Energy, Exergy, and Economic (3E) Analysis of Transcritical Carbon Dioxide Refrigeration System Based on ORC System

Abstract

:1. Introduction

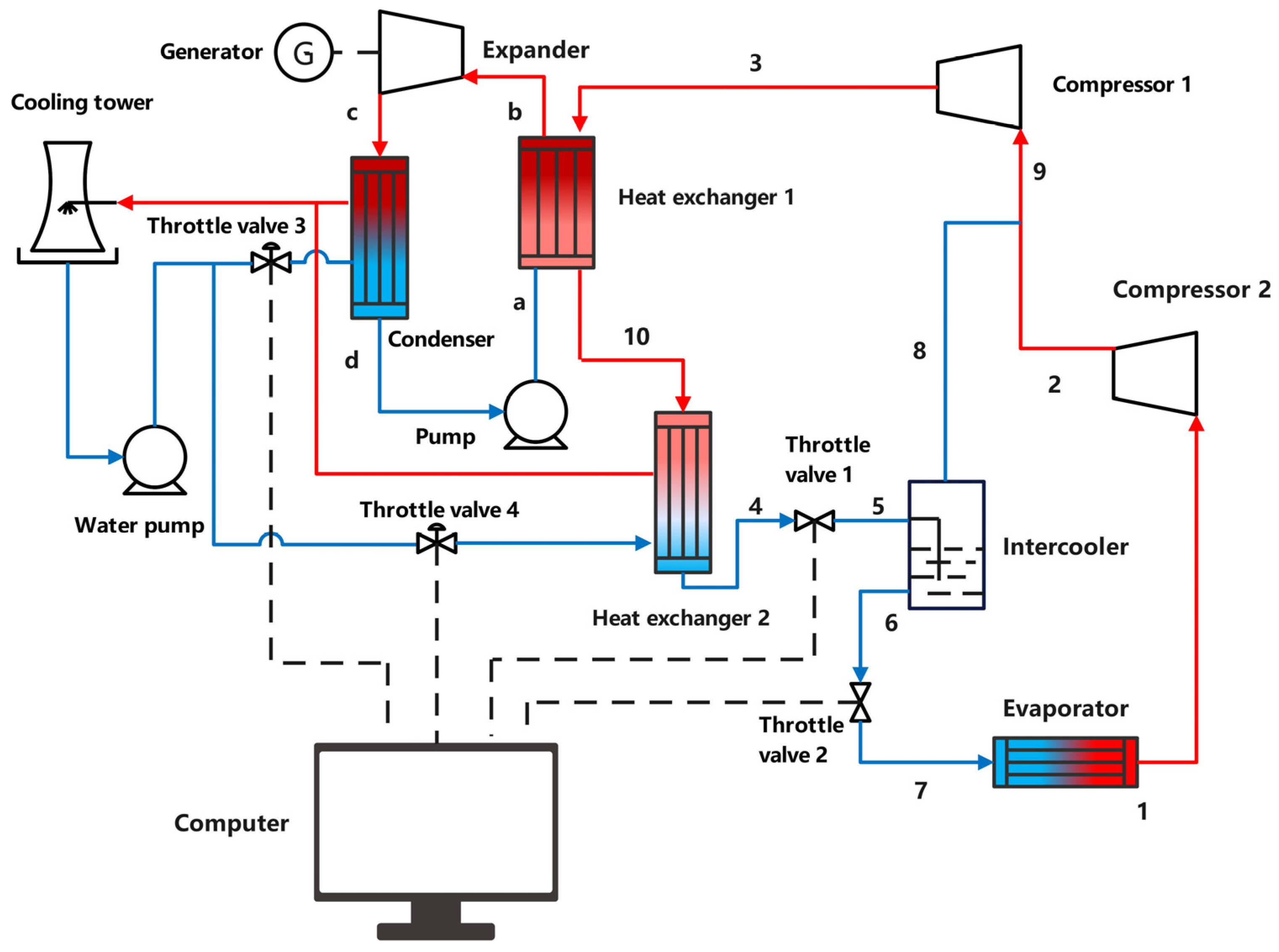

2. System Description

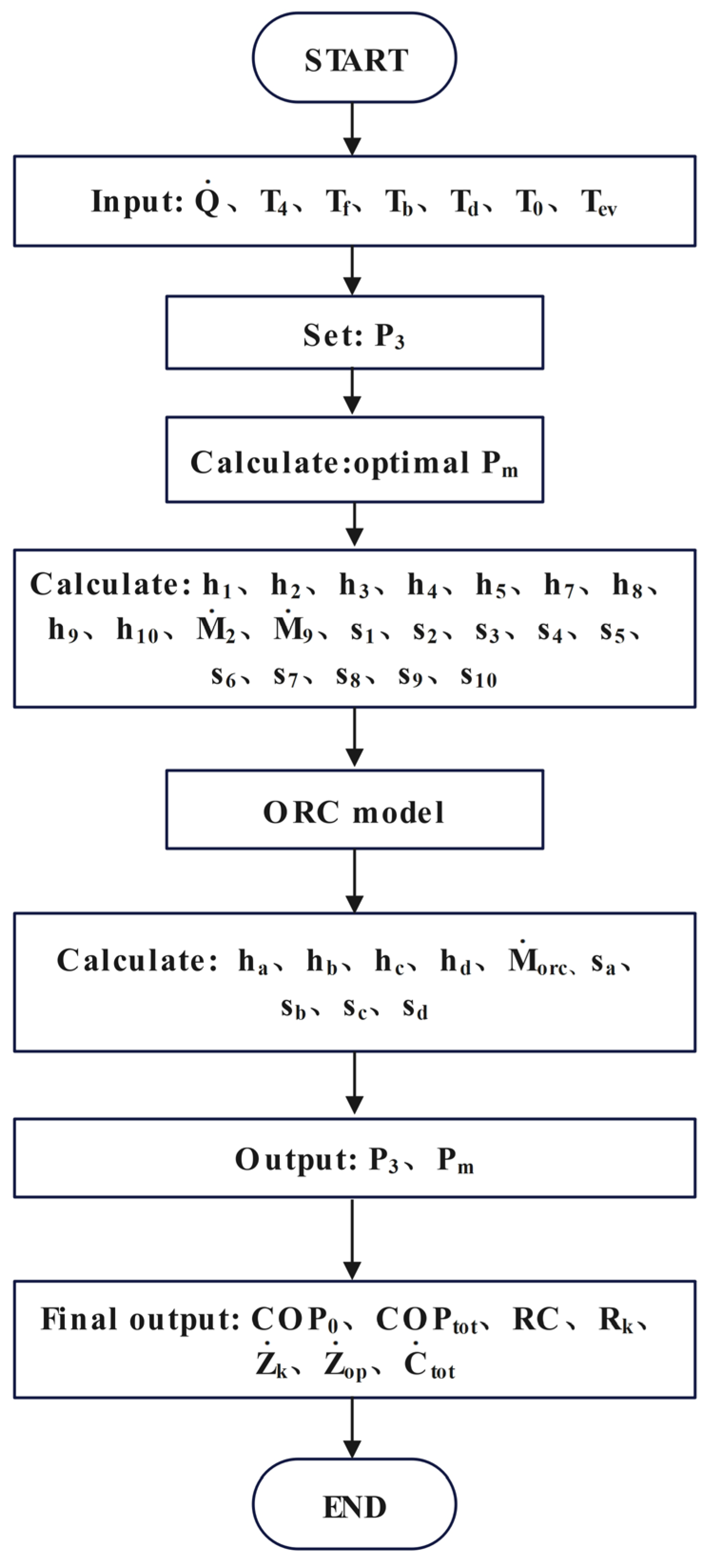

3. Modeling and Analysis

3.1. Assumption of the Model

- Modeling and subsequent calculation under steady-state conditions;

- In the compression process, the efficiency of the high-pressure and low-pressure compressor was constant, both of which were 0.75 [33];

- In the throttling process, all were treated in accordance with constant enthalpy;

- The kinetic energy and potential energy were ignored;

- Exergy loss due to flow in the pipeline was ignored.

