Life Cycle Environmental Impacts Assessment of Post-Combustion Carbon Capture for Natural Gas Combined Cycle Power Plant in Iraq, Considering Grassroots and Retrofit Design

Abstract

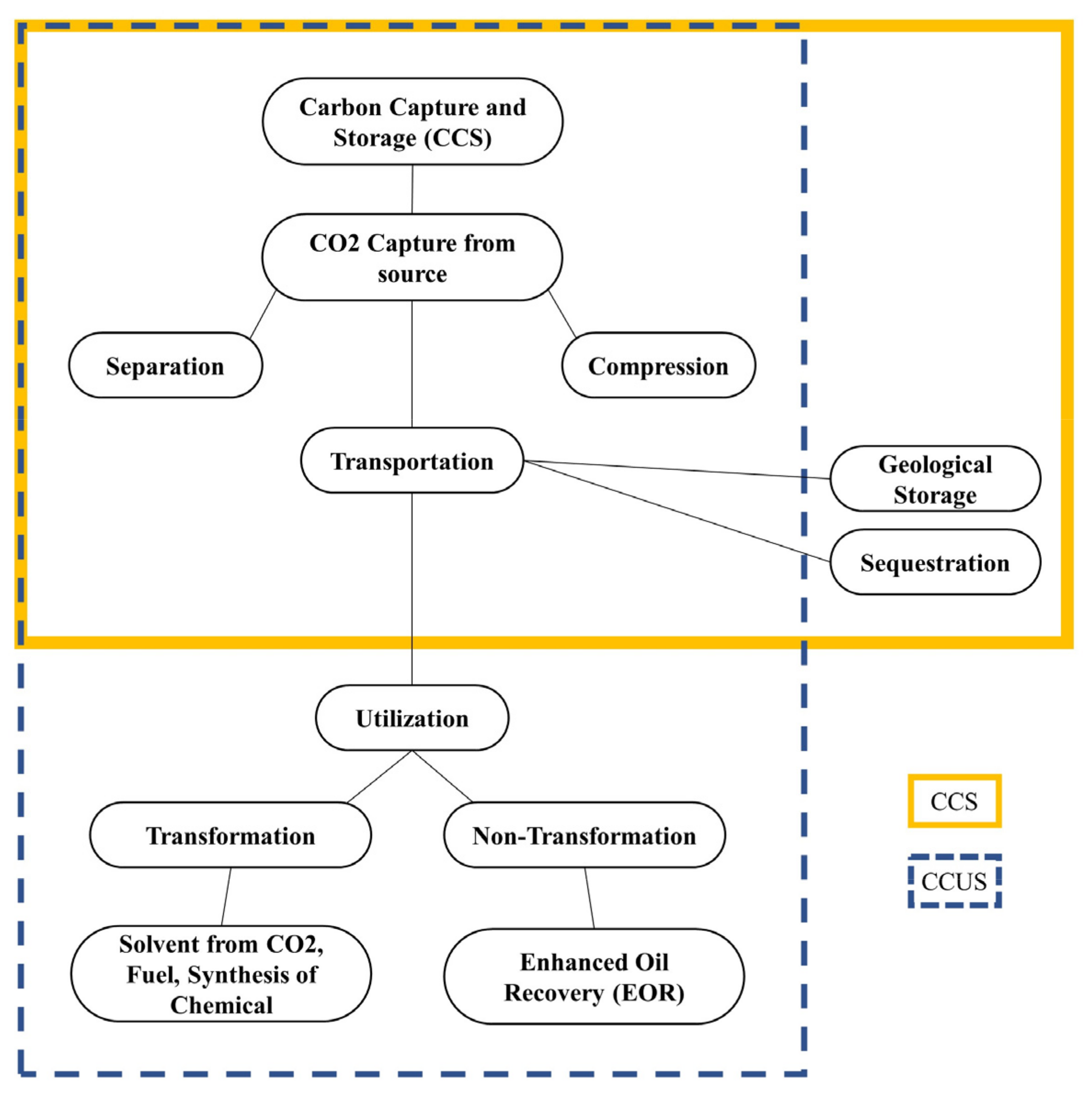

1. Introduction

1.1. Background

1.2. Literature Review

1.3. Research Gap and Originalities

2. Materials and Methods

2.1. Case Study

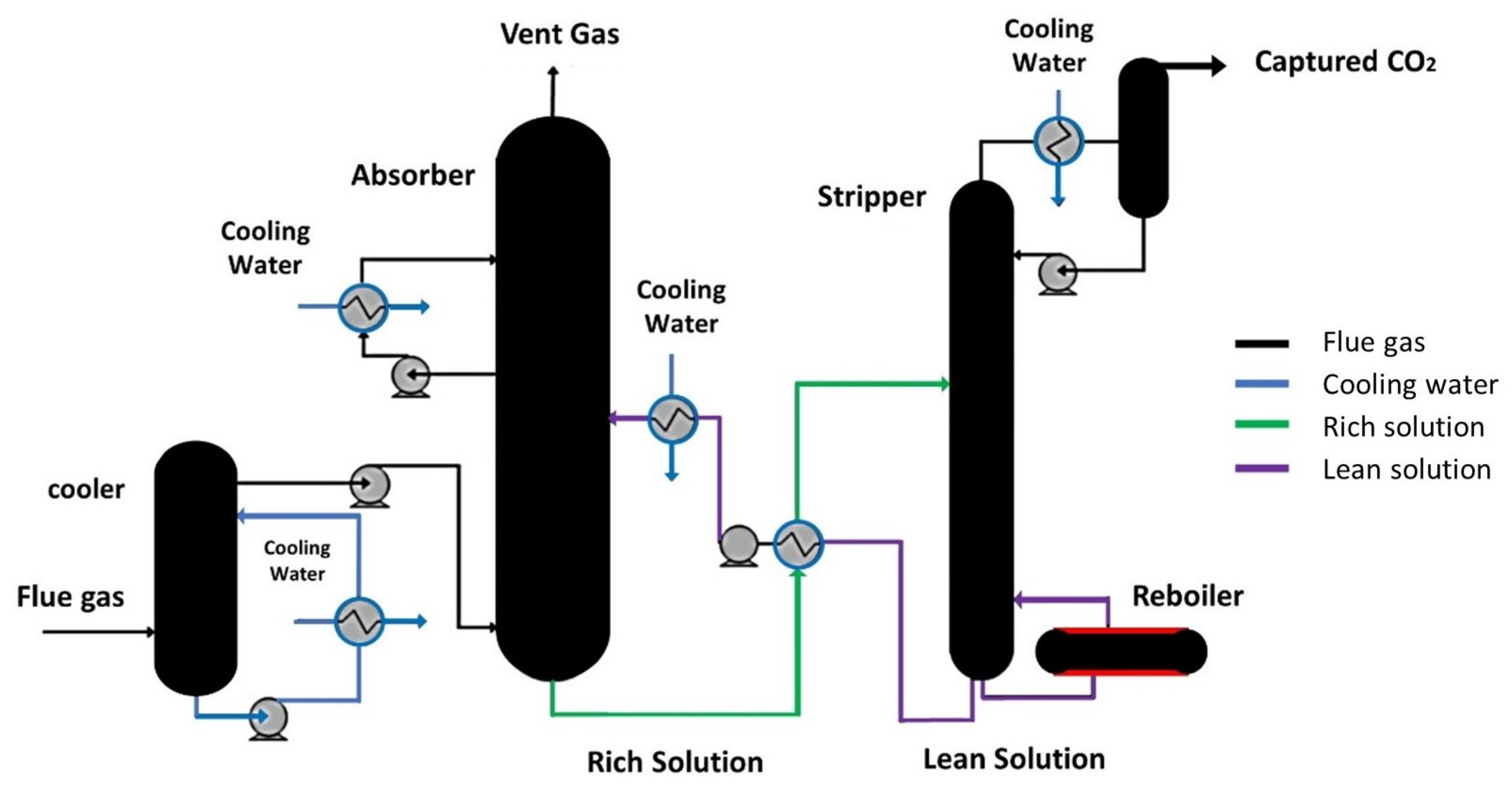

2.2. Proposed CO2 Capture Unit

2.3. Life Cycle Impact Assessment Model

3. Data Inventories

4. Results and Discussions

4.1. MEA Capture Unit Simulation Results

4.2. LCA Analysis Results

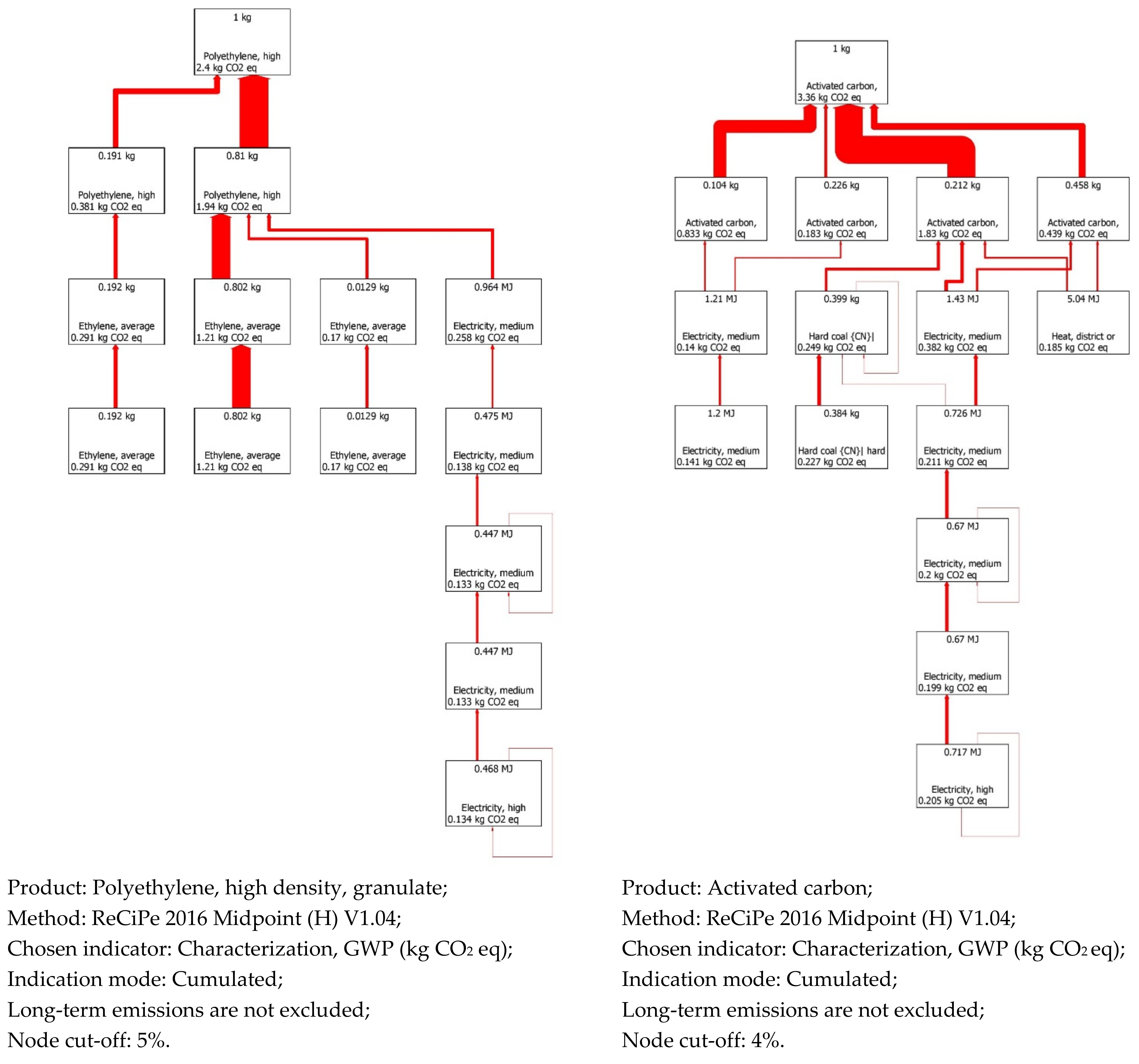

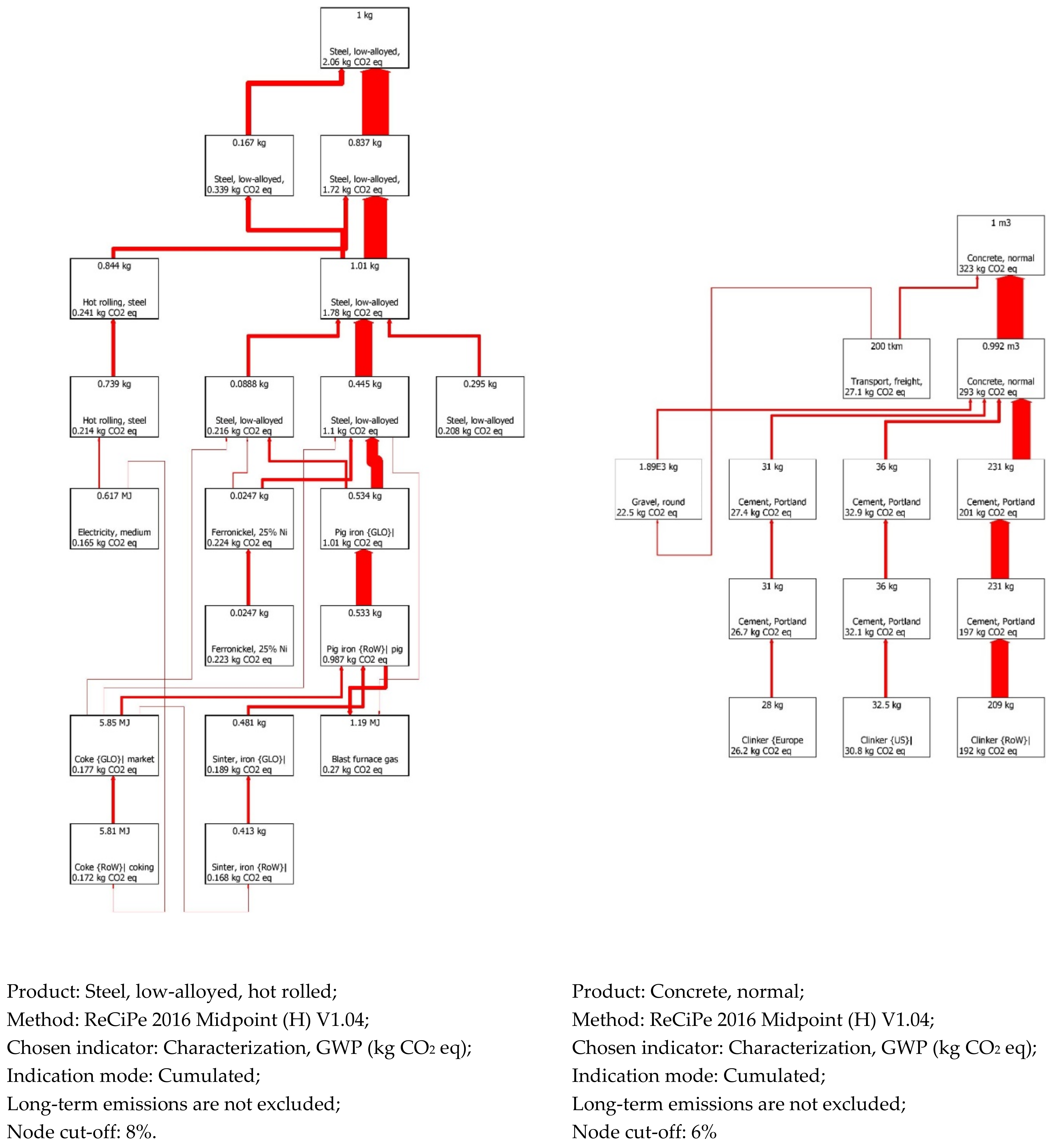

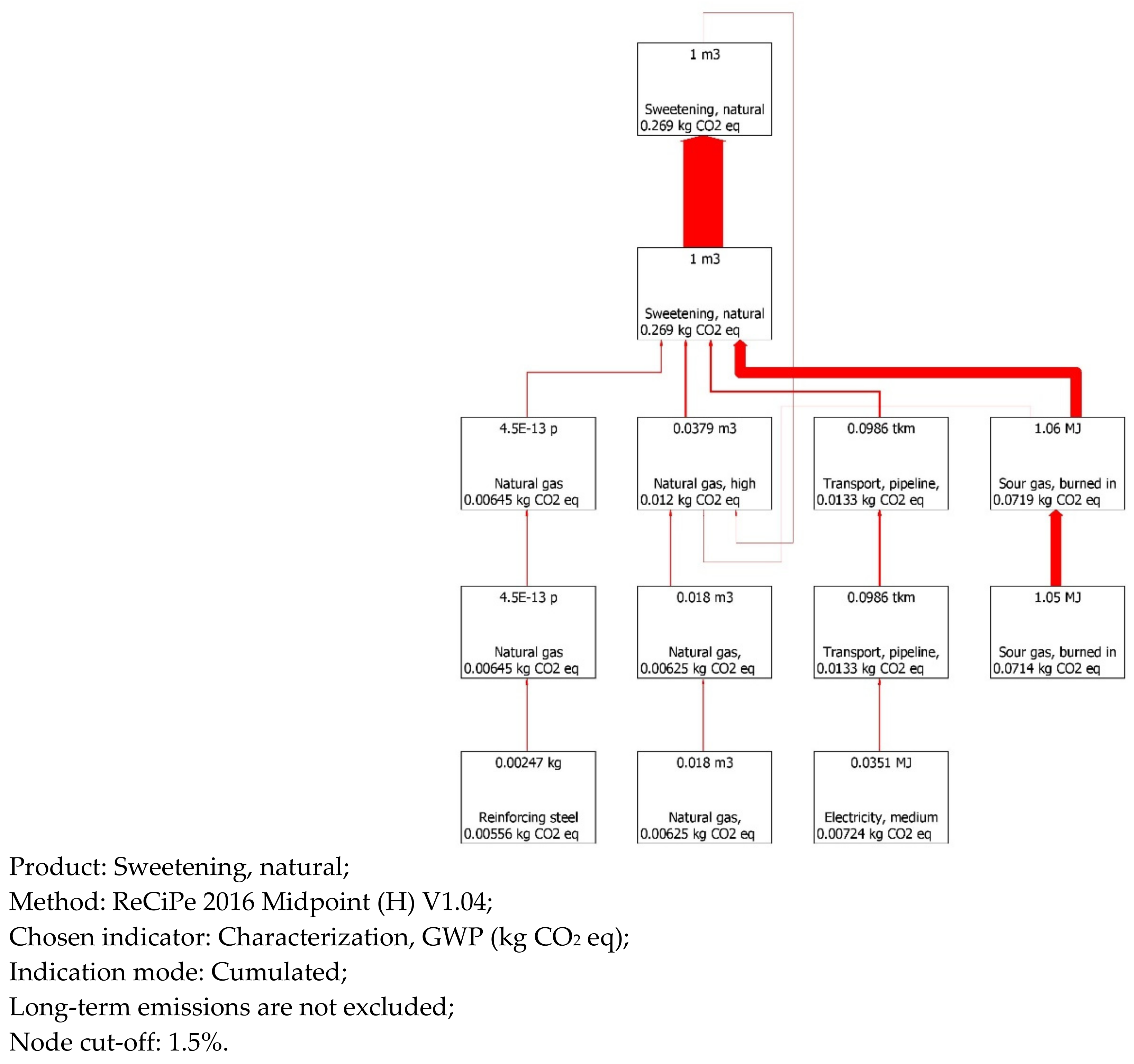

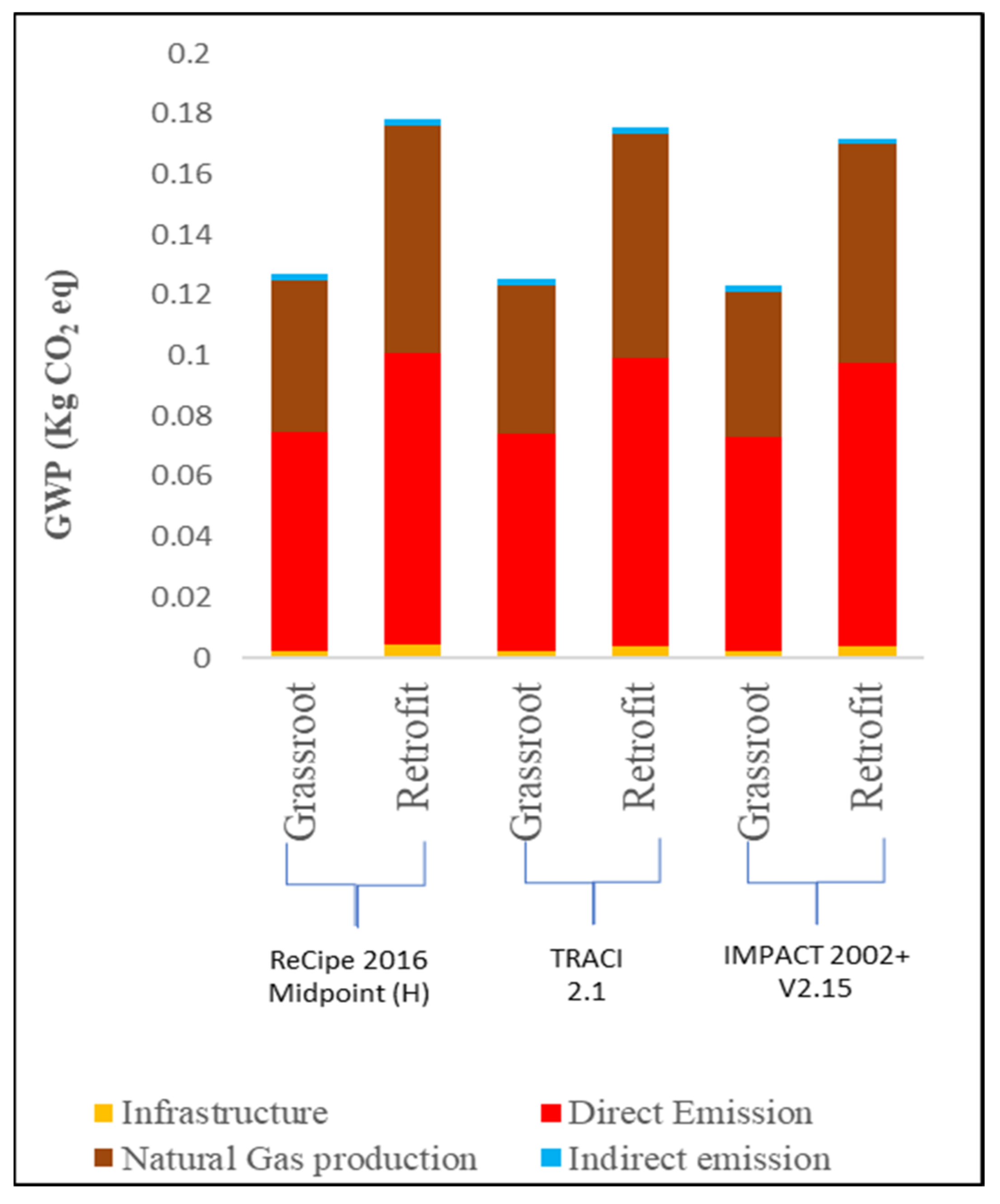

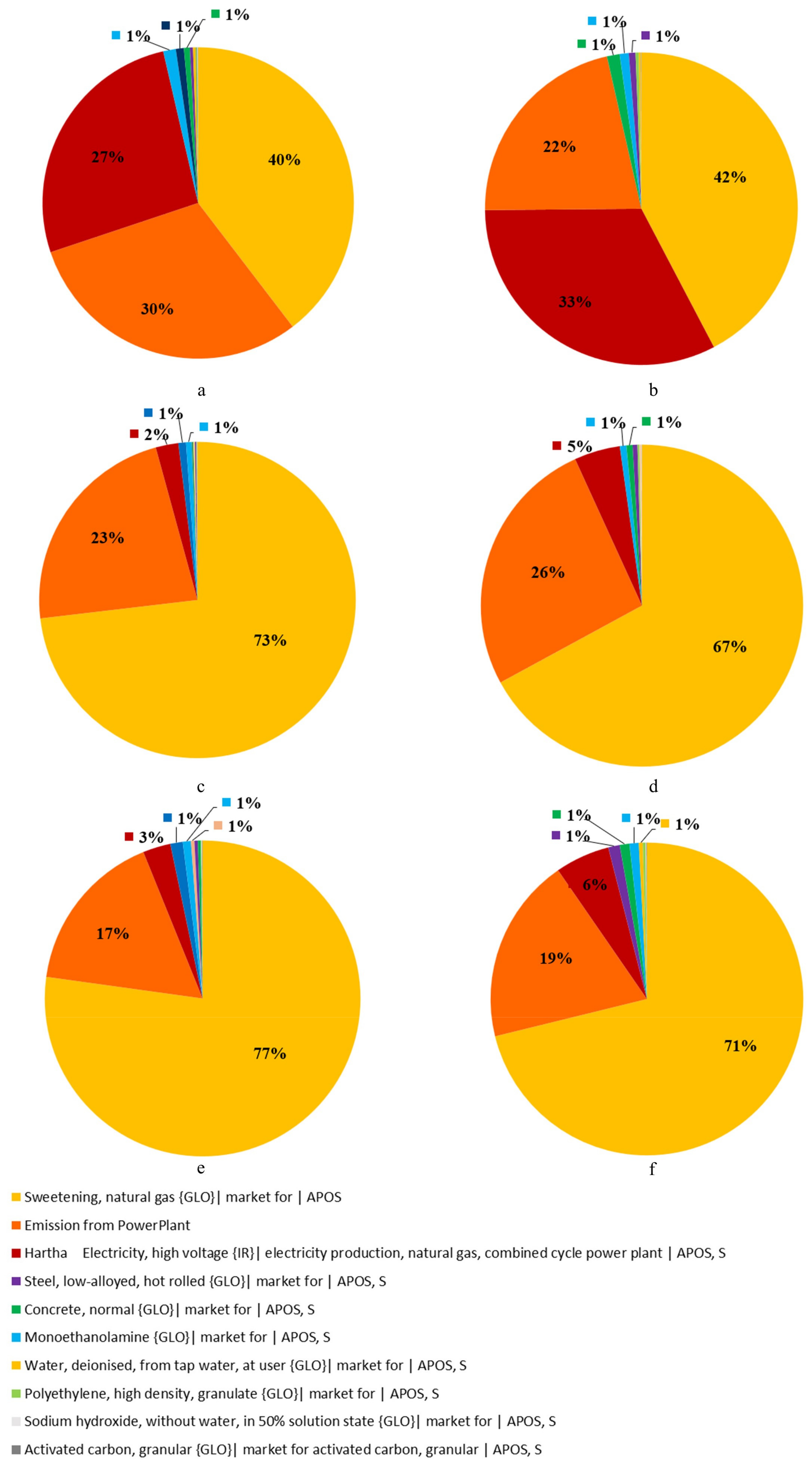

4.2.1. Global Warming Potential (GWP)

