Self-Cleaning Mortar Façades with Addition of Anatase and Rutile Titanium Dioxide for Cool Façades

Abstract

1. Introduction

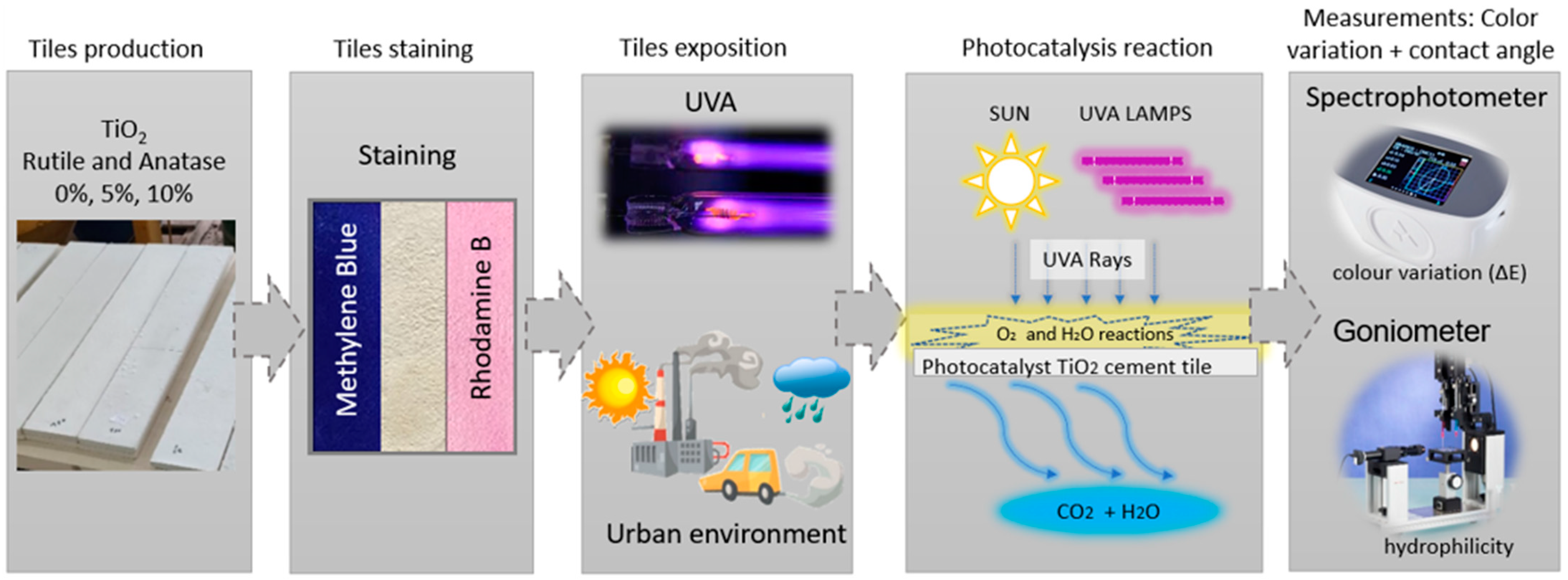

2. Materials and Methods

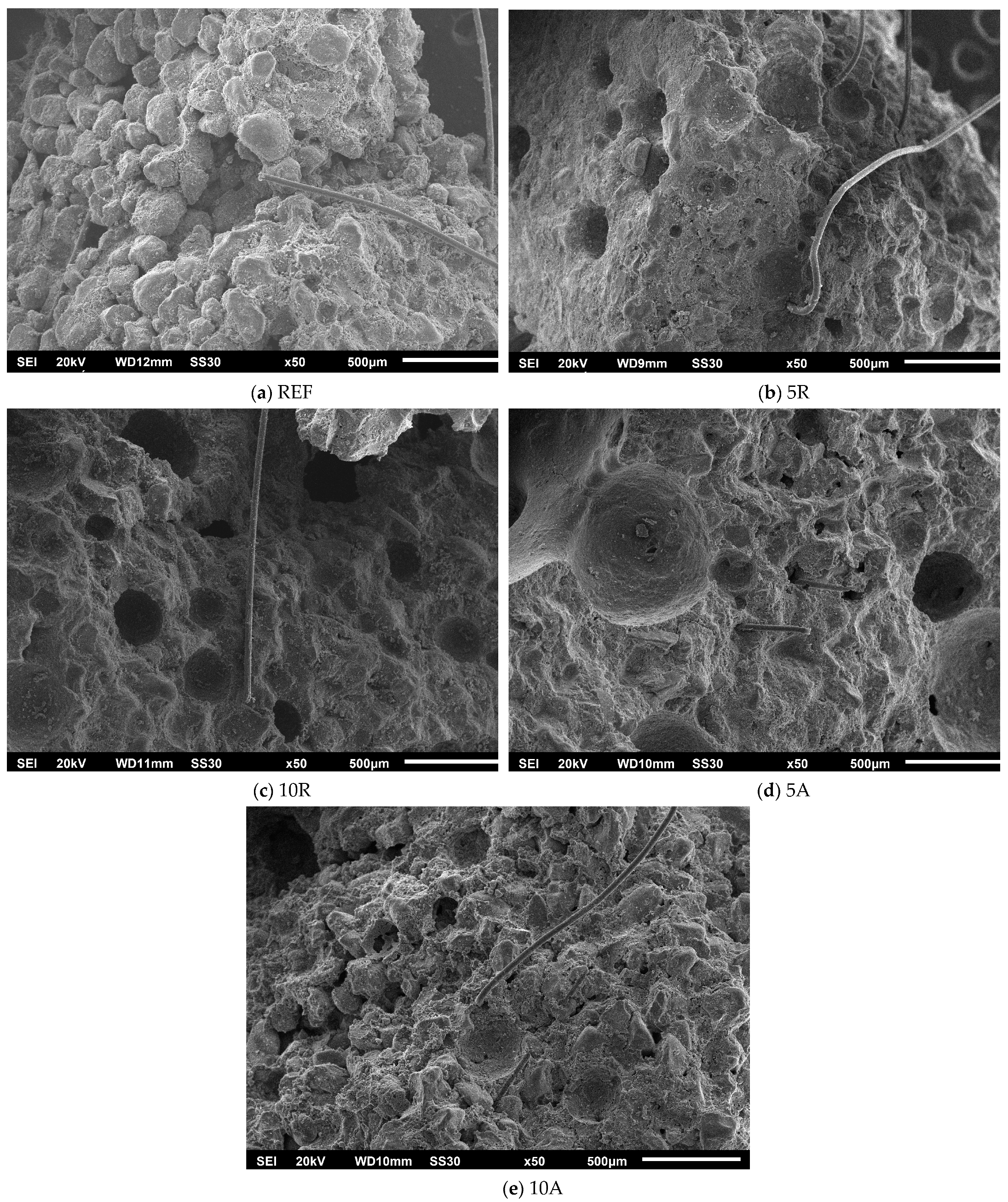

2.1. Materials

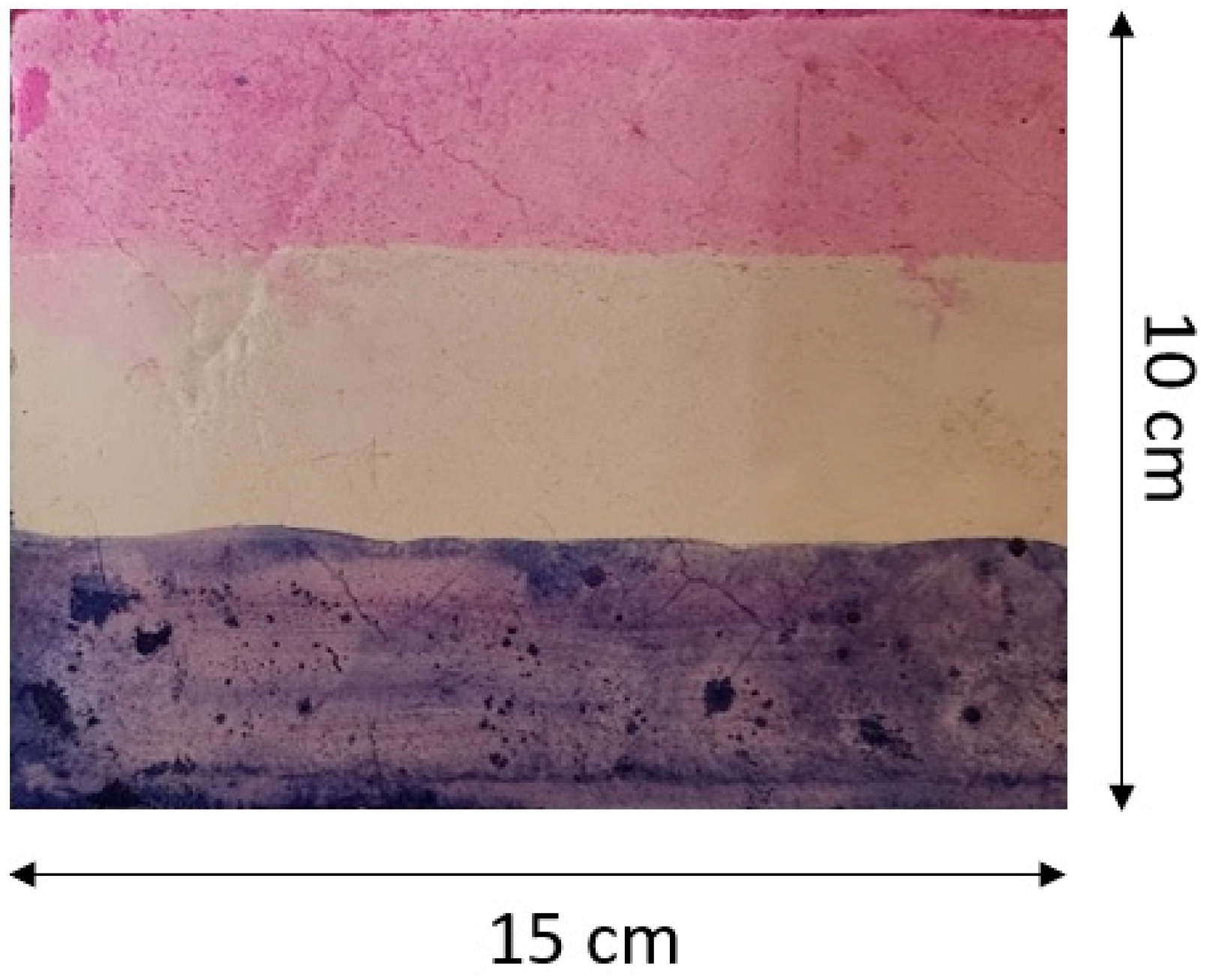

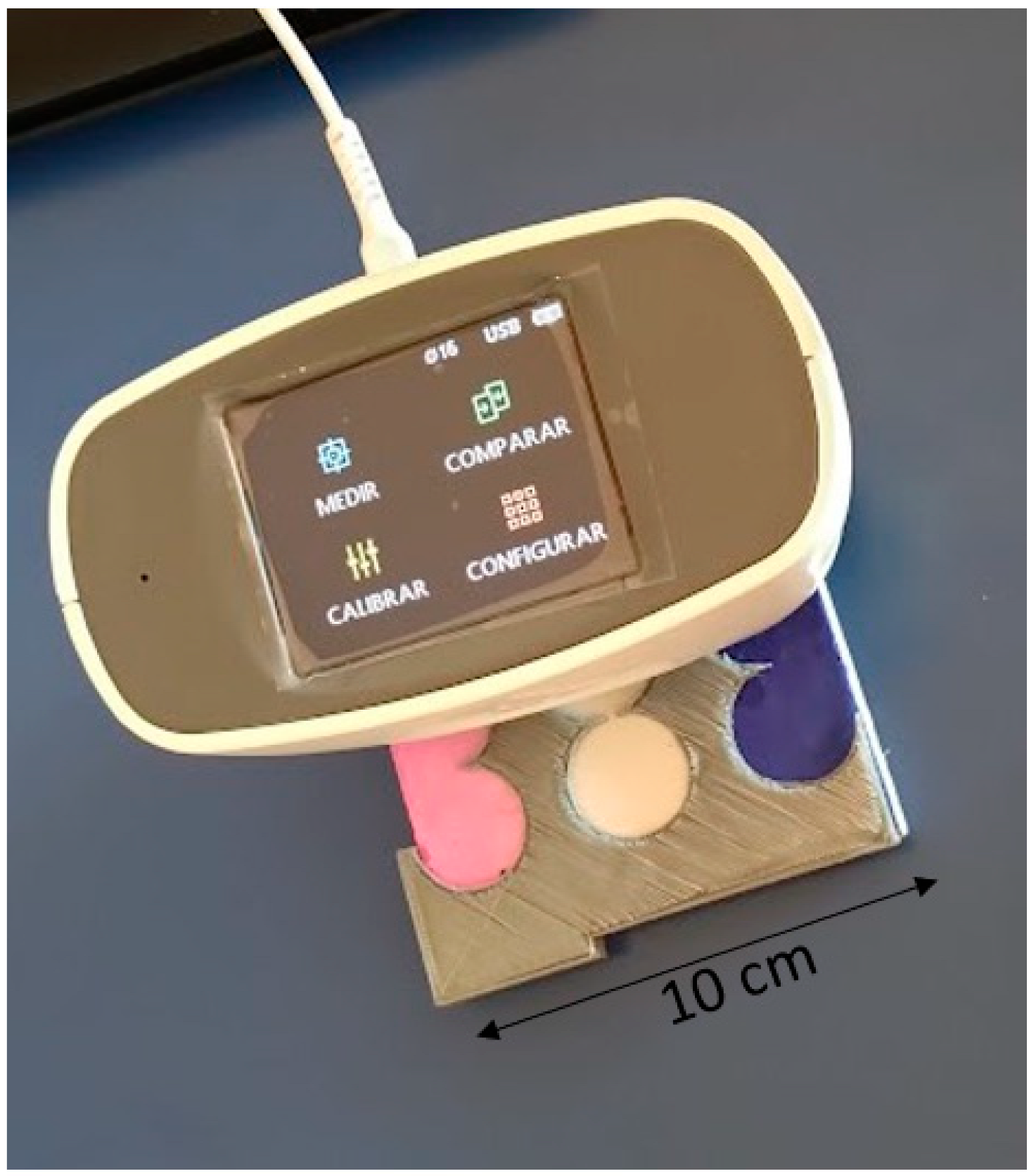

2.2. Methodology of Tests Performed

3. Results

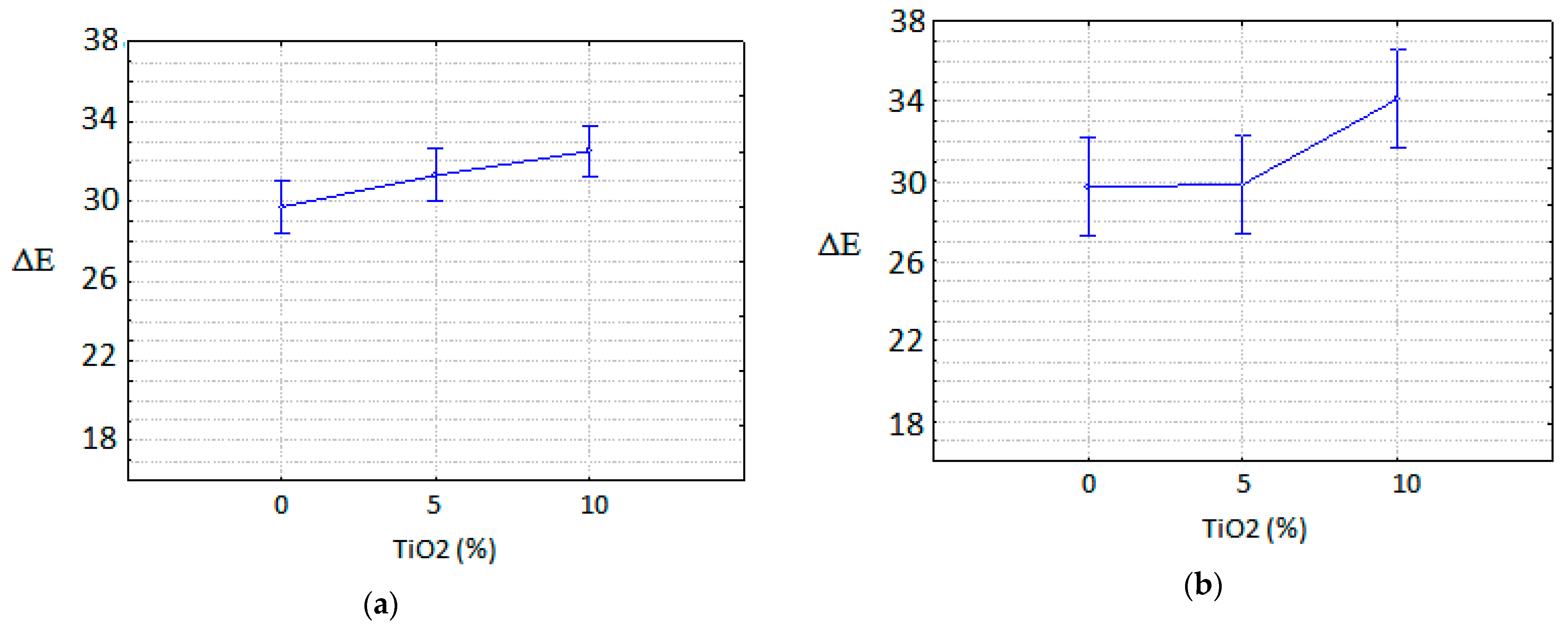

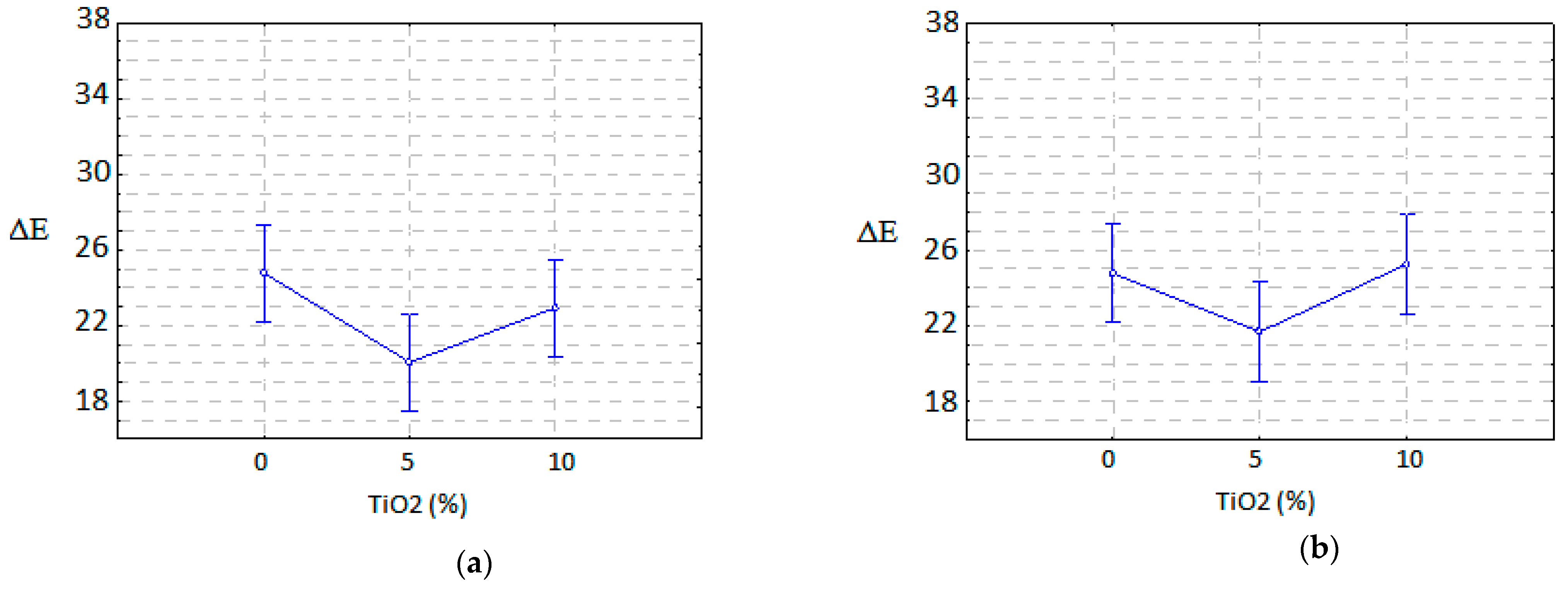

3.1. Photocatalysis Analysis

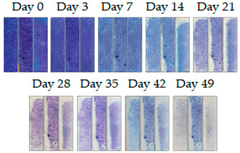

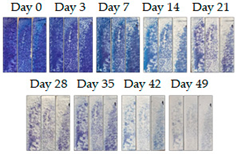

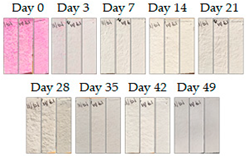

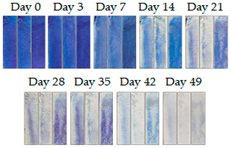

3.1.1. Cement Tiles Exposed to the Urban Environment

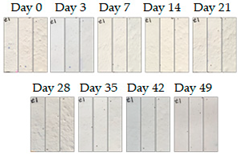

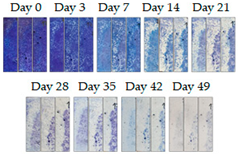

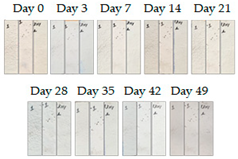

3.1.2. Cement Tiles Exposed to a UVA Chamber

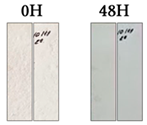

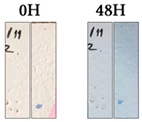

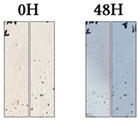

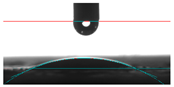

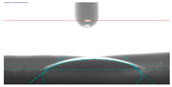

3.1.3. Evaluation of the Superficial Tension through Contact Angle

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| UVA Cure | |||||||

|---|---|---|---|---|---|---|---|

| Sample | CP | ΔE Point 1 | ΔE Point 2 | ΔE Point 3 | Average ΔE | ||

