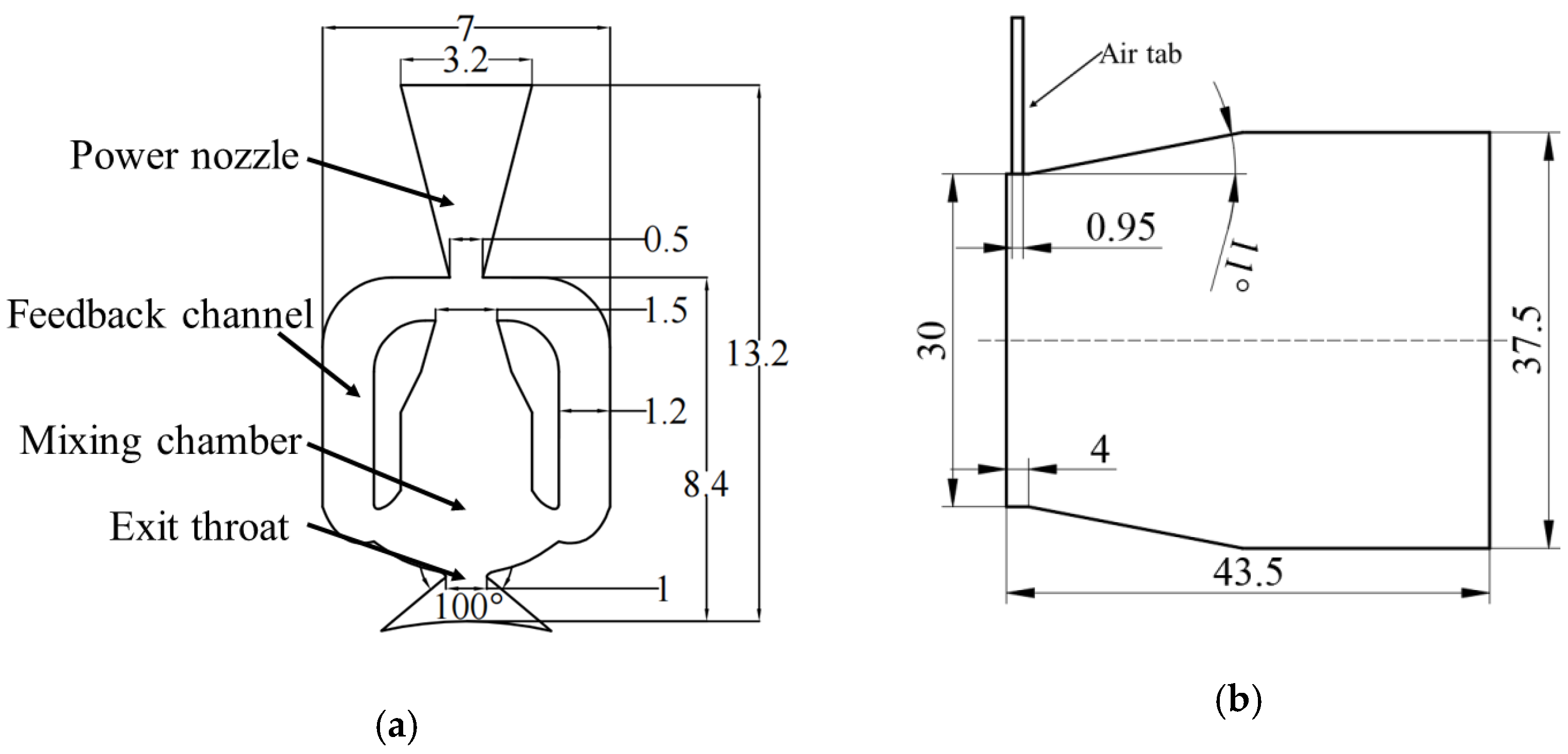

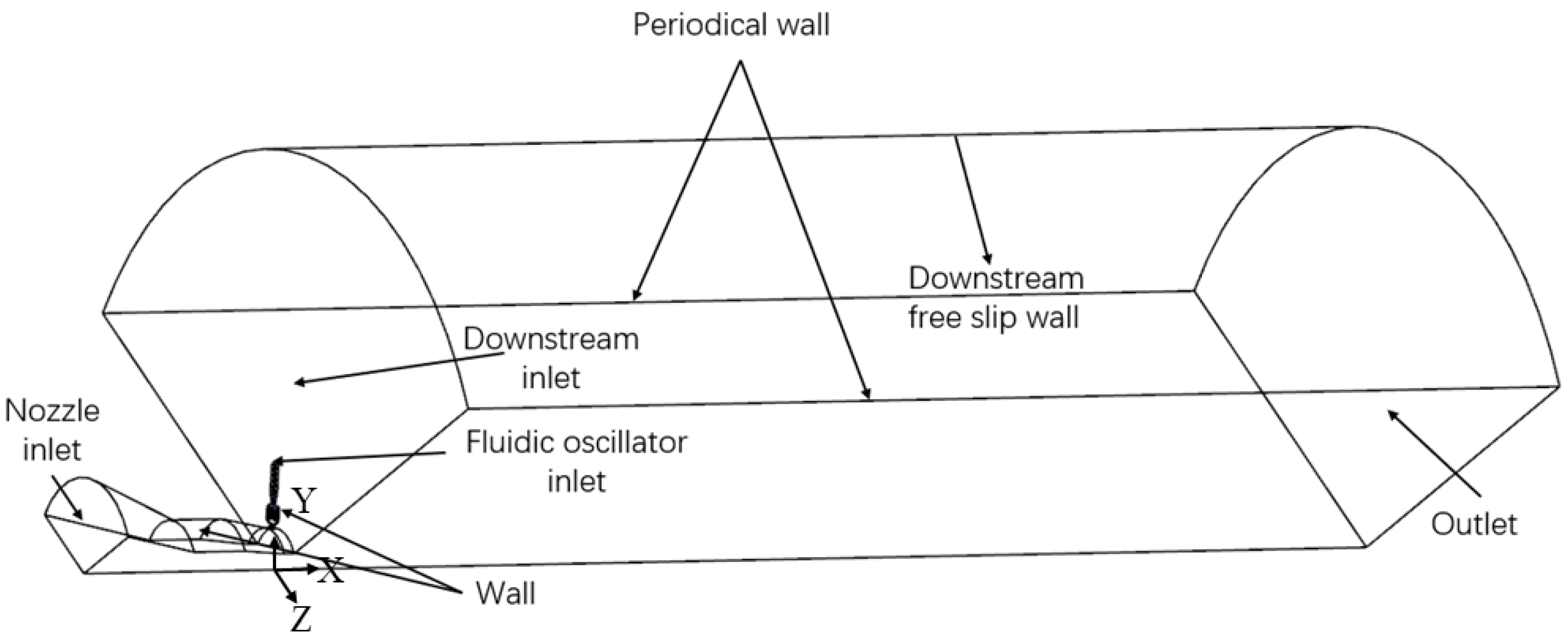

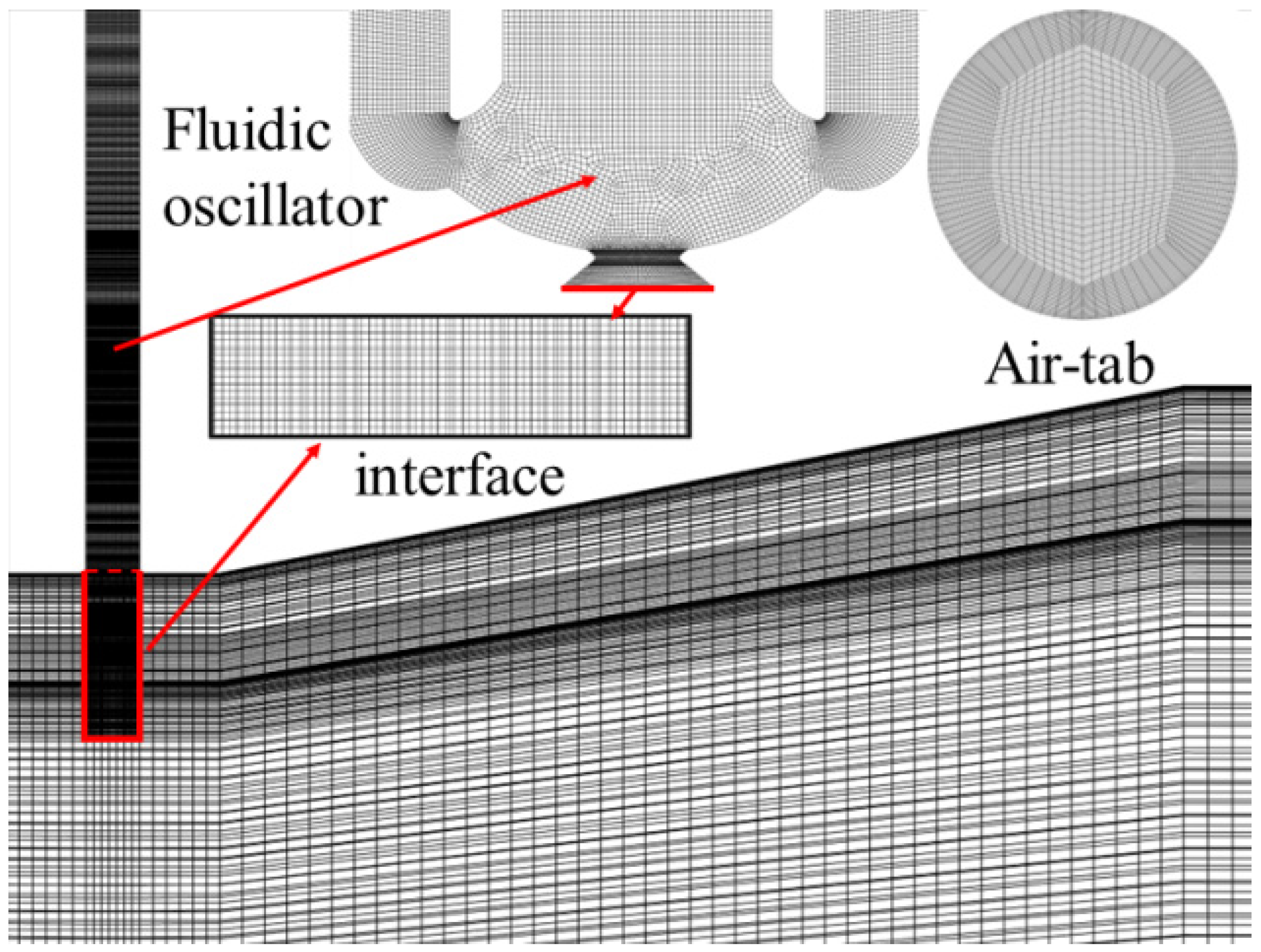

3.1. Mechanism of Fluidic Mixer

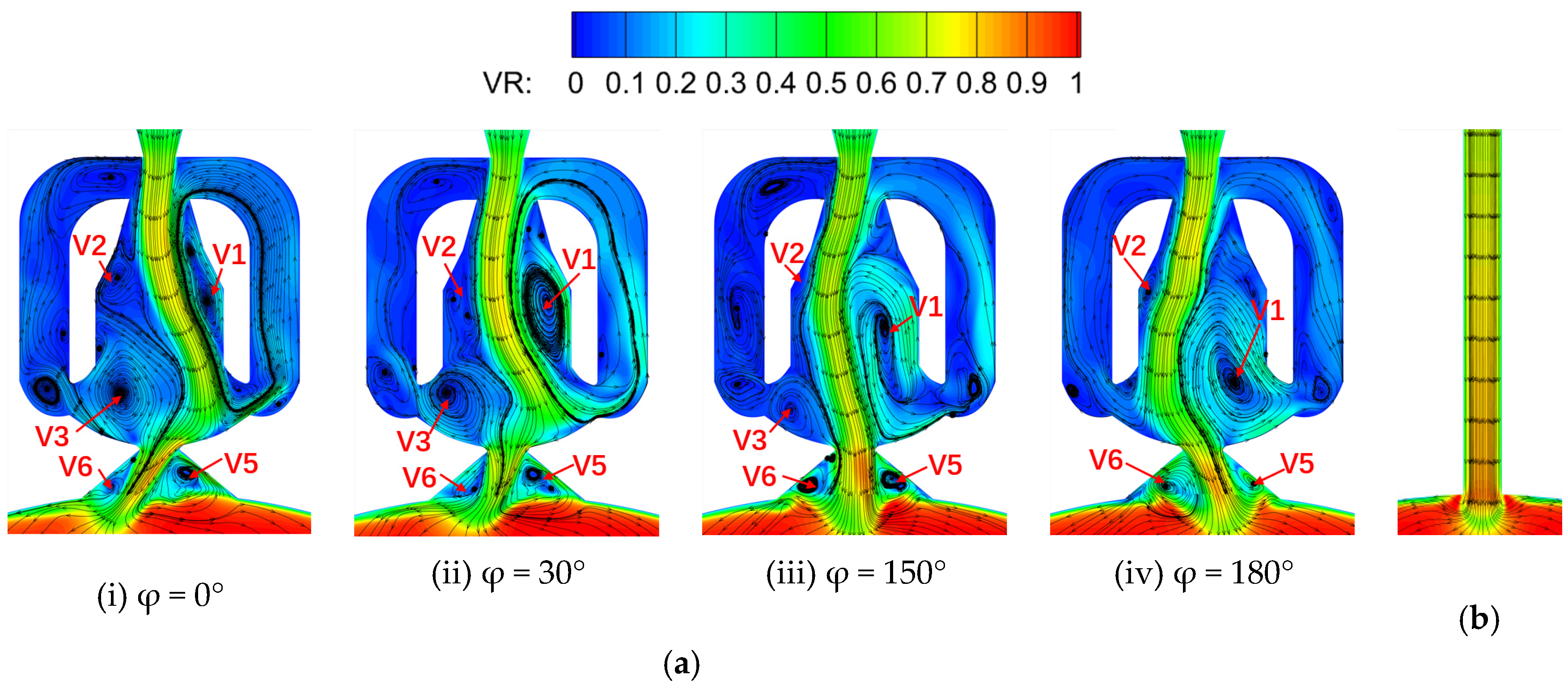

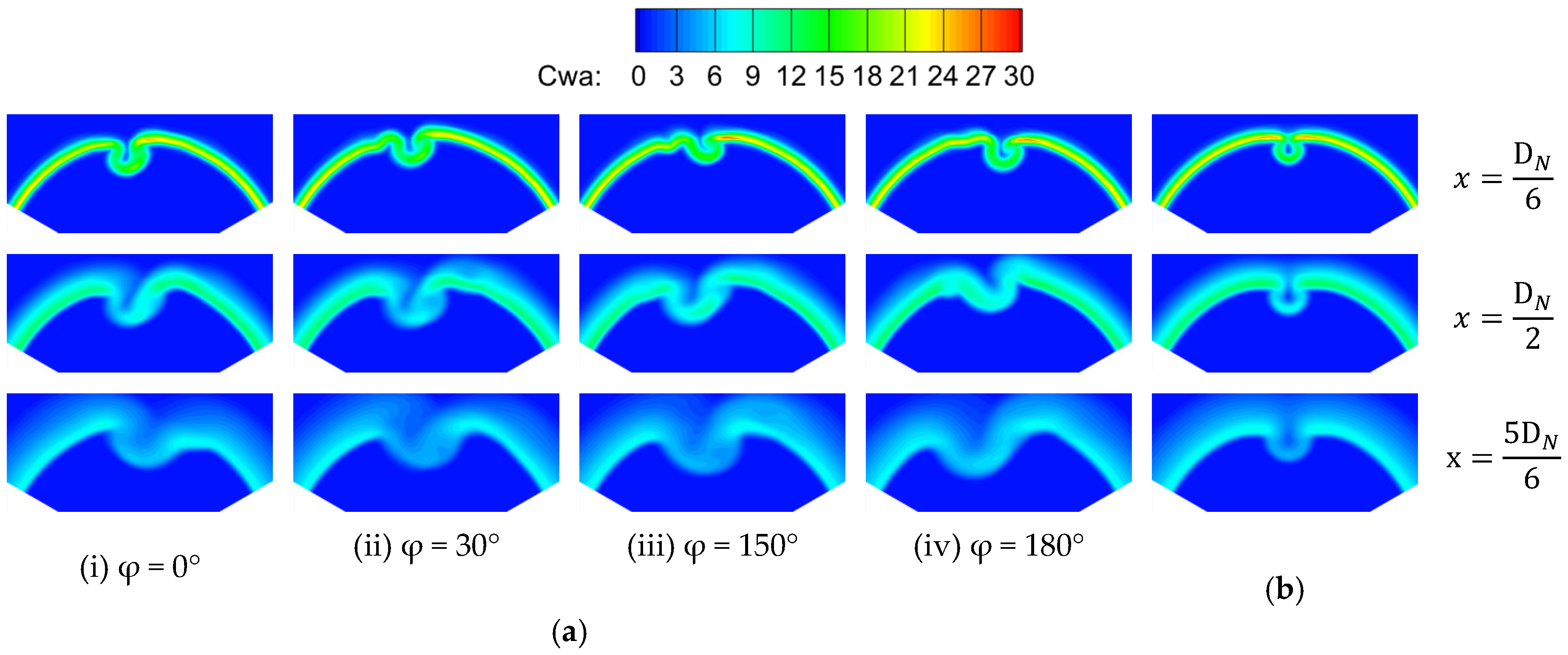

Figure 7 shows the instantaneous flow field inside the fluidic oscillator at four phase positions during a half-sweeping cycle with an inlet total pressure of 140 kPa, and compares it with that of the steady air tab. In this paper, the phase with φ = 0° was defined as the moment at which the jet entered the main flow from the left extreme boundary of the oscillator exit. At the φ = 0° phase, the jets attached to the right wall of the mixing chamber, and most of them entered the throat through the right side of the mixing chamber and sprayed into the main flow, while a small amount of the jets entered the right feedback channel driven by vortex V3 on the left, and this feedback flow in turn pushed the main jet to move to the left at the entrance of the mixing chamber, thus gradually forming a separation vortex V1 on the right side of the mixing chamber. As this separation vortex increased (e.g., φ = 30°–180°), the main jet inside the mixing chamber was gradually pushed to the left wall, the separation vortex V2 on the left wall was reduced, and the vortex V3 on the left side of the throat was also continuously squeezed. When φ = 180°, the vortex V1 developed to its maximum scale: on the one hand, it basically blocked the right feedback channel; on the other hand, it pushed the flow in the mixing chamber close to the wall on the left side, which made the separation vortex V2 on the left side squeeze to its minimum scale. Finally, the main jet entered the throat from the left side and ejected into the main flow from the right side, realizing the conversion of the main jet direction. At the same time, the vortex V3 blocking the left feedback channel was squeezed out of sight, resulting in a portion of the jet entering the left feedback channel. With the enhancement of this feedback flow on the left side, the jet in the mixing chamber was driven to move toward the right wall. Finally, an unsteady jet sweeping back and forth was formed at the outlet of the fluidic oscillator.

