Electric Vehicle Supply Chain Management: A Bibliometric and Systematic Review

Abstract

:1. Introduction

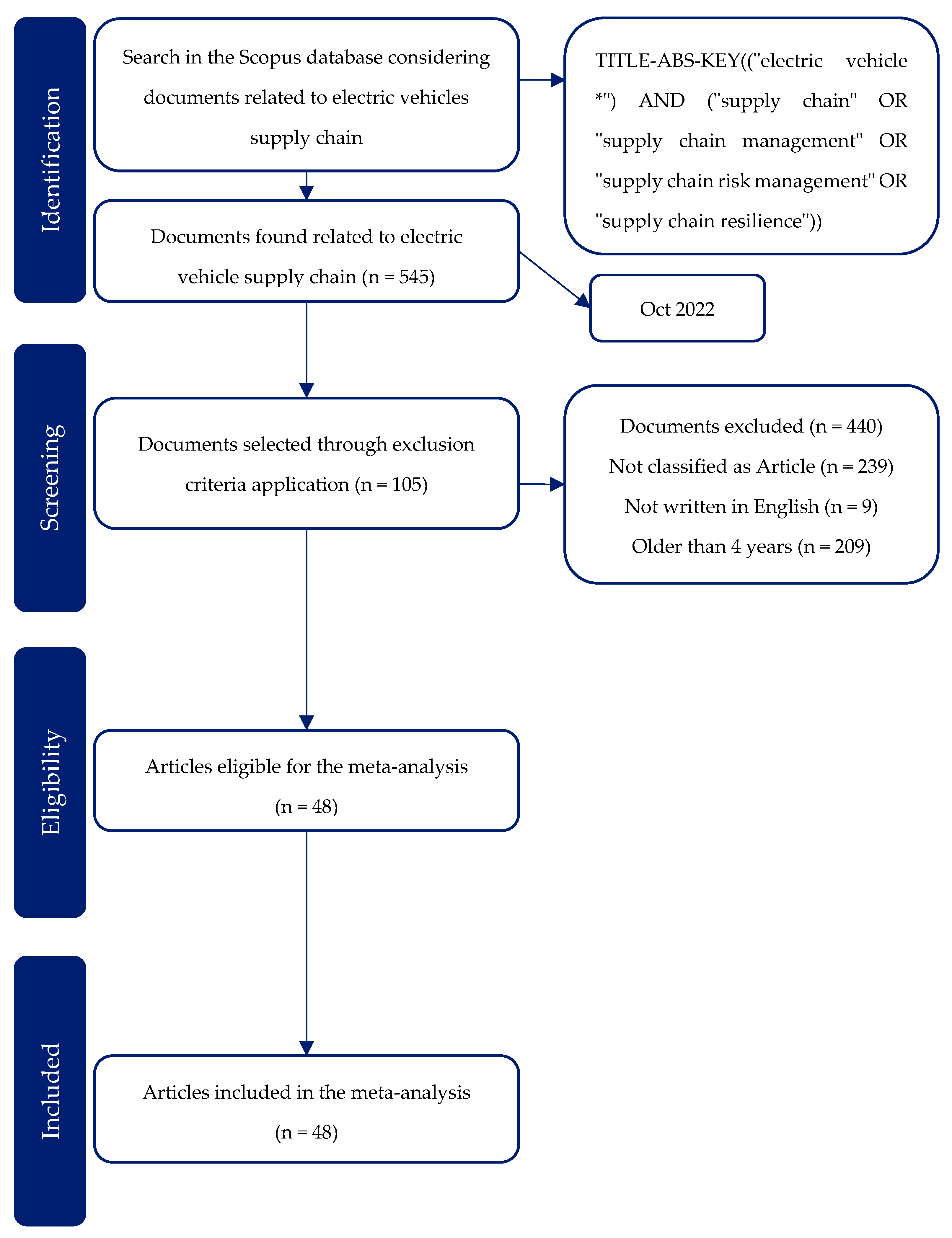

2. Materials and Methods

2.1. Bibliometric Review

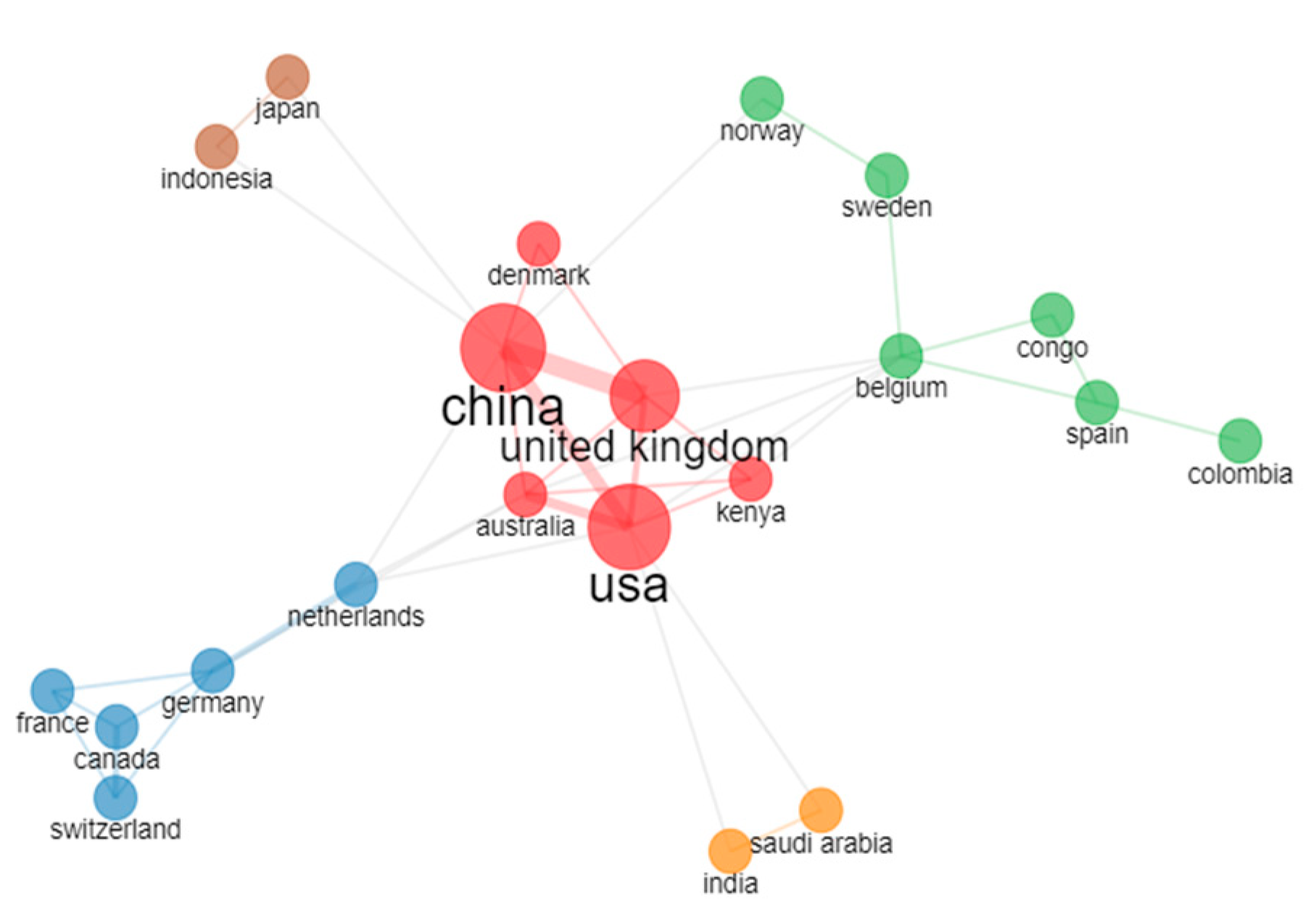

2.1.1. Partnership between Countries

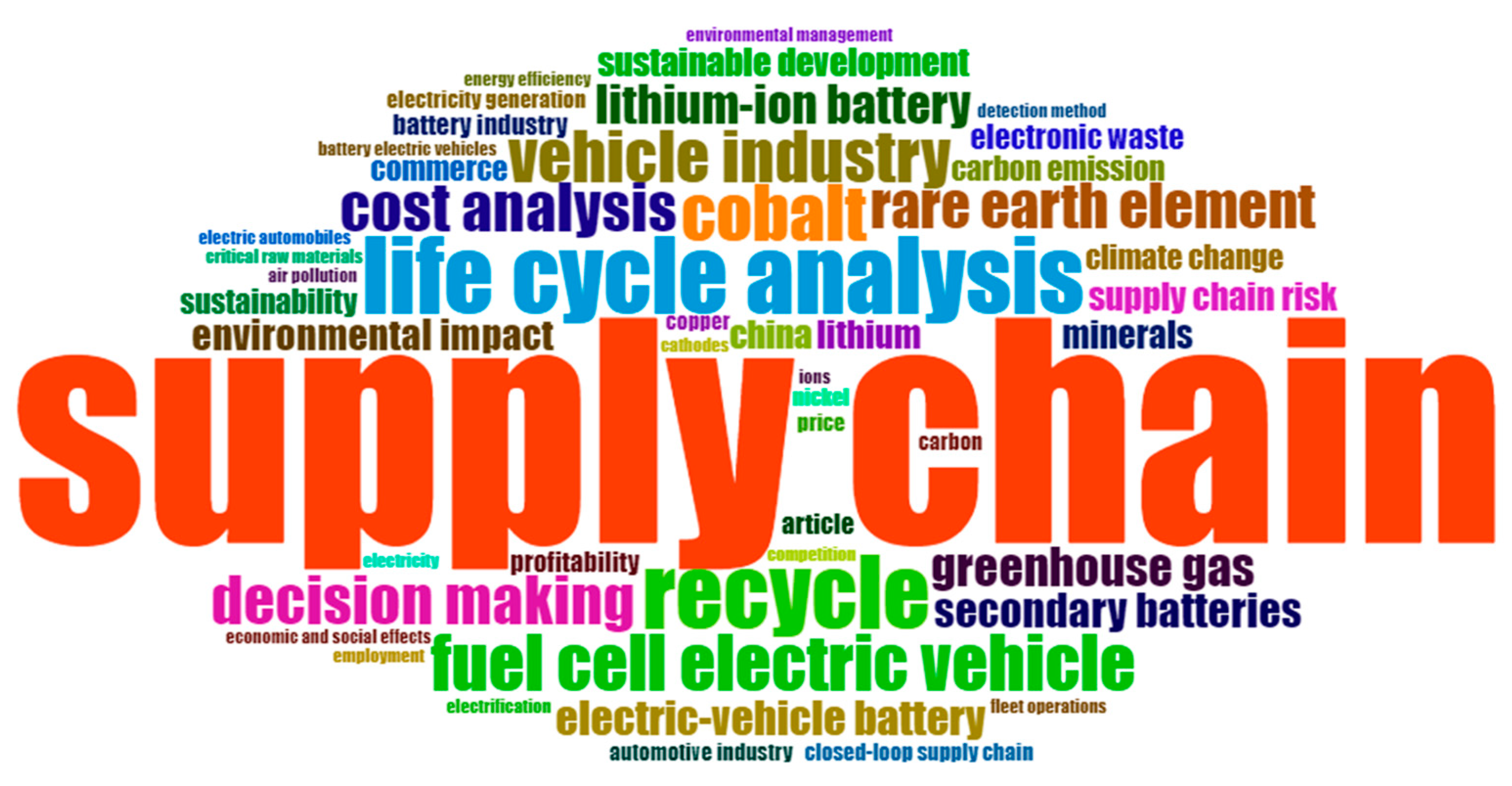

2.1.2. Co-Occurrence of the Authors’ Keywords