| Reference | UVA | REF | CP1 | −1.20 | −0.25 | −0.66 | 1.39 |

| UVA | REF | CP2 | −3.63 | 0.31 | 0.34 | 3.66 | |

| UVA | 5R | CP1 | −1.43 | −0.97 | −0.45 | 1.79 | |

| UVA | 5R | CP2 | −0.85 | −0.25 | 0.61 | 1.08 | |

| UVA | 10R | CP1 | −0.63 | 0.27 | 0.88 | 1.12 | |

| UVA | 10R | CP2 | −0.10 | 0.93 | 2.86 | 3.01 | |

| UVA | 5A | CP1 | −1.31 | −0.24 | 0.04 | 1.34 | |

| UVA | 5A | CP2 | −2.49 | 0.47 | 0.79 | 2.66 | |

| UVA | 10A | CP1 | 0.04 | −0.35 | 0.11 | 0.37 | |

| UVA | 10A | CP2 | 1.40 | −0.46 | 0.13 | 1.48 | |

| Methylene blue | UVA | REF | CP1 | 0.46 | −3.11 | 3.75 | 4.89 |

| UVA | REF | CP2 | 5.75 | −14.16 | 8.92 | 17.70 | |

| UVA | 5R | CP1 | 0.35 | −1.92 | 4.75 | 5.14 | |

| UVA | 5R | CP2 | −1.24 | −1.42 | 6.98 | 7.23 | |

| UVA | 10R | CP1 | 1.43 | −3.98 | 5.30 | 6.78 | |

| UVA | 10R | CP2 | 5.53 | −7.73 | 10.05 | 13.83 | |

| UVA | 5A | CP1 | 0.90 | −2.12 | 4.57 | 5.11 | |

| UVA | 5A | CP2 | 2.62 | −4.07 | 7.97 | 9.32 | |

| UVA | 10A | CP1 | 1.69 | −3.07 | 6.73 | 7.59 | |

| UVA | 10A | CP2 | 9.40 | −4.26 | 10.77 | 14.91 | |

| Rhodamine B | UVA | REF | CP1 | 2.75 | −5.59 | 5.81 | 8.52 |

| UVA | REF | CP2 | 1.08 | −3.03 | 7.07 | 7.77 | |

| UVA | 5R | CP1 | 6.60 | −21.52 | 11.06 | 25.08 | |

| UVA | 5R | CP2 | 6.06 | −19.24 | 11.72 | 23.33 | |

| UVA | 10R | CP1 | 6.34 | −17.12 | 9.03 | 20.37 | |

| UVA | 10R | CP2 | 5.39 | −15.91 | 10.48 | 19.80 | |

