Advanced Method of Variable Refrigerant Flow (VRF) Systems Designing to Forecast On-Site Operation—Part 1: General Approaches and Criteria

Abstract

1. Introduction

- -

- determine a rational design refrigeration capacity of an ambient air conditioning system (ACS) to provide practically maximum annual refrigeration energy generation according to its current consumption without overestimation;

- -

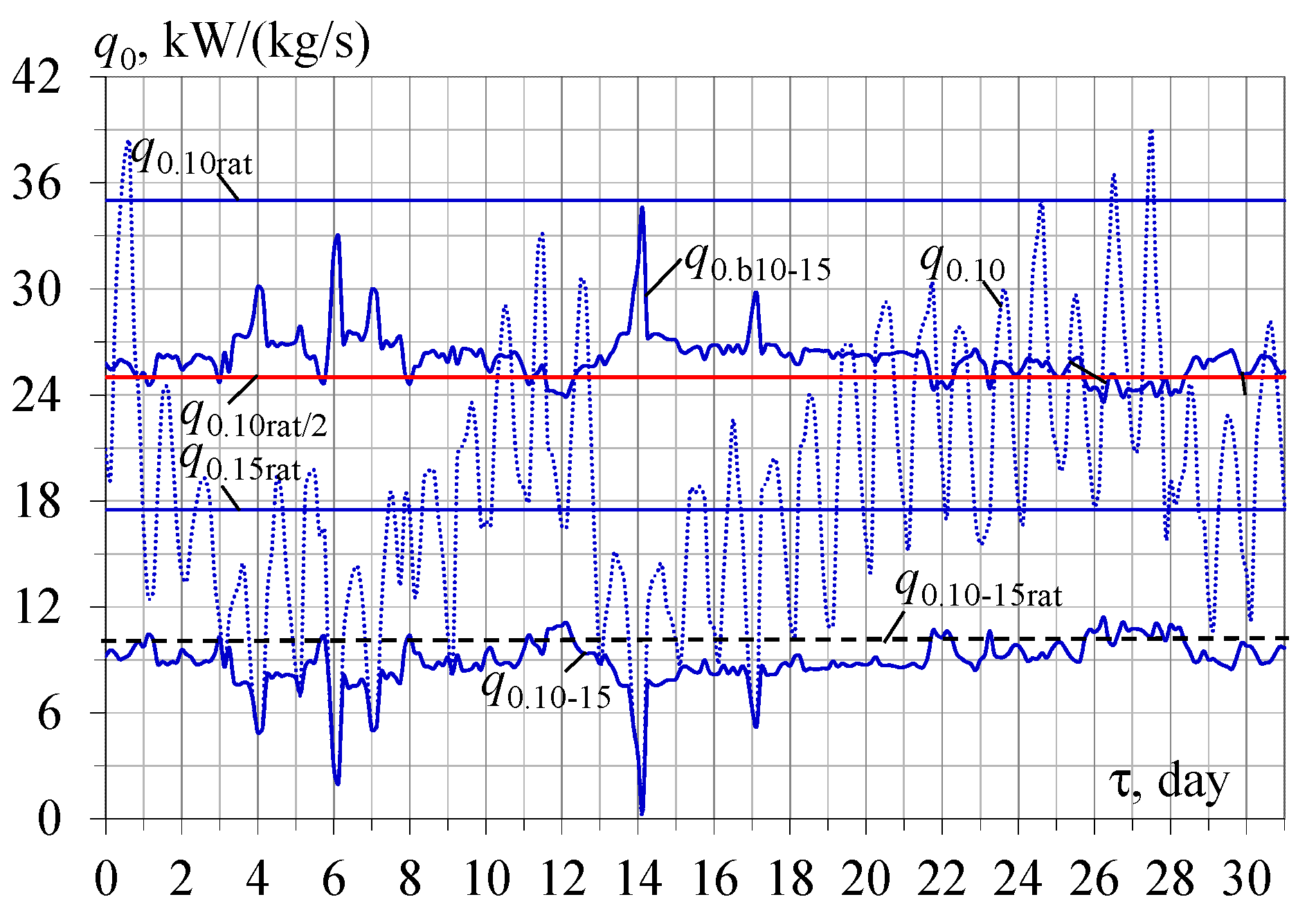

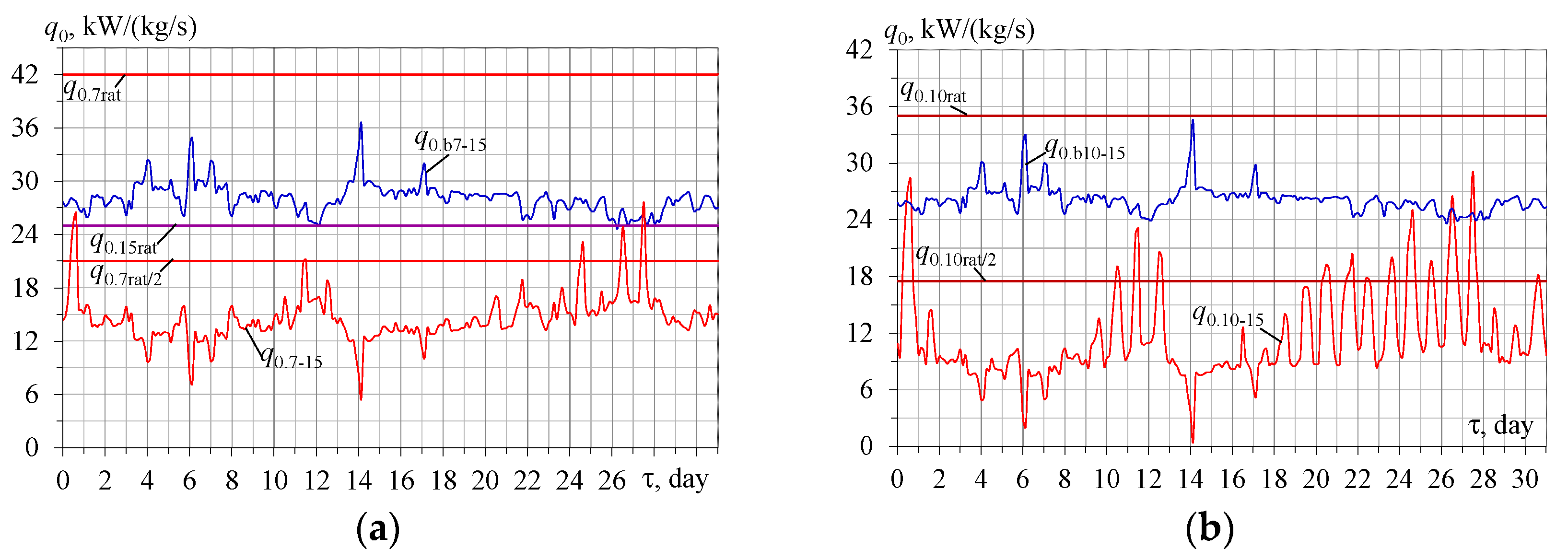

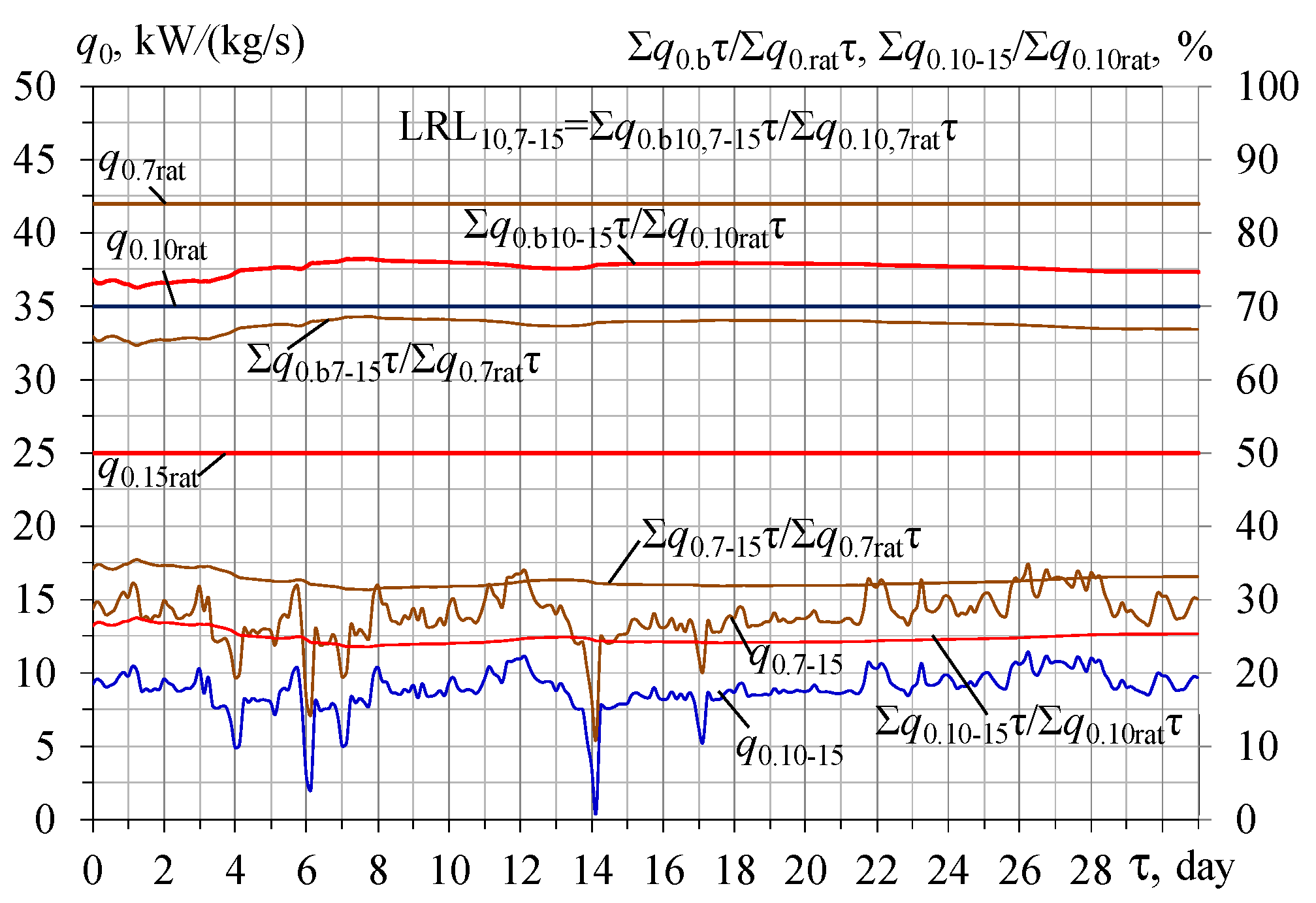

- develop a method for shearing the overall range of actual thermal loads on ACS into the ranges of changeable and unchangeable loads and, accordingly, adopt a design refrigeration capacity to cover both loads;

