Eddy Current Loss Reduction in Axial-Flux Motors Using 3D Printing †

Abstract

1. Introduction

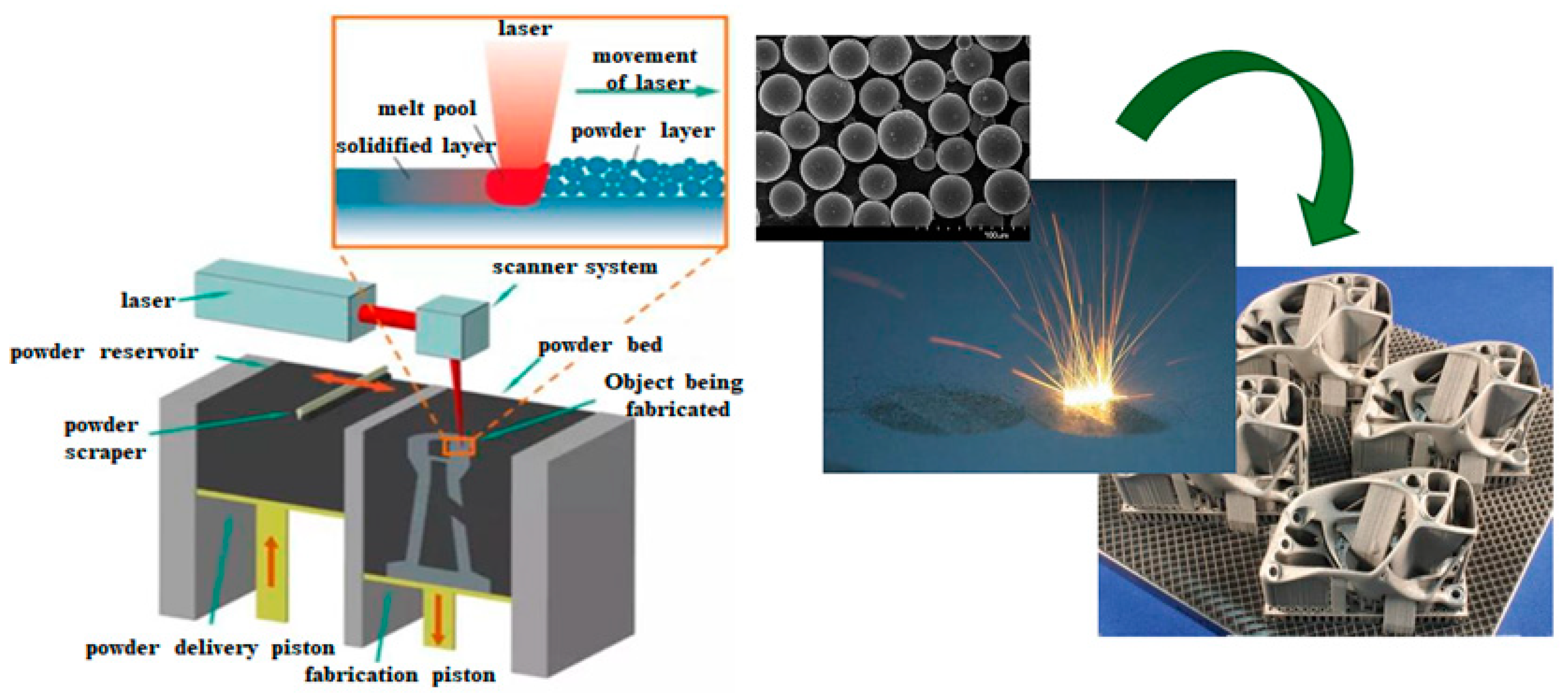

2. Principle of 3D Printing Technology

2.1. Process of 3D Printing

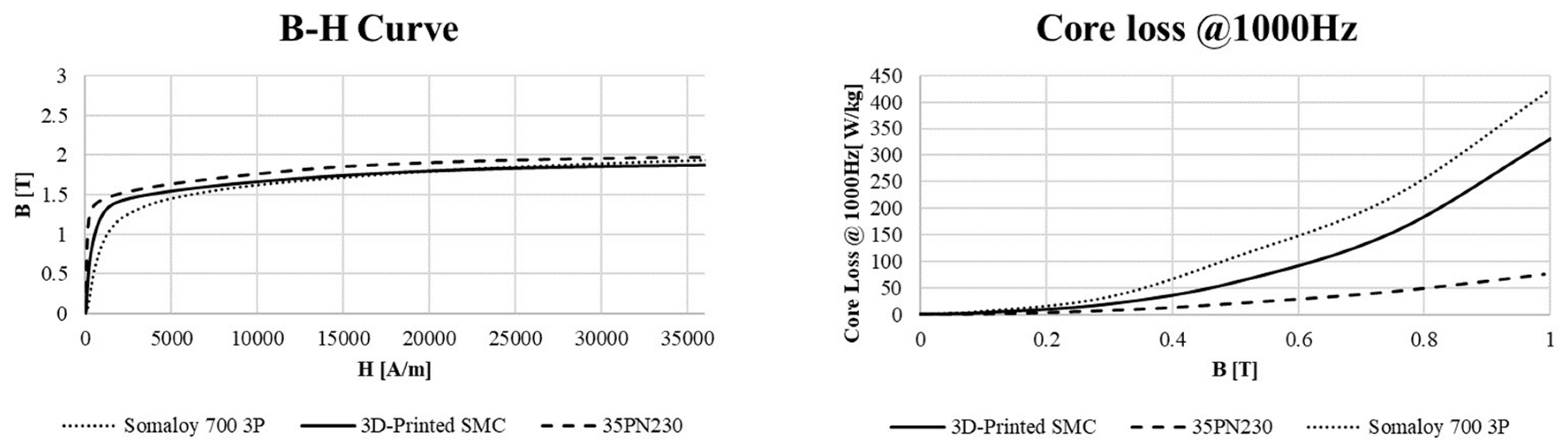

2.2. Comprehensive Core Loss Comparison of Three Materials

3. Core Loss Analysis Using 3D Printing Technology

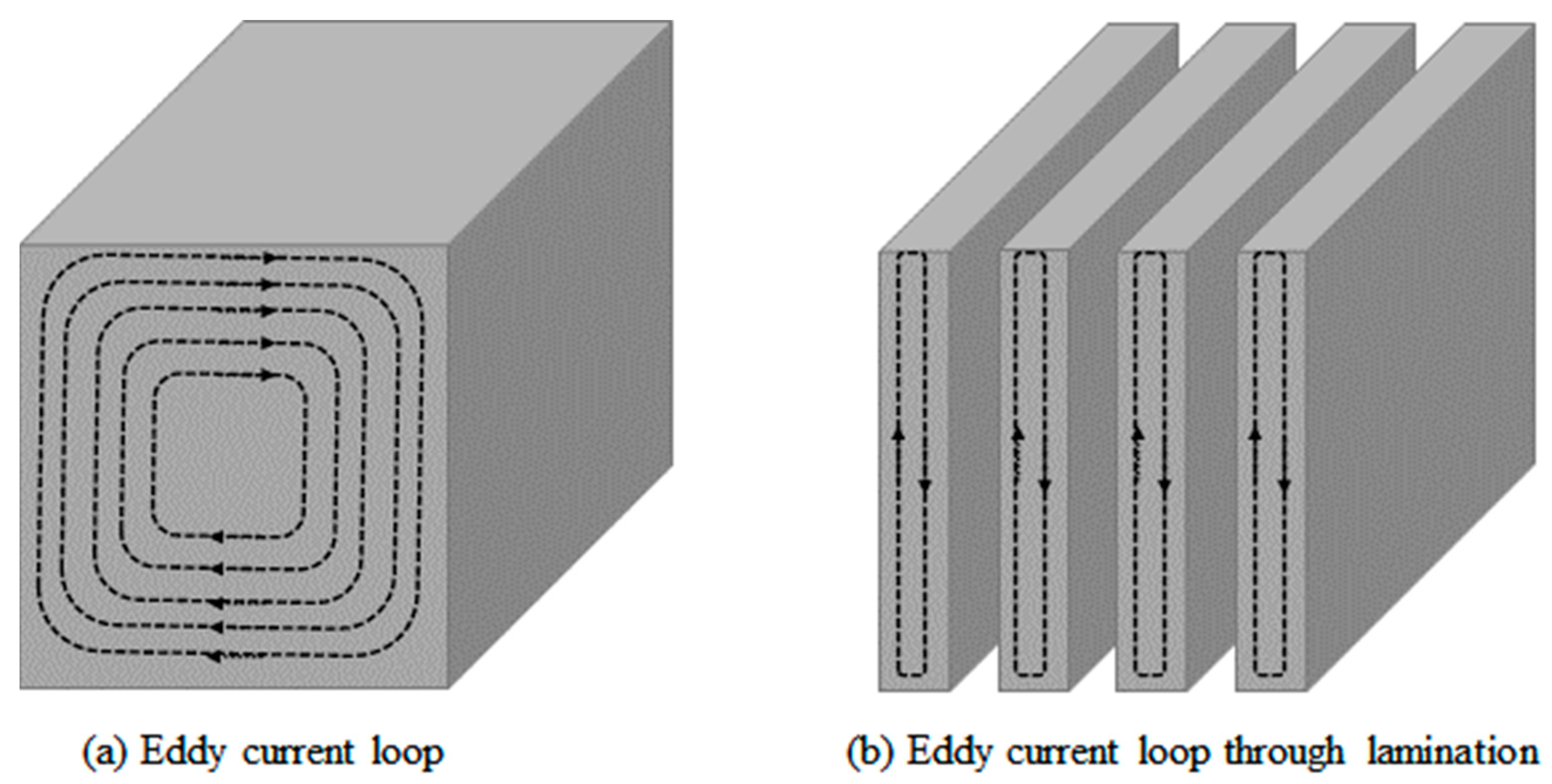

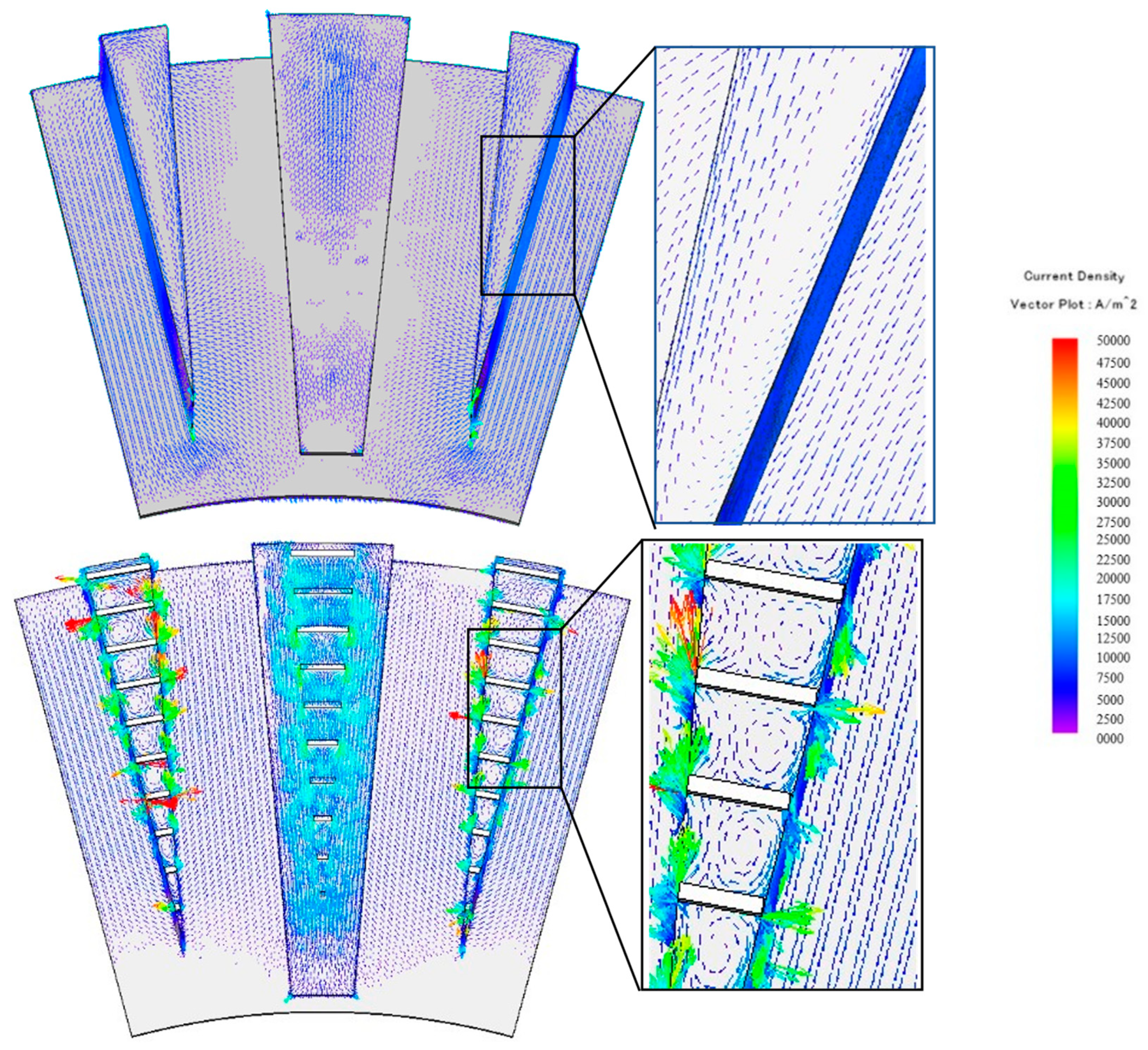

3.1. Principle of Eddy Current Loss

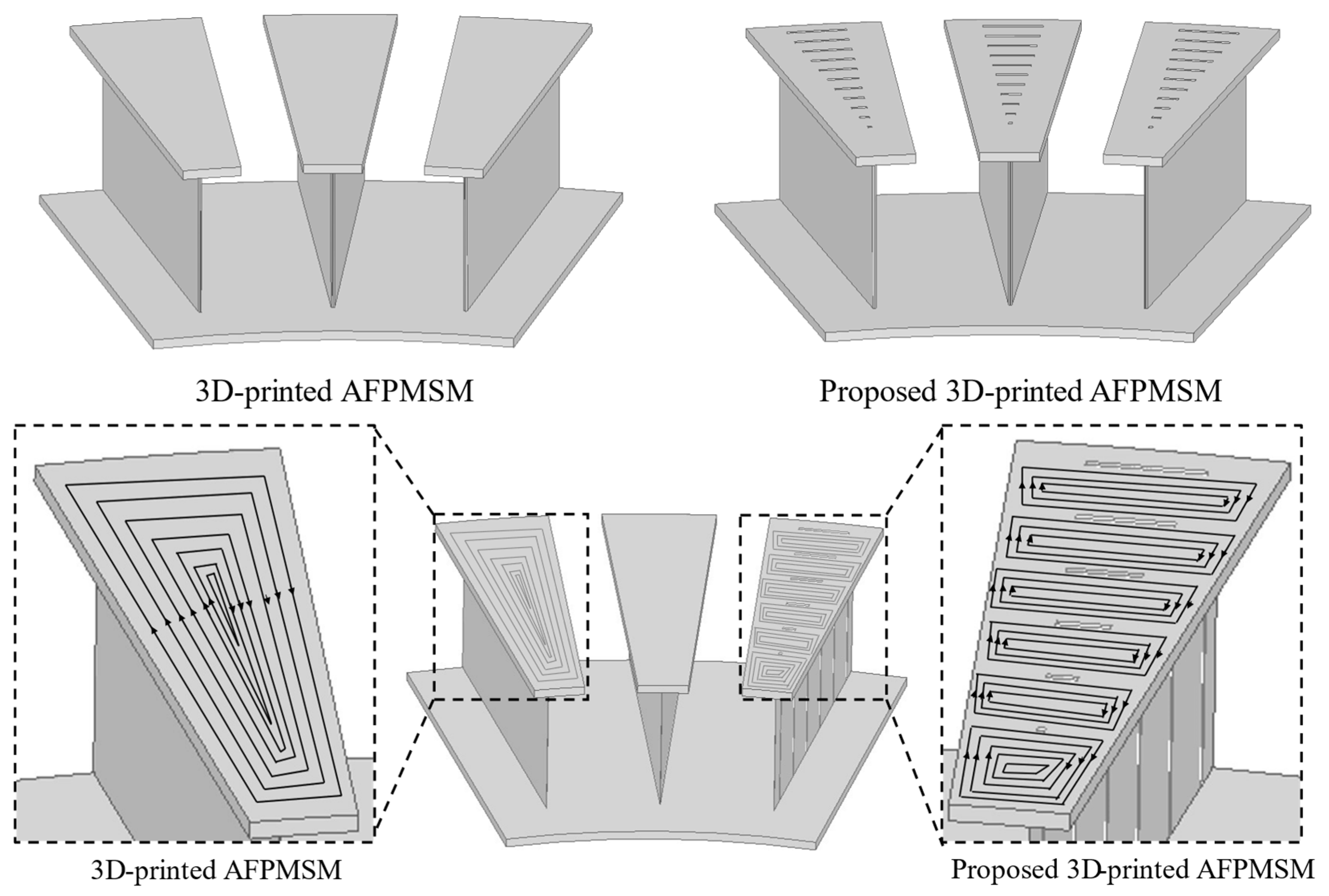

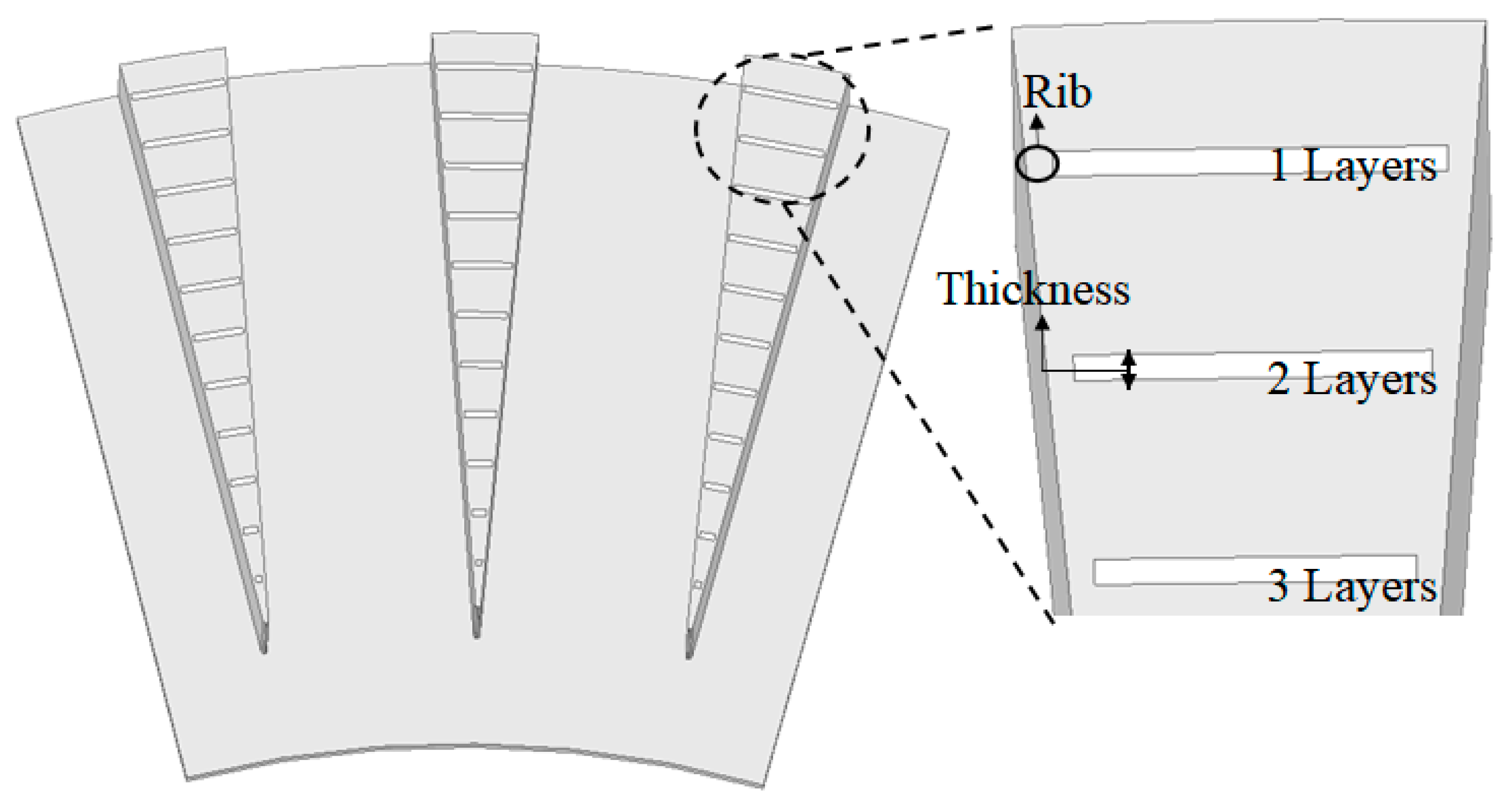

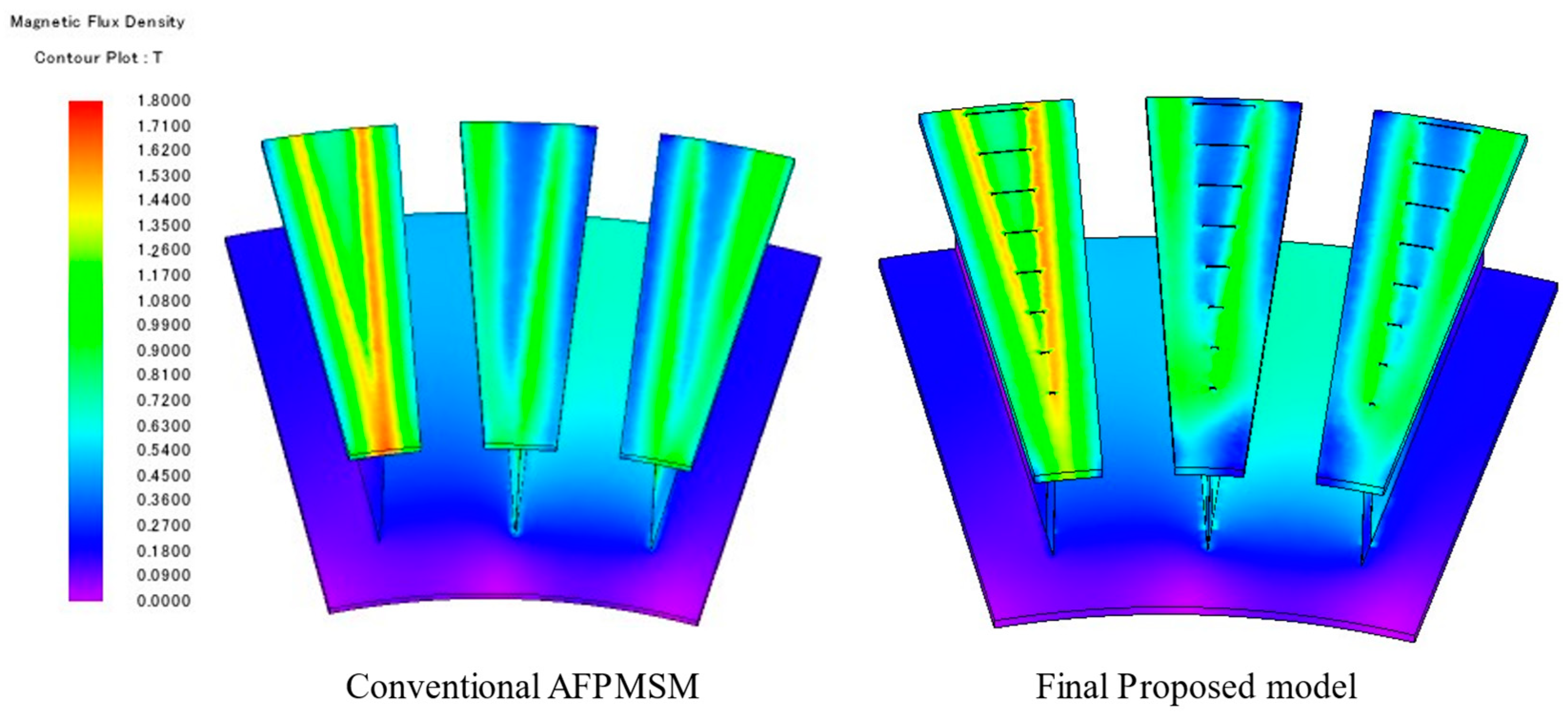

3.2. Proposed Stator Structure of AFPMSM

4. Parametric Analysis for an Optimal Design

4.1. Parameters of Stator Core with Slits

