Nonimaging High Concentrating Photovoltaic System Using Trough

Abstract

1. Introduction

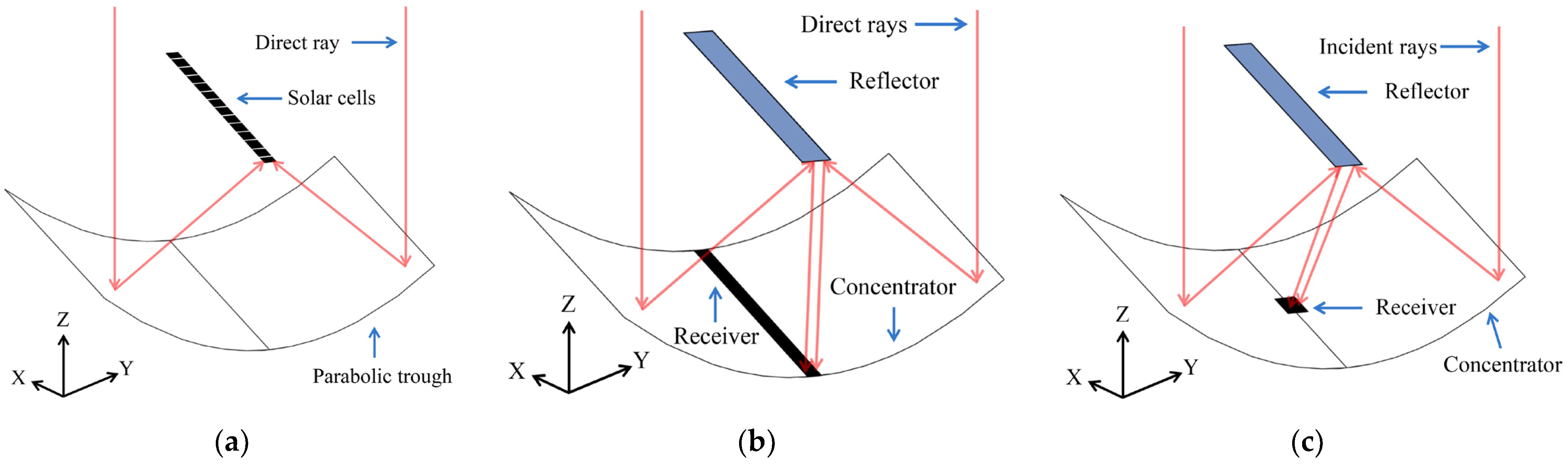

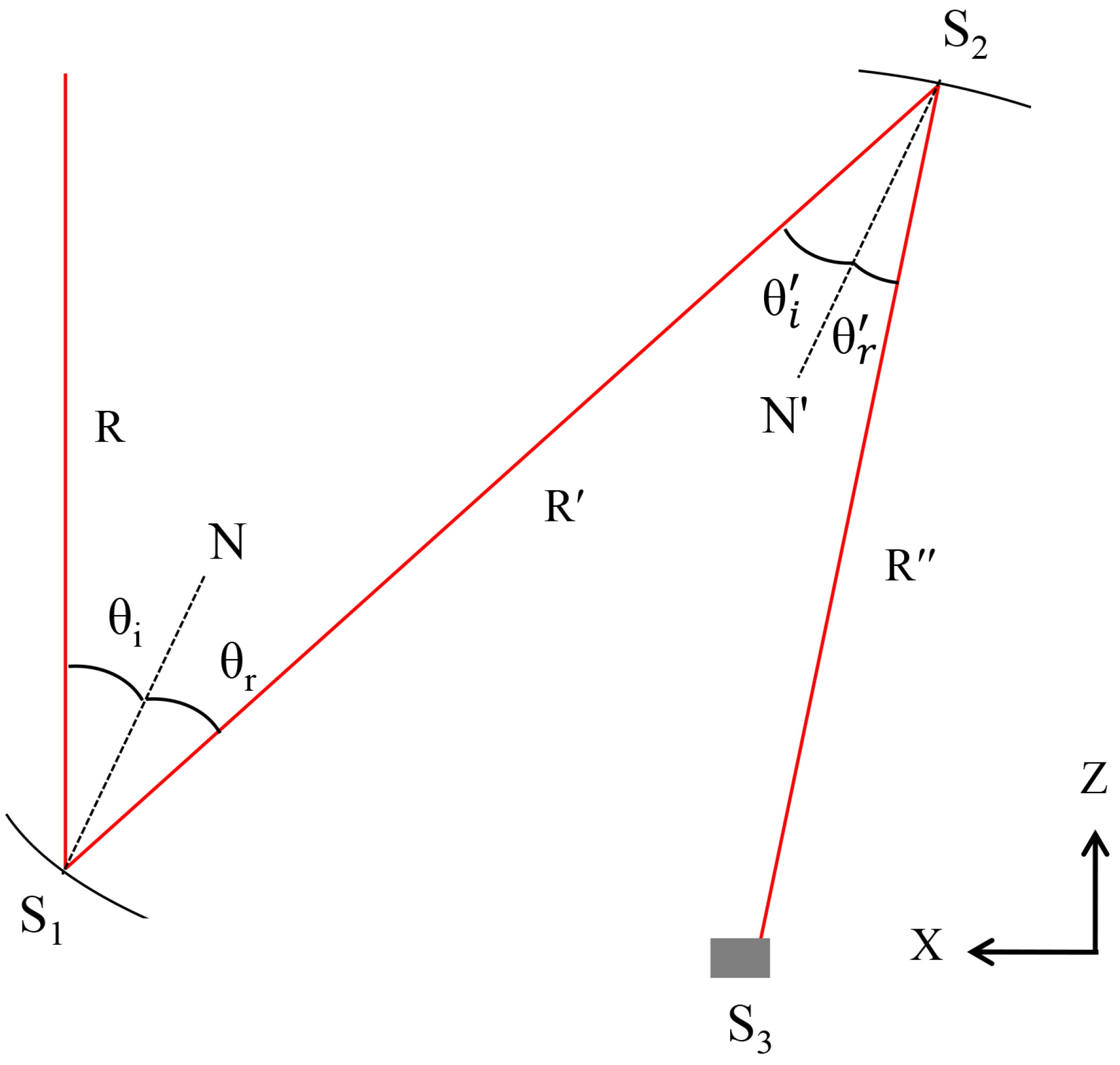

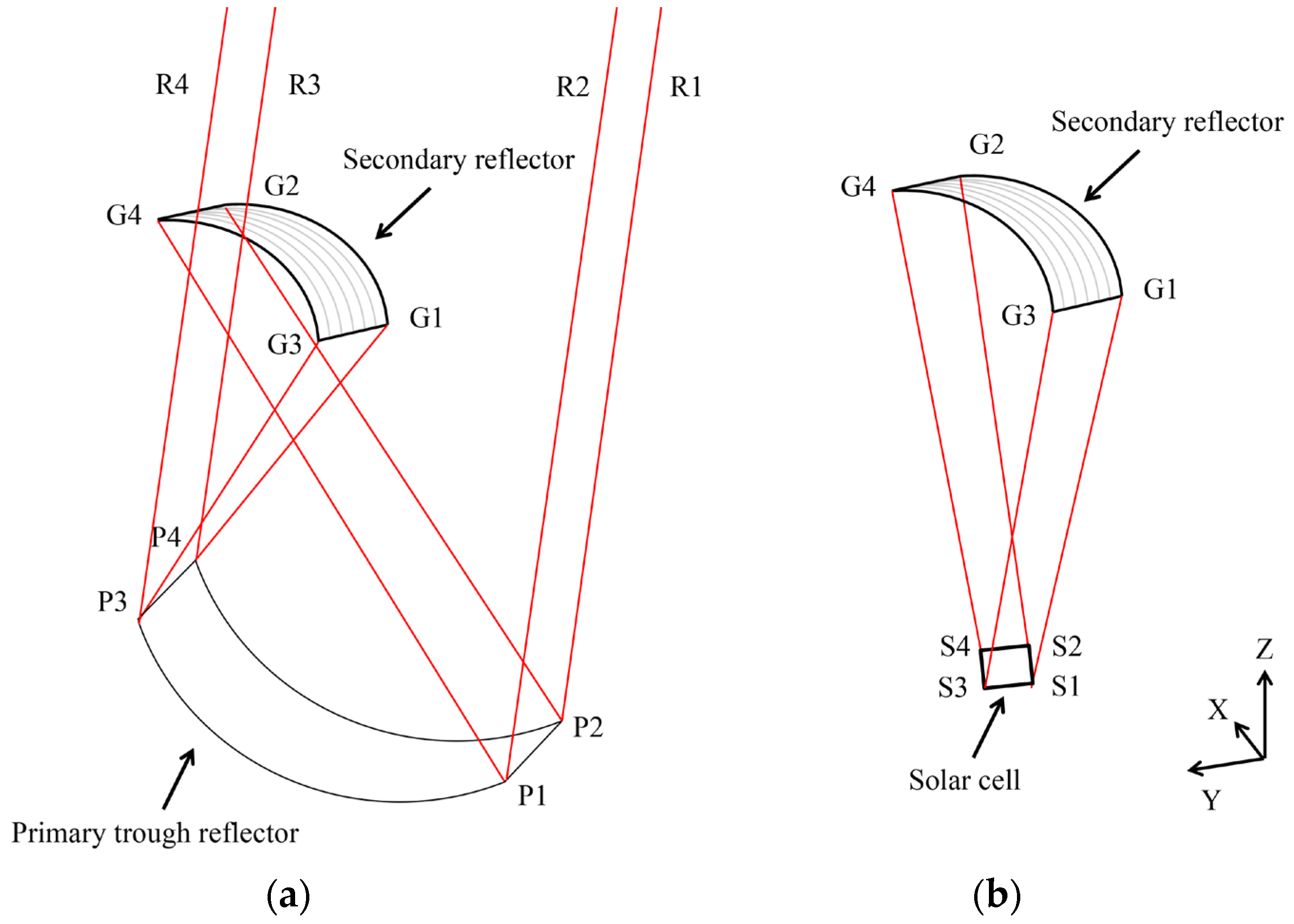

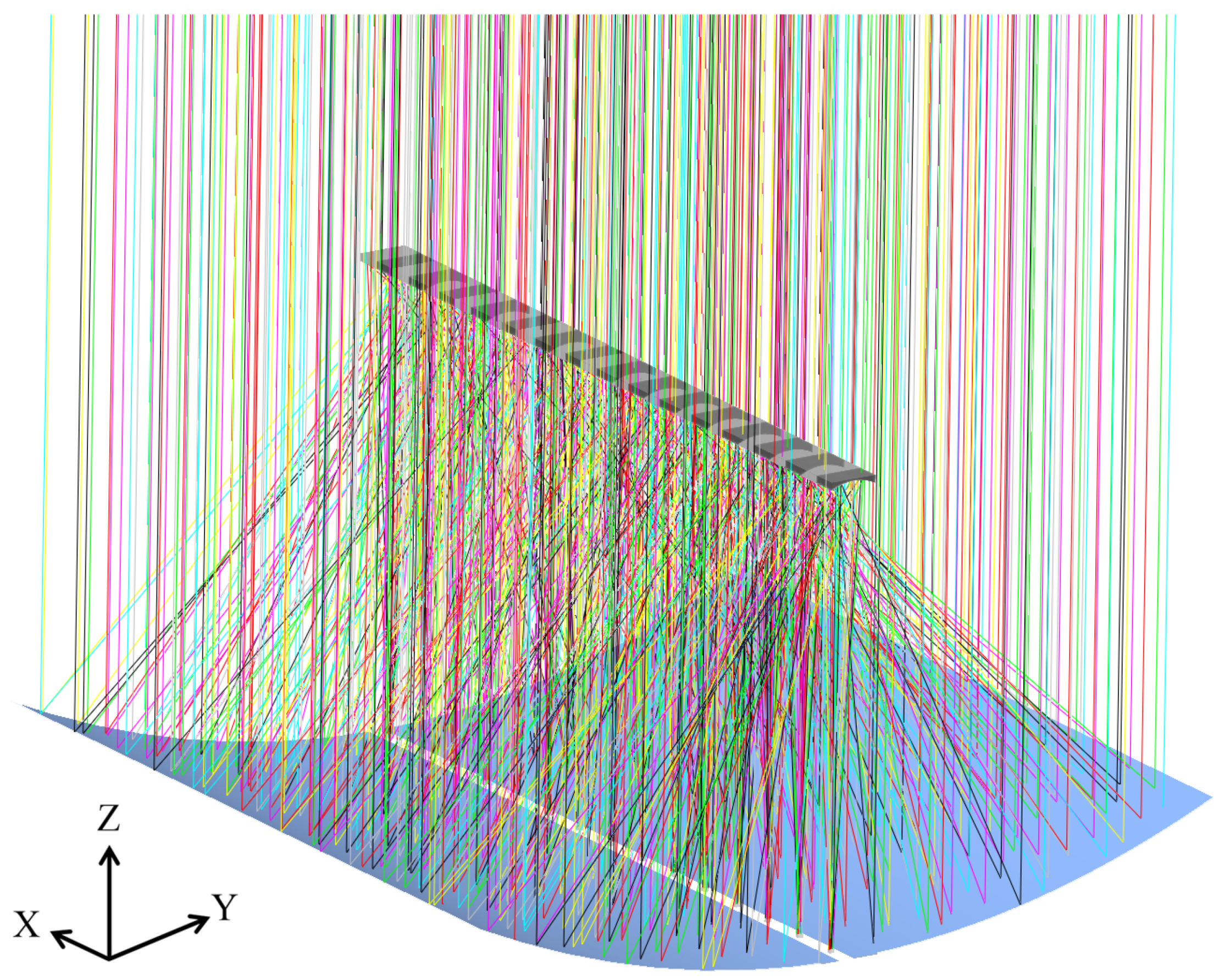

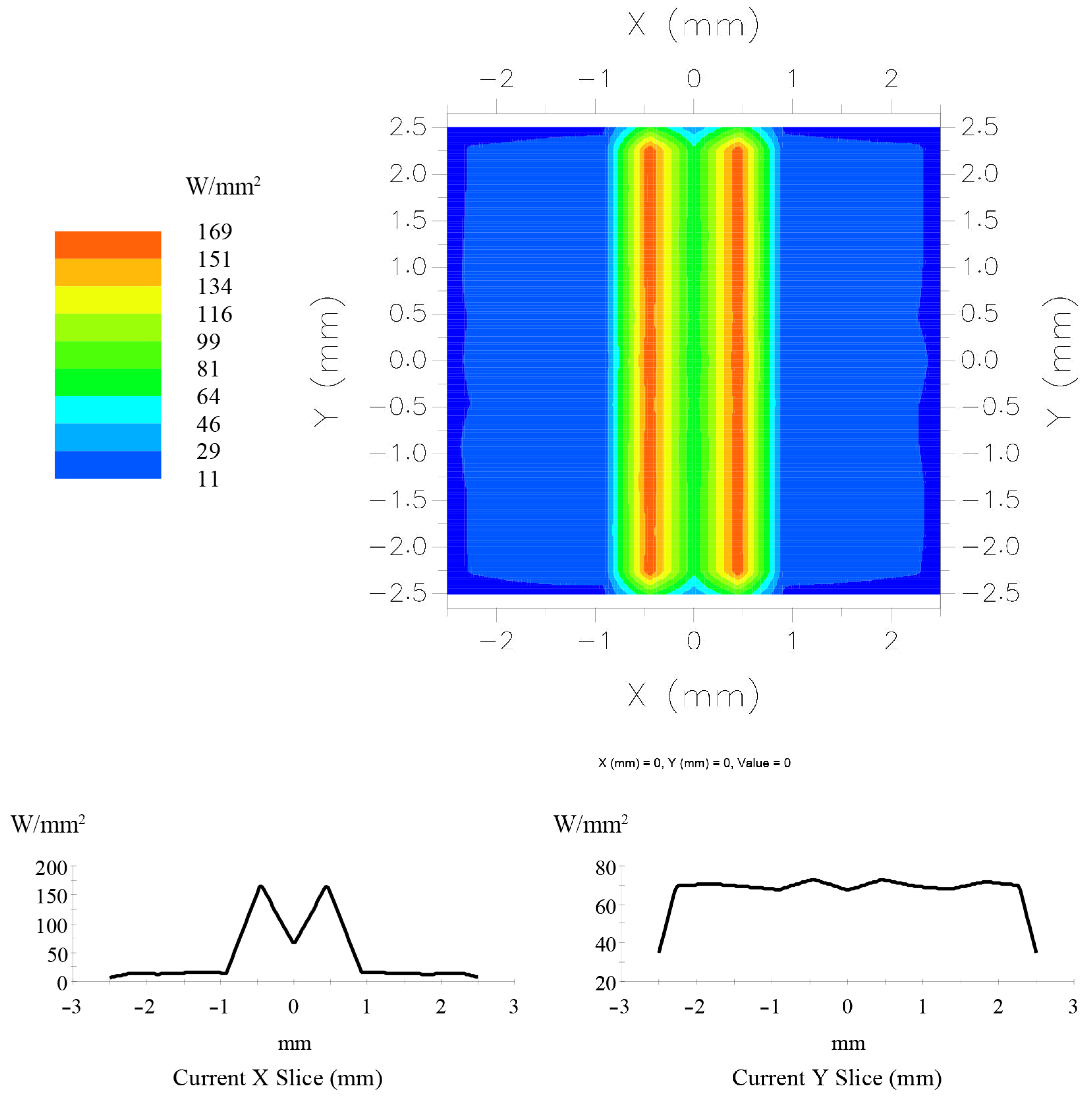

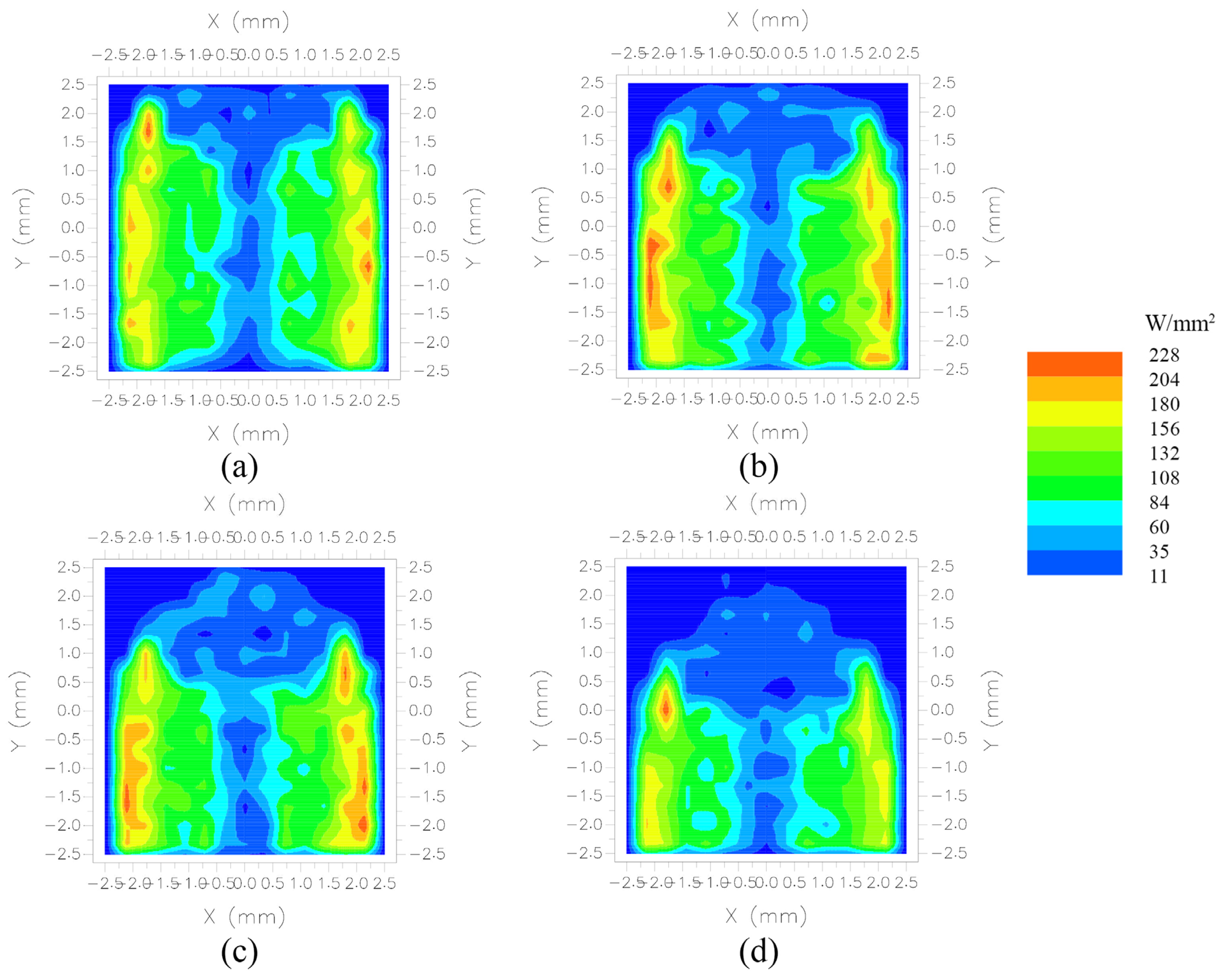

2. Design and Optical Modeling of the Proposed CPV System

3. Simulation Results and Discussion

4. Conclusions and Future Works

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Greek symbols | |

| θ | Acceptance angle |

| ηOptical | Optical efficiency |

| θi | Angle of incidence at S1 |

| θr | Angle of reflection at S1 |

| θ′i | Angle of incidence at S2 |

| θ′r | Angle of reflection at S2 |

| α | Tilted angle of a groove along y-z plane |