2.1.3. Publications Per Year

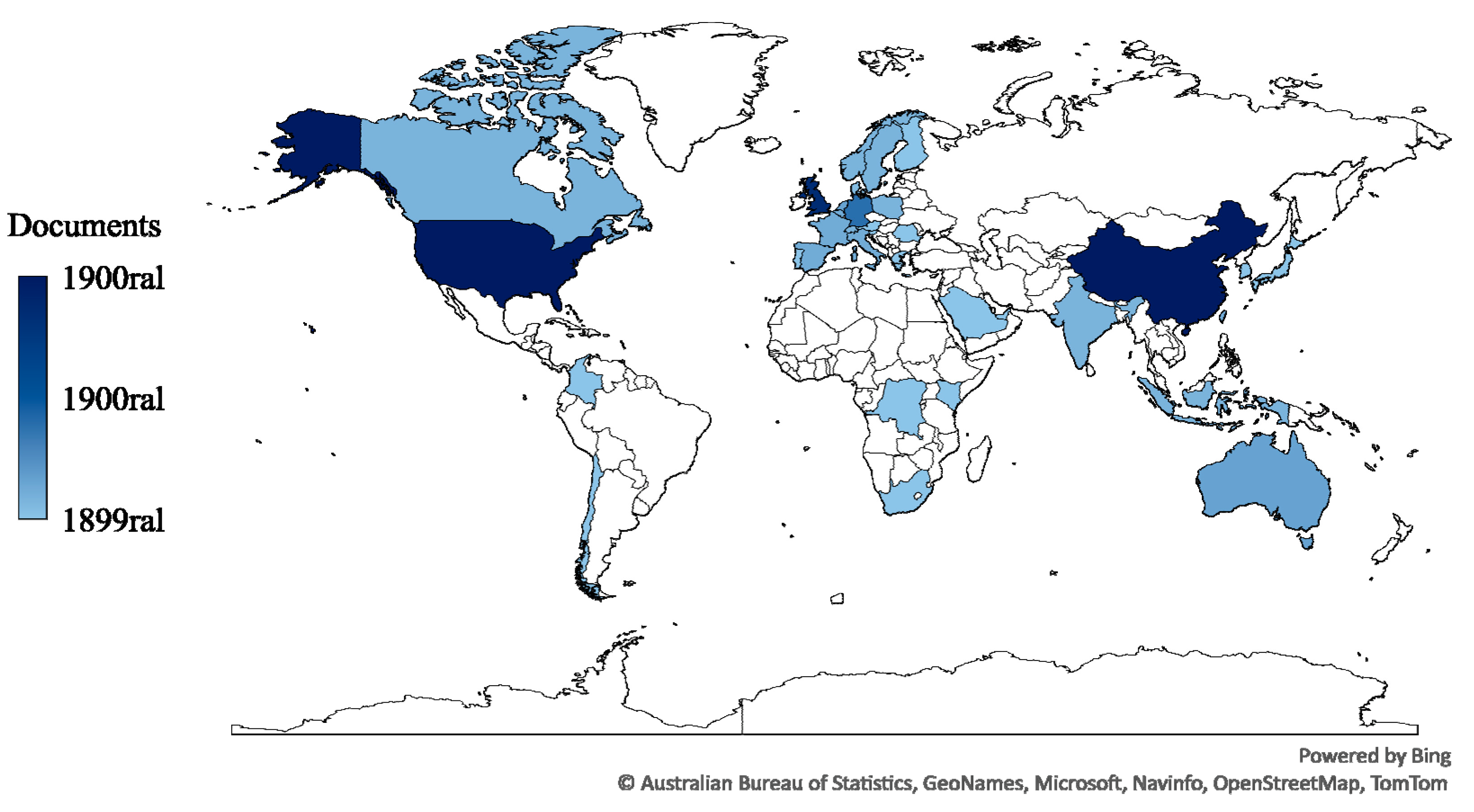

2.1.4. Publications by Country

2.1.5. Impact Factor of Journals

2.1.6. Areas of Research

2.2. Systematic Review

- At what point in the supply chain was the study focused?

- What type of analysis was used?

- Which supply chain process was analysed?

- Which component did the analysis focus on?