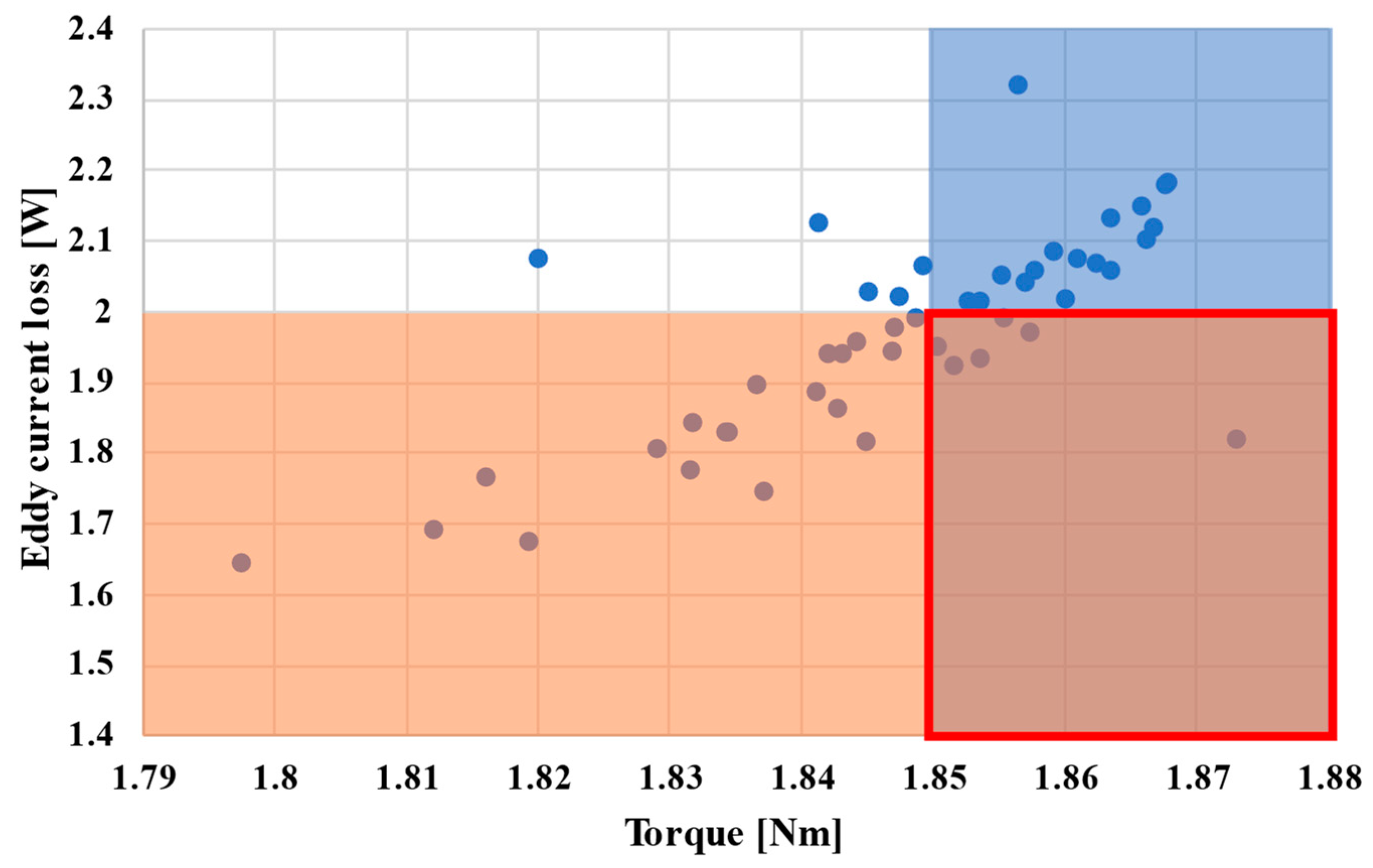

4.2. The Result of the Parametric Analysis

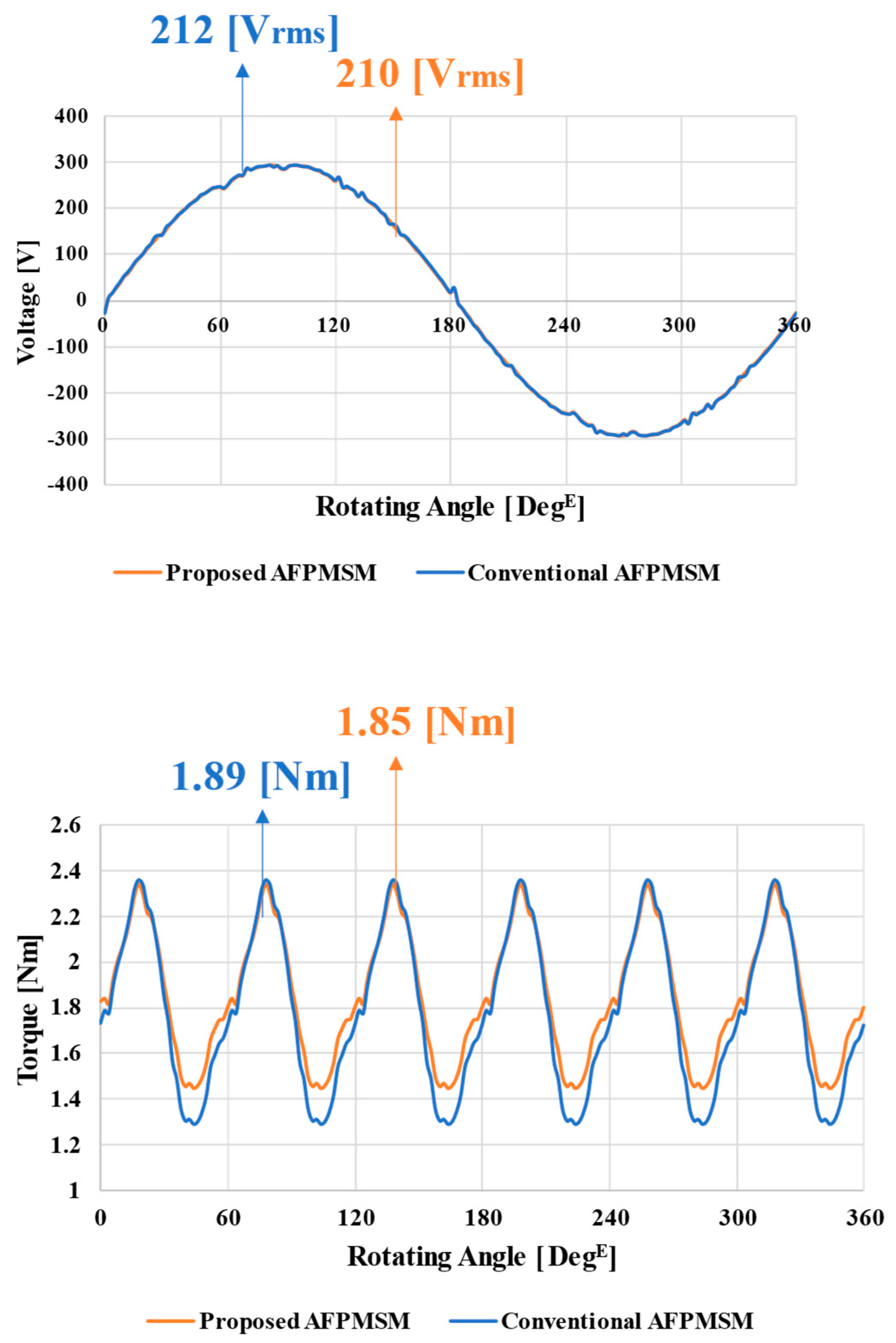

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bertola, L.; Cox, T.; Wheeler, P.; Garvey, S.; Morvan, H. Thermal design of linear induction and synchronous motors for electromagnetic launch of civil aircraft. IEEE Trans. Plasma Sci. 2017, 45, 1146–1153. [Google Scholar] [CrossRef]

- Qiwei, X.; Cui, S.; Zhang, Q.; Song, L.; Li, X. Research on a new accurate thrust control strategy for linear induction motor. IEEE Trans. Plasma Sci. 2015, 43, 1321–1325. [Google Scholar] [CrossRef]

- Braun, N.J. Some aspects of the application of induction motors to aircraft. Electr. Eng. 1944, 63, 769–772. [Google Scholar] [CrossRef]

