Modeling of Changes in the Resistivity of Semi Insulating Gallium Phosphide under the Influence of Lighting

Abstract

1. Introduction

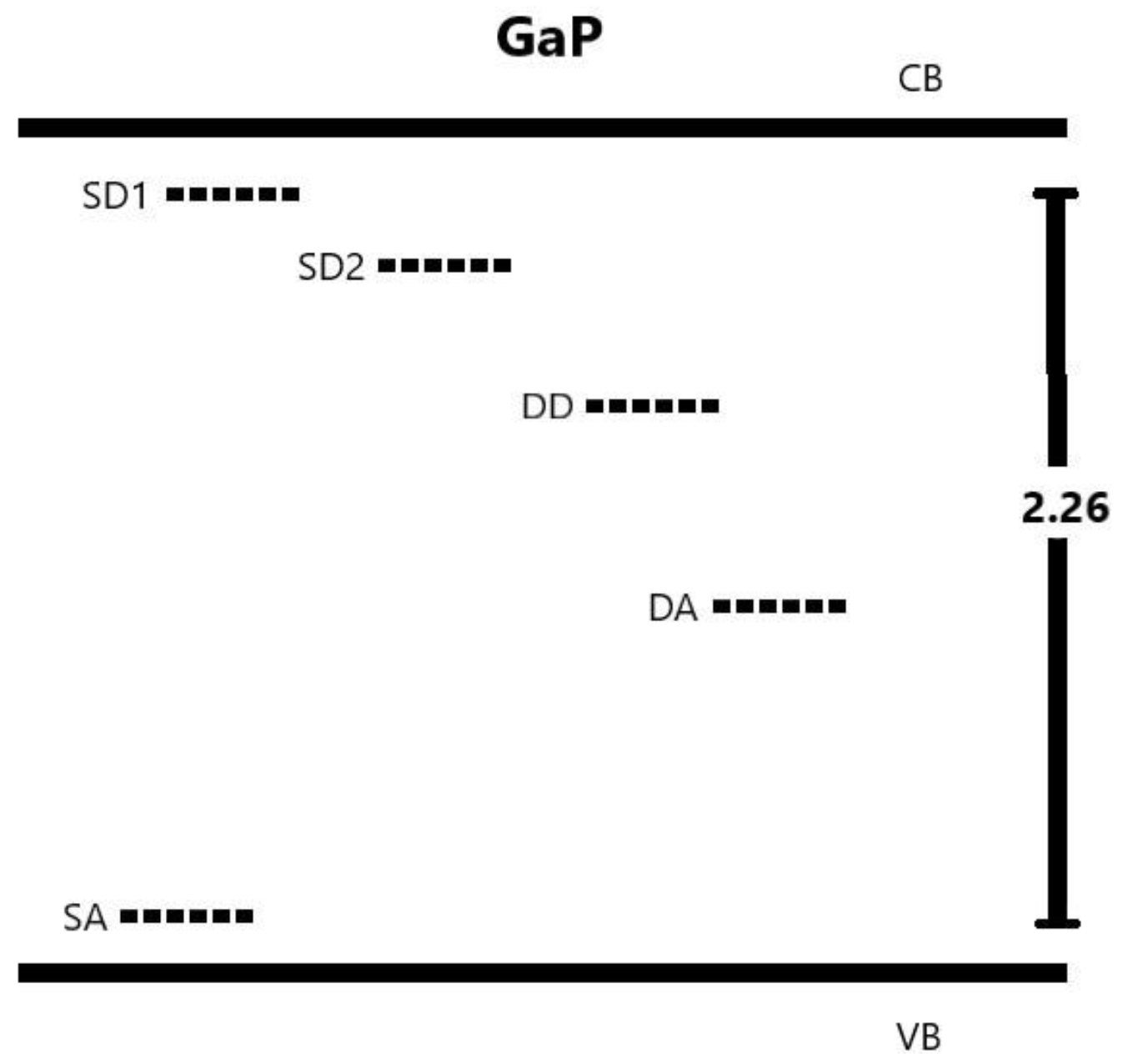

2. Material Properties

3. Simulation Procedures

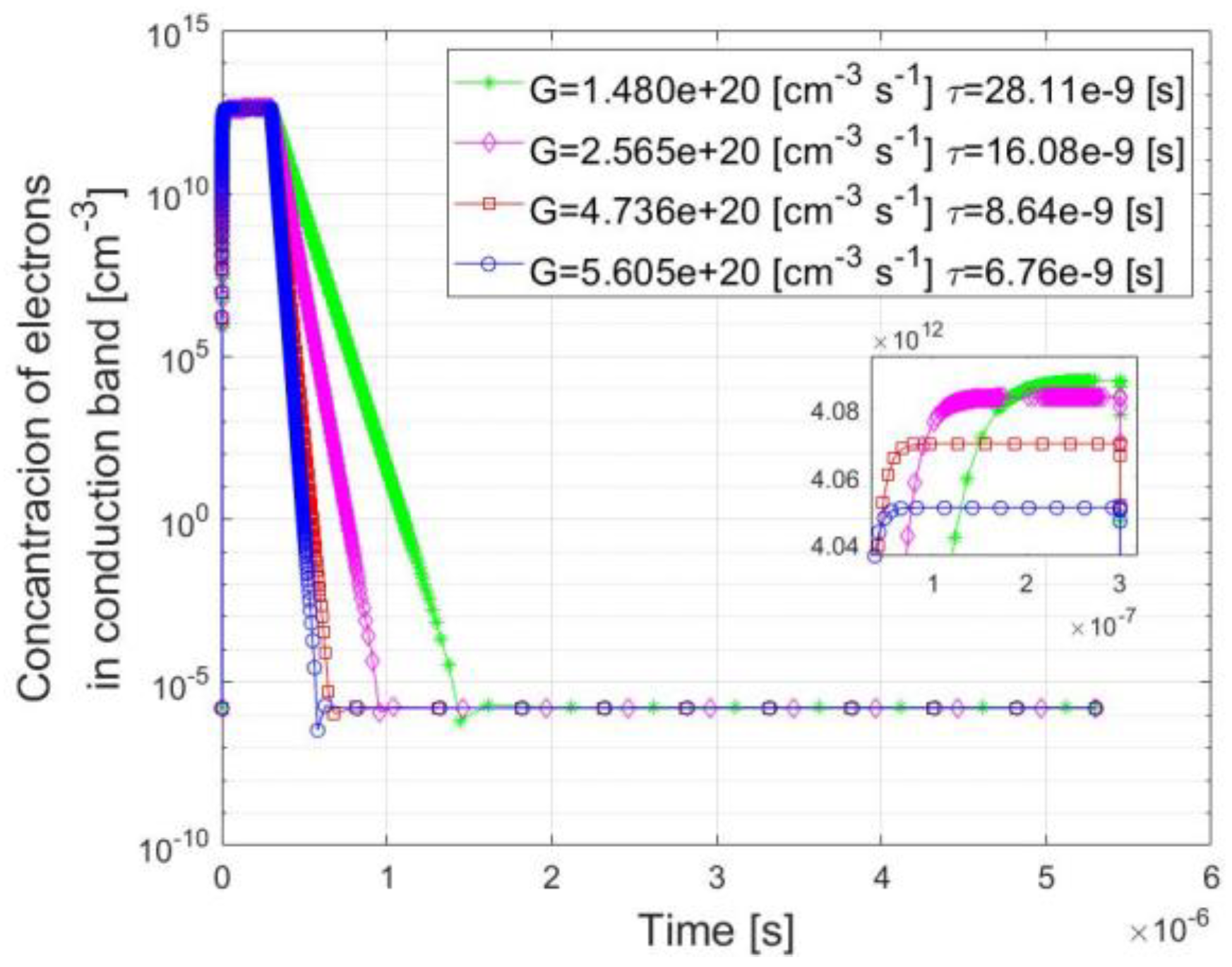

4. Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tabcheh, N.; Orlacchio, R.; Couderc, V.; Leveque, P.; Arnaud-Cormos, D. High Voltage Generator with Adjustable Delay between Two Nanosecond Pulses. IEE Photonics Technol. Lett. 2022, 34, 553–556. [Google Scholar] [CrossRef]

