Challenges of Phasing out Emergency Diesel Generators: The Case Study of Lacor Hospital’s Energy Community

Abstract

1. Introduction

2. Materials and Methods

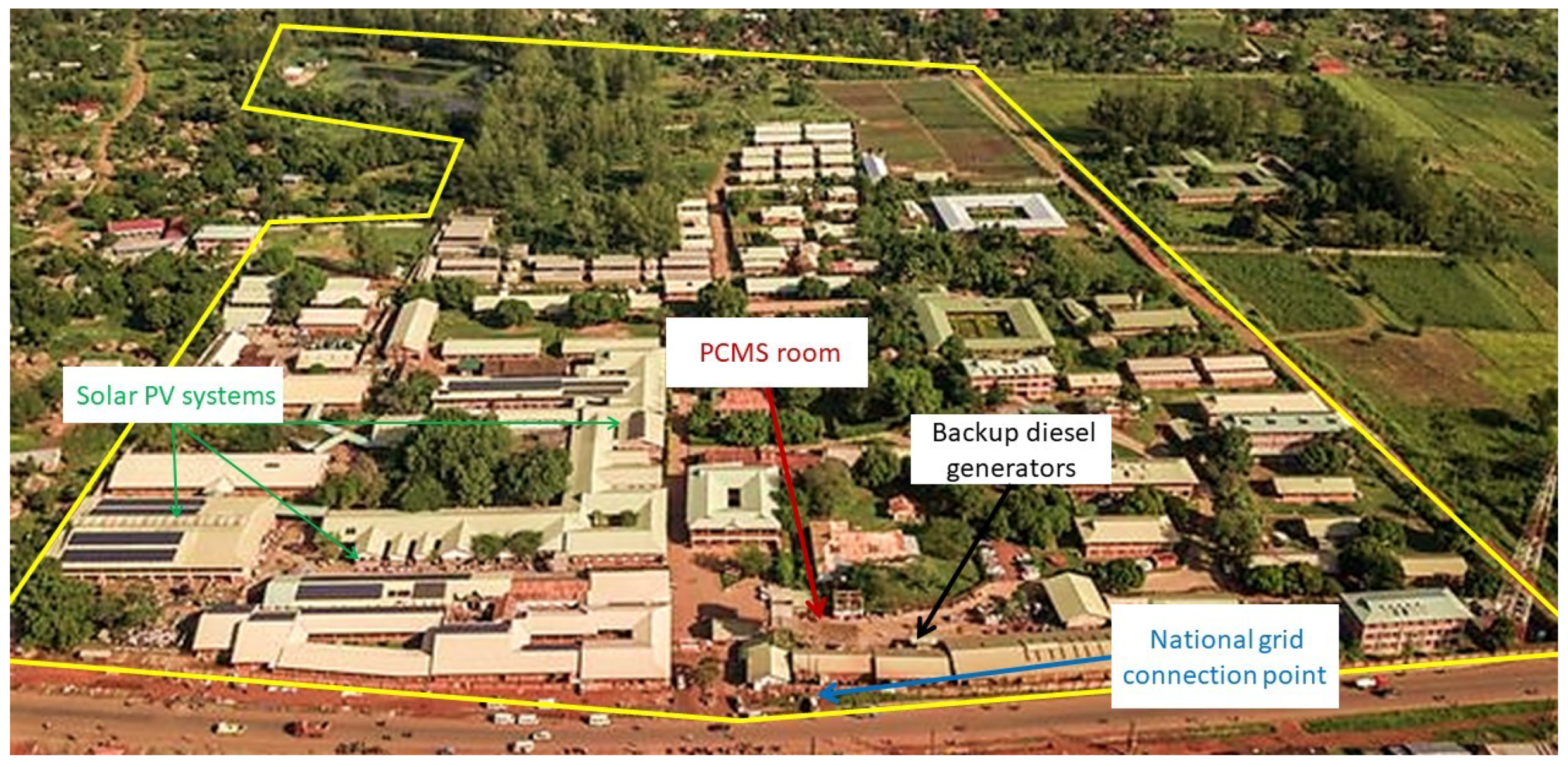

2.1. St. Mary’s Hospital Lacor and Its Power System

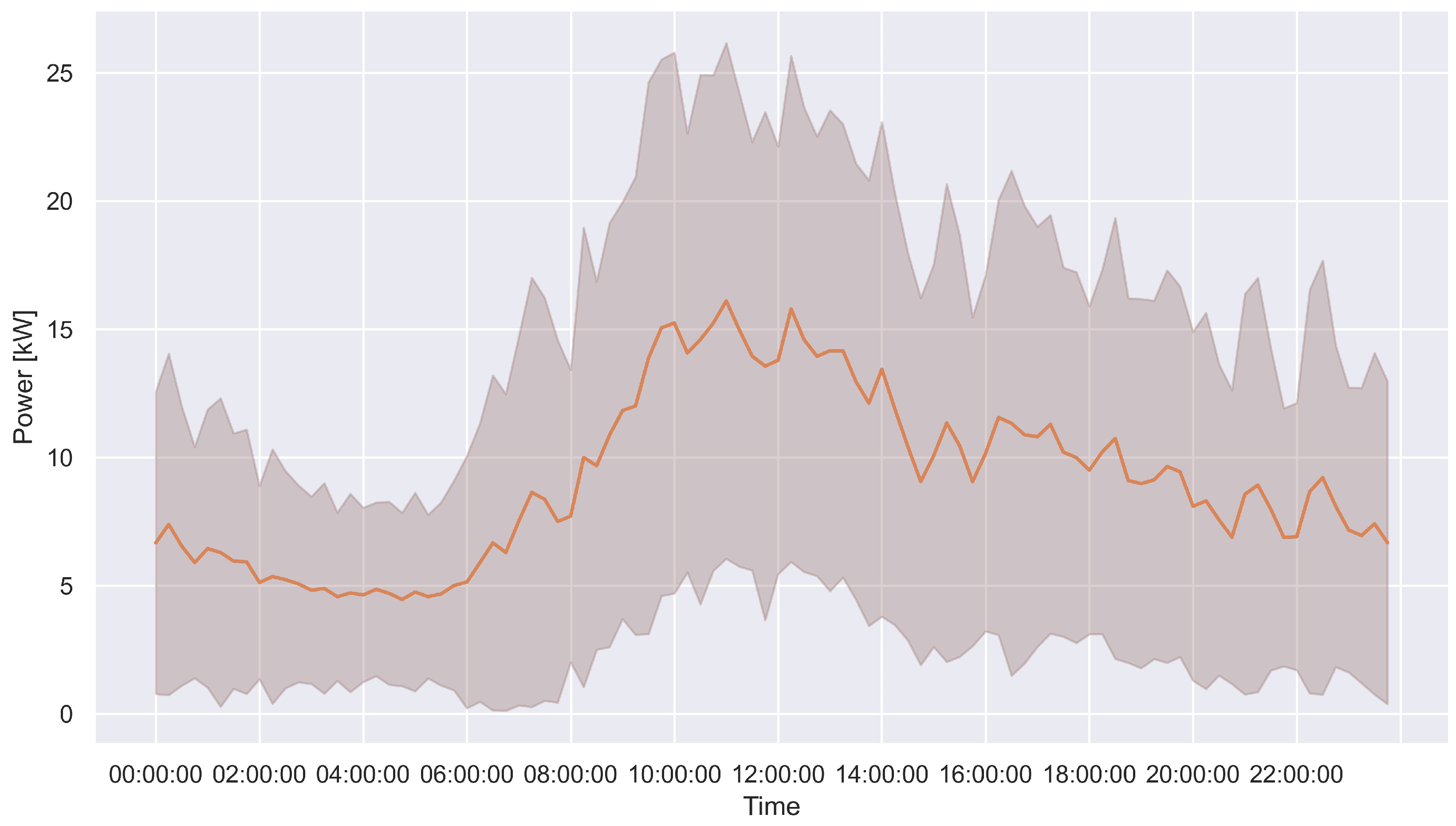

2.2. Data Collection and Preparation

2.3. Scenarios Construction

2.4. Optimisation Problem Formulation

2.5. Stakeholder Engagement Workshop

3. Results

3.1. Optimisation Results

3.2. Workshop Results

4. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Singer, B.C.; Tschudi, W.F. High Performance Healthcare Buildings: A Roadmap to Improved Energy Efficiency; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2009. [Google Scholar]

- Wang, T.; Li, X.; Liao, P.C.; Fang, D. Building energy efficiency for public hospitals and healthcare facilities in China: Barriers and drivers. Energy 2016, 103, 588–597. [Google Scholar] [CrossRef]

- IEA. Africa Energy Outlook 2022; IEA: Paris, France, 2022. [Google Scholar] [CrossRef]

- Farquharson, D.V.; Jaramillo, P.; Samaras, C. Sustainability implications of electricity outages in sub-Saharan Africa. Nat. Sustain. 2018, 1, 589–597. [Google Scholar] [CrossRef]

