Development and Experimental Characterization of an Innovative Tank-in-Tank Hybrid Sensible–Latent Thermal Energy Storage System

Abstract

:1. Introduction

2. Materials and Methods

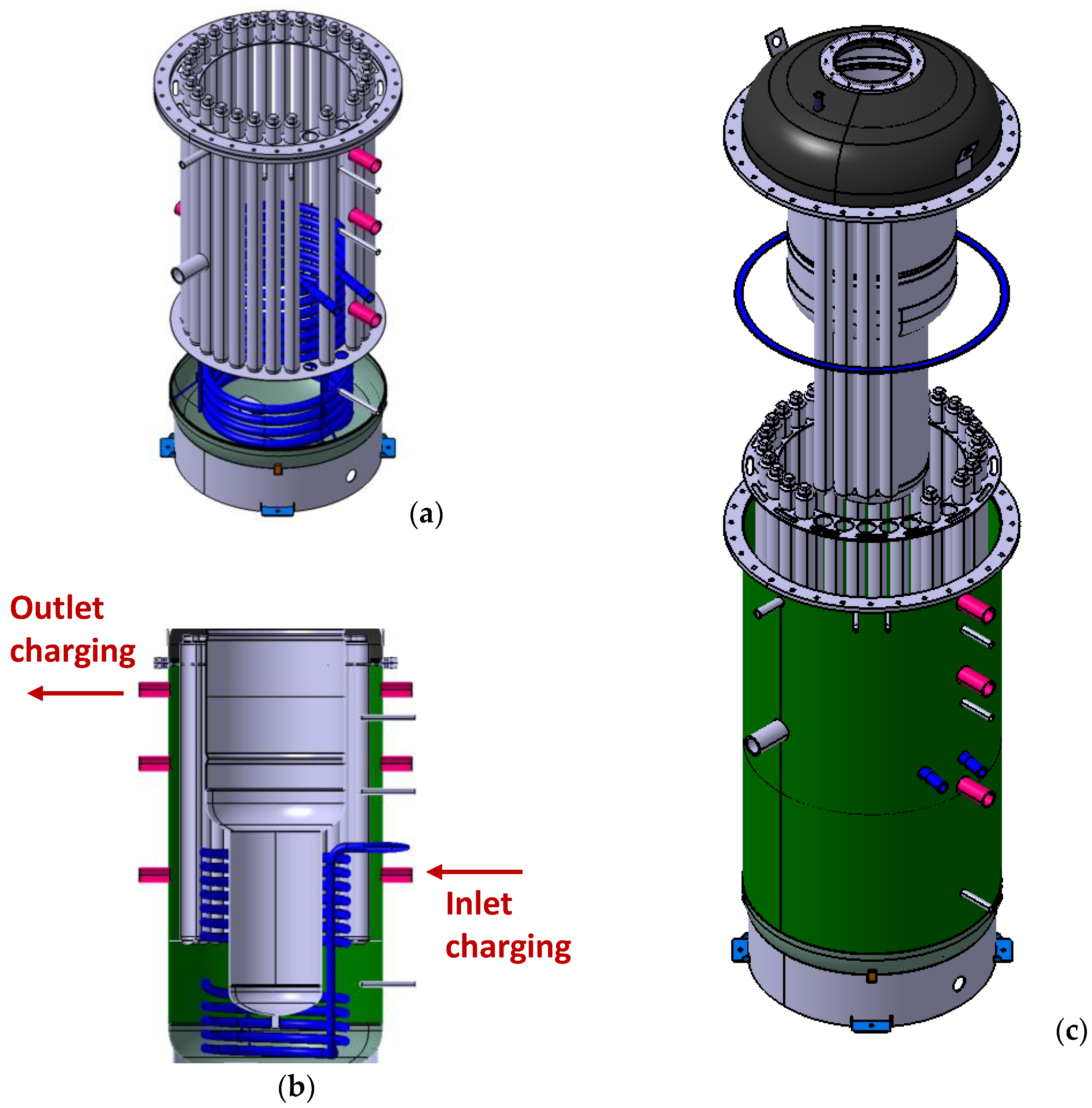

2.1. Hybrid Tank-in-Tank Storage Configuration

- To employ a robust TES design, which was already commercially available, to minimize the cost and make the TES system suitable for integration in standard heating systems;

- To investigate the possibility of physically separating technical water (used as heat transfer fluid) and DHW in order to avoid pollution of the DHW by PCM;

- To integrate macro-encapsulated PCM with an optimized shape to maximize the amount of PCM inside the TES system.