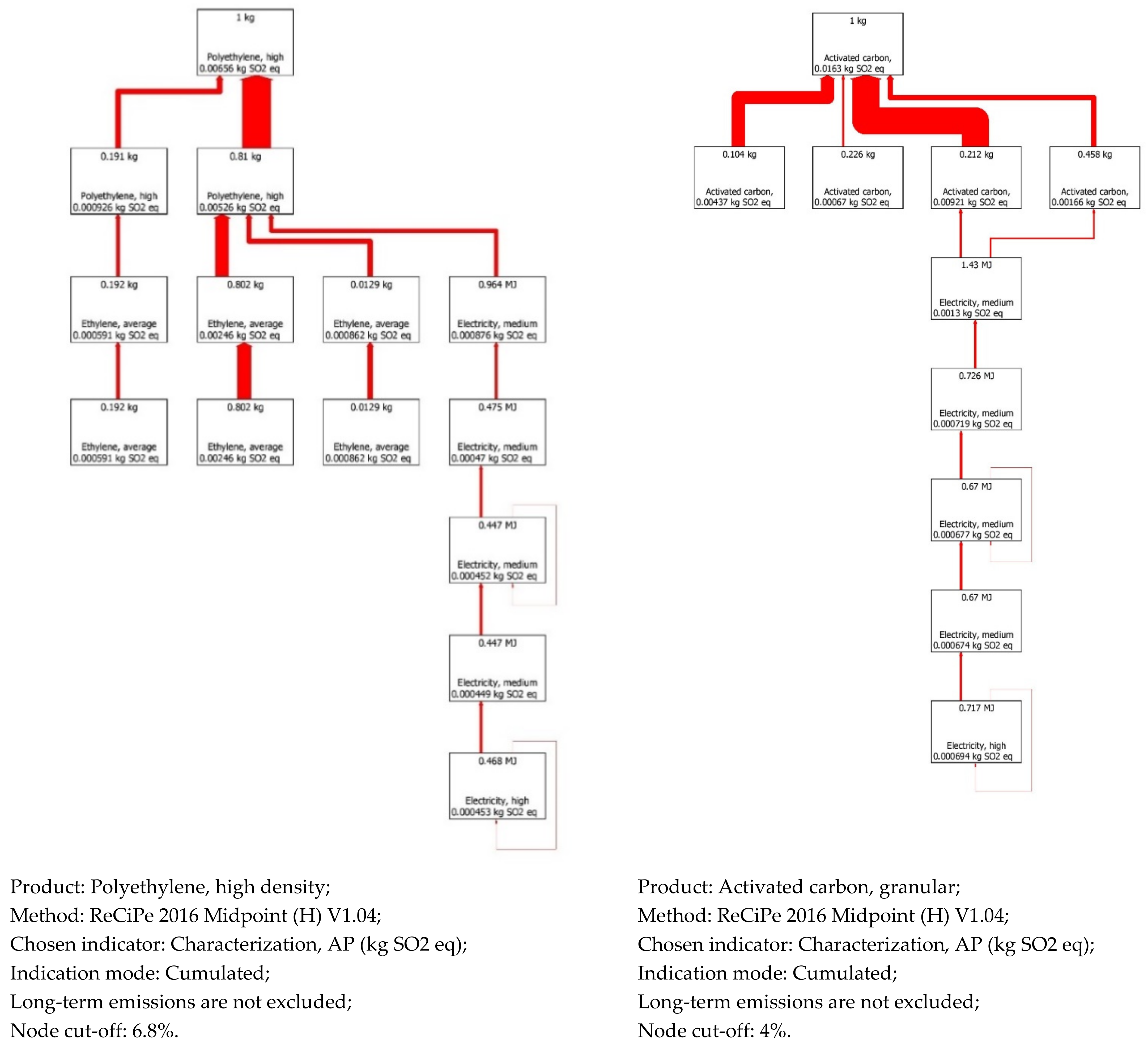

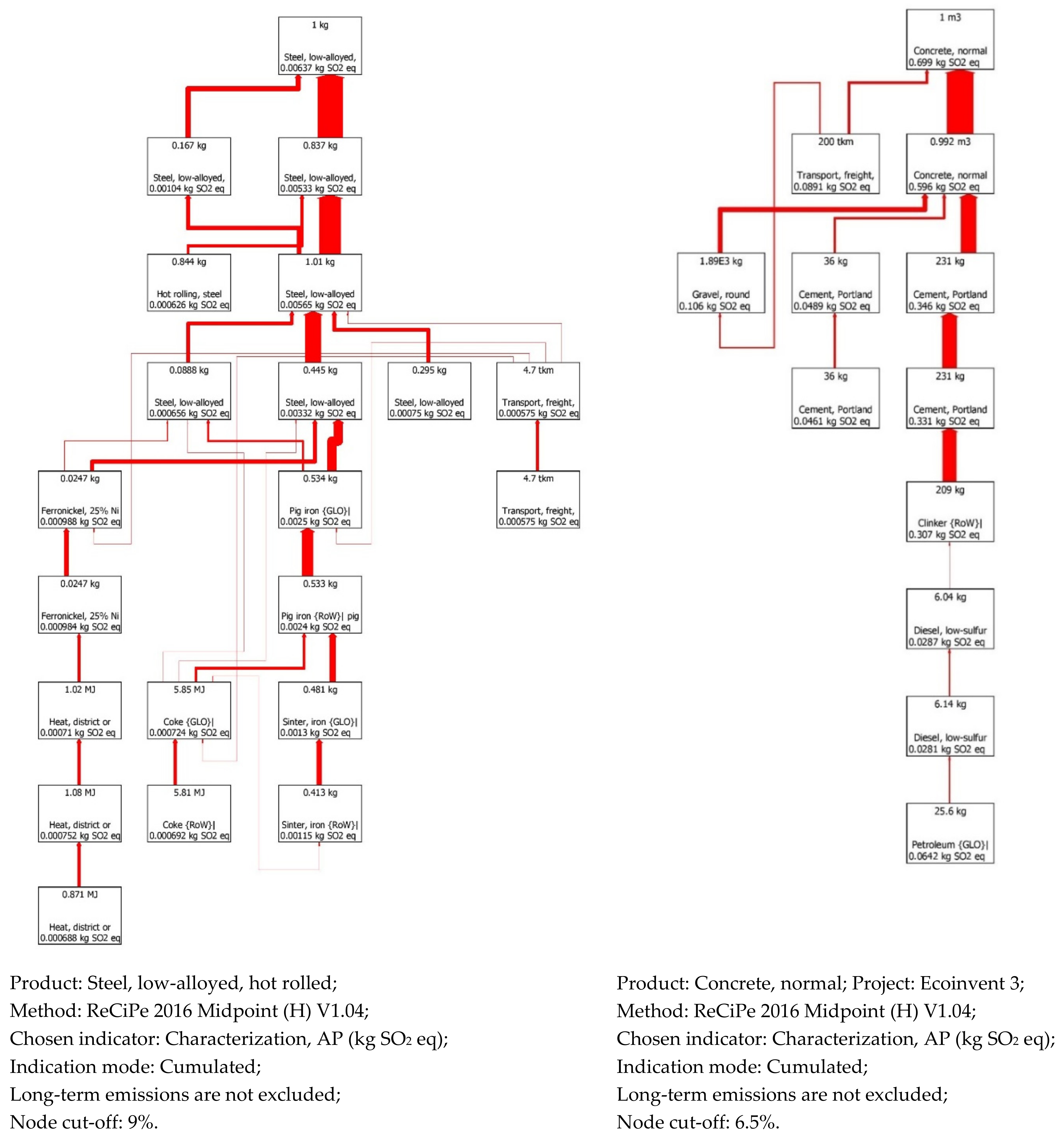

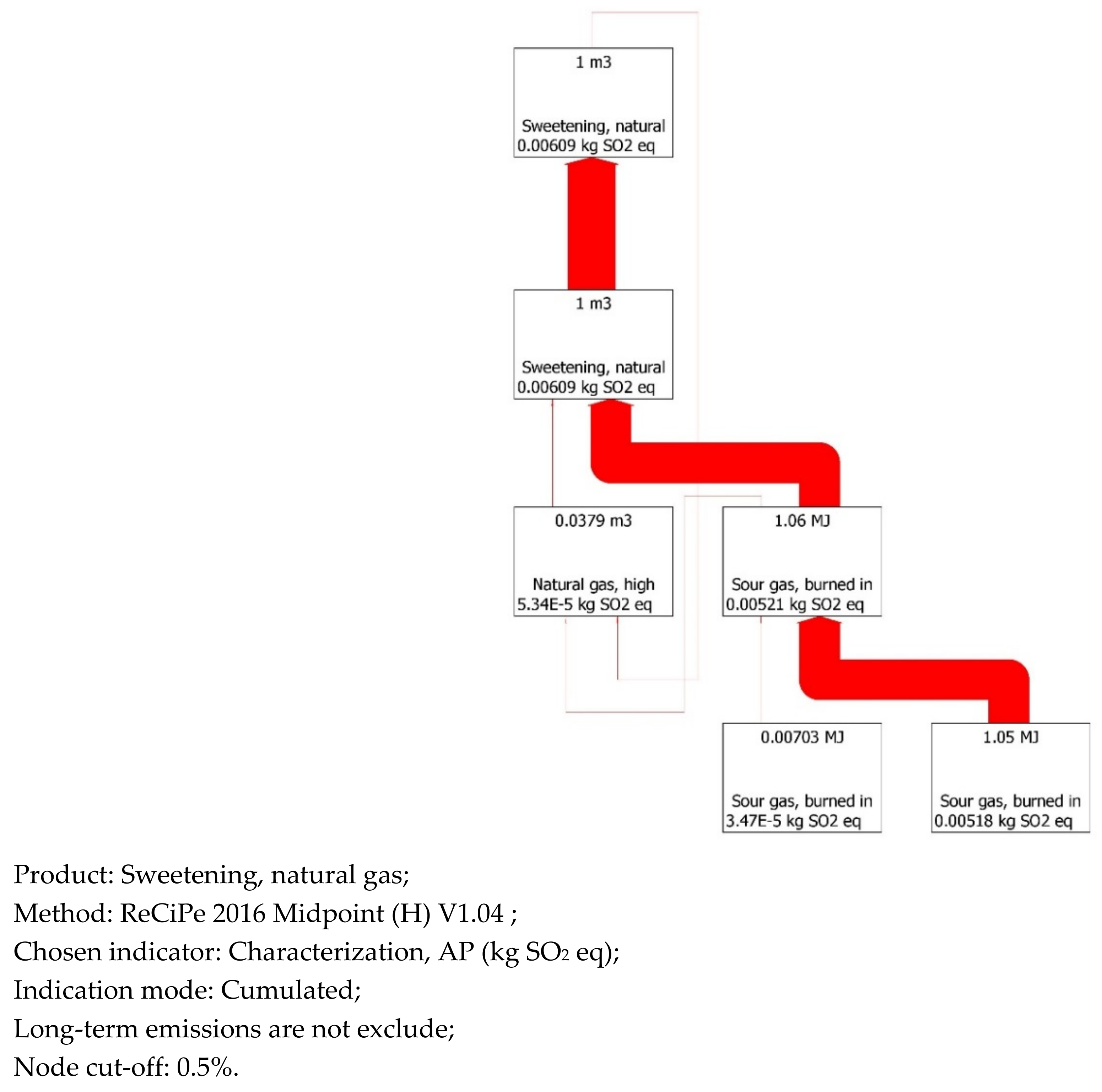

4.2.2. Acidification Potential (AP)

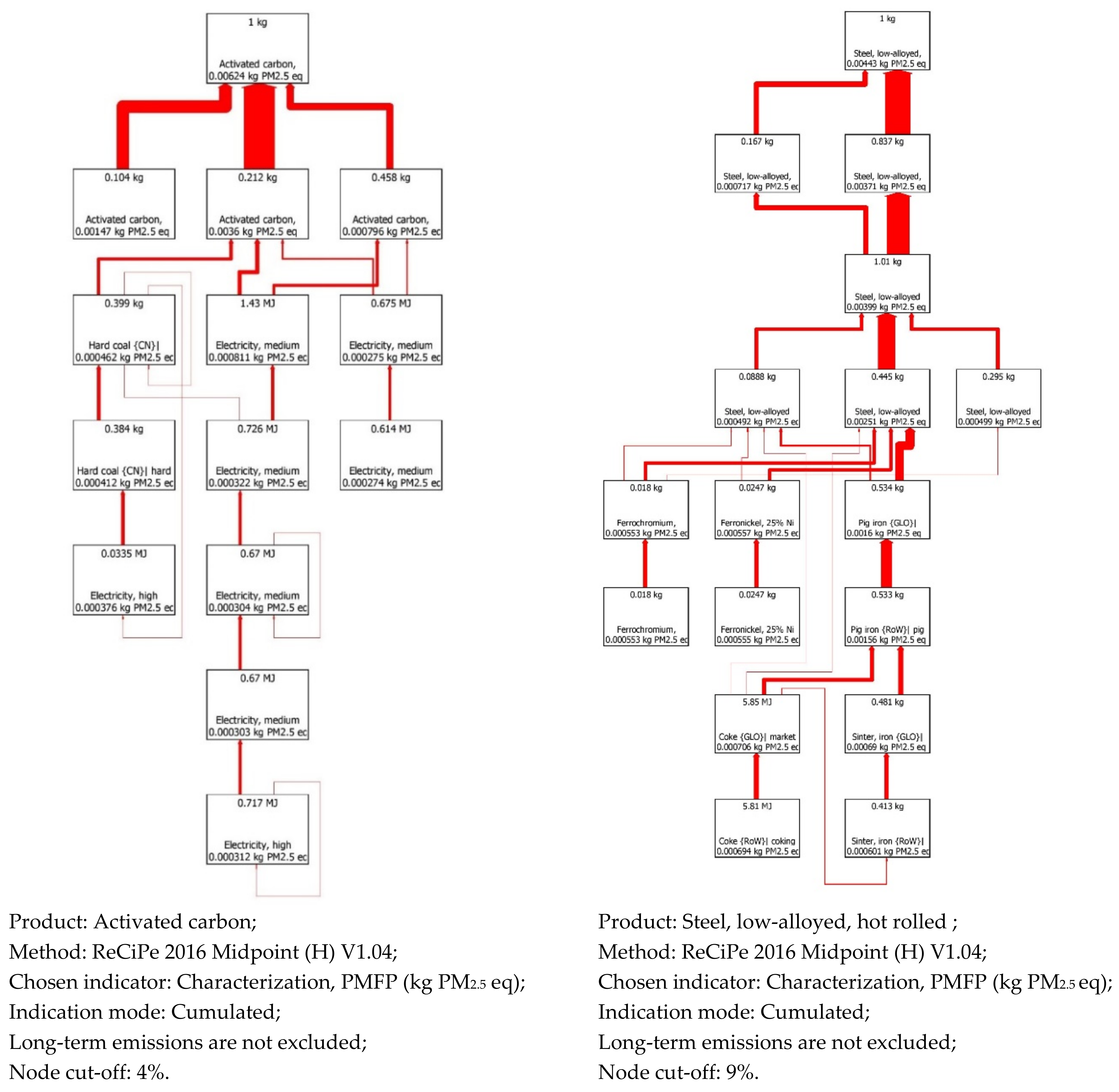

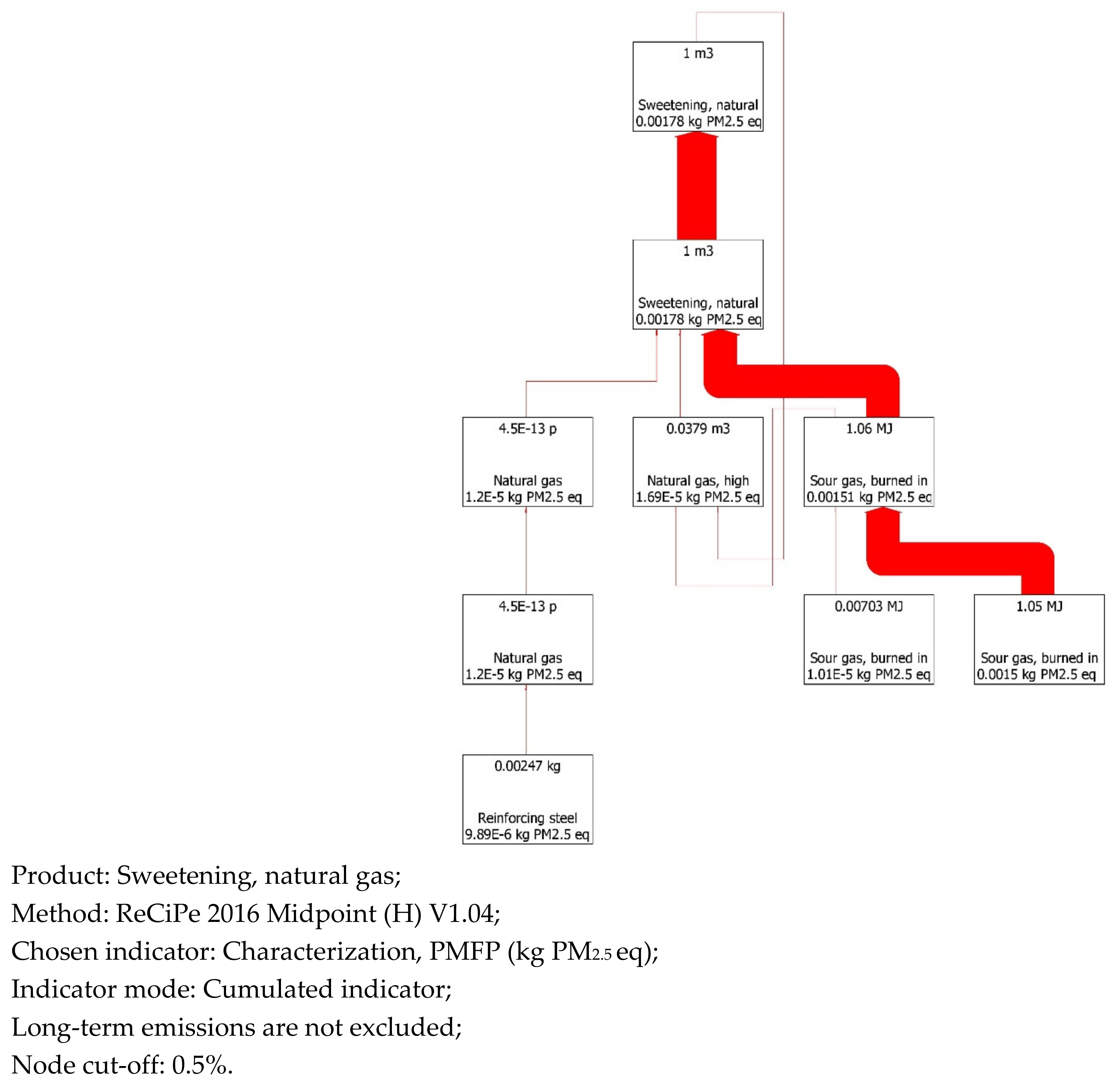

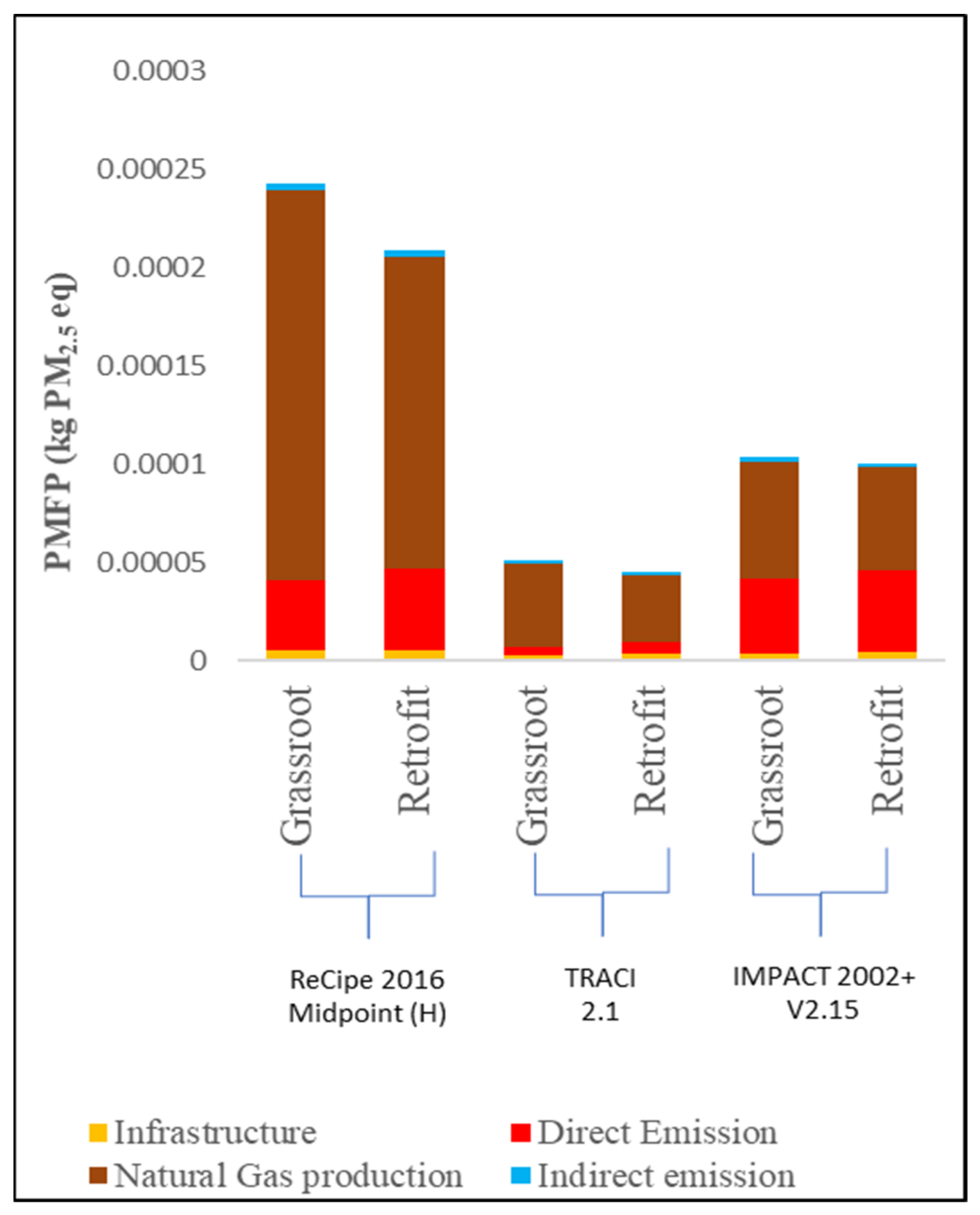

4.2.3. Particulate Matter Formation Potential (PMFP)

4.3. Sensitivity Analysis of the Impact Categories

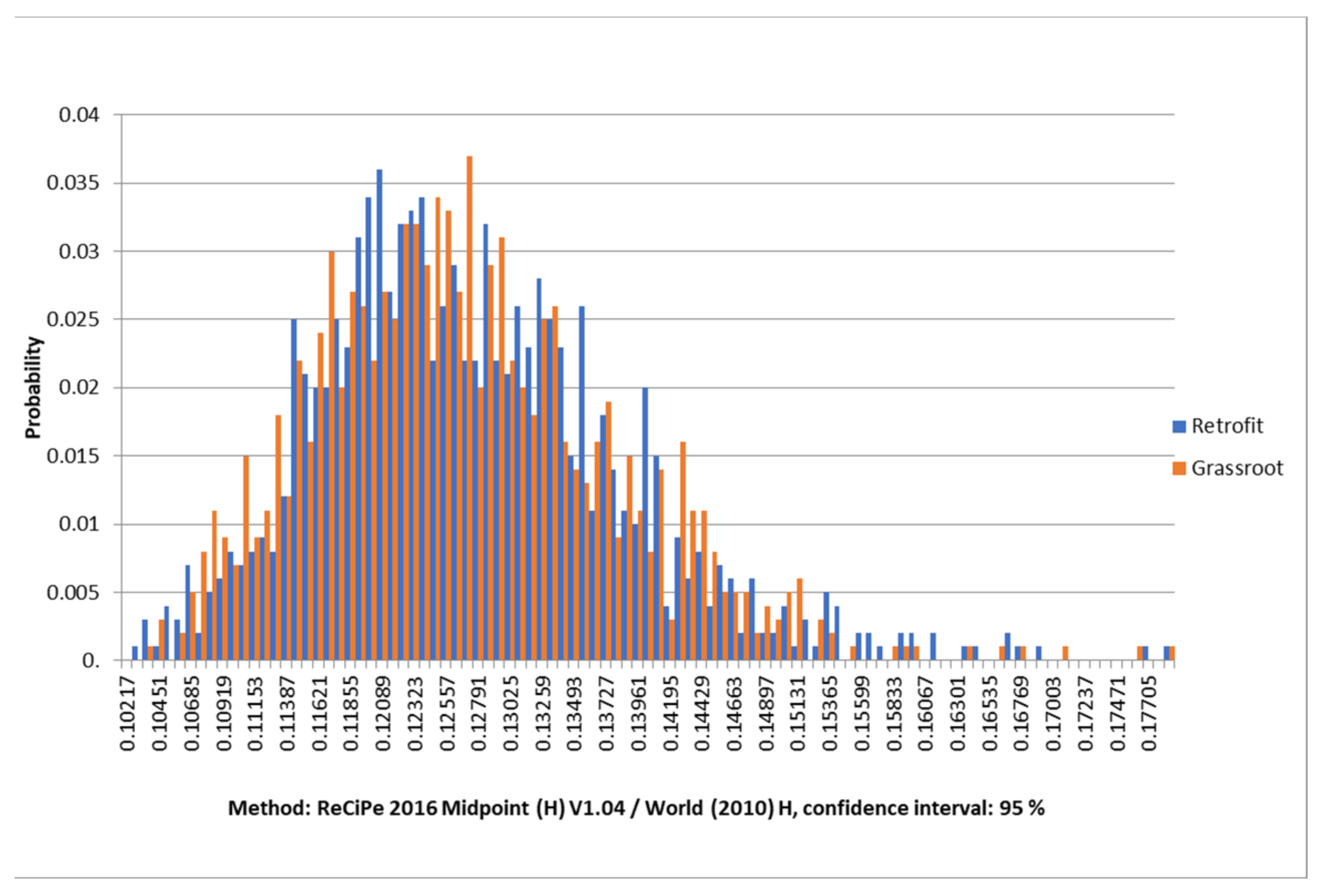

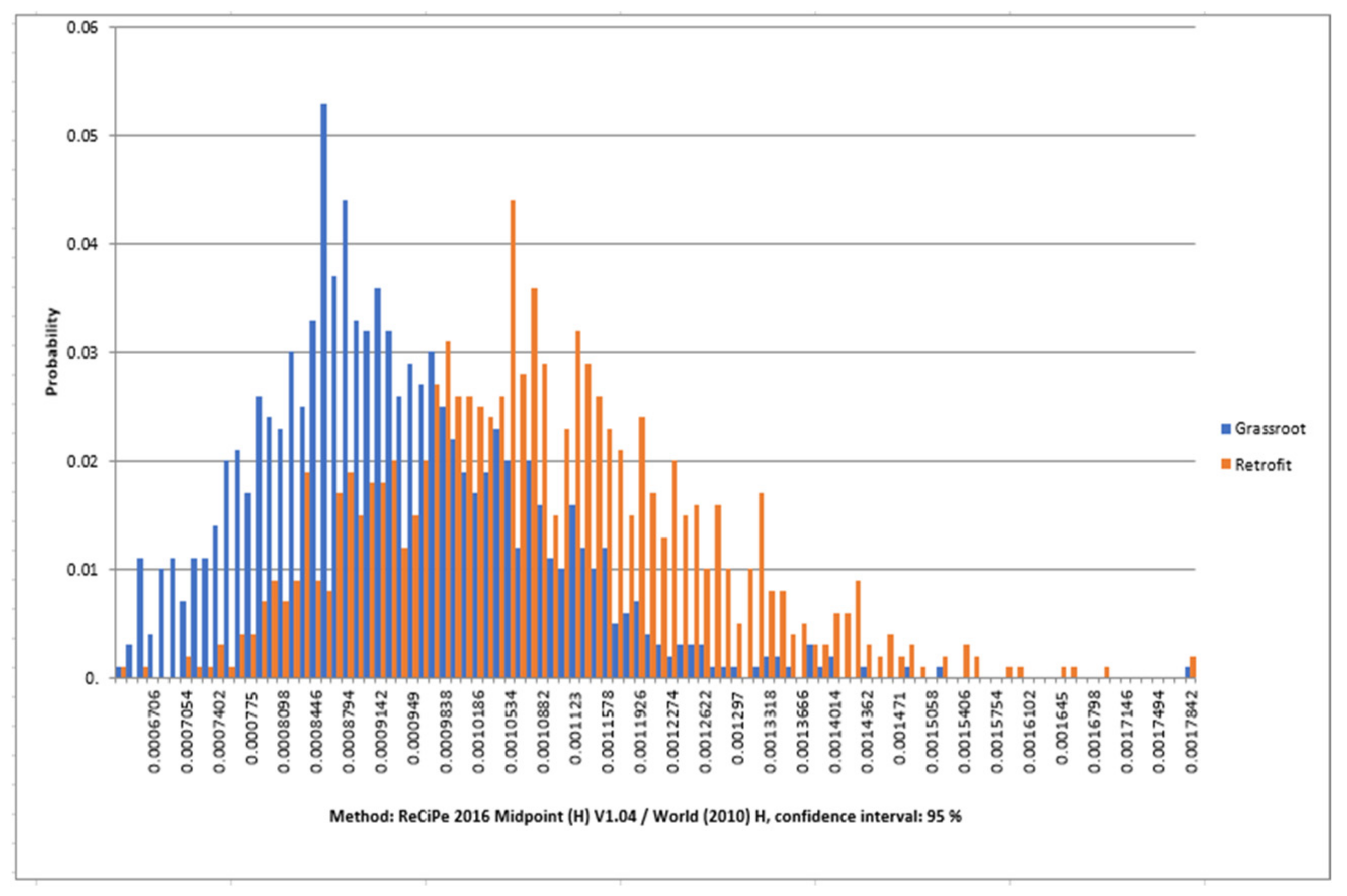

4.4. Uncertainty Analysis of the Input Data

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ADP | Abiotic Depletion Potential |

| AP | Acidification potential |

| CCP | climate change potential |

| CCS | Carbon capture and storage |

| CCUS | Carbon capture, utilization, and storage |

| CCU | Carbon capture and utilization |