- Wolfe, T.S.; Francis, S.A.; Langley, D.; Petrosky, J.C.; Roos, J.; Terzuoli, A.; Zens, T. Integrated Computational Investigation of Photoconductive Semiconductor Switches in Pulsed Power Radio Frequency Applications. IEEE Trans. Plasma Sci. 2016, 44, 60–70. [Google Scholar] [CrossRef]

- Xu, M.; Liu, X.; Li, M.; Liu, K.; Qu, G.; Wang, V.; Hu, L.; Schneider, H. Transient characteristic of interdigitated GaAs photoconductive semiconductor switch at 1-kHz excitation. IEEE Electron. Device Lett. 2019, 40, 1136–1138. [Google Scholar] [CrossRef]

- Tian, L.; Shi, W. Analysis and operation mechanism of semi-insulating GaAs photoconductive semiconductor switches. J. Appl. Phys. 2008, 103, 124512. [Google Scholar] [CrossRef]

- Shi, W.; Tian, L.; Liu, Z.; Zhang, L.; Zhang, Z.; Zhou, L.; Liu, H.; Xie, W. 30 kV and 3 kA semi-insulating GaAs photoconductive semiconductor switch. Appl. Phys. Lett. 2008, 92, 043511. [Google Scholar] [CrossRef]

- Yang, X.; Hu, L.; Dang, X.; Li, X.; Liu, W.; Han, C.; Li, S. Low Specific Contact Resistivity of 10−3 Ω·cm2 for Ti/Al/Ni/Au Multilayer Metals on SI-GaN:Fe Substrate. IEEE Trans. Electron. Devices 2022, 69, 5773–5779. [Google Scholar] [CrossRef]

- Hu, Z.; Li, J.; Zhao, C.; Feng, Z.; Tian, X.; Zhang, Y.; Zhang, Y.; Ning, J.; Zhou, H.; Zhang, C.; et al. Design and Fabrication of Vertical Metal/TiO2/β-Ga2O3Dielectric Heterojunction Diode with Reverse Blocking Voltage of 1010 V. IEEE Trans. Electron. Devices 2020, 67, 5628–5632. [Google Scholar] [CrossRef]

- Mazumder, S.K. An Overview of Photonic Power Electronic Devices. IEEE Trans. Power Electron. 2016, 31, 6562–6574. [Google Scholar] [CrossRef]

- Górecki, P.; Górecki, K. The analysis of accuracy of selected methods of measuring the thermal resistance of IGBTs. Metrol. Meas. Syst. 2015, 22, 455–464. [Google Scholar] [CrossRef]

- Nikoo, M.S.; Jafari, A.; Perera, N.; Matioli, E. Output Capacitance Losses in Wide-Band-Gap Transistors: A Small-Signal Modelling Approach. In Proceedings of the International Symposium on Power Semiconductor Devices and ICs, Vienna, Austria, 13–18 September 2020; pp. 190–193. [Google Scholar] [CrossRef]

- Zhang, H.; Yuan, L.; Tang, X.; Hu, J.; Sun, J.; Zhang, Y.; Zhang, Y.; Jia, R. Progress of Ultra-Wide Bandgap Ga2O3 Semiconductor Materials in Power MOSFETs. IEEE Trans. Power Electron. 2020, 35, 5157–5179. [Google Scholar] [CrossRef]

- Zhao, L.; Ge, Q.; Zhou, Z.; Yang, B.; Li, Y. Research of high-power converter based on the wide band gap power semiconductor devices for rail transit electrical drive. In Proceedings of the 2018 1st Workshop on Wide Bandgap Power Devices and Applications in Asia (WiPDA Asia 2018), Xi’an, China, 16–18 May 2018; pp. 36–39. [Google Scholar] [CrossRef]