| UVA | 5A | CP1 | 5.09 | −18.53 | 6.94 | 20.43 | |

| UVA | 5A | CP2 | 4.03 | −17.71 | 7.78 | 19.76 | |

| UVA | 10A | CP1 | 4.47 | −17.65 | 8.14 | 19.95 | |

| UVA | 10A | CP2 | 7.99 | −18.43 | 6.78 | 21.20 | |

| Curing in an Urban Environment | ||||||

|---|---|---|---|---|---|---|

| Sample | CP | ΔE Point 1 | ΔE Point 2 | ΔE Point 3 | Average ΔE | |

| Reference | REF | CP1 | 1.03 | 1.27 | 1.45 | 1.25 |

| REF | CP2 | 0.70 | 0.81 | 1.58 | 1.03 | |

| REF | CP3 | 2.41 | 2.06 | 2.15 | 2.21 | |

| 5R | CP1 | 0.56 | 0.33 | 0.50 | 0.46 | |

| 5R | CP2 | 1.41 | 0.57 | 0.48 | 0.82 | |

| 5R | CP3 | 0.76 | 0.48 | 0.95 | 0.73 | |

| 10R | CP1 | 1.98 | 3.97 | 4.08 | 3.34 | |

| 10R | CP2 | 1.46 | 3.72 | 2.07 | 2.42 | |

| 10R | CP3 | 1.34 | 2.67 | 3.40 | 2.47 | |

| 5A | CP1 | 9.19 | 0.86 | 5.47 | 5.17 | |

| 5A | CP2 | 0.44 | 2.13 | 5.18 | 2.58 | |

| 5A | CP3 | 0.47 | 0.17 | 2.87 | 1.17 | |

| 10A | CP1 | 2.12 | 1.94 | 1.90 | 1.99 | |

| 10A | CP2 | 1.87 | 2.68 | 1.24 | 1.93 | |

| 10A | CP3 | 1.22 | 2.65 | 1.82 | 1.89 | |

| Methylene blue | REF | CP1 | 54.34 | 61.47 | 56.15 | 57.32 |

| REF | CP2 | 53.24 | 64.70 | 56.18 | 58.04 | |

| REF | CP3 | 58.46 | 61.60 | 55.40 | 58.49 | |

| 5R | CP1 | 63.38 | 65.48 | 60.25 | 63.04 | |

| 5R | CP2 | 51.52 | 62.43 | 64.04 | 59.33 | |

| 5R | CP3 | 66.25 | 58.67 | 65.55 | 63.49 | |

| 10R | CP1 | 58.22 | 57.57 | 72.16 | 62.65 | |