3. Results and Discussion

3.1. Partnerships between Countries

3.2. Co-Occurrence of Authors’ Keywords

3.3. Publications Per Year

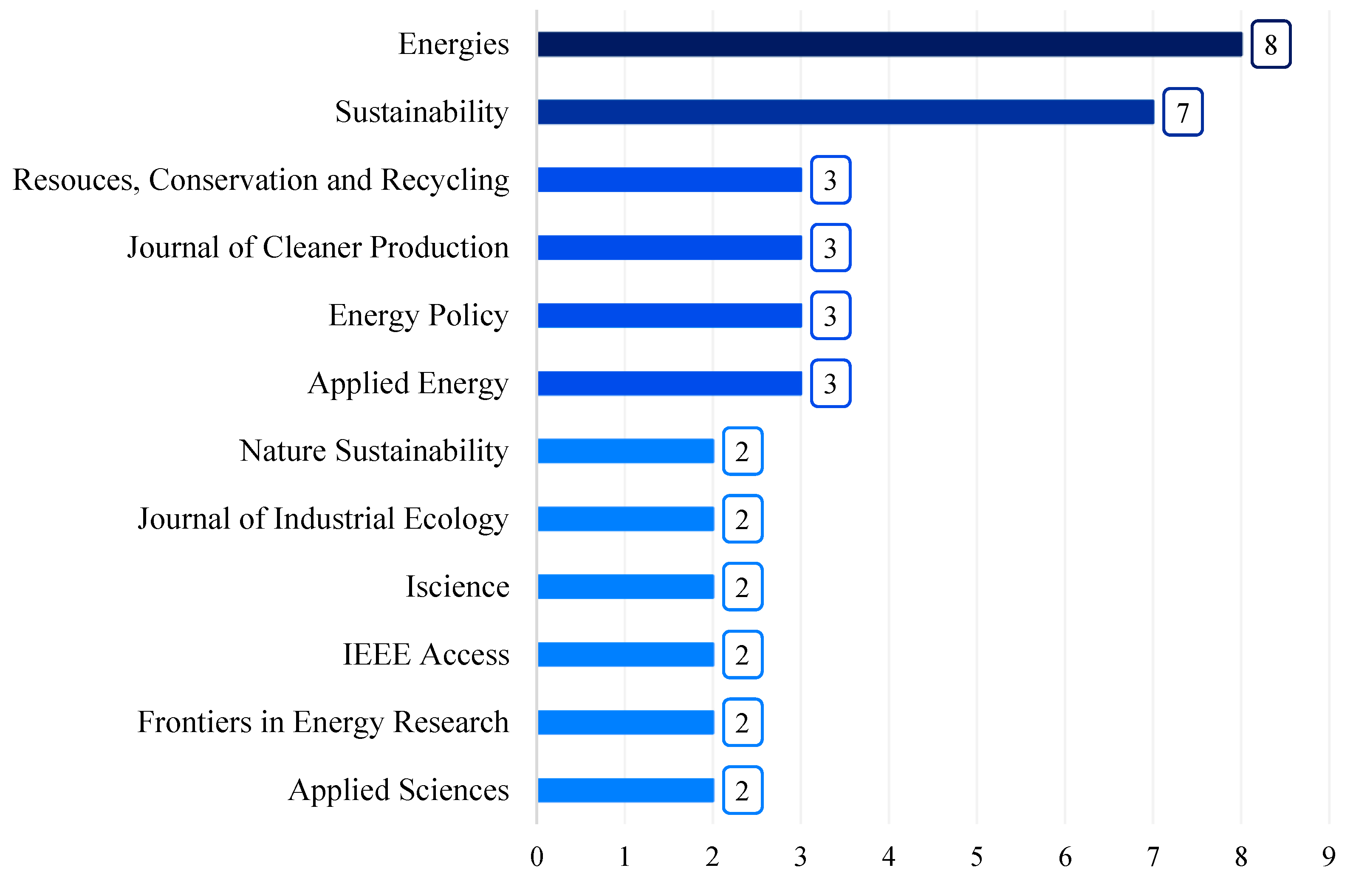

3.4. Publications by Country

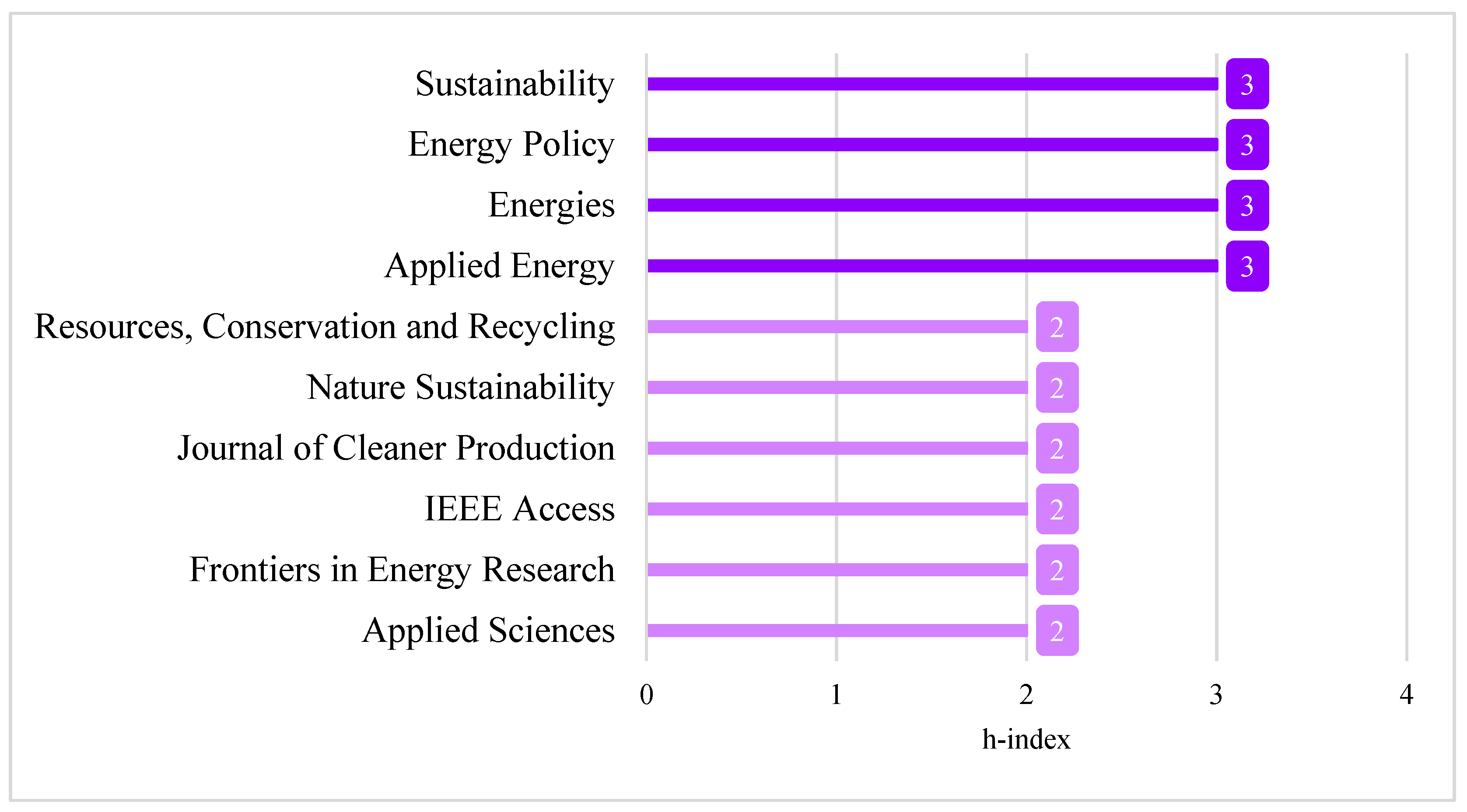

3.5. Impact Factor by Journals

3.6. Areas of Research

3.7. PRISMA Meta-Analysis

- At what point in the supply chain was the study focused? In Appendix A, it is possible to observe that raw material supply chain management was extensively studied. However, the focus of the studies was on recycling components for reuse in remanufacturing processes. This view was supported by the authors’ keywords indicator used in the bibliometric analysis. Recycling is seen as an alternative to reduce metal and mineral extraction practices and reduce negative environmental impacts related to improper disposal of chemical components. Moreover, it appeared as the focus even before the COVID-19 pandemic. The approaches to reuse and allocation of electric vehicle batteries, which can be understood as the use of a component for another purpose, have been poorly analysed and further studies should focus on this point. This can be easily found in studies that investigate electric vehicle batteries in the energy storage system.