| CED | Cumulative energy demand |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| DQIs | Data quality indicators |

| EOR | Enhanced oil recovery |

| FEC | Fresh water ecotoxicity |

| FAETP | Fresh aquatic ecotoxicity potential |

| FEU | Freshwater eutrophication |

| FRS | Acidification potential fossil resource scarcity |

| GWP | Global warming potential |

| GHG | Greenhouse gas |

| HCT | Human carcinogenic toxicity |

| HDLPE | High Density Linear Polyethylene |

| HETP | Height Equivalent to One Theoretical Plate |

| HnCT | Human non-carcinogenic toxicity |

| HPT | high-pressure turbine |

| HTP | Human toxicity potential |

| IEA | International Energy Agency |

| IECM | Integrated Environmental Control Model |

| INDC | Intended Nationally Determined Contributions |

| IPCC | Intergovernmental Panel on Climate Change |

| IR | Ionizing radiation |

| ISO | International Organization for Standardization |

| LCA | Life Cycle Assessment |

| LCIA | Life Cycle Impact Assessment |

| LCI | Life Cycle Inventory |

| LPT | Low-pressure turbine |

| LU | Land use |

| MAETP | Marine/aquatic ecotoxicity potential |

| MEA | Monoethanolamine |

| MEC | Marine ecotoxicity |

| MEP | Marine eutrophication potential |

| MEU | Marine eutrophication |

| MRS | Mineral resource scarcity |

| NG | Natural Gas |

| NGCC | Natural Gas Combined Cycle |

| ODP | Ozone layer depletion potential |

| OFHH | Ozone formation affecting human health |

| OFTE | Ozone formation affecting terrestrial ecosystems |

| PCC | Post-combustion carbon capture |

| PMFP | particulate matter formation potential |

| POCP | photochemical ozone creation potential |

| POFP | Photochemical oxidant formation potential |

| SDg95 | Overall uncertainty for a flow with a lognormal distribution |

| SO2 | Sulfur dioxide |

| SOD | Stratospheric ozone depletion |

| TWC | Total water consumption |

| TETP | Terrestrial ecotoxicity potential |

| TAC | Terrestrial acidification |

| LCI | Life Cycle Inventory |

| LPT | Low-pressure turbine |

| LU | Land use |

Appendix A

References

- Hoegh-Guldberg, O.; Jacob, D.; Taylor, M.; Bindi, M.; Brown, S.; Camilloni, I.; Diedhiou, A.; Djalante, R.; Ebi, K.; Engelbrecht, F.; et al. IPCC Impacts of 1.5 °C Global Warming on Natural and Human Systems. In Global Warming of 1.5 °C.; Masson-Delmotte, V., Zhai, P., Pörtner, H.O., Roberts, D., Skea, J., Shukla, P.R., Pirani, A., Moufouma-Okia, W., Péan, C., Pidcock, R., et al., Eds.; IPCC: Geneva, Switzerland, 2022; pp. 175–312. [Google Scholar] [CrossRef]