- -

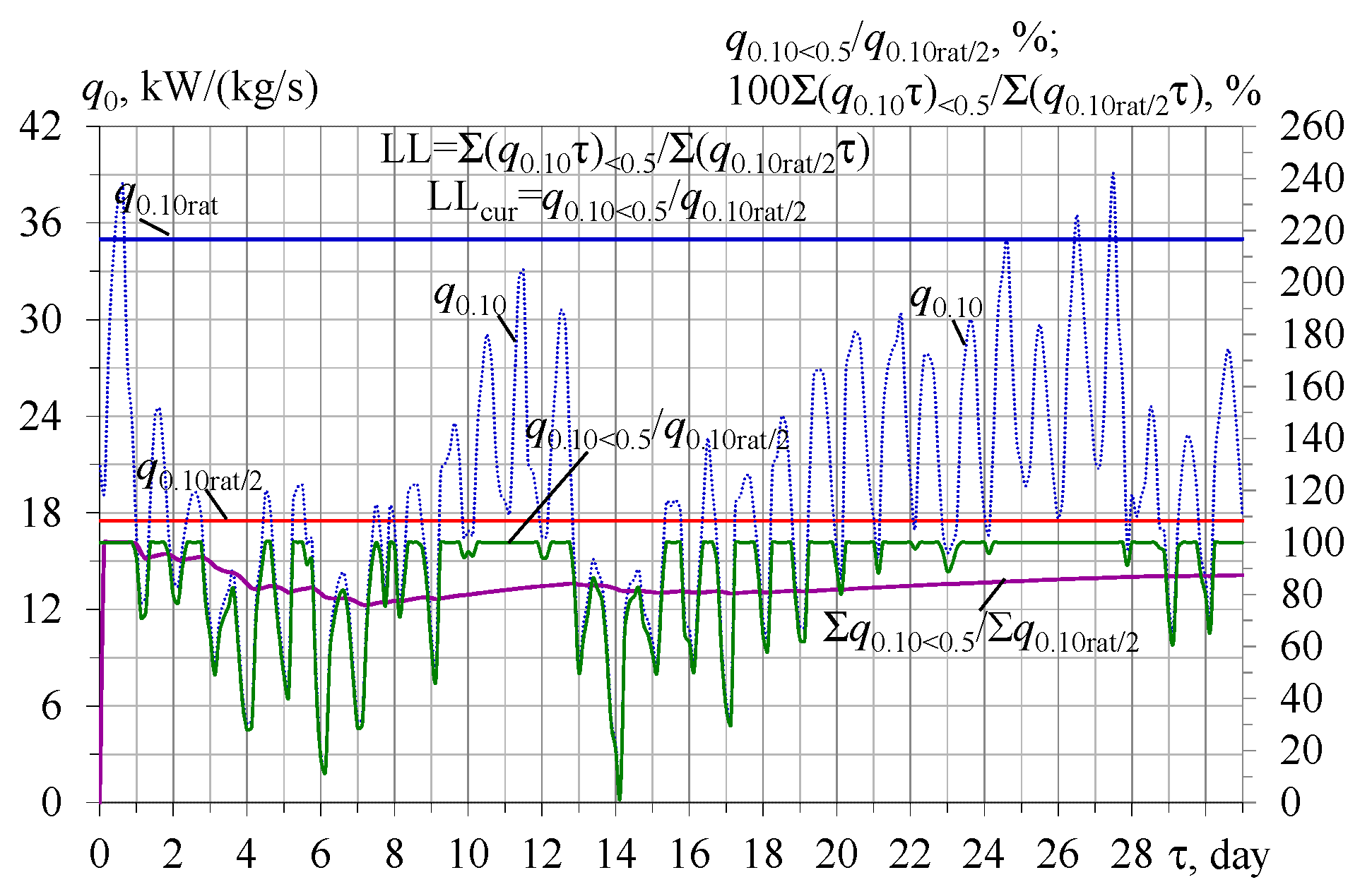

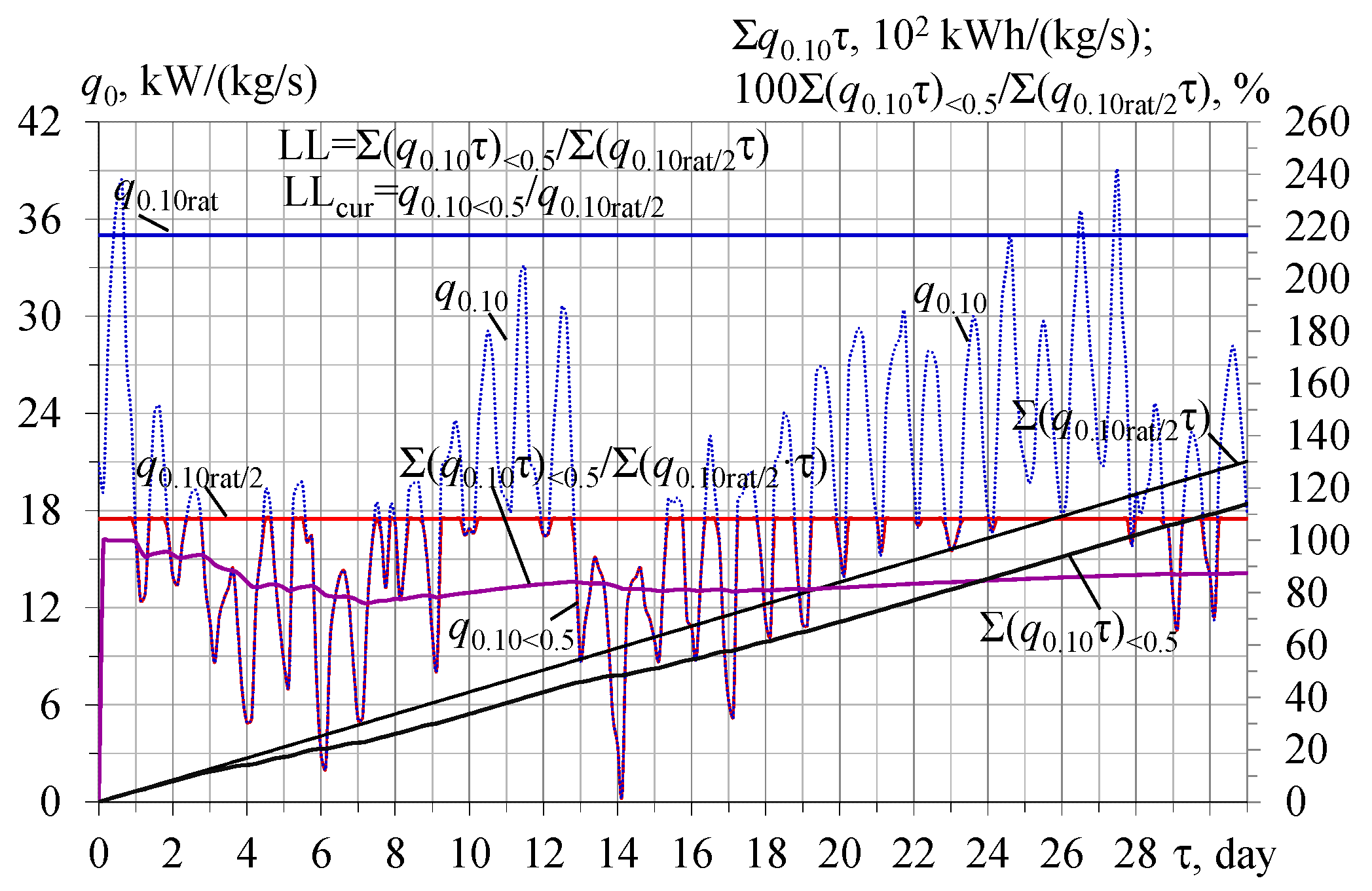

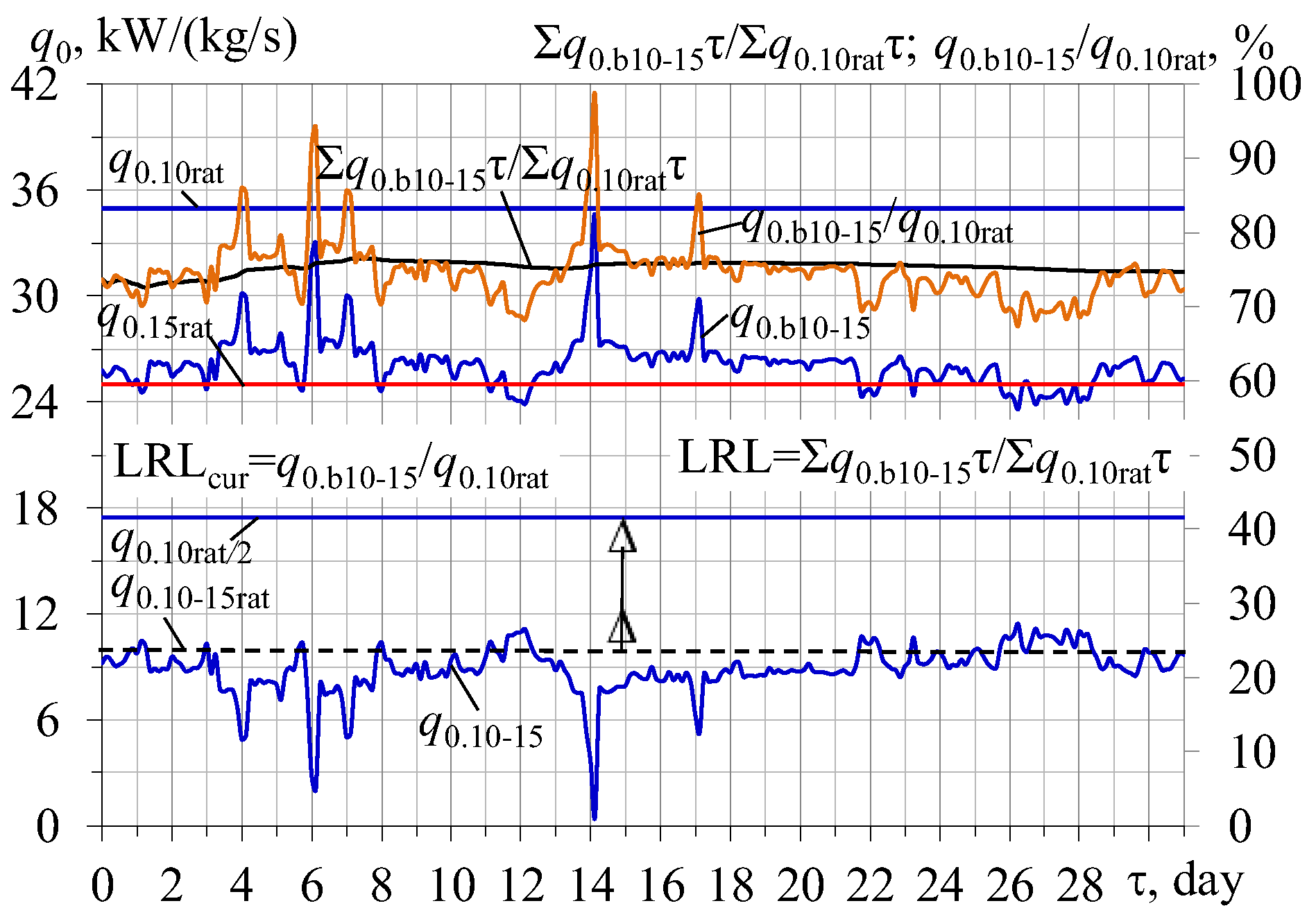

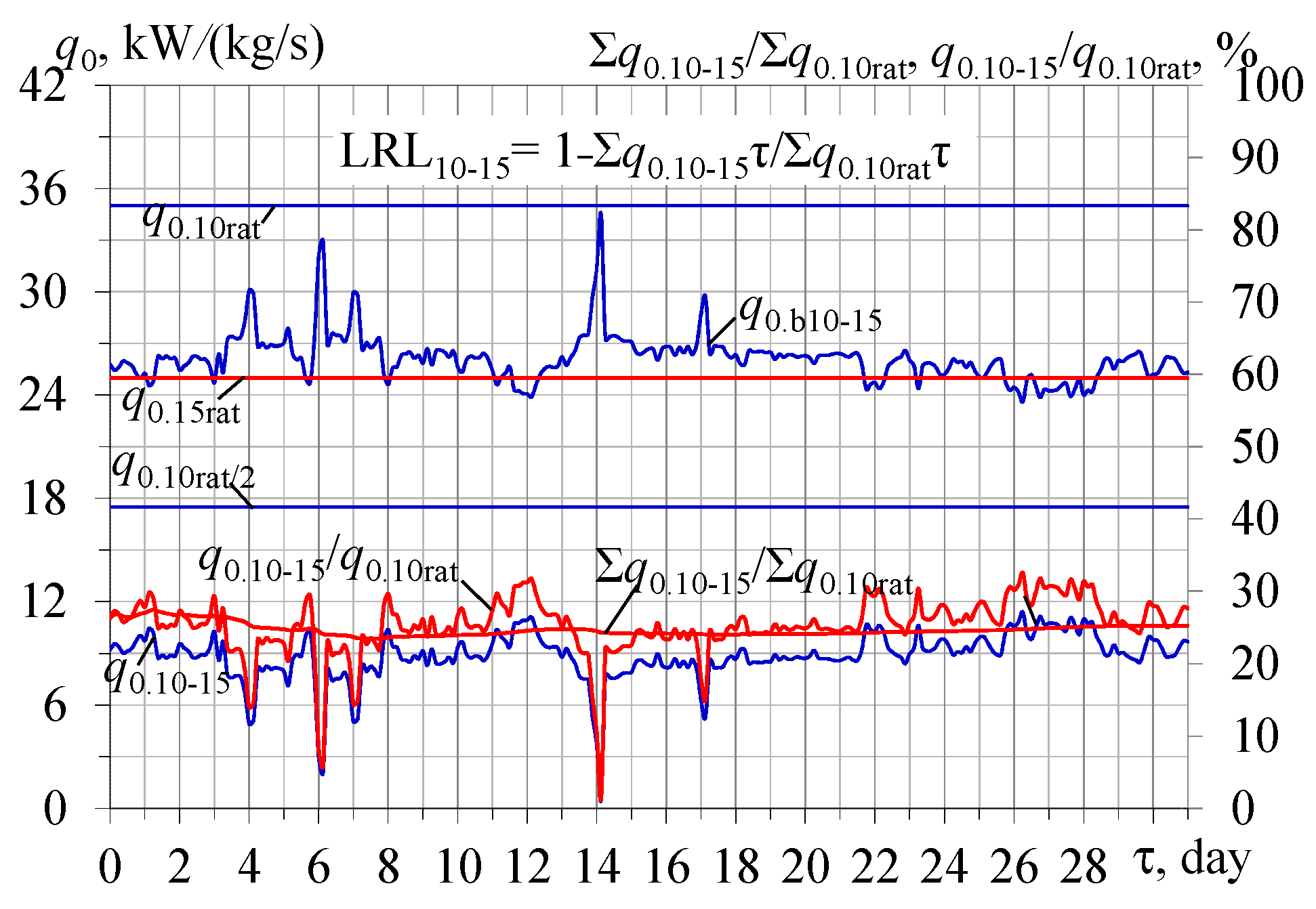

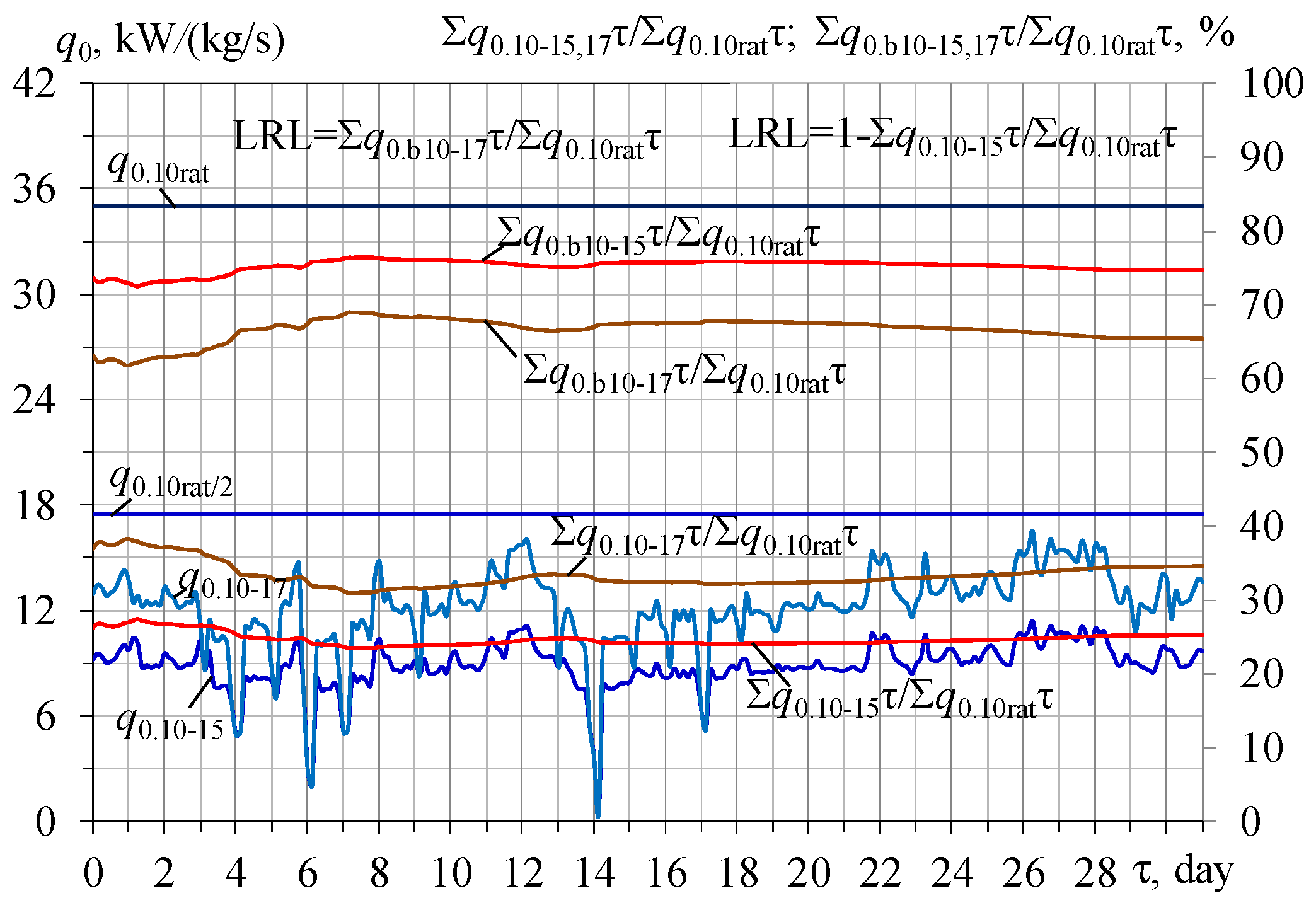