- What type of analysis was used? Environmental impact assessments were presented in several studies. Highlighting the environmental impacts caused by the production of chemical components and their inappropriate disposal allows decision-makers and government agencies, together with society, to create awareness programs and encourage recycling. Not only must the environmental analysis be conducted, but also the costs and profits analysis in the production chain, because when the cost of recycling exceeds the profit of the manufacturer, there is no interest in mitigating pollution. This emphasizes the need for contributions from government agencies to create subsidies in this sector. The importance of cost analysis is illustrated by the number of studies found on this topic. In addition, life cycle assessment was the third most studied term. However, the analysis and development of policies and subsidies have been little studied and require further investigations so that electric vehicles and their supply chains are viable and arouse consumers’ interest in purchasing electric vehicles. Regarding the bibliometric analysis, this question can be easily answered by the authors’ keywords and partnership between countries indicators, which led to similar conclusions.

- Which supply chain process was analysed? The keyword “supply chain risk management” does not appear among the keywords indexed in the articles found. However, this term was the most recurrent topic when assessing the risks related to the raw material of chemical components of electric vehicle batteries. Additionally, several studies applied the concept of a closed-loop supply chain, which considers the production chain and the collection of the product at the end of its useful life. Although this concept was scarcely discussed in the bibliometric review of this work, through the authors’ keywords indicator, its frequency among the selected articles in the systematic analysis reinforces the importance of applying the closed-loop supply chain concept in different areas. This could be because the keyword “closed-loop supply chain” was not frequently included in the keyword section. The partnership between countries is another bibliometric indicator that can answer this question since cooperation in studies arose from the need to bring together pioneering countries in extracting critical materials to mitigate demand and supply risks. On the other hand, the application of methods that enable transparency between supply chain processes, and their sustainability, is still poorly studied, which suggests a possible direction for further studies.

- Which component did the analysis focus on? Electric vehicle batteries were the focus of the supply chain analysis, and cobalt and lithium were the most studied elements. Considering the studies analysed in the bibliometric review and the authors’ keywords indicator, the demand for these elements tends to increase proportionally with the number of electric vehicles, since they are important constituents of the lithium-ion battery. In this way, the researchers sought to investigate alternative ways of meeting the demand for cobalt and lithium, mainly through recycling. Other important chemical components such as nickel and other critical raw materials (i.e., aluminium, copper, and manganese), and rare-earth elements were also analysed. Only one selected article analysed a specific point in the electric vehicle supply chain, which was the use of steel for chassis manufacturing. The recycling of electric and electronic equipment was rarely analysed among the selected articles. Therefore, these are points that further studies can focus on.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Title [Reference] | Keywords | (I) at What Point in the Supply Chain Was the Study Focused? | (II) What Type of Analysis/Model Was Used? | (III) Which Supply Chain Process Was Analysed? | (IV) Which Component Did the Analysis Focus on? |

|---|---|---|---|---|---|

| The Rare Earth Elements: Demand, Global Resources, and Challenges for Resourcing Future Generations [26] | Rare earth elements; Resources; Supply chain; Minerals processing | Raw material supply | Not specified. | Supply chain risk management. | Rare earth elements |

| Sustainability of artisanal mining of cobalt in DR Congo [27] | - | Raw material supply | Environmental assessment; Exposure assessment. | Supply chain risk management; Sustainable supply chain management. | Cobalt |

| Sustainable minerals and metals for a low-carbon future [28] | - | Recycling | Environmental assessment; Policy recommendations | Closed-loop supply chain. | Exposed 35 critical materials, including: Cobalt, Graphite, Lithium, Manganese, and Rare earth elements |

| The case for recycling: Overview and challenges in the material supply chain for automotive li-ion batteries [29] | Cathode; Electric vehicles; End-of-lifeLi-ion batteries; Recycling | Recycling | Value of final product | Closed-loop supply chain. | Cobalt; Nickel; Manganese; Aluminium; Lithium; Graphite |

| Future material demand for automotive lithium-based batteries [30] | - | Recycling | Sensitivity analysis | Closed-loop supply chain. | Cobalt; Nickel; Manganese; Lithium |

| Circular economy strategies for electric vehicle batteries reduce reliance on raw materials [31] | - | Raw material supply; Recycling | Material flow analysis | Closed-loop supply chain. | Cobalt |

| Modelling reverse supply chain through system dynamics for realizing the transition towards the circular economy: A case study on electric vehicle batteries [32] | Circular economy; Reverse logistics; Remanufacturing; System dynamics (SD); Electric vehicle battery (EVB); Repurposing | Remanufacturing; Repurposing | System dynamics; Cost analysis | Reverse supply chain | Battery |

| Title [Reference] | Keywords | (I) at What Point in the Supply Chain Was the Study Focused? | (II) What Type of Analysis/Model Was Used? | (III) Which Supply Chain Process Was Analysed? | (IV) Which Component Did the Analysis Focus on? |

|---|---|---|---|---|---|

| Developing pricing strategy to optimise total profits in an electric vehicle battery closed loop supply chain [33] | Closed-loop supply chain; Electric vehicle battery; Recycle; Reuse; Profit | Manufacturing; Remanufacturing | Total profit analysis | Closed-loop supply chain. | Battery |

| Critical raw materials and transportation sector electrification: A detailed bottom-up analysis in world transport [36] | World transportation; Electrification; Critical raw materials; Lithium; Bottom-up modelling | Raw material supply | Times integrated assessment model | Not specified. | Lithium |

| Lithium Iron Aluminium Nickelate, LiNixFeyAlzO2—New Sustainable Cathodes for Next-Generation Cobalt-Free Li-Ion Batteries [34] | Cobalt-free cathodes; Iron redox; Layered cathodes; Lithium-ion batteries; Nickel-rich materials | Raw material supply | Neutron diffraction analysis; Microstructural analysis; Compositional analysis | Not specified. | Battery |

| The EV revolution: The road ahead for critical raw materials demand [35] | Decarbonisation; Electric vehicles; Metal; Mined commodities | Raw material supply; Recycling | Cost, Macro, Iinfrastructure, Technology (CoMIT) model | Supply chain risk management | Lithium, Cobalt |

| Optimising quantity of manufacturing and remanufacturing in an electric vehicle battery closed-loop supply chain [37] | Closed-loop supply chain; Recycle; Profit; Reuse; Electric vehicle battery; Purchasing price | Manufacturing; Remanufacturing | Nash equilibirum; Profit analysis; Purshasing price analysis | Closed-loop supply chain. | Battery |

| Raw material criticality assessment as a complement to environmental life cycle assessment: Examining methods for product-level supply risk [38] | Critical raw material; Industrial ecology; Life cycle assessment; Life cycle sustainability assessment; Raw material criticality assessment; Supply risk | Raw material supply | Life cycle assessment; Life cycle sustainability assessment;Raw material criticality assessment | Supply chain risk management | Critical raw materials |

| Title [Reference] | Keywords | (I) at What Point in the Supply Chain Was the Study Focused? | (II) What Type of Analysis/Model Was Used? | (III) Which Supply Chain Process Was Analysed? | (IV) Which Component Did the Analysis Focus on? |

|---|---|---|---|---|---|

| Globally regional life cycle analysis of automotive lithium-ion nickel manganese cobalt batteries [39] | Lithium-ion battery; Life cycle assessment; Automotive; Supply chain | Raw material supply | Life cycle analysis | Supply chain risk management | Lithium; Cobalt; Nickel |