- Ibraheem, F.; Jassim, H.M.; Ibraheem, F.H.; Jasim, H.A. Environmental Impact of Electrical Power Generators in Iraq. Int. J. Eng. Technol. Manag. Appl. Sci. 2016, 4, 122–134. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2022. 2022. Available online: www.iea.org/t&c/ (accessed on 1 October 2022).

- Ministry of Environment. United Nations Development Programme IraqIraq’s Nationally Determined Contributions to UNFCCC.; Ministry of Environment: Baghdad, Iraq, 2015. [Google Scholar]

- International Energy Agency. Key World Energy Statistics 2021; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Faramawy, S.; Zaki, T.; Sakr, A.-E. Natural gas origin, composition, and processing: A review. J. Nat. Gas Sci. Eng. 2016, 34, 34–54. [Google Scholar] [CrossRef]

- Dellano-Paz, F.; Fernandez, P.M.; Soares, I. Addressing 2030 EU policy framework for energy and climate: Cost, risk and energy security issues. Energy 2016, 115, 1347–1360. [Google Scholar] [CrossRef]

- Atilgan, B.; Azapagic, A. Life cycle environmental impacts of electricity from fossil fuels in Turkey. J. Clean. Prod. 2015, 106, 555–564. [Google Scholar] [CrossRef]

- Gibbins, J.; Chalmers, H. Carbon capture and storage. Energy Policy 2008, 36, 4317–4322. [Google Scholar] [CrossRef]

- IEA. Putting CO2 to Use Creating Value from Emissions; International Energy Agency: Paris, France, 2019. [Google Scholar]

- ISO 14044; Environmental Management-Life Cycle Assessment-Requirements and Guidelines. International Standards Organization: Geneva, Switzerland, 2006.

- ISO 14040; Environmental Management-Life Cycle Assessment-Principles and Framework. International Standards Organization: Geneva, Switzerland, 2006.

- Muthu, S.S. Assessing the Environmental Impact of Textiles and the Clothing Supply Chain; Woodhead Publishing: Sawston, UK, 2014. [Google Scholar] [CrossRef]

- Corsten, M.; Ramirez, A.; Shen, L.; Koornneef, J.; Faaij, A. Environmental impact assessment of CCS chains—Lessons learned and limitations from LCA literature. Int. J. Greenh. Gas Control 2013, 13, 59–71. [Google Scholar] [CrossRef]

- Sathre, R.; Masanet, E.; Cain, J.; Chester, M. The role of Life Cycle Assessment in Identifying and Reducing Environmental Impacts of CCS Environmental Energy Technologies Division. In Proceedings of the 10th Annual Conference on Carbon Capture and Sequestration, Pittsburgh, PA, USA, 2–5 May 2011. [Google Scholar]

- Strazza, C.; Del Borghi, A.; Gallo, M. Development of Specific Rules for the Application of Life Cycle Assessment to Carbon Capture and Storage. Energies 2013, 6, 1250–1265. [Google Scholar] [CrossRef]

- Schreiber, A.; Zapp, P.; Marx, J. Meta-Analysis of Life Cycle Assessment Studies on Electricity Generation with Carbon Capture and Storage. J. Ind. Ecol. 2012, 16, S155–S168. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.; de Coninck, H.; Loos, M.; Leo Meyer, L. Carbon Dioxide Capture and Storage; Cambridge University Press: New York, NY, USA, 2005. [Google Scholar]

- Wang, Y.; Pan, Z.; Zhang, W.; Borhani, T.N.; Li, R.; Zhang, Z. Life cycle assessment of combustion-based electricity generation technologies integrated with carbon capture and storage: A review. Environ. Res. 2021, 207, 112219. [Google Scholar] [CrossRef]

- Lombardi, L. Life cycle assessment comparison of technical solutions for CO2 emissions reduction in power generation. Energy Convers. Manag. 2003, 44, 93–108. [Google Scholar] [CrossRef]

- Singh, B.; Strømman, A.H.; Hertwich, E. Life cycle assessment of natural gas combined cycle power plant with post-combustion carbon capture, transport and storage. Int. J. Greenh. Gas Control 2011, 5, 457–466. [Google Scholar] [CrossRef]

- Odeh, N.A.; Cockerill, T.T. Life cycle GHG assessment of fossil fuel power plants with carbon capture and storage. Energy Policy 2008, 36, 367–380. [Google Scholar] [CrossRef]

- Dones, R.; Bauer, C.; Heck, T.; Mayer-Spohn, O.; Blesl, M. Life Cycle Assessment of Future Fossil Technologies with and without Carbon Capture and Storage. MRS Proc. 2007, 1041. [Google Scholar] [CrossRef]

- Schreiber, A.; Zapp, P.; Kuckshinrichs, W. Environmental assessment of German electricity generation from coal-fired power plants with amine-based carbon capture. Int. J. Life Cycle Assess. 2009, 14, 547–559. [Google Scholar] [CrossRef]

- Christian, B.; Thomas, H.; Roberto, D.; Mayer-Spohn, O.; Markus, B. Final Report on Technical Data, Costs, and Life Cycle Inventories of Advanced Fossil Power Generation Systems. 2008. Available online: https://www.researchgate.net/publication/272130888_Final_report_on_technical_data_costs_and_life_cycle_inventories_of_advanced_fossil_power_generation_systems (accessed on 1 December 2022).

- Garðarsdóttir, S.; Normann, F.; Andersson, K.; Prölß, K.; Emilsdóttir, S.; Johnsson, F. Post-combustion CO2 capture applied to a state-of-the-art coal-fired power plant—The influence of dynamic process conditions. Int. J. Greenh. Gas Control 2015, 33, 51–62. [Google Scholar] [CrossRef]

- Wang, J.; Yu, Z.; Zeng, X.; Wang, Y.; Li, K.; Deng, S. Water-energy-carbon nexus: A life cycle assessment of post-combustion carbon capture technology from power plant level. J. Clean. Prod. 2021, 312, 127727. [Google Scholar] [CrossRef]

- Bao, J.; Zhang, L.; Song, C.; Zhang, N.; Guo, M.; Zhang, X. Reduction of efficiency penalty for a natural gas combined cycle power plant with post-combustion CO2 capture: Integration of liquid natural gas cold energy. Energy Convers. Manag. 2019, 198, 111852. [Google Scholar] [CrossRef]

- Nie, Z.; Korre, A.; Durucan, S. Life cycle modelling and comparative assessment of the environmental impacts of oxy-fuel and post-combustion CO2 capture, transport and injection processes. Energy Procedia 2011, 4, 2510–2517. [Google Scholar] [CrossRef]

- Matin, N.S.; Flanagan, W.P. Life cycle assessment of amine-based versus ammonia-based post combustion CO2 capture in coal-fired power plants. Int. J. Greenh. Gas Control 2021, 113, 103535. [Google Scholar] [CrossRef]

- Giordano, L.; Roizard, D.; Favre, E. Life cycle assessment of post-combustion CO2 capture: A comparison between membrane separation and chemical absorption processes. Int. J. Greenh. Gas Control 2018, 68, 146–163. [Google Scholar] [CrossRef]

- Muramatsu, E.; Iijima, M. Greenhouse Gas Control Technologies; Gale, J., Kaya, Y., Eds.; Elsevier Science Ltd.: Kyoto, Japan, 2003; Volume I. [Google Scholar]

- Koornneef, J.; van Keulen, T.; Faaij, A.; Turkenburg, W. Life cycle assessment of a pulverized coal power plant with post-combustion capture, transport and storage of CO2. Int. J. Greenh. Gas Control 2008, 2, 448–467. [Google Scholar] [CrossRef]

- Barros, M.V.; Salvador, R.; Piekarski, C.M.; de Francisco, A.C.; Freire, F.M.C.S. Life cycle assessment of electricity generation: A review of the characteristics of existing literature. Int. J. Life Cycle Assess. 2019, 25, 36–54. [Google Scholar] [CrossRef]

- Singh, B.; Strømman, A.H.; Hertwich, E.G. Comparative life cycle environmental assessment of CCS technologies. Int. J. Greenh. Gas Control 2011, 5, 911–921. [Google Scholar] [CrossRef]

- Wu, Y.; Hua, J. Investigating a Retrofit Thermal Power Plant from a Sustainable Environment Perspective—A Fuel Lifecycle Assessment Case Study. Sustainability 2022, 14, 4556. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Kanagaraj, N.; Sadeghi, S.; Yousefi, H. Midpoint and endpoint impacts of electricity generation by renewable and nonrenewable technologies: A case study of Alberta, Canada. Renew. Energy 2022, 197, 22–39. [Google Scholar] [CrossRef]

- Türkmen, B.A. Environmental performance of high-efficiency natural gas combined cycle plant. Energy Sources Part A Recover. Util. Environ. Eff. 2021, 44, 57–74. [Google Scholar] [CrossRef]

- Gargiulo, A.; Carvalho, M.L.; Girardi, P. Life Cycle Assessment of Italian Electricity Scenarios to 2030. Energies 2020, 13, 3852. [Google Scholar] [CrossRef]

- Viebahn, P.; Nitsch, J.; Fischedick, M.; Esken, A.; Schüwer, D.; Supersberger, N.; Zuberbühler, U.; Edenhofer, O. Comparison of carbon capture and storage with renewable energy technologies regarding structural, economic, and ecological aspects in Germany. Int. J. Greenh. Gas Control 2007, 1, 121–133. [Google Scholar] [CrossRef]

- Al Monsur, A.; Paddo, A.R.; Mohammedy, F.M. Life Cycle Assessment of Climate Change and GHG Emission from Natural Gas Thermal Power Plant. In Proceedings of the 2020 IEEE Region 10 Symposium (TENSYMP), Dhaka, Bangladesh, 5–7 June 2020; pp. 1628–1631. [Google Scholar] [CrossRef]

- Agrawal, K.K.; Jain, S.; Jain, A.K.; Dahiya, S. A life cycle environmental impact assessment of natural gas combined cycle thermal power plant in Andhra Pradesh, India. Environ. Dev. 2014, 11, 162–174. [Google Scholar] [CrossRef]

- Annisa, R.; Faridah, L.; Yuliawan, D.M.; Sinisuka, N.I.; Dinata, I.S.; Leilan, F.; Revina, T.; Iman, D.; Darma, S. Environmental Impact Assessment of Steam Cycle and Combine Cycle Power Plants Using Life Cycle Assessment Methodology. In Proceedings of the 2018 Conference on Power Engineering and Renewable Energy (ICPERE), Solo, Indonesia, 29–31 October 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Kannan, R.; Leong, K.; Osman, R.; Ho, H.; Tso, C. Gas fired combined cycle plant in Singapore: Energy use, GWP and cost—A life cycle approach. Energy Convers. Manag. 2005, 46, 2145–2157. [Google Scholar] [CrossRef]

- Fadeyi, S.; Arafat, H.A.; Abu-Zahra, M.R. Life cycle assessment of natural gas combined cycle integrated with CO2 post combustion capture using chemical solvent. Int. J. Greenh. Gas Control 2013, 19, 441–452. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J. ReCiPe 2016 A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level Report I: Characterization; RIVM: Bilthoven, The Netherlands, 2016. [Google Scholar]

- Bare, J. TRACI 2.0: The tool for the reduction and assessment of chemical and other environmental impacts 2.0. Clean Technol. Environ. Policy 2011, 13, 687–696. [Google Scholar] [CrossRef]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef]

- World Bank Group. Iraq—Emergency Electricity Reconstruction Project: Environmental Assessment (Vol. 2) Rapid Risk Assessment of Atmospheric Dispersion of Stack Emissions from Al-Hartha Power Plant (English); World Bank Group: Washington, DC, USA, 2006; Available online: http://documents.worldbank.org/curated/en/640751468253482219/Rapid-risk-assessment-of-atmospheric-dispersion-of-stack-emissions-from-Al-Hartha-power-plant (accessed on 1 November 2022).