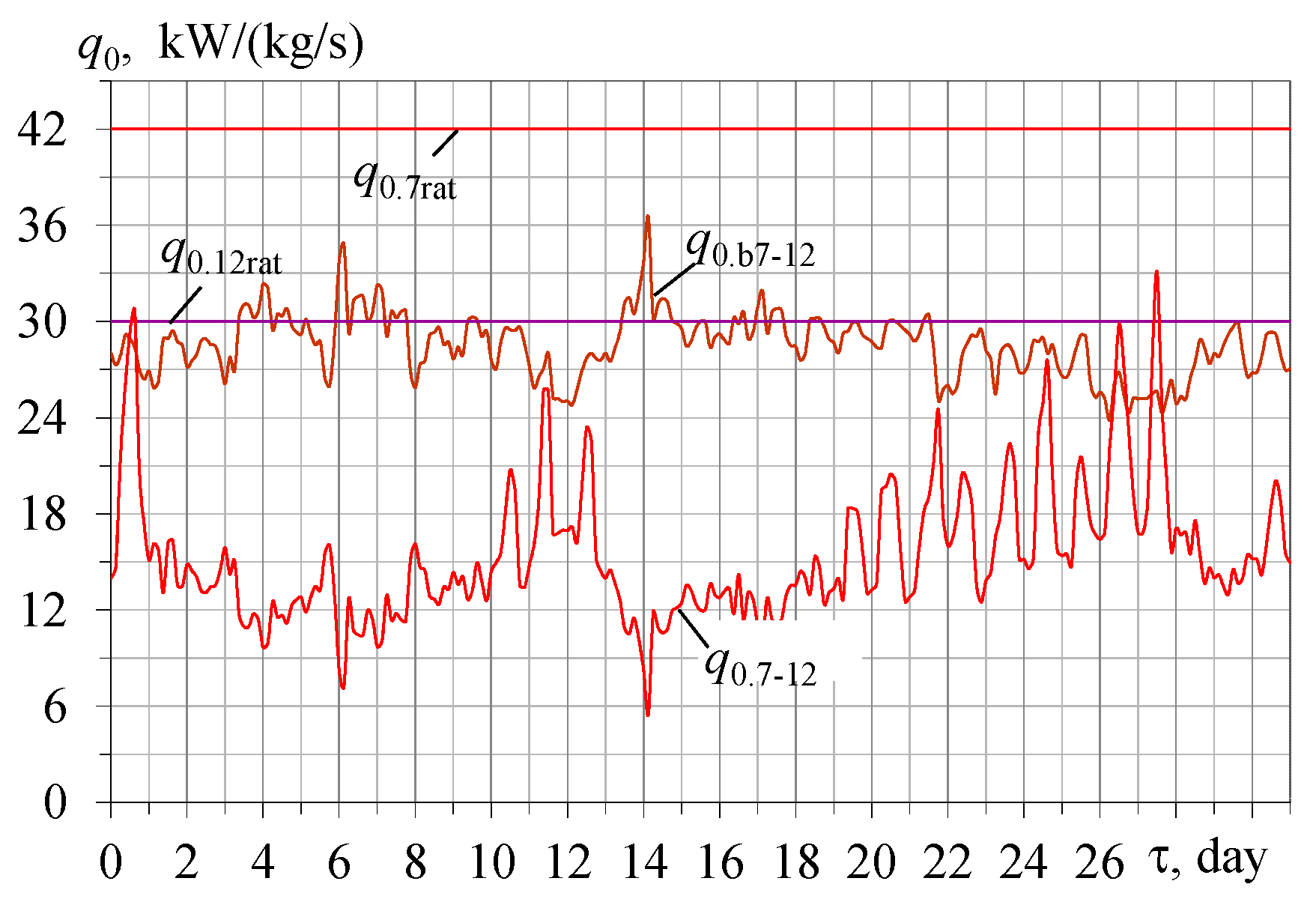

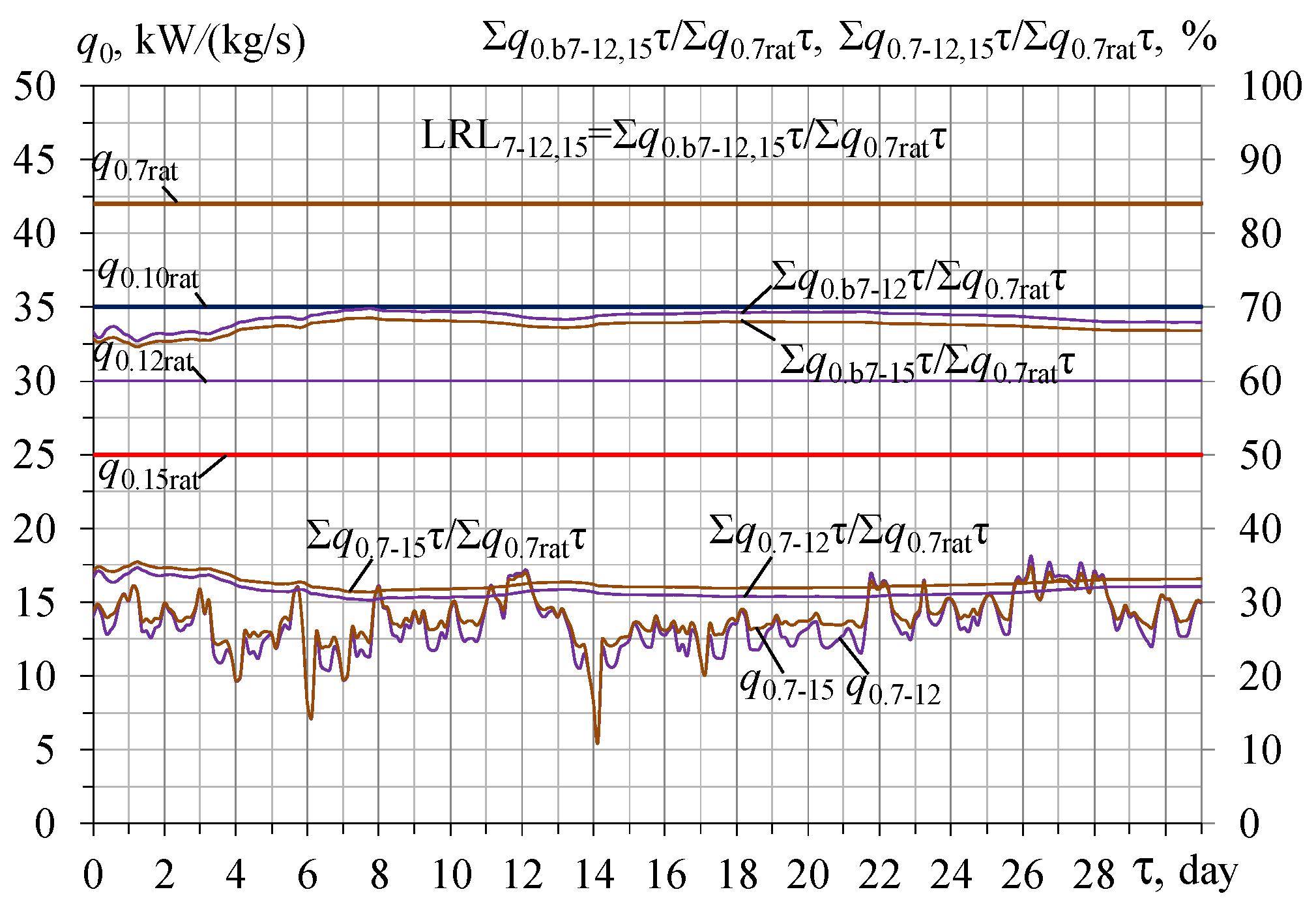

- develop a method to determine the required load regulation level (LRL) of RSC proceeding from the relation between the ranges of changeable and unchangeable thermal loads as the objects for refrigeration capacity regulation by RSC and estimation of the RSC application efficiency by the level of loading both ranges, with emphasis on the second range.

