Energy Consumption Reduction and Sustainable Development for Oil & Gas Transport and Storage Engineering

Abstract

:1. Introduction

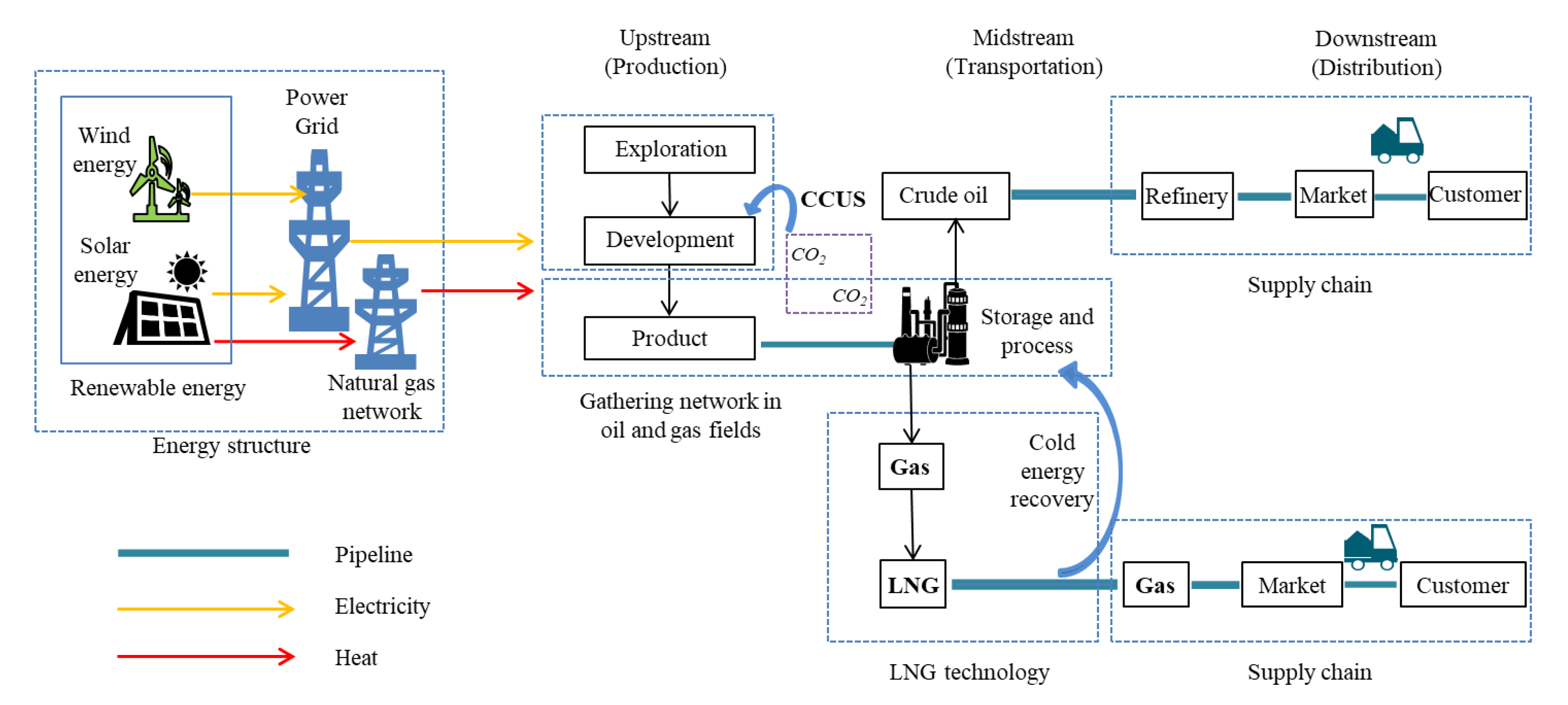

2. Sustainable OGTS Development in Oilfields

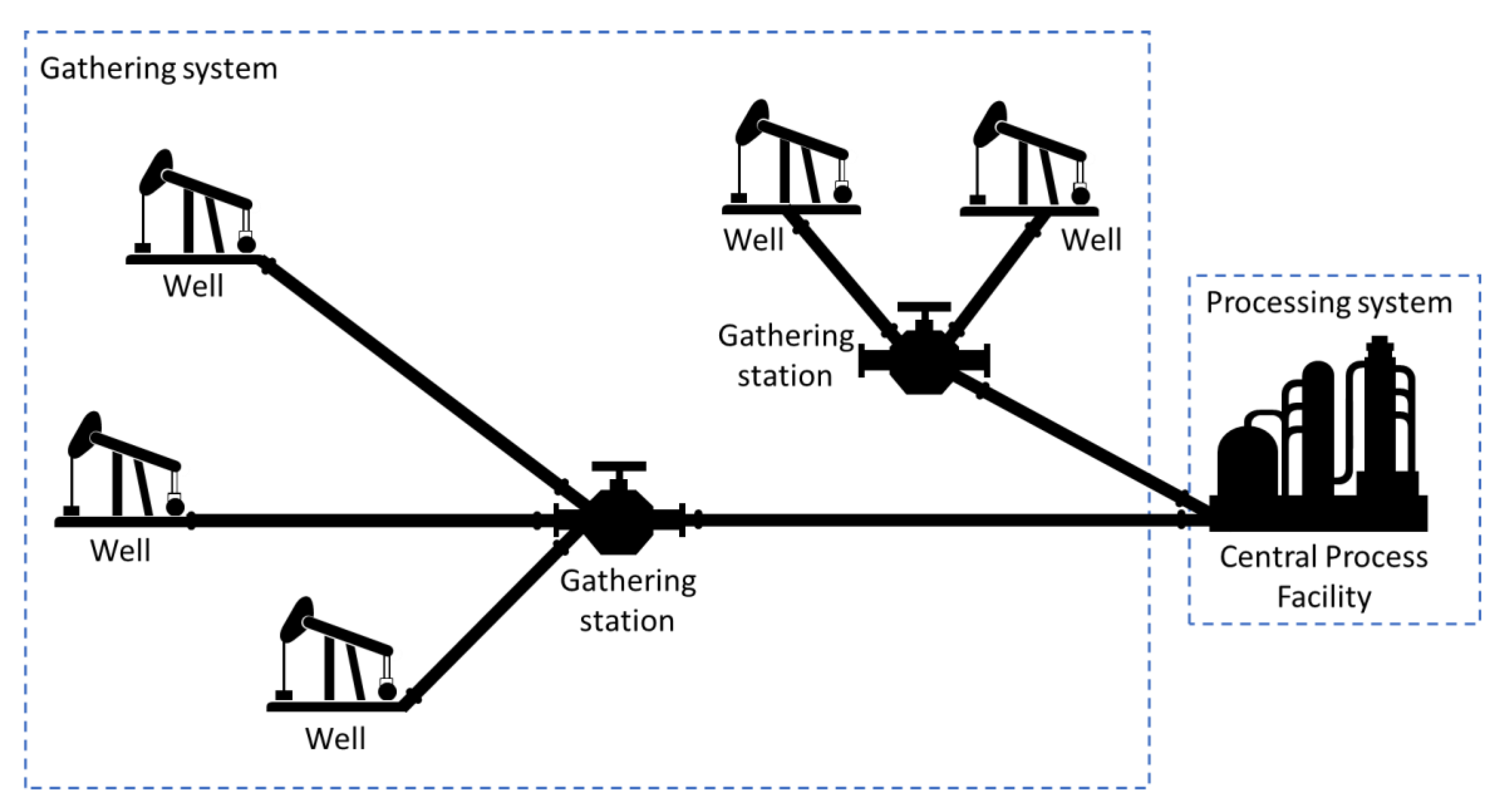

2.1. Gathering System

2.2. Oil and Gas Process System

2.3. Pollution Reduction

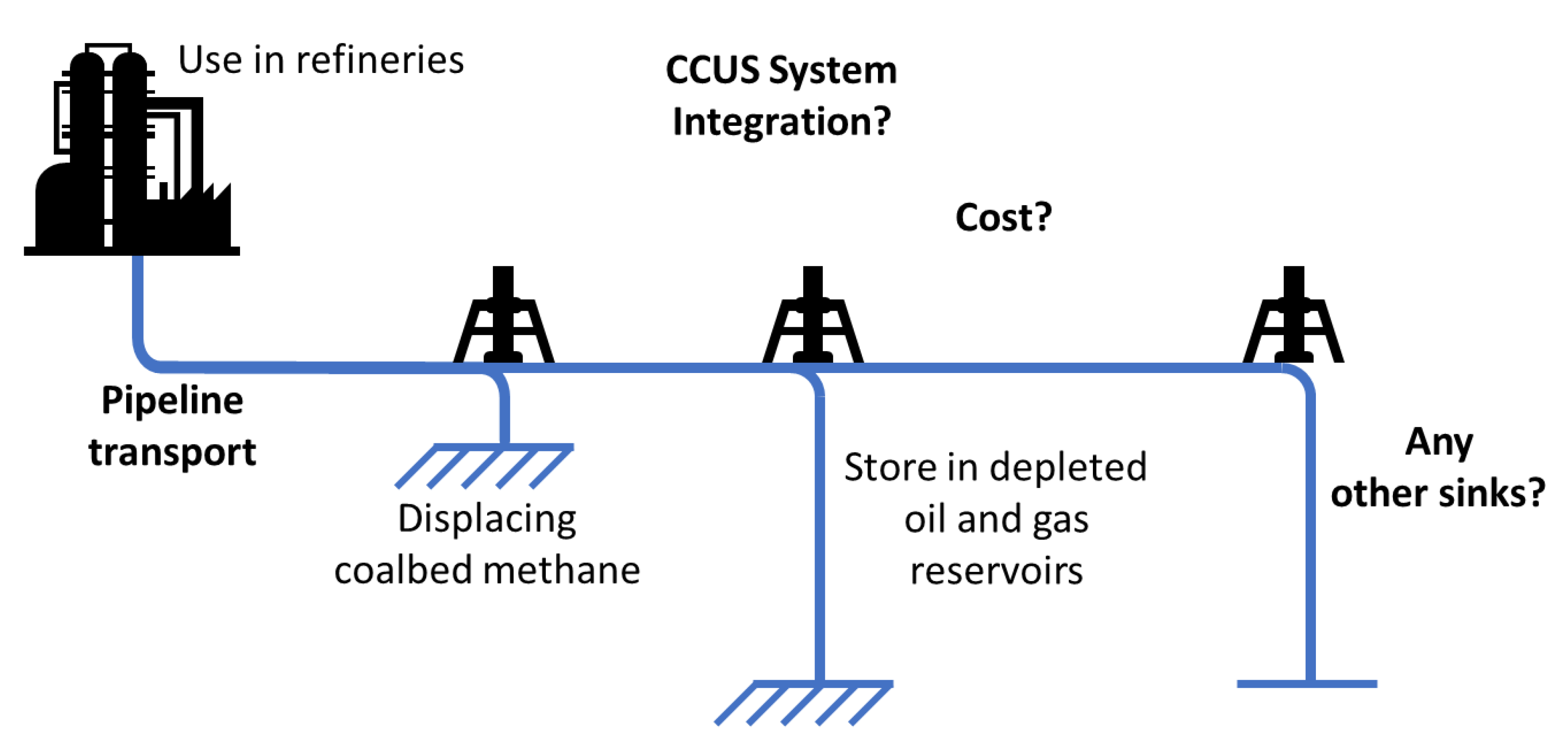

2.4. Carbon Dioxide Capture, Utilisation and Storage (CCUS)

3. Sustainable OGTS Development in Long-Distance Pipelines

3.1. Design Stage

3.2. Operating Stage

4. Sustainable OGTS Development in the Supply Chain