3.2. Thermodynamic Model

3.3. Economic Analysis Model

| Component | Capital Cost Function (Zk) |

|---|---|

| High-pressure compressor | |

| Low-pressure compressor | |

| Evaporator | |

| Throttle valve | |

| Expander | |

| Heat exchanger | |

| Condenser | |

| Pump |

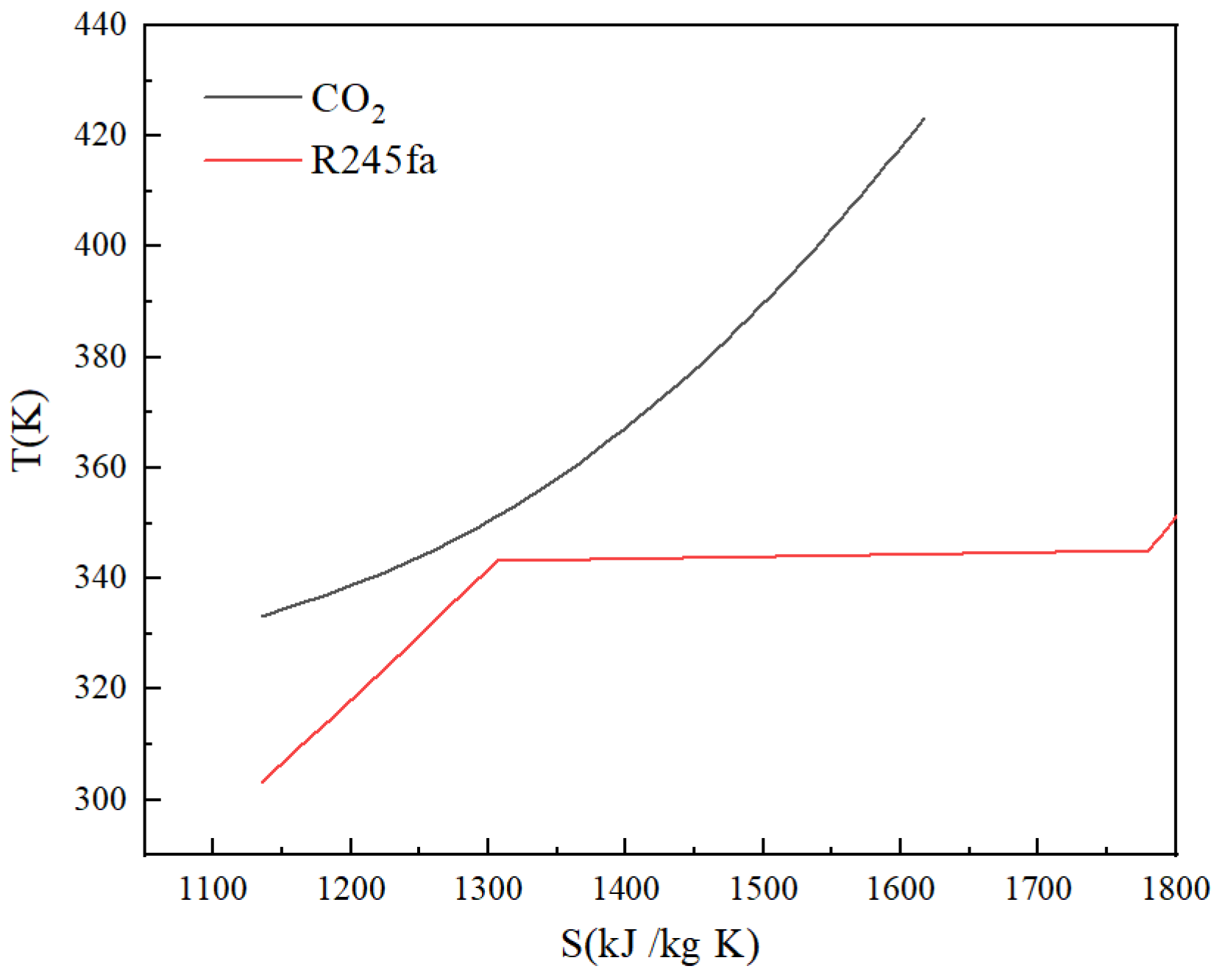

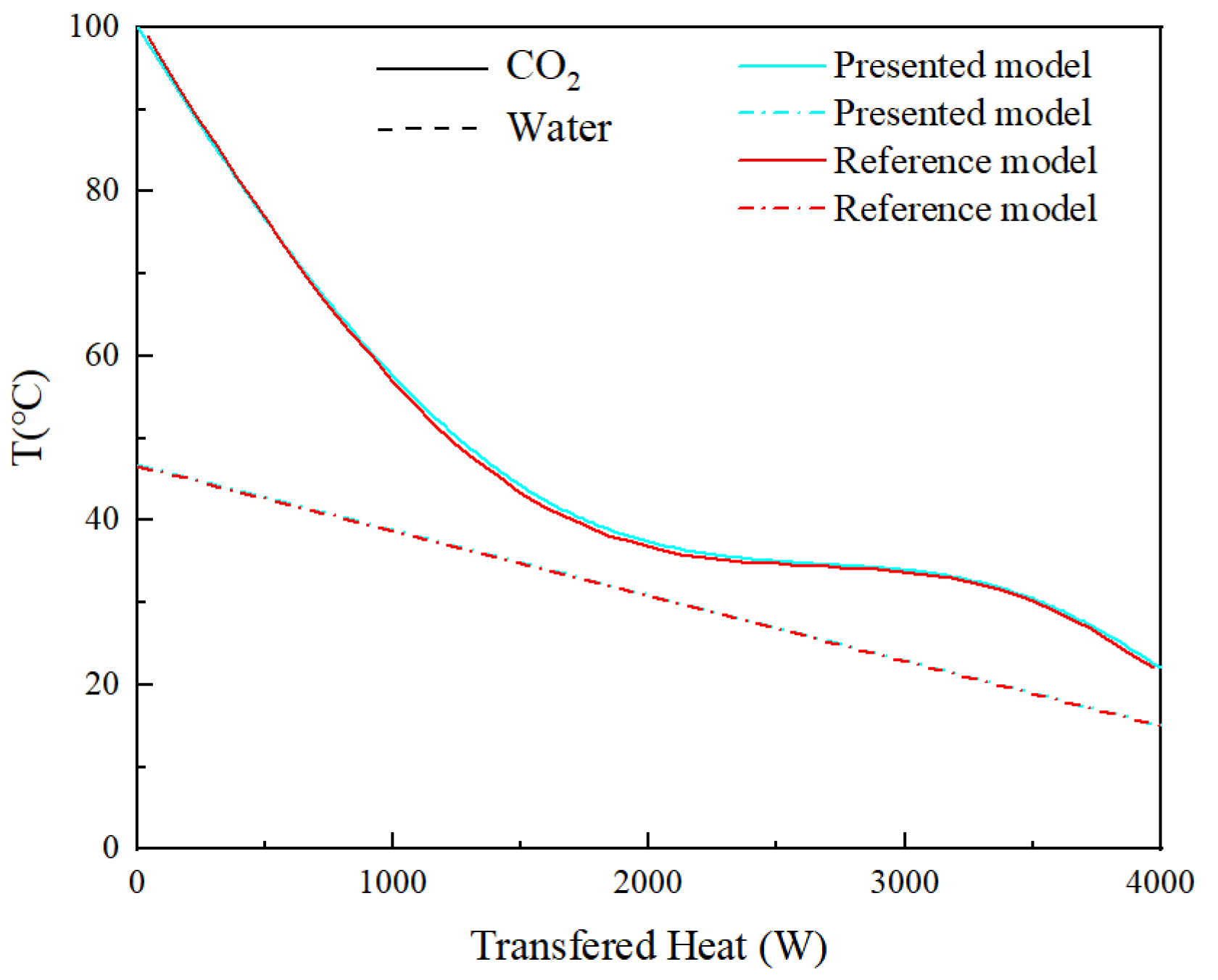

4. Model Verification

5. Results and Discussion

5.1. Energy Analysis

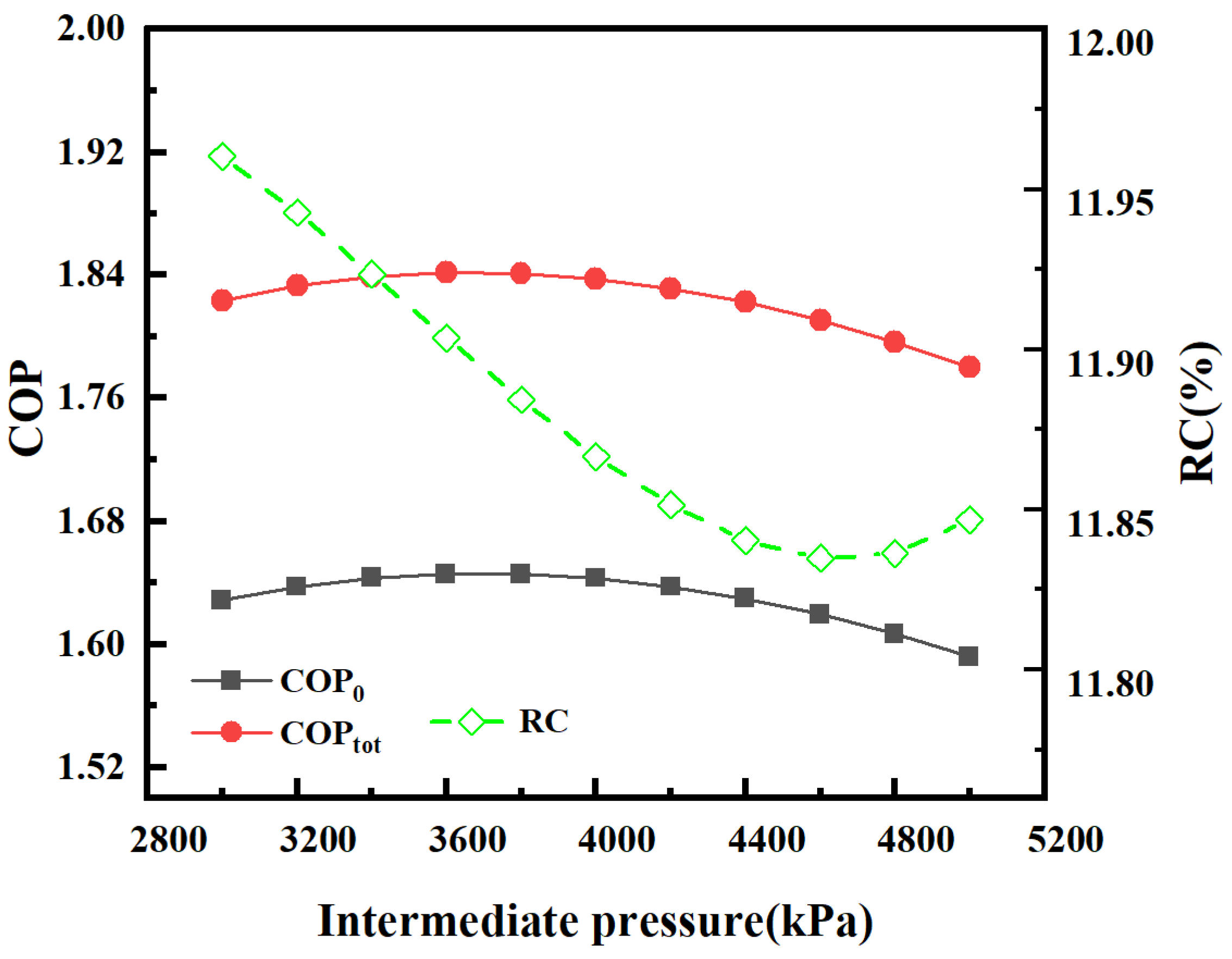

5.1.1. Analysis of Influence of Intermediate Pressure Change on COP

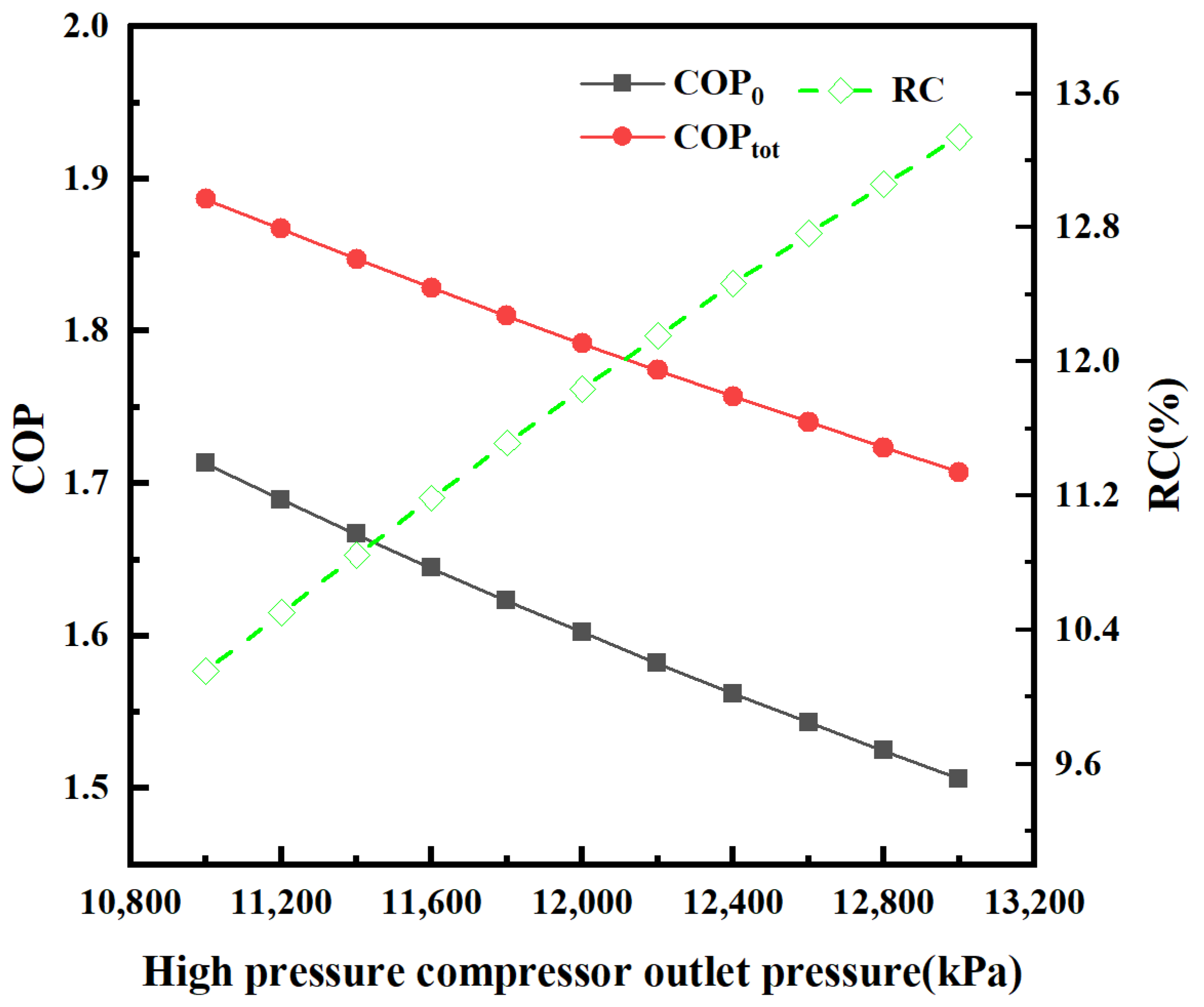

5.1.2. Analysis of Influence of Outlet Pressure on COP of High-Pressure Compressor

5.2. Exergy Analysis

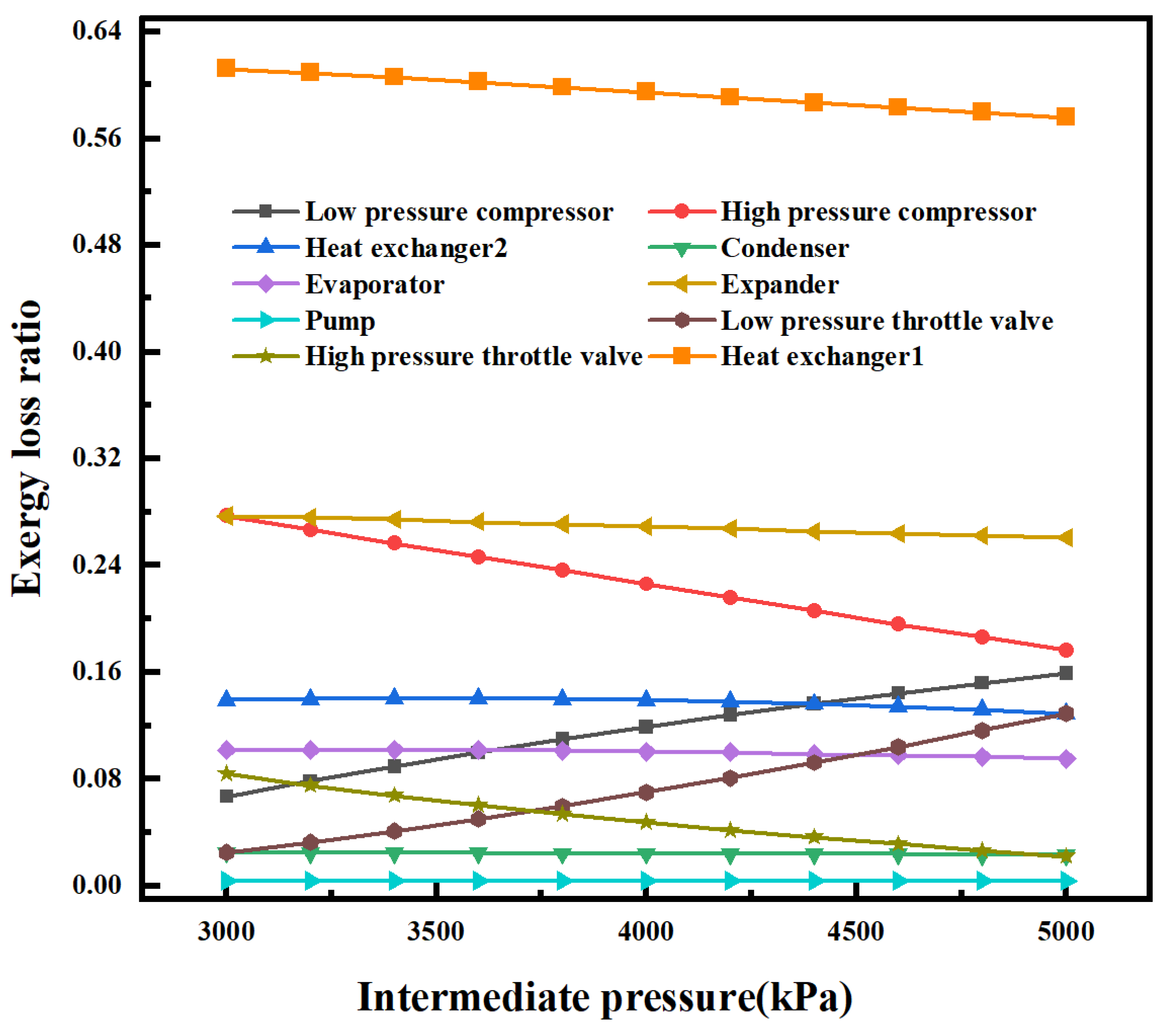

5.2.1. Analysis of the Influence of Intermediate Pressure Change on Exergy Loss Ratio