| Impacts of COVID-19 on the electric vehicle industry: Evidence from China [40] | COVID-19 impacts; Electric vehicle; Market analysis; Supply chain; Policy trend; Future outlook | Raw material supply; Manufacturer; Distributors; Consumers | Not specified. | Supply chain risk management | Not specified. |

| LiNixFeyAlzO2, a new cobalt-free layered cathode material for advanced Li-ion batteries [41] | Li-ion batteries; Cobalt-free; Layered cathodes; NFA; Electrochemistry; Electric vehicles | Raw material supply | Complex non-linear least-squares regression analysis. | Not specified. | Cobalt-free NFA class cathodes |

| Financial viability of electric vehicle lithium-ion battery recycling [42] | - | Recycling | Cost analysis; Profit analysis | Supply chain risk management | Battery |

| Electric vehicle battery secondary use under government subsidy: A closed-loop supply chain perspective [43] | Battery secondary use; Recycle and remanufacturing; Incentive policy design | Reuse; Recycling; Remanufacturing | Political analysis | Closed-loop supply chain | Battery |

| Electric vehicle battery capacity allocation and recycling with downstream competition [44] | Supply chain management; Electric vehicle; Channel choice; Capacity allocation; Battery recycling | Recycling; Allocation | Equilibrium analysis; Profit analysis | Not specified. | |

| Li-ion batteries: A review of a key technology for transport decarbonization [45] | Lithium batteries; Electric vehicles; Sustainability; Emissions; Environment | Raw material supply | Environmental assessment and impacts; Cost analysis | Supply chain risk management | Lithium; Cobalt; Nickel; Graphite; Rare-earth elements |

| Title [Reference] | Keywords | (I) at What Point in the Supply Chain Was the Study Focused? | (II) What Type of Analysis/Model Was Used? | (III) Which Supply Chain Process Was Analysed? | (IV) Which Component Did the Analysis Focus on? |

|---|---|---|---|---|---|

| Managing resource dependencies in electric vehicle supply chains: a multi-tier case study [46] | Electric vehicle; Resource dependence theory; Supply chain management; Production ramp-up; Case study | Supply | Process-orientated honolic model; Cost analysis | Supply chain risk management | Not specified. |

| Energy, greenhouse gas, and water life cycle analysis of lithium carbonate and lithium hydroxide monohydrate from brine and ore resources and their use in lithium ion battery cathodes and lithium ion batteries [47] | Lithium; Life cycle analysis; Battery electric vehicle; Brine-vs. ore-based lithium; Salar de Atacama | Raw material supply | Life cycle analysis | Supply chain risk management | Lithium |

| Global Electrification of Vehicles and Intertwined Material Supply Chains of Cobalt, Copper and Nickel [2] | - | Raw material supply | Sensitivity analysis | Supply chain risk management | Cobalt; Copper; Nickel |

| Mineral processing simulation based-environmental life cycle assessment for rare earth project development: A case study on the Songwe Hill project [48] | Rare earth elements; Mineral processing simulation; Life cycle assessment (LCA); Process simulation; Energy selection | Raw material supply | Life cycle analysis; Environmental analysis | Not specified. | Rare earth elements |

| Transparency for multi-tier sustainable supply chain management: A case study of a multi-tier transparency approach for SSCM in the automotive industry [49] | Sustainable supply chain management (SSCM); Supply chain transparency; Multi-tier SSCM; Sustainability; Automotive industry; Case study research | Raw material supply | Within-case analysis | Sustainable supply chain management; Supply chain transparency | Cobalt |

| Title [Reference] | Keywords | (I) at What Point in the Supply Chain Was the Study Focused? | (II) What Type of Analysis/Model Was Used? | (III) Which Supply Chain Process Was Analysed? | (IV) Which Component Did the Analysis Focus on? |

|---|---|---|---|---|---|

| Emerging supply chain of utilising electrical vehicle retired batteries in distributed energy systems [50] | Electrical vehicle (EV); Retired battery; Distributed energy system (DES); Supply chain; Game theory; Optimisation model | Recycling | Profit-allocation model; Distributed energy system design optimisation model | Not specified. | Battery |

| Enabling the Electric Future of Mobility: Robotic Automation for Electric Vehicle Battery Assembly [51] | Automation; Digital simulation; Digital twin; Electric vehicles; EV batteries; Industrial robots; Lithium-ion batteries; Robots; Robotic assembly | Manufacturing | Not specified. | Supply chain risk management | Battery |

| Recycling 4.0-digitalization as a key for the advanced circular economy [52] | Industry 4.0; Intelligent systems; Internet of Things (IoT); Recycling; Information marketplace; Sustainability | Recycling | Holistic approach | Circular economy | Battery |

| An Obsolescing Bargain in a Rentier State: Multinationals, artisanal miners, and cobalt in the Democratic Republic of Congo [53] | DRC; Rentier state; Obsolescing bargain; Cobalt; ASM; Electric vehicle; Responsible sourcing; Political economy | Raw material supply | Political-economy analysis | Supply chain risk management | Cobalt |

| Closed-loop supply chain planning model of rare metals [54] | Rare metal; Closed-loop supply chain; Supply chain planning model; Sustainable supply chain; Extended producer responsibility; Rare metal stockpile | Raw material supply; Recycling | Supply chain planning model; Sensitivity analysis | Closed-loop supply chain. | Rare earth elements |

| Title [Reference] | Keywords | (I) at What Point in the Supply Chain Was the Study Focused? | (II) What Type of Analysis/Model Was Used? | (III) Which Supply Chain Process Was Analysed? | (IV) Which Component Did the Analysis Focus on? |

|---|---|---|---|---|---|

| Implementation of Hybrid Blockchain in a Pre-Owned Electric Vehicle Supply Chain [55] | Automobile sector; Blockchain; Distributed ledger; Cloud; Mobile application; Ethereum sandbox; Meta mask; Transaction; Vehicle; Transparency; Truffle; QR code | Manufacturing | Not specified. | Supply chain transparency; Blockchain | Not specified. |

| Challenges to the European automotive industry in securing critical raw materials for electric mobility: The case of rare earths [56] | Rare earths; Critical metals; Criticality; Mitigation strategies; Electric vehicles; Automotive industry | Raw material supply | Not specified. | Supply chain risk management | Rare earth elements |

| Sources of uncertainty in the closed-loop supply chain of lithium-ion batteries for electric vehicles [57] | Supply chain uncertainty; Closed-loop supply chain; Electric vehicle; Lithium-ion battery; Automotive industry | Recycling | Uncertainty analysis | Closed-loop supply chain | Battery |

| Prospective environmental impacts of passenger cars under different energy and steel production scenarios [58] | Life cycle assessment; Battery electric vehicles; Plug-in electric vehicles; Fossil-free steel; Prospective LCA | Supply | Life cycle assessment; Environmental impacts | Not specified. | Iron; Steel |

| Assessment of the supply chain under uncertainty: The case of Lithium [59] | Lithium; Batteries; Electric vehicles; Supply chain; Demand; Uncertainty | Raw material supply | Uncertainty analysis; Material flow analysis | Not specified. | Lithium |

| Agent-based modelling of supply disruptions in the global rare earths market [60] | Rare earth; Critical material; Agent-based model; Supply disruption; Supply chain | Raw material supply | Agent-based model | Supply chain risk management | Rare earth elements |

| Title [Reference] | Keywords | (I) at What Point in the Supply Chain Was the Study Focused? | (II) What Type of Analysis/Model Was Used? | (III) Which Supply Chain Process Was Analysed? | (IV) Which Component Did the Analysis Focus on? |

|---|---|---|---|---|---|

| From “obligated embeddedness” to “obligated Chineseness”? Bargaining processes and evolution of international automotive firms in China’s New Energy Vehicle sector [61] | - | Supply; Manufacturing | Not specified. | Supply chain risk management | Battery |

| Policy competition in clean technology: Scaling up or innovating up? [62] | Industrial policy; Environmental policy; Competitiveness; Solar; Electric vehicles | Manufacturing | Environmental policy | Not specified. | Not specified. |

