Accurate Modeling and Control System Design for a Spherical Radial AC HMB for a Flywheel Battery System

Abstract

1. Introduction

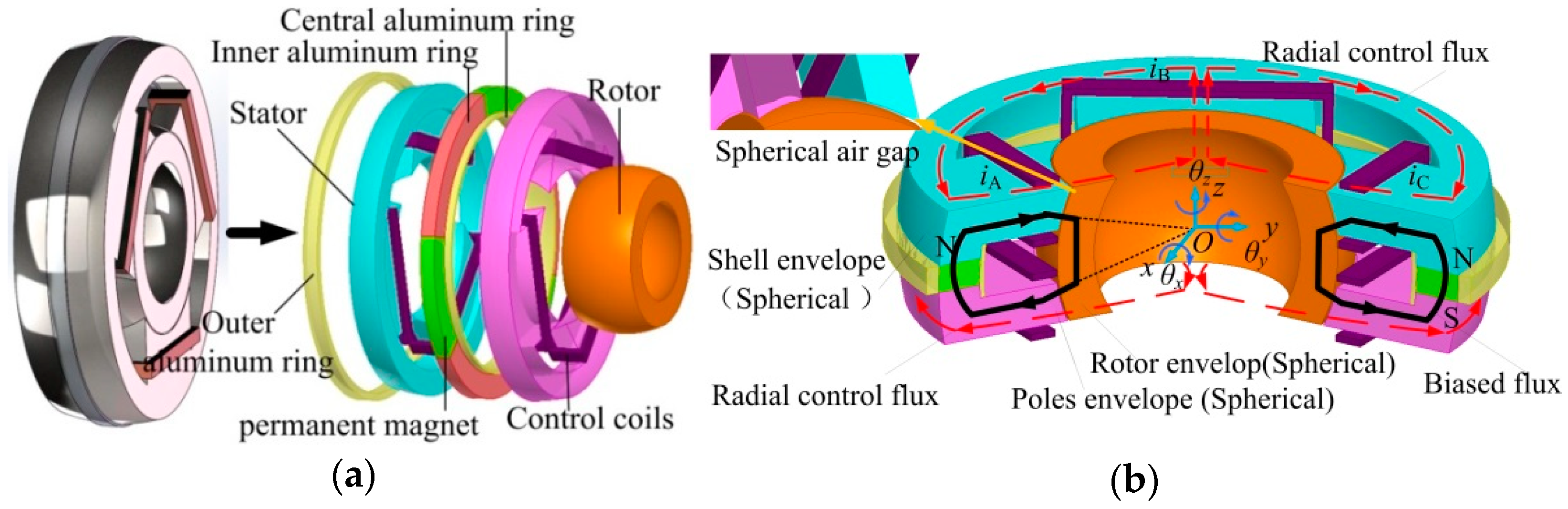

2. Configuration and Principle

3. Mathematical Models

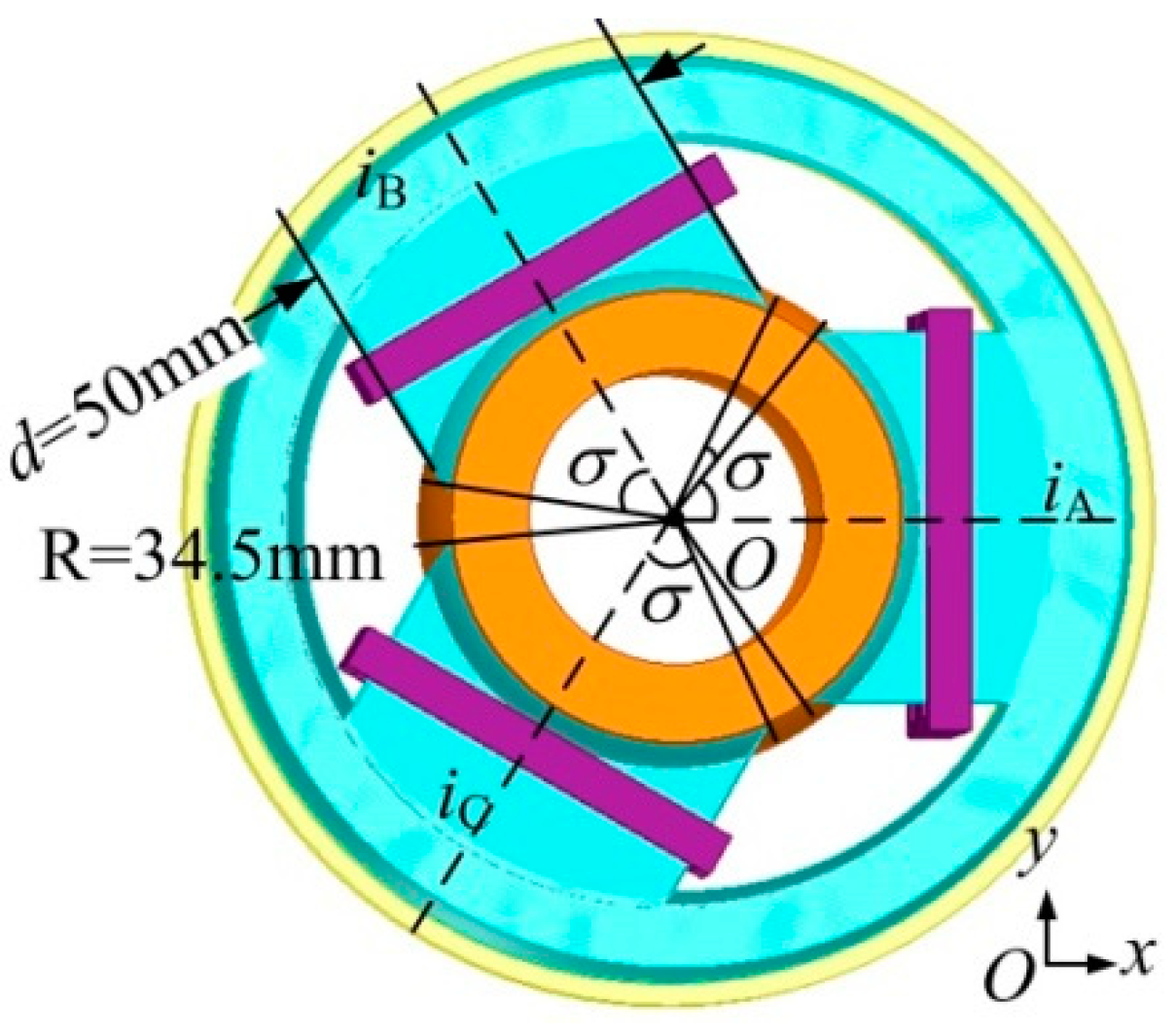

3.1. Coordinate Systems

3.2. Forces Acting on the Rotor

3.3. Magnetic Flux Density Generated by Control Coils

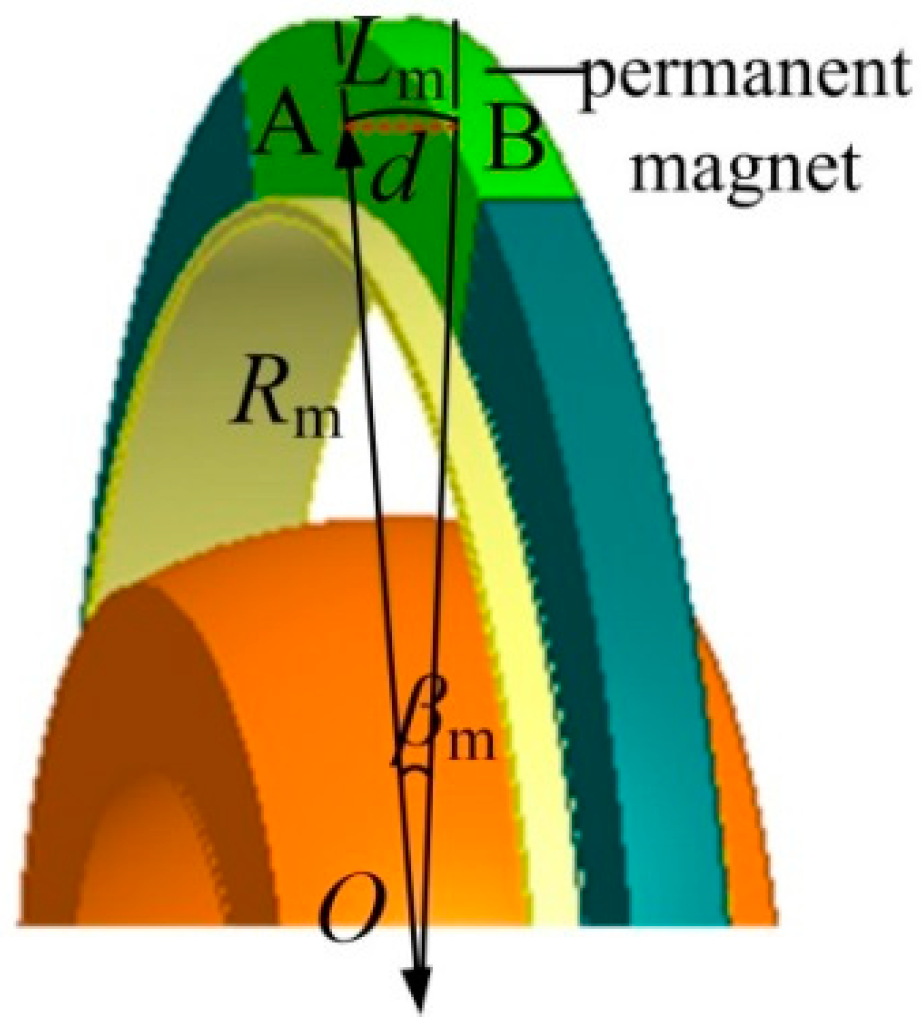

3.4. Calculation of Magnetic Flux Density Generated by a Permanent Magnet

3.5. Calculation of Force Fx and Fy

3.6. Calculation of Force Fix and Fiy

3.7. Calculation of Force Flx and Fly

3.8. Calculation of Force Fxx and Fyy

3.9. Mathematical Models of Magnetic Force versus Deflection Angle

3.10. Accuracy Analysis

- (1)

- During the modeling process for the improved Maxwell tensor method, the Maxwell force is actually determined by the area of the main magnetic flux acting on the rotor, rather than the equivalent area of the magnetic pole adopted by the traditional equivalent magnetic circuit method. Therefore, the proposed method in this paper is direct and accurate to the rotor as the object for force decomposition.

- (2)

- The traditional equivalent magnetic circuit method cannot be modeled accurately for the irregular magnetic circuit because it is a simple substitution of the equivalent magnetic circuit, and therefore the accuracy of modeling is greatly reduced. However, the method proposed in this paper can modify the value of the magnetomotive force according to the shape of the magnetic circuit so as to ensure the accuracy of the modeling results.

- (3)

- The traditional Maxwell tensor method based on cylindrical a two-dimensional coordinate system is unable to build the model for a spherical structure of magnetic bearing; nevertheless, the improved Maxwell tensor method based on a spherical three-dimensional coordinate system can establish the model of a cylindrical magnetic bearing. Therefore, the improved Maxwell tensor method is more accurate in building spherical magnetic bearings than using the traditional Maxwell tensor method.