- Zeng, F.; Wang, Q.; Lin, S.; Wang, L.; Zhou, G.; Cheng, W.-C.; He, M.; Jiang, Y.; Ge, Q.; Li, M.; et al. Study on the Optimization of Off-State Breakdown Performance of p-GaN HEMTs. In Proceedings of the 4th Electron Devices Technology and Manufacturing Conference (EDTM 2020), Penang, Malaysia, 6–21 April 2020; p. 9117814. [Google Scholar] [CrossRef]

- Qiu, Y.; Vanderkloot, J.; Hou, R.; Lu, J. Diagnosing for Cross-conduction in GaN Half-Bridge. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), New Orleans, LA, USA, 15–19 March 2020; pp. 2577–2583. [Google Scholar] [CrossRef]

- Barth, H.; Hofmann, W. Potentials and Boundaries of Discrete SiC-Transistors in AC Drives. In Proceedings of the 2018 20th European Conference on Power Electronics and Applications (EPE 2018 ECCE Europe), Riga, Latvia, 17–21 September 2018; p. 8515479. [Google Scholar]

- Mao, S.; Yao, Z.; Zhu, D.; Popovic, J.; Ferreira, J.A. A high frequency 110 kV output-voltage, 8 kW output-power high voltage generator with silicon carbide power semiconductor devices. In Proceedings of the 2019 21st European Conference on Power Electronics and Applications, (EPE 2019 ECCE Europe), Genova, Italy, 3–5 September 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Shah, P.B.; Jones, K.A. Two-dimensional numerical investigation of the impact of material-parameter uncertainty on the steady-state performance of passivated 4H-SiC thyristors. J. Appl. Phys. 1998, 84, 4625–4630. [Google Scholar] [CrossRef]

- Aparnaa, A.R.; Brahmajiraob, V.; Karthikeyanc, T.V. Review on Synthesis and Characterization of Gallium Phosphide. Procedia Mater. Sci. 2014, 6, 1650–1657. [Google Scholar] [CrossRef]

- Pawlowski, M.; Kaminski, P.; Kozlowski, R.; Jankowski, S.; Wierzbowski, M. Intelligent measuring system for characterisation of defect centres in semi-insulating materials by photoinduced transient spectroscopy. Metrol. Meas. Syst. 2005, 12, 207–228. [Google Scholar]

- Kamiński, P.; Kozłowski, R.; Surma, B.; Kozubal, M.; Hindrichsen, C.; Sveigaard, T.; Jensen, L.; Kwestarz, M.; Jabłoński, J. Effect of nitrogen-doping on the properties of radiation defect centers in FZ silicon. Solid State Phenom. 2016, 242, 279–284. [Google Scholar] [CrossRef]

- Krupka, J.; Karcz, W.; Avdeyev, S.P.; Kamiński, P.; Kozłowski, R. Electrical properties of deuteron irradiated high resistivity silicon. Nucl. Instrum. Methods Phys. Res. B 2014, 325, 107–114. [Google Scholar] [CrossRef]

- Suproniuk, M.; Pawłowski, M.; Wierzbowski, M.; Majda-Zdancewicz, E.; Pawłowski, M. Comparison of methods applied in photoinduced transient spectroscopy to determining the defect center parameters: The correlation procedure and the signal analysis based on inverse Laplace transformation. Rev. Sci. Instrum. 2018, 89, 044702. [Google Scholar] [CrossRef] [PubMed]

- Kamiński, P.; Kozlowski, R.; Strzelecka, S.; Hruban, A.; Jurkiewicz-Wegner, E.; Piersa, M.; Pawlowski, M.; Suproniuk, M. Tailoring the Electrical Properties of Undoped GaP. Solid State Phenom. 2011, 178–179, 410–415. [Google Scholar] [CrossRef]

- Kamiński, P.; Kozłowski, R.; Strzelecka, S.; Hruban, A.; Jurkiewicz-Wegner, E.; Piersa, M. High-resolution photoinduced transient spectroscopy of defect centres in semi-insulating GaP. Phys. Status Solidi C 2011, 8, 1361–1365. [Google Scholar] [CrossRef]

- Khmelevskaia, D.; Markina, D.I.; Fedorov, V.V.; Ermolaev, G.A.; Arsenin, A.V.; Volkov, V.S.; Goltaev, A.S.; Zadiranov, Y.M.; Tzibizov, I.A.; Pushkarev, A.P.; et al. Optical Constants of GaP (Gallium phosphide). Refractiveindex. 2021. Available online: https://refractiveindex.info/?shelf=main&book=GaP&page=Khmelevskaia (accessed on 1 February 2022).