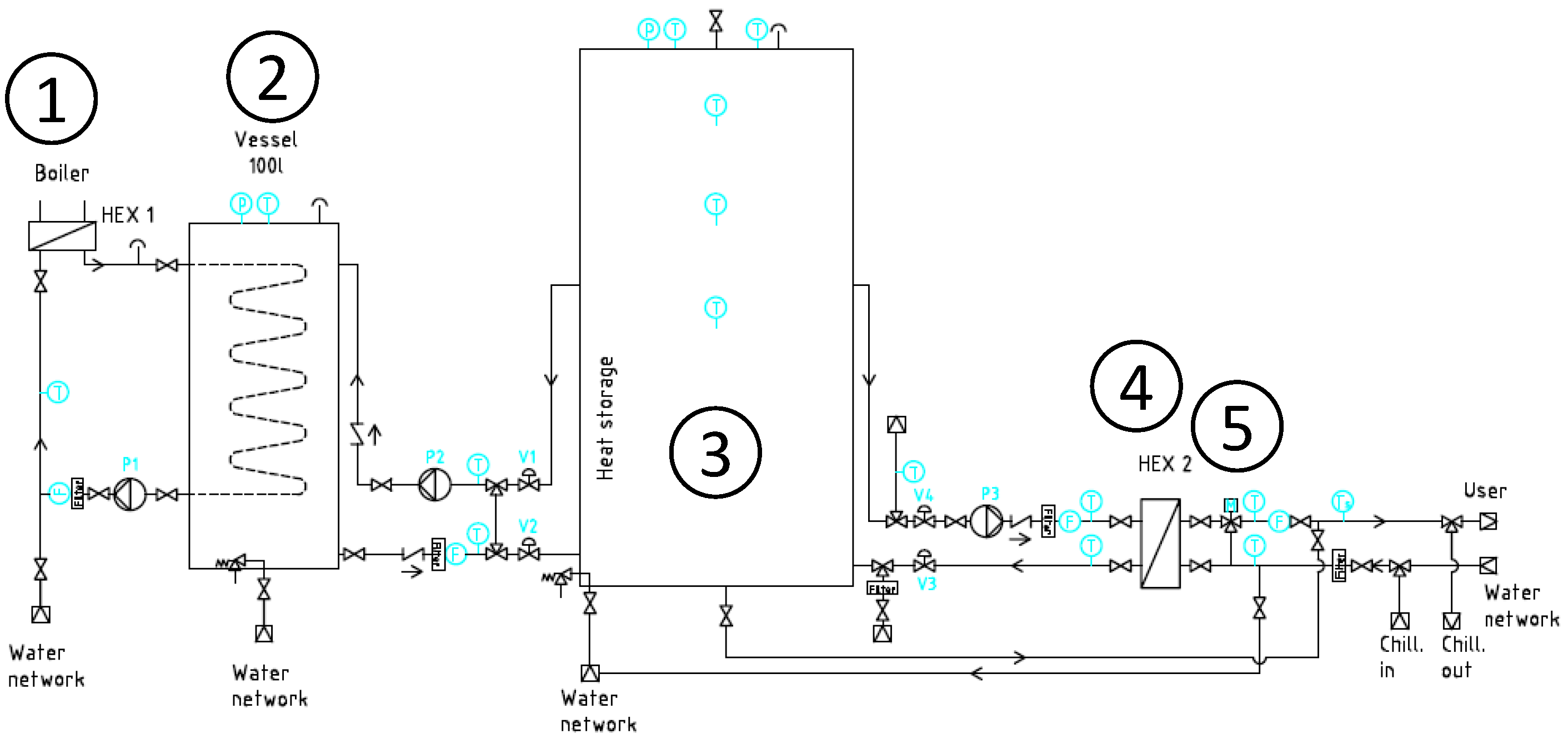

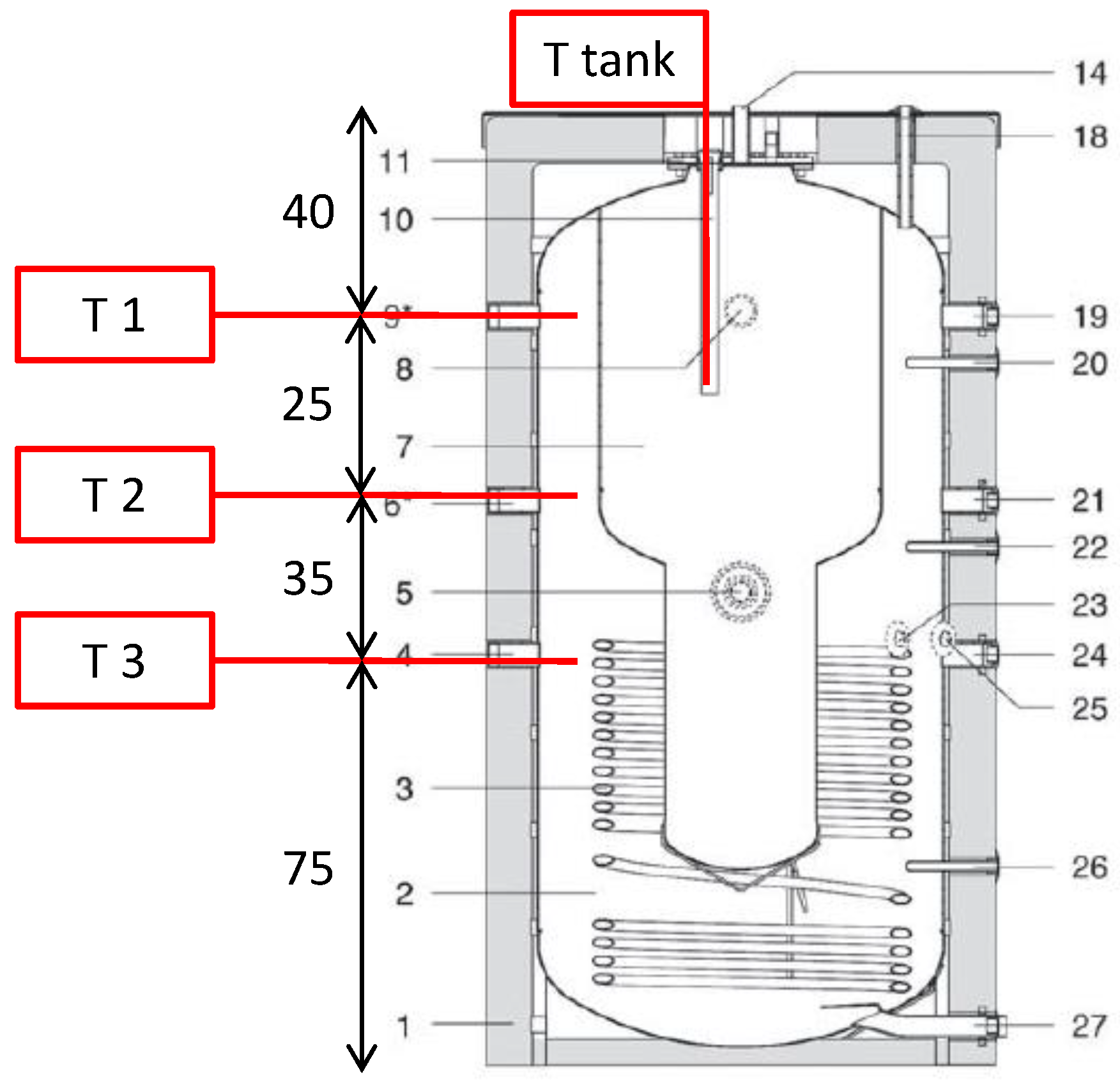

2.2. Testing Rig and Uncertainty Analysis

2.3. Testing Conditions and Data Analysis

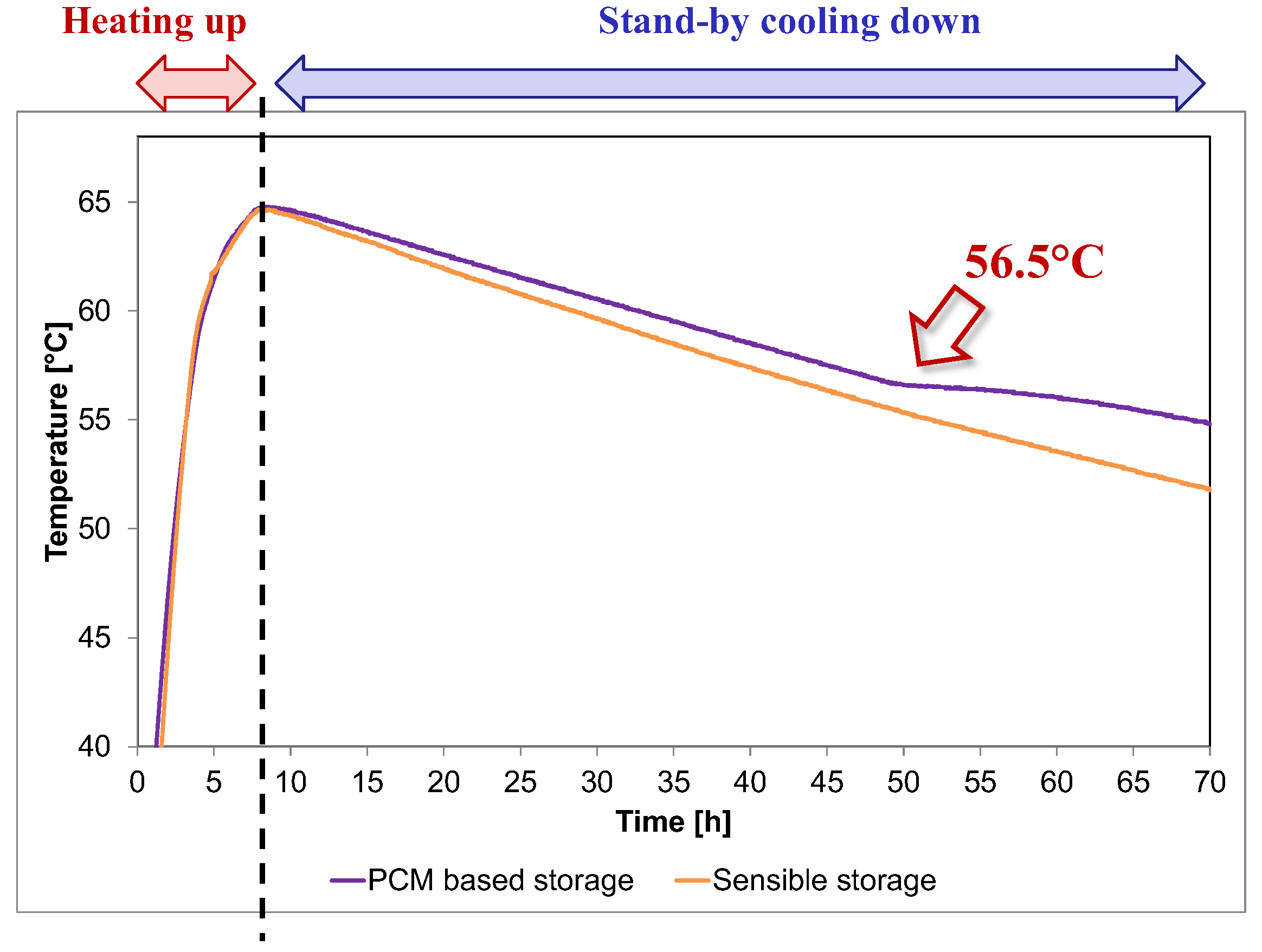

- Stand-by cooldown. This test was mainly employed to evaluate the rate of heat dissipation to the surrounding environment (heat loss coefficient). The TES system is heated to a temperature above PCM’s melting point. Then, the heating is stopped, and the system is allowed to cool down for 60 h solely through heat loss, with the surrounding ambient temperature maintained at about 20 °C.