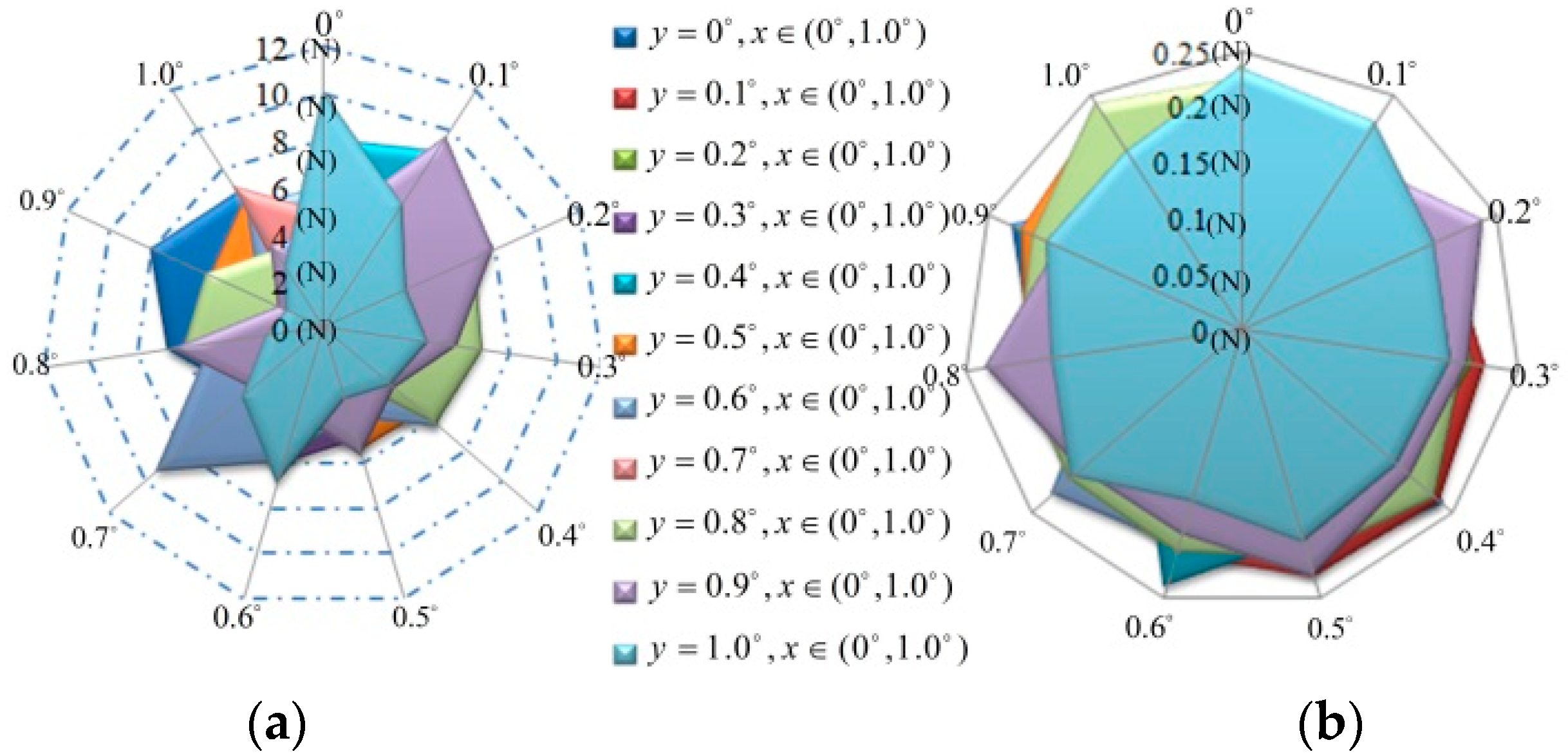

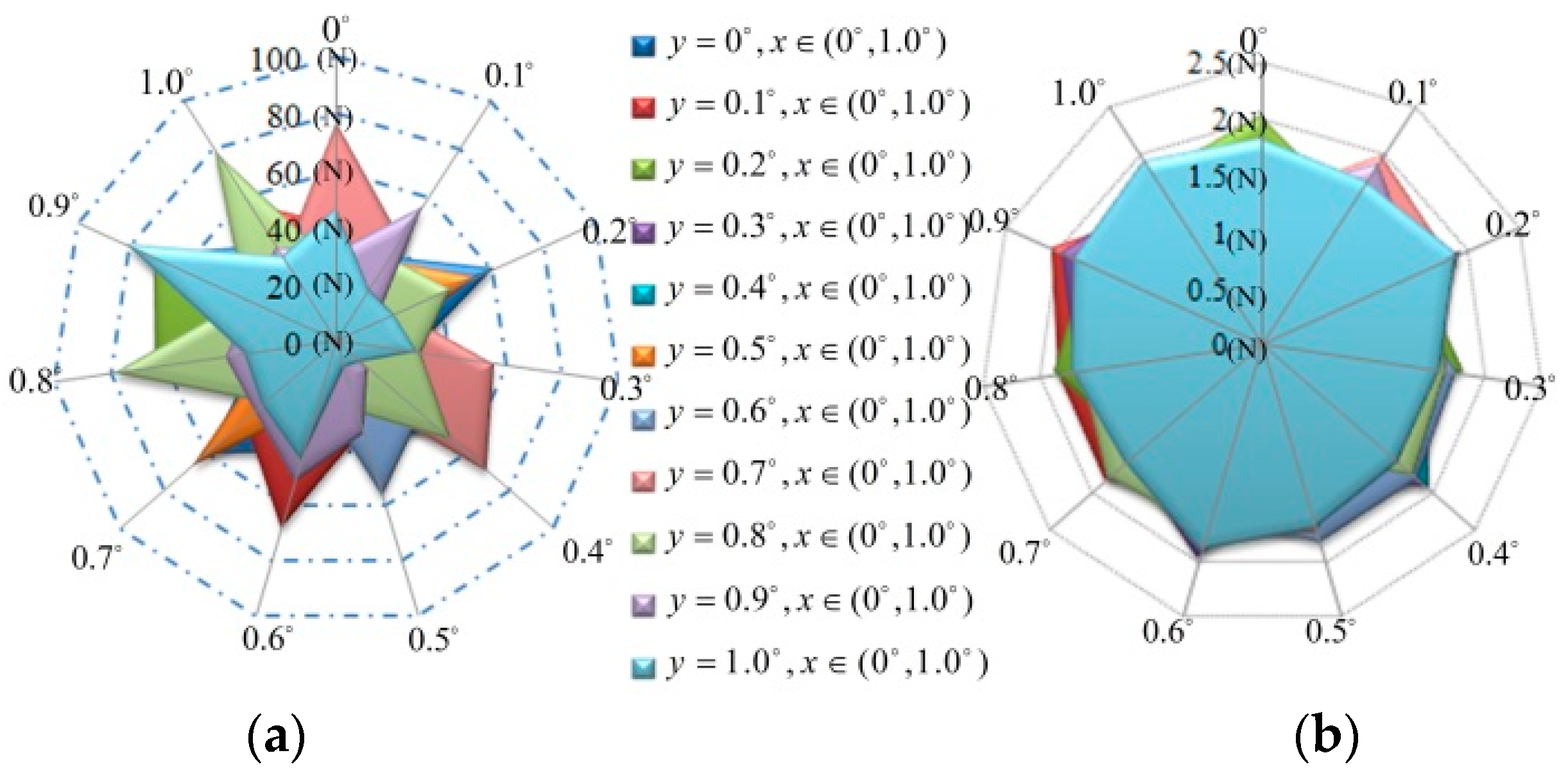

3.11. Wide-Area and Universality Analyses

- (1)

- Determination of coordinate system

- (2)

- Magnetic flux density generated by control coils

- (3)