- Suproniuk, M.; Wierzbowski, M.; Paziewski, P. Effect of generation rate on transient photoconductivity of semi-insulating rate on transient photoconductivity of semi-insulating 4H-SiC. Sci. Rep. 2020, 10, 11865. [Google Scholar] [CrossRef] [PubMed]

- GaP—Gallium Phosphide. Ioffe. Available online: http://www.ioffe.ru/SVA/NSM/Semicond/GaP/electric.html (accessed on 1 February 2022).

| Symbol | Defect Type | Activation Energy (eV) | Capture Cross-Section (cm2) | Identification | |

|---|---|---|---|---|---|

| Electrons | Holes | ||||

| SD1 | shallow donor | 0.085 | 1.95 × 10−15 | - | SiGa0 [23,24] |

| SD2 | shallow donor | 0.110 | 6.23 × 10−16 | - | SP [23,24] |

| DD | deep donor | 1.035 | 1.25 × 10−14 | - | PGa [23] |

| DA | deep acceptor | 0.850 | - | 7.04 × 10−15 | Unidentified [23] |

| SA | shallow acceptor | 0.055 | - | 1.44 × 10−16 | CP [23,24] |

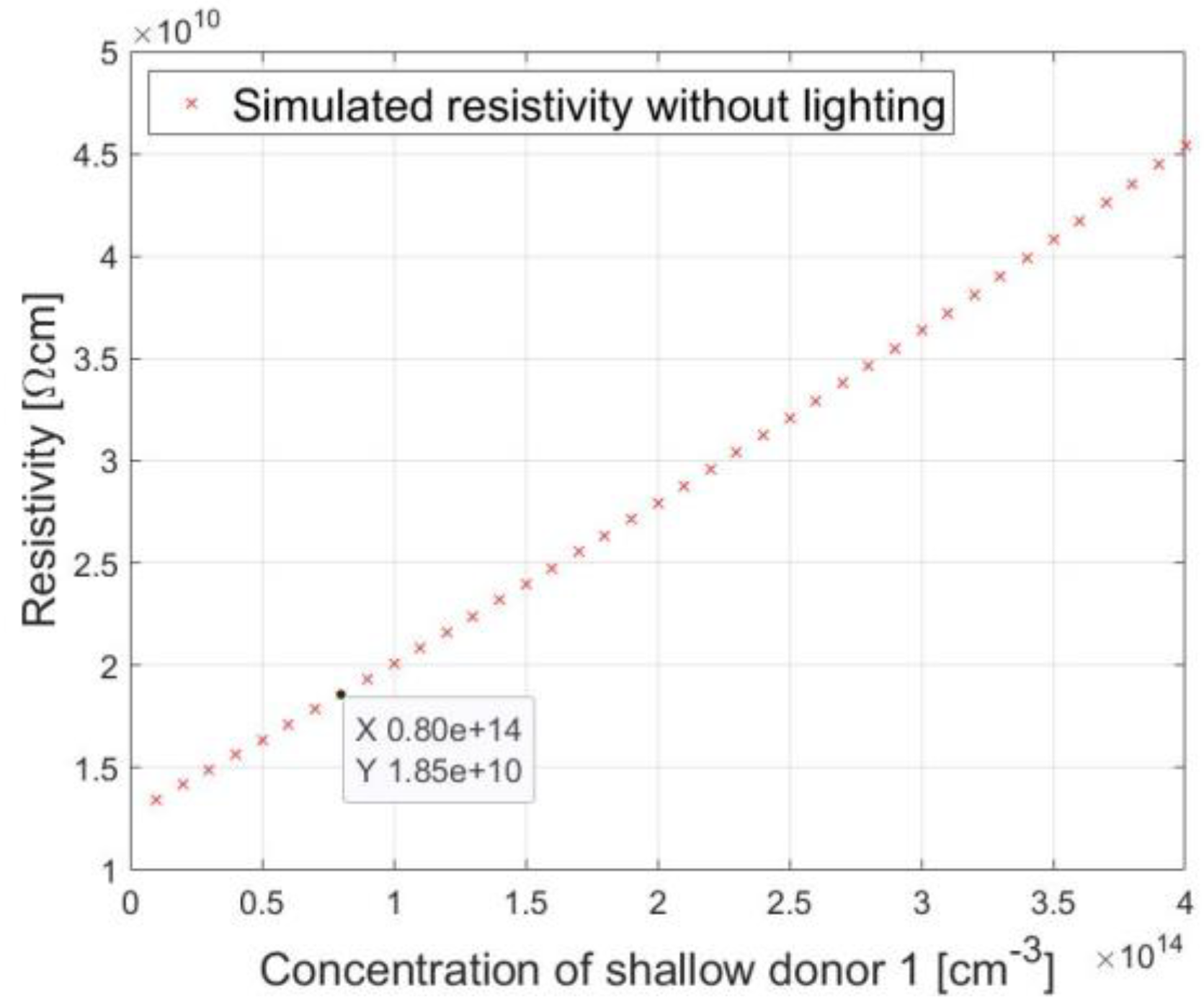

| Symbol | Concentration (cm−3) | Thermal Emission (s−1) | Capture (cm3s−1) | ||

|---|---|---|---|---|---|

| Electrons | Holes | Electrons | Holes | ||

| SD1 | 0.8 × 1014 | 1.6837 × 1011 | - | 3.900 × 10−7 | - |

| SD2 | 1.3 × 1014 | 2.0452 × 109 | - | 1.246 × 10−8 | - |

| DD | 3.4 × 1014 | 1.1852 × 10−5 | - | 2.500 × 10−7 | - |

| DA | 3.3 × 1015 | - | 0.0090 | - | 9.152 × 10−8 |

| SA | 2.8 × 1014 | - | 4.1688 × 109 | - | 1.872 × 10−9 |

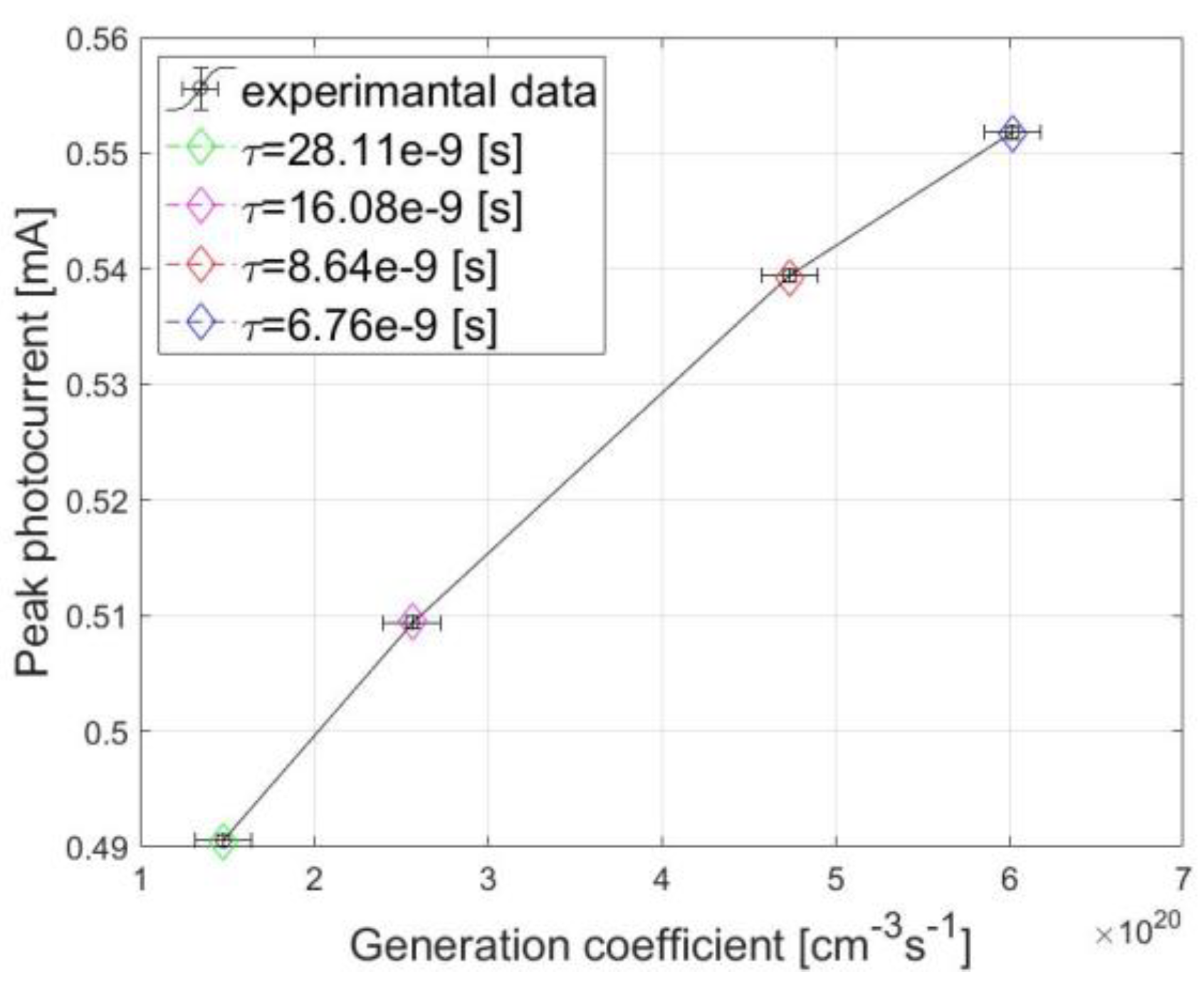

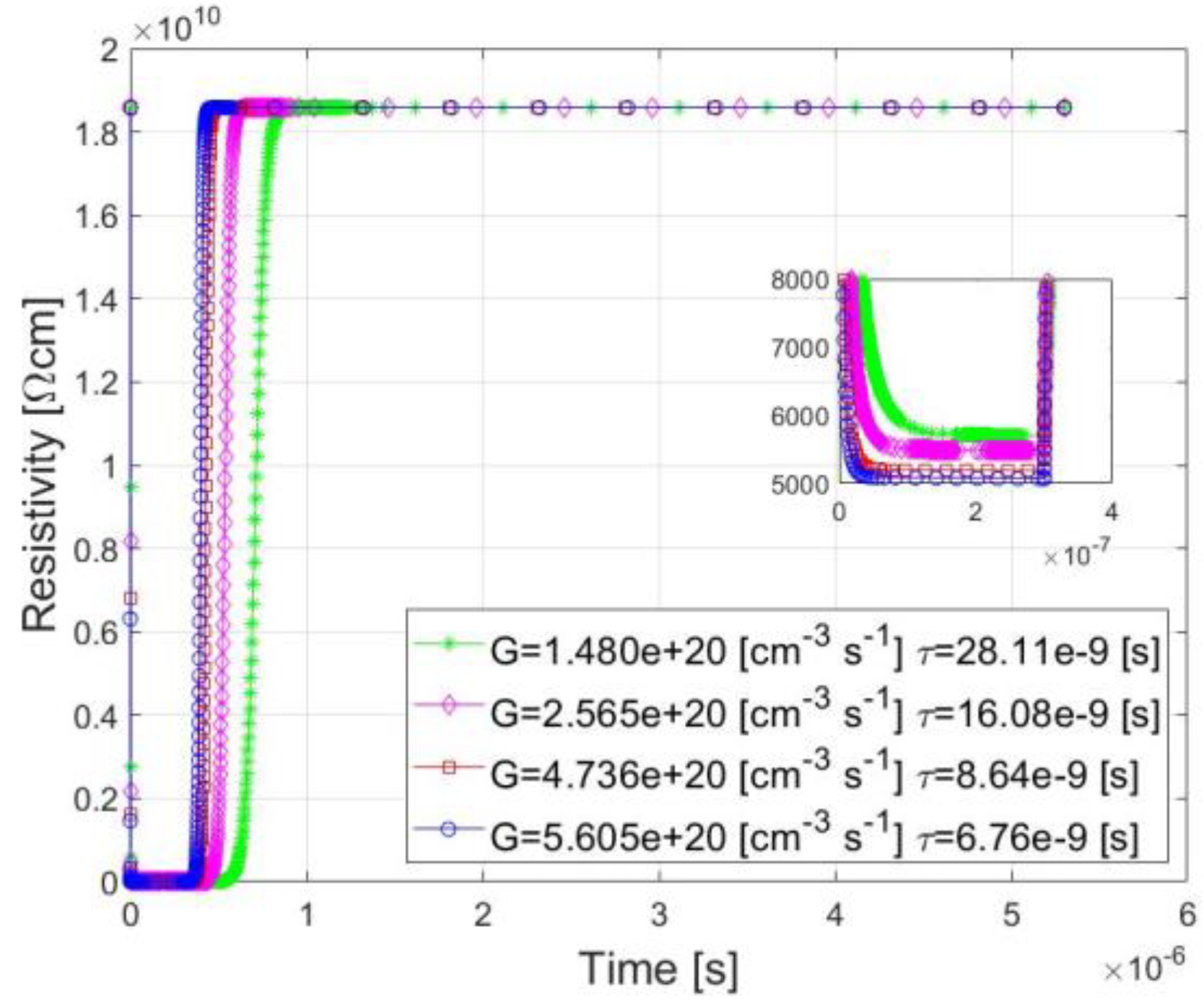