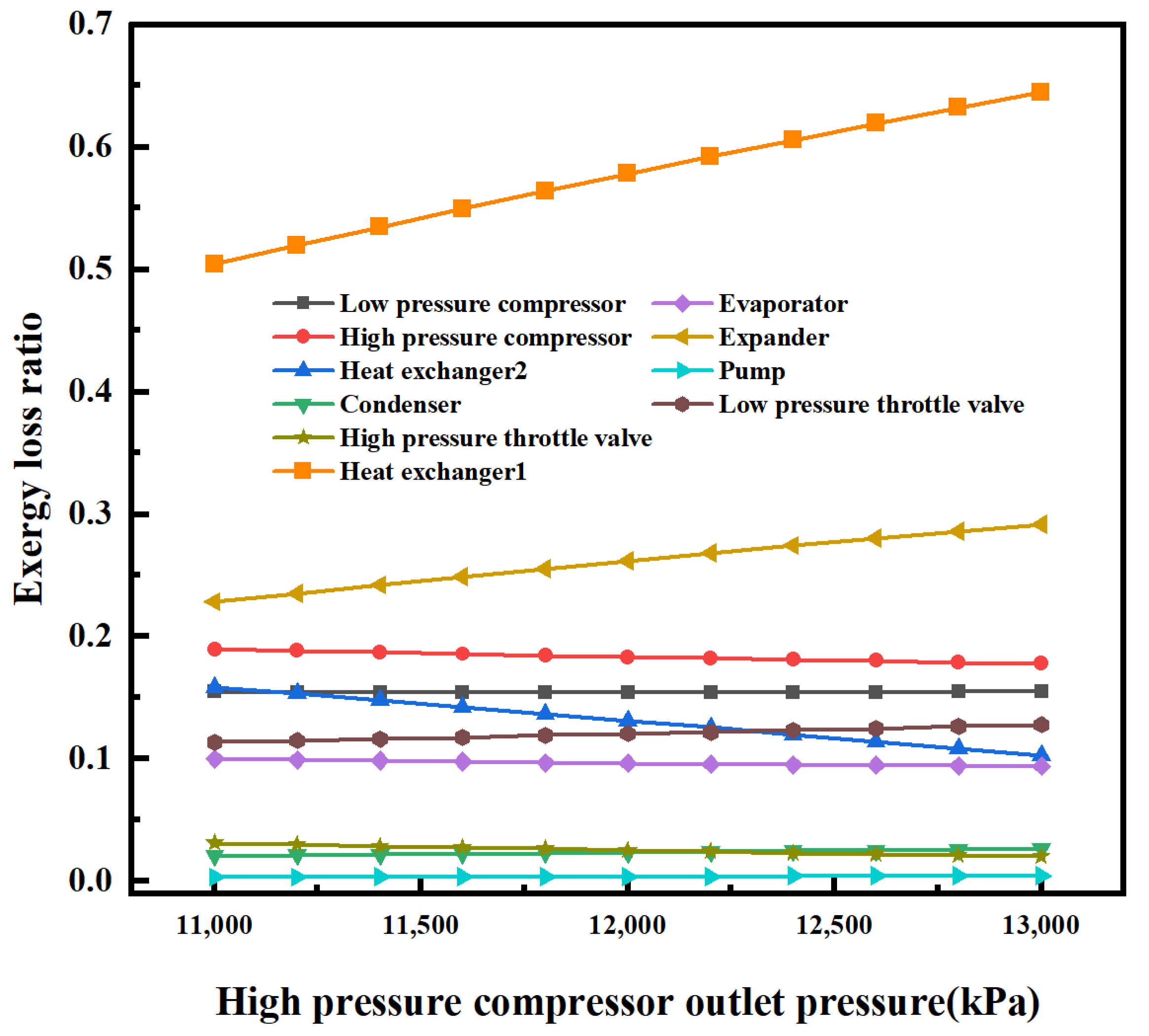

5.2.2. Analysis of the Influence of Exergy Loss Ratio on the Change of Outlet Pressure of High-Pressure Compressor

5.3. Economic Analysis

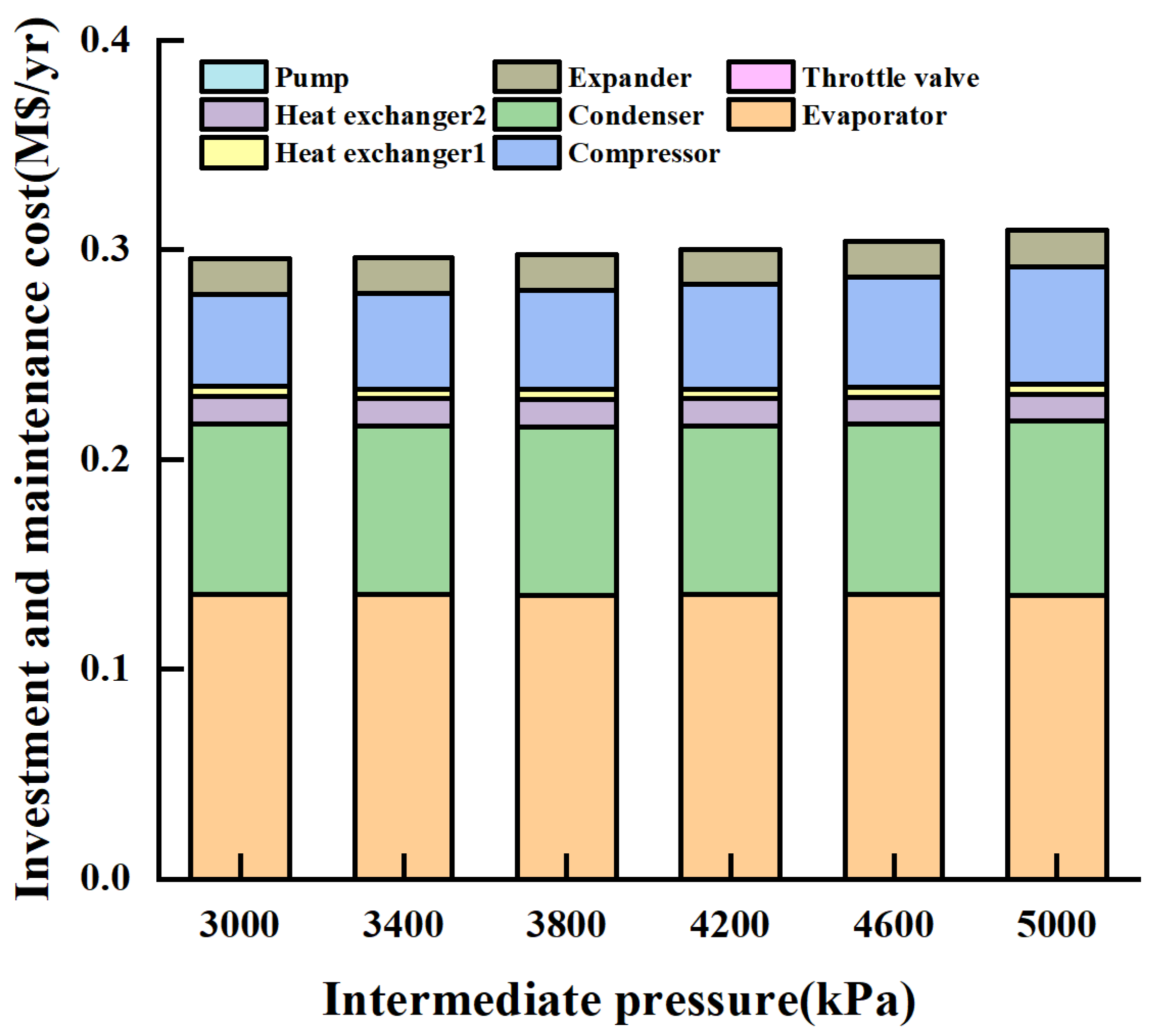

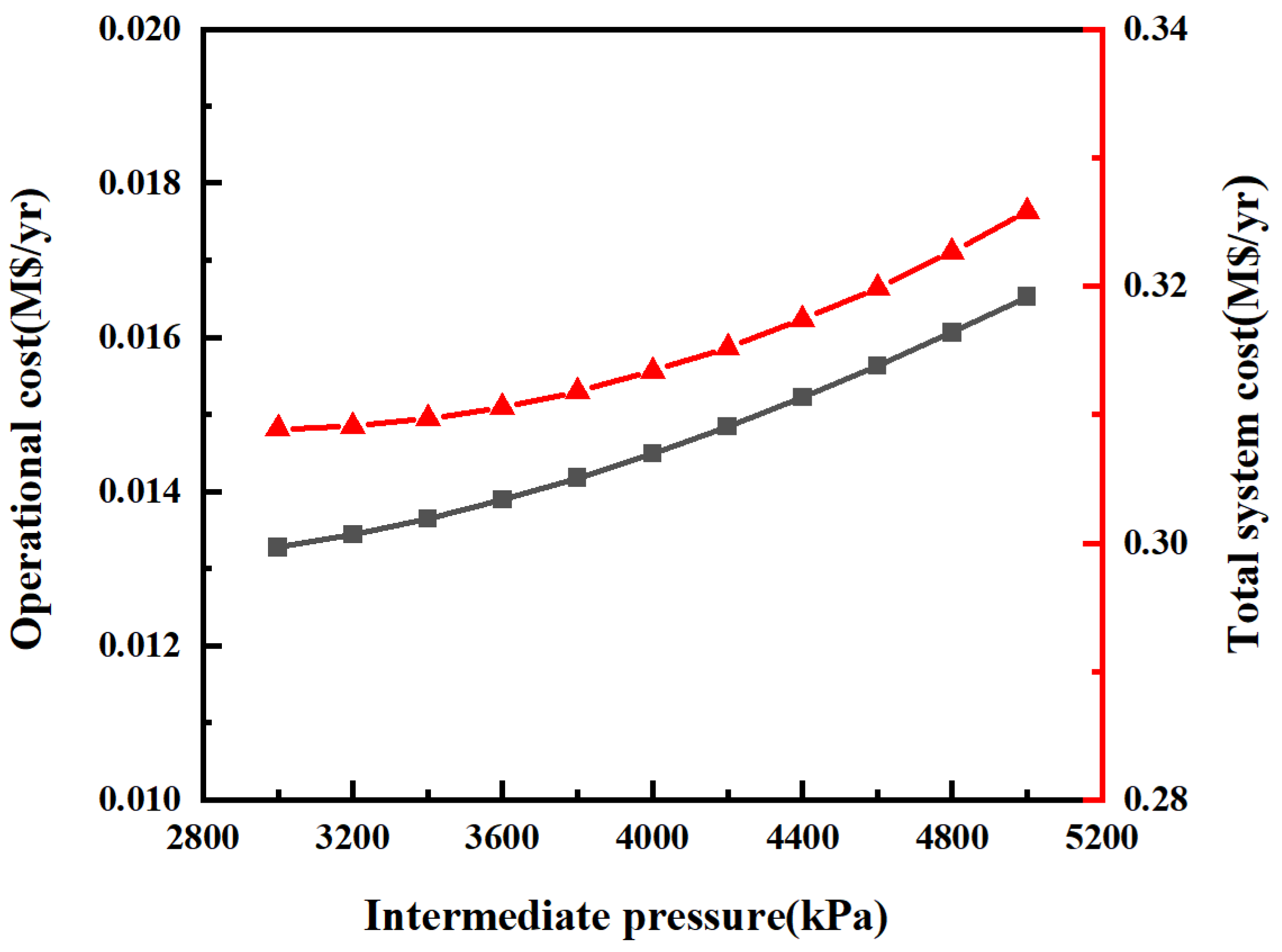

5.3.1. Economic Analysis of Coupling Systems under Different Intermediate Pressure

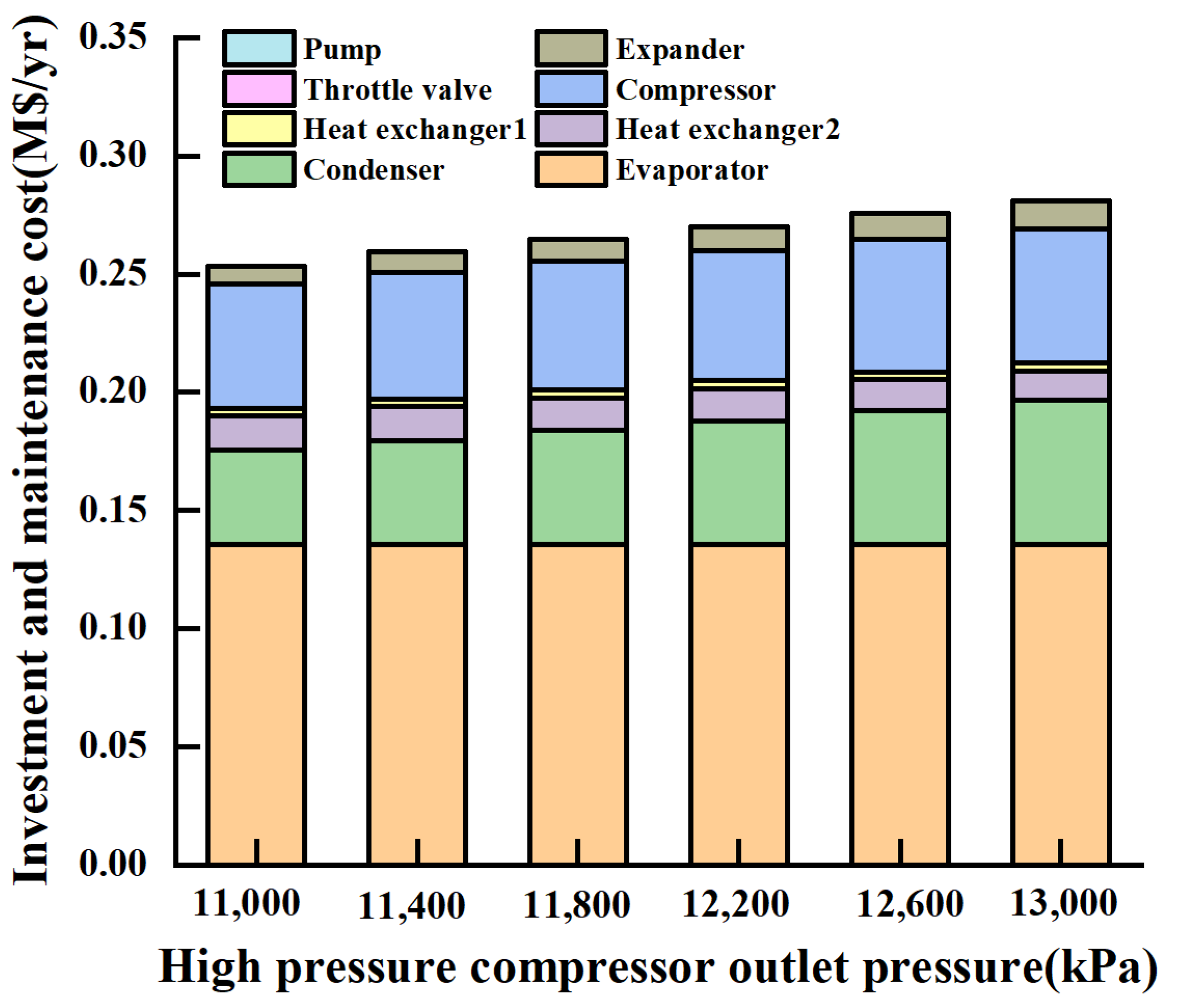

5.3.2. Economic Analysis of Coupling System under Different High Pressure Compressor Outlet Pressure

6. Conclusions

- In terms of the energy analysis, the effect of adding an ORC system for waste heat recovery on the system performance was simulated. It was verified that the system COP increased with the increase in the high-pressure compressor outlet pressure, while the trend increased and then decreased