- Li, J.; Niu, D.; Wu, M.; Wang, Y.; Li, F.; Dong, H. Research on Battery Energy Storage as Backup Power in the Operation Optimization of a Regional Integrated Energy System. Energies 2018, 11, 2990. [Google Scholar] [CrossRef]

- Rodríguez-Gallegos, C.D.; Gandhi, O.; Bieri, M.; Reindl, T.; Panda, S.K. A diesel replacement strategy for off-grid systems based on progressive introduction of PV and batteries: An Indonesian case study. Appl. Energy 2018, 229, 1218–1232. [Google Scholar] [CrossRef]

- Kiray, V.; Orhan, M.; Chijioke, J.N. Significant Increase in Fuel Efficiency of Diesel Generators with Lithium-Ion Batteries Documented by Economic Analysis. Energies 2021, 14, 6904. [Google Scholar] [CrossRef]

- RENAISSANCE EU H2020. Renaissance H2020 Project towards Sustainable Energy Communities. Available online: https://www.renaissance-h2020.eu/ (accessed on 20 December 2022).

- Coosemans, T.; Brosius, W.; Ramirez Camargo, L.; Heuninckx, S.; Luisa Lode, M.; Felice, A.; Martinez Alonso, A.; Arapoglou, S.; Hueting, R.; Meitern, M. D6.3 Report on Replication Validation—Renaissance H2020 Project; Technical Report, EC Grant Agreement No 824342. 2022. Available online: https://www.renaissance-h2020.eu/resource/d6-3-report-on-replication-validation/ (accessed on 20 December 2022).