| Experimental Results | Simulation Results | ||||

|---|---|---|---|---|---|

| Photocurrent (mA) | G Coefficient (cm−3s−1) | τ (s−1) | ρmin (Ωm) | tρon (ns) | tρoff (ns) |

| 0.491 | 1.480 × 1020 | 28.11 × 10−9 | 5706 | 65 | 150 |

| 0.509 | 2.565 × 1020 | 16.08 × 10−9 | 5496 | 78 | 220 |

| 0.539 | 4.736 × 1020 | 8.64 × 10−9 | 5205 | 175 | 400 |

| 0.552 | 6.018 × 1020 | 6.76 × 10−9 | 5087 | 270 | 700 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piwowarski, K.; Kaczmarek, W.; Suproniuk, M.; Perka, B.; Paziewski, P. Modeling of Changes in the Resistivity of Semi Insulating Gallium Phosphide under the Influence of Lighting. Energies 2023, 16, 1725. https://doi.org/10.3390/en16041725

Piwowarski K, Kaczmarek W, Suproniuk M, Perka B, Paziewski P. Modeling of Changes in the Resistivity of Semi Insulating Gallium Phosphide under the Influence of Lighting. Energies. 2023; 16(4):1725. https://doi.org/10.3390/en16041725

Chicago/Turabian StylePiwowarski, Karol, Witold Kaczmarek, Marek Suproniuk, Bogdan Perka, and Piotr Paziewski. 2023. "Modeling of Changes in the Resistivity of Semi Insulating Gallium Phosphide under the Influence of Lighting" Energies 16, no. 4: 1725. https://doi.org/10.3390/en16041725

APA StylePiwowarski, K., Kaczmarek, W., Suproniuk, M., Perka, B., & Paziewski, P. (2023). Modeling of Changes in the Resistivity of Semi Insulating Gallium Phosphide under the Influence of Lighting. Energies, 16(4), 1725. https://doi.org/10.3390/en16041725