| 10R | CP2 | 59.16 | 59.15 | 69.68 | 62.66 | |

| 10R | CP3 | 65.36 | 55.69 | 63.62 | 61.56 | |

| 5A | CP1 | 50.06 | 61.75 | 56.34 | 56.05 | |

| 5A | CP2 | 53.22 | 59.03 | 60.30 | 57.52 | |

| 5A | CP3 | 58.74 | 46.23 | 64.63 | 56.53 | |

| 10A | CP1 | 64.79 | 67.99 | 67.44 | 66.74 | |

| 10A | CP2 | 67.05 | 67.80 | 69.36 | 68.07 | |

| 10A | CP3 | 58.68 | 64.35 | 69.34 | 64.12 | |

| Rhodamine B | REF | CP1 | 47.37 | 54.79 | 47.74 | 49.97 |

| REF | CP2 | 45.28 | 52.71 | 47.41 | 48.46 | |

| REF | CP3 | 44.29 | 47.81 | 45.27 | 45.79 | |

| 5R | CP1 | 34.10 | 34.02 | 38.39 | 35.50 | |

| 5R | CP2 | 39.12 | 35.51 | 38.01 | 37.55 | |

| 5R | CP3 | 41.90 | 44.50 | 49.58 | 45.33 | |

| 10R | CP1 | 41.12 | 39.54 | 45.92 | 42.19 | |

| 10R | CP2 | 45.21 | 46.82 | 42.91 | 44.98 | |

| 10R | CP3 | 42.32 | 41.32 | 43.02 | 42.22 | |

| 5A | CP1 | 37.08 | 43.23 | 40.35 | 40.22 | |

| 5A | CP2 | 37.39 | 39.24 | 38.25 | 38.29 | |

| 5A | CP3 | 44.94 | 43.57 | 39.52 | 42.68 | |

| 10A | CP1 | 50.17 | 43.83 | 44.16 | 46.06 | |

| 10A | CP2 | 52.16 | 51.92 | 50.29 | 51.46 | |

| 10A | CP3 | 51.93 | 45.94 | 46.81 | 48.23 | |

References

- UN (United Nations). Sustainable Cities and Human Settlements. Available online: https://sdgs.un.org/topics/sustainable-cities-and-human-settlements (accessed on 20 December 2022).