4.1. Economic Benefits

4.2. Environmental Issues in the Oil and Gas Supply Chain

4.3. Reliability

5. LNG Technology Development

6. Energy Structure

6.1. Solar Energy

6.2. Geothermal Utilisation

7. Conclusions and Future Directions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liao, Q.; Liang, Y.; Tu, R.; Huang, L.; Zheng, J.; Wang, G.; Zhang, H. Innovations of Carbon-Neutral Petroleum Pipeline: A Review. Energy Rep. 2022, 8, 13114–13128. [Google Scholar] [CrossRef]

- Huang, L.; Liao, Q.; Yan, J.; Liang, Y.; Zhang, H. Carbon Footprint of Oil Products Pipeline Transportation. Sci. Total Environ. 2021, 783, 146906. [Google Scholar] [CrossRef] [PubMed]

- Song, X.; Qu, D.; Zou, C. Low Cost Development Strategy for Oilfields in China under Low Oil Prices. Pet. Explor. Dev. 2021, 48, 1007–1018. [Google Scholar] [CrossRef]

- Wang, B.; Liang, Y.; Yuan, M. Water Transport System Optimisation in Oilfields: Environmental and Economic Benefits. J. Clean. Prod. 2019, 237, 117768. [Google Scholar] [CrossRef]

- Zhou, J.; Fu, T.; Wu, K.; Zhao, Y.; Feng, L.; Liang, G. Optimization Design of Multi-Gathering Mode for the Surface System in Coalbed Methane Field. Petroleum 2022. [Google Scholar] [CrossRef]