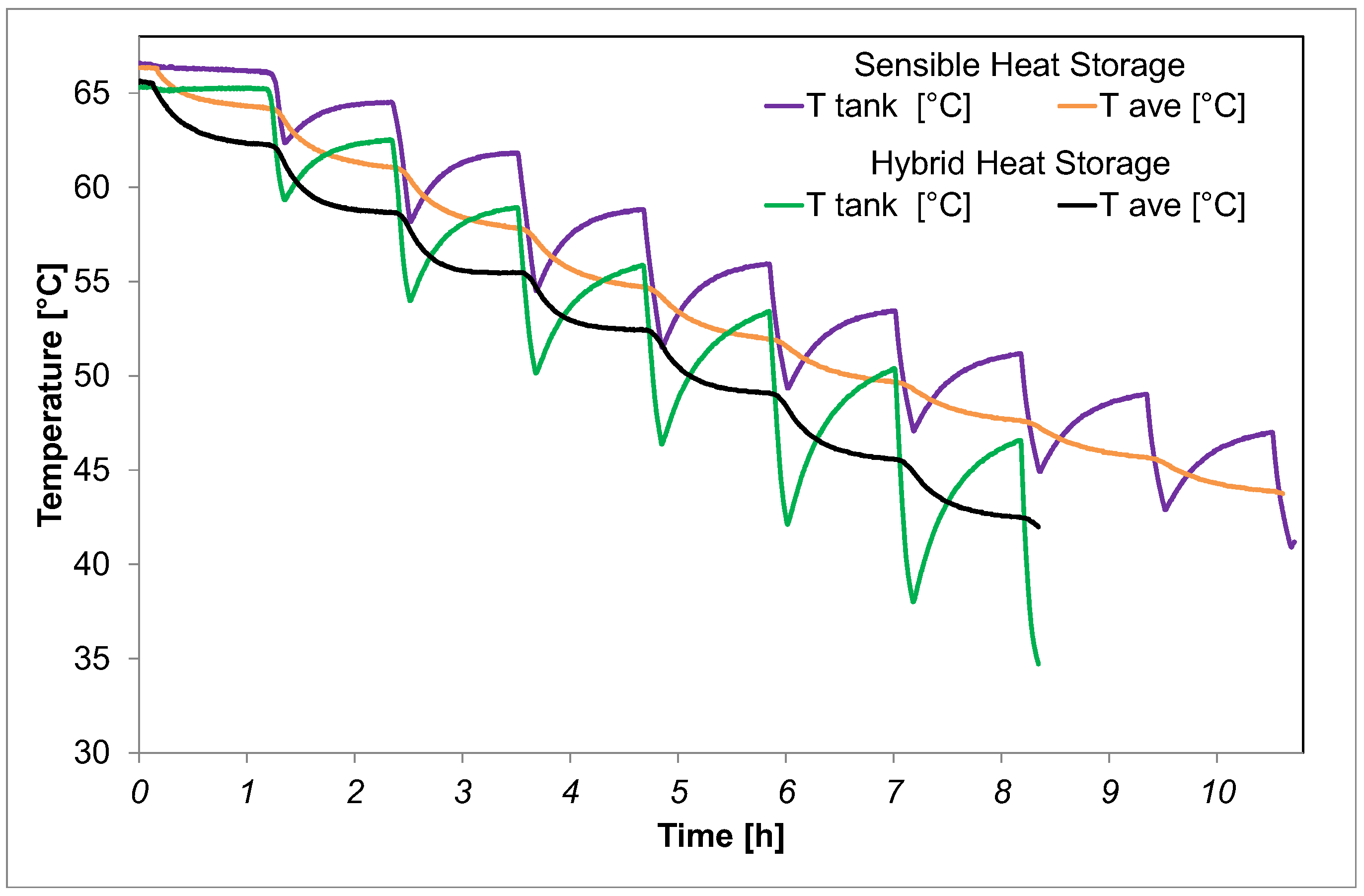

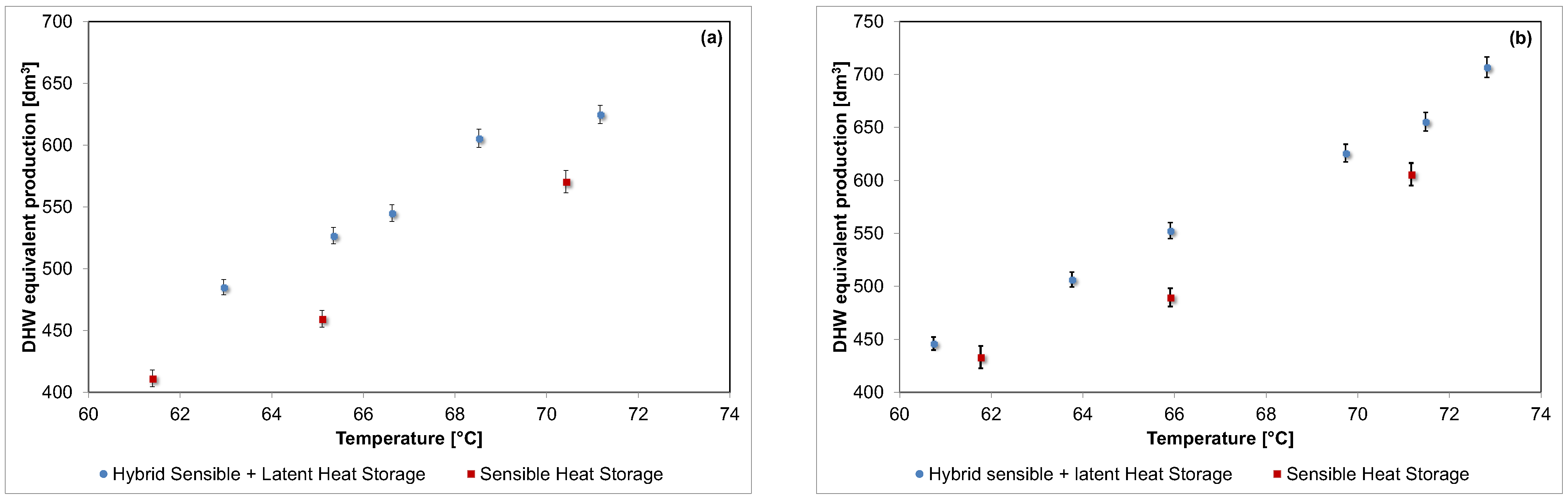

- Test A. This test simulates the periodic DHW demand by the user. It consists of multiple 5 min discharges followed by a stand-by period. The TES system under examination is heated; afterwards, the DHW is withdrawn for 5 min with a subsequent stand-by period of 60 min. This procedure is repeated until the storage system is able to deliver DHW at a temperature of at least 45 °C.

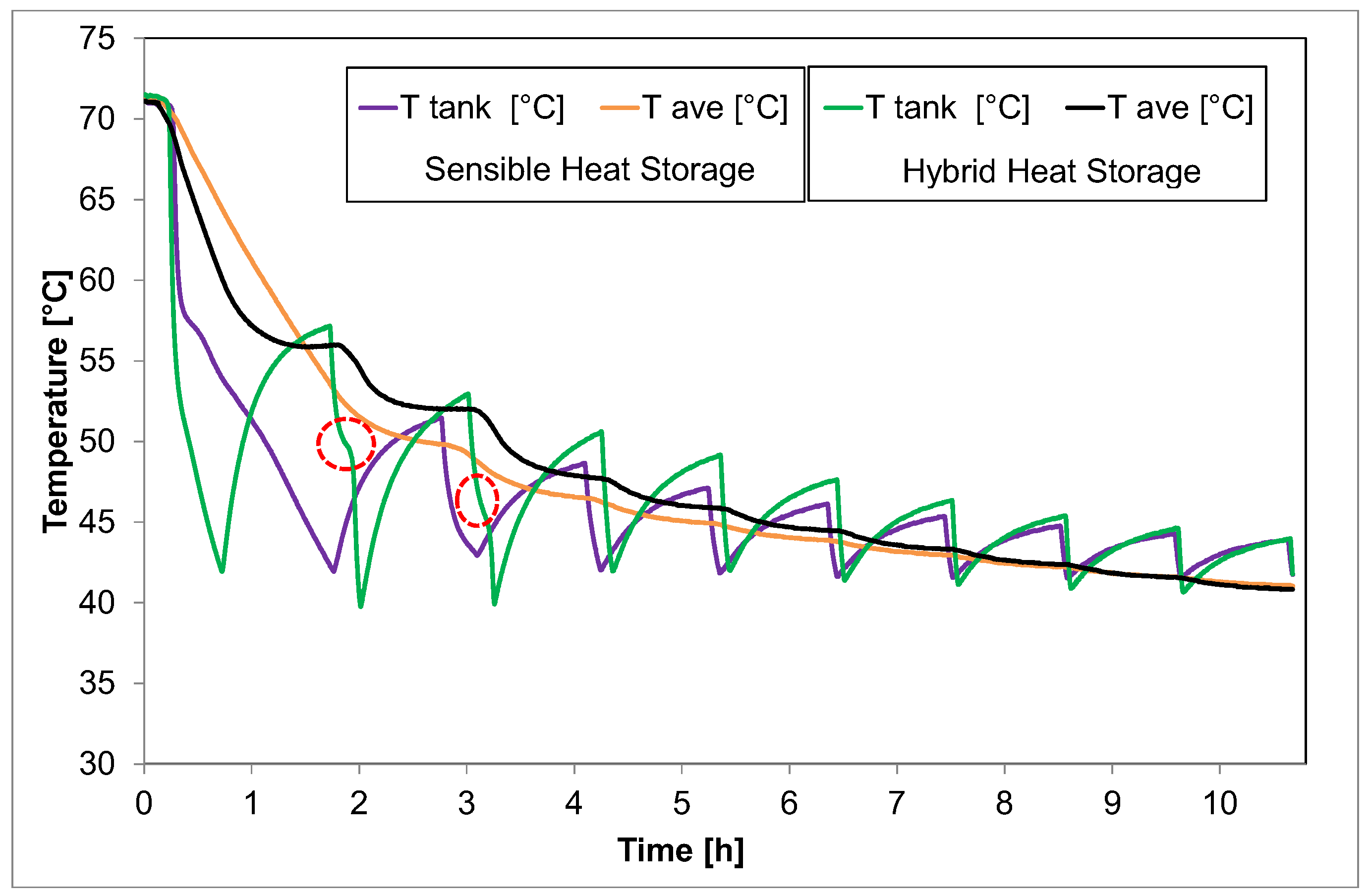

- Test B. This test simulates a continuous DHW demand by the user. The TES system under examination is heated; afterwards, the DHW is continuously withdrawn as long as the DHW temperature is higher than 45 °C. Subsequently, the storage system is put on standby for 60 min, and then the procedure is repeated.