- Yi, Y.K. Building Facade Multi-Objective Optimization for Daylight and Aesthetical Perception. Build. Environ. 2019, 156, 178–190. [Google Scholar] [CrossRef]

- Pozo-Antonio, J.S.; Dionísio, A. Self-Cleaning Property of Mortars with TiO2 Addition Using Real Diesel Exhaust Soot. J. Clean. Prod. 2017, 161, 850–859. [Google Scholar] [CrossRef]

- Dantas, S.R.A.; Vittorino, F.; Loh, K. Comparison of Reflectance to Solar Radiation between Mortars Treated with TiO2 and Painted Mortars after Three Years of Exposure. J. Build. Eng. 2022, 46, 103829. [Google Scholar] [CrossRef]

- Schreck, M.; Niederberger, M. Photocatalytic Gas Phase Reactions. Chem. Mater. 2019, 31, 597–618. [Google Scholar] [CrossRef]

- Sakar, M.; Mithun Prakash, R.; Trong-On, D. Insights into the Tio2-Based Photocatalytic Systems and Their Mechanisms. Catalysts 2019, 9, 680. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, A.; Krishnan, V. Perovskite Oxide Based Materials for Energy and Environment-Oriented Photocatalysis. ACS Catal. 2020, 10, 10253–10315. [Google Scholar] [CrossRef]

- Khan, S.; Park, J.S.; Ishihara, T. A Review of the Single-Step Flame Synthesis of Defective and Heterostructured TiO2 Nanoparticles for Photocatalytic Applications. Catalysts 2023, 13, 196. [Google Scholar] [CrossRef]