- Mandelli, S.; Barbieri, J.; Mereu, R.; Colombo, E. Off-grid systems for rural electrification in developing countries: Definitions, classification and a comprehensive literature review. Renew. Sustain. Energy Rev. 2016, 58, 1621–1646. [Google Scholar] [CrossRef]

- Holmgren, W.F.; Hansen, C.W.; Mikofski, M.A. pvlib python: A python package for modeling solar energy systems. J. Open Source Softw. 2018, 3, 884. [Google Scholar] [CrossRef]

- Copernicus. Copernicus Climate Data Store. Available online: https://cds.climate.copernicus.eu/#!/home (accessed on 20 December 2022).

- Ramirez Camargo, L.; Schmidt, J. Simulation of multi-annual time series of solar photovoltaic power: Is the ERA5-land reanalysis the next big step? Sustain. Energy Technol. Assessments 2020, 42, 100829. [Google Scholar] [CrossRef]

- Romare, M.; Dahllöf, L. The Life Cycle Energy Consumption and Greenhouse Gas Emissions from Lithium-Ion Batteries. A Study with Focus on Current Technology and Batteries for Light-Duty Vehic; Number C. 2017, p. 58. Available online: https://www.ivl.se/download/18.694ca0617a1de98f473b98/1628417788414/FULLTEXT01.pdf (accessed on 20 December 2022).