3. Results

3.1. Experimental Results

3.1.1. Stand-by Tests

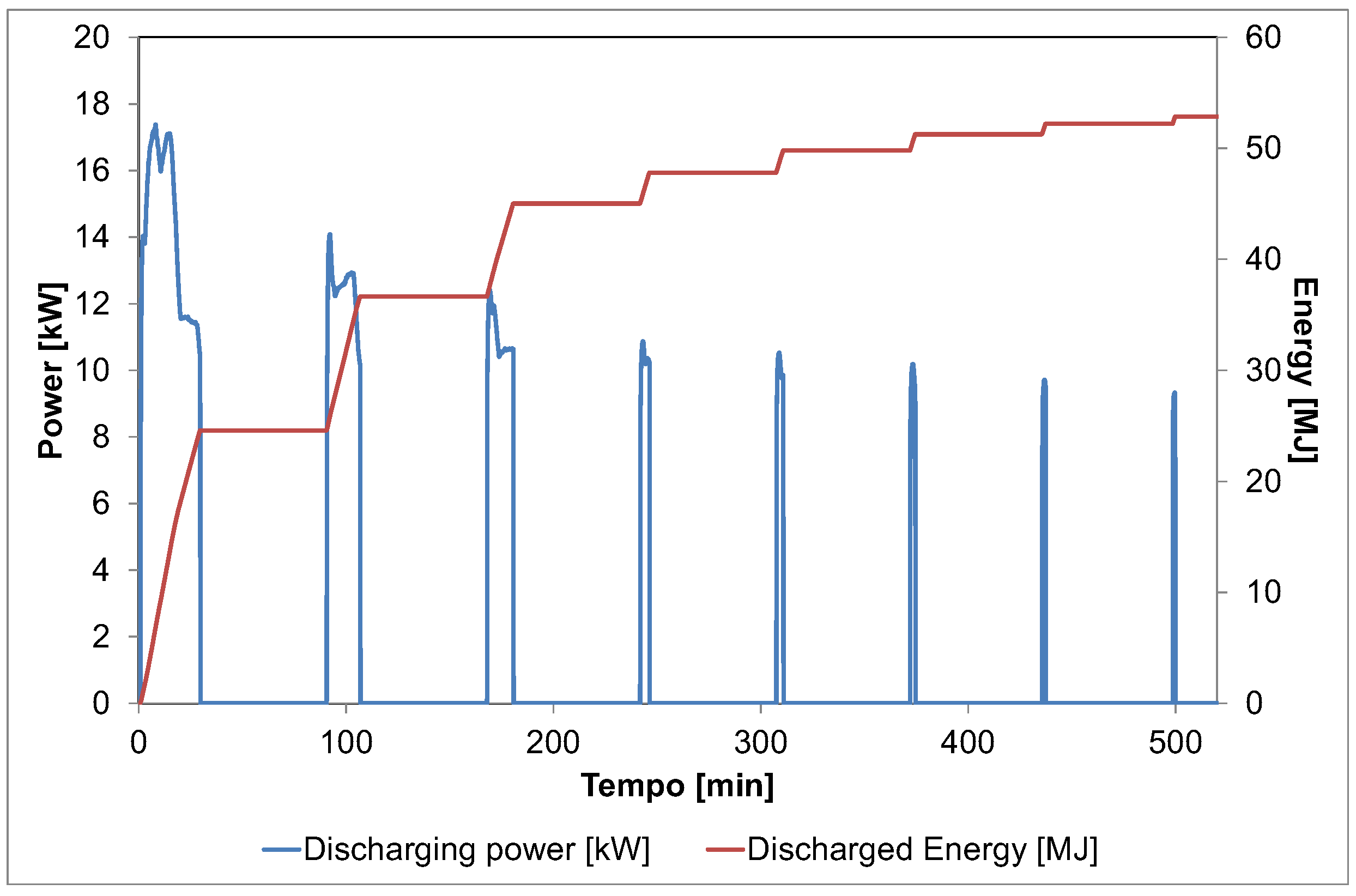

3.1.2. Dynamic Tests

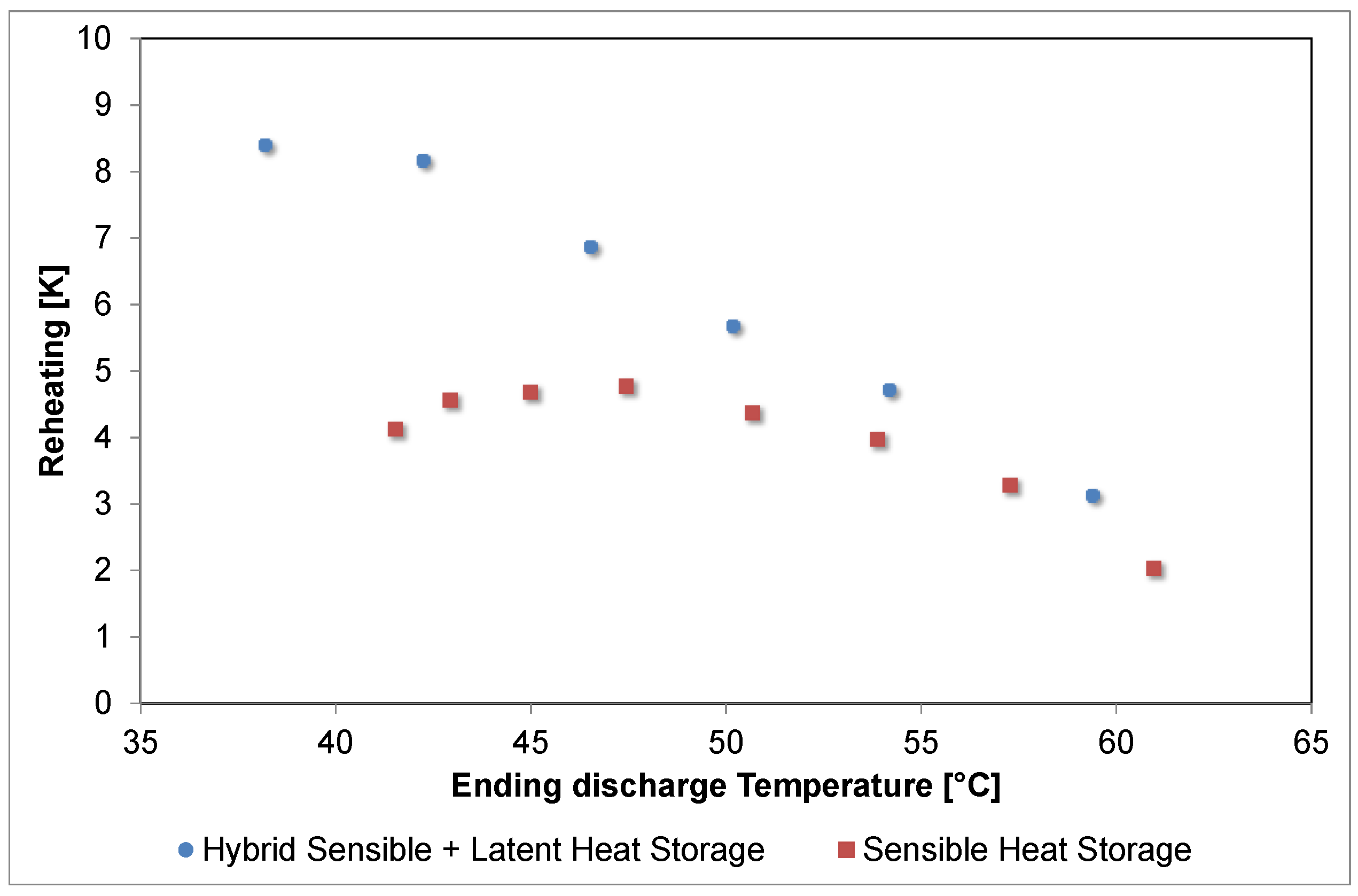

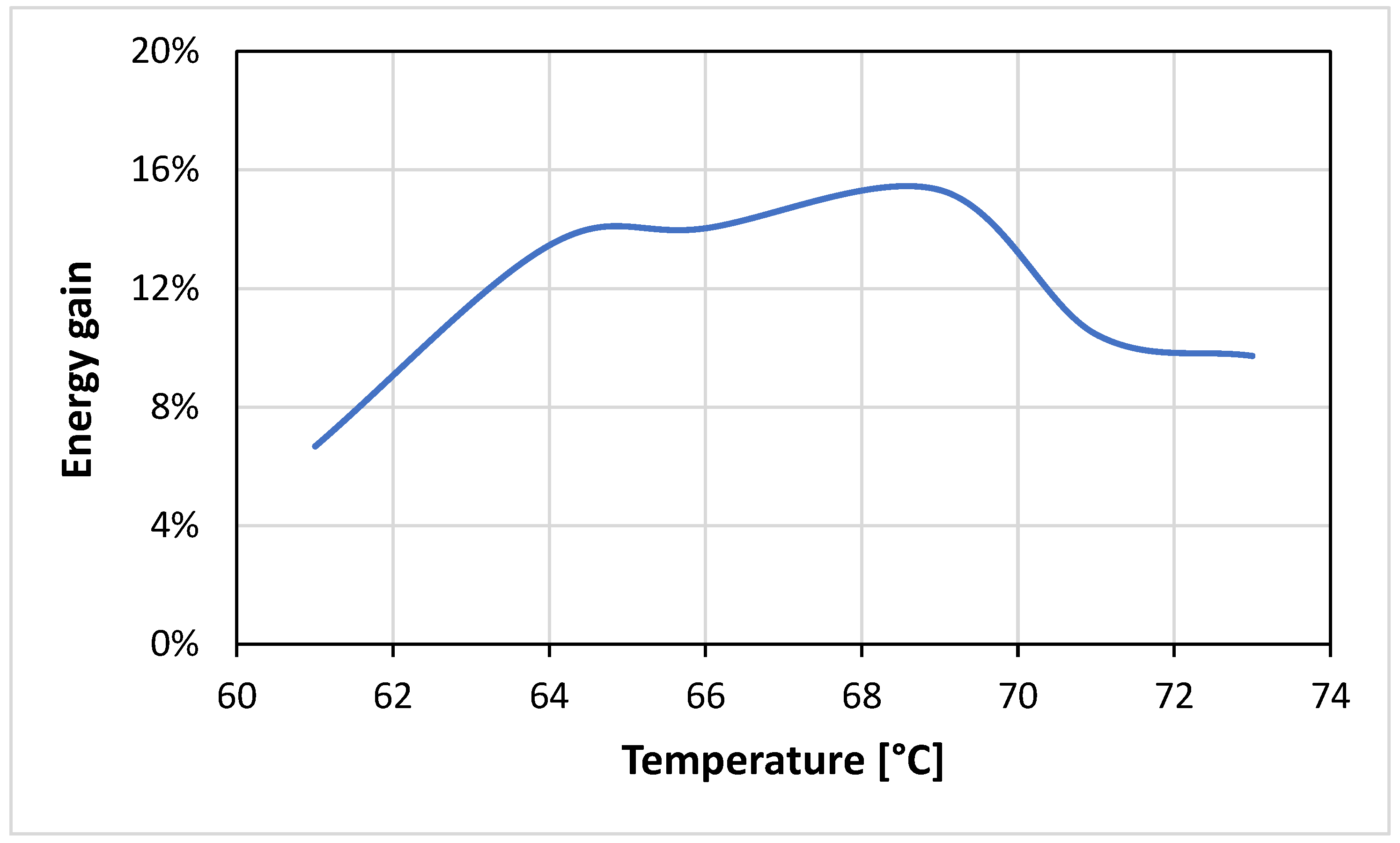

3.2. Performance Evaluation

4. Discussion

4.1. Comparison with Other Studies and Heat Transfer Considerations

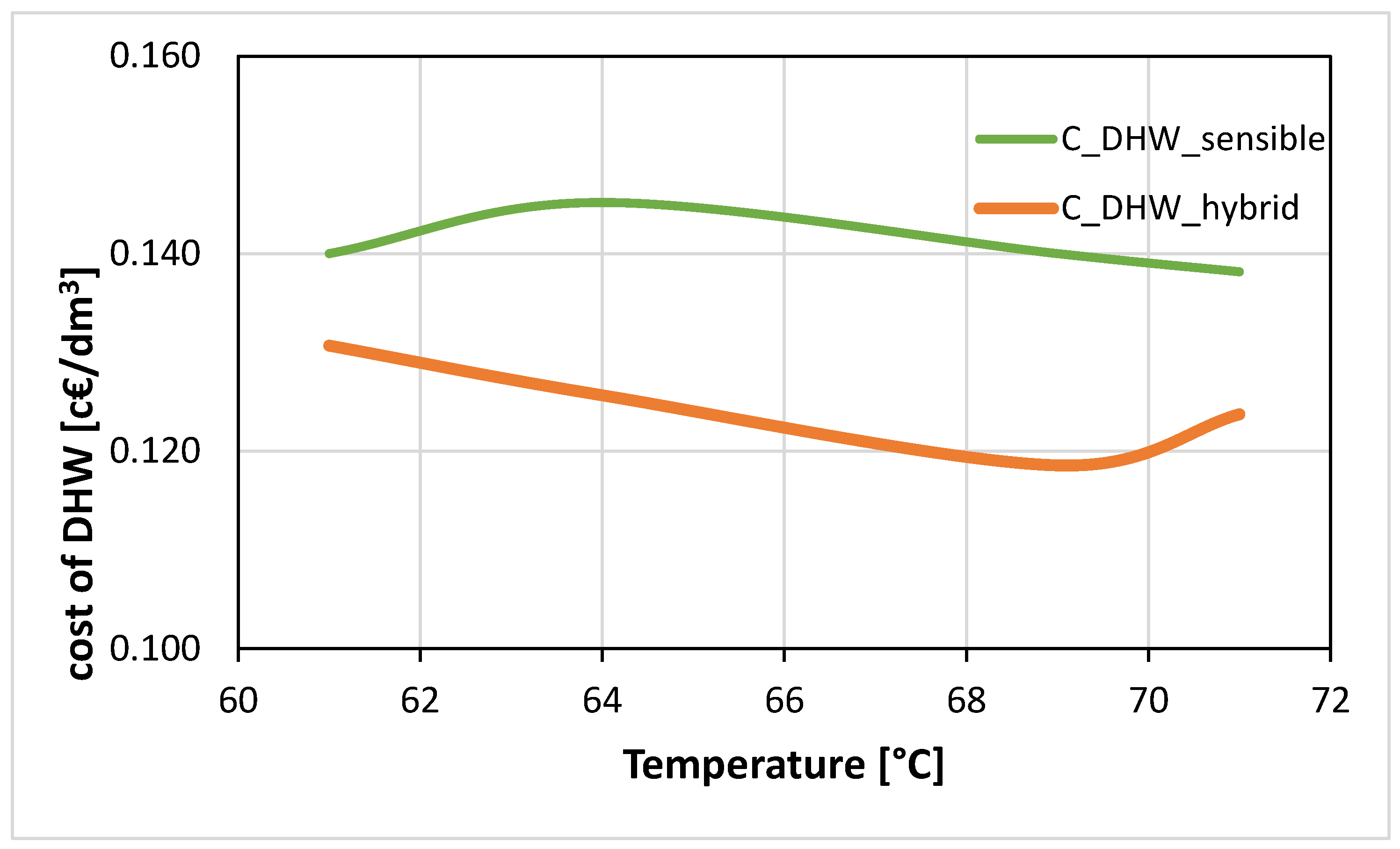

4.2. Energy and Economic Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maturo, A.; Buonomano, A.; Athienitis, A. Design for energy flexibility in smart buildings through solar based and thermal storage systems: Modelling, simulation and control for the system optimization. Energy 2022, 260, 125024. [Google Scholar] [CrossRef]

- Rehman, O.A.; Palomba, V.; Frazzica, A.; Cabeza, L.F. Enabling Technologies for Sector Coupling: A Review on the Role of Heat Pumps and Thermal Energy Storage. Energies 2021, 14, 8195. [Google Scholar] [CrossRef]

- Kauko, H.; Sevault, A.; Vasta, S.; Zondag, H.A.; Beck, A.; Drexler-Schmid, G.; Garcia Polanco, N.R.; Ma, Z.; Roskilly, A.P. Industrial Thermal Energy Storage Supporting the Transition to Decarbonise Industry; SINTEF: Trondheim, Norway, 2022. [Google Scholar]

- Hansen, A.R.; Leiria, D.; Johra, H.; Marszal-Pomianowska, A. Who Produces the Peaks? Household Variation in Peak Energy Demand for Space Heating and Domestic Hot Water. Energies 2022, 15, 9505. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. A review on phase change materials for thermal energy storage in buildings: Heating and hybrid applications. J. Energy Storage 2021, 33, 101913. [Google Scholar] [CrossRef]