It can be seen that the vortex V3 upstream from the throat and the vortex V4 (not shown here) at its opposite side have two functions: on the one hand, they jointly drive the sweeping of the jet, thus controlling the direction of the outlet jet; on the other hand, they also control the flow entering the feedback channel, so as to indirectly control the size of the separation vortex in the mixing chamber and the frequency of the outlet sweeping jet. Compared with the steady jet of the air tab, the influence range of the fluidic oscillator’s jet in the circumferential direction was qualitatively larger, due to its left–right sweeping characteristics. For the radial penetration of the jet, the penetration of the sweeping jet was slightly lower than that of the air tab only at the phase of φ = 30° (as shown in

Figure 6), and the penetrations at other phases are basically the same as the latter; some of them have even increased.

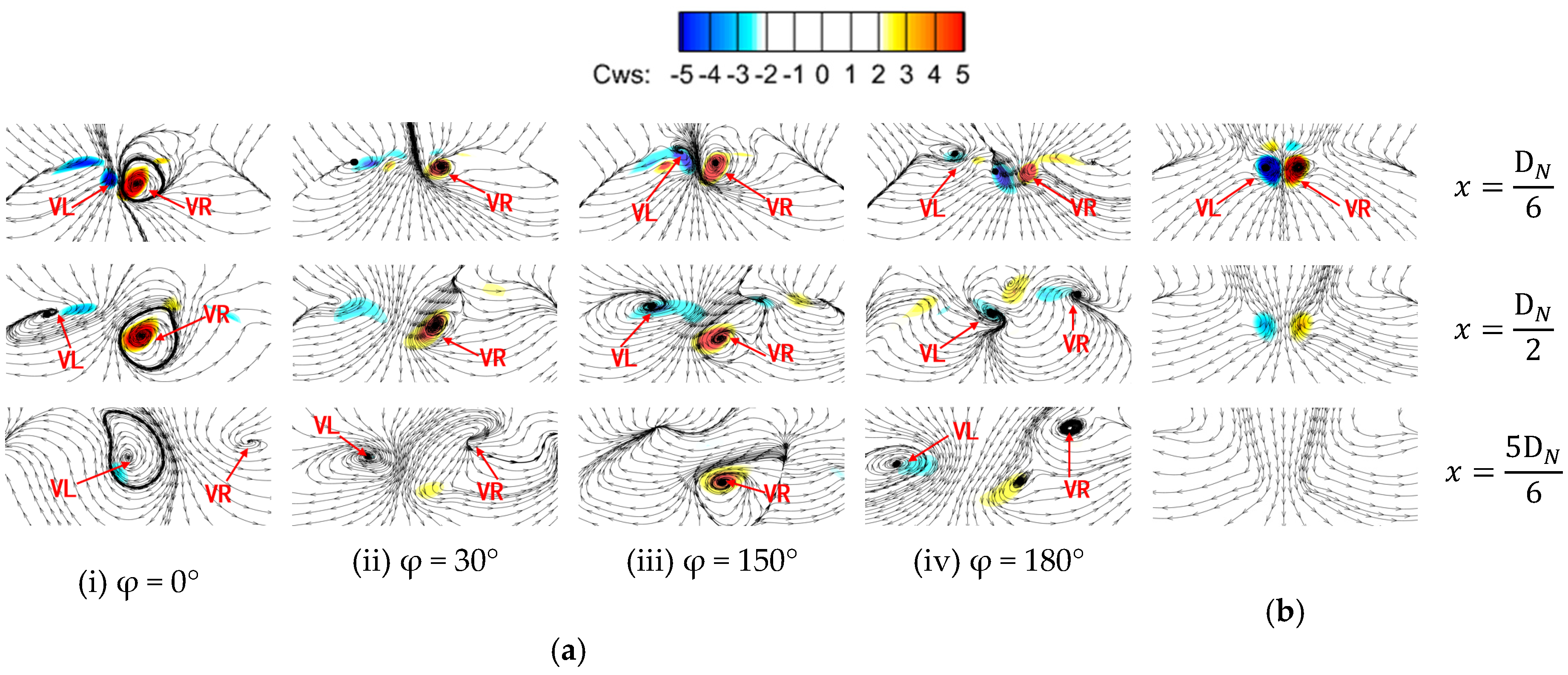

When the sweeping jet ejected into the main flow, the streamwise vortices, induced at the boundary of the main flow, were among the important factors accelerating the mixing.

Figure 8 shows the streamwise vorticity distribution of the sweeping jet at different phases and different axial sections for the case with the inlet total pressure of 140 kPa, and compares it with that of the steady air tab. After the sweeping jet entered the main flow, it induced the formation of a pair of streamwise vortices, as shown by VR and VL in

Figure 8. As shown by the four phases in

Figure 7, the jet’s outlet position gradually changed from the left side of the fluidic oscillator’s exit to the right side, and the jet direction also changed accordingly. When the jet entered the main stream from the left side (such as φ = 0° and 30°), it could be observed that the vortex VL was obviously smaller than the vortex VR in peak magnitude and vortex size (as shown in the axial sections