- Flux density generated by permanent magnet

- (4)

- Total Maxwell force

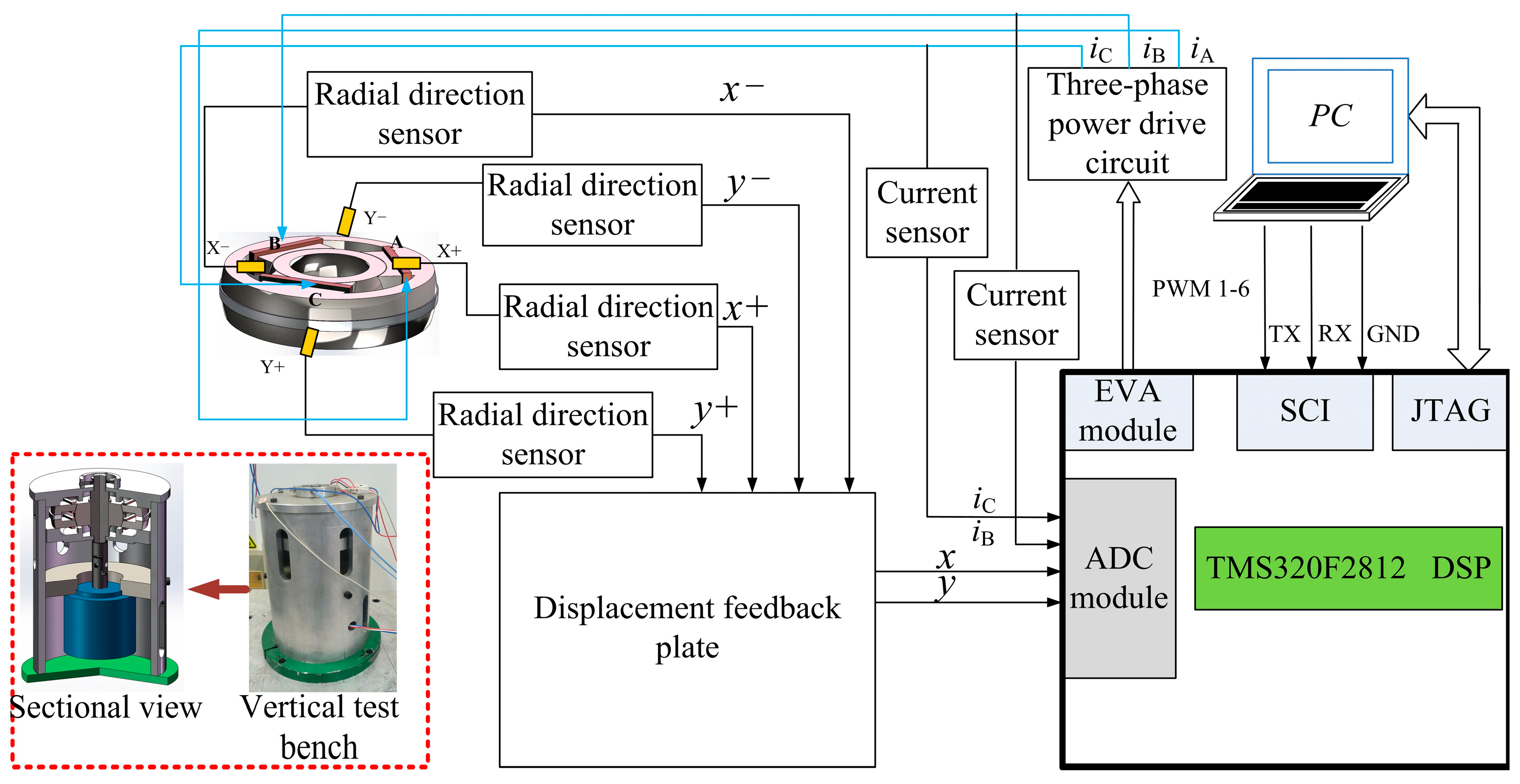

4. Control System Design for a Flywheel Battery Supported with Spherical Radial AC HMB

4.1. Digital Control System Hardware Design

- (1)