- Koçak, B.; Fernandez, A.I.; Paksoy, H. Review on sensible thermal energy storage for industrial solar applications and sustainability aspects. Sol. Energy 2020, 209, 135–169. [Google Scholar] [CrossRef]

- Gao, Y.; He, F.; Xu, T.; Meng, X.; Zhang, M.; Yan, L.; Gao, W. Thermal performance analysis of sensible and latent heat thermal energy storage tanks: A contrastive experiment. J. Build. Eng. 2020, 32, 101713. [Google Scholar] [CrossRef]

- Mehling, H.; Brütting, M.; Haussmann, T. PCM products and their fields of application—An overview of the state in 2020/2021. J. Energy Storage 2022, 51, 104354. [Google Scholar] [CrossRef]

- Fumey, B.; Weber, R.; Baldini, L. Sorption based long-term thermal energy storage—Process classification and analysis of performance limitations: A review. Renew. Sustain. Energy Rev. 2019, 111, 57–74. [Google Scholar] [CrossRef]

- Palomba, V.; Frazzica, A. Recent advancements in sorption technology for solar thermal energy storage applications. Sol. Energy 2019, 192, 69–105. [Google Scholar] [CrossRef]

- Mazman, M.; Cabeza, L.F.; Mehling, H.; Nogues, M.; Evliya, H.; Paksoy, H.Ö. Utilization of phase change materials in solar domestic hot water systems. Renew. Energy 2009, 34, 1639–1643. [Google Scholar] [CrossRef]

- Aridi, R.; Yehya, A. Review on the sustainability of phase-change materials used in buildings. Energy Convers. Manag. X 2022, 15, 100237. [Google Scholar] [CrossRef]