| Resilient NdFeB magnet recycling under the impacts of COVID-19 pandemic: Stochastic programming and Benders decomposition [64] | Rare earth magnet; Supply chain optimization; Reverse logistics; Stochastic programming; Bender’s decomposition; COVID-19 pandemic | Recycling | Chance-constrained two-stage stochastic programming model | Reverse logistics | Neodymium-iron-boron magnets |

| Circularity for electric and electronic equipment (Eee), the edge and distributed ledger (edge&dl) model [65] | Circularity; Circular supply chains; Distributed ledger; Edger computing; E-waste; WEEE; Case study | Recycling | Material flow analysis | Reverse supply chain | Electric and electronic equipment |

| A swot analysis of the uk ev battery supply chain [66] | Electric vehicle; Battery; Supply chain management; SWOT analysis | Supply; Manufacturing | SWOT analysis | Supply chain risk management | Battery |

| Lithium in the green energy transition: The quest for both sustainability and security [67] | Lithium; Energy security; Sustainability; EVs; LIB; Battery; Lithium-ion | Raw material supply; Recycling | Not specified. | Not specified. | Lithium |

| Title [Reference] | Keywords | (I) at What Point in the Supply Chain Was the Study Focused? | (II) What Type of Analysis/Model Was Used? | (III) Which Supply Chain Process Was Analysed? | (IV) Which Component Did the Analysis Focus on? |

|---|---|---|---|---|---|

| Promoting electric vehicle cell innovation diffusion considering patent licensing strategy: A combination of evolutionary game and optimization algorithm approach [68] | Innovation diffusion; Patent; System dynamics; Evolutionary game; Optimization algorithm | Manufacturing | Multistage and multichannel diffusion model | Supply chain risk management | Electric vehicle cell |

| Modelling potential impact of COVID-19 pandemic on global electric vehicle supply chain [69] | - | Not specified. | Economic analysis | Supply chain risk management | Not specified. |

| The impacts of subsidy policies and channel encroachment on the power battery recycling of new energy vehicles [70] | Closed-loop supply chain; Government subsidy; Recycling channel encroachment; Retired power battery; New energy vehicles | Recycling; Reusing | Economic analysis; Environmental analysis | Closed-loop supply chain | Battery |

| Policy competition in clean technology: Scaling up or innovating up? [62] | Industrial policy; Environmental policy; Competitiveness; Solar; Electric vehicles | Manufacturing | Environmental policy | Not specified. | Not specified. |

| Driving mechanism of power battery recycling systems in companies [71] | Battery recycling; Technological innovation; Alternatives; System dynamics | Recycling | System dynamics; Cost analysis | Closed-loop supply chain. | Battery |

References

- Rüdisüli, M.; Bach, C.; Bauer, C.; Beloin-Saint-Pierre, D.; Elber, U.; Georges, G.; Limpach, R.; Pareschi, G.; Kannan, R.; Teske, S.L. Prospective Life-Cycle Assessment of Greenhouse Gas Emissions of Electricity-Based Mobility Options. Appl. Energy 2022, 306. [Google Scholar] [CrossRef]

- Nguyen, R.T.; Eggert, R.G.; Severson, M.H.; Anderson, C.G. Global Electrification of Vehicles and Intertwined Material Supply Chains of Cobalt, Copper and Nickel. Resour. Conserv. Recycl. 2021, 167. [Google Scholar] [CrossRef]

- Castillo-Vergara, M.; Alvarez-Marin, A.; Placencio-Hidalgo, D. A Bibliometric Analysis of Creativity in the Field of Business Economics. J. Bus. Res. 2018, 85, 1–9. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Altman, D.; Antes, G.; Atkins, D.; Barbour, V.; Barrowman, N.; Berlin, J.A.; et al. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6. [Google Scholar] [CrossRef]

- Agusdinata, D.B.; Eakin, H.; Liu, W. Critical Minerals for Electric Vehicles: A Telecoupling Review. Environ. Res. Lett. 2022, 17. [Google Scholar] [CrossRef]

- Murugan, M.; Saravanan, A.; Elumalai, P.V.; Murali, G.; Dhineshbabu, N.R.; Kumar, P.; Afzal, A. Thermal Management System of Lithium-Ion Battery Packs for Electric Vehicles: An Insight Based on Bibliometric Study. J. Energy Storage 2022, 52, 104723. [Google Scholar] [CrossRef]

- Gbey, E.; Turkson, R.F.; Lee, S. A Bibliometric Survey of Research Output on Wireless Charging for Electric Vehicles. World Electr. Veh. J. 2022, 13, 37. [Google Scholar] [CrossRef]

- Barbosa, W.; Prado, T.; Batista, C.; Câmara, J.C.; Cerqueira, R.; Coelho, R.; Guarieiro, L. Electric Vehicles: Bibliometric Analysis of the Current State of the Art and Perspectives. Energies 2022, 15, 395. [Google Scholar] [CrossRef]

- Kirli, D.; Couraud, B.; Robu, V.; Salgado-Bravo, M.; Norbu, S.; Andoni, M.; Antonopoulos, I.; Negrete-Pincetic, M.; Flynn, D.; Kiprakis, A. Smart Contracts in Energy Systems: A Systematic Review of Fundamental Approaches and Implementations. Renew. Sustain. Energy Rev. 2022, 158, 112013. [Google Scholar] [CrossRef]

- Unterluggauer, T.; Rich, J.; Andersen, P.B.; Hashemi, S. Electric Vehicle Charging Infrastructure Planning for Integrated Transportation and Power Distribution Networks: A Review. eTransportation 2022, 12, 100163. [Google Scholar] [CrossRef]

- Wicki, M.; Brückmann, G.; Quoss, F.; Bernauer, T. What Do We Really Know about the Acceptance of Battery Electric Vehicles?–Turns out, Not Much. Transp. Rev. 2022, 1–26. [Google Scholar] [CrossRef]

- Mardani, A.; Zavadskas, E.K.; Khalifah, Z.; Zakuan, N.; Jusoh, A.; Nor, K.M.; Khoshnoudi, M. A Review of Multi-Criteria Decision-Making Applications to Solve Energy Management Problems: Two Decades from 1995 to 2015. Renew. Sustain. Energy Rev. 2017, 71, 216–256. [Google Scholar] [CrossRef]

- Boloy, R.A.M.; da Cunha Reis, A.; Rios, E.M.; de Araújo Santos Martins, J.; Soares, L.O.; de Sá Machado, V.A.; de Moraes, D.R. Waste-to-Energy Technologies Towards Circular Economy: A Systematic Literature Review and Bibliometric Analysis. Water. Air. Soil Pollut. 2021, 232. [Google Scholar] [CrossRef]

- Benzouai, M.C.; Djeffal, K. A Bibliometric Review of Research on Venture Capital. Asian Acad. Manag. J. 2021, 26, 47–88. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, X.; Ye, Y.; Ma, J.; Zhou, C.; Liang, P.; Liu, B. The 100 Top-Cited Studies on Postoperative Hyperalgesia in the Last 30 Years: A Bibliometric Analysis. Ann. Palliat. Med. 2021, 10, 12538–12545. [Google Scholar] [CrossRef]

- Chien, S.-C.; Chen, Y.-L.; Chien, C.-H.; Chin, Y.-P.; Yoon, C.H.; Chen, C.-Y.; Yang, H.-C.; Li, Y.-C. (Jack) Alerts in Clinical Decision Support Systems (CDSS): A Bibliometric Review and Content Analysis. Healthcare 2022, 10, 601. [Google Scholar] [CrossRef]

- Turzo, T.; Marzi, G.; Favino, C.; Terzani, S. Non-Financial Reporting Research and Practice: Lessons from the Last Decade. J. Clean. Prod. 2022, 345, 1–30. [Google Scholar] [CrossRef]

- Monasterolo, I.; Pasqualino, R.; Janetos, A.C.; Jones, A. Sustainable and Inclusive Food Systems through the Lenses of a Complex System Thinking Approach—A Bibliometric Review. Agric. 2016, 6, 44. [Google Scholar] [CrossRef]