- Yang, L.; Hakki, A.; Zheng, L.; Jones, M.R.; Wang, F.; Macphee, D.E. Photocatalytic Concrete for NOx Abatement: Supported TiO2 Efficiencies and Impacts. Cem. Concr. Res. 2019, 116, 57–64. [Google Scholar] [CrossRef]

- Constantino, J.C.P.; Garcia, D.C.S.; Palhares, H.G.; Houmard, M.; Figueiredo, R.B. Development of Functional TiO2 Coatings Deposited on Cementitious Materials. Constr. Build. Mater. 2020, 250, 118732. [Google Scholar] [CrossRef]

- Poon, C.S.; Cheung, E. NO Removal Efficiency of Photocatalytic Paving Blocks Prepared with Recycled Materials. Constr. Build. Mater. 2007, 21, 1746–1753. [Google Scholar] [CrossRef]

- Ibrahim, A.; Phoohinkong, W.; Mekprasart, W.; Pecharapa, W. Anatase/Rutile TiO2 Composite Thin Films Prepared via Dip Coating Technique and Their Hydrophilicity, Stability and Photocatalytic Activity. Mater. Today Proc. 2018, 5, 10903–10909. [Google Scholar] [CrossRef]

- Croce, S.; D’Agnolo, E.; Caini, M.; Paparella, R. The Use of Cool Pavements for the Regeneration of Industrial Districts. Sustain. 2021, 13, 6322. [Google Scholar] [CrossRef]

- Mansouri, O.; Belarbi, R.; Bourbia, F. Albedo Effect of External Surfaces on the Energy Loads and Thermal Comfort in Buildings. Energy Procedia 2017, 139, 571–577. [Google Scholar] [CrossRef]

- Ramos, N.M.M.; Souza, A.R.; Maia, J.; Almeida, R.M.S.F. Colour Degradation of Façade Coatings - The Effect of Nanopigments Incorporation. E3S Web Conf. 2020, 172, 24004. [Google Scholar] [CrossRef]