- TMS320F2812DSP control board

- (2)

- Displacement feedback plate

- (3)

- Driving board

- (4)

- Power output board

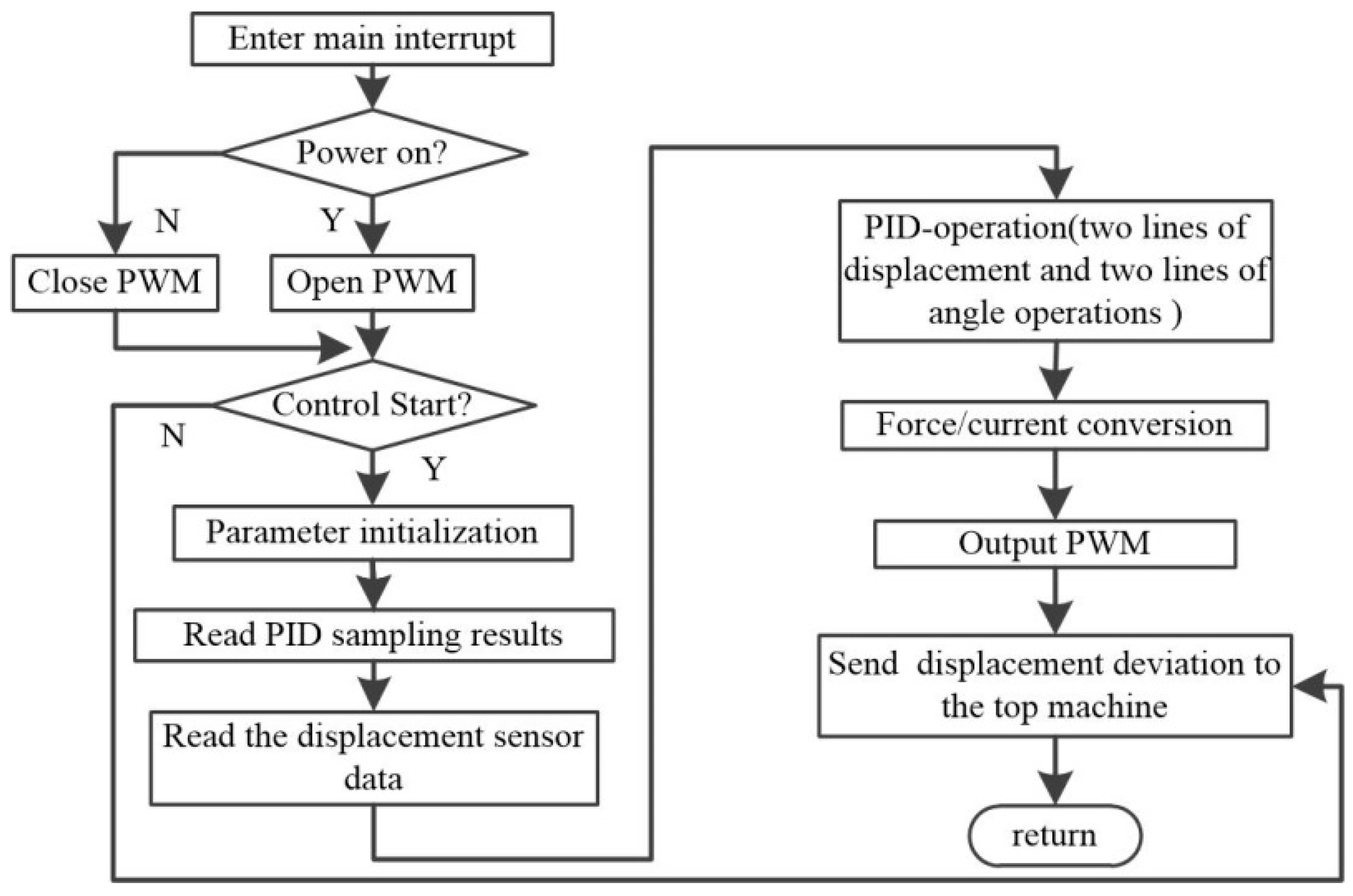

4.2. Control System Software Programming

5. Experiment and Analysis

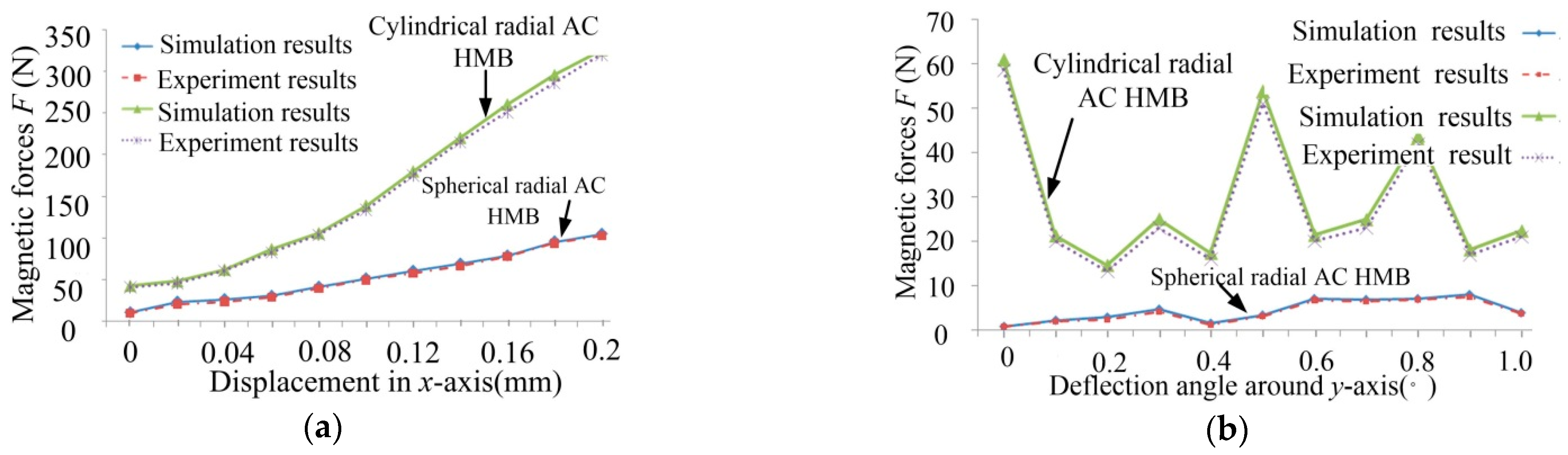

5.1. Stiffness Tests

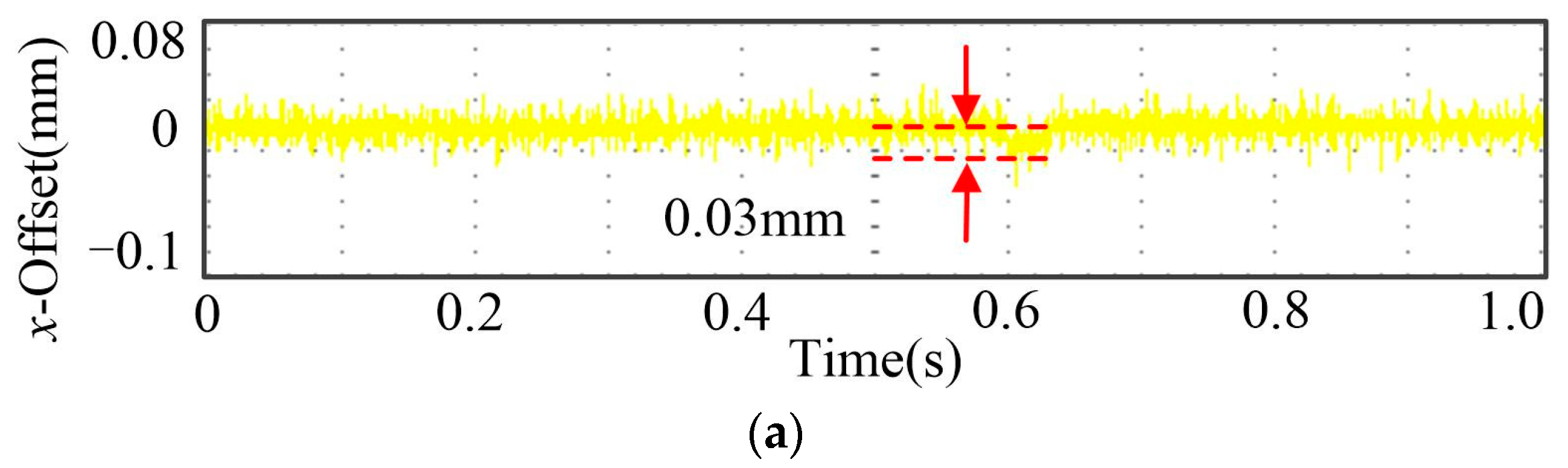

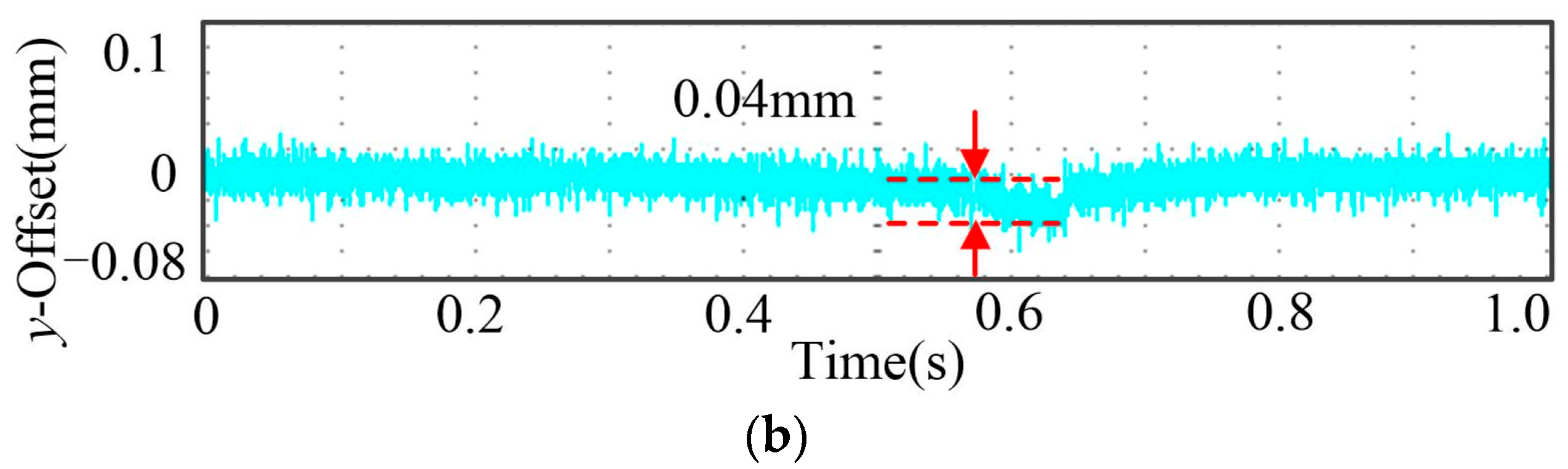

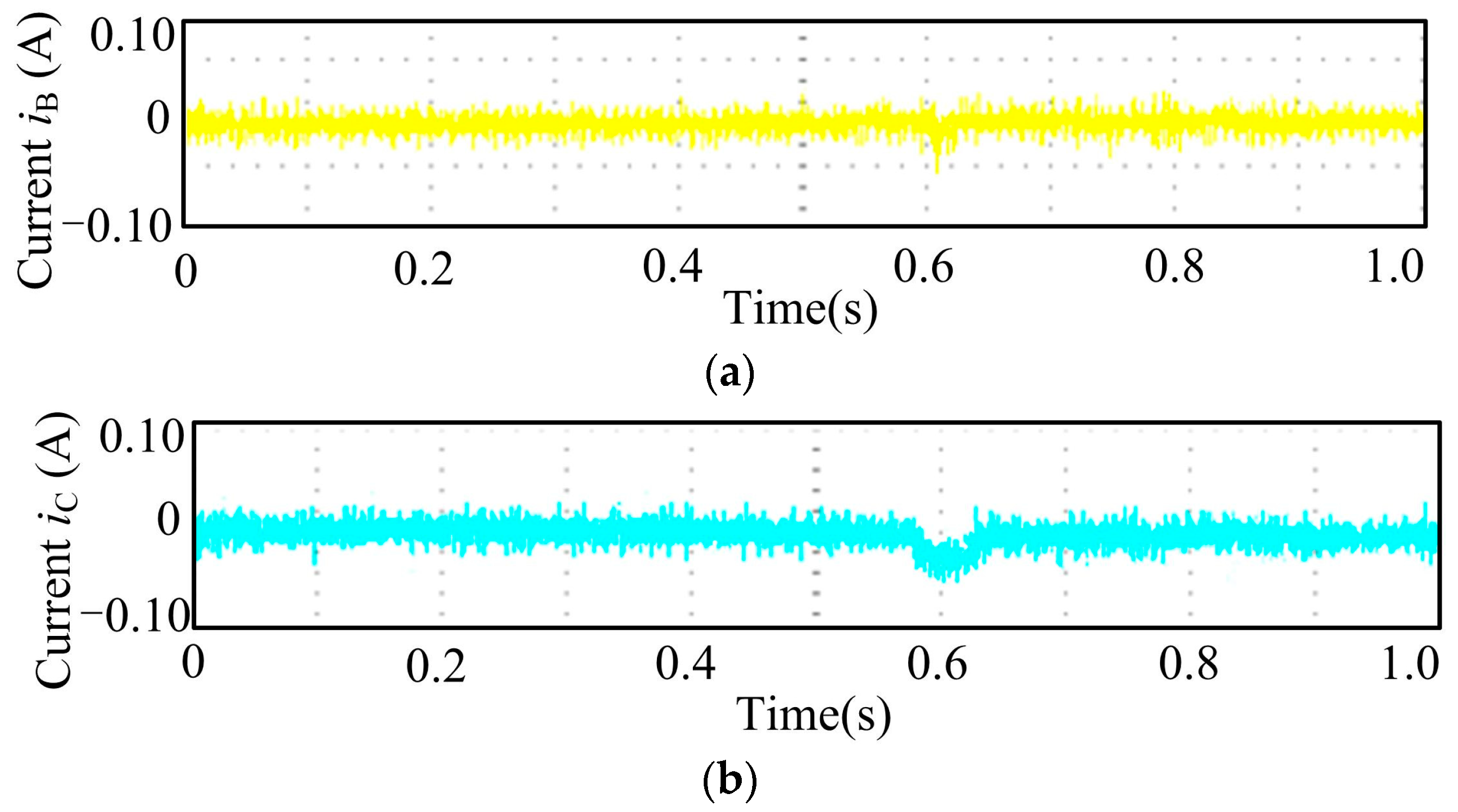

5.2. Performance Tests

- (1)

- Acceleration disturbance experiment

- (2)

- Turning disturbance experiment

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, B.; Dragičević, T.; Freijedo, F.D.; Vasquez, J.C.; Guerrero, J.M. A control algorithm for electric vehicle fast charging stations equipped with flywheel energy storage systems. IEEE Trans. Power Electron. 