- Ma, C.; Xu, Q.; Li, B. Comparative Study on Intelligent Education Research among Countries Based on Bibliographic Coupling Analysis. Libr. Hi Tech 2022, 786–804. [Google Scholar] [CrossRef]

- Galjani, K.; Marovi, I. Decision Support Systems for Managing Construction Projects: A Scientific Evolution Analysis. Sustainability 2022, 14, 4977. [Google Scholar] [CrossRef]

- Xu, Z.; Zhu, Y.; Hu, Y.; Huang, M.; Xu, F.; Wang, J. Bibliometric and Visualized Analysis of Neuropathic Pain Using Web of Science and CiteSpace for the Past 20 Years. World Neurosurg. 2021, 162, e21–e34. [Google Scholar] [CrossRef]

- Wang, Z.; Bai, C.; Hu, T.; Luo, C.; Yu, H.; Ma, X.; Liu, T.; Gu, X. Emerging Trends and Hotspot in Gut–Lung Axis Research from 2011 to 2021: A Bibliometrics Analysis. Biomed. Eng. Online 2022, 21, 1–20. [Google Scholar] [CrossRef]

- Garfield, E. KeyWords Plus: ISI’s Breakthrough Retrieval Method. Part 1. Expanding Your Searching Power on Current Contents on Diskette. Curr. Contents 1990, 32, 5–9. [Google Scholar]

- Ensslin, L.; Moreno, E.A. Sustainability in Library Management in Higher Education Institutions: A Bibliometric Analysis. Int. J. Sustain. High. Educ. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Page, M.J.; Mckenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, 372:n71. [Google Scholar] [CrossRef]

- Goodenough, K.M.; Wall, F.; Merriman, D. The Rare Earth Elements: Demand, Global Resources, and Challenges for Resourcing Future Generations. Nat. Resour. Res. 2018, 27, 201–216. [Google Scholar] [CrossRef]

- Banza Lubaba Nkulu, C.; Casas, L.; Haufroid, V.; De Putter, T.; Saenen, N.D.; Kayembe-Kitenge, T.; Musa Obadia, P.; Kyanika Wa Mukoma, D.; Lunda Ilunga, J.-M.; Nawrot, T.S.; et al. Sustainability of Artisanal Mining of Cobalt in DR Congo. Nat. Sustain. 2018, 1, 495–504. [Google Scholar] [CrossRef]

- Sovacool, B.K.; Ali, S.H.; Bazilian, M.; Radley, B.; Nemery, B.; Okatz, J.; Mulvaney, D. Sustainable Minerals and Metals for a Low-Carbon Future. Science 2020, 367, 30–33. [Google Scholar] [CrossRef]

- Mayyas, A.; Steward, D.; Mann, M. The Case for Recycling: Overview and Challenges in the Material Supply Chain for Automotive Li-Ion Batteries. Sustain. Mater. Technol. 2019, 19. [Google Scholar] [CrossRef]

- Xu, C.; Dai, Q.; Gaines, L.; Hu, M.; Tukker, A.; Steubing, B. Future Material Demand for Automotive Lithium-Based Batteries. Commun. Mater. 2020, 1. [Google Scholar] [CrossRef]

- Baars, J.; Domenech, T.; Bleischwitz, R.; Melin, H.E.; Heidrich, O. Circular Economy Strategies for Electric Vehicle Batteries Reduce Reliance on Raw Materials. Nat. Sustain. 2021, 4, 71–79. [Google Scholar] [CrossRef]

- Alamerew, Y.A.; Brissaud, D. Modelling Reverse Supply Chain through System Dynamics for Realizing the Transition towards the Circular Economy: A Case Study on Electric Vehicle Batteries. J. Clean. Prod. 2020, 254. [Google Scholar] [CrossRef]

- Gu, X.; Ieromonachou, P.; Zhou, L.; Tseng, M.-L. Developing Pricing Strategy to Optimise Total Profits in an Electric Vehicle Battery Closed Loop Supply Chain. J. Clean. Prod. 2018, 203, 376–385. [Google Scholar] [CrossRef]

- Muralidharan, N.; Essehli, R.; Hermann, R.P.; Amin, R.; Jafta, C.; Zhang, J.; Liu, J.; Du, Z.; Meyer, H.M.; Self, E.; et al. Lithium Iron Aluminum Nickelate, LiNixFeyAlzO2—New Sustainable Cathodes for Next-Generation Cobalt-Free Li-Ion Batteries. Adv. Mater. 2020, 32. [Google Scholar] [CrossRef]

- Jones, B.; Elliott, R.J.R.; Nguyen-Tien, V. The EV Revolution: The Road Ahead for Critical Raw Materials Demand. Appl. Energy 2020, 280. [Google Scholar] [CrossRef]

- Hache, E.; Seck, G.S.; Simoen, M.; Bonnet, C.; Carcanague, S. Critical Raw Materials and Transportation Sector Electrification: A Detailed Bottom-up Analysis in World Transport. Appl. Energy 2019, 240, 6–25. [Google Scholar] [CrossRef]

- Gu, X.; Ieromonachou, P.; Zhou, L.; Tseng, M.-L. Optimising Quantity of Manufacturing and Remanufacturing in an Electric Vehicle Battery Closed-Loop Supply Chain. Ind. Manag. Data Syst. 2018, 118, 283–302. [Google Scholar] [CrossRef]

- Cimprich, A.; Bach, V.; Helbig, C.; Thorenz, A.; Schrijvers, D.; Sonnemann, G.; Young, S.B.; Sonderegger, T.; Berger, M. Raw Material Criticality Assessment as a Complement to Environmental Life Cycle Assessment: Examining Methods for Product-Level Supply Risk Assessment. J. Ind. Ecol. 2019, 23, 1226–1236. [Google Scholar] [CrossRef]

- Kelly, J.C.; Dai, Q.; Wang, M. Globally Regional Life Cycle Analysis of Automotive Lithium-Ion Nickel Manganese Cobalt Batteries. Mitig. Adapt. Strateg. Glob. Chang. 2019, 371–396. [Google Scholar] [CrossRef]

- Wen, W.; Yang, S.; Zhou, P.; Gao, S.Z. Impacts of COVID-19 on the Electric Vehicle Industry: Evidence from China. Renew. Sustain. Energy Rev. 2021, 144. [Google Scholar] [CrossRef]

- Muralidharan, N.; Essehli, R.; Hermann, R.P.; Parejiya, A.; Amin, R.; Bai, Y.; Du, Z.; Belharouak, I. LiNixFeyAlzO2, a New Cobalt-Free Layered Cathode Material for Advanced Li-Ion Batteries. J. Power Sources 2020, 471. [Google Scholar] [CrossRef]

- Lander, L.; Cleaver, T.; Rajaeifar, M.A.; Nguyen-Tien, V.; Elliott, R.J.R.; Heidrich, O.; Kendrick, E.; Edge, J.S.; Offer, G. Financial Viability of Electric Vehicle Lithium-Ion Battery Recycling. iScience 2021, 24, 102787. [Google Scholar] [CrossRef]

- Gu, X.; Zhou, L.; Huang, H.; Shi, X.; Ieromonachou, P. Electric Vehicle Battery Secondary Use under Government Subsidy: A Closed-Loop Supply Chain Perspective. Int. J. Prod. Econ. 2021, 234, 108035. [Google Scholar] [CrossRef]

- Zhu, M.; Liu, Z.; Li, J.; Zhu, S.X. Electric Vehicle Battery Capacity Allocation and Recycling with Downstream Competition. Eur. J. Oper. Res. 2020, 283, 365–379. [Google Scholar] [CrossRef]

- Stampatori, D.; Raimondi, P.P.; Noussan, M. Li-Ion Batteries: A Review of a Key Technology for Transport Decarbonization. Energies 2020, 13, 2638. [Google Scholar] [CrossRef]