- Larabee, J.; Pellegrino, B.; Flick, B. Induction motor starting methods and issues. In Proceedings of the Record of Conference Papers Industry Applications Society 52nd Annual Petroleum and Chemical Industry Conference, Denver, CO, USA, 12–14 September 2005; pp. 217–222. [Google Scholar]

- Simba, K.G.; Quilumba, F.L.; Granda, N.V. Parameter estimation of a three-phase induction motor from direct starting stator transient measurements. In Proceedings of the IEEE ANDESCON 2020, Quito, Ecuador, 13-16 October 2020; pp. 1–5. [Google Scholar]

- Guven, M.; Lee, K.; Dong, Y.; Lee, W. Shunt-connected solar microinverter for induction motor soft-starting and active and reactive power compensation. In Proceedings of the 2022 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 9–13 October 2022; pp. 1–6. [Google Scholar]

- Morimoto, S.; Ooi, S.; Inoue, Y.; Sanada, M. Experimental evaluation of a rare-earth-free pmasynrm with ferrite magnets for automotive applications. IEEE Trans. Ind. Electron. 2014, 61, 5749–5756. [Google Scholar] [CrossRef]

- Bostanci, E.; Moallem, M.; Parsapour, A.; Fahimi, B. Opportunities and challenges of switched reluctance motor drives for electric propulsion: A comparative study. IEEE Trans. Transp. Electrif. 2017, 3, 58–75. [Google Scholar] [CrossRef]