with the increase in intermediate pressure, and the results prove that the optimized energy efficiency had a large improvement.

- In terms of the exergy analysis, the exergy loss rate of each component of the coupled system was calculated. Heat exchanger 1 had the largest heat loss and was significantly higher than the other components when the intermediate pressure and the high-pressure compressor outlet pressure were varied, respectively.

- In terms of economic analysis, the economic cost of the coupled system was calculated. Among all of the components, the evaporator had the highest capital investment and maintenance costs, followed by the condenser and the compressor. Furthermore, as the intermediate pressure and the high-pressure compressor outlet pressure increase, the total system cost also continuously increases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations | |

| COP | Coefficient of performance |

| CRF | Capital recovery factor |

| Symbols | |

| A | Area (m2) |

| Cost rate ($/year) | |

| F | Correction factor |

| h | Specific enthalpy (kJ/kg) |

| Exergic loss (kW) | |

| i | Annual interest rate |

| Mass flow rate (kg/s) | |

| n | System lifetime (years) |

| N | Annual operational hours (h) |

| Heat transfer rate (kW) | |

| R | Exergic loss ratio |

| RC | Change rate |

| s | Specific entropy (kJ/kg K) |

| T | Temperature (K or °C) |

| U | Overall heat transfer coefficient (kW/m2 K) |

| Power consumption (kW) | |

| Capital cost rate ($/year) | |

| Z | Capital cost ($) |

| Greek symbols | |

| Cost of electricity ($/kWh) | |

| Maintenance factor | |

| Efficiency(%) | |

| Difference | |

| Subscripts | |

| 0 | Ambient state |

| c | Condenser |

| ci | Condenser side water inlet |

| co | Condenser side water outlet |

| comd | Low-pressure compressor |

| comg | High-pressure compressor |

| e | Expander |

| ei | Evaporator side air inlet |

| eo | Evaporator side air outlet |

| ev | Evaporator |

| he | Heat exchanger |

| k | kth component |

| net | Net work |

| p | Pump |

| thd | Low-pressure stage throttle valve |

| thg | High-pressure stage throttle valve |

| tot | The whole system |

References

- Kasaeian, A.; Hosseini, S.M.; Sheikhpour, M.; Mahian, O.; Yan, W.M.; Wongwises, S. Applications of eco-friendly refrigerants and nanorefrigerants: A review. Renew. Sustain. Energy Rev. 2018, 96, 91–99. [Google Scholar] [CrossRef]