- Kundu, R.; Kar, S.P.; Sarangi, R. Performance enhancement with inorganic phase change materials for the application of thermal energy storage: A critical review. Energy Storage 2022, 4, e320. [Google Scholar] [CrossRef]

- Sheikh, Y.; Fatih Orhan, M.; Kanoglu, M. Heat transfer enhancement of a bio-based PCM/metal foam composite heat sink. Therm. Sci. Eng. Prog. 2022, 36, 101536. [Google Scholar] [CrossRef]

- Liu, G.; Xiao, T.; Guo, J.; Wei, P.; Yang, X.; Hooman, K. Melting and solidification of phase change materials in metal foam filled thermal energy storage tank: Evaluation on gradient in pore structure. Appl. Therm. Eng. 2022, 212, 118564. [Google Scholar] [CrossRef]

- Yazici, M.Y.; Saglam, M.; Aydin, O.; Avci, M. Thermal energy storage performance of PCM/graphite matrix composite in a tube-in-shell geometry. Therm. Sci. Eng. Prog. 2021, 23, 100915. [Google Scholar] [CrossRef]

- Mselle, B.D.; Zsembinszki, G.; Borri, E.; Vérez, D.; Cabeza, L.F. Trends and future perspectives on the integration of phase change materials in heat exchangers. J. Energy Storage 2021, 38, 102544. [Google Scholar] [CrossRef]

- Sciacovelli, A.; Gagliardi, F.; Verda, V. Maximization of performance of a PCM latent heat storage system with innovative fins. Appl. Energy 2015, 137, 707–715. [Google Scholar] [CrossRef]

- Sun, X.; Mahdi, J.M.; Mohammed, H.I.; Majdi, H.S.; Zixiong, W.; Talebizadehsardari, P. Solidification Enhancement in a Triple-Tube Latent Heat Energy Storage System Using Twisted Fins. Energies 2021, 14, 7179. [Google Scholar] [CrossRef]