- JICA. Baseline Survey for Supporting Electric Power Sector in Republic of Iraq Final Report; Japan International Cooperation Agency: Tokyo, Japan, 2004. [Google Scholar]

- MHPS. MHPS Receives Order for Refurbishment of Unit 1 at Hartha Thermal Power Station in Iraq—Project to Restore Gas-and Oil-Fired Steam Turbine Equipment to the Rated 200 MW; Mitsubishi Heavy Industries, Ltd.: Yokohama, Japan, 2018. [Google Scholar]

- Liang, Z.; Rongwong, W.; Liu, H.; Fu, K.; Gao, H.; Cao, F.; Zhang, R.; Sema, T.; Henni, A.; Sumon, K.Z.; et al. Recent progress and new developments in post-combustion carbon-capture technology with amine based solvents. Int. J. Greenh. Gas Control 2015, 40, 26–54. [Google Scholar] [CrossRef]

- Hasan, S.; Abbas, A.; Nasr, G. Improving the Carbon Capture Efficiency for Gas Power Plants through Amine-Based Absorbents. Sustainability 2020, 13, 72. [Google Scholar] [CrossRef]

- Chowdhury, F.A.; Yamada, H.; Matsuzaki, Y.; Goto, K.; Higashii, T.; Onoda, M. Development of Novel Synthetic Amine Absorbents for CO2 Capture. Energy Procedia 2014, 63, 572–579. [Google Scholar] [CrossRef]

- Hirata, T.; Kishimoto, S.; Shimada, D.; Kawasaki, S. MHI’s Commercial Experiences with CO2 Capture and Recent R&D Activities. In Mitsubishi Heavy Industries Technical Review; Mitsubishi Heavy Industries, Ltd.: Yokohama, Japan, 2018. [Google Scholar]

- Peeters, A.; Faaij, A.; Turkenburg, W. Techno-economic analysis of natural gas combined cycles with post-combustion CO2 absorption, including a detailed evaluation of the development potential. Int. J. Greenh. Gas Control 2007, 1, 396–417. [Google Scholar] [CrossRef]

- Kadono, K.; Suzuki, A.; Iijima, M.; Ohishi, T.; Tanaka, H.; Hirata, T.; Kondo, M. New Energy Efficient Processes and Newly Developed Absorbents for Flue Gas CO2 Capture. Energy Procedia 2013, 37, 1785–1792. [Google Scholar] [CrossRef]

- Jha, A.; Ravuru, V.; Yadav, M.; Mandal, S.; Das, A. A Critical Analysis of CO2 Capture Technologies. Hydrocarb. Process. 2021, 6, 59–65. [Google Scholar]

- Heijungs, R.; Guinée, J.B.; Huppes, G.; Lankreijer, R.M.; Udo de Haes, H.A.; Wegener Sleeswijk, A.; Ansems, A.M.M.; Eggels, P.G.; van Duin, R.; Goede, H.P.; et al. Environmental Life Cycle Assessment of Products: Guide and Backgrounds; Centre of Environmental Science: Leiden, The Netherlands, 1992. [Google Scholar]

- Eggleston, H.S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. IPCC 2006. Japan: The Institute for Global Environmental Strategies (IGES); IPCC: Geneva, Switzerland, 2006. [Google Scholar]

- van Zelm, R.; Preiss, P.; van Goethem, T.; Van Dingenen, R.; Huijbregts, M. Regionalized life cycle impact assessment of air pollution on the global scale: Damage to human health and vegetation. Atmospheric Environ. 2016, 134, 129–137. [Google Scholar] [CrossRef]

- Roy, P.-O.; Huijbregts, M.; Deschênes, L.; Margni, M. Spatially-differentiated atmospheric source–receptor relationships for nitrogen oxides, sulfur oxides and ammonia emissions at the global scale for life cycle impact assessment. Atmospheric Environ. 2012, 62, 74–81. [Google Scholar] [CrossRef]

- Panja, P.; McPherson, B.; Deo, M. Techno-Economic Analysis of Amine-based CO2 Capture Technology: Hunter Plant Case Study. Carbon Capture Sci. Technol. 2022, 3. [Google Scholar] [CrossRef]

- Ecoinvent. Database. 2019. Available online: https://www.ecoinvent.org/ (accessed on 12 November 2019).

- Goedkoop, M.; Oele, M.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction to LCA with SimaPro Title: Introduction to LCA with SimaPro. 2016. Available online: www.pre-sustainability.com (accessed on 10 August 2022).

- Mcpherson, B. Carbonsafe Rocky Mountain Phase I: Ensuring Safe Subsurface Storage of Carbon Dioxide in the Intermountain WEST Final Report; University of Utah: Salt Lake City, UT, USA, 2017. [Google Scholar]

- Bellotti, D.; Rivarolo, M.; Magistri, L.; Massardo, A. Feasibility study of methanol production plant from hydrogen and captured carbon dioxide. J. CO2 Util. 2017, 21, 132–138. [Google Scholar] [CrossRef]

- Ravikumar, D.; Keoleian, G.; Miller, S. The environmental opportunity cost of using renewable energy for carbon capture and utilization for methanol production. Appl. Energy 2020, 279, 115770. [Google Scholar] [CrossRef]

- Koiwanit, J.; Piewkhaow, L.; Zhou, Q.; Manuilova, A.; Chan, C.W.; Wilson, M.; Tontiwachwuthikul, P. A life cycle assessment study of a Canadian post-combustion carbon dioxide capture process system. Int. J. Life Cycle Assess. 2013, 19, 357–369. [Google Scholar] [CrossRef]

- von der Assen, N.; Müller, L.J.; Steingrube, A.; Voll, P.; Bardow, A. Selecting CO2 Sources for CO2 Utilization by Environmental-Merit-Order Curves. Environ. Sci. Technol. 2016, 50, 1093–1101. [Google Scholar] [CrossRef]

- CMU IECM Technical Documentation: Amine-based Post-Combustion CO2 Capture. Pittsburgh, PA, USA. 2018. Available online: www.iecm-online.com (accessed on 1 August 2022).

- Rao, A.B.; Rubin, E.S. A Technical, Economic, and Environmental Assessment of Amine-Based CO2 Capture Technology for Power Plant Greenhouse Gas Control. Environ. Sci. Technol. 2002, 36, 4467–4475. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Exposure Factors Handbook; EPA/600/P-95/002Fa-c; U.S. Environmental Protection Agency: Washington, DC, USA, 1997.

- United Nations. World Population Prospects: The 2008 Revision; United Nations: New York, NY, USA, 2009. [Google Scholar]

- Jane Bare TRACI V 2.1. 2012. Available online: https://www.epa.gov/chemical-research/tool-reduction-and-assessment-chemicals-and-other-environmental-impacts-traci (accessed on 1 December 2022).

- Ou, Y.; Zhai, H.; Rubin, E.S. Life cycle water use of coal- and natural-gas-fired power plants with and without carbon capture and storage. Int. J. Greenh. Gas Control 2016, 44, 249–261. [Google Scholar] [CrossRef]

- Humbert, S. Geographically Differentiated Life-Cycle Impact Assessment of Human Health. Ph.D. Thesis, University of California, Berkeley, CA, USA, 2009. [Google Scholar]

- Humbert, S.; Marshall, J.D.; Shaked, S.; Spadaro, J.V.; Nishioka, Y.; Preiss, P.; McKone, T.E.; Horvath, A.; Jolliet, O. Intake Fraction for Particulate Matter: Recommendations for Life Cycle Impact Assessment. Environ. Sci. Technol. 2011, 45, 4808–4816. [Google Scholar] [CrossRef]

- Wang, E.; Shen, Z. A hybrid Data Quality Indicator and statistical method for improving uncertainty analysis in LCA of complex system—application to the whole-building embodied energy analysis. J. Clean. Prod. 2013, 43, 166–173. [Google Scholar] [CrossRef]

- Weidema, B.P.; Wesnæs, M. Data quality management for life cycle inventories—an example of using data quality in-dicators☆. J. Clean. Prod. 1996, 4, 167–174. [Google Scholar] [CrossRef]

- Barahmand, Z.; Eikeland, M.S. Life Cycle Assessment under Uncertainty: A Scoping Review. World 2022, 3, 692–717. [Google Scholar] [CrossRef]

- Heijungs, R.; Huijbregts, M.A.J. A Review of Approaches to Treat Uncertainty in LCA. International Congress on Environmental Modelling and Software. 197. 2004. Available online: https://scholarsarchive.byu.edu/iemssconference/2004/all/197 (accessed on 1 November 2022).

- Huijbregts, M.A.J. Uncertainty and Variability in Environmental Life-Cycle Assessment. Ph.D. Thesis, Universiteit van Amsterdam, Amsterdam, The Netherlands, 2001. [Google Scholar]

| Area | Life Cycle Inventory | LCIA Method | Impact Categories | Ref. |

|---|---|---|---|---|

| Norway | Norway 2000 statistical database, modeling data, Ecoinvent v2 | ReCiPe 2008 | GWP, AP, MEP, POFP, PMFP, HTP, TETP, FAETP, MAETP | [35] |

| Taiwan | Ecoinvent database | IPCC 2007, IMPACT2002+ | GWP, PM10, SOx, NOx, and CO | [36] |

| Canada | Ecoinvent 3.7.1 database, specific regional data | ReCiPe 2016 Endpoint, Cumulative Energy Demand (CED) | PMFP, FRS, MEC, MRS, TEC, FEC, FEU, LU, GWP, HCT, HnCT, IR, MEU, OFHH, OFTE, SOD, TWC, and TAC | [37] |

| Turkey | Ecoinvent, Öko Institute, Sphera database | CML 2001 | ADP, AP, EP, FAETP, GWP, HTP, MAETP, ODP, POCP, TETP | [38] |

| Italy | Italian power plants, Eurostat, TERNA, INECP, Ecoinvent 3.3 | Different methods applied | GWP, FEU, MAETP, MEP, POFP,PMFP, HTP, TETP, FAETP, ODP | [39] |

| Germany | Umberto LCA database, Ecoinvent v1.01 | UBA-Verfahren | GWP, PMFP, HTP, POFP, ADP | [40] |

| Bangladesh | Plant authority, Ecoinvent database V3 | CML 2001 and Eco-Indicator 99 (H) | GHG, CCP | [41] |

| India | Plant Visit, Ecoinvent Database V2.2 | Eco-Indicator 99 (H), CML 2001 | GWP, AP, EP HTP, MAETP, FAETP | [42] |

| Indonesia | Industrial data | CML, ILCD. and ReCiPe IPCC 2013, IPCC 2007 | GWP, AP, POCP, EP, PMFP | [43] |

