Impact of the Internal Combustion Engine Thermal State during Start-Up on the Exhaust Emissions in the Homologation Test

Abstract

1. Introduction

2. Literature Review

- Direct injection: multi phases, UHP > 35 (50+) MPa;

- Extended Miller and Atkinson cycles;

- Dethrottling: VVT and VVL;

- Combined EGR; water injection;

- Combined boosting (turbocharging; electric booster);

- VCR;

- Homogeneous and/or lean mixture;

- HCCI;

- Thermal management;

- 48 V mild HEV (additionally 20–30 kW);

- Advanced exhaust aftertreatment system.

3. Research Methodology

4. Results and Discussion

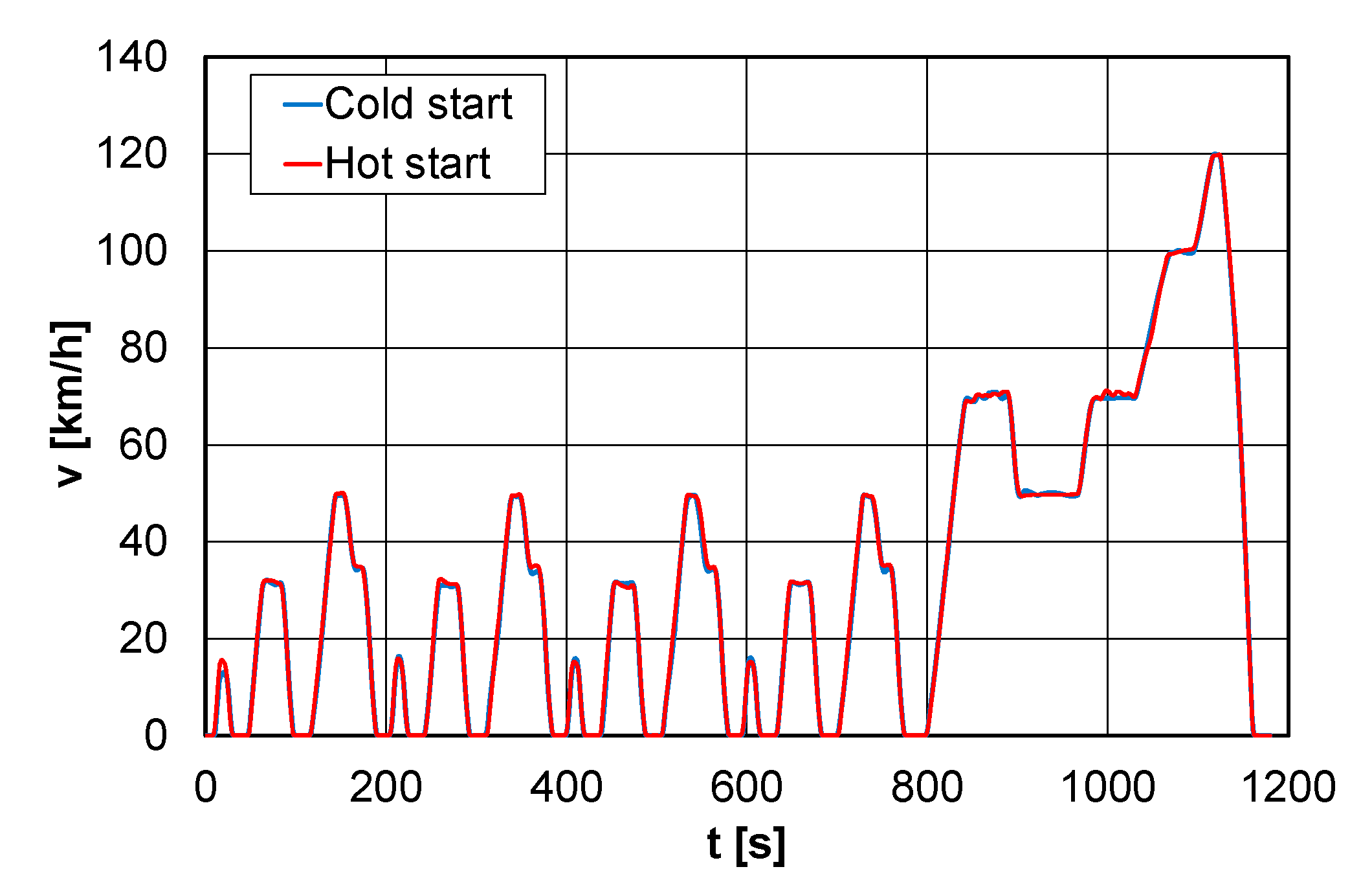

5. Analysis of the Empirical Tests Results for a Car in NEDC Tests

6. Conclusions

- The cold engine start was found to have a significant impact on the engine’s operational and emission parameters for spark ignition engines.