2016, 31, 6674–6685. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Zhu, P.F.; Cheng, L.; Zhu, H.Q. Improved centripetal force type-magnetic bearing with superior stiffness and anti-interference characteristics for flywheel battery system. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 713–726. [Google Scholar] [CrossRef]

- Oh, Y.; Kwon, D.-S.; Eun, Y.; Kim, W.; Kim, M.-O.; Ko, H.-J.; Kang, S.G.; Kim, J. Flexible energy harvester with piezoelectric and thermoelectric hybrid mechanisms for sustainable harvesting. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 6, 691–698. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Gu, X.W.; Zhang, L.D. Robust controller considering road disturbances for a vehicular flywheel battery system. Energies 2022, 15, 5432. [Google Scholar] [CrossRef]

- Park, H. Vibratory electromagnetic induction energy harvester on wheel surface of mobile sources. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 59–66. [Google Scholar] [CrossRef]

- Zheng, S.Q.; Yang, J.Y.; Song, X.D.; Ma, C. Tracking compensation control for nutation mode of high-speed rotors with strong gyroscopic effects. IEEE Trans. Ind. Electron. 2018, 65, 4156–4165. [Google Scholar] [CrossRef]

- Li, X.J.; Anvari, B.; Palazzolo, A.; Wang, Z.Y.; Toliyat, H. A utility-scale flywheel energy storage system with a shaftless, hubless, high-strength steel rotor. IEEE Trans. Ind. Electron. 2018, 65, 6667–6675. [Google Scholar] [CrossRef]