- Yuxuan, Z.; Yunyun, Z.; Jianrong, Y.; Xiaoqiang, Z. Energy Saving Performance of Thermochromic Coatings with Different Colors for Buildings. Energy Build. 2020, 215, 109920. [Google Scholar] [CrossRef]

- Jimenez-Relinque, E.; Rodriguez-Garcia, J.R.; Castillo, A.; Castellote, M. Characteristics and Efficiency of Photocatalytic Cementitious Materials: Type of Binder, Roughness and Microstructure. Cem. Concr. Res. 2015, 71, 124–131. [Google Scholar] [CrossRef]

- Cárdenas, C.; Tobón, J.I.; García, C.; Vila, J. Functionalized Building Materials: Photocatalytic Abatement of NO x by Cement Pastes Blended with TiO2 Nanoparticles. Constr. Build. Mater. 2012, 36, 820–825. [Google Scholar] [CrossRef]

- Mohseni, E.; Khotbehsara, M.M.; Naseri, F.; Monazami, M.; Sarker, P. Polypropylene Fiber Reinforced Cement Mortars Containing Rice Husk Ash and Nano-Alumina. Constr. Build. Mater. 2016, 111, 429–439. [Google Scholar] [CrossRef]

- Diamanti, M.V.; Del Curto, B.; Ormellese, M.; Pedeferri, M.P. Photocatalytic and Self-Cleaning Activity of Colored Mortars Containing TiO2. Constr. Build. Mater. 2013, 46, 167–174. [Google Scholar] [CrossRef]

- Shen, W.; Zhang, C.; Li, Q.; Zhang, W.; Cao, L.; Ye, J. Preparation of Titanium Dioxide Nano Particle Modified Photocatalytic Self-Cleaning Concrete. J. Clean. Prod. 2015, 87, 762–765. [Google Scholar] [CrossRef]

- Infibra. Manual de Instalação—Placas Cimentícias NTF; Infibra: Leme, Brazil, 2021. [Google Scholar]

- Brasilit. Catálogo de Produtos Brasilit: Soluções Para Telhados e Construções Industrializadas; Brasilit: Brasilit, Brazil, 2018. [Google Scholar]

- Valcan. Ceramapanel Technical Information A1; Valcan: Bridgwater, UK, 2022; pp. 3–4. [Google Scholar]

- NBR 7215; Cimento Portland―Determinação Da Resistência à Compressão de Corpos de Prova Cilíndricos. ABNT: Rio de Janeiro, Brazil, 2019.

- NBR 13276; Argamassa Para Assentamento e Revestimento de Paredes e Tetos—Determinação Do Índice de Consistência. ABNT: Rio de Janeiro, Brazil, 2016.

- NBR 13278; Argamassa Para Assentamento e Revestimento de Paredes e Tetos—Determinação Da Densidade de Massa e Do Teor de Ar Incorporado. ABNT: Rio de Janeiro, Brazil, 2005.

- NBR 15498; Placa de Fibrocimento Sem Amianto—Requisitos e Métodos de Ensaio. ABNT: Rio de Janeiro, Brazil, 2021.

- UNI 11259; Photocatalysis—Determination of the Photocatalytic Activity of Hidraulic Binders—Rodammina Test Method. UNI: Milan, Italy, 2016.

- ASTM C1378-04(2014); Standard Test Method for Determination of Resistance to Staining. American National Standards Institute: West Conshohocken, PA, USA, 2014.

- Rosales, A.; Maury-Ramírez, A.; De Gutiérrez, R.M.; Guzmán, C.; Esquivel, K. SiO2@TiO2 Coating: Synthesis, Physical Characterization and Photocatalytic Evaluation. Coatings 2018, 8, 120. [Google Scholar] [CrossRef]

| Property | Results | NBR 16697-2018 Limits |

|---|---|---|

| Fire loss | ≤5% | ≤12% |

| Insoluble residue | ≤5% | ≤3.5% |

| Sulfate content | ≤4% | ≤4% |

| Chloride content | ≤0.1% | ≤0.1% |

| Set time | ≥45 min | ≥60 min |

| Expandability | ≤10 mm | ≤5 mm |

| Compressive strength—2 days | >37 MPa | >15 MPa |

| Compressive strength—28 days | ≥60 MPa | ≥40 MPa |

| Physical–Chemical Characteristics | Anatase | Rutile |

|---|---|---|

| Titanium dioxide concentration (%) | 99.10 | 96.3 |

| Evaporated material (%, 105 °C) | 0.20 | 0.26 |

| pH in aqueous solution | 7.7 | 7.3 |

| Oil absorption (g/100 g) | 24 | 19.2 |

| Fineness (% retained on a 45 μm sieve) | 0.03 | 0.05 |

| Cement Tile | Permeability (Qualitative) | Dimensional Variation (mm/m) | Water Absorption (%) | Flexural Tensile Strength (MPa) | ||