x = D

N/6–D

N/2 in

Figure 8). This may have been because the development of the VL was restrained by the double constraints of the left-leaning jet and the nozzle wall. However, in the downstream flow development, the stronger vortex VR dissipated faster and was exhausted at

x = 5 D

N/6, where the vortex VL further developed without the nozzle constraints. As the jet entered the main flow almost vertically (i.e., φ = 150°), the VR and VL had roughly the same peak magnitudes and scale (as shown in section

x = D

N/2).

As the jet entered the main stream from the right side (i.e., φ = 180°), the situation was exactly the opposite to that of the left side. At x = DN/3–DN/2, the peak magnitude and scale of the VL were larger than those of the VR, and the VR developed further at x = 5 DN/6 where the VL was almost exhausted. Compared with that of the steady air tab, the peak vorticity of the streamwise vortices induced by the fluidic oscillator was lower in each phase. The peak vorticity of the air tab was 11.0, and that of fluidic oscillator was 10.1. However, compared with the streamwise vortex range shown by the streamline, it was found that the streamwise vortex scale of the sweeping jet was obviously larger than that of the steady jet. At x = 5 DN/6, the streamwise vortices induced by the air tab were completely dissipated, while the streamwise vortices induced by the fluidic oscillator still had a distinct structure in each phase, which suggests that the latter lasts longer. Under the same inlet conditions, the peak streamwise vorticity of the steady air-tab jet was higher than that of the sweeping jet, while the sweeping jet had a streamwise vortex pair with a larger scale and a longer duration. Therefore, further study is required to determine which kind of jet is more conducive to accelerating jet mixing.

The azimuthal vorticity, as the sum of the vorticity on the section perpendicular to the streamwise direction, can represent the strength of planar vortices; therefore, it can also characterize the intensity of small-scale mixing to a certain extent.

