrenne, N.; Lefebvre, S. Life Cycle Assessment of a 150 kW Electronic Power Inverter. Energies 2023, 16, 2192. https://doi.org/10.3390/en16052192

Baudais B, Ben Ahmed H, Jodin G, Degrenne N, Lefebvre S. Life Cycle Assessment of a 150 kW Electronic Power Inverter. Energies. 2023; 16(5):2192. https://doi.org/10.3390/en16052192

Chicago/Turabian StyleBaudais, Briac, Hamid Ben Ahmed, Gurvan Jodin, Nicolas Degrenne, and Stéphane Lefebvre. 2023. "Life Cycle Assessment of a 150 kW Electronic Power Inverter" Energies 16, no. 5: 2192. https://doi.org/10.3390/en16052192

APA StyleBaudais, B., Ben Ahmed, H., Jodin, G., Degrenne, N., & Lefebvre, S. (2023). Life Cycle Assessment of a 150 kW Electronic Power Inverter. Energies, 16(5), 2192. https://doi.org/10.3390/en16052192