- Kong, H.; Lee, K.; Pyo, H.; Jeong, M.; Kim, W. Robust design process to restrain irreversible demagnetization of interior permanent magnet synchronous motor applied in railway vehicles using dysprosium-free permanent magnet. J. Electr. Eng. Technol. 2021, 16, 617–623. [Google Scholar] [CrossRef]

- Zhang, Z.; Profumo, F.; Tenconi, A. Axial Flux Versus Radial Flux PM Motors; SPEEDAM: Capri, Italy, 1996; pp. A4-19–A4-25. [Google Scholar]

- Cavagnino, A.; Lazzari, M.; Profumo, F.; Tenconi, A. A comparison between the axial flux and the radial flux structures for PM synchronous motors. IEEE Trans. Ind. Appl. 2002, 38, 1517–1524. [Google Scholar] [CrossRef]

- Aydin, M.; Huang, S.; Lipo, T.A. Torque quality and comparison of internal and external rotor axial flux surface-magnet disc machines. IEEE Trans. Ind. Electron. 2006, 53, 822–830. [Google Scholar] [CrossRef]

- Bi, Y.; Pei, Y.; Chai, F. A novel axial flux interior permanent magnet motor with high torque density. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–5. [Google Scholar]

- Aydin, M.; Gulec, M. A new coreless axial flux interior permanent magnet synchronous motor with sinusoidal rotor segments. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Su, J.; Wang, Y.P.; Tsai, M.; Tsai, K.; Lai, D. Flip chip assembly on coreless substrate challenge with die bond solution. In Proceedings of the 2019 22nd European Microelectronics and Packaging Conference & Exhibition (EMPC), Pisa, Italy, 16–19 September 2019; pp. 1–5. [Google Scholar]

- Pyo, H.J.; Jeong, J.W.; Yu, J.; Nam, D.W.; Yang, S.H.; Kim, W.H. Eddy current loss reduction in 3d-printed axial flux motor using 3d-printed smc core. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 1121–1125. [Google Scholar]

- Li, X.; Roberts, M.; O’Keeffe, S.; Sercombe, T. Selective laser melting of Zr-based bulk metallic glasses: Processing, microstructure and mechanical properties. Mater. Des. 2016, 112, 217–226. [Google Scholar] [CrossRef]

- Gu, D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Hong, H.S.; Liu, H.C.; Cho, S.Y.; Lee, J.; Jin, C.S. Design of high-end synchronous reluctance motor using 3-d printing technology. IEEE Trans. Magn. 2017, 53, 1–5. [Google Scholar] [CrossRef]