Figure 9 shows the azimuthal vorticity distribution of the sweeping jet at different phases and different axial sections for the case with the inlet total pressure of 140 kPa and compares it with that of the steady air-tab jet. The jet at the outlet of the fluidic oscillator and the vortices on its left and right sides (V5 and V6 in

Figure 7) distorted the planar vortices band downstream from the main nozzle, and the deflection direction of the planar vortices band at different phases was consistent with the direction of the sweeping jet (as shown on the axial section

x = D

N/6 in

Figure 9). Compared with that of the steady air tab, the peak azimuthal vorticity of the sweeping jet did not increase significantly, but its radial and circumferential scale increased, especially the latter. Moreover, this difference became greater with the development of jet mixing. This means that sweeping jets with larger planar vortices can be more conducive to promoting small-scale mixing. At

x = 5 D

N/6, the residual azimuthal vorticity downstream from the air tab was significantly smaller than that of the fluidic oscillator at each phase, which indicated that the planar vortices induced by the steady air-tab jet dissipated more rapidly. The planar vortices downstream from the two fluidic mixers were almost dissipated completely on the axial section

x = 1.0 D

N. Combined with the above analysis on the streamwise vortices, the following conclusion could be inferred: the action regions of the streamwise vortices and planar vortices induced by the two jets were confined to the range of 1.00 × D

N downstream from the nozzle.

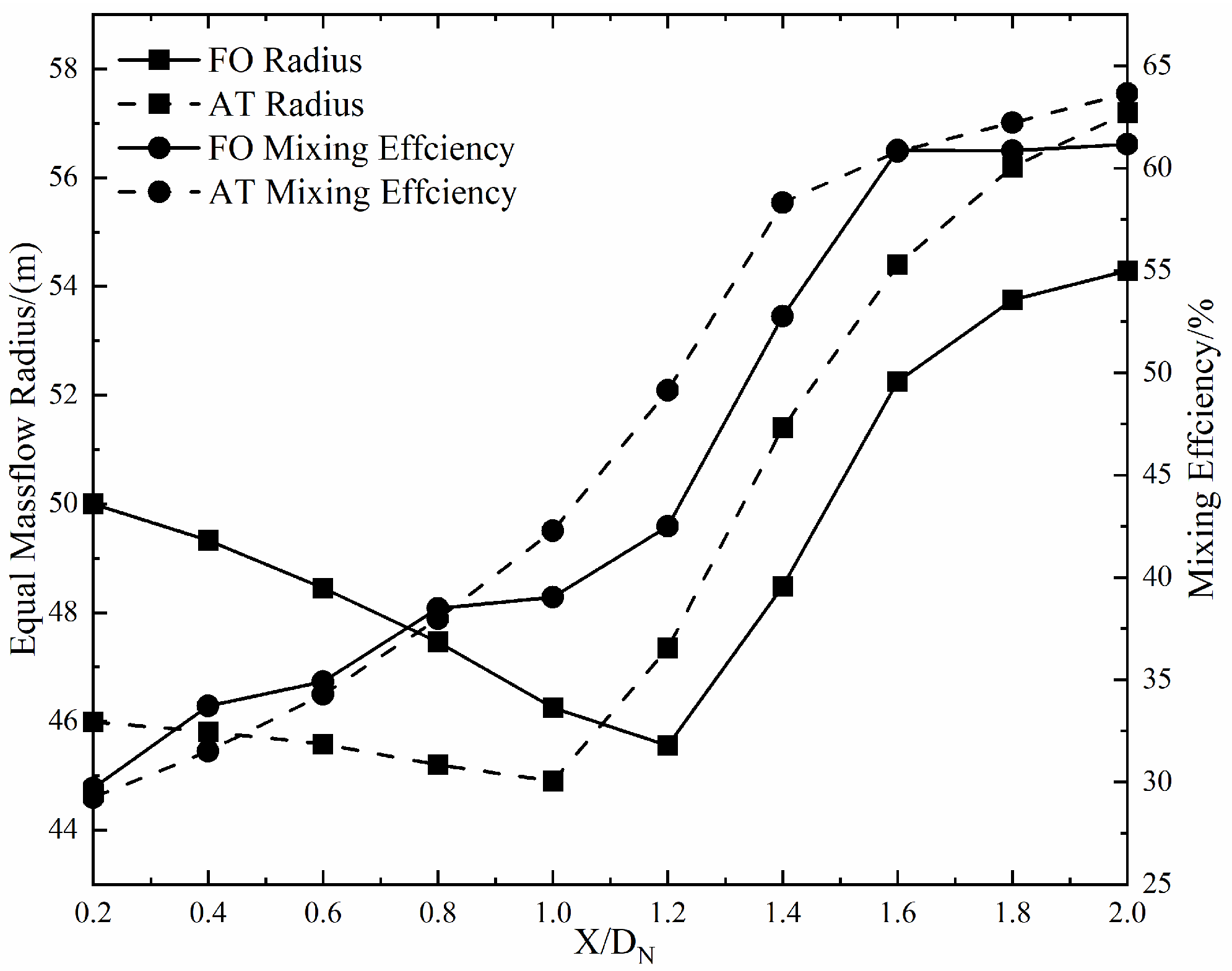

Figure 10 compares the jet-mixing efficiency and the expansion radius of the two fluidic mixers downstream from the nozzle when the inlet total pressure is 140 kPa. The mixing efficiency is defined as follows:

where

and

are the time-averaged mass flow and total temperature, respectively,

is the time-averaged mass flow through point i of the calculation section, and the subscripts

N,

f, and

u represent the inlet of main nozzle, the inlet of fluidic exciter, and the uniformly mixed section (i.e.,

x = 9.8 D

N section downstream of the main nozzle in this paper), respectively. In the range of

x = 0.2 D

N–0.8 D

N, the mixing efficiency of the sweeping jet was higher than that of the steady air-tab jet. Based on the above conclusion, the flow mixing in this axial range is dominated by the streamwise vortices and planar vortices, which means that the vortices induced by the fluidic oscillator are more conducive to enhancing jet mixing than those induced by the air tab. This is consistent with the above comparative-analysis conclusion of the streamwise vortices and planar vortices. However, the jet-mixing efficiency downstream from the air tab exceeded that of the fluidic oscillator when

x > 0.8 D

N. At this time, the streamwise vortices and planar vortices downstream from the two fluidic mixers were completely dissipated, and the shear layer between the main flow and the surrounding air was the dominant factor for jet mixing. The expansion radius is defined as the section with twice the mass flow of inlet (including nozzle inlet and fluidic mixer inlet) downstream from the nozzle. Two times the inlet mass flow is an empirical value, below which the outer contour of the jet is not circular, and above which the influence on this radius of the inlet parameters will be weakened. To a certain extent, this radius can represent the boundary affected by the jet and quantitatively characterize the contact area between the jet and the surrounding air. It can be seen that the jet expansion radius decreased first and then increased, which indicated that the jet converged first and then expanded, due to the influence of the nozzle convergence angle. Compared with the steady air-tab jet, the jet radius with the equal mass flow of the sweeping jet converged faster in the jet convergence stage and was smaller than that of the air tab on the same axial section in the jet-expansion stage. This shows that the sweeping jet can restrain the expansion of the main jet in the case with the fluidic oscillator, thus making the contact area between the main flow and the surrounding air smaller than that of the air tab. Therefore, the mixing efficiency of the fluidic oscillator was smaller than that of the air tab for the region with

x > 0.8 D

N, where the shear layer dominated the jet mixing between the cross- and the surrounding air. In the same way, for the region (0 <

x < 0.8 D

N), where the streamwise vortices and the planar vortices dominated the jet mixing, the mixing effect of the shear layer between the main stream and the surrounding air in the case with the fluidic oscillator was actually lower than that of the air tab., This in turn suggested that, compared with the case with the air tab, the mixing efficiency gain brought about by the streamwise vortices and the planar vortices in the case with the fluidic oscillator was a little higher than that shown in

Figure 10.