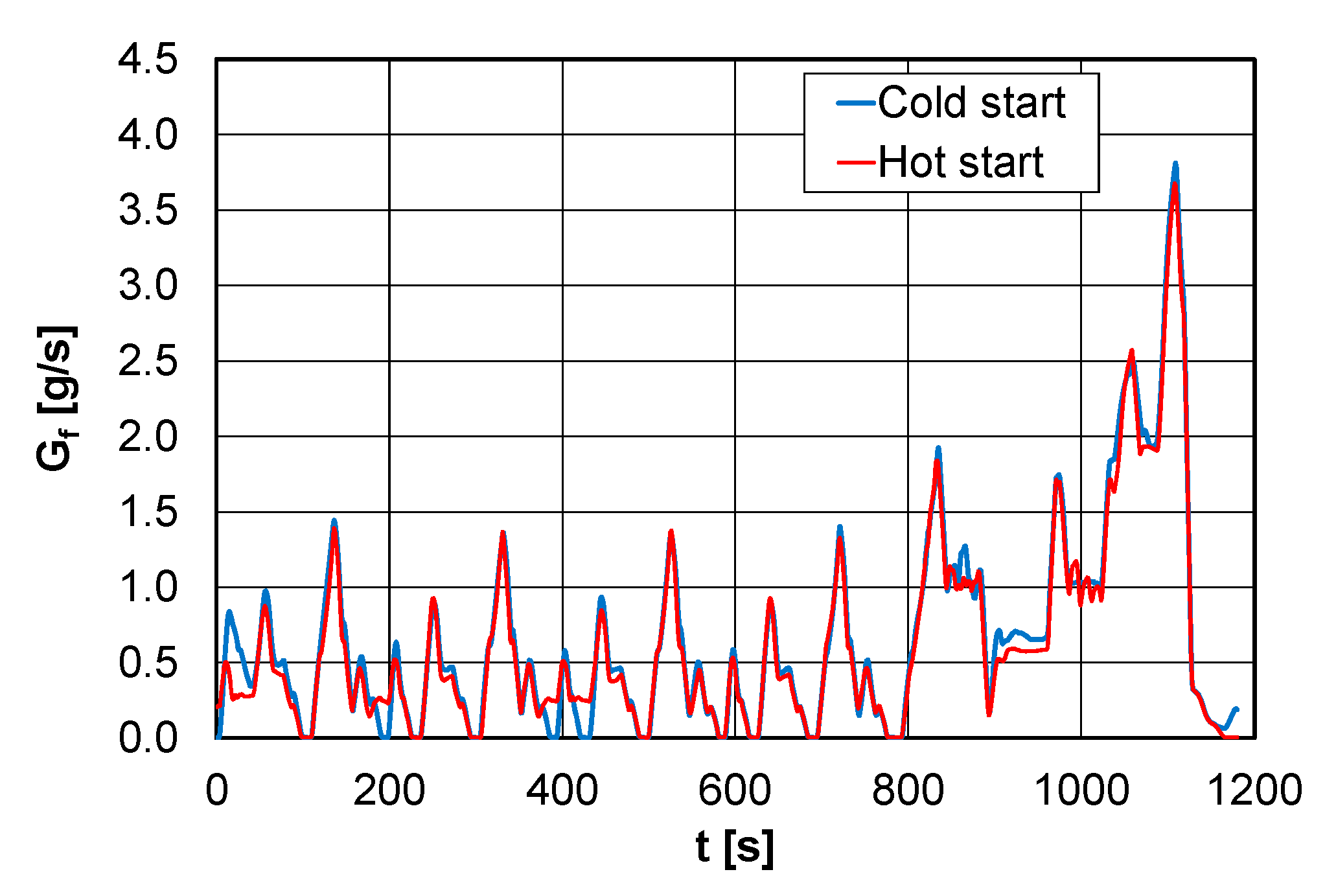

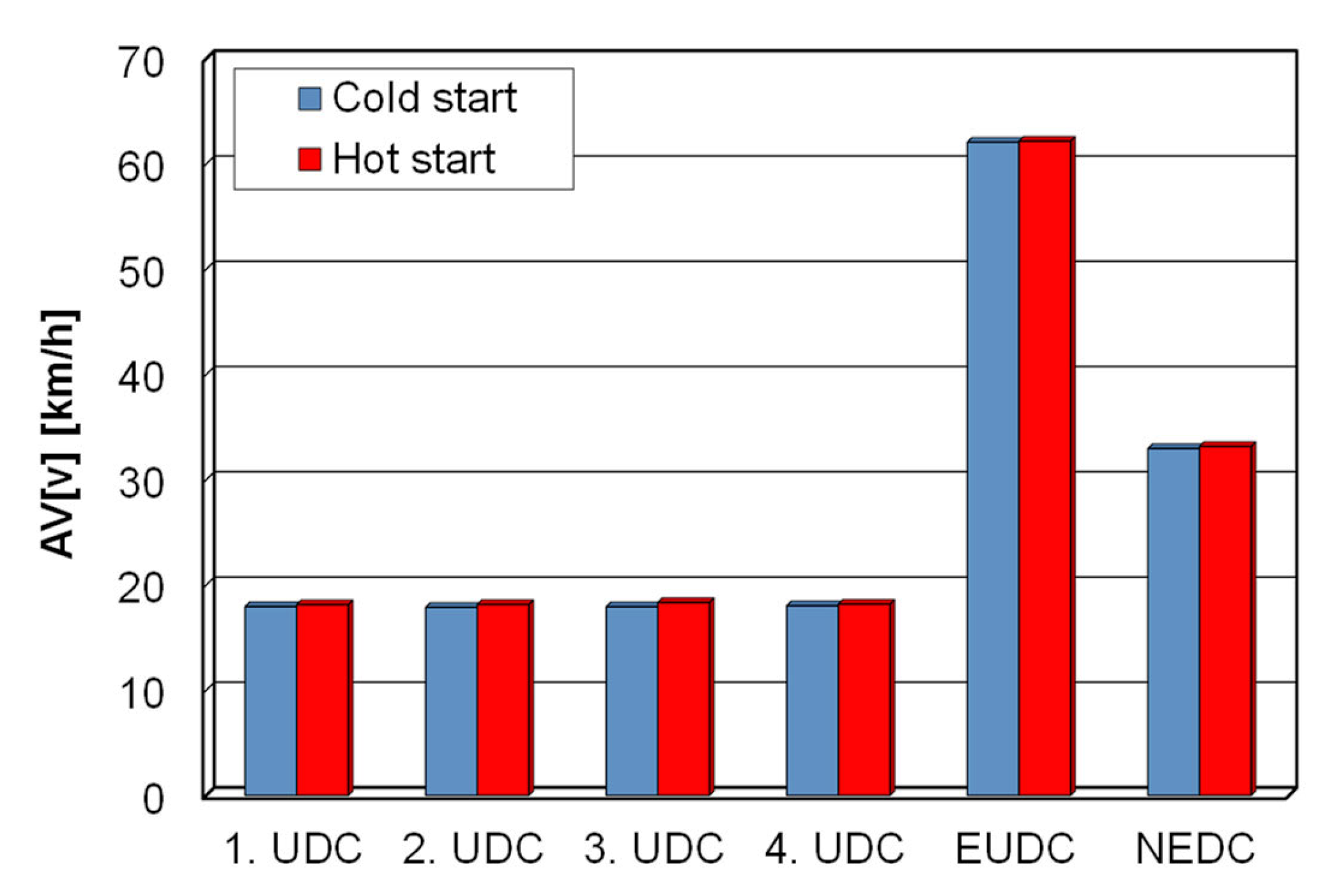

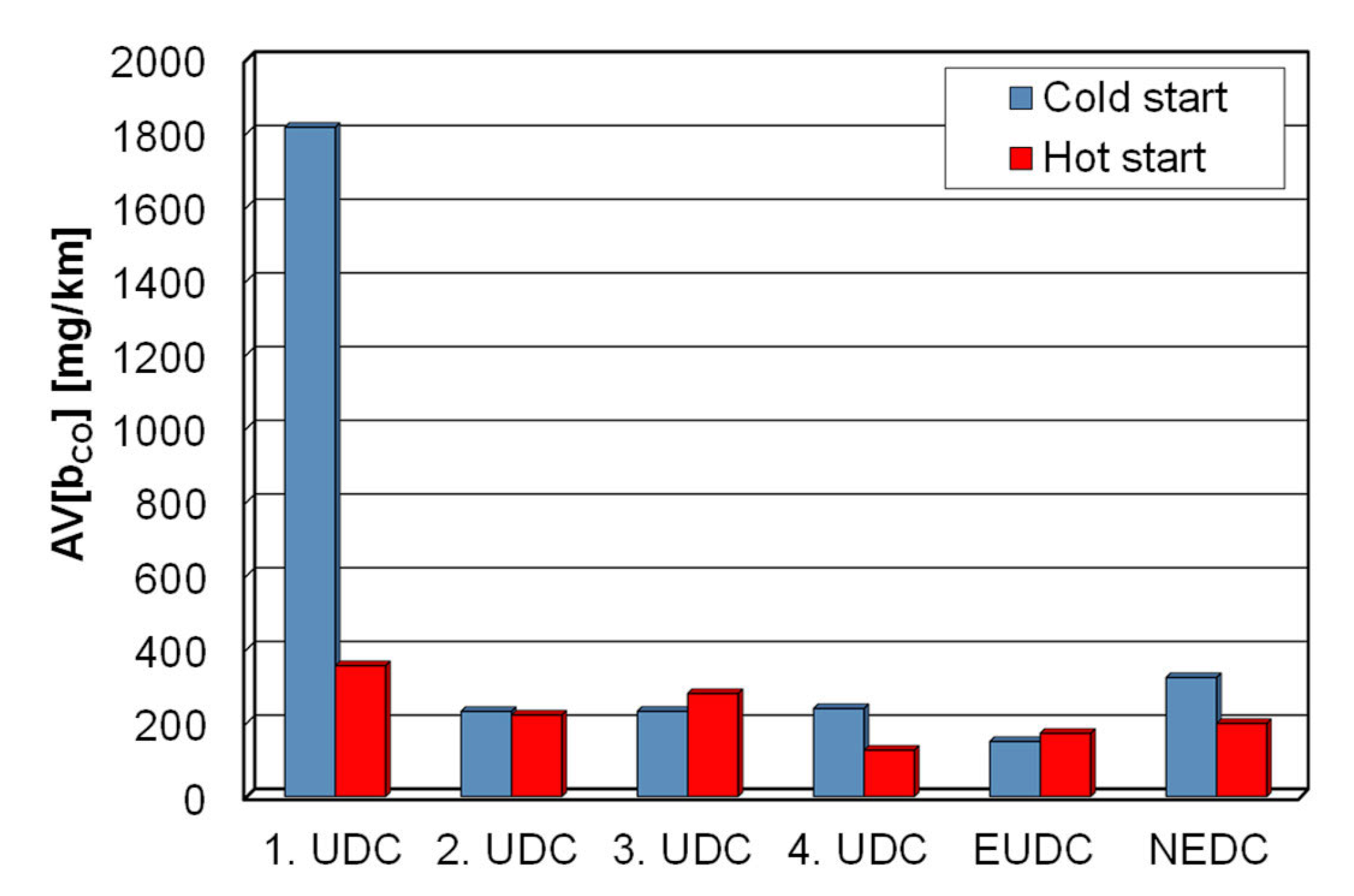

- The most important aspects responsible for the increase in fuel consumption and the exhaust emissions for cold engine starts, especially aspects with reducing properties in relation to oxygen, are the fact that the engine was supplied with richer mixtures due to disturbances in the power supply process and—even more so—the combustion process. In addition, the increased exhaust emission was favored by the low temperature of the exhaust aftertreatment systems. Even in the case of nitrogen oxides emission, where the low engine temperature favors a reduction in forming nitrogen oxides, the low temperature of the exhaust aftertreatment systems turned out to be decisive, resulting in the overall exhaust emissions being higher.