- Montagna, A.F.; Cafaro, D.C.; Grossmann, I.E.; Burch, D.; Shao, Y.; Wu, X.-H.; Furman, K. Pipeline Network Design for Gathering Unconventional Oil and Gas Production Using Mathematical Optimization. Optim. Eng. 2021. [Google Scholar] [CrossRef]

- Almedallah, M.K.; Branch, G.; Walsh, S.D.C. Combined Well Path, Submarine Pipeline Network, Route and Flow Rate Optimization for Shallow-Water Offshore Fields. Appl. Ocean Res. 2020, 105, 102396. [Google Scholar] [CrossRef]

- Zheng, T.; Liang, Y.; Wang, B.; Sun, H.; Zheng, J.; Li, D.; Chen, Y.; Shao, L.; Zhang, H. A Two-Stage Improved Genetic Algorithm-Particle Swarm Optimization Algorithm for Optimizing the Pressurization Scheme of Coal Bed Methane Gathering Networks. J. Clean. Prod. 2019, 229, 941–955. [Google Scholar] [CrossRef]

- Zhao, Y.; Yao, L.; Liu, L.; Xu, Y. Optimization of Energy Saving Gathering and Transportation Mode in a Block of Tahe Oilfield. Case Stud. Therm. Eng. 2019, 13, 100378. [Google Scholar] [CrossRef]

- Wang, B.; Liang, Y.; Zheng, J.; Lei, T.; Yuan, M.; Zhang, H. A Methodology to Restructure a Pipeline System for an Oilfield in the Mid to Late Stages of Development. Comput. Chem. Eng. 2018, 115, 133–140. [Google Scholar] [CrossRef]

- Bai, Y.; Hou, J.; Liu, Y.; Zhao, D.; Bing, S.; Xiao, W.; Zhao, W. Energy-Consumption Calculation and Optimization Method of Integrated System of Injection-Reservoir-Production in High Water-Cut Reservoir. Energy 2022, 239, 121961. [Google Scholar] [CrossRef]

- Allahyarzadeh-Bidgoli, A.; Dezan, D.J.; Salviano, L.O.; de Oliveira Junior, S.; Yanagihara, J.I. Lifetime Sensitivity Analysis of FPSO Operating Parameters on Energy Consumption and Overall Oil Production in a Pre-Salt Oil Field. Chem. Eng. Commun. 2020, 207, 1483–1507. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, B.; Liang, Y.; Yuan, M.; Varbanov, P.S.; Klemeš, J.J. A Method for Simultaneous Retrofit of Heat Exchanger Networks and Tower Operations for an Existing Natural Gas Purification Process. e-Prime—Adv. Electr. Eng. Electron. Energy 2021, 1, 100019. [Google Scholar] [CrossRef]

- Wang, B.; Liang, Y.; Zheng, T.; Yuan, M.; Zhang, H. Multi-Objective Site Selection Optimization of the Gas-Gathering Station Using NSGA-II. Process Saf. Environ. Prot. 2018, 119, 350–359. [Google Scholar] [CrossRef]

- Li, J.; Guo, Y.; Zhang, X.; Fu, Z. Using Hybrid Machine Learning Methods to Predict and Improve the Energy Consumption Efficiency in Oil and Gas Fields. Mob. Inf. Syst. 2021, 2021, e5729630. [Google Scholar] [CrossRef]

- Amakiri, K.T.; Canon, A.R.; Molinari, M.; Angelis-Dimakis, A. Review of Oilfield Produced Water Treatment Technologies. Chemosphere 2022, 298, 134064. [Google Scholar] [CrossRef] [PubMed]

- Ghafoori, S.; Omar, M.; Koutahzadeh, N.; Zendehboudi, S.; Malhas, R.N.; Mohamed, M.; Al-Zubaidi, S.; Redha, K.; Baraki, F.; Mehrvar, M. New Advancements, Challenges, and Future Needs on Treatment of Oilfield Produced Water: A State-of-the-Art Review. Sep. Purif. Technol. 2022, 289, 120652. [Google Scholar] [CrossRef]