- Wild-Scholten. Solar resources and carbon footprint of photovoltaic power in different regions in europe. Katalog BPS 2014, XXXIII, 81–87. [Google Scholar] [CrossRef]

- Uganda Diesel Prices. Available online: https://www.globalpetrolprices.com/ (accessed on 7 November 2022).

- IRENA. Uganda—Country Indicators and Sdgs; Technical Report; IRENA: Deblin, Poland, 2019. [Google Scholar]

- UBA. Umweltbundesamt|Für Mensch und Umwelt; UBA: Seoul, Republic of Korea, 2022. [Google Scholar]

- Felice, A.; Rakocevic, L.; Peeters, L.; Messagie, M.; Coosemans, T.; Ramirez Camargo, L. Renewable energy communities: Do they have a business case in Flanders? Appl. Energy 2022, 322, 119419. [Google Scholar] [CrossRef]

- Hart, W.E.; Laird, C.D.; Watson, J.P.; Woodruff, D.L.; Hackebeil, G.A.; Nicholson, B.L.; Siirola, J.D. Pyomo—Optimization Modeling in Python. In Springer Optimization and Its Applications; Springer International Publishing: Cham, Swizerland, 2017; Volume 67. [Google Scholar] [CrossRef]

- Gurobi Optimization, LLC. Gurobi Optimizer Reference Manual. Available online: https://www.gurobi.com/wp-content/plugins/hd_documentations/documentation/9.0/refman.pdf (accessed on 20 December 2022).

- Lode, M.L.; Heuninckx, S.; te Boveldt, G.; Macharis, C.; Coosemans, T. Designing successful energy communities: A comparison of seven pilots in Europe applying the Multi-Actor Multi-Criteria Analysis. Energy Res. Soc. Sci. 2022, 90, 102671. [Google Scholar] [CrossRef]

| Electricity Source | Cost |

|---|---|

| UMEME | UGX 555,063,000 |

| Backup DGs | UGX 72,650,000 |

| PV (savings) | (UGX 203,845,000) |

| Total expenditure | UGX 627,613,000 |

| Data | Financial Year 21/22 | Reconstructed Data |

|---|---|---|

| Total load | 945 MWh/year | 1154 MWh/year |

| Backup DGs | 46 MWh/year | 48 MWh/year |

| Capacity (kWp) | Orientation | Tilt (°) |

|---|---|---|

| 155 | North | 6 |

| 110 | South | 6 |

| 25 | East | 20 |

| 25 | West | 20 |

| Scenario Name | DG Allowed | Demand-Side Management | BESS Investment | Additional PV Investment |

|---|---|---|---|---|

| BAU | ✓ | × | × | × |

| Flex | ✓ | ✓ | × | × |

| BESS | ✓ | ✓ | ✓ | × |

| RES | ✓ | ✓ | ✓ | ✓ |

| NoGen | × | ✓ | ✓ | ✓ |

| Parameter | Symbol | Value |

|---|---|---|

| DG efficiency | 22% | |

| DG minimum partial load | 80 kW | |

| Maximum power of flexible load | 70 kW | |

| BESS efficiencies | / | 95% |

| BESS minimum SOC | 0.1 | |

| Maximum charging C-rate | 0.5 h | |

| Maximum discharging C-rate | 0.5 h | |

| BESS CAPEX | UGX 1,688,000 /kWh | |

| BESS lifetime | 10 years | |

| BESS carbon content | 90 kg CO/kWh [14] | |

| PV CAPEX | UGX 1,875,684 /kWp | |

| PV lifetime | 25 years | |

| PV carbon content | 1798 kg CO/kWp [15] | |

| Electricity price | UGX 891 /kWh | |

| Higher diesel price | UGX 532 /kWh [16] | |

| Lower diesel price | UGX 345 /kWh | |

| Ugandan average grid carbon content | 106 g CO/kWh [17] | |

| Diesel carbon content | 270 g CO/kWh [18] | |

| Discount rate | d | 5% |

| Scenario Name | Total PV Capacity (kWp) | Additional PV Capacity (kWp) | BESS Capacity (kWh) |