| Abbreviations | |

| CPC | Compound parabolic concentrator |

| CPV | Concentrator photovoltaic |

| CSP | Concentrated solar power |

| HCPV | High concentrating photovoltaic |

| PV | Photovoltaic |

| POE | Primary optical element |

| SOE | Secondary optical element |

| Latin symbols | |

| Acell | Area of the solar cell |

| Cg | Geometrical concentration ratio |

| Cmax | Maximum concentration ratio |

| D | Depth of the parabola |

| Dnr | Depth of the secondary nonimaging reflector |

| f | Focal length of the parabola |

| G | Edge of a reflected grooves |

| H | Distance between the trough and secondary reflectors |

| L | Length of the parabola |

| Lengtharc | Arc length of the parabola |

| MJ | Multi-junction |

| N | Unit normal vector into the primary concentrator |

| N′ | Unit normal vector into the secondary reflector |

| p | Length along the parabola axis |

| q | Length perpendicular to the axis making a chord |

| R | Incident light ray |

| S | Edge of a solar cell |

| v | Unit vectors along incident rays |

| v″ | Unit vectors along reflected rays |

| W | Width of the parabola |

| Ws | Width of the secondary nonimaging reflector |

| Wn | Width of a groove |

References

- Gasparotto, J.; Da Boit Martinello, K. Coal as an energy source and its impacts on human health. Energy Geosci. 2021, 2, 113–120. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Outlook 2021; OECD Publishing: Paris, France, 2021. [Google Scholar] [CrossRef]

- Rejeb, O.; Shittu, S.; Ghenai, C.; Li, G.; Zhao, X.; Bettayeb, M. Optimization and performance analysis of a solar