- Samuel, O.; Othman, M.H.D.; Kamaludin, R.; Sinsamphanh, O.; Abdullah, H.; Puteh, M.H.; Kurniawan, T.A.; Li, T.; Ismail, A.F.; Rahman, M.A.; et al. Oilfield-Produced Water Treatment Using Conventional and Membrane-Based Technologies for Beneficial Reuse: A Critical Review. J. Environ. Manag. 2022, 308, 114556. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Lu, H.; Pan, Z.; Dai, P.; Sun, G.; Yang, Q. A Full-Scale Process for Produced Water Treatment on Offshore Oilfield: Reduction of Organic Pollutants Dominated by Hydrocarbons. J. Clean. Prod. 2021, 296, 126511. [Google Scholar] [CrossRef]

- Wu, J.; Zeng, R.J.; Zhang, F.; Yuan, Z. Application of Iron-Crosslinked Sodium Alginate for Efficient Sulfide Control and Reduction of Oilfield Produced Water. Water Res. 2019, 154, 12–20. [Google Scholar] [CrossRef]

- de Carvalho Neto, S.L.; Toledo Viviani, J.C.; Weschenfelder, S.E.; da Cunha, M.D.F.R.; Orlando Junior, A.E.; dos Santos Costa, B.R.; Mazur, L.P.; Marinho, B.A.; da Silva, A.; de Souza, A.A.U.; et al. Evaluation of Petroleum as Extractor Fluid in Liquid-Liquid Extraction to Reduce the Oil and Grease Content of Oilfield Produced Water. Process Saf. Environ. Prot. 2022, 161, 263–272. [Google Scholar] [CrossRef]

- Esmaeilnezhad, E.; Choi, H.J. Polyindole Nanoparticle-Based Electrorheological Fluid and Its Green and Clean Future Potential Conformance Control Technique to Oil Fields. J. Clean. Prod. 2019, 231, 1218–1225. [Google Scholar] [CrossRef]

- Cao, X.; Gao, X.; Zheng, K.; Wu, S.; Wu, Y.; Meng, G.; Hu, Z.; Niu, Q.; Su, J. Efficient Pollutants Removal and Microbial Flexibility under High-Salt Gradient of an Oilfield Wastewater Treatment System. Sci. Total Environ. 2022, 823, 153619. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Zheng, P.; Zhang, Y.; Dong, C.; Han, G.; Li, H.; Yang, X.; Liu, Y.; Sun, J.; Li, H.; et al. Characteristics and Formation Mechanisms of Atmospheric Carbonyls in an Oilfield Region of Northern China. Atmos. Environ. 2022, 274, 118958. [Google Scholar] [CrossRef]

- Xin, Y.; Zhang, Y.; Xue, P.; Wang, K.; Adu, E.; Tontiwachwuthikul, P. The Optimization and Thermodynamic and Economic Estimation Analysis for CO2 Compression-Liquefaction Process of CCUS System Using LNG Cold Energy. Energy 2021, 236, 121376. [Google Scholar] [CrossRef]

- Leonzio, G.; Bogle, D.; Foscolo, P.U.; Zondervan, E. Optimization of CCUS Supply Chains in the UK: A Strategic Role for Emissions Reduction. Chem. Eng. Res. Des. 2020, 155, 211–228. [Google Scholar] [CrossRef]

- El-kaseeh, G.; Will, R.; Balch, R.; Grigg, R. Multi-Scale Seismic Measurements for CO2 Monitoring in an EOR/CCUS Project. Energy Procedia 2017, 114, 3656–3670. [Google Scholar] [CrossRef]

- Andersen, P.Ø.; Brattekås, B.; Zhou, Y.; Nadeau, P.; Nermoen, A.; Yu, Z.; Fjelde, I.; Oelkers, E. Carbon Capture Utilization and Storage (CCUS) in Tight Gas and Oil Reservoirs. J. Nat. Gas Sci. Eng. 2020, 81, 103458. [Google Scholar] [CrossRef]

- Suicmez, V.S. Feasibility Study for Carbon Capture Utilization and Storage (CCUS) in the Danish North Sea. J. Nat. Gas Sci. Eng. 2019, 68, 102924. [Google Scholar] [CrossRef]

- Fukai, I.; Mishra, S.; Pasumarti, A. Technical and Economic Performance Metrics for CCUS Projects: Example from the East Canton Consolidated Oil Field, Ohio, USA. Energy Procedia 2017, 114, 6968–6979. [Google Scholar] [CrossRef]

- Li, P.; Yi, L.; Liu, X.; Hu, G.; Lu, J.; Zhou, D.; Hovorka, S.; Liang, X. Screening and Simulation of Offshore CO2-EOR and Storage: A Case Study for the HZ21-1 Oilfield in the Pearl River Mouth Basin, Northern South China Sea. Int. J. Greenh. Gas Control 2019, 86, 66–81. [Google Scholar] [CrossRef]

