Study on Source Identification of Mixed Gas Emission and Law of Gas Emission Based on Isotope Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Determination Method of Mixed Gas Emission Source in the Working Face

2.1.1. Theoretical Foundation

2.1.2. Calculation Model of Mixed Gas Emission Source in the Working Face

2.2. Test Method for Hydrocarbon Isotope Value

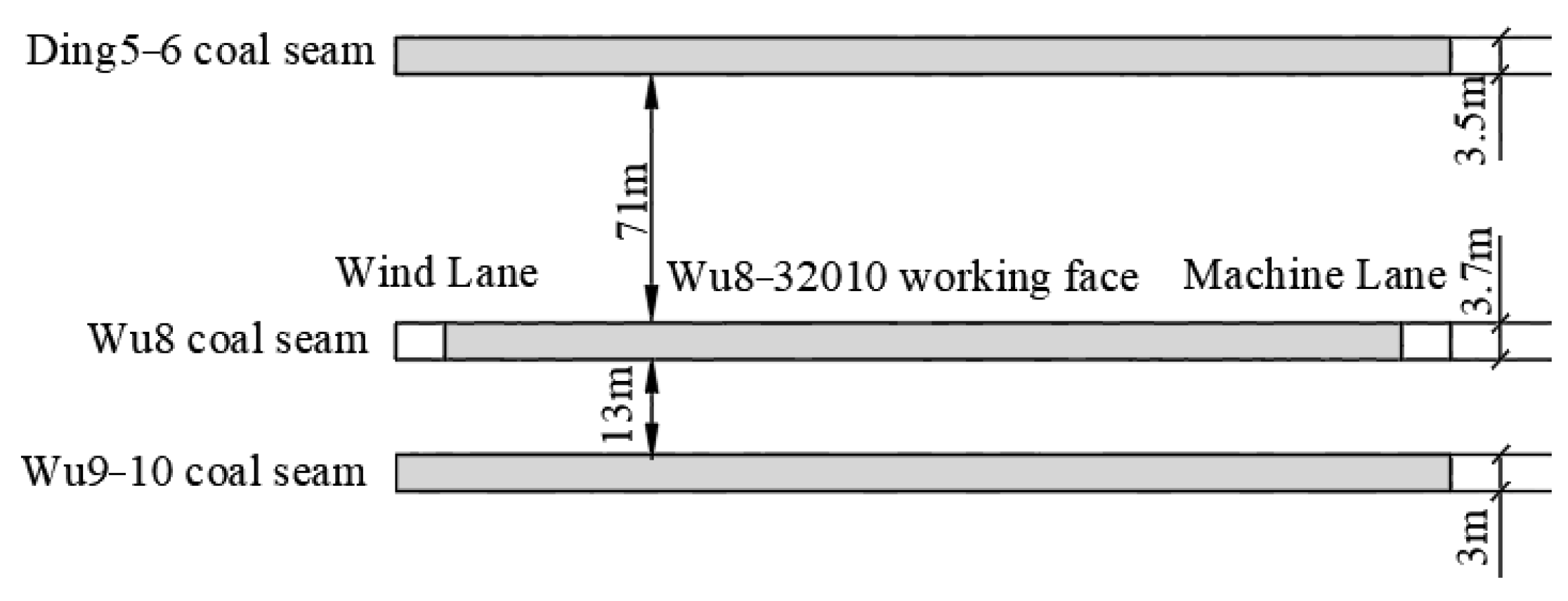

2.2.1. Field Test Background and Conditions

2.2.2. Testing of Hydrocarbon Isotope Value of Gas in Each Coal Seam

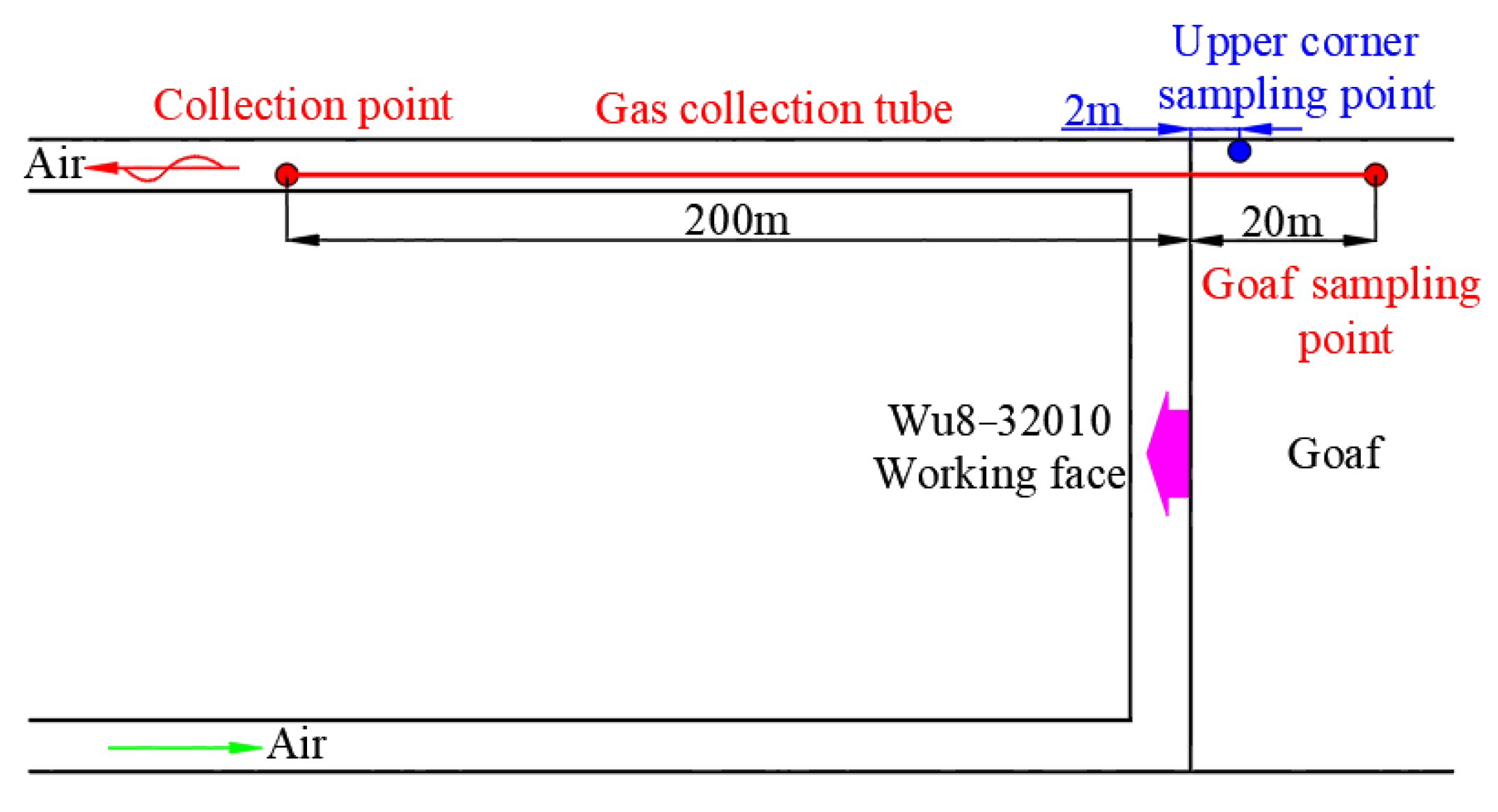

2.2.3. Testing of CH4 Hydrocarbon Isotope Value of Mixed Gas in the Working Face

- (1)

- Working face mixed gas CH4 hydrocarbon isotope value determination scheme

- (2)