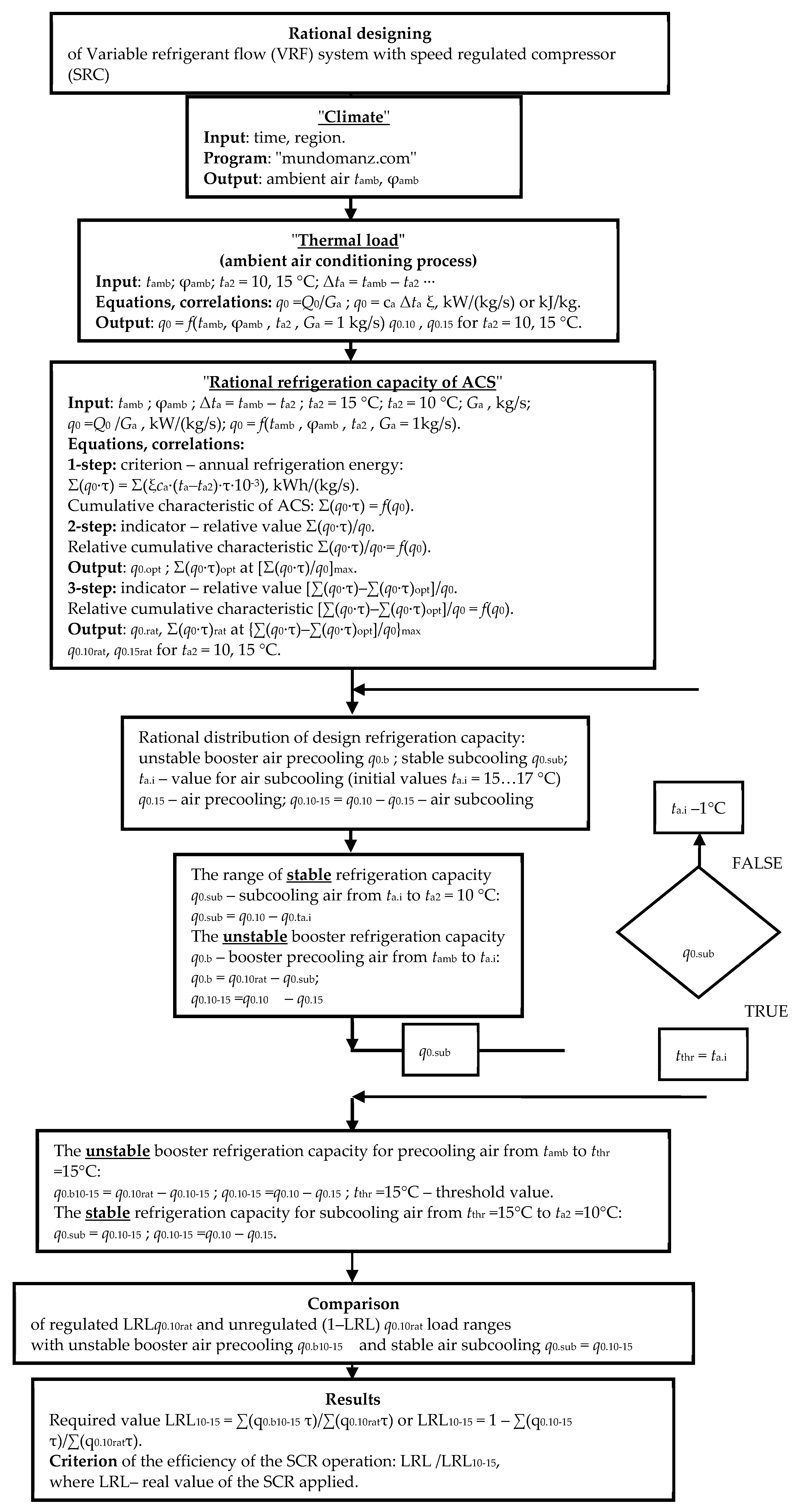

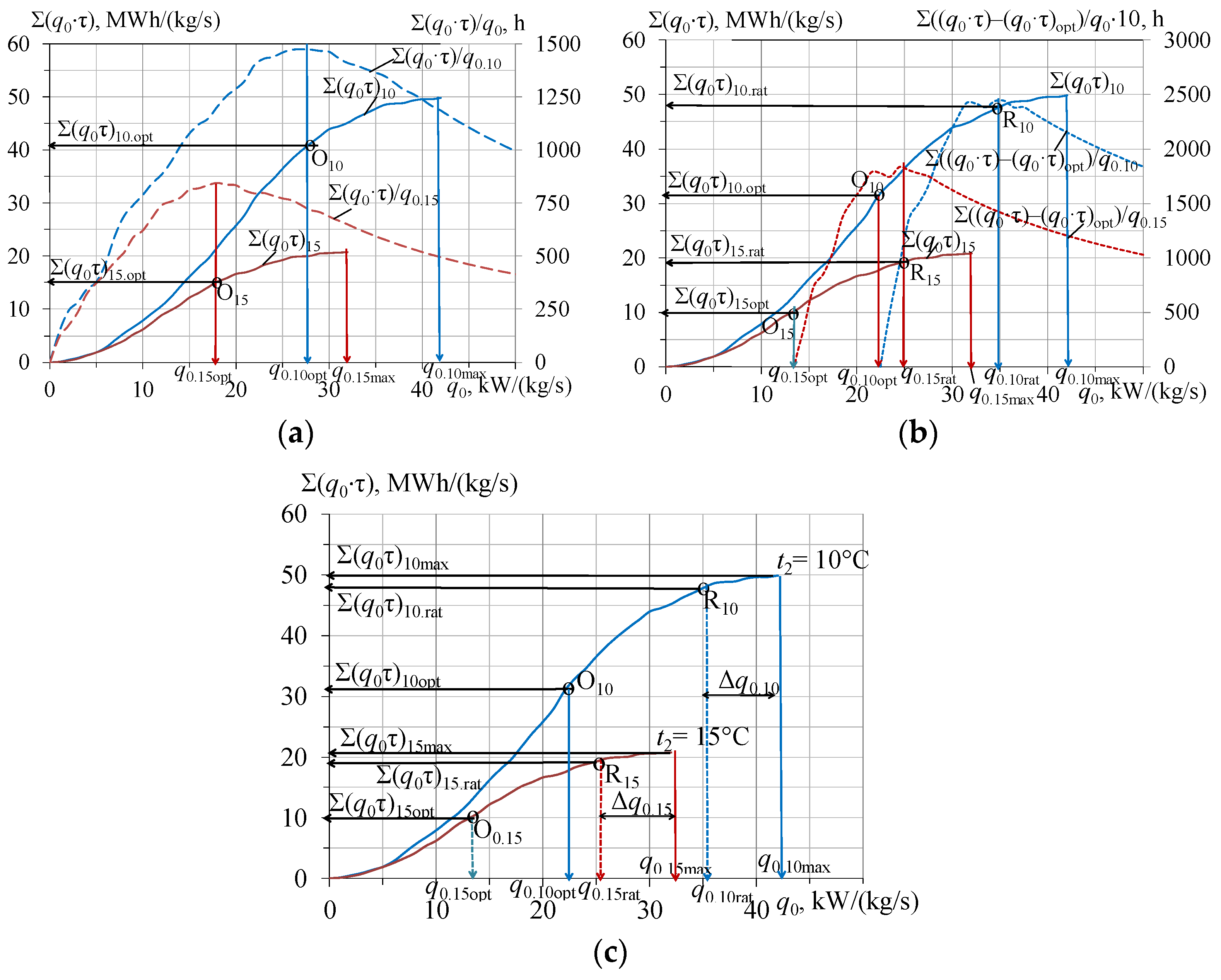

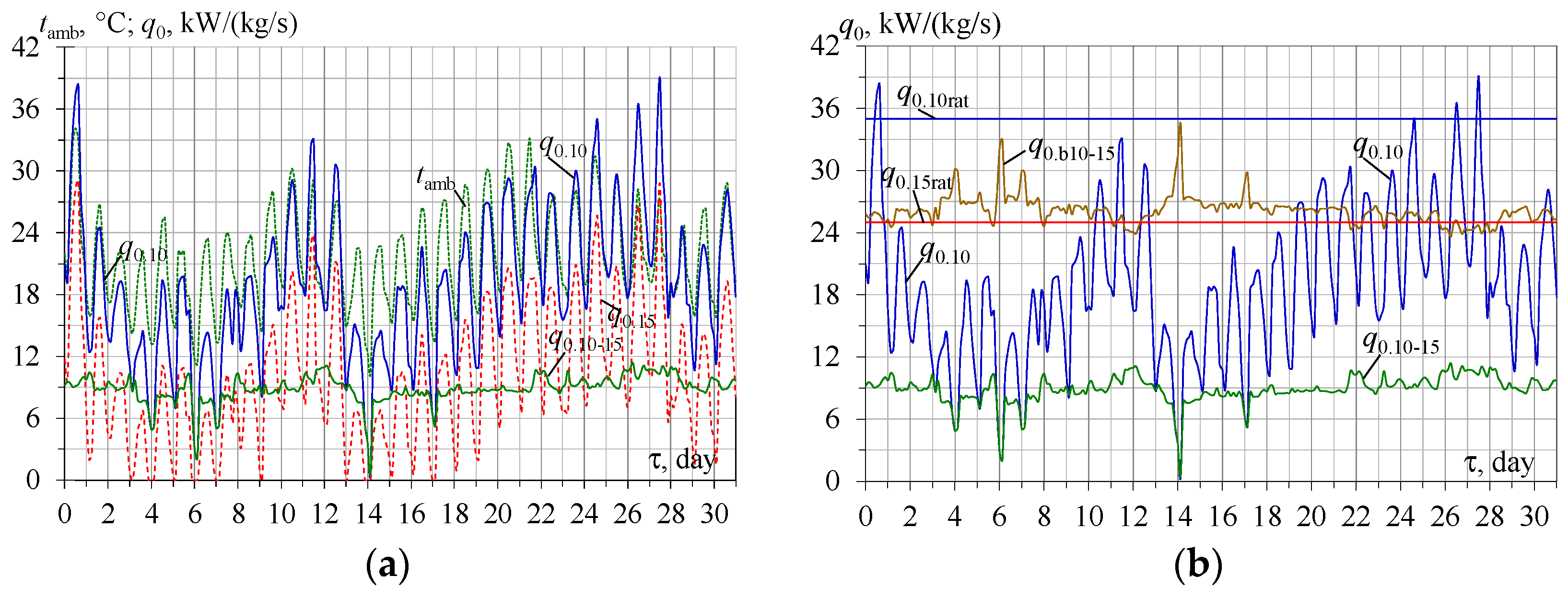

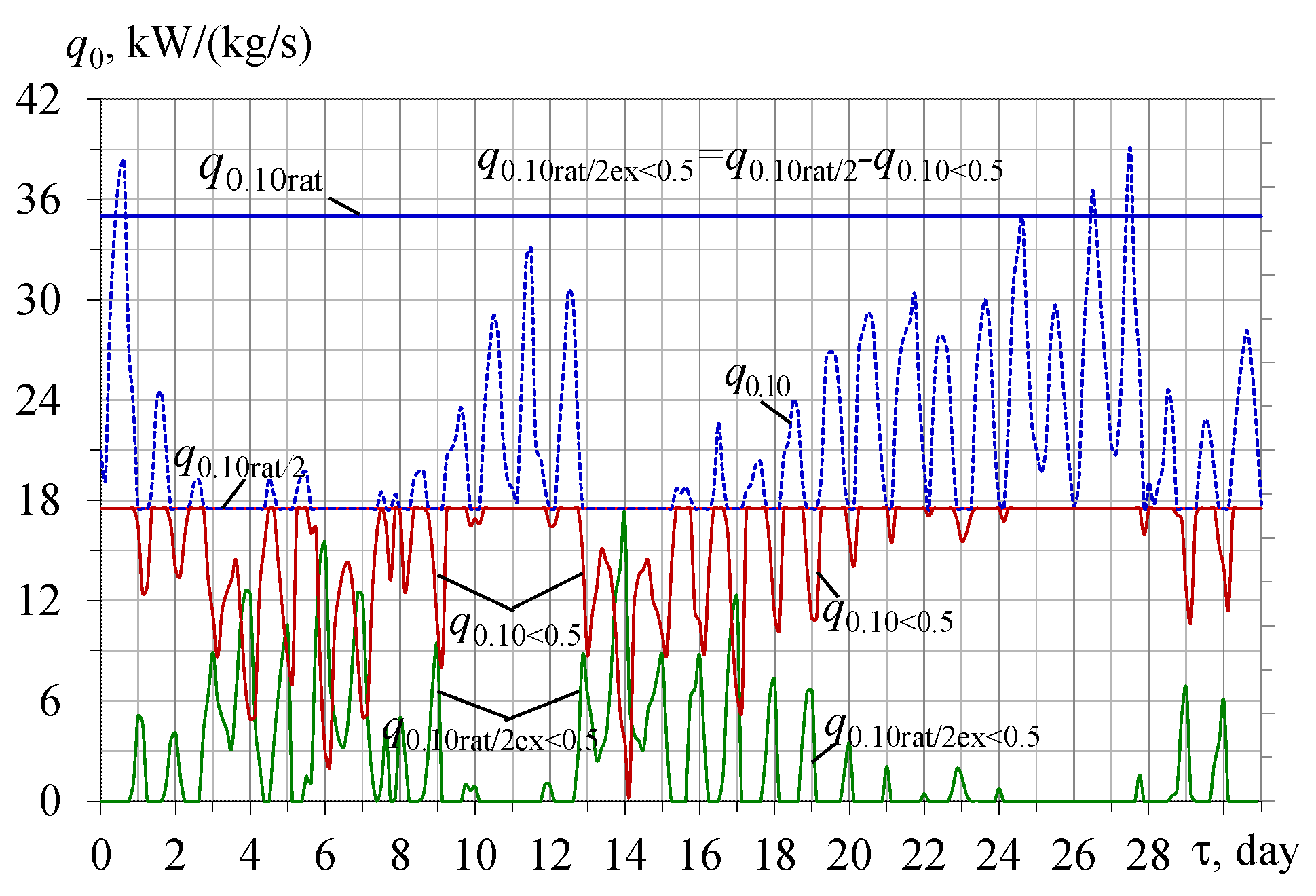

2. Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| ACS | air conditioning system |

| LL | level of load |

| LRL | load regulation level |

| SRC | speed regulated compressor |

| VRF | variable refrigerant flow |

| Symbols and units | |

| b | booster |

| ca | specific heat of humid air; kJ/(kg·K) |

| damb | absolute humidity; g/kg |

| Ga | air mass flow rate; kg/s |

| Q0 | total refrigeration capacity; kW |

| q0 | specific refrigeration capacity referring to air mass flow rate; kW/(kg/s) |

| q0 τ | specific refrigeration energy referring to air mass flow rate; kW/(kg/s) |

| tamb | ambient (outdoor) air temperature; K, °C |

| ta2 | set air temperature; K, °C |

| ξ | specific thermal ratio of latent and sensible heat to sensible heat |

| τ | time interval; h |

| φamb | relative humidity; % |

| Δt | temperature decrease; K, °C |

| ∑(q0 τ) | annual (monthly) specific refrigeration energy consumption (per unit air mass rate); kWh/(kg/s) |

| Subscripts | |

| 10, 20 | air temperature; K, °C |

| a | air |

| amb | ambient |

| b | booster |

| max | maximum |

| rat | rational |

Appendix A

References

- Southard, L.E.; Liu, X.; Spitler, J.D. Performance of HVAC systems at ASHRAE HQ. ASHRAE J. 2014, 56, 14–24. [Google Scholar]

- Gayeski, N.T.; Armstrong, P.R.; Norford, L.K. Predictive pre-cooling of thermo-active building systems with low-lift chillers. HVAC&R Res. 2012, 18, 858–873. [Google Scholar]

- Radchenko, A.; Radchenko, M.; Mikielewicz, D.; Pavlenko, A.; Radchenko, R.; Forduy, S. Energy saving in trigeneration plant for food industries. Energies 2022, 15, 1163. [Google Scholar] [CrossRef]