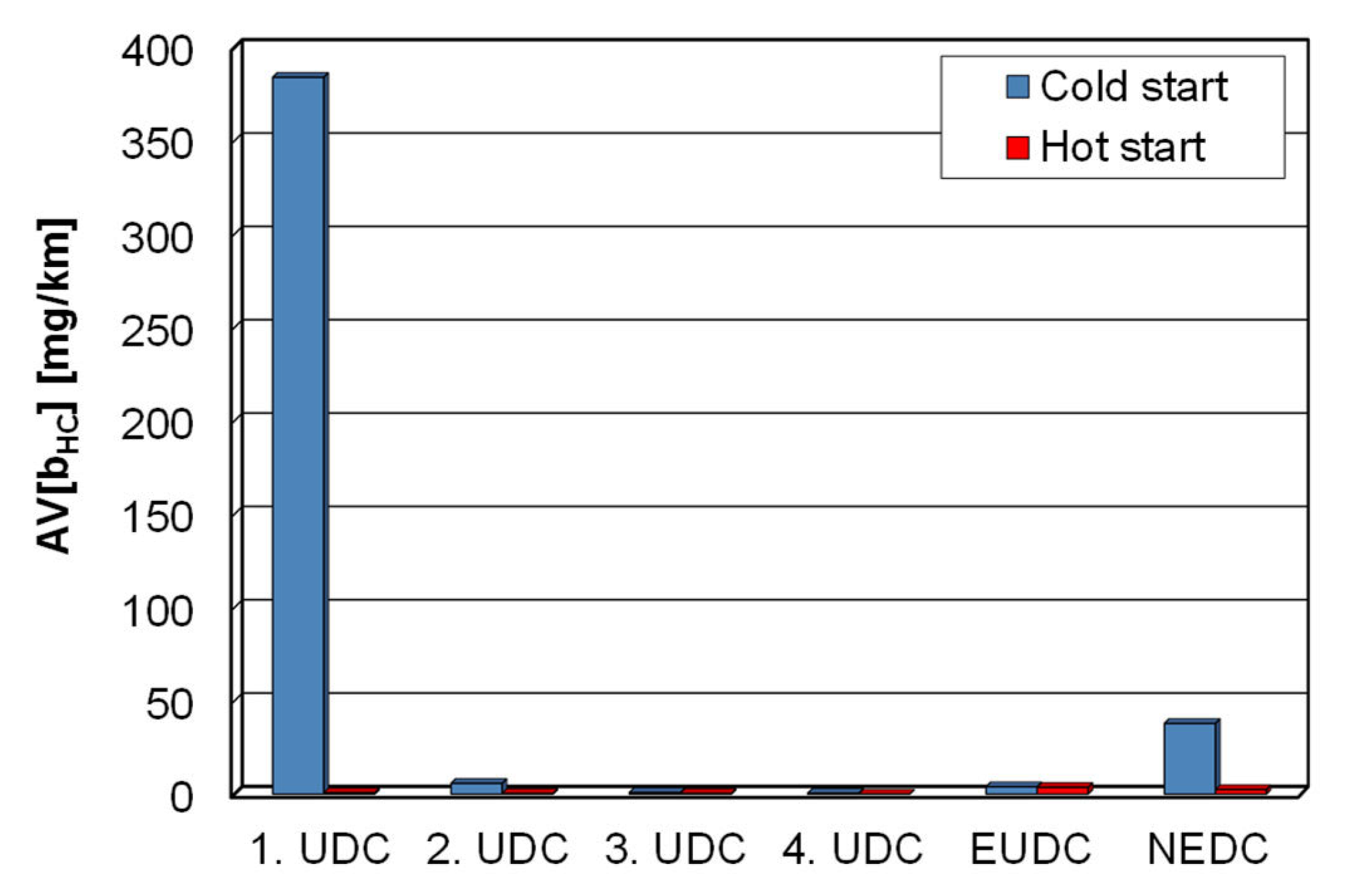

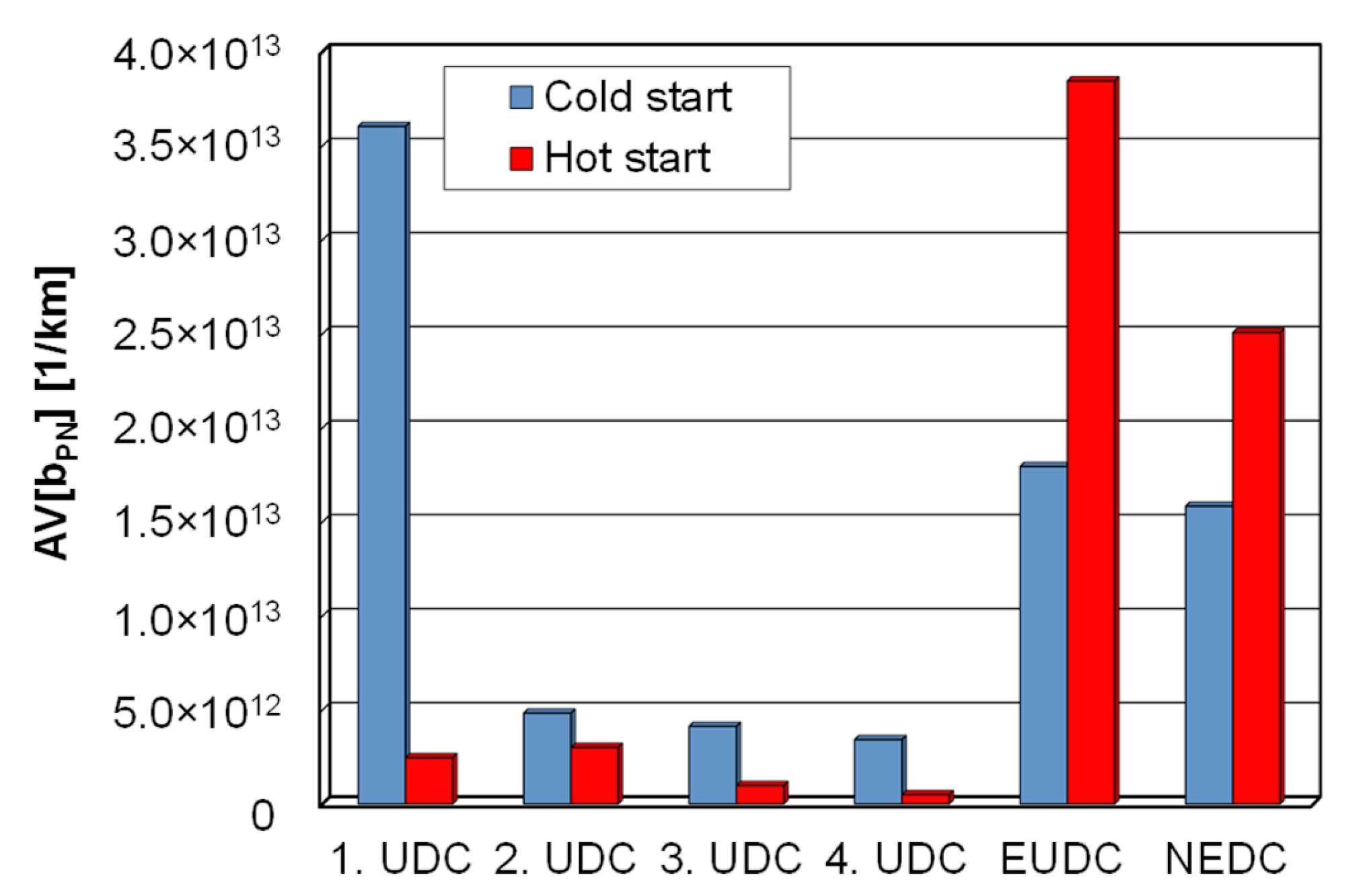

- Starting a cold engine has the greatest impact on the increase in the exhaust emissions of organic compounds, nitrogen oxide, and particulate matter, especially the number of particles.