concentrated photovoltaic-thermoelectric (CPV-TE) hybrid system. Renew. Energy 2020, 152, 1342–1353. [Google Scholar] [CrossRef]

- Pintanel, M.T.; Martínez-Gracia, A.; Uche, J.; del Amo, A.; Bayod-Rújula, Á.A.; Usón, S.; Arauzo, I. Energy and environmental benefits of an integrated solar photovoltaic and thermal hybrid, seasonal storage and heat pump system for social housing. Appl. Therm. Eng. 2022, 213, 118662. [Google Scholar] [CrossRef]

- Bergmann, R. Crystalline Si thin-film solar cells: A review. Appl. Phys. A 1999, 69, 187–194. [Google Scholar] [CrossRef]

- Peibst, R.; Rienäcker, M.; Larionova, Y.; Folchert, N.; Haase, F.; Hollemann, C.; Wolter, S.; Krügener, J.; Bayerl, P.; Bayer, J.; et al. Towards 28%-efficient Si single-junction solar cells with better passivating POLO junctions and photonic crystals. Sol. Energy Mater. Sol. Cells 2022, 238, 111560. [Google Scholar] [CrossRef]

- Sharma, M.K.; Bhattacharya, J. Deciding between concentrated and non-concentrated photovoltaic systems via direct comparison of experiment with opto-thermal computation. Renew. Energy 2021, 178, 1084–1096. [Google Scholar] [CrossRef]

- Wiesenfarth, M.; Anton, I.; Bett, A.W. Challenges in the design of concentrator photovoltaic (CPV) modules to achieve highest efficiencies. Appl. Phys. Rev. 2018, 5, 041601. [Google Scholar] [CrossRef]

- Dimroth, F.; Tibbits, T.N.D.; Niemeyer, M.; Predan, F.; Beutel, P.; Karcher, C.; Oliva, E.; Siefer, G.; Lackner, D.; Fus-Kailuweit, P.; et al. Four-Junction Wafer-Bonded Concentrator Solar Cells. IEEE J. Photovolt. 2016, 6, 343–349. [Google Scholar] [CrossRef]