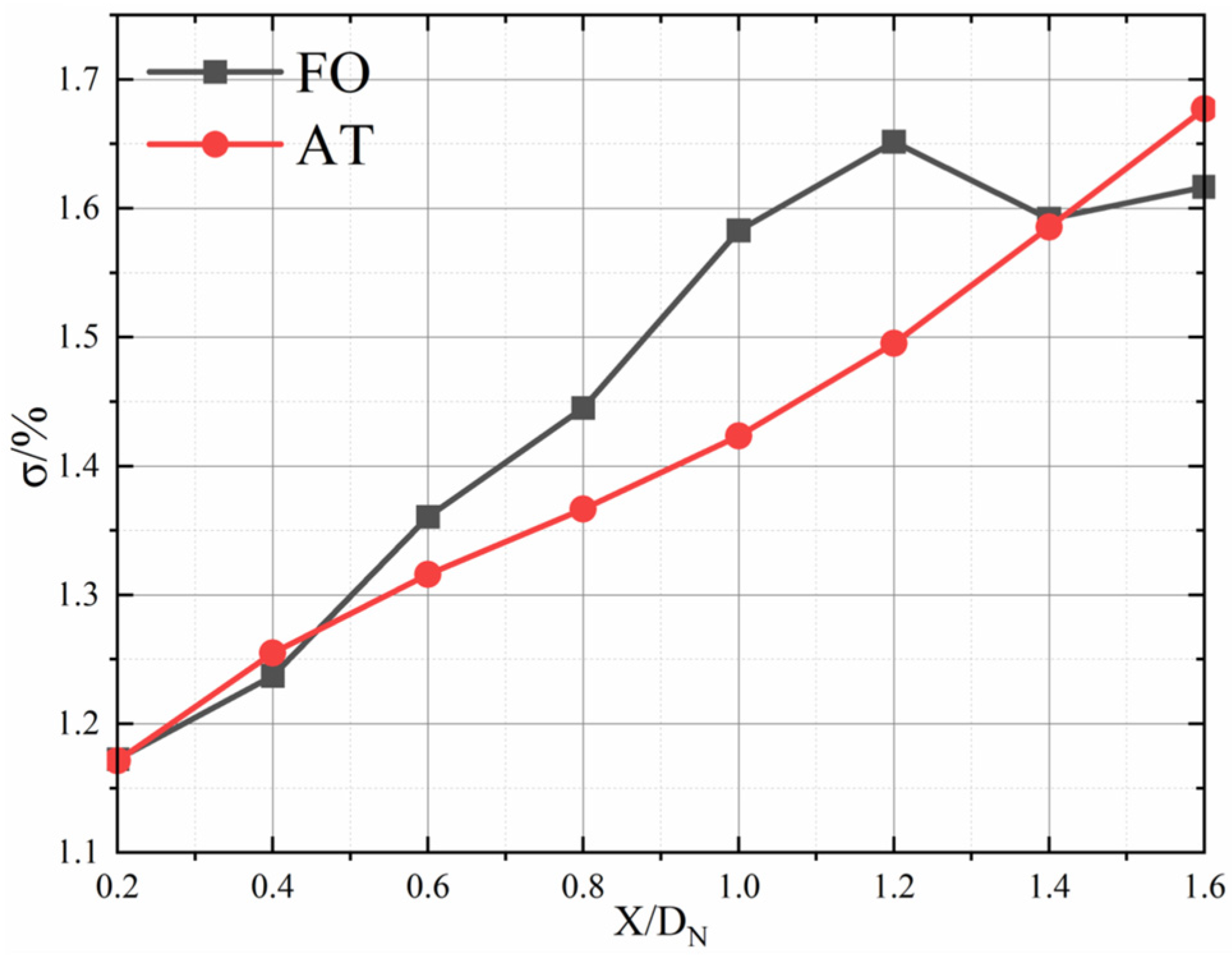

Figure 11 compares the mixing loss distribution of the two fluidic mixers for the cases with the inlet total pressure of 140 kPa. The mixing loss is defined as follows:

where

is the time-averaged total pressure and the subscripts

N,

f, and

i represent the inlet of main nozzle, the inlet of fluidic exciter, and the point

i of the calculation section. For the steady air-tab jet, the curve of mixing loss changed linearly with the axial distance. When

x < 1.2 D

N, the mixing loss of the sweeping jet also increased linearly and the total pressure loss was greater than that of the steady air-tab jet. For the region of

x < 0.8 D

N, the higher mixing loss of the fluidic oscillator was mainly related to its greater mixing efficiency, but the increment of the mixing loss was not proportional to the increment of the mixing efficiency, which may have been due to the additional loss caused by the high internal flow loss of the fluidic oscillator itself. For the region of 0.8 D

N <

x < 1.2 D

N, the mixing efficiency of the fluidic oscillator was decreased, but the cumulative total pressure loss in the prior period was high, which made the loss in this region keep growing. In the region of 1.2 D

N <

x < 1.6 D

N, the mixing loss of the fluidic oscillator was approximately stable, and the total pressure loss of the air tab surpassed that of the fluidic oscillator, due to the improvement of its mixing efficiency.