- Lv, G.; Li, Q.; Wang, S.; Li, X. Key Techniques of Reservoir Engineering and Injection–Production Process for CO2 Flooding in China’s SINOPEC Shengli Oilfield. J. CO2 Util. 2015, 11, 31–40. [Google Scholar] [CrossRef]

- Yang, L.; Xu, M.; Yang, Y.; Fan, J.; Zhang, X. Comparison of Subsidy Schemes for Carbon Capture Utilization and Storage (CCUS) Investment Based on Real Option Approach: Evidence from China. Appl. Energy 2019, 255, 113828. [Google Scholar] [CrossRef]

- Jiang, K.; Ashworth, P. The Development of Carbon Capture Utilization and Storage (CCUS) Research in China: A Bibliometric Perspective. Renew. Sustain. Energy Rev. 2021, 138, 110521. [Google Scholar] [CrossRef]

- Li, Q.; Liu, G.; Leamon, G.; Liu, L.-C.; Cai, B.; Chen, Z.-A. A National Survey of Public Awareness of the Environmental Impact and Management of CCUS Technology in China. Energy Procedia 2017, 114, 7237–7244. [Google Scholar] [CrossRef]

- Li, Q.; Chen, Z.A.; Zhang, J.-T.; Liu, L.-C.; Li, X.C.; Jia, L. Positioning and Revision of CCUS Technology Development in China. Int. J. Greenh. Gas Control 2016, 46, 282–293. [Google Scholar] [CrossRef]

- Yang, W.; Peng, B.; Wu, M.; Li, J.; Ni, P. Evaluation for CO2 Geo-Storage Potential and Suitability in Dagang Oilfield. Energy Procedia 2016, 86, 41–46. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, H.; Yuan, M.; Wang, Y.; Menezes, B.C.; Li, Z.; Liang, Y. Sustainable Crude Oil Transportation: Design Optimization for Pipelines Considering Thermal and Hydraulic Energy Consumption. Chem. Eng. Res. Des. 2019, 151, 23–39. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, H.; Xin, S.; Yan, Y.; Long, Y.; Yuan, M.; Liang, Y. Future Scenario of China’s Downstream Oil Supply Chain: Low Carbon-Oriented Optimization for the Design of Planned Multi-Product Pipelines. J. Clean. Prod. 2020, 244, 118866. [Google Scholar] [CrossRef]

- Wang, B.; Yuan, M.; Yan, Y.; Yang, K.; Zhang, H.; Liang, Y. Optimal Design of an Oil Pipeline with a Large-Slope Section. Eng. Optim. 2019, 51, 1480–1494. [Google Scholar] [CrossRef]

- Hassan, K.A.; Elgendi, E.O.; Shehata, A.S.; Elmasry, M.I. Energy Saving and Environment Protection Solution for the Submarine Pipelines Based on Deep Learning Technology. Energy Rep. 2022, 8, 1261–1274. [Google Scholar] [CrossRef]

- Yuan, M.; Zhang, H.; Long, Y.; Shen, R.; Wang, B.; Liang, Y. Economic, Energy-Saving and Carbon-Abatement Potential Forecast of Multiproduct Pipelines: A Case Study in China. J. Clean. Prod. 2019, 211, 1209–1227. [Google Scholar] [CrossRef]

- Cheng, Q.; Zheng, A.; Yang, L.; Pan, C.; Sun, W.; Liu, Y. Studies on Energy Consumption of Crude Oil Pipeline Transportation Process Based on the Unavoidable Exergy Loss Rate. Case Stud. Therm. Eng. 2018, 12, 8–15. [Google Scholar] [CrossRef]

- Yuan, M.; Zhang, H.; Wang, B.; Zhang, Y.; Zhou, X.; Liang, Y. Future Scenario of China’s Downstream Oil Reform: Improving the Energy-Environmental Efficiency of the Pipeline Networks through Interconnectivity. Energy Policy 2020, 140, 111403. [Google Scholar] [CrossRef]

- Lima, C.; Relvas, S.; Barbosa-Póvoa, A. Stochastic Programming Approach for the Optimal Tactical Planning of the Downstream Oil Supply Chain. Comput. Chem. Eng. 2018, 108, 314–336. [Google Scholar] [CrossRef]