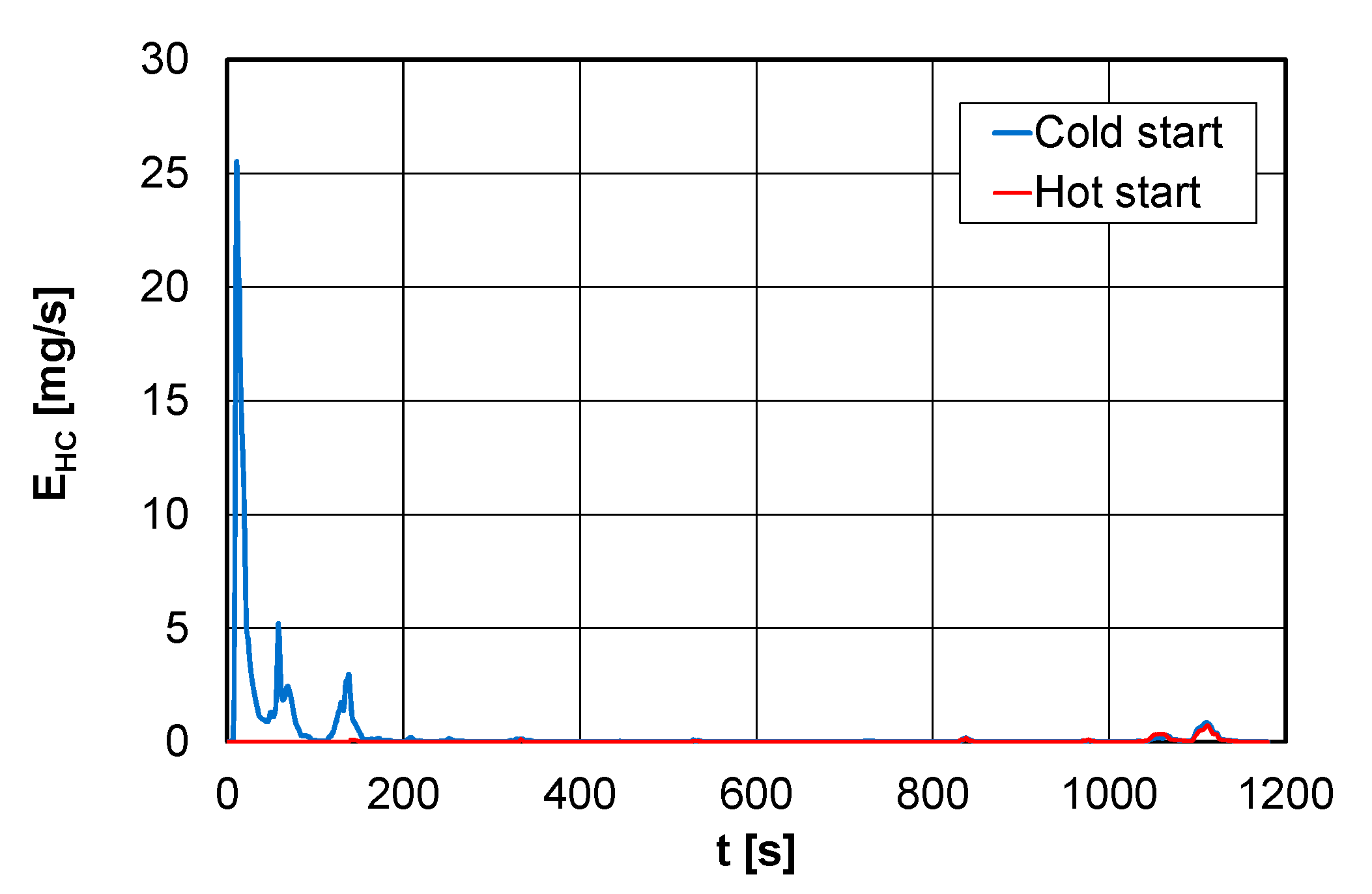

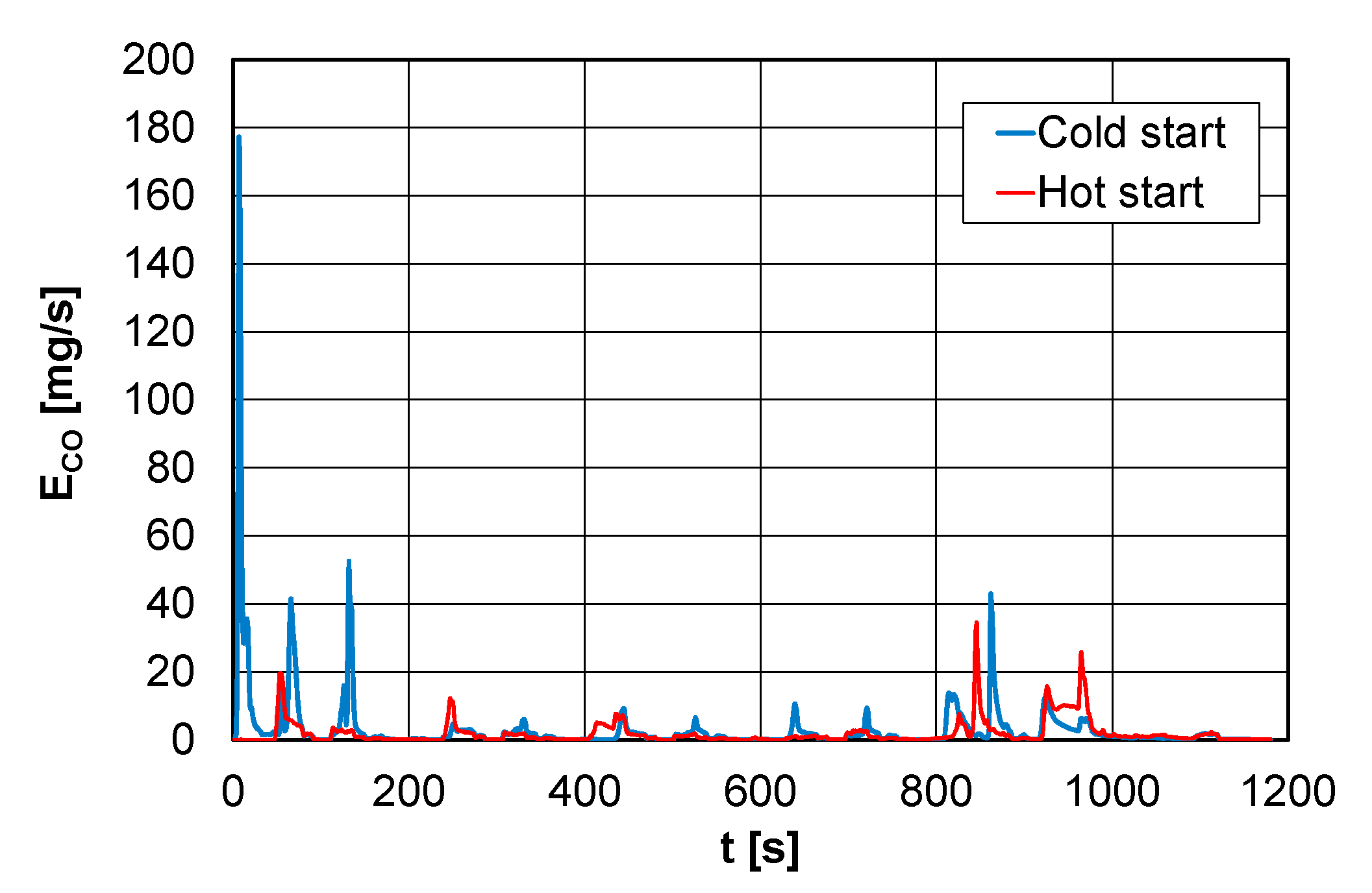

- The carbon monoxide exhaust emission intensity during the engine cold start was several times greater (180 mg/s) than the emission intensity of this compound for a hot engine (20 mg/s); this applied to the first 200 s of the NEDC test. Thermal stabilization of the exhaust aftertreatment systems caused the emission intensity results to become more similar to each other in the later parts of the test. A similar situation occurred in the case of the hydrocarbon emission intensity.