- Siefer, G.; Beutel, P.; Lackner, D.; Oliva, E.; Predan, F.; Schachtner, M.; Dimroth, F.; Ledoux, O.; Guiot, E. Four-Junction Wafer Bonded Solar Cells for Space Applications. In 2019 European Space Power Conference (ESPC); IEEE: Piscataway, NJ, USA, 2019; pp. 1–4. [Google Scholar]

- Ullah, I. Optical design of centered-receiver trough-based CPV system. J. Photonics Energy 2021, 11, 035502. [Google Scholar] [CrossRef]

- Saura, J.M.; Rodrigo, P.M.; Almonacid, F.M.; Chemisana, D.; Fernández, E.F. Experimental characterisation of irradiance and spectral non-uniformity and its impact on multi-junction solar cells: Refractive vs. reflective optics. Sol. Energy Mater. Sol. Cells 2021, 225, 111061. [Google Scholar] [CrossRef]

- Mortadi, M.; El Fadar, A. Novel design of concentrating photovoltaic thermal collector—A comparative analysis with existing configurations. Energy Convers. Manag. 2022, 268, 116016. [Google Scholar] [CrossRef]

- Dhakal, R.; Lee, J.; Kim, J. Bio-inspired thin and flat solar concentrator for efficient, wide acceptance angle light collection. Appl. Opt. 2014, 53, 306–315. [Google Scholar] [CrossRef] [PubMed]

- Chemisana, D.; Ibáñez, M.; Barrau, J. Comparison of Fresnel concentrators for building integrated photovoltaics. Energy Convers. Manag. 2009, 50, 1079–1084. [Google Scholar] [CrossRef]

- Xie, W.T.; Dai, Y.J.; Wang, R.Z.; Sumathy, K. Concentrated solar energy applications using Fresnel lenses: A review. Renew. Sustain. Energy Rev. 2011, 15, 2588–2606. [Google Scholar] [CrossRef]

- Indira, S.S.; Vaithilingam, C.A.; Sivasubramanian, R.; Chong, K.-K.; Saidur, R.; Narasingamurthi, K. Optical performance of a hybrid compound parabolic concentrator and parabolic trough concentrator system for dual concentration. Sustain. Energy Technol. Assess. 2021, 47, 101538. [Google Scholar]

- Yang, J.; Xiao, Y.; Liang, J. Chapter 5 Concentrator PV and solar tracker. In Solar Photovoltaic Power Generation; De Gruyter: Berlin, Germany, 2020; pp. 163–200. [Google Scholar]

- Badr, F.; Radwan, A.; Ahmed, M.; Hamed, A.M. Performance assessment of a dual-axis solar tracker for concentrator photovoltaic systems. Int. J. Energy Res. 2022, 46, 13424–13440. [Google Scholar] [CrossRef]

- Winston, R.; Miñano, J.C.; Benitez, P.G. Nonimaging Optics; Elsevier Academic Press: New York, NY, USA, 2005. [Google Scholar]

- Anandhi Parthiban, T.K.; Mallick, K.S. Reddy Integrated optical-thermal-electrical modeling of compound parabolic concentrator based photovoltaic-thermal system. Energy Convers. Manag. 2022, 251, 115009. [Google Scholar] [CrossRef]

- Da Rosa, A.V.; Ordóñez, J.C. Chapter 12-Solar Radiation. In Fundamentals of Renewable Energy Processes, 4th ed.; Academic Press: Cambridge, MA, USA, 2022; pp. 519–576. [Google Scholar]

- Chen, F.; Chen, J. A novel solution method for reflector shape of solar Compound Parabolic Concentrator and verification. Renew. Energy 2022, 192, 385–395. [Google Scholar] [CrossRef]

- Linderman, R.J.; Judkins, Z.S.; Shoecraft, M.; Dawson, M.J. Thermal Performance of the SunPower Alpha-2 PV Concentrator. IEEE J. Photovolt. 2012, 2, 196–201. [Google Scholar] [CrossRef]

- Oh, S.J.; Kim, H.; Hong, Y. Monte Carlo Ray-Tracing Simulation of a Cassegrain Solar Concentrator Module for CPV. Front. Energy Res. 2021, volume 9, 722842. [Google Scholar] [CrossRef]

- Ferrer-Rodríguez, J.P.; Fernández, E.F.; Almonacid, F.; Baig, H.; Mallick, T.K.; Pérez-Higueras, P. Indoor characterization and comparison with optical modelling of four Fresnel-based High-CPV units equipped with secondary optics. In AIP Conference Proceedings; AIP Publishing LLC.: Melville, NY, USA, 2018. [Google Scholar]

- Rahmanian, S.; Moein-Jahromi, M.; Rahmanian-Koushkaki, H.; Sopian, K. Performance investigation of inclined CPV system with composites of PCM, metal foam and nanoparticles. Sol. Energy 2021, 230, 883–901. [Google Scholar] [CrossRef]