- Yang, Z.; Korobko, V.; Radchenko, M.; Radchenko, R. Improving thermoacoustic low temperature heat recovery systems. Sustainability 2022, 14, 12306. [Google Scholar] [CrossRef]

- Maraver, D.; Sin, A.; Royo, J.; Sebastian, F. Assessment of CCHP systems based on biomass combustion for small-scale applications through a review of the technology and analysis of energy efficiency parameters. Appl. Energy 2013, 102, 1303–1313. [Google Scholar] [CrossRef]

- Yang, Z.; Radchenko, R.; Radchenko, M.; Radchenko, A.; Kornienko, V. Cooling potential of ship engine intake air cooling and its realization on the route line. Sustainability 2022, 14, 15058. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sharma, A.; Sharma, M.; Mishra, S. Performance Improvement of Simple Gas Turbine Cycle with Vapor Compression Inlet Air Cooling. Mater. Today Proc. 2018, 5, 19172–19180. [Google Scholar] [CrossRef]

- Kalhori, S.B.; Rabiei, H.; Mansoori, Z. Mashad trigeneration potential—An opportunity for CO2 abatement in Iran. Energy Conv. Manag. 2012, 60, 106–114. [Google Scholar] [CrossRef]

- Radchenko, A.; Radchenko, N.; Tsoy, A.; Portnoi, B.; Kantor, S. Increasing the efficiency of gas turbine inlet air cooling in actual climatic conditions of Kazakhstan and Ukraine. AIP Conf. Proc. 2020, 2285, 030071. [Google Scholar] [CrossRef]

- Shukla, A.K.; Singh, O. Impact of Inlet Fogging on the Performance of Steam Injected Cooled Gas Turbine Based Combined Cycle Power Plant. In Proceedings of the Gas Turbine India Conference, Bangalore, India, 7–8 December 2017. [Google Scholar]

- Radchenko, M.; Mikielewicz, D.; Andreev, A.; Vanyeyev, S.; Savenkov, O. Efficient Ship Engine Cyclic Air Cooling by Turboexpander Chiller for Tropical Climatic Conditions. In Integrated Computer Technologies in Mechanical Engineering; ICTM 2020 Lecture Notes in Networks and Systems; Nechyporuk, M., Pavlikov, V., Kritskiy, D., Eds.; Springer: Cham, Switzerland, 2020; Volume 188, pp. 498–507. [Google Scholar]