- Sample collection method of mixed gas

3. Results

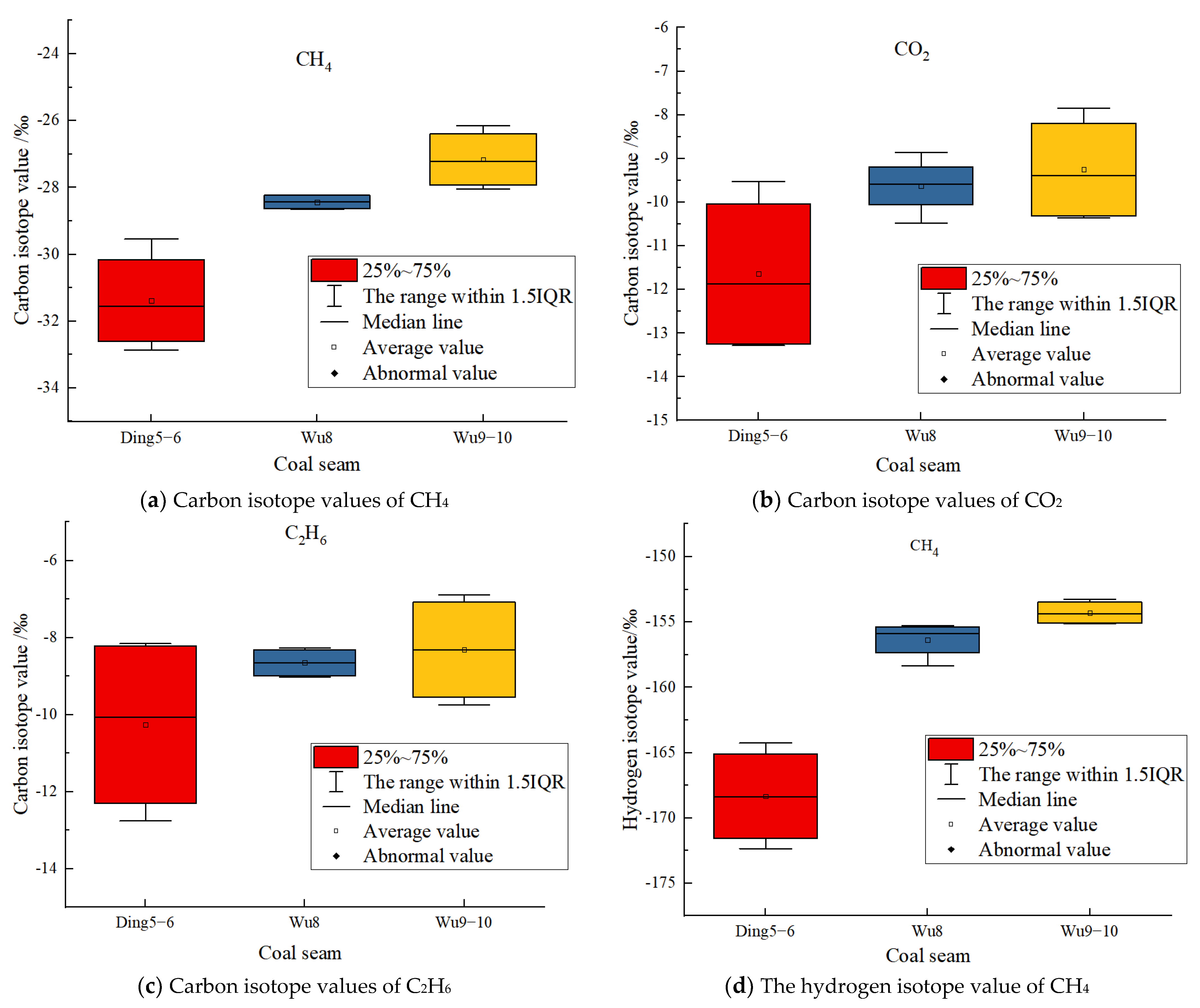

3.1. Test Results of Hydrocarbon Isotope Value of Gas in Each Coal Seam