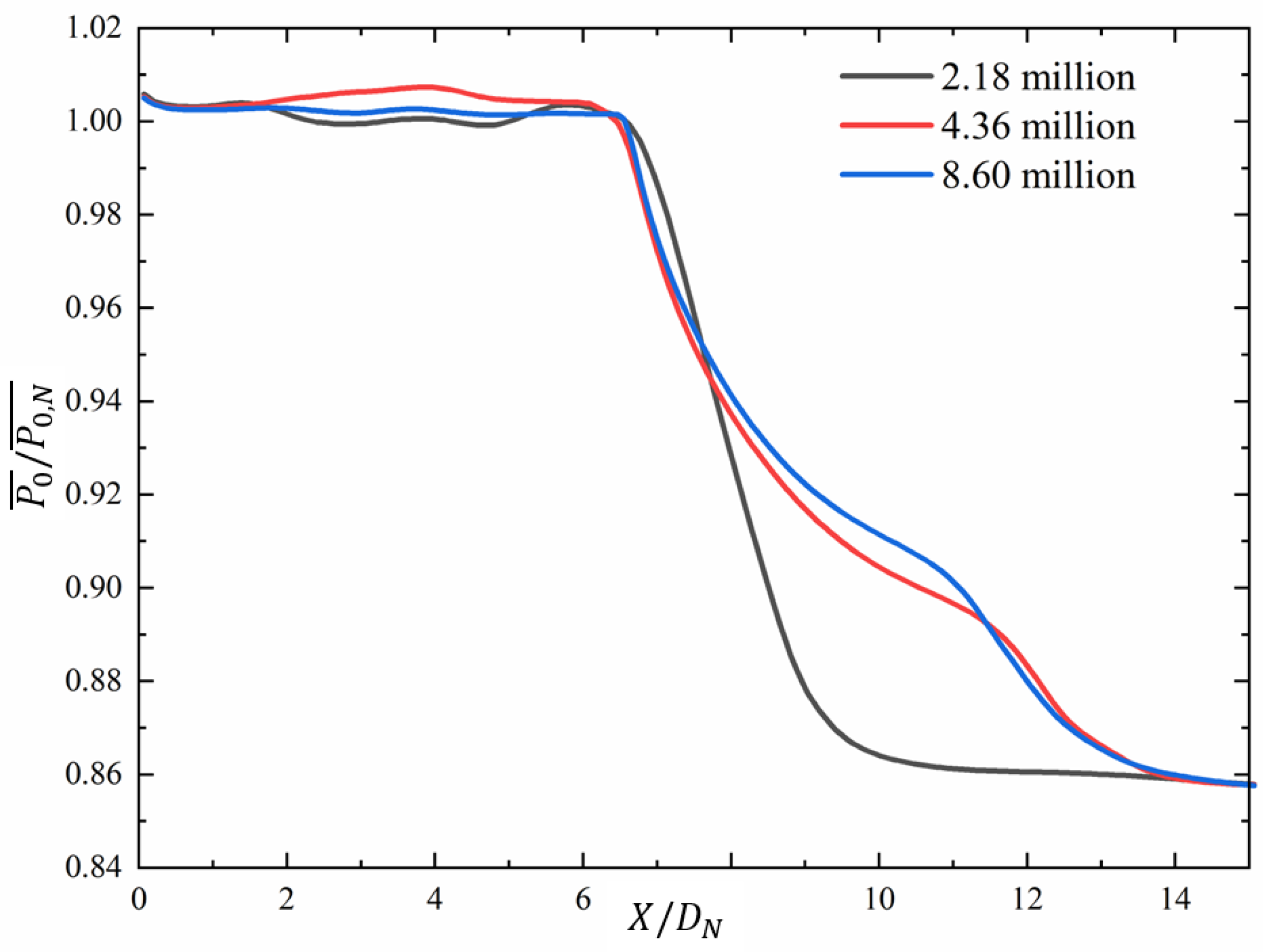

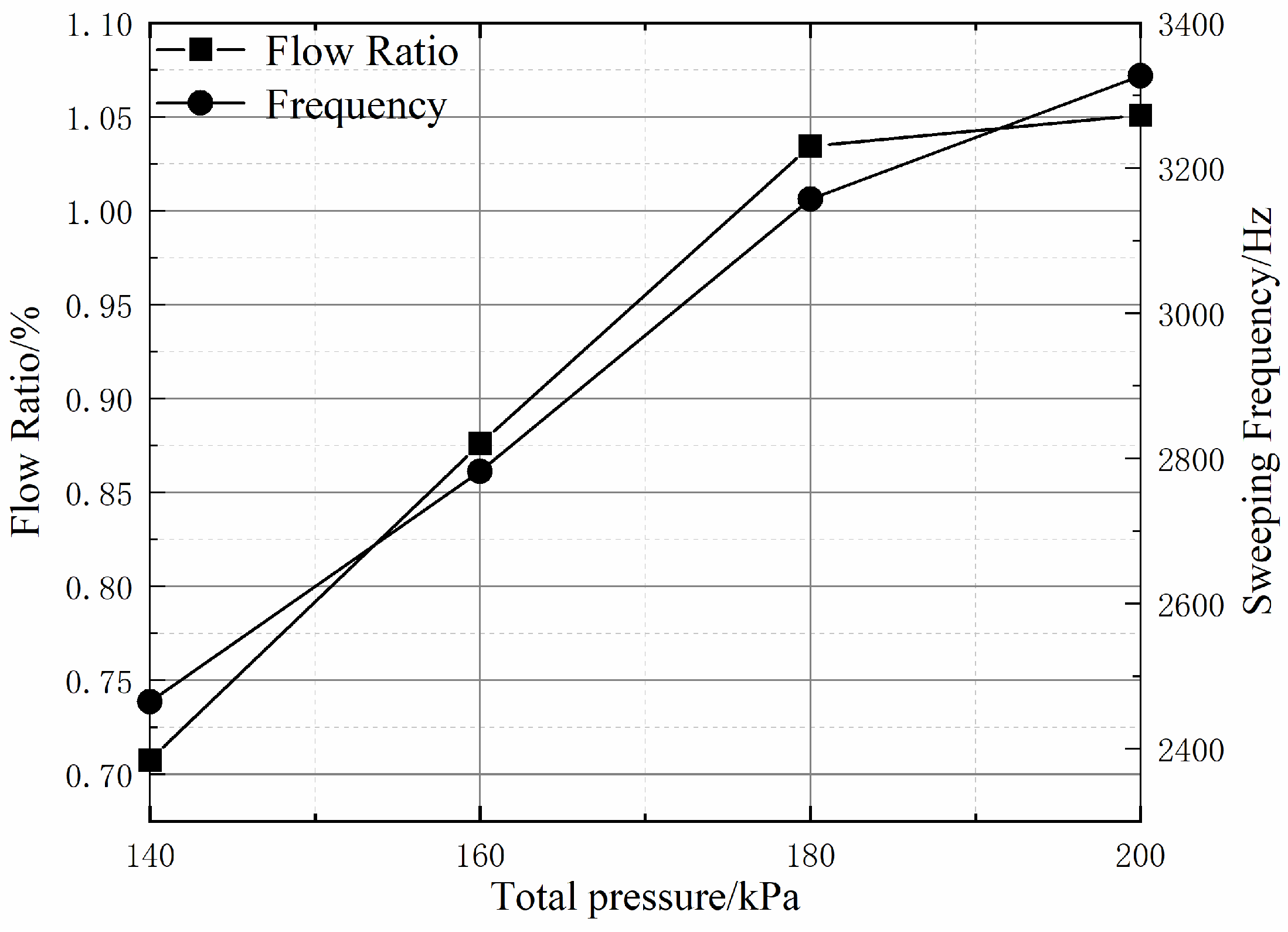

3.2. Influence of Inlet Total Pressure

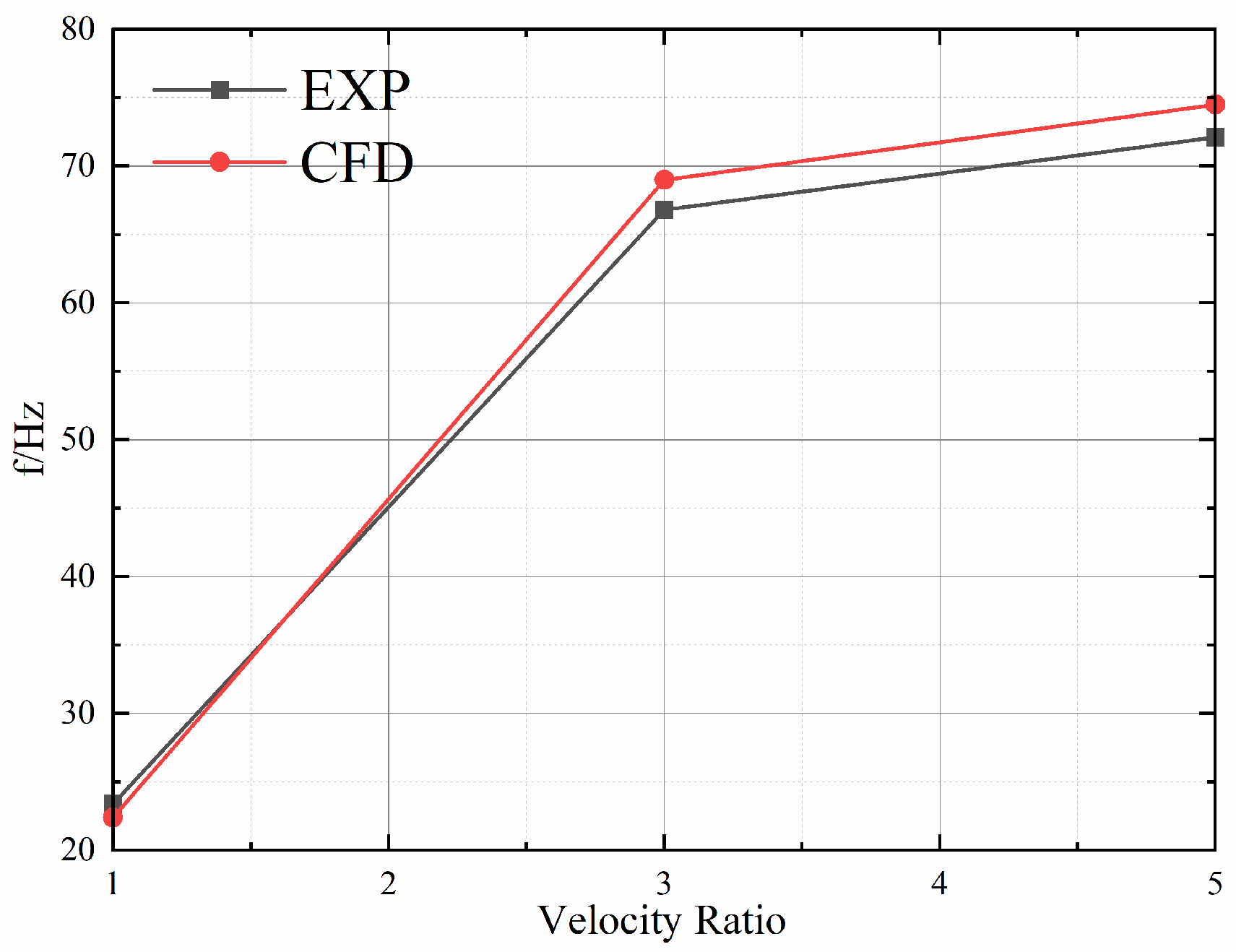

Figure 12 shows the mass flow ratio and the sweeping frequency of the fluidic oscillator for various inlet total pressures. With the increasing inlet total pressure of the fluidic oscillator, its mass flow rate and sweeping frequency increased linearly. On the other hand, it was not difficult to find that the sweeping frequency also increased linearly with the jet flow rate, which was consistent with the findings of previous works [

12]. When the inlet total pressure reached 200 kPa, the flow rate increased by only 0.02%, compared with the case of 180 kPa. The reason was that the throat of the fluidic oscillator reached the critical state in this case, and increasing the inlet total pressure could no longer further increase the mass flow rate of the fluidic oscillator. However, the increase in the inlet total pressure could obviously affect the sweeping frequency of the fluidic oscillator.