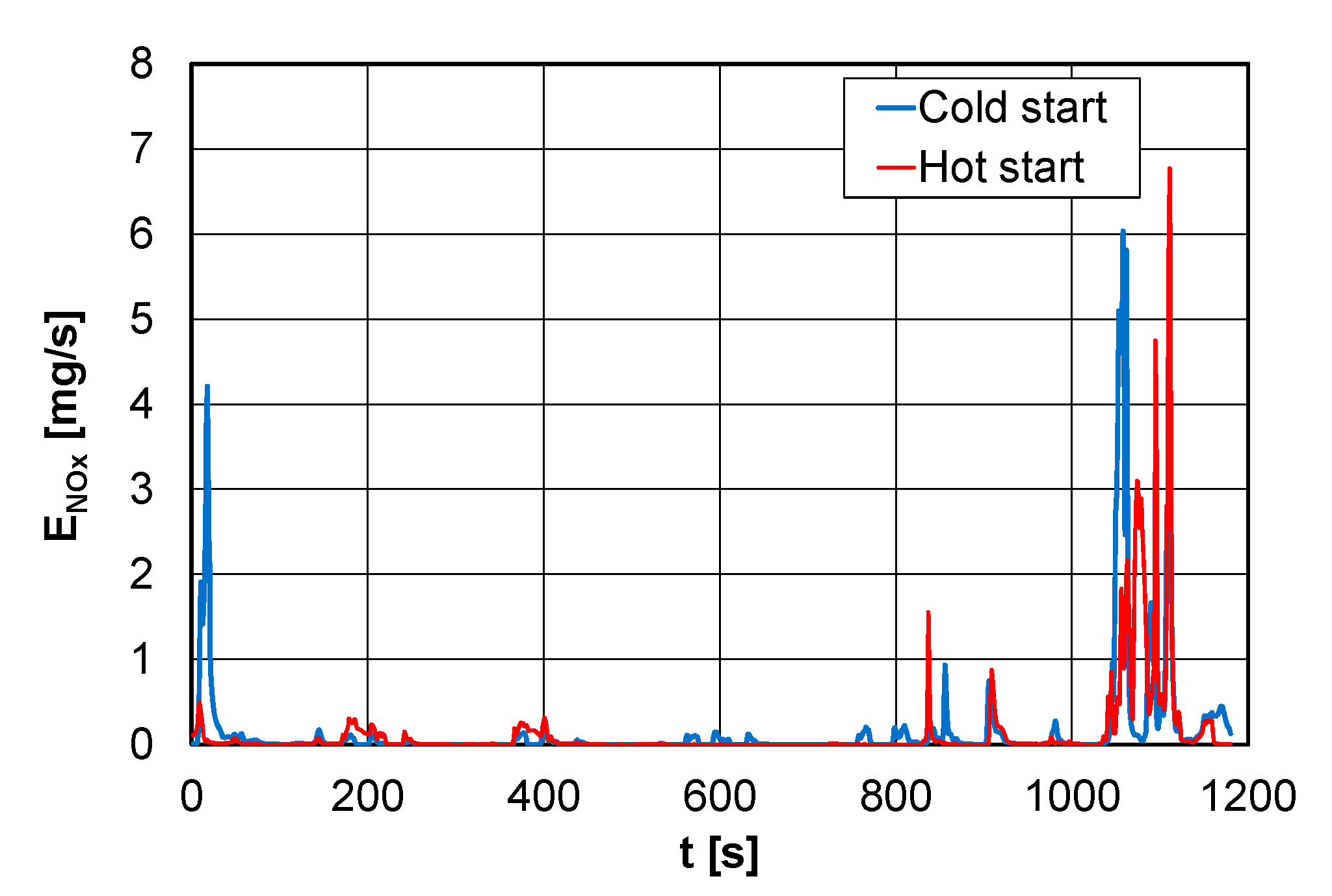

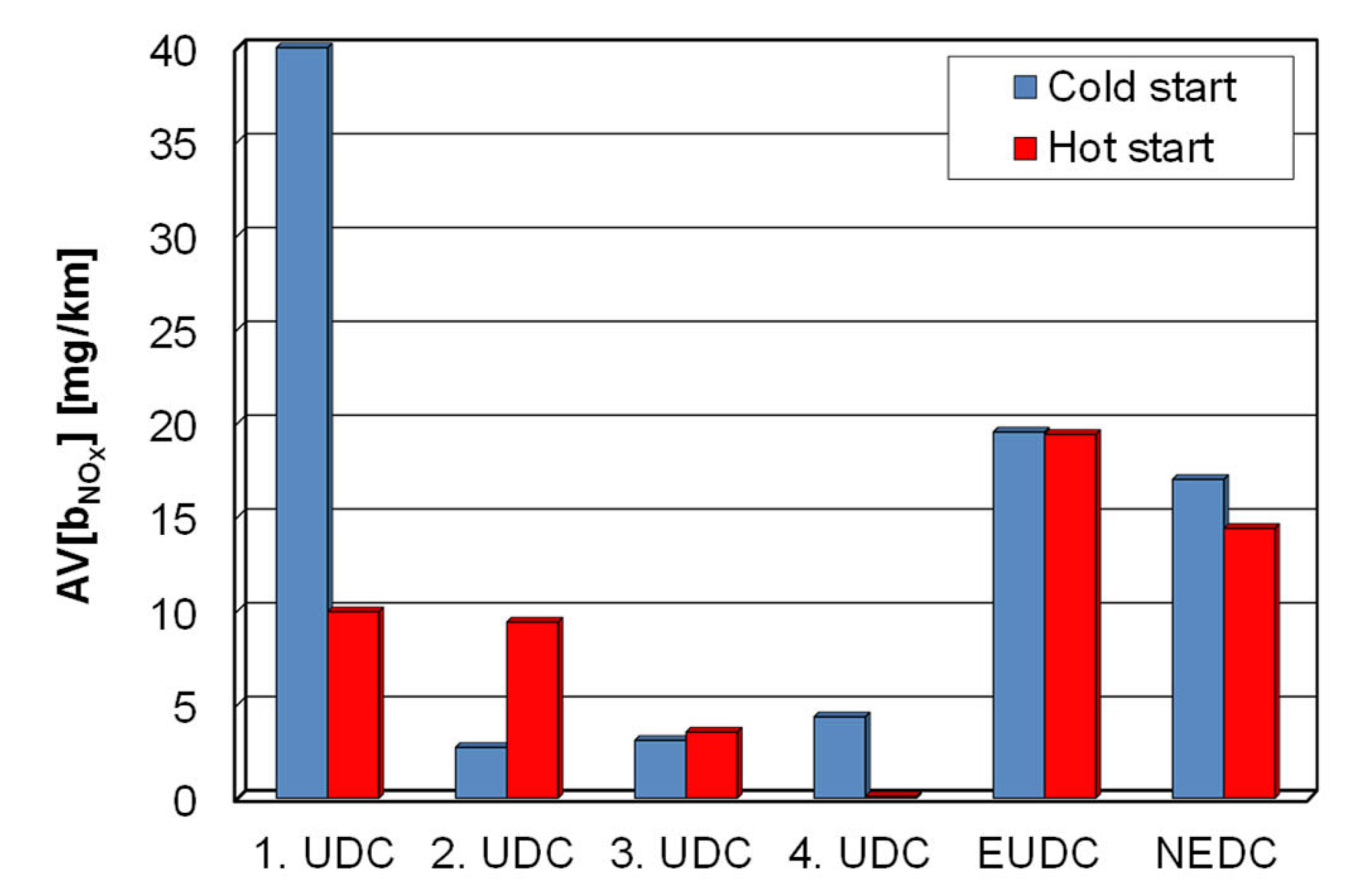

- Increased emission of nitrogen oxides in the NEDC test occurred only during the first seconds after the cold engine start, stabilizing after a period of about 200 s. The last high-speed phase (EUDC) was not significant, since the efficiency of the exhaust aftertreatment system was similar due to the heating of the catalytic reactor.

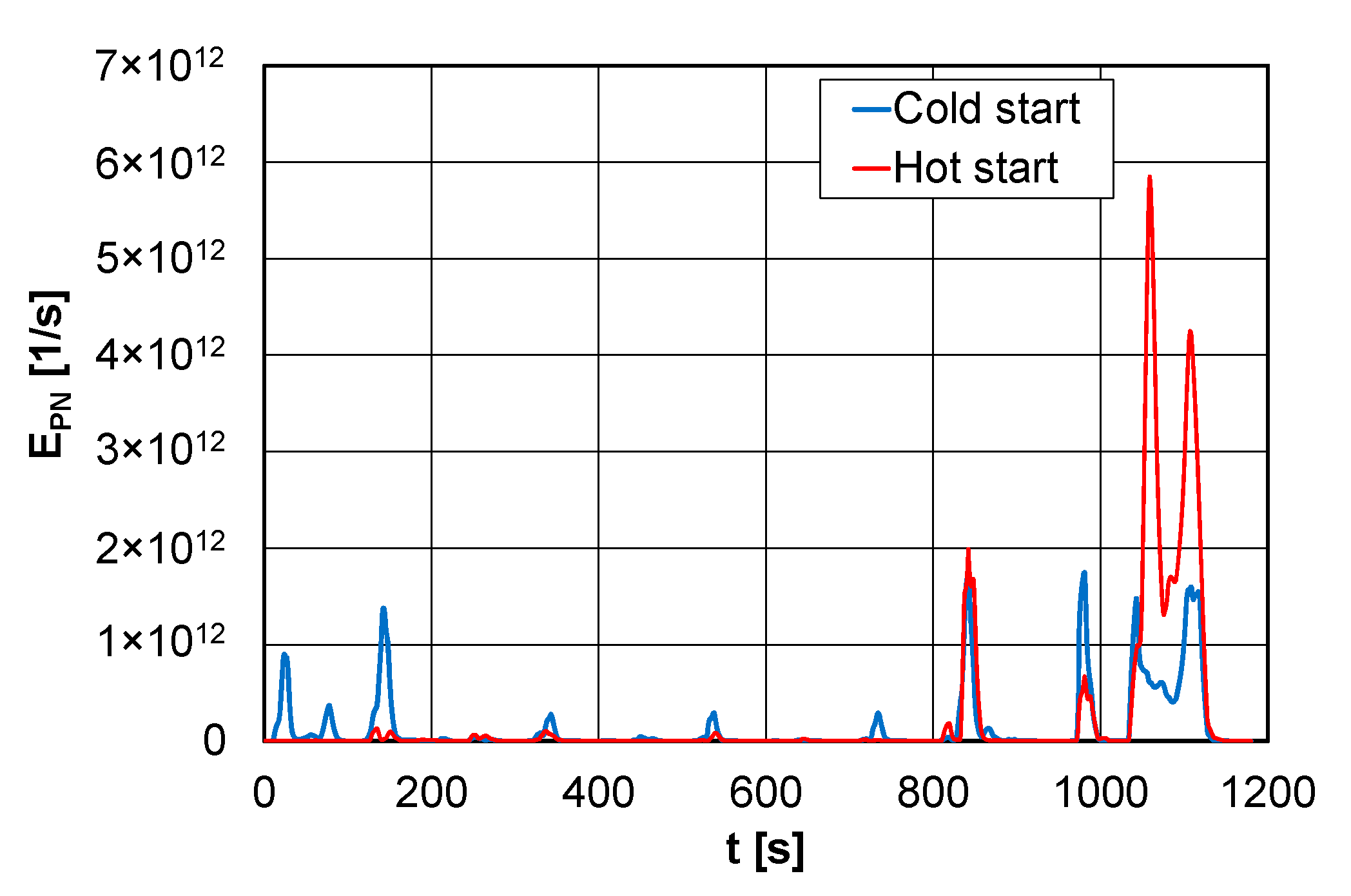

- A significant increase in the number of emitted particles during the engine cold start (1 × 1012 1/s) was observed for about 150 s after the start of the test. In the rest of the NEDC test, the particle number intensity was similar.

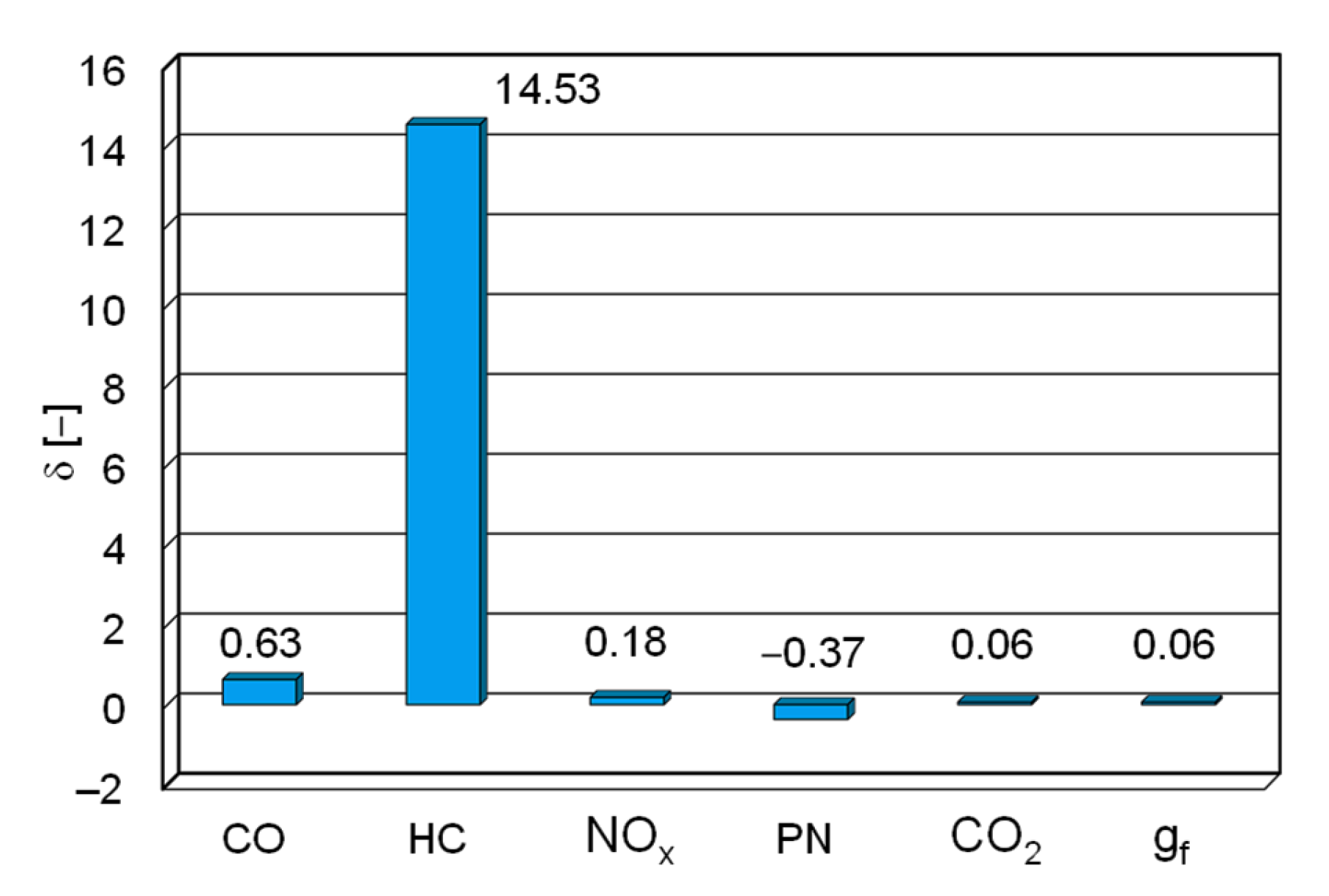

- The obtained values of road emission of exhaust components in the NEDC test indicated that during the engine cold start (compared to the hot one), the following occurred:

- road emission of CO was 63% greater,

- road emission of HC was 1500% greater,

- road emission of NOx was 18% greater,

- number of emitted particles was 37% lower,

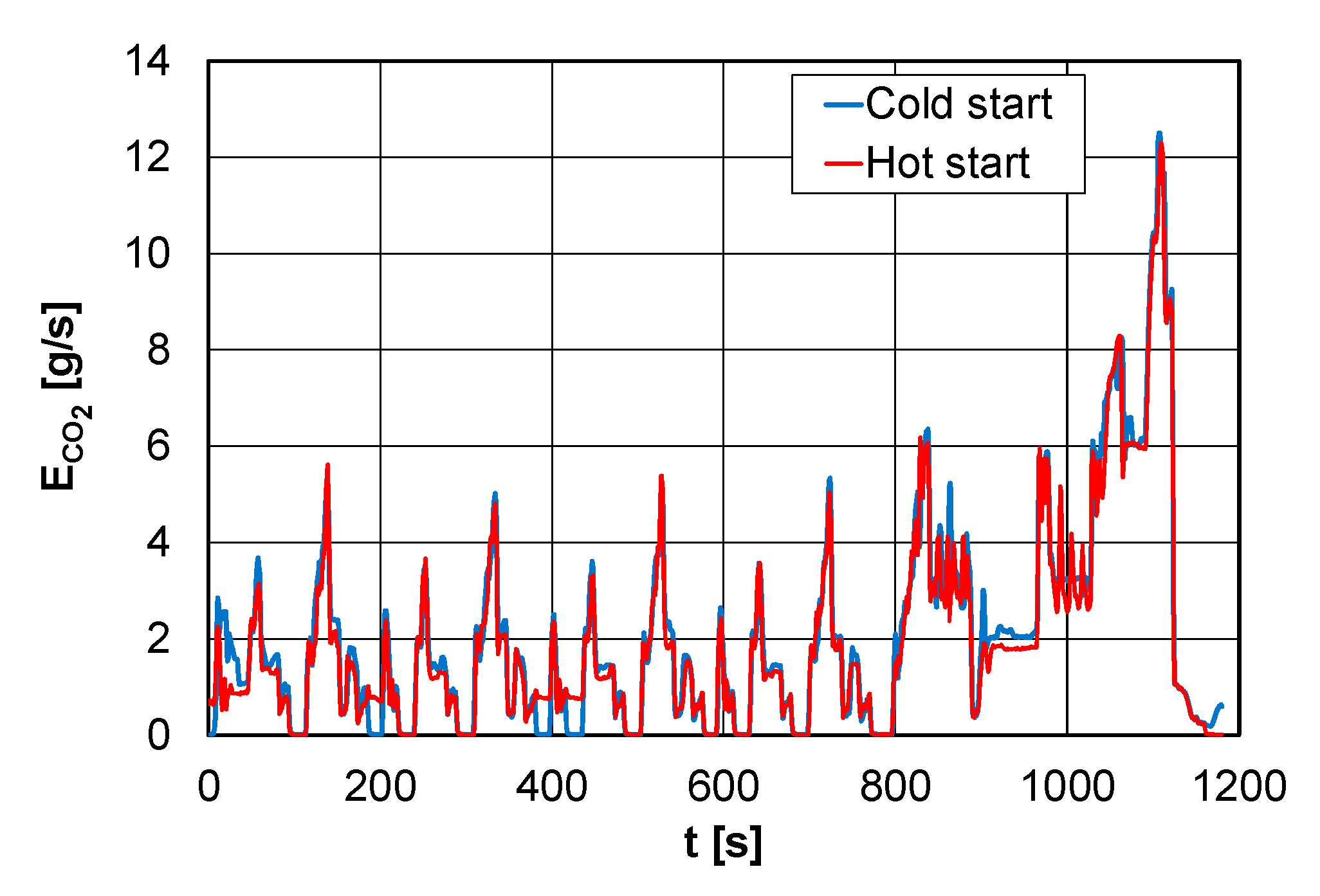

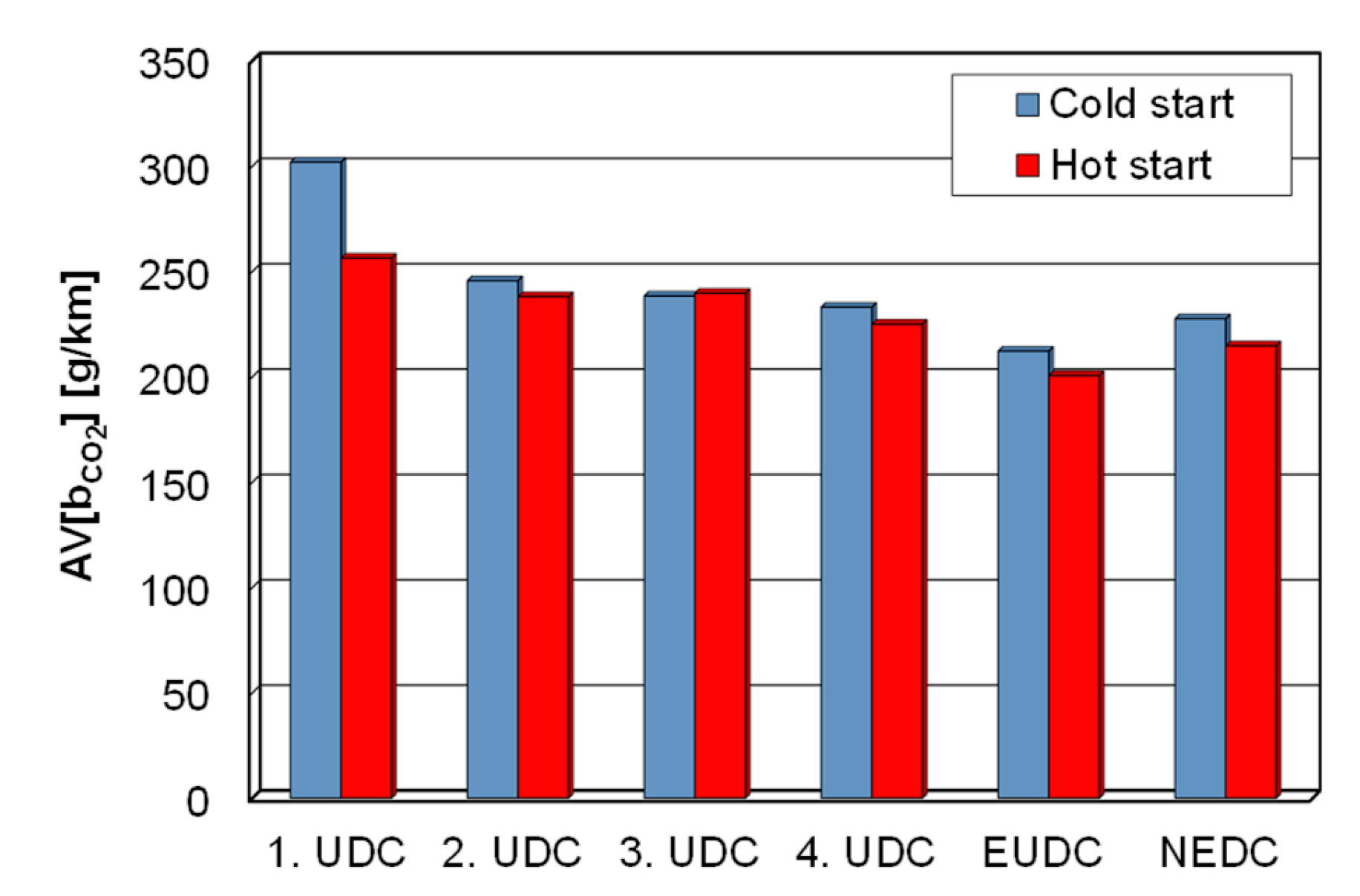

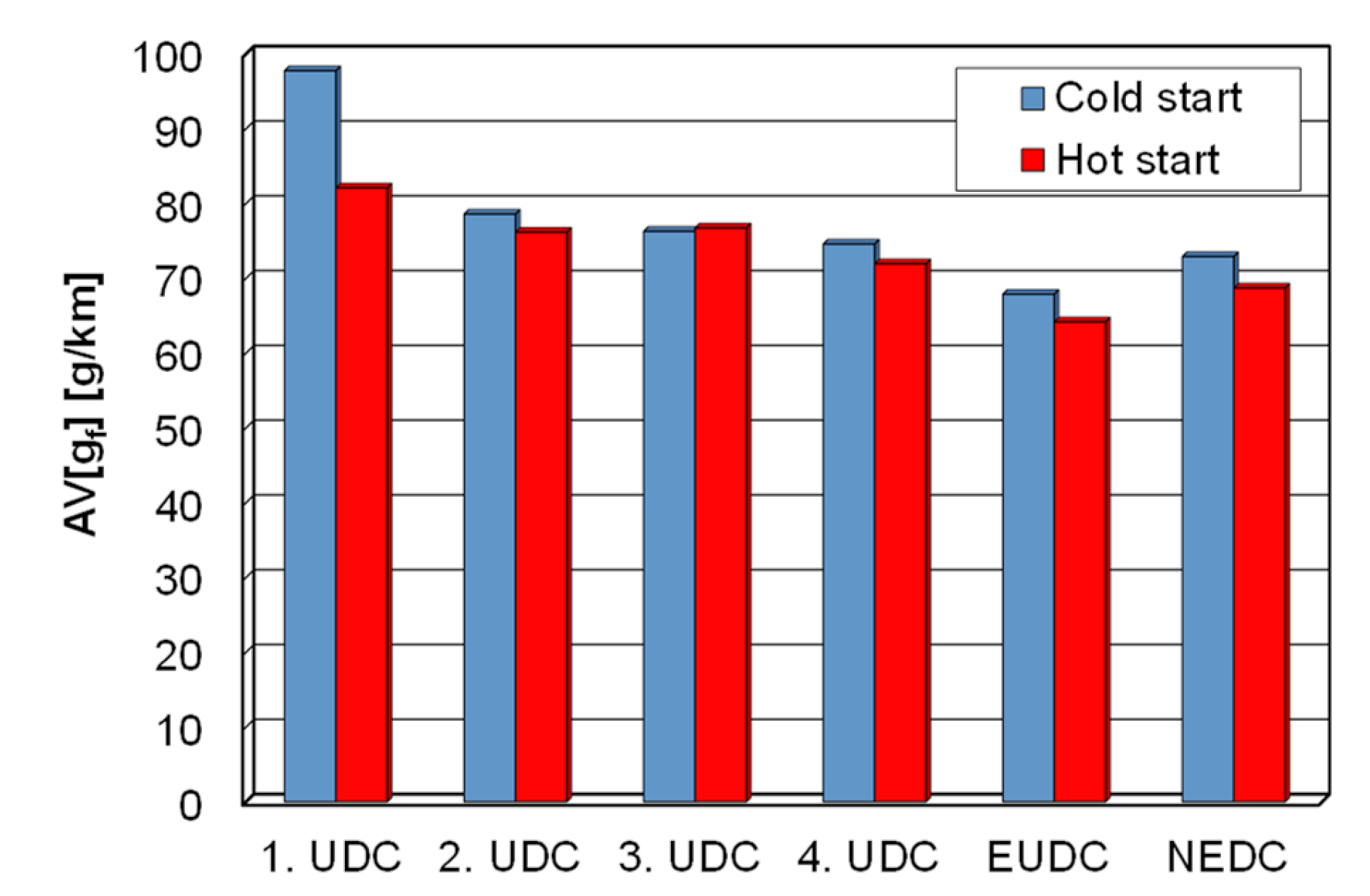

- fuel consumption (road emission of CO2) was 6% greater.

7. Further Research

- Conducting research using a greater repetition of tests, thanks to which it would be possible to assess the repeatability of the obtained results.

- Conducting research in accordance with other types of tests, making it possible to determine the impact of various vehicle motion characteristics on the operational properties of engines in the warm-up phase.

- Conducting simulation tests representing the real conditions of vehicle operation, determined using the results of previous empirical tests. These tests could be considered the implementation of vehicle speed processes—stochastic processes in simulated traffic conditions.

- Conducting research on the engine thermal state’s impact on its operational properties for various parameters, which is possible to achieve using various technical solutions. The results of these studies could provide a possibility of proposing practical technical solutions for engine warm up during its start-up phase.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASC | ammonia slip catalyst |

| AV | average value operator |

| b | road emissions of gases/road emission of particles |

| C | cold (meaning a cold start of an engine) |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| CLD | chemiluminescence detector |

| CPC | condensation particle counter |

| E | exhaust emission intensity of gases/exhaust emission intensity of particles |

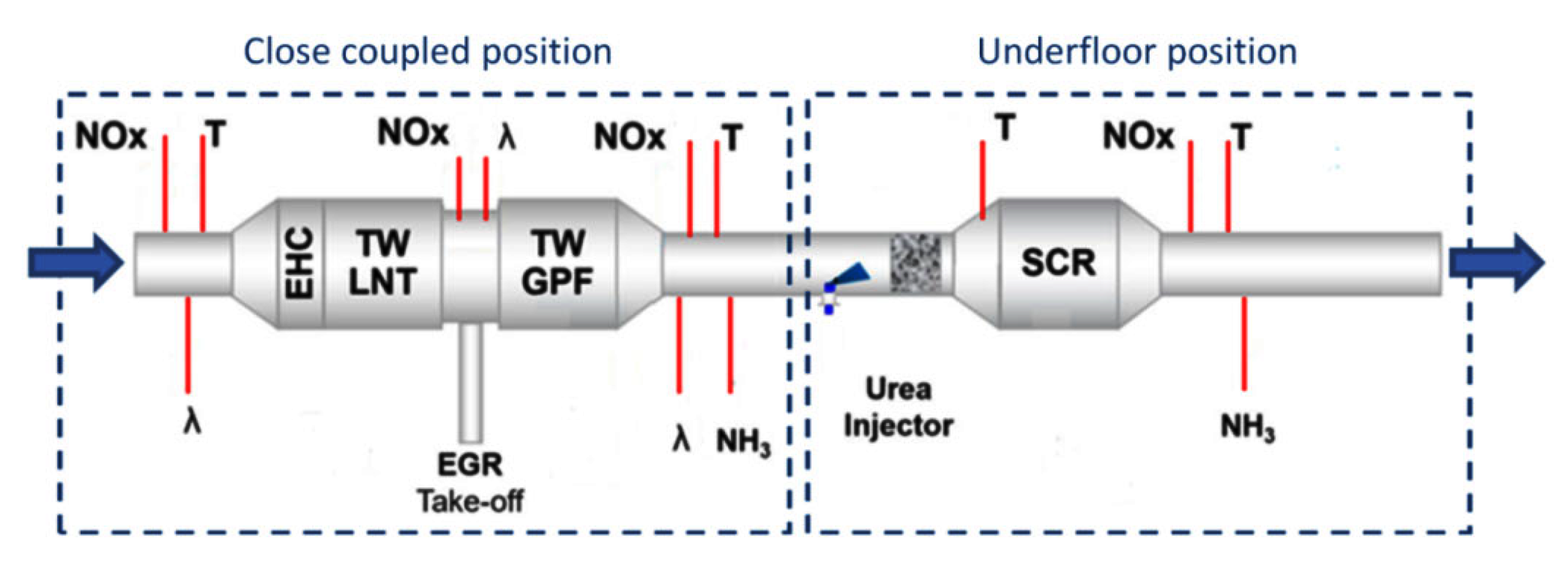