- Wang, B.; Klemeš, J.J.; Yu, X.; Qiu, R.; Zheng, J.; Lin, Y.; Zhu, B. Planning of a Flexible Refined Products Transportation Network in Response to Emergencies. J. Pipeline Sci. Eng. 2022. [Google Scholar] [CrossRef]

- Wang, B.; Liang, Y.; Zheng, T.; Yuan, M.; Zhang, H. Optimisation of a Downstream Oil Supply Chain with New Pipeline Route Planning. Chem. Eng. Res. Des. 2019, 145, 300–313. [Google Scholar] [CrossRef]

- Ni, W.; Liang, Y.; Li, Z.; Liao, Q.; Cai, S.; Wang, B.; Zhang, H.; Wang, Y. Resilience Assessment of the Downstream Oil Supply Chain Considering the Inventory Strategy in Extreme Weather Events. Comput. Chem. Eng. 2022, 163, 107831. [Google Scholar] [CrossRef]

- Lima, C.; Relvas, S.; Barbosa-Póvoa, A. Designing and Planning the Downstream Oil Supply Chain under Uncertainty Using a Fuzzy Programming Approach. Comput. Chem. Eng. 2021, 151, 107373. [Google Scholar] [CrossRef]

- Wang, B.; Fan, Y.V.; Chin, H.H.; Klemeš, J.J.; Liang, Y. Emission-Cost Nexus Optimisation and Performance Analysis of Downstream Oil Supply Chains. J. Clean. Prod. 2020, 266, 121831. [Google Scholar] [CrossRef]

- Yuan, M.; Zhang, H.; Wang, B.; Shen, R.; Long, Y.; Liang, Y. Future Scenario of China’s Downstream Oil Supply Chain: An Energy, Economy and Environment Analysis for Impacts of Pipeline Network Reform. J. Clean. Prod. 2019, 232, 1513–1528. [Google Scholar] [CrossRef]

- Ghatee, A.; Zarrinpoor, N. Designing an Oil Supply Chain Network Considering Sustainable Development Paradigm and Uncertainty. Chem. Eng. Res. Des. 2022, 184, 692–723. [Google Scholar] [CrossRef]

- Ebrahimi, S.B.; Bagheri, E. Optimizing Profit and Reliability Using a Bi-Objective Mathematical Model for Oil and Gas Supply Chain under Disruption Risks. Comput. Ind. Eng. 2022, 163, 107849. [Google Scholar] [CrossRef]

- Piya, S.; Shamsuzzoha, A.; Khadem, M. Analysis of Supply Chain Resilience Drivers in Oil and Gas Industries during the COVID-19 Pandemic Using an Integrated Approach. Appl. Soft Comput. 2022, 121, 108756. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, T.; Tan, J.; Wu, W.; Xie, S.; Li, D. Energy, Exergy and Economic Benefits Deriving from LNG-Fired Power Plant: Cold Energy Power Generation Combined with Carbon Dioxide Capture. Renew. Energy 2022, 195, 214–229. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J.; Cho, H.; Kim, J. Novel Cryogenic Carbon Dioxide Capture and Storage Process Using LNG Cold Energy in a Natural Gas Combined Cycle Power Plant. Chem. Eng. J. 2022, 140980. [Google Scholar] [CrossRef]

- Aryanfar, Y.; Mohtaram, S.; García Alcaraz, J.L.; Sun, H. Energy and Exergy Assessment and a Competitive Study of a Two-Stage ORC for Recovering SFGC Waste Heat and LNG Cold Energy. Energy 2023, 264, 126191. [Google Scholar] [CrossRef]

- Shaikh, A.A.; AlNouss, A.; Al-Ansari, T. A Heat Integration Case Study for the Dehydration and Condensate Stabilization Units in LNG Plants for Economic and Energy Savings. Comput. Chem. Eng. 2022, 168, 108062. [Google Scholar] [CrossRef]

- Chen, S.; Xu, J.; Dong, X.; Zhang, H.; Gao, Q.; Tan, C. Pinch Point Analysis of Heat Exchange for Liquid Nature Gas (LNG) Cryogenic Energy Using in Air Separation Unit. Int. J. Refrig. 2018, 90, 264–276. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, H.; Meng, J.; Long, Y.; Yan, Y.; Li, M.; Huang, Z.; Liang, Y. Reducing Carbon Footprint of Deep-Sea Oil and Gas Field Exploitation by Optimization for Floating Production Storage and Offloading. Appl. Energy 2020, 261, 114398. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, H.; Yan, Y.; Yan, J.; He, J.; Li, Z.; Shang, W.; Liang, Y. Sustainable and Clean Oilfield Development: How Access to Wind Power Can Make Offshore Platforms More Sustainable with Production Stability. J. Clean. Prod. 2021, 294, 126225. [Google Scholar] [CrossRef]