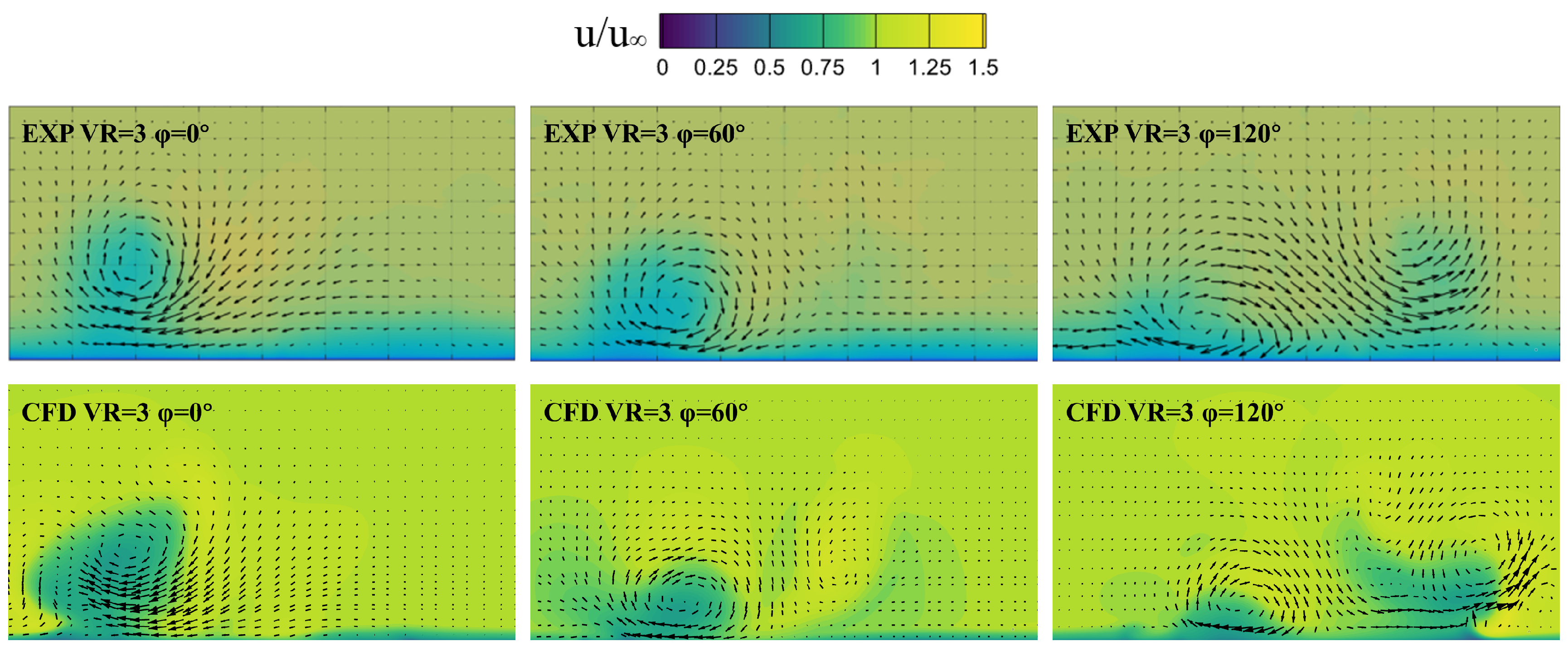

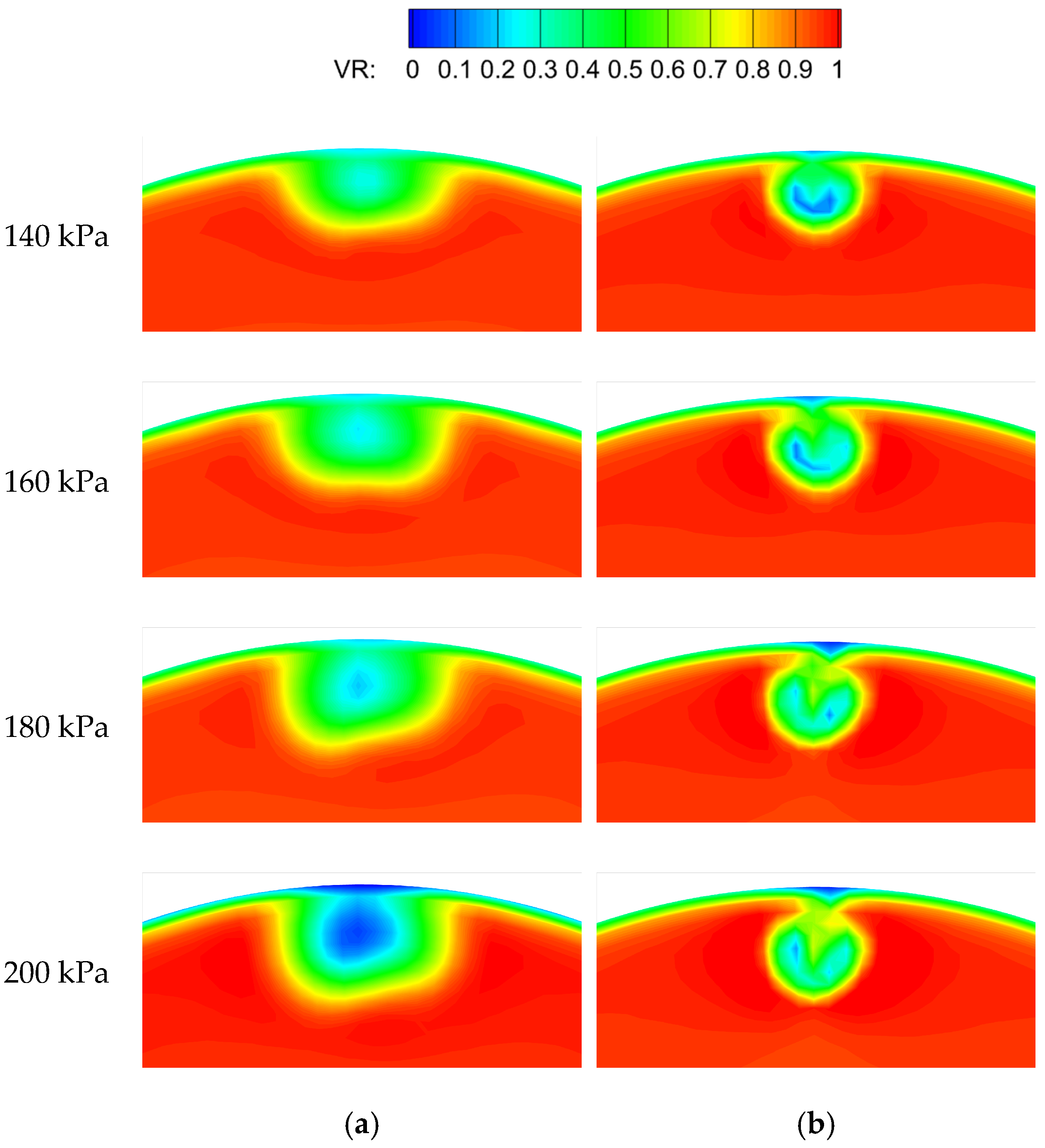

Figure 13 shows the contours of time-averaged velocity at the central section of the two fluidic mixers for cases with different inlet total pressures. With the increase in the inlet total pressure, there was no obvious change in the left and right boundaries of the sweeping jet, while the time-averaged penetration increased. Moreover, the low-velocity region influenced by the sweeping jet developed from an initial semi-circle to a fuller rounded rectangle; that is, the area of this region increased. These developments indicated that the increase in the inlet total pressure enlarged the influence range of the sweeping jet to some extent. For the steady air-tab jet, the penetration increased with the increasing inlet total pressure, causing its influence region to be farther and farther away from the nozzle, but its influence range did not increase significantly. Under the same inlet total pressure, the time-averaged penetration of the sweeping jet was basically the same as that of the steady air-tab jet, but the circumferential influence range of the sweeping jet was significantly larger than that of the steady air-tab jet, and this difference increased with the increase in the inlet total pressure.

The length of the potential core region can directly reflect the mixing efficiency between the main jet and the ambient air.