|---|---|---|---|

| BAU | 315 | × | × |

| Flex | 315 | × | × |

| BESS | 315 | × | 0 |

| RES | 815 | 500 | 1591 |

| NoGen | 815 | 500 | 1591 |

| Scenario Name | PV Capacity (kWp) | Additional PV Capacity (kWp) | BESS Capacity (kWh) |

|---|---|---|---|

| BAU | 315 | × | × |

| Flex | 315 | × | × |

| BESS | 315 | × | 50 |

| RES | 815 | 500 | 1591 |

| NoGen | 815 | 500 | 1591 |

| Scenario Name | LCOE (UGX/kWh) | Yearly Savings (%) | Total Investment (MUGX) | Simple Payback Time (years) |

|---|---|---|---|---|

| BAU | 567.81 | - | - | - |

| Flex | 538.03 | 5.25 | 0 | 0 |

| BESS | 538.03 | 5.25 | 0 | 0 |

| RES | 421.64 | 25.74 | 3624 | 6.20 |

| NoGen | 421.64 | 25.74 | 3624 | 6.20 |

| Scenario Name | LCOE (UGX/kWh) | Yearly Savings (%) | Total Investment (MUGX) | Simple Payback Time (Years) |

|---|---|---|---|---|

| BAU | 599.91 | - | - | - |

| Flex | 566.36 | 5.59 | 0 | 0 |

| BESS | 564.81 | 5.85 | 85 | 1.63 |

| RES | 421.64 | 29.72 | 3624 | 5.82 |

| NoGen | 421.64 | 29.72 | 3624 | 5.82 |

| Scenario Name | Self-Consumption Ratio (%) | Self-Sufficiency Ratio (%) | Emissions (g CO/kWh) | Emissions Reduction (%) |

|---|---|---|---|---|

| BAU | 89.59 | 39.15 | 288.35 | - |

| Flex | 95.82 | 42.16 | 272.04 | 5.65 |

| BESS | 95.82 | 42.16 | 272.04 | 5.65 |

| RES | 82.20 | 96.83 | 74.73 | 74.08 |

| NoGen | 82.20 | 96.83 | 74.73 | 74.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Felice, A.; Barbieri, J.; Martinez Alonso, A.; Messagie, M.; Coosemans, T. Challenges of Phasing out Emergency Diesel Generators: The Case Study of Lacor Hospital’s Energy Community. Energies 2023, 16, 1369. https://doi.org/10.3390/en16031369

Felice A, Barbieri J, Martinez Alonso A, Messagie M, Coosemans T. Challenges of Phasing out Emergency Diesel Generators: The Case Study of Lacor Hospital’s Energy Community. Energies. 2023; 16(3):1369. https://doi.org/10.3390/en16031369

Chicago/Turabian StyleFelice, Alex, Jacopo Barbieri, Ander Martinez Alonso, Maarten Messagie, and Thierry Coosemans. 2023. "Challenges of Phasing out Emergency Diesel Generators: The Case Study of Lacor Hospital’s Energy Community" Energies 16, no. 3: 1369. https://doi.org/10.3390/en16031369

APA StyleFelice, A., Barbieri, J., Martinez Alonso, A., Messagie, M., & Coosemans, T. (2023). Challenges of Phasing out Emergency Diesel Generators: The Case Study of Lacor Hospital’s Energy Community. Energies, 16(3), 1369. https://doi.org/10.3390/en16031369