- Zou, X.; Qiu, R.; Yuan, M.; Liao, Q.; Yan, Y.; Liang, Y.; Zhang, H. Sustainable Offshore Oil and Gas Fields Development: Techno-Economic Feasibility Analysis of Wind–Hydrogen–Natural Gas Nexus. Energy Rep. 2021, 7, 4470–4482. [Google Scholar] [CrossRef]

- Huang, C.; Gu, B.; Chen, Y.; Tan, X.; Feng, L. Energy Return on Energy, Carbon, and Water Investment in Oil and Gas Resource Extraction: Methods and Applications to the Daqing and Shengli Oilfields. Energy Policy 2019, 134, 110979. [Google Scholar] [CrossRef]

- Abd, A.S.; Abushaikha, A.; Bicer, Y. A Comprehensive Thermodynamic Analysis of an Integrated Solar Enhanced Oil Recovery System for Applications in Heavy Oil Fields. Energy Convers. Manag. 2022, 253, 115161. [Google Scholar] [CrossRef]

- Absi Halabi, M.; Al-Qattan, A.; Al-Otaibi, A. Application of Solar Energy in the Oil Industry—Current Status and Future Prospects. Renew. Sustain. Energy Rev. 2015, 43, 296–314. [Google Scholar] [CrossRef]

- Alimonti, C.; Soldo, E.; Scrocca, D. Looking Forward to a Decarbonized Era: Geothermal Potential Assessment for Oil & Gas Fields in Italy. Geothermics 2021, 93, 102070. [Google Scholar] [CrossRef]

- Mahmoodpour, S.; Singh, M.; Mahyapour, R.; Tangirala, S.K.; Bär, K.; Sass, I. Numerical Simulation of Thermo-Hydro-Mechanical Processes at Soultz-Sous-Forêts. Energies 2022, 15, 9285. [Google Scholar] [CrossRef]

- Singh, M.; Mahmoodpour, S.; Ershadnia, R.; Soltanian, M.R.; Sass, I. Comparative Study on Heat Extraction from Soultz-Sous-Forêts Geothermal Field Using Supercritical Carbon Dioxide and Water as the Working Fluid. Energy 2023, 266, 126388. [Google Scholar] [CrossRef]

- Sahana, C.; De, S.; Mondal, S. Integration of CO2 Power and Refrigeration Cycles with a Desalination Unit to Recover Geothermal Heat in an Oilfield. Appl. Therm. Eng. 2021, 189, 116744. [Google Scholar] [CrossRef]

- Wang, B.; Klemeš, J.J.; Varbanov, P.S.; Shahzad, K.; Kabli, M.R. Total Site Heat Integration Benefiting from Geothermal Energy for Heating and Cooling Implementations. J. Environ. Manag. 2021, 290, 112596. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Wang, M.; Wang, B.; Hao, H.; Shi, H.; Wu, Z.; Chen, J.; Gai, L.; Tao, H.; Zhu, B.; et al. Energy Consumption Reduction and Sustainable Development for Oil & Gas Transport and Storage Engineering. Energies 2023, 16, 1775. https://doi.org/10.3390/en16041775

Chen X, Wang M, Wang B, Hao H, Shi H, Wu Z, Chen J, Gai L, Tao H, Zhu B, et al. Energy Consumption Reduction and Sustainable Development for Oil & Gas Transport and Storage Engineering. Energies. 2023; 16(4):1775. https://doi.org/10.3390/en16041775

Chicago/Turabian StyleChen, Xianlei, Manqi Wang, Bin Wang, Huadong Hao, Haolei Shi, Zenan Wu, Junxue Chen, Limei Gai, Hengcong Tao, Baikang Zhu, and et al. 2023. "Energy Consumption Reduction and Sustainable Development for Oil & Gas Transport and Storage Engineering" Energies 16, no. 4: 1775. https://doi.org/10.3390/en16041775

APA StyleChen, X., Wang, M., Wang, B., Hao, H., Shi, H., Wu, Z., Chen, J., Gai, L., Tao, H., Zhu, B., & Wang, B. (2023). Energy Consumption Reduction and Sustainable Development for Oil & Gas Transport and Storage Engineering. Energies, 16(4), 1775. https://doi.org/10.3390/en16041775