- Felsberger, R.; Buchroithner, A.; Gerl, B.; Schweighofer, B.; Preßmair, R.; Mitter, T.; Wegleiter, H. Optical performance and alignment characterization of a parabolic trough collector using a multi-junction CPV solar cell. Sol. Energy 2022, 239, 40–49. [Google Scholar] [CrossRef]

- Ullah, I. Optical modeling of two-stage concentrator photovoltaic system using parabolic trough. J. Photonics Energy 2019, 9, 043102. [Google Scholar] [CrossRef]

- Carlo, R. Characterization of spherical optics performance compared to other types of optical systems in a point-focus CPV system. Therm. Sci. Eng. Prog. 2022, 29, 101201. [Google Scholar]

- Bel Hadj, O.; Kechiche, B.; Sammouda, H. Concentrator Photovoltaic System (CPV): Maximum Power Point Techniques (MPPT) Design and Performance. In Solar Radiation-Measurement, Modeling and Forecasting Techniques for Photovoltaic Solar Energy Applications; IntechOpen Limited: London, UK, 2022. [Google Scholar]

- Renno, C.; Perone, A. Experimental modeling of the optical and energy performances of a point-focus CPV system applied to a residential user. Energy 2021, 215, 119156. [Google Scholar] [CrossRef]

- Vu, H.; Vu, N.H.; Shin, S. Static Concentrator Photovoltaics Module for Electric Vehicle Applications Based on Compound Parabolic Concentrator. Energies 2022, 15, 6951. [Google Scholar] [CrossRef]

- Lokeswaran, S.; Mallick, T.K.; Reddy, K.S. Design and analysis of dense array CPV receiver for square parabolic dish system with CPC array as secondary concentrator. Sol. Energy 2020, 199, 782–795. [Google Scholar] [CrossRef]

- Venegas-Reyes, E.; Ortega-Avila, N.; Peña-Cruz, M.; García-Ortiz, O.; Rodriguez-Muñoz, N. A Linear Hybrid Concentrated Photovoltaic Solar Collector: A Methodology Proposal of Optical and Thermal Analysis. Energies 2021, 14, 8155. [Google Scholar] [CrossRef]

- Widyolar, B.; Jiang, L.; Abdelhamid, M.; Winston, R. Design and modeling of a spectrum-splitting hybrid CSP-CPV parabolic trough using two-stage high concentration optics and dual junction InGaP/GaAs solar cells. Sol. Energy 2018, 165, 75–84. [Google Scholar] [CrossRef]

- Naveenkumar, R.; Ravichandran, M.; Stalin, B.; Ghosh, A.; Karthick, A.; Aswin, L.S.R.L.; Kumar, S.P.; Kumar, S.K. Comprehensive review on various parameters that influence the performance of parabolic trough collector. Environ. Sci. Pollut. Res. 2021, 28, 22310–22333. [Google Scholar] [CrossRef]

- Zhao, K.; Jin, H.; Gai, Z.; Hong, H. A thermal efficiency-enhancing strategy of parabolic trough collector systems by cascadingly applying multiple solar selective-absorbing coatings. Appl. Energy 2022, 309, 118508. [Google Scholar] [CrossRef]

- Häberle, A.; Krüger, D. Concentrating solar technologies for industrial process heat. Conc. Sol. Power Technol. 2021, volume, 659–675. [Google Scholar] [CrossRef]

- Groulx, D.; Sponagle, B. Ray-Tracing Analysis of a Two-Stage Solar Concentrator. Trans. Can. Soc. Mech. Eng. 2010, 34, 263–275. [Google Scholar] [CrossRef]

- Brogren, M.; Karlsson, B.; Roos, A.; Werner, A. Analysis of the effects of outdoor and accelerated ageing on the optical properties of reflector materials for solar energy applications. Sol. Energy Mater. Sol. Cells 2004, 82, 491–515. [Google Scholar] [CrossRef]

- Baig, H.; Heasman, K.C.; Mallick, T.K. Non-uniform illumination in concentrating solar cells. Renew. Sustain. Energy Rev. 2012, 16, 5890–5909. [Google Scholar] [CrossRef]

- Spiegel, M.R.; Lipschutz, S.; Liu, J. Mathematical Handbook of Formulas and Tables, 3rd ed.; McGraw Hill: New York, NY, USA, 2009. [Google Scholar]

- Lovegrove, K.; Stein, W. Concentrating Solar Power Technology: Principles, Developments and Applications; Woodhead Publishing Limited: Cambridge, UK, 2012. [Google Scholar]

- Azure Space Solar Power GmbH. Concentrator Triple Junction Solar Cell 3C44. 2015. Available online: https://www.azurspace.com/images/products/0004356-00-01_3C44_AzurDesign_5.pdf (accessed on 10 October 2022).

- Azure Space Solar Power GmbH. Concentrator Triple Junction Solar Cell 3C44. 2015. Available online: http://www.azurspace.com/images/products/0004355-00-01_3C44_AzurDesign_10x10.pdf (accessed on 10 October 2022).

- NREL. Reference solar spectral irradiance: Air mass 1.5. ASTM (G-173-03). Available online: https://rredc.nrel.gov/solar/spectra/am1.5/ (accessed on 11 August 2022).