- Kornienko, V.; Radchenko, R.; Radchenko, M.; Radchenko, A.; Pavlenko, A.; Konovalov, D. Cooling cyclic air of marine engine with water-fuel emulsion combustion by exhaust heat recovery chiller. Energies 2022, 15, 248. [Google Scholar] [CrossRef]

- Yu, Z.; Shevchenko, S.; Radchenko, M.; Shevchenko, O.; Radchenko, A. Methodology of Designing Sealing Systems for Highly Loaded Rotary Machines. Sustainability 2022, 14, 15828. [Google Scholar] [CrossRef]

- Ravache, B.; Singh, R.; Dutton, S.M. Climate-Specific modeling and analysis for best-practice Indian office buildings 2015 Association. In Proceedings of the BS2015: 4th Conference of International Building Performance Simulation, Hyderabad, India, 7–9 December 2015; pp. 2190–2197. [Google Scholar]

- Yang, Z.; Radchenko, M.; Radchenko, A.; Mikielewicz, D.; Radchenko, R. Gas turbine intake air hybrid cooling systems and a new approach to their rational designing. Energies 2022, 15, 1474. [Google Scholar] [CrossRef]

- Radchenko, A.; Scurtu, I.-C.; Radchenko, M.; Forduy, S.; Zubarev, A. Monitoring the efficiency of cooling air at the inlet of gas engine in integrated energy system. Therm. Sci. 2022, 26, 185–194. [Google Scholar] [CrossRef]

- Radchenko, A.; Radchenko, M.; Koshlak, H.; Radchenko, R.; Forduy, S. Enhancing the efficiency of integrated energy system by redistribution of heat based of monitoring data. Energies 2022, 15, 8774. [Google Scholar] [CrossRef]

- Yang, Z.; Kornienko, V.; Radchenko, M.; Radchenko, A.; Radchenko, R. Research of Exhaust Gas Boiler Heat Exchange Surfaces with Reduced Corrosion when Water-fuel Emulsion Combustion. Sustainability 2022, 14, 11927. [Google Scholar] [CrossRef]

- Radchenko, N.; Trushliakov, E.; Radchenko, A.; Tsoy, A.; Shchesiuk, O. Methods to determine a design cooling capacity of ambient air conditioning systems in climatic conditions of Ukraine and Kazakhstan. AIP Conf. Proc. 2020, 2285, 030074. [Google Scholar] [CrossRef]

- Radchenko, M.; Radchenko, A.; Radchenko, R.; Kantor, S.; Konovalov, D.; Kornienko, V. Rational loads of turbine inlet air absorption-ejector cooling systems. Proc. Inst. Mech. Eng. Part A J. Power Energy 2021, 236, 095765092110454. [Google Scholar] [CrossRef]

- Kruzel, M.; Bohdal, T.; Dutkowski, K.; Kuczyński, W.; Chliszcz, K. Current Research Trends in the Process of Condensation of Cooling Zeotropic Mixtures in Compact Condensers. Energies 2022, 15, 2241. [Google Scholar] [CrossRef]

- Yang, Z.; Kornienko, V.; Radchenko, M.; Radchenko, A.; Radchenko, R.; Pavlenko, A. Capture of pollutants from exhaust gases by low-temperature heating surfaces. Energies 2022, 15, 120. [Google Scholar] [CrossRef]

- Pavlenko, A.M.; Koshlak, H. Application of thermal and cavitation effects for heat and mass transfer process intensification in multicomponent liquid media. Energies 2021, 14, 7996. [Google Scholar] [CrossRef]

- Pavlenko, A. Energy conversion in heat and mass transfer processes in boiling emulsions. Therm. Sci. Eng. Prog. 2020, 15, 00439. [Google Scholar] [CrossRef]

- Pavlenko, A. Change of emulsion structure during heating and boiling. Int. J. Energy Clean Environ. 2019, 20, 291–302. [Google Scholar] [CrossRef]

- Kruzel, M.; Bohdal, T.; Dutkowski, K.; Radchenko, M. The Effect of Microencapsulated PCM Slurry Coolant on the Efficiency of a Shell and Tube Heat Exchanger. Energies 2022, 15, 5142. [Google Scholar] [CrossRef]

- Dąbrowski, P.; Klugmann, M.; Mikielewicz, D. Channel Blockage and Flow Maldistribution during Unsteady Flow in a Model Microchannel Plate Heat Exchanger. J. Appl. Fluid Mech. 2019, 12, 1023–1035. [Google Scholar] [CrossRef]

- Dąbrowski, P.; Klugmann, M.; Mikielewicz, D. Selected studies of flow maldistribution in a minichannel plate heat exchanger. Arch. Thermodyn. 2017, 38, 135–148. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, G.; Mikielewicz, D. A New Approach for the Mitigating of Flow Maldistribution in Parallel Microchannel Heat Sink. J. Heat Transf. 2018, 140, 72401–72410. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, G.; Mikielewicz, D. Numerical Study on Mitigation of Flow Maldistribution in Parallel Microchannel Heat Sink: Channels Variable Width versus Variable Height Approach. J. Electron. Packag. 2019, 141, 21009–21011. [Google Scholar] [CrossRef]

- Yaïci, W.; Ghorab, M.; Entchev, E. 3D CFD study of the effect of inlet air flow maldistribution on plate-fin-tube heat exchanger design and thermal–hydraulic performance. Int. J. Heat Mass Transf. 2016, 101, 527–541. [Google Scholar] [CrossRef]

- Mikielewicz, D.; Klugmann, M.; Wajs, J. Flow boiling intensification in minichannels by means of mechanical flow turbulising inserts. Int. J. Therm. Sci. 2013, 65, 79–91. [Google Scholar] [CrossRef]

- Bohdal, T.; Kuczynski, W. Boiling of R404A refrigeration medium under the conditions of periodically generated disturbances. Heat Transf. Eng. 2011, 32, 359–368. [Google Scholar] [CrossRef]

- Dutkowski, K.; Kruzel, M. Microencapsulated PCM slurries’ dynamic viscosity experimental investigation and temperature ependent prediction model. Int. J. Heat Mass Transf. 2019, 145, 118741. [Google Scholar] [CrossRef]

- Wajs, J.; Mikielewicz, D.; Jakubowska, B. Performance of the domestic micro ORC equipped with the shell-and-tube condenser with minichannels. Energy 2018, 157, 853–861. [Google Scholar] [CrossRef]

- Kuczyński, W.; Kruzel, M.; Chliszcz, K. A Regressive Model for Periodic Dynamic Instabilities during Condensation of R1234yf and R1234ze Refrigerants. Energies 2022, 15, 2117. [Google Scholar] [CrossRef]

- Kuczyński, W.; Kruzel, M.; Chliszcz, K. Regression Model of Dynamic Pulse Instabilities during Condensation of Zeotropic and Azeotropic Refrigerant Mixtures R404A, R448A and R507A in Minichannels. Energies 2022, 15, 1789. [Google Scholar] [CrossRef]

- Liao, G.; Li, Z.; Zhang, F.; Liu, L.E.J. A Review on the Thermal-Hydraulic Performance and Optimization of Compact Heat Exchangers. Energies 2021, 14, 6056. [Google Scholar] [CrossRef]

- Blecich, P. Experimental investigation of the effects of airflow nonuniformity on performance of a fin-and-tube heat exchanger. Int. J. Refrig. 2015, 59, 65–74. [Google Scholar] [CrossRef]

- Korzen, A.; Taler, D. Modeling of transient response of a plate fin and tube heat exchanger. Int. J. Therm. Sci. 2015, 92, 188–198. [Google Scholar] [CrossRef]

- Taler, D. Mathematical modeling and control of plate fin and tube heat exchangers. Energy Convers. Manag. 2015, 96, 452–462. [Google Scholar] [CrossRef]

- Yu, Z.; Løvås, T.; Konovalov, D.; Trushliakov, E.; Radchenko, M.; Kobalava, H.; Radchenko, R.; Radchenko, A. Investigation of thermopressor with incomplete evaporation for gas turbine intercooling systems. Energies 2023, 16, 20. [Google Scholar] [CrossRef]

- Kornienko, V.; Radchenko, R.; Konovalov, D.; Andreev, A.; Pyrysunko, M. Characteristics of the Rotary Cup Atomizer Used as Afterburning Installation in Exhaust Gas Boiler Flue. In Advances in Design, Simulation and Manufacturing III (DSMIE 2020); Ivanov, V., Pavlenko, I., Liaposhchenko, O., Machado, J., Edl, M., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2020; pp. 302–311. [Google Scholar] [CrossRef]

- Butrymowicz, D.; Gagan, J.; Śmierciew, K.; Łukaszuk, M.; Dudar, A.; Pawluczuk, A.; Łapiński, A.; Kuryłowic, A. Investigations of prototype ejection refrigeration system driven by low grade heat. HTRSE-2018 E3S Web Conf. 2020, 70, 03002. [Google Scholar] [CrossRef]

- Radchenko, R.; Radchenko, N.; Tsoy, A.; Forduy, S.; Zybarev, A.; Kalinichenko, I. Utilizing the heat of gas module by an absorption lithium-bromide chiller with an ejector booster stage. AIP Conf. Proc. 2020, 2285, 030084. [Google Scholar] [CrossRef]