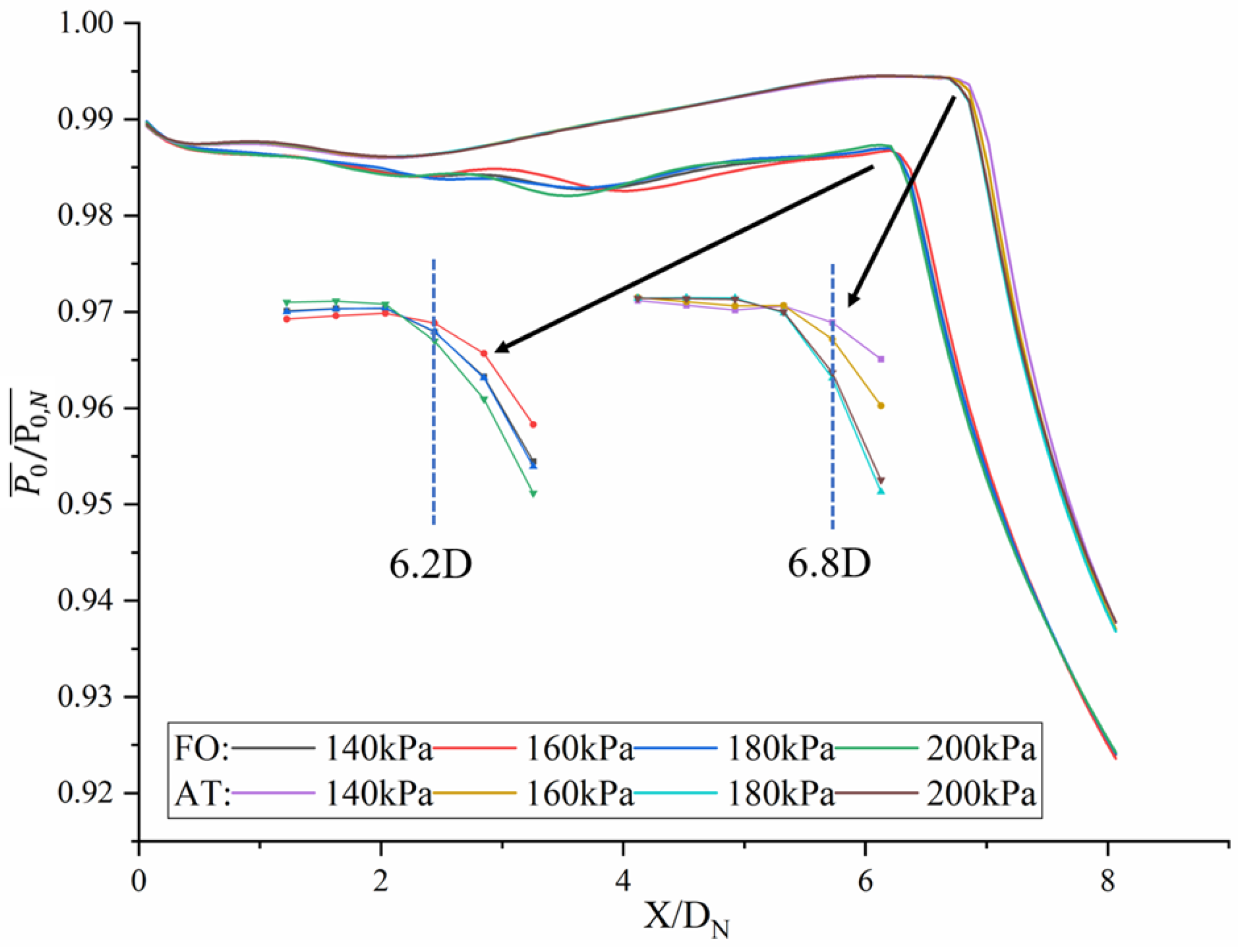

Figure 14 compares the total pressure distribution of the central line downstream from the main nozzle for the two fluidic mixers in cases with different inlet total pressures. In the region of

x < 1.0 D

N, where the streamwise vortices and planar vortices dominant the jet mixing, the following observations were possible (1) the greater the inlet pressure, the faster the attenuation rate of the total pressure for the two fluidic mixers, and (2) the total pressure attenuation rate of the fluidic oscillator was greater than that of the air tab under different inlet total pressure conditions. When 1.0 D

N <

x < 4.0 D

N, the attenuation rate of the total pressure along the centerline downstream from the fluidic oscillator still increased with the increase in the inlet total pressure, but it remained the same in the case with an inlet total pressure of 140 kPa (a slight increase in appearances may have been related to numerical errors). With the continuous mixing between the main jet and the surrounding air, the total pressure of the potential core region downstream from the fluidic oscillator started to decrease gradually at

x = 6.2 D

N for all cases; that is, the length of the potential core region was 6.2 D

N for all cases. In order to ensure that the fluidic oscillator was not blocked, the narrow inlet total pressure variation range (140–200 kPa) selected in this paper was the main reason for its small impact on the potential core-region length. For the actual nozzle, by increasing the size of the fluidic oscillator’s throat, the inlet total pressure could be further increased to improve the mixing efficiency, but it led to the problem of a too-large fluidic oscillator and a too-high mass flow ratio. This needs further study and clarification. For the air tab, the length of the potential core region was about 6.8 D

N, which was greater than that of the fluidic oscillator. This suggests that the mixing effect of the sweeping jet is better than that of the steady air-tab jet under the same inlet total pressure.

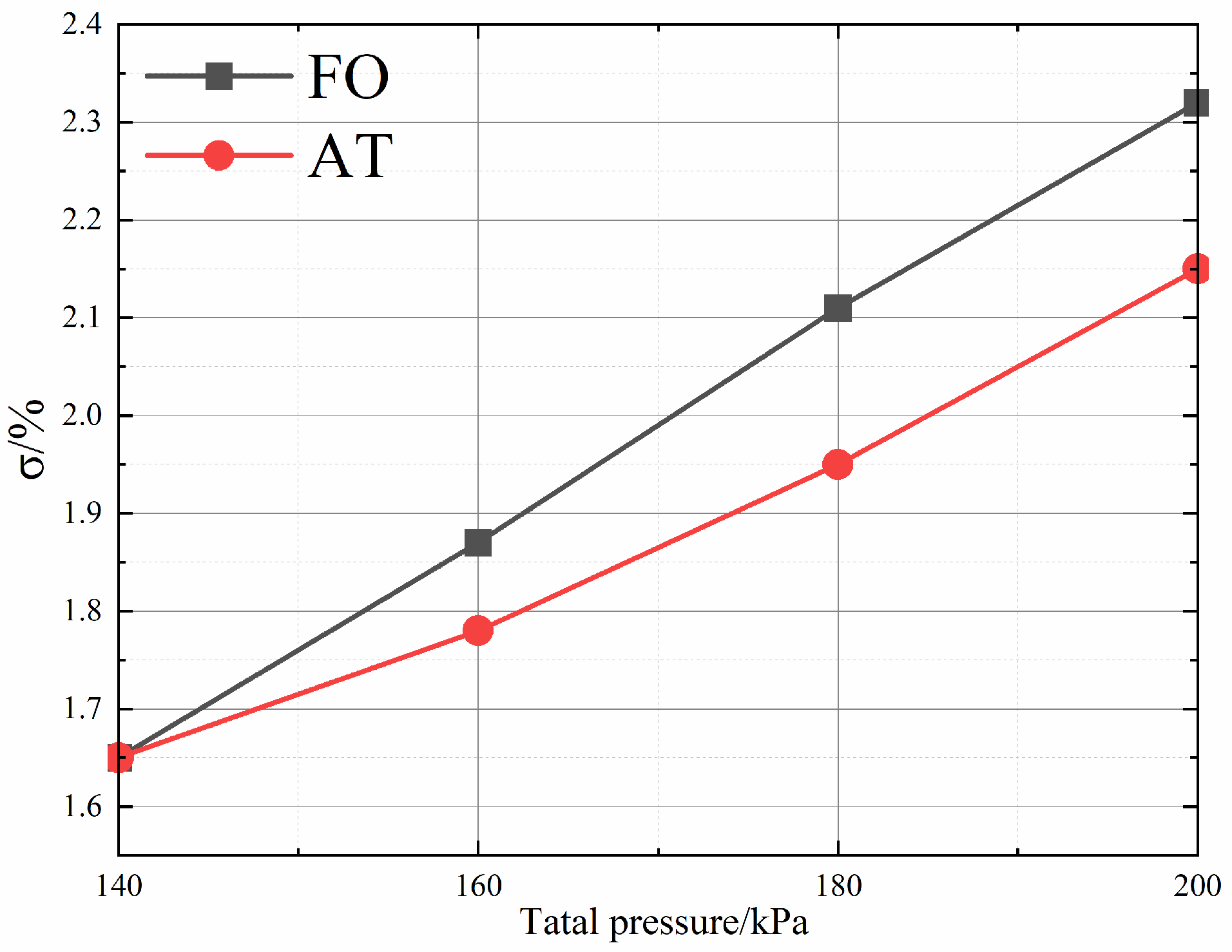

Figure 15 compares the total pressure loss of the two fluidic mixers for cases with different inlet total pressures. With the increase in inlet total pressure, the total pressure loss of the two fluidic mixers showed an approximately linear growth trend. Compared with the air tab, the total pressure loss of the fluidic oscillator was larger, and this difference increased with the increasing inlet total pressure. The increasing total pressure loss of the fluidic oscillator was related to its greater mixing efficiency, and it was also influenced by its higher internal flow loss. Overall, the fluidic oscillator can use a small jet flow (<5%) to achieve a high mixing efficiency (i.e., 60% at

x = 2.0 D

N) at the expense of low total-pressure loss (<2.3%), which indicates that it has good engineering applicability.