- Chaudhary, G.Q.; Kousar, R.; Ali, M.; Amar, M.; Amber, K.P.; Lodhi, S.K.; Din, M.R.; Ditta, A. Small-Sized Parabolic Trough Collector System for Solar Dehumidification Application: Design, Development, and Potential Assessment. Int. J. Photoenergy 2018, 2018, 5759034. [Google Scholar] [CrossRef]

- Chargui, R.; Tashtoush, B.; Awani, S. Experimental study and performance testing of a novel parabolic trough collector. Int. J. Energy Res. 2021, 46, 1518–1537. [Google Scholar] [CrossRef]

- Felsberger, R.; Buchroithner, A.; Gerl, B.; Wegleiter, H. Conversion and testing of a solar thermal parabolic trough collector for CPV-T application. Energies 2020, 13, 6142. [Google Scholar] [CrossRef]

- Schmitz, M.; Cooper, T.; Ambrosetti, G.; Steinfeld, A. Two-stage solar concentrators based on parabolic troughs: Asymmetric versus symmetric designs. Appl. Opt. 2015, 54, 9709–9721. [Google Scholar] [CrossRef]

- Otanicar, T.P.; Wingert, R.; Orosz, M.; McPheeters, C. Concentrating photovoltaic retrofit for existing parabolic trough solar collectors: Design, experiments, and levelized cost of electricity. Appl. Energy 2020, 265, 114751. [Google Scholar] [CrossRef]

- Felsberger, R.; Buchroithner, A.; Gerl, B.; Schweighofer, B.; Wegleiter, H. Design and testing of concentrated photovoltaic arrays for retrofitting of solar thermal parabolic trough collectors. Appl. Energy 2021, 300, 117427. [Google Scholar] [CrossRef]

- Cooper, T.; Ambrosetti, G.; Malnati, F.; Pedretti, A.; Steinfeld, A. Experimental demonstration of high-concentration photovoltaics on a parabolic trough using tracking secondary optics. Prog. Photovolt. Res. Appl. 2016, 24, 1410–1426. [Google Scholar] [CrossRef]

- Cooper, T.; Ambrosetti, G.; Pedretti, A.; Steinfeld, A. Surpassing the 2D limit: A 600x high-concentration PV collector based on a parabolic trough with tracking secondary optics. Energy Procedia 2014, 57, 285–290. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| W | 500 mm |

| L | 500 mm |

| D | 57 mm |

| Ws | 33.3 mm |

| H | 286 |

| Cg | 622 |

| Acell | 5 × 5 mm2 |

| Paper | Concentrator | Secondary Optics | Technology | Cell Type | Concentration | Acceptance Angle (°) | Irradiance Uniformity | Electrical Efficiency (%) | Optical Efficiency (%) |

|---|---|---|---|---|---|---|---|---|---|

| Cooper et al., 2014 [55] | Trough | ✓ | CPV | MJ | 600× | - | ✓ | 25 | 78 |

| Schmitz et al., 2015 [51] | Trough | ✓ | CPV | MJ | 68× | 0.6 | ✓ | - | - |

| Cooper et al., 2016 [54] | Trough | ✓ | CPV | MJ | 364× | 3.2 |  | 20.2 | - |

| Chaudhary et al., 2018 [48] | Trough |  | CPV-T | - | 9.93× | - |  | - | 46–62 |

| Widyolar et al., 2018 [36] | Trough | ✓ | CPV | MJ | 50× | 0.6 | ✓ | 23 | - |

| Ullah, 2019 [29] | Trough | ✓ | CPV | MJ | 285× | ±1.1 | ✓ | - | 72 |

| Felsberger et al., 2020 [50] | Trough |  | CPV-T | MJ | 53× | - |  | 28 | - |

| Otanicar et al., 2020 [52] | Trough | ✓ | CPV-T | Si | 74× | - |  | 21 | - |

| Indira et al., 2021 [17] | Hybrid CPC/Trough | ✓ | CPV | MJ | - | - |  | - | 73 |

| Chargui et al., 2021 [49] | Trough |  | T | - | 23.4× | - | ✓ | - | 60 |

| Felsberger et al., 2021 [53] | Trough |  | CPV-T | MJ | 220× | - | ✓ | 26.8 | 48.8 |

| Ullah, 2021 [11] | Trough | ✓ | CPV | MJ | 285× | ±2 | ✓ | - | 60 |

| Proposed design | Trough | ✓ | CPV | MJ | 622× | ±0.4 | ✓ | - | 79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iqbal, W.; Ullah, I.; Shin, S. Nonimaging High Concentrating Photovoltaic System Using Trough. Energies 2023, 16, 1336. https://doi.org/10.3390/en16031336

Iqbal W, Ullah I, Shin S. Nonimaging High Concentrating Photovoltaic System Using Trough. Energies. 2023; 16(3):1336. https://doi.org/10.3390/en16031336

Chicago/Turabian StyleIqbal, Waseem, Irfan Ullah, and Seoyong Shin. 2023. "Nonimaging High Concentrating Photovoltaic System Using Trough" Energies 16, no. 3: 1336. https://doi.org/10.3390/en16031336

APA StyleIqbal, W., Ullah, I., & Shin, S. (2023). Nonimaging High Concentrating Photovoltaic System Using Trough. Energies, 16(3), 1336. https://doi.org/10.3390/en16031336