- Emani, M.S.; Kumar Mandal, B. The use of natural refrigerants in refrigeration and air con-ditioning systems: A review. Iop. Conf. 2018, 377, 012064. [Google Scholar]

- Wang, H.; Zhao, L.; Cao, R.; Zeng, W. Refrigerant alternative and optimization under the constraint of the greenhouse gas emissions reduction target. J. Clean. Prod. 2021, 296, 126580. [Google Scholar] [CrossRef]

- Zhao, Y.A.; Bf, A.; Hm, B.; Lei, Z.A.; Cd, B.; Bing, L.A. Analysis of lower gwp and flammable alternative refrigerants. Int. J. Refrig. 2021, 126, 12–22. [Google Scholar]

- Aktemur, C.; Ozturk, I.T.; Cimsit, C. Comparative energy and exergy analysis of a subcritical cascade refrigeration system using low global warming potential refrigerants. Appl. Therm. Eng. 2021, 184, 116254. [Google Scholar] [CrossRef]

- Halon, T.; Gil, B.; Zajaczkowski, B. Comparative investigation of low-GWP binary and ternary blends as potential replacements of HFC refrigerants for air conditioning systems. Appl. Therm. Eng. 2022, 210, 118354. [Google Scholar] [CrossRef]

- Belman-Flores, J.M.; Pérez-García, V.; Ituna-Yudonago, J.F.; Rodríguez-Muñoz, J.L.; Ramí-rez-Minguela, J.D.J. General aspects of carbon dioxide as a refrigerant. J. Energy S. Afr. 2014, 25, 96–106. [Google Scholar]

- Du, Y.; Tian, G.; Pekris, M. A comprehensive review of micro-scale expanders for carbon dioxide related power and refrigeration cycles. Appl. Therm. Eng. 2022, 201, 117722. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, L.; Chen, Y.; Tong, L. Effect of an internal heat exchanger on performance of the transcritical carbon dioxide refrigeration cycle with an expander. Entropy 2014, 16, 5919–5934. [Google Scholar]

- Casi, Á.; Aranguren, P.; Araiz, M.; Alegría, P.; Astrain, D. Impact of a thermoelectric subcooler heat exchanger on a carbon dioxide transcritical refrigeration facility. Appl. Therm. Eng. 2022, 215, 118866. [Google Scholar]

- Zhang, F.; Chen, B.; Liao, G.; Jiaqiang, E. Performance assessment and comparative study on novel carbon dioxide based power cycles for the cascade engine waste heat recovery. Appl. Therm. Eng. 2022, 214, 118764. [Google Scholar] [CrossRef]

- Dai, B.; Liu, S.; Zhu, K.; Sun, Z.; Ma, Y. Thermodynamic performance evaluation of transcritical carbon dioxide refrigeration cycle integrated with thermoelectric subcooler and expander. Energy 2017, 122, 787–800. [Google Scholar] [CrossRef]

- Crespi, F.; Gavagnin, G.; Sánchez, D.; Martínez, G.S. Analysis of the thermodynamic potential of supercritical carbon dioxide cycles: A systematic approach. J. Eng. Gas Turbines Power 2018, 140, 051701. [Google Scholar] [CrossRef]

- Kang, J.; Zhou, Z. Current Situation and Prospect of Supercritical Carbon Dioxide Cycle Power Generation Technology. World Sci. Res. J. 2021, 7, 111–121. [Google Scholar]

- Sadeghi, S.; Javani, N.; Ghandehariun, S.; Ahmadi, P. Design and optimization of a novel wind-powered liquefied air energy storage system integrated with a supercritical carbon dioxide cycle. Energy Storage 2021, 3, e274. [Google Scholar] [CrossRef]

- Sharan, P.; Neises, T.; Turchi, C. Thermal desalination via supercritical CO2 Brayton cycle: Optimal system design and techno-economic analysis without reduction in cycle efficiency. Appl. Therm. Eng. 2019, 152, 499–514. [Google Scholar] [CrossRef]

- Mohammadi, K.; Ellingwood, K.; Powell, K. Novel hybrid solar tower-gas turbine combined power cycles using supercritical carbon dioxide bottoming cycles. Appl. Therm. Eng. 2020, 178, 115588. [Google Scholar]

- Baheta, A.T.; Hassan, S.; Reduan, A.R.B.; Woldeyohannes, A.D. Performance investigation of transcritical carbon dioxide refrigeration cycle. Procedia Cirp. 2015, 26, 482–485. [Google Scholar] [CrossRef]

- Purjam, M.; Thu, K.; Miyazaki, T. Thermodynamic modeling of an improved transcritical carbon dioxide cycle with ejector: Aiming low-temperature refrigeration. Appl. Therm. Eng. 2021, 188, 116531. [Google Scholar] [CrossRef]

- Kwan, T.H.; Shen, Y.; Wu, Z.; Yao, Q. Performance analysis of the thermoelectric device as the internal heat exchanger of the trans-critical carbon dioxide cycle. Energy Convers. Manag. 2020, 208, 112585. [Google Scholar] [CrossRef]

- Dzido, A.; Wołowicz, M.; Krawczyk, P. Transcritical carbon dioxide cycle as a way to improve the efficiency of a Liquid Air Energy Storage system. Renew. Energy 2022, 196, 1385–1391. [Google Scholar] [CrossRef]

- Srinivasan, K. Identification of optimum inter-stage pressure for two-stage transcritical carbon dioxide refrigeration cycles. J. Supercrit. Fluids 2011, 58, 26–30. [Google Scholar]

- Sun, Y.; Wang, J.; Xie, J. Performance Optimizations of the Transcritical CO2 Two-Stage Compression Refrigeration System and Influences of the Auxiliary Gas Cooler. Energies 2021, 14, 5578. [Google Scholar] [CrossRef]

- Mohammadi, S.H. Theoretical investigation on performance improvement of a low-temperature transcritical carbon dioxide compression refrigeration system by means of an absorption chiller after-cooler. Appl. Therm. Eng. 2018, 138, 264–279. [Google Scholar]

- Liu, Y.; Liu, J.; Yu, J. Theoretical analysis on a novel two-stage compression transcritical CO2 dual-evaporator refrigeration cycle with an ejector. Int. J. Refrig. 2020, 119, 268–275. [Google Scholar]

- Teng, S.; Wang, M.; Xi, H.; Wen, S. Energy, exergy, economic (3E) analysis, optimization and comparison of different ORC based CHP systems for waste heat recovery. Case Stud. Therm. Eng. 2021, 28, 101444. [Google Scholar]

- Gupta, P.R.; Tiwari, A.K.; Said, Z. Solar organic Rankine cycle and its poly-generation applications—A review. Sustain. Energy Technol. Assess. 2022, 49, 101732. [Google Scholar]

- Canbolat, A.S.; Bademlioglu, A.H.; Kaynakli, O. A modeling of electricity generation by using geothermal assisted organic Rankine cycle with internal heat recovery. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 1–17. [Google Scholar] [CrossRef]

- Roy, D.; Samanta, S.; Ghosh, S. Techno-economic and environmental analyses of a biomass based system employing solid oxide fuel cell, externally fired gas turbine and organic Rankine cycle. J. Clean. Prod. 2019, 225, 36–57. [Google Scholar]