| EGR | exhaust gas recirculation |

| EHC | electrically heated catalyst |

| Gf | fuel mass consumption |

| GPF | gasoline particle filter |

| H | hot (meaning a hot start of an engine) |

| HCCI | homogeneous charger compression ignition |

| HEV | hybrid electric vehicle |

| LNT | lean trap NOx |

| NDIR | non-dispersive infrared detector |

| NEDC | New European Driving Cycle |

| NH3 | ammonia |

| NOx | nitrogen oxides |

| PN | particle number |

| qf | road fuel mass consumption |

| UHP | ultra-high injection pressure |

| HC | hydrocarbons |

| TWC | three-way catalyst |

| TW GPF | TWC + GPF |

| TW LNT | TWC + LNT |

| VCR | variable compression ratio |

| VVL | variable valves lift |

| VVT | variable valves timing |

| v | vehicle speed |

References

- Bielaczyc, P.; Merkisz, J. Exhaust Emission from Passenger Cars during Engine Cold Start and Warm-Up; SAE Technical Paper; SAE: Warrendale, PA, USA, 1997; 970740. [Google Scholar] [CrossRef]

- Bielaczyc, P.; Merkisz, J. Cold Start Emissions Investigation at Different Ambient Temperatures Conditions; SAE Technical Paper; SAE: Warrendale, PA, USA, 1998; 980401. [Google Scholar] [CrossRef]

- Bielaczyc, P.; Merkisz, J. Euro III/Euro IV Emissions—A Study of Cold Start and Warm up Phases with a SI (Spark Ignition) Engine; SAE Technical Paper; SAE: Warrendale, PA, USA, 1999. [Google Scholar] [CrossRef]

- Bielaczyc, P.; Merkisz, J.; Pielecha, J. Exhaust Emission from Diesel Engine during Cold Start in Ambient Temperature Conditions; SAE Technical Paper; SAE: Warrendale, PA, USA, 2001. [Google Scholar] [CrossRef]

- Pielecha, J.; Skobiej, K.; Kurtyka, K. Testing and evaluation of cold-start emissions from a gasoline engine in RDE test at two different ambient temperatures. Open Eng. 2021, 11, 425–434. [Google Scholar] [CrossRef]