3.2. Test Results of Mixed Gas Emission Source in the Working Face

4. Discussion

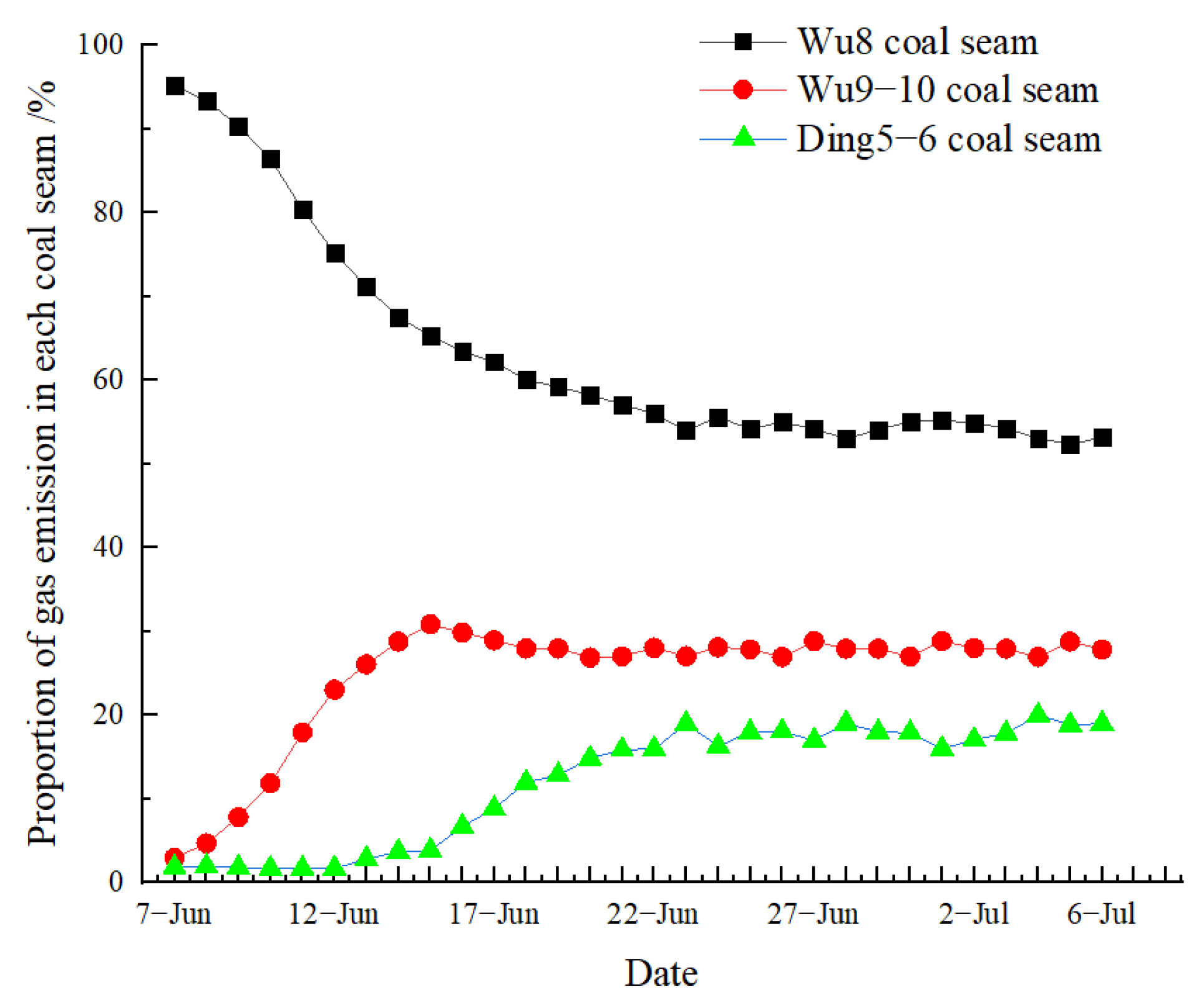

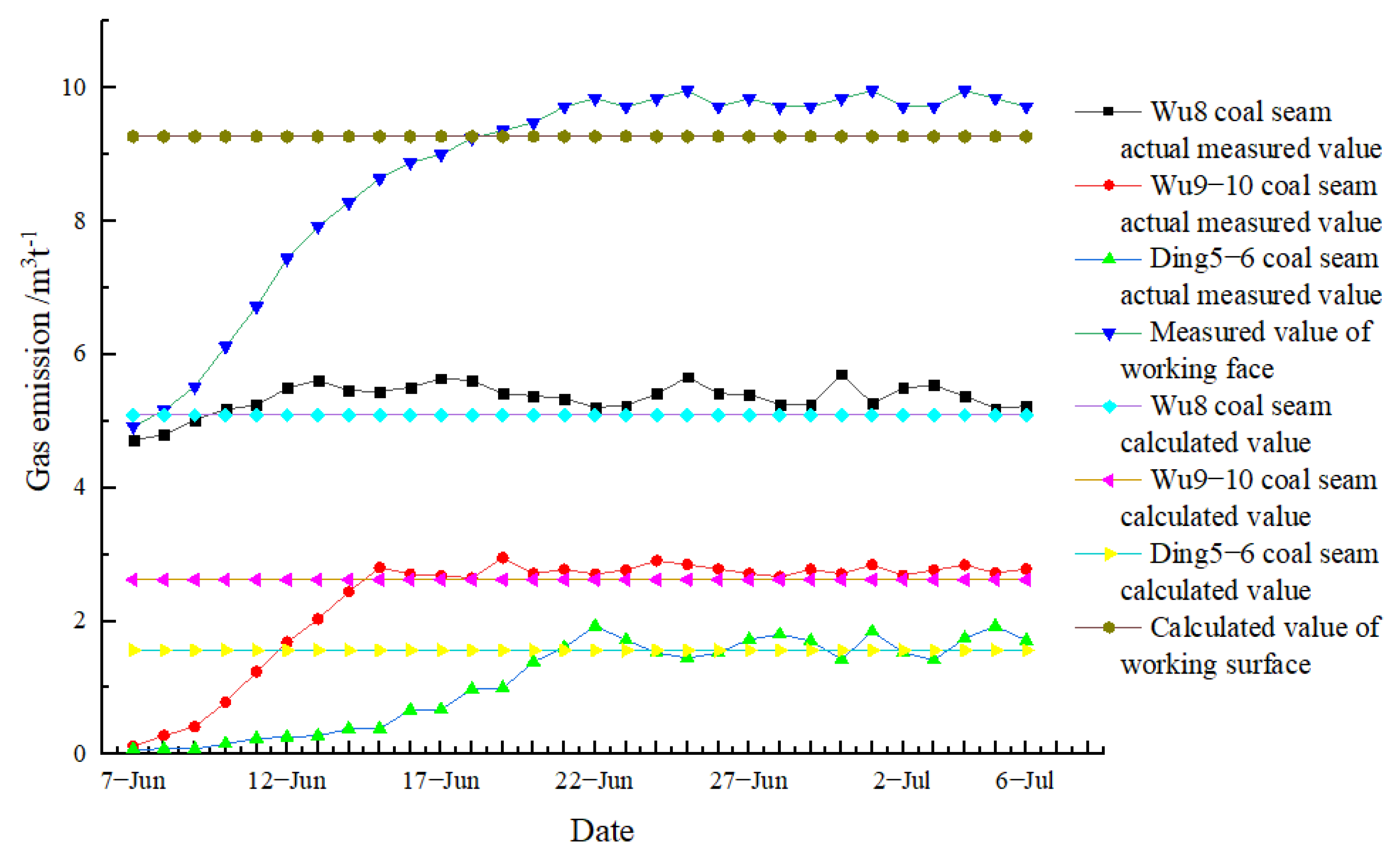

4.1. Gas Emission Law of the Working Face and Each Coal Seam

4.2. Analysis of Influencing Factors of Gas Emission

4.2.1. Analysis of Influencing Factors of Gas Emission in the Mining Layer