- He, F.; Yan, B.; Zou, J.; Hu, C.; Meng, X.; Gao, W. Experimental evaluation of the effect of perforated spiral fins on the thermal performance of latent heat storage units. J. Energy Storage 2023, 58, 106359. [Google Scholar] [CrossRef]

- Herbinger, F.; Groulx, D. Experimental comparative analysis of finned-tube PCM-heat exchangers’ performance. Appl. Therm. Eng. 2022, 211, 118532. [Google Scholar] [CrossRef]

- Frazzica, A.; Manzan, M.; Palomba, V.; Brancato, V.; Freni, A.; Pezzi, A.; Vaglieco, B.M. Experimental Validation and Numerical Simulation of a Hybrid Sensible-Latent Thermal Energy Storage for Hot Water Provision on Ships. Energies 2022, 15, 2596. [Google Scholar] [CrossRef]

- Suresh, C.; Saini, R.P. Experimental study on combined sensible-latent heat storage system for different volume fractions of PCM. Sol. Energy 2020, 212, 282–296. [Google Scholar] [CrossRef]

- Aziz, S.; Amin, N.A.M.; Abdul Majid, M.S.; Bruno, F.; Belusko, M. Effectiveness-NTU correlation for a TES tank comprising a PCM encapsulated in a sphere with heat transfer enhancement. Appl. Therm. Eng. 2018, 143, 1003–1010. [Google Scholar] [CrossRef]

- Grabo, M.; Acar, E.; Kenig, E.Y. Modeling and improvement of a packed bed latent heat storage filled with non-spherical encapsulated PCM-Elements. Renew. Energy 2021, 173, 1087–1097. [Google Scholar] [CrossRef]

- Pop, O.G.; Balan, M.C. A numerical analysis on the performance of DHW storage tanks with immersed PCM cylinders. Appl. Therm. Eng. 2021, 197, 117386. [Google Scholar] [CrossRef]

- Erdemir, D.; Ozbekler, A.; Altuntop, N. Experimental investigation on the effect of the ratio of tank volume to total capsulized paraffin volume on hot water output for a mantled hot water tank. Sol. Energy 2022, 239, 294–306. [Google Scholar] [CrossRef]

- Englmair, G.; Furbo, S.; Dannemand, M.; Fan, J. Experimental investigation of a tank-in-tank heat storage unit utilizing stable supercooling of sodium acetate trihydrate. Appl. Therm. Eng. 2020, 167, 114709. [Google Scholar] [CrossRef]

- Frazzica, A.; Manzan, M.; Sapienza, A.; Freni, A.; Toniato, G.; Restuccia, G. Experimental testing of a hybrid sensible-latent heat storage system for domestic hot water applications. Appl. Energy 2016, 183, 1157–1167. [Google Scholar] [CrossRef]

- PCM Products Catalogue. Available online: https://www.pcmproducts.net/files/PlusICERange2021-1.pdf (accessed on 2 January 2023).

- Riello combi Tanks. Available online: File:///C:/Users/Andrea/Downloads/Schedatecnicocommerciale-0.pdf (accessed on 2 January 2023).

- UNI EN 12977-3:2018; Impianti Solari Termici e loro Componenti. Impianti Assemblati su Specifica. Parte 3: Metodi di Prova Della Prestazione per Serbatoi di Stoccaggio Degli Scaldacqua Solari. UNI: Tokyo, Japan, 2009.

- Carmona, M.; Rincón, A.; Gulfo, L. Energy and exergy model with parametric study of a hot water storage tank with PCM for domestic applications and experimental validation for multiple operational scenarios. Energy Convers. Manag. 2020, 222, 113189. [Google Scholar] [CrossRef]

- Fadl, M.; Mahon, D.; Eames, P.C. Thermal performance analysis of compact thermal energy storage unit-An experimental study. Int. J. Heat Mass Transf. 2021, 173, 121262. [Google Scholar] [CrossRef]

- Fadl, M.; Eames, P.C. An experimental investigation of the heat transfer and energy storage characteristics of a compact latent heat thermal energy storage system for domestic hot water applications. Energy 2019, 188, 116083. [Google Scholar] [CrossRef]

- Deng, J.; Furbo, S.; Kong, W.; Fan, J. Thermal performance assessment and improvement of a solar domestic hot water tank with PCM in the mantle. Energy Build. 2018, 172, 10–21. [Google Scholar] [CrossRef]

- Mercato Elettrico Italiano. Available online: https://luce-gas.it/guida/mercato/andamento-prezzo/energia-elettrica (accessed on 2 January 2023).

| PCM 58—Macro Encapsulation | |

|---|---|

| Nominal melting temperature (°C) | 58 |

| Density (kg/m3) | 1505 |

| Nominal latent heat (kJ/kg) | 145 |

| Specific heat capacity (solid) (kJ/kg K) | 2.55 |

| Thermal conductivity (W/m K) | 0.69 |

| Macro capsule (tube) length (m) | 1 |

| Macro capsule (tube) diameter (m) | 0.05 |

| Macro capsule (tube) weight (kg) | 2.65 |

| Hybrid Sensible–Latent TES system Features | |

|---|---|

| External tank volume (dm3) | 380 |

| Internal DHW tank volume (dm3) | 160 |

| Tank external diameter (m) | 0.89 |

| Tank height (m) | 1.74 |

| PCM macro-capsules number | 27 |

| Maximum nominal operating temperature (°C) | 80 |

| Theoretical energy storage capacity (MJ) | 55 |

| Theoretical energy storage density (MJ/m3) | 137.5 |

| Insulating material | expanded polyurethane |

| Thermal conductivity of insulation (W/(mK)) | 0.03 |

| Insulating material thickness (mm) | 90 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frazzica, A.; Palomba, V.; Freni, A. Development and Experimental Characterization of an Innovative Tank-in-Tank Hybrid Sensible–Latent Thermal Energy Storage System. Energies 2023, 16, 1875. https://doi.org/10.3390/en16041875

Frazzica A, Palomba V, Freni A. Development and Experimental Characterization of an Innovative Tank-in-Tank Hybrid Sensible–Latent Thermal Energy Storage System. Energies. 2023; 16(4):1875. https://doi.org/10.3390/en16041875

Chicago/Turabian StyleFrazzica, Andrea, Valeria Palomba, and Angelo Freni. 2023. "Development and Experimental Characterization of an Innovative Tank-in-Tank Hybrid Sensible–Latent Thermal Energy Storage System" Energies 16, no. 4: 1875. https://doi.org/10.3390/en16041875

APA StyleFrazzica, A., Palomba, V., & Freni, A. (2023). Development and Experimental Characterization of an Innovative Tank-in-Tank Hybrid Sensible–Latent Thermal Energy Storage System. Energies, 16(4), 1875. https://doi.org/10.3390/en16041875