| Singapore | Literature | IPCC 2000 | GWP | [44] |

| Algeria | Ecoinvent V2.2 | Not mentioned | GWP, AP, TETP, MAETP, FAETP, MEP, POFP | [45] |

| Parameter | Value 1 |

|---|---|

| Net power output (MW) | 371 |

| Annual load (hours) | 7451 |

| Net power plant efficiency (%) | 33 |

| Number of stacks | 4 |

| Height of stack, (m) | 100 |

| Natural gas Specific gravity | 0.7076 |

| Natural gas consumption rate (kg/kWh) | 280 |

| Lifetime (years) | 10 |

| Industrial wastewater effluents discharge (m3/h) | 350 2 |

| Flow rate of cooling water (m3/h) | 101,400 2 |

| CO2 flue gas (1000 m3/h) | 252 2 |

| CO flue gas (1000 m3/h) | 194 2 |

| SO2 flue gas (1000 m3/h) | 15 2 |

| Parameter | 90% Capture |

|---|---|

| Purity of CO2 stream (%) | ≥95 |

| Temperature of CO2 product (°C | 95 |

| Stream pressure of CO2 product (psia) | 2215 |

| CO2 emissions (lb/MWh) | 193 |

| Steam 1 (ton/tCO2) | 1.19 |

| Cooling Water 2 (ton/tCO2) | 105 |

| Component | Ref. | ||

|---|---|---|---|

| Construction | |||

| Power Plant | Eoinvent Database, Gas power plant, combined cycle, 400 MW construction | [64,65] | |

| MEA plant 1 [tonne] | |||

| Stripper | Stainless steel | 4107.1 | [66] |

| Absorber | Stainless steel | 2657.4 | [66] |

| Reboiler | Stainless steel | 3060.1 | [66] |

| Pre-scrubber | Stainless steel | 1911.4 | [66] |

| Amine recovery tank | HDLPE 2 | 945.8 | [66] |

| Condensate tank | HDLPE | 1527.5 | [66] |

| Amine storage tank | HDLPE | 1436.5 | [66] |

| Reclaimer polyethylene tank | HDLPE | 3874.3 | [66] |

| NaOH storage polyethylene tank | HDLPE | 792.1 | [66] |

| Piping and small equipment | Stainless steel | 4107.1 | [66] |

| Concrete | Reinforced | 191.6 | [66] |

| Operation (Chemicals) [kg/tCO2] | |||

| Activated carbon | 0.059 | [67,68] | |

| MEA input | 1.65 | [69] | |

| NaOH | 0.1565 | [67,70] | |

| Water | 655 | [68,70] | |

| Utility (kWh/tCO2) | |||

| Electricity 3 | 230 | [68] | |

| Simulation Results | Nominal Value |

|---|---|

| CO2 removal efficiency a | 90% |

| NO2 removal efficiency a | 25% |

| SO2 removal efficiency a | 99% |

| PM10 removal efficiency a | 50% |

| MEA concentration (wt) a | 32% |

| Activated Carbon Flow Rate (tonne/h) | 0.007245 |

| Cooling water Make-up (tonne/h) | 0.0228 |

| Captured CO2 Flow Rate (tonne/h) | 96.62 |

| Scrubber Solids Disposed Flow Rate (tonne/h) | 0.01969 |

| Flue Gas Fan Use (MW) | 3.742 |

| Sorbent Pump Use (MW) | 0.1916 |

| CO2 Compression Use (MW) | 8.985 |

| Sorbent Regen. Equiv. Energy (MW) | 28.16 |

| Amine Steam Use (Elec. Equiv.) (MW) | 28.16 |

| CO2 Pressure (MPa) | 13.74 |

| Impact Categories | GWP (kg CO2 eq) | PMFP (g PM2.5 eq) | AP (g SO2 eq) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Life Cycle Impact Assessment Method (LCIA) | ReCipe 2016 Midpoint (H) | TRACI 2.1 | IMPACT 2002+ V2.15 | ReCipe 2016 Midpoint (H) | TRACI 2.1 | IMPACT 2002+ V2.15 | ReCipe 2016 Midpoint (H) | TRACI 2.1 | IMPACT 2002+ V2.15 | |

| Total Impact | Retrofit | 0.178 | 0.175 | 0.172 | 0.21 | 0.045 | 0.1 | 0.69 | 0.82 | 0.82 |

| Grassroots | 0.127 | 0.125 | 0.123 | 0.24 | 0.051 | 0.1 | 0.81 | 0.9 | 0.93 | |

| Infrastructure | Retrofit | 0.0041 | 0.00408 | 0.00398 | 0.006 | 0.004 | 0.004 | 0.01 | 0.014 | 0.014 |

| Grassroots | 0.0024 | 0.00239 | 0.00233 | 0.005 | 0.003 | 0.004 | 0.011 | 0.013 | 0.014 | |

| Direct Emissions1 | Retrofit | 0.0964 | 0.09520 | 0.09360 | 0.042 | 0.006 | 0.042 | 0.132 | 0.234 | 0.234 |

| Grassroots | 0.0721 | 0.07150 | 0.07060 | 0.036 | 0.004 | 0.038 | 0.116 | 0.212 | 0.212 | |

| Natural Gas Production | Retrofit | 0.0753 | 0.07390 | 0.07220 | 0.159 | 0.035 | 0.053 | 0.537 | 0.566 | 0.566 |

| Grassroots | 0.0503 | 0.04940 | 0.04820 | 0.198 | 0.043 | 0.06 | 0.677 | 0.696 | 0.696 | |

| Indirect Emissions2 | Retrofit | 0.0021 | 0.00206 | 0.00195 | 0.003 | 0.002 | 0.002 | 0.007 | 0.008 | 0.008 |

| Grassroots | 0.0021 | 0.00206 | 0.00195 | 0.003 | 0.002 | 0.002 | 0.007 | 0.009 | 0.010 | |

| Variables | Lower Limit | Upper Limit |

|---|---|---|

| Activated carbon a (kg/tone CO2) | 0.038 | 0.081 |

| MEA input b (kg/tone CO2) | 0.2 | 3.2 |

| NaOH a (kg/tone CO2) | 0.014 | 0.3 |

| Ammonia emissions a (kg/tone CO2) | 0.036 | 0.32 |

| MEA emissions a (g/tone CO2) | 0.0628 | 0.064 |

| Water a (kg/tone CO2) | 210 | 1100 |

| Formaldehyde emissions a (g/tone CO2) | 0.0002 | 0.263 |

| Acetaldehyde emissions a (g/tone CO2) | 0.0001 | 0.168 |

| Quality Score | Data Quality Indicators | ||||

|---|---|---|---|---|---|

| Reliability | Completeness | Geographic Factor | Technological Correlation | Temporal Factor | |

| 5 | Measurable data that have been verified | Date from all sources related to the market considered | Date from the study area | Process-related data related to enterprises and the identical technology | More than 15 years or unknown |

| 4 | Data either validated based on assumption or measurements-based data | Date from ≥50% of relevant sources for the considered market | Average data from which the study area is included | Process data from different enterprises with identical technology | Less than 15 years |

| 3 | Data that has not been verified and is based on qualified estimations | Data from ≤50% of relevant sources for the considered market | Regional data | Technologically different data but with same materials and process | Less than 10 years |

| 2 | Qualified estimate, data derived from theoretical information | Data from a single relevant source | National data | Data from the process studied of the enterprise with similar technology on the laboratory scale | Less than 6 years |

| 1 | Non-qualified estimate | Data from a small number of sources during a short period | Unknown data or other international data | Laboratory scale of different technology | Less than 3 years to the baseline year |

| Phase | Dataset | Reliability | Completeness | Temporal Correlation | Geographical Correlation | Additional Technology Correlation | |

|---|---|---|---|---|---|---|---|

| Raw materials | Cement | 2 | 1 | 4 | 2 | 1 | 3.05 |

| Steel | 1 | 2 | 4 | 3 | 1 | 3.05 | |

| Polyethylene | 2 | 3 | 3 | 2 | 1 | 3.02 | |

| Concrete | 1 | 2 | 4 | 4 | 1 | 3.05 | |

| Air emissions | Carbon dioxide | 1 | 2 | 3 | 1 | 1 | 1.12 |

| Methane | 1 | 2 | 3 | 2 | 1 | 1.52 | |

| Carbon monoxide | 1 | 3 | 4 | 2 | 2 | 5.06 | |

| Hydrogen dioxide | 1 | 2 | 3 | 2 | 1 | 1.52 | |

| Sulfur dioxide | 1 | 3 | 4 | 3 | 1 | 1.21 | |

| Nitrogen dioxide | 1 | 2 | 4 | 2 | 1 | 1.56 | |

| Ammonia | 1 | 2 | 3 | 1 | 1 | 1.52 | |

| PM 2.5 μm | 2 | 2 | 3 | 5 | 1 | 3.05 | |

| PM 10 μm | 1 | 2 | 4 | 2 | 1 | 2.05 | |

| Water emissions | COD | 1 | 4 | 5 | 5 | 1 | 1.59 |

| Ammonia | 1 | 2 | 3 | 4 | 1 | 1.52 | |

| Soil emissions | Lead | 1 | 2 | 2 | 4 | 2 | 1.51 |

| Chromium | 1 | 2 | 3 | 4 | 1 | 1.52 | |

| Arsenic | 2 | 1 | 4 | 2 | 1 | 1.56 | |

| Cadmium | 1 | 2 | 4 | 3 | 1 | 1.57 | |

| Mercury | 2 | 3 | 3 | 2 | 1 | 1.53 | |

| Waste treatment | Water | 1 | 2 | 4 | 4 | 1 | 5.06 |

| Impact Category | Scenario | Unit | Mean | Median | CV | SD | SEM |

|---|---|---|---|---|---|---|---|

| GWP | Retrofit | (kg CO2 eq) | 0.178 | 0.176 | 9.32% | 0.0166 | 5.26 × 10−4 |

| Grassroots | 0.127 | 0.126 | 8.34% | 0.0106 | 3.34 × 10−4 | ||

| PMFP | Retrofit | (kg PM2.5 eq) | 2.24 × 10−4 | 2.19 × 10−4 | 15.2% | 3.41 × 10−5 | 1.08 × 10−6 |

| Grassroots | 2.57 × 10−4 | 2.51 × 10−4 | 16.8% | 4.32 × 10−5 | 1.37 × 10−6 | ||

| AP | Retrofit | (kg SO2 eq) | 8.04 × 10−4 | 7.91 × 10−4 | 15% | 1.21 × 10−4 | 3.81 × 10−6 |

| Grassroots | 9.27 × 10−4 | 9.06 × 10−4 | 15.9% | 1.47 × 10−4 | 4.66 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, R.K.; Farzaneh, H. Life Cycle Environmental Impacts Assessment of Post-Combustion Carbon Capture for Natural Gas Combined Cycle Power Plant in Iraq, Considering Grassroots and Retrofit Design. Energies 2023, 16, 1545. https://doi.org/10.3390/en16031545

Mohammed RK, Farzaneh H. Life Cycle Environmental Impacts Assessment of Post-Combustion Carbon Capture for Natural Gas Combined Cycle Power Plant in Iraq, Considering Grassroots and Retrofit Design. Energies. 2023; 16(3):1545. https://doi.org/10.3390/en16031545

Chicago/Turabian StyleMohammed, Rudha Khudhair, and Hooman Farzaneh. 2023. "Life Cycle Environmental Impacts Assessment of Post-Combustion Carbon Capture for Natural Gas Combined Cycle Power Plant in Iraq, Considering Grassroots and Retrofit Design" Energies 16, no. 3: 1545. https://doi.org/10.3390/en16031545

APA StyleMohammed, R. K., & Farzaneh, H. (2023). Life Cycle Environmental Impacts Assessment of Post-Combustion Carbon Capture for Natural Gas Combined Cycle Power Plant in Iraq, Considering Grassroots and Retrofit Design. Energies, 16(3), 1545. https://doi.org/10.3390/en16031545