|---|---|---|---|---|---|---|

| X Axis | Y Axis | Not Saturated | Saturated | |||

| REF | Moisture | 2.49 | 2.90 | 7.17 | 4.27 | 4.06 |

| 5A | Not present | 2.02 | 1.94 | 6.08 | 4.15 | 4.04 |

| 10A | Not present | 2.12 | 2.90 | 6.11 | 3.91 | 3.27 |

| 5R | Not present | 3.02 | 2.86 | 6.67 | 4.25 | 4.12 |

| 10R | Not present | 2.84 | 3.19 | 6.52 | 3.42 | 3.16 |

| TiO2 | Variable | SS | DF | MS | Fcalc | p-Factor | Significative |

|---|---|---|---|---|---|---|---|

| Rutile | Staining | 15,714.69 | 1 | 15,714.69 | 7035.721 | 0.000000 | Yes |

| TiO2 (%) | 23.56 | 2 | 11.78 | 5.273 | 0.019635 | Yes | |

| Error | 31.27 | 14 | 2.23 | ||||

| Anatase | Staining | 15,234.43 | 1 | 15,234.43 | 1927.017 | 0.000000 | Yes |

| TiO2 (%) | 75.50 | 2 | 37.75 | 4.775 | 0.026243 | Yes | |

| Error | 110.68 | 14 | 7.91 |

| TiO2 | Variable | SS | DF | MS | Fcalc | p-Factor | Significative |

|---|---|---|---|---|---|---|---|

| Rutile | Staining | 7906.950 | 1 | 7906.950 | 922.301 | 0.000000 | Yes |

| TiO2 (%) | 67.882 | 2 | 33.941 | 3.959 | 0.043379 | Yes | |

| Error | 120.023 | 14 | 8.573 | ||||

| Anatase | Staining | 8534.28 | 1 | 8534.28 | 941.792 | 0.000000 | Yes |

| TiO2 (%) | 45.23 | 2 | 22.62 | 2.496 | 0.118295 | No | |

| Error | 126.86 | 14 | 9.06 |

| No Staining | Methylene Blue | Rhodamine B | |

|---|---|---|---|

| REF |  |  |  |

| 5A |  |  |  |

| 10A |  |  |  |

| 5R |  |  |  |

| 10R |  |  |  |

| TiO2 | Variable | SS | DGF | MS | F | p-Factor | Significative |

|---|---|---|---|---|---|---|---|

| Rutile | Staining | 157.8325 | 1 | 157.8325 | 10.24568 | 0.012596 | Yes |

| TiO2 (%) | 21.0350 | 2 | 10.5175 | 0.68274 | 0.532401 | No | |

| Error | 123.2384 | 8 | 15.4048 | ||||

| Anatase | Staining | 196.9920 | 1 | 196.9920 | 11.63158 | 0.009216 | Yes |

| TiO2 (%) | 10.8912 | 2 | 5.4456 | 0.32154 | 0.733982 | No | |

| Error | 135.4877 | 8 | 16.9360 |

| TiO2 | Variable | SS | DGF | MS | F | p-Factor | Significative |

|---|---|---|---|---|---|---|---|

| Rutile | Staining | 717.963 | 1 | 717.963 | 35.15020 | 0.000350 | Yes |

| TiO2 (%) | 122.690 | 2 | 61.345 | 3.00336 | 0.106418 | No | |

| Error | 163.405 | 8 | 20.426 | ||||

| Anatase | Staining | 626.8411 | 1 | 626.8411 | 40.55731 | 0.000216 | Yes |

| TiO2 (%) | 82.7245 | 2 | 41.3623 | 2.67618 | 0.128863 | No | |

| Error | 123.6455 | 8 | 15.4557 |

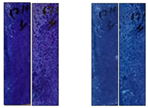

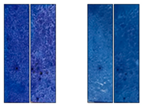

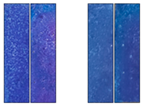

| REF | 5A | 10A | 5R | 10R | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 h | 48 h | 0 h | 48 h | 0 h | 48 h | 0 h | 48 h | 0 h | 48 h | |

| No staining |  |  |  |  |  | |||||

| Methylene blue |  |  |  |  |  | |||||

| Rhodamine B |  |  |  |  |  | |||||

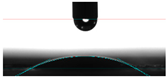

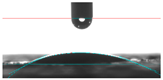

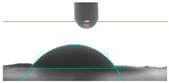

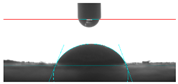

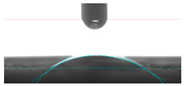

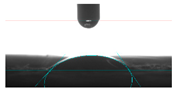

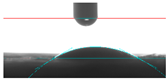

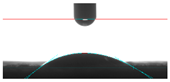

| CP | Initial Reading (°) | Reading after Application of UVA Light (°) | ||

|---|---|---|---|---|

| Air Conditioned | Aged | Air Conditioned | Aged | |

| REF |  22.05 |  27.25 |  26.35 |  24.20 |

| 5R |  53.90 |  55.80 |  57.95 |  68.95 |

| 10R |  59.95 |  32.30 |  44.20 |  50.70 |

| 5A |  21.60 |  28.90 |  24.25 |  32.75 |

| 10A |  22.40 |  40.05 |  28.60 |  36.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qualharini, E.L.; Stolz, C.M.; Martini, M.; Polesello, E.; da Silva, C.R. Self-Cleaning Mortar Façades with Addition of Anatase and Rutile Titanium Dioxide for Cool Façades. Energies 2023, 16, 1874. https://doi.org/10.3390/en16041874

Qualharini EL, Stolz CM, Martini M, Polesello E, da Silva CR. Self-Cleaning Mortar Façades with Addition of Anatase and Rutile Titanium Dioxide for Cool Façades. Energies. 2023; 16(4):1874. https://doi.org/10.3390/en16041874

Chicago/Turabian StyleQualharini, Eduardo Linhares, Carina Mariane Stolz, Matheus Martini, Eduardo Polesello, and Clara Rocha da Silva. 2023. "Self-Cleaning Mortar Façades with Addition of Anatase and Rutile Titanium Dioxide for Cool Façades" Energies 16, no. 4: 1874. https://doi.org/10.3390/en16041874

APA StyleQualharini, E. L., Stolz, C. M., Martini, M., Polesello, E., & da Silva, C. R. (2023). Self-Cleaning Mortar Façades with Addition of Anatase and Rutile Titanium Dioxide for Cool Façades. Energies, 16(4), 1874. https://doi.org/10.3390/en16041874