- Ren, Y.; Chen, X.C.; Cai, Y.W.; Zhang, H.J.; Xin, C.J.; Liu, Q. Attitude-rate measurement and control integration using magnetically suspended control and sensitive gyroscopes. IEEE Trans. Ind. Electron. 2018, 65, 4921–4932. [Google Scholar] [CrossRef]

- Lyu, X.; Di, L.; Yoon, S.Y.; Lin, Z.; Hu, Y. A platform for analysis and control design: Emulation of energy storage flywheels on a rotor-AMB test rig. Mechatronics 2016, 33, 146–160. [Google Scholar] [CrossRef]

- Matsuzaki, T.; Takemoto, M.; Ogasawara, S.; Ota, S.; Oi, K.; Matsuhashi, D. Novel structure of three-axis active-control-type magnetic bearing for reducing rotor iron loss. IEEE Trans. Magn. 2016, 52, 81054043. [Google Scholar] [CrossRef]

- Han, B.C.; Xu, Q.J.; Yuan, Q. Multiobjective optimization of a Combined radial-axial magnetic bearing for magnetically suspended compressor. IEEE Trans. Ind. Electron. 2016, 63, 2284–2293. [Google Scholar]

- Ravaud, R.; Lemarquand, G.; Lemarquand, V. Force and stiffness of passive magnetic bearing using permanent magnets. Part 1: Axial magnetization. IEEE Trans. Magn. 2009, 45, 2996–3002. [Google Scholar] [CrossRef]

- Sun, J.J.; Ju, Z.Y.; Peng, C. A novel 4-DOF hybrid magnetic bearing for DGMSCMG. IEEE Trans. Ind. Electron. 2017, 64, 2196–2204. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Zhu, H.Q. Control system design for a five-degree-of-freedom electrospindle supported with AC hybrid magnetic bearings. IEEE/ASME Trans. Mechatron. 2015, 20, 2525–2537. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Wang, J.P.; Zhu, P.F. Design and analysis of a centripetal force type-magnetic bearing for a flywheel battery system. Rev. Sci. Instrum. 2018, 89, 064708. [Google Scholar] [CrossRef]

- Mushi, S.E.; Lin, Z.L.; Allaire, P.E. Design construction and modeling of a flexible rotor active magnetic bearing test rig. IEEE/ASME Trans. Mechatron. 2012, 17, 1170–1182. [Google Scholar] [CrossRef]

- Zad, H.S.; Khan, T.I.; Lazoglu, I. Design and adaptive sliding-mode control of hybrid magnetic bearings. IEEE Trans. Ind. Electron. 2018, 65, 2449–2457. [Google Scholar]

- Soni, T.; Dutt, J.K.; Das, A.S. Parametric stability analysis of active magnetic bearing-supported rotor system with a novel control law subject to periodic base motion. IEEE Trans. Ind. Electron. 2020, 67, 1160–1170. [Google Scholar] [CrossRef]

- Park, S.-H.; Lee, C.-W. Decoupled control of a disk-type rotor equipped with a three-pole hybrid magnetic bearing. IEEE Trans. Ind. Electron. 2010, 15, 793–804. [Google Scholar]

- Zhang, W.; Zhu, H.; Yang, Z.; Sun, X.; Yuan, Y. Nonlinear model analysis and “switching model” of AC-DC three-degree of freedom hybrid magnetic bearing. IEEE/ASME Trans. Mechatron. 2016, 21, 1102–1115. [Google Scholar] [CrossRef]

- Tang, J.Q.; Wang, K.; Xiang, B. Stable control of high-speed rotor suspended by superconducting magnetic bearings and active magnetic bearings. IEEE Trans. Ind. Electron. 2017, 64, 3319–3328. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Yang, H.K.; Cheng, L.; Zhu, H.Q. Modeling based on exact segmentation of magnetic field for a centripetal force type-magnetic bearing. IEEE Trans. Ind. Electron. 2020, 67, 7691–7701. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Cheng, L.; Zhu, H.Q. Suspension force error source analysis and multidimensional dynamic model for a centripetal force type-magnetic bearing. IEEE Trans. Ind. Electron. 2020, 67, 7617–7628. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Zhu, H.Q. Precision modeling method specifically for AC magnetic bearings. IEEE Trans. Magn. 2013, 49, 5543–5553. [Google Scholar] [CrossRef]

| Item | Value | Item | Value |

|---|---|---|---|

| Spherical air gap length δ0 (mm) | 0.5 | Axial length of permanent magnet (mm) | 6 |

| Radius of auxiliary bearing (mm) | 0.25 | Inner diameter of permanent magnet (mm) | 106 |

| Number of turns of windings | 350 | Outside diameter of outer aluminum ring (mm) | 132 |

| Wire diameter of control windings (mm) | 0.45 | Inside diameter of outer aluminum ring (mm) | 126 |

| Maximum outer diameter of stator (mm) | 126 | Axial length of outer aluminum ring (mm) | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Wang, Z. Accurate Modeling and Control System Design for a Spherical Radial AC HMB for a Flywheel Battery System. Energies 2023, 16, 1973. https://doi.org/10.3390/en16041973

Zhang W, Wang Z. Accurate Modeling and Control System Design for a Spherical Radial AC HMB for a Flywheel Battery System. Energies. 2023; 16(4):1973. https://doi.org/10.3390/en16041973

Chicago/Turabian StyleZhang, Weiyu, and Zhen Wang. 2023. "Accurate Modeling and Control System Design for a Spherical Radial AC HMB for a Flywheel Battery System" Energies 16, no. 4: 1973. https://doi.org/10.3390/en16041973

APA StyleZhang, W., & Wang, Z. (2023). Accurate Modeling and Control System Design for a Spherical Radial AC HMB for a Flywheel Battery System. Energies, 16(4), 1973. https://doi.org/10.3390/en16041973