- Pielecha, J.; Merkisz, J.; Kurtyka, K.; Skobiej, K. Cold start emissions of passenger cars with gasoline and diesel engines in Real Driving Emissions tests. Combust. Engines 2019, 179, 160–168. [Google Scholar] [CrossRef]

- Merkisz, J.; Bielaczyc, P.; Pielecha, J.; Woodburn, J. RDE Testing of Passenger Cars: The Effect of the Cold Start on the Emissions Results; SAE Technical Paper; SAE: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Andrych-Zalewska, M.; Merkisz, J.; Pielecha, J. Analysis of the efficiency of the in-cylinder catalyst to reduce exhaust emissions during cold start combustion engine. Combust. Engines 2019, 177, 38–45. [Google Scholar] [CrossRef]

- Kurtyka, K.; Pielecha, J. Cold start emissions from a gasoline engine in RDE tests at different ambient temperatures. Combust. Engines 2020, 181, 24–30. [Google Scholar] [CrossRef]

- Bielaczyc, P.; Merkisz, J.; Pielecha, J.; Woodburn, J. RDE-Compliant PEMS Testing of a Gasoline Euro 6d-TEMP Passenger Car at Two Ambient Temperatures with a Focus on the Cold Start Effect; SAE Technical Paper; SAE: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Chłopek, Z. Modeling of Exhaust Emission Processes in the Conditions of Traction Operation of Internal Combustion Engines; Oficyna Wydawnicza Politechniki Warszawskiej: Warszawa, Poland, 1999. [Google Scholar]

- Chłopek, Z.; Biedrzycki, J.; Lasocki, J.; Wójcik, P. Assessment of the impact of dynamic states of an internal combustion engine on its operational properties. Eksploat. i Niezawodn. Maint. Reliab. 2015, 17, 35–41. [Google Scholar] [CrossRef]

- Worldwide Emission Standards. Passenger Cars and Light Duty Vehicles; Innovation for the Real World; Delphi: London, UK, 2020–2021. [Google Scholar]

- Worldwide Emission Standards. Heavy Duty & Off-Road Vehicles; Innovation for the Real World; Delphi: London, UK, 2020–2021. [Google Scholar]

- Marecka-Chłopek, E.; Budny, E.; Chłopek, Z.; Chłosta, M. Identification of combustion engine static states in real operation conditions of a building machine. Sci. Probl. Mach. Oper. Maint. 2008, 156, 69–84. Available online: https://t.tribologia.org/plik/spm/spmom-08v43n4_p-069.pdf (accessed on 15 November 2022).

- Alashaab, A.; Saleh, H.; Abo-Serie, E.; Rabee, B.; Aal, M.A. Gaseous fuel for lower emissions during the cold start and warming up of spark ignition engines. Int. J. Glob. Warm. 2016, 10, 115–132. Available online: https://www.inderscienceonline.com/doi/epdf/10.1504/IJGW.2016.077909 (accessed on 1 November 2022). [CrossRef]

- Birkavs, A.; Dukulis, I. Amount of Toxic Exhaust Gases Emitted during Engine Warm up. In Proceedings of the International Scientific Conference 2016, Jelgava, Latvia, 25–27 May 2016; Engineering for Rural Development. Available online: https://www.tf.llu.lv/conference/proceedings2016/Papers/N086.pdf (accessed on 12 December 2022).

- Fiengo, G.; Santini, S.; Glielmo, L. Emission reduction during TWC warm-up: Control synthesis and hardware-in-the-loop verification. Int. J. Model. Identif. Control 2008, 3, 233–246. [Google Scholar] [CrossRef]

- Gao, J.; Tian, G.; Sorniotti, A.; Karci, A.E.; Di Palo, R. Review of thermal management of catalytic converters to decrease engine emissions during cold start and warm up. Appl. Therm. Eng. 2019, 147, 177–187. [Google Scholar] [CrossRef]

- Hamedi, M.R.; Doustdar, O.; Tsolakis, A.; Hartland, J. Thermal energy storage system for efficient diesel exhaust aftertreatment at low temperatures. Appl. Energy 2019, 235, 874–887. [Google Scholar] [CrossRef]

- Ibrahim, T.M.; Syahir, A.Z.; Zulkifli, N.W.M.; Masjuki, H.H.; Osman, A. Enhancing vehicle’s engine warm up using integrated mechanical approach. IOP Conf. Ser. Mater. Sci. Eng. 2017, 210, 012064. [Google Scholar] [CrossRef]

- Jeong, S.-J.; Kim, W.-S. A new strategy for improving the warm-up performance of a light-off auto-catalyst for reducing cold-start emissions. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2001, 215, 1179–1196. [Google Scholar] [CrossRef]

- Kaltakkıran, G.; Akif Ceviz, M.; Bakirci, K. Instantaneous energy balance and performance analysis during warm up period of a spark ignition engine under several thermal energy management strategies. Energy Convers. Manag. 2022, 269, 116102. [Google Scholar] [CrossRef]

- Leblanc, M.; Noël, L.; R’Mili, B.; Boreave, A.; D’Anna, B.; Raux, S. Impact of engine warm-up and DPF active regeneration on regulated & unregulated emissions of a Euro 6 Diesel SCR equipped vehicle. J. Earth Sci. Geotech. Eng. 2016, 6, 29–50. Available online: http://www.scienpress.com/Upload/GEO/Vol%206_4_3.pdf (accessed on 1 January 2023).

- Lodi, F.; Zare, A.; Arora, P.; Stevanovic, S.; Jafari, M.; Ristovski, Z.; Brown, R.J.; Bodisco, T. Engine performance and emissions analysis in a cold, intermediate and hot start diesel engine. Appl. Sci. 2020, 10, 3839. [Google Scholar] [CrossRef]

- Vittorini, D.; Di Battista, D.; Cipollone, R. Engine oil warm-up through heat recovery on exhaust gases—Emissions reduction assessment during homologation cycles. Therm. Sci. Eng. Prog. 2018, 5, 412–421. [Google Scholar] [CrossRef]

- Vlachos, T.; Bonnel, P.; Weiss, M. Including Cold-Start Emissions in the Real-Driving Emissions (RDE) Test Procedure: An Assessment of Cold-Start Frequencies and Emission Effects; Joint Research Centre, Publications Office of the European Union: Luxembourg, 2017. [Google Scholar] [CrossRef]

- Chłopek, Z.; Biedrzycki, J.; Lasocki, J.; Wójcik, P. Examination of pollutant emissions and fuel consumption at tests simulating the real conditions of operation of a passenger car. Arch. Automot. Eng. 2014, 65, 81–96. Available online: http://www.aaejournal.com/pdf-99350-31554?filename=Examination%20of%20pollutant.pdf (accessed on 25 December 2022).

- Demuynck, J.; Favre, C.; Bosteels, D.; Randlshofer, G.; Bunar, F.; Spitta, J.; Friedrichs, O.; Kuhrt, A.; Brauer, M. Integrated diesel system achieving ultra-low urban and motorway NOx emissions on the road. In Proceedings of the 40th International Vienna Motor Symposium, Vienna, Austria, 16 May 2019; Available online: https://www.aecc.eu/wp-content/uploads/2020/11/190516-AECC-IAV-IPA-Integrated-Diesel-System-achieving-Ultra-Low-NOx-on-the-road-Vienna-Symposium-1.pdf (accessed on 12 December 2022).

- Bunar, F. Holistic ECT Cost Estimation; Final Report (Executive Summary) v.2; Automotive Engineering. 2021. Available online: https://www.iav.com (accessed on 21 November 2021).

| Technical Parameters | Vehicle |

|---|---|

| Engine | Gasoline, Turbo, R4, 16 V |

| Fuel system | direct injection |

| Engine displacement | 1984 cm3 |

| Max. power | 195 kW at 5000 rpm |

| Max. torque | 370 Nm/1600—4200 rpm |

| Transmission | automatic, seven gears |

| Curb weight | 1770 kg |

| Specific power output | 9.1 kg/kW |

| Average CO2 emissions | 228 g/km (WLTC) |

| Euro standard | Euro 6 |

| Technical Parameters | Details |

|---|---|

| Sample flow rate | 8 dm3/min |

| CO2 ranges (NDIR method) | 0–20% |

| CO ranges (NDIR method) | 0–10,000 ppm |

| HC ranges (FID method) | 0–5000 ppm |

| NOx ranges (CLD method) | 0–500 ppm |

| PN (CPC method) | 0–10,000 1/cm3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrych-Zalewska, M.; Chlopek, Z.; Merkisz, J.; Pielecha, J. Impact of the Internal Combustion Engine Thermal State during Start-Up on the Exhaust Emissions in the Homologation Test. Energies 2023, 16, 1937. https://doi.org/10.3390/en16041937

Andrych-Zalewska M, Chlopek Z, Merkisz J, Pielecha J. Impact of the Internal Combustion Engine Thermal State during Start-Up on the Exhaust Emissions in the Homologation Test. Energies. 2023; 16(4):1937. https://doi.org/10.3390/en16041937

Chicago/Turabian StyleAndrych-Zalewska, Monika, Zdzislaw Chlopek, Jerzy Merkisz, and Jacek Pielecha. 2023. "Impact of the Internal Combustion Engine Thermal State during Start-Up on the Exhaust Emissions in the Homologation Test" Energies 16, no. 4: 1937. https://doi.org/10.3390/en16041937

APA StyleAndrych-Zalewska, M., Chlopek, Z., Merkisz, J., & Pielecha, J. (2023). Impact of the Internal Combustion Engine Thermal State during Start-Up on the Exhaust Emissions in the Homologation Test. Energies, 16(4), 1937. https://doi.org/10.3390/en16041937