- Ni, T.; Si, J.; Lu, F.; Zhu, Y.; Pan, M. Performance analysis and optimization of cascade waste heat recovery system based on transcritical CO2 cycle for waste heat recovery in waste-to-energy plant. J. Clean. Prod. 2022, 331, 129949. [Google Scholar] [CrossRef]

- Toolbox, S.M. MATLAB; Mathworks Inc.: Natick, MA, USA, 1993. [Google Scholar]

- Lemmon, E.W.; Huber, M.L.; Mclinden, M.O. Nist Standard Referencedatabase 23: Reference Fluid Thermodynamic and Transport Properties-Refprop. 9.0; NIST NSRDS: Gaithersburg, MD, USA, 2010. [Google Scholar]

- Zhao, R.; Shen, J.; Hu, K.; Bian, Y. Thermo dynamic analysis of transcritical CO2 two-stage compression booster system. Refrigeration 2018, 46, 81–86. [Google Scholar]

- Aminyavari, M.; Najafi, B.; Shirazi, A.; Rinaldi, F. Exergetic, economic and environmental (3E) analyses, and multi-objective optimization of a CO2/NH3 cascade refrigeration system. Appl. Therm. Eng. 2014, 65, 42–50. [Google Scholar]

- Singh, K.K.; Kumar, R.; Gupta, A. Comparative energy, exergy and economic analysis of a cascade refrigeration system incorporated with flash tank (HTC) and a flash intercooler with indirect subcooler (LTC) using natural refrigerant couples. Sustain. Energy Technol. Assess. 2020, 39, 100716. [Google Scholar]

- Navidbakhsh, M.; Shirazi, A.; Sanaye, S. Four E analysis and multi-objective optimization of an ice storage system incorporating PCM as the partial cold storage for air-conditioning applications. Appl. Therm. Eng. 2013, 58, 30–41. [Google Scholar] [CrossRef]

- Bejan, A.; Tsatsaronis, G.; Moran, M.J. Thermal Design and Optimization; John Wiley & Sons: Hoboken, NJ, USA, 1995. [Google Scholar]

- Smith, R. Chemical Process Design and Integration; John Wiley & Sons: Chichester, UK, 2005. [Google Scholar]

- Fettaka, S.; Thibault, J.; Gupta, Y. Design of shell-and-tube heat exchangers using multiobjective optimization. Int. J. Heat Mass Transf. 2013, 60, 343–354. [Google Scholar]

- Herath, H.; Wijewardane, M.A.; Ranasinghe, R.; Jayasekera, J. Working fluid selection of organic rankine cycles. Energy Rep. 2020, 6, 680–686. [Google Scholar] [CrossRef]

- Chen, Y.G. Pinch point analysis and design considerations of CO2 gas cooler for heat pump water heaters. Int. J. Refrig. 2016, 69, 136–146. [Google Scholar] [CrossRef]

| Component | Energy Balance Equation | Exergy Balance Equation | Proportion of Exergy Loss of Each Component |

|---|---|---|---|

| Evaporator | |||

| Compressor 1 | |||

| Compressor 2 | |||

| Heat exchanger 1 | |||

| Heat exchanger 2 | |||

| Throttle valve 1 | |||

| Throttle valve 2 | |||

| Expander | |||

| Condenser | |||

| Pump |

| Parameters | Value |

|---|---|

| Two-stage CO2 cycle | |

| Cooling capacity () | 100 kW |

| Cold storage temperature () | 263.15 K |

| Evaporation temperature () | 253.15 K |

| Evaporator superheat | 5 K |

| Heat exchanger 2 outlet temperature () | 303.15 K |

| Indicated efficiency of compressor (, ) | 0.75 |

| ORC cycle | |

| Condenser outlet temperature () | 303.15 K |

| Temperature at point f inside heat exchanger 1 () | 343.15 K |

| Heat exchanger 1 outlet temperature () | 353.15 K |

| Isentropic efficiency of expander () | 0.85 |

| Isentropic efficiency of pump () | 0.85 |

| External work efficiency of expander () | 0.9 |

| Evaporating Pressure (MPa) | Gas Cooler Pressure (MPa) | Gas Cooler Exit Temperature (°C) | COP | |||

|---|---|---|---|---|---|---|

| R | M | D | ||||

| Group 1 | 4 | 11 | 40 | 3.16 | 3.17 | 0.32% |

| Group 2 | 4 | 10 | 35 | 3.82 | 3.91 | 2.36% |

| Group 3 | 4 | 13 | 35 | 3.18 | 3.20 | 0.63% |

| Evaporating Temperature (°C) | Condensation Temperature (°C) | Working Fluid | Thermal Efficiency | |||

|---|---|---|---|---|---|---|

| R | M | D | ||||

| Group 1 | 101.23 | 35 | R245fa | 0.133 | 0.124 | 6.77% |

| Group 2 | 104.61 | 35 | R245fa | 0.138 | 0.129 | 6.52% |

| Group 3 | 107.81 | 35 | R245fa | 0.144 | 0.134 | 6.94% |

| Component | Capital Cost Function (M$/yr) | |

|---|---|---|

| 4000 kPa | 5000 kPa | |

| Compressor | 0.0484 | 0.0559 |

| Evaporator | 0.1354 | 0.1354 |

| Throttle valve | 1.1376 × 10−8 | 1.1378 × 10−8 |

| Expander | 0.0169 | 0.0174 |

| Heat exchanger 1 | 0.0048 | 0.0048 |

| Heat exchanger 2 | 0.0131 | 0.0131 |

| Condenser | 0.0803 | 0.0828 |

| Pump | 7.2690 × 10−9 | 7.4911 × 10−9 |

| Component | Capital Cost Function (M$/yr) | |

|---|---|---|

| 12,000 kPa | 13,000 kPa | |

| Compressor | 0.0547 | 0.0564 |

| Evaporator | 0.1354 | 0.1354 |

| Throttle valve | 1.1385 × 10−8 | 1.1215 × 10−8 |

| Expander | 0.0098 | 0.0119 |

| Heat exchanger 1 | 0.0034 | 0.0038 |

| Heat exchanger 2 | 0.0136 | 0.0124 |

| Condenser | 0.0506 | 0.0611 |

| Pump | 5.8801 × 10−9 | 7.1016 × 10−8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, K.; Zhang, Y.; Yang, W.; Liu, Z.; Sun, H.; Sun, Z. Energy, Exergy, and Economic (3E) Analysis of Transcritical Carbon Dioxide Refrigeration System Based on ORC System. Energies 2023, 16, 1675. https://doi.org/10.3390/en16041675

Hu K, Zhang Y, Yang W, Liu Z, Sun H, Sun Z. Energy, Exergy, and Economic (3E) Analysis of Transcritical Carbon Dioxide Refrigeration System Based on ORC System. Energies. 2023; 16(4):1675. https://doi.org/10.3390/en16041675

Chicago/Turabian StyleHu, Kaiyong, Yumeng Zhang, Wei Yang, Zhi Liu, Huan Sun, and Zhili Sun. 2023. "Energy, Exergy, and Economic (3E) Analysis of Transcritical Carbon Dioxide Refrigeration System Based on ORC System" Energies 16, no. 4: 1675. https://doi.org/10.3390/en16041675

APA StyleHu, K., Zhang, Y., Yang, W., Liu, Z., Sun, H., & Sun, Z. (2023). Energy, Exergy, and Economic (3E) Analysis of Transcritical Carbon Dioxide Refrigeration System Based on ORC System. Energies, 16(4), 1675. https://doi.org/10.3390/en16041675