- Yang, Z.; Konovalov, D.; Radchenko, M.; Radchenko, R.; Kobalava, H.; Radchenko, A.; Kornienko, V. Analyzing the efficiency of thermopressor application for combustion engine cyclic air cooling. Energies 2022, 15, 2250. [Google Scholar] [CrossRef]

- Konovalov, D.; Radchenko, M.; Kobalava, H.; Radchenko, A.; Radchenko, R.; Kornienko, V.; Maksymov, V. Research of characteristics of the flow part of an aerothermopressor for gas turbine intercooling air. Proc. Inst. Mech. Eng. Part A J. Power Energy 2021, 236, 4. [Google Scholar] [CrossRef]

- Im, P.; Malhotra, M.; Munk, J.D.; Lee, J. Cooling season full and part load performance evaluation of variable refrigerant flow (VRF) system using an occupancy simulated research building. In Proceedings of the 16th International Refrigeration and Air Conditioning Conference at Purdue, West Lafayette, IN, USA, 11–14 July 2016. [Google Scholar]

- Canova, A.; Cavallero, C.; Freschi, F.; Giaccone, L.; Repetto, M.; Tartaglia, M. Optimal energy management. IEEE Ind. Appl. Mag. 2009, 15, 62–65. [Google Scholar] [CrossRef]

- Radchenko, N.; Radchenko, A.; Tsoy, A.; Mikielewicz, D.; Kantor, S.; Tkachenko, V. Improving the efficiency of railway conditioners in actual climatic conditions of operation. AIP Conf. Proc. 2020, 2285, 030072. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, T.; Zhang, J. Operational electricity consumption analyze of VRF air conditioning system and air conditioning system based on building energy monitoring and management system. Procedia Eng. 2015, 121, 1856–1863. [Google Scholar] [CrossRef]

- Khatri, R.; Joshi, A. Energy performance comparison of inverter based variable refrigerant flow unitary AC with constant volume unitary AC. Energy Procedia 2017, 109, 18–26. [Google Scholar] [CrossRef]

- Park, D.Y.; Yun, G.; Kim, K.S. Experimental evaluation and simulation of a variable refrigerant-flow (VRF) air-conditioning system with outdoor air processing unit. Energy Build 2017, 146, 122–140. [Google Scholar] [CrossRef]

- Thornton, B.; Wagner, A. Variable Refrigerant Flow Systems; Pacific Northwest National Laboratory: Seattle, WA, USA, 2012. Available online: http://www.gsa.gov/portal/mediaId/197399/fileName/GPG_Variable_Refrigerant_Flow_12-2012.action (accessed on 19 January 2020).

- Chen, J.; Xie, W. Analysis on load-undertaking of fan coil unit with fresh air system. Adv. Mater. Res. 2013, 614, 678–681. [Google Scholar] [CrossRef]

- Zhu, Y.; Jin, X.; Du, Z.; Fang, X.; Fan, B. Control and energy simulation of variable refrigerant flow air conditioning system combined with outdoor air processing unit. Appl. Therm. Eng. 2014, 64, 385–395. [Google Scholar] [CrossRef]

- Lee, J.H.; Yoon, H.J.; Im, P.; Song, Y.H. Verification of energy reduction effect through control optimization of supply air temperature in VRF-OAP system. Energies 2018, 11, 49. [Google Scholar] [CrossRef]

- Radchenko, M.; Radchenko, A.; Mikielewicz, D.; Radchenko, R.; Andreev, A. A novel degree-hour method for rational design loading. Proc. Inst. Mech. Eng. Part A J. Power Energy 2022. [Google Scholar] [CrossRef]

- Suamir, I.N.; Tassou, S.A. Performance evaluation of integrated trigeneration and CO2 refrigeration systems. Appl. Therm. Eng. 2013, 50, 1487–1495. [Google Scholar] [CrossRef]

- Ortiga, J.; Bruno, J.C.; Coronas, A. Operational optimization of a complex trigeneration system connected to a district heating and cooling network. Appl. Therm. Eng. 2013, 50, 1536–1542. [Google Scholar] [CrossRef]

- Rodriguez-Aumente, P.A.; Rodriguez-Hidalgo, M.d.C.; Nogueira, J.I.; Lecuona, A.; Venegas, M.d.C. District heating and cooling for business buildings in Madrid. Appl. Therm. Eng. 2013, 50, 1496–1503. [Google Scholar] [CrossRef]

- Freschi, F.; Giaccone, L.; Lazzeroni, P.; Repetto, M. Economic and environmental analysis of a trigeneration system for food-industry: A case study. Appl. Energy 2013, 107, 157–172. [Google Scholar] [CrossRef]

- Radchenko, A.; Radchenko, M.; Trushliakov, E.; Kantor, S.; Tkachenko, V. Statistical Method to Define Rational Heat Loads on Railway Air Conditioning System for Changeable Climatic Conditions. In Proceedings of the 5th International Conference on Systems and Informatics, ICSAI 2018, Nanjing, Jiangsu, China, 10–12 November 2018; pp. 1294–1298. [Google Scholar] [CrossRef]

- Cardona, E.; Piacentino, A. A methodology for sizing a trigeneration plant in mediterranean areas. Appl. Therm. Eng. 2003, 23, 15. [Google Scholar] [CrossRef]

- Fumo, N.; Mago, P.J.; Smith, A.D. Analysis of combined cooling, heating, and power systems operating following the electric load and following the thermal load strategies with no electricity export. Proc. Inst. Mech. Eng. Part A J. Power Energy 2011, 225, 1016–1025. [Google Scholar] [CrossRef]

- Giaccone, L.; Canova, A. Economical comparison of CHP systems for industrial user with large steam demand. Appl. Energy 2009, 86, 904–914. [Google Scholar] [CrossRef]

- Kavvadias, K.C.; Tosios, A.P.; Maroulis, Z.B. Design of a combined heating, cooling and power system: Sizing, operation strategy selection and parametric analysis. Energy Convers. Manag. 2010, 51, 833–845. [Google Scholar] [CrossRef]

- Konovalov, D.; Trushliakov, E.; Radchenko, M.; Kobalava, G.; Maksymov, V. Research of the aerothermopresor cooling system of charge air of a marine internal combustion engine under variable climatic conditions of operation. In Advanced Manufacturing Processes: Selected Papers from the Grabchenko’s International Conference on Advanced Manufacturing Processes (InterPartner-2019), September 10–13, 2019, Odessa, Ukraine; Tonkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Edl, M., Kuric, I., Pavlenko, I., Dasic, P., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2020; pp. 520–529. [Google Scholar] [CrossRef]

- Popli, S.; Rodgers, P.; Eveloy, V. Trigeneration scheme for energy efficiency enhancement in a natural gas processing plant through turbine exhaust gas waste heat utilization. Appl. Energy 2012, 93, 623–636. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, W. Development of an Optimal Start Control Strategy for a Variable Refrigerant Flow (VRF) System. Energies 2021, 14, 271. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.K.; Yang, W.M.; Yan, J. Achieving better energy-efficient air conditioning—A review of technologies and strategies. Appl. Energy 2013, 104, 87–104. [Google Scholar] [CrossRef]

- Carvalho, M.; Lozano, M.A.; Serra, L.M. Multicriteria synthesis of trigeneration systems considering economic and environmental aspects. Appl. Energy 2012, 91, 245–254. [Google Scholar] [CrossRef]

- Geldermann, J.; Rentz, O. Multi-criteria analysis for the assessment of environmentally relevant installations. J. Ind. Ecol. 2020, 9, 127–142. [Google Scholar] [CrossRef]

- Piacentino, A.; Cardona, F. EABOT—Energetic Analysis as a Basis for robust Optimization of Trigeneration systems by linear programming. Energy Convers. Manag. 2008, 49, 3006–3016. [Google Scholar] [CrossRef]

- Forsyth, J.L. Gas turbine inlet air chilling for LNG. IGT Int. Liq. Nat. Gas Conf. Proc. 2013, 3, 1763–1778. [Google Scholar]

- Available online: http://www.meteomanz.com (accessed on 1 January 2020).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radchenko, M.; Radchenko, A.; Trushliakov, E.; Pavlenko, A.; Radchenko, R. Advanced Method of Variable Refrigerant Flow (VRF) Systems Designing to Forecast On-Site Operation—Part 1: General Approaches and Criteria. Energies 2023, 16, 1381. https://doi.org/10.3390/en16031381

Radchenko M, Radchenko A, Trushliakov E, Pavlenko A, Radchenko R. Advanced Method of Variable Refrigerant Flow (VRF) Systems Designing to Forecast On-Site Operation—Part 1: General Approaches and Criteria. Energies. 2023; 16(3):1381. https://doi.org/10.3390/en16031381

Chicago/Turabian StyleRadchenko, Mykola, Andrii Radchenko, Eugeniy Trushliakov, Anatoliy Pavlenko, and Roman Radchenko. 2023. "Advanced Method of Variable Refrigerant Flow (VRF) Systems Designing to Forecast On-Site Operation—Part 1: General Approaches and Criteria" Energies 16, no. 3: 1381. https://doi.org/10.3390/en16031381

APA StyleRadchenko, M., Radchenko, A., Trushliakov, E., Pavlenko, A., & Radchenko, R. (2023). Advanced Method of Variable Refrigerant Flow (VRF) Systems Designing to Forecast On-Site Operation—Part 1: General Approaches and Criteria. Energies, 16(3), 1381. https://doi.org/10.3390/en16031381