- Kalaitzi, D.; Matopoulos, A.; Clegg, B. Managing Resource Dependencies in Electric Vehicle Supply Chains: A Multi-Tier Case Study. Supply Chain Manag. 2019, 24, 256–270. [Google Scholar] [CrossRef]

- Kelly, J.C.; Wang, M.; Dai, Q.; Winjobi, O. Energy, Greenhouse Gas, and Water Life Cycle Analysis of Lithium Carbonate and Lithium Hydroxide Monohydrate from Brine and Ore Resources and Their Use in Lithium Ion Battery Cathodes and Lithium Ion Batteries. Resour. Conserv. Recycl. 2021, 174. [Google Scholar] [CrossRef]

- Pell, R.; Wall, F.; Yan, X.; Li, J.; Zeng, X. Mineral Processing Simulation Based-Environmental Life Cycle Assessment for Rare Earth Project Development: A Case Study on the Songwe Hill Project. J. Environ. Manag. 2019, 249. [Google Scholar] [CrossRef]

- Fraser, I.J.; Müller, M.; Schwarzkopf, J. Transparency for Multi-Tier Sustainable Supply Chain Management: A Case Study of a Multi-Tier Transparency Approach for SSCM in the Automotive Industry. Sustainability 2020, 12, 1814. [Google Scholar] [CrossRef]

- Jing, R.; Wang, J.; Shah, N.; Guo, M. Emerging Supply Chain of Utilising Electrical Vehicle Retired Batteries in Distributed Energy Systems. Adv. Appl. Energy 2021, 1. [Google Scholar] [CrossRef]

- Sharma, A.; Zanotti, P.; Musunur, L.P. Enabling the Electric Future of Mobility: Robotic Automation for Electric Vehicle Battery Assembly. IEEE Access 2019, 7, 170961–170991. [Google Scholar] [CrossRef]

- Kintscher, L.; Lawrenz, S.; Poschmann, H.; Sharma, P. Recycling 4.0-Digitalization as a Key for the Advanced Circular Economy. J. Commun. 2020, 15, 652–660. [Google Scholar] [CrossRef]

- Zeuner, B. An Obsolescing Bargain in a Rentier State: Multinationals, Artisanal Miners, and Cobalt in the Democratic Republic of Congo. Front. Energy Res. 2018, 6. [Google Scholar] [CrossRef]

- Son, D.; Kim, S.; Park, H.; Jeong, B. Closed-Loop Supply Chain Planning Model of Rare Metals. Sustainability 2018, 10, 1061. [Google Scholar] [CrossRef]

- Subramanian, G.; Thampy, A.S. Implementation of Hybrid Blockchain in a Pre-Owned Electric Vehicle Supply Chain. IEEE Access 2021, 9, 82435–82454. [Google Scholar] [CrossRef]

- Schmid, M. Challenges to the European Automotive Industry in Securing Critical Raw Materials for Electric Mobility: The Case of Rare Earths. Mineral. Mag. 2020, 84, 5–17. [Google Scholar] [CrossRef]

- Marcos, J.T.; Scheller, C.; Godina, R.; Spengler, T.S.; Carvalho, H. Sources of Uncertainty in the Closed-Loop Supply Chain of Lithium-Ion Batteries for Electric Vehicles. Clean. Logist. Supply Chain 2021, 1, 100006. [Google Scholar] [CrossRef]

- Koroma, M.S.; Brown, N.; Cardellini, G.; Messagie, M. Prospective Environmental Impacts of Passenger Cars under Different Energy and Steel Production Scenarios. Energies 2020, 13, 6236. [Google Scholar] [CrossRef]

- Calisaya-Azpilcueta, D.; Herrera-Leon, S.; Lucay, F.A.; Cisternas, L.A. Assessment of the Supply Chain under Uncertainty: The Case of Lithium. Minerals 2020, 10, 604. [Google Scholar] [CrossRef]

- Riddle, M.E.; Tatara, E.; Olson, C.; Smith, B.J.; Bennett Irion, A.; Harker, B.; Pineault, D.; Alonso, E.; Graziano, D.J. Agent-Based Modeling of Supply Disruptions in the Global Rare Earths Market. Resour. Conserv. Recycl. 2021, 164. [Google Scholar] [CrossRef]

- Schwabe, J. From “Obligated Embeddedness” to “Obligated Chineseness”? Bargaining Processes and Evolution of International Automotive Firms in China’s New Energy Vehicle Sector. Growth Chang. 2020, 51, 1102–1123. [Google Scholar] [CrossRef]

- Hughes, L.; Meckling, J. Policy Competition in Clean Technology: Scaling up or Innovating Up? Bus. Polit. 2018, 20, 588–614. [Google Scholar] [CrossRef]

- Lu, L.; Zhou, T.; Zhang, Q.; Stanley, H.E. The H-Index of a Network Node and Its Relation to Degree and Coreness. Nat. Commun. 2016, 1–7. [Google Scholar] [CrossRef]

- Cheramin, M.; Saha, A.K.; Cheng, J.; Paul, S.K.; Jin, H. Resilient NdFeB Magnet Recycling under the Impacts of COVID-19 Pandemic: Stochastic Programming and Benders Decomposition. Transp. Res. Part E Logist. Transp. Rev. 2021, 155. [Google Scholar] [CrossRef]

- Andersen, T.; Jæger, B. Circularity for Electric and Electronic Equipment (Eee), the Edge and Distributed Ledger (Edge&Dl) Model. Sustainability 2021, 13, 9924. [Google Scholar] [CrossRef]

- Zhang, Y.; Rysiecki, L.; Gong, Y.; Shi, Q. A Swot Analysis of the Uk Ev Battery Supply Chain. Sustainability 2020, 12, 9807. [Google Scholar] [CrossRef]

- Graham, J.D.; Rupp, J.A.; Brungard, E. Lithium in the Green Energy Transition: The Quest for Both Sustainability and Security. Sustainability 2021, 13, 11274. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Z. Promoting Electric Vehicle Cell Innovation Diffusion Considering Patent Licensing Strategy: A Combination of Evolutionary Game and Optimization Algorithm Approach. World Electr. Veh. J. 2021, 12, 95. [Google Scholar] [CrossRef]

- Sun, X.; Liu, G.; Hao, H.; Liu, Z.; Zhao, F. Modeling Potential Impact of COVID-19 Pandemic on Global Electric Vehicle Supply Chain. iScience 2022, 25. [Google Scholar] [CrossRef]

- Liu, K.; Wang, C. The Impacts of Subsidy Policies and Channel Encroachment on the Power Battery Recycling of New Energy Vehicles. Int. J. Low-Carbon Technol. 2021, 16, 770–789. [Google Scholar] [CrossRef]

- Zhang, B.; Li, J.; Yue, X. Driving Mechanism of Power Battery Recycling Systems in Companies. Int. J. Environ. Res. Public Health 2020, 17, 8204. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soares, L.O.; Reis, A.d.C.; Vieira, P.S.; Hernández-Callejo, L.; Boloy, R.A.M. Electric Vehicle Supply Chain Management: A Bibliometric and Systematic Review. Energies 2023, 16, 1563. https://doi.org/10.3390/en16041563

Soares LO, Reis AdC, Vieira PS, Hernández-Callejo L, Boloy RAM. Electric Vehicle Supply Chain Management: A Bibliometric and Systematic Review. Energies. 2023; 16(4):1563. https://doi.org/10.3390/en16041563

Chicago/Turabian StyleSoares, Laene Oliveira, Augusto da Cunha Reis, Pedro Senna Vieira, Luis Hernández-Callejo, and Ronney Arismel Mancebo Boloy. 2023. "Electric Vehicle Supply Chain Management: A Bibliometric and Systematic Review" Energies 16, no. 4: 1563. https://doi.org/10.3390/en16041563

APA StyleSoares, L. O., Reis, A. d. C., Vieira, P. S., Hernández-Callejo, L., & Boloy, R. A. M. (2023). Electric Vehicle Supply Chain Management: A Bibliometric and Systematic Review. Energies, 16(4), 1563. https://doi.org/10.3390/en16041563