- Wu, S.T.; Huang, P.W.; Chang, T.W.; Jiang, I.H.; Tsai, M.C. Application of magnetic metal 3-d printing on the integration of axial-flow impeller fan motor design. IEEE Trans. Magn. 2021, 57, 1–5. [Google Scholar] [CrossRef]

- Shin, D.; Jeong, M.; Lee, K.; Lee, K.; Kim, W. A study on the improvement of torque density of an axial slot-less flux permanent magnet synchronous motor for collaborative robot. Energies 2022, 15, 3464. [Google Scholar] [CrossRef]

- Kim, C.-W.; Jang, G.-H.; Kim, J.-M.; Ahn, J.-H.; Baek, C.-H.; Choi, J.-Y. Comparison of Axial Flux Permanent Magnet Synchronous Machines with Electrical Steel Core and Soft Magnetic Composites Core. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, J.; Liu, C.; Lei, G.; Guo, Y.; Zhu, J. Development of a High-Performance Axial Flux PM Machine With SMC Cores for Electric Vehicle Application. IEEE Trans. Magn. 2019, 55, 1–4. [Google Scholar] [CrossRef]

- Scheerlinck, B.; De Gersem, H.; Sergeant, P. 3-D Eddy current and fringing-flux distribution in an axial-flux permanent-magnet synchronous machine with stator in laminated iron or SMC. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, S.; Wu, L.; Zhao, M.; Hu, C. Iron loss and thermal analysis of high speed pm motor using soft magnetic composite material. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–4. [Google Scholar]

| Parameter | Value | Unit | |

|---|---|---|---|

| Characteristic Performance | Pole/Slot | 48/36 | - |

| Speed | 1200 | RPM | |

| Torque | 1.85 | Nm | |

| Current | 2.02 | Arms | |

| Power | 230 | W | |

| Eddy current loss | 2.24 | W | |

| Winding | Material | Aluminum | - |

| Diameter | 1.3 | mm | |

| Turns | 63 | - | |

| Y-Connection | - | - | |

| Fill Factor | 45 | % | |

| Permanent Magnet | Material | Ferrite 7BE | - |

| Core | Material | 3D-printed SMC | - |

| Dimension | Outer Diameter | 288 | mm |

| Inner Diameter | 178.3 | mm | |

| Stator Back-Yoke | 1.2 | mm | |

| Teeth Length | 21.5 | mm | |

| Air Gap | 1 | mm | |

| Shoe Thick | 1.2 | mm | |

| Magnet Thick | 3.1 | mm | |

| Rotor Back-Yoke | 2 | mm | |

| Value | 6 Layers Thick 0.1 mm Rib 0.6 mm | 10 Layers Thick 0.7 mm Rib 0 mm | Unit |

|---|---|---|---|

| Rotor Back-Yoke | 0.033 | 0.032 | W |

| Total Shoe | 0.88 | 0.733 | W |

| Stator Back-Yoke | 0.203 | 0.186 | W |

| Total Teeth | 1.064 | 0.689 | W |

| Total Eddy Current Loss | 2.18 | 1.64 | W |

| Models | Eddy Current Loss [W] | Torque [Nm] | Loss Reduction [%] |

|---|---|---|---|

| 8 Layers_Thick0.1mm_Rib0.6mm | 1.82 | 1.87 | 18.75 |

| 6 Layers_Thick0.3mm_Rib0mm | 1.93 | 1.85 | 13.84 |

| 6 Layers_Thick0.3mm_Rib0.2mm | 1.97 | 1.86 | 12.05 |

| 8 Layers_Thick0.3mm_Rib0.2mm | 1.99 | 1.86 | 11.16 |

| 10 Layers_Thick0.3mm_Rib0.4mm | 1.92 | 1.85 | 14.29 |

| 6 Layers_Thick0.5mm_Rib0.2mm | 1.95 | 1.85 | 12.95 |

| Loss and Performance | Conventional | Proposed |

|---|---|---|

| Rotor Back Yoke [W] | 0.037 | 0.034 |

| Total Stator [W] | 2.21 | 1.76 |

| Total Eddy Current Loss [W] | 2.24 | 1.82 |

| Hysteresis Loss [W] | 33.32 | 36.3 |

| Torque [Nm] | 1.89 | 1.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pyo, H.-J.; Lee, K.; Min, J.-Y.; Hong, M.-K.; Kim, W.-H. Eddy Current Loss Reduction in Axial-Flux Motors Using 3D Printing. Energies 2023, 16, 1318. https://doi.org/10.3390/en16031318

Pyo H-J, Lee K, Min J-Y, Hong M-K, Kim W-H. Eddy Current Loss Reduction in Axial-Flux Motors Using 3D Printing. Energies. 2023; 16(3):1318. https://doi.org/10.3390/en16031318

Chicago/Turabian StylePyo, Hyun-Jo, Kangbeen Lee, Jeong-Yeon Min, Min-Ki Hong, and Won-Ho Kim. 2023. "Eddy Current Loss Reduction in Axial-Flux Motors Using 3D Printing" Energies 16, no. 3: 1318. https://doi.org/10.3390/en16031318

APA StylePyo, H.-J., Lee, K., Min, J.-Y., Hong, M.-K., & Kim, W.-H. (2023). Eddy Current Loss Reduction in Axial-Flux Motors Using 3D Printing. Energies, 16(3), 1318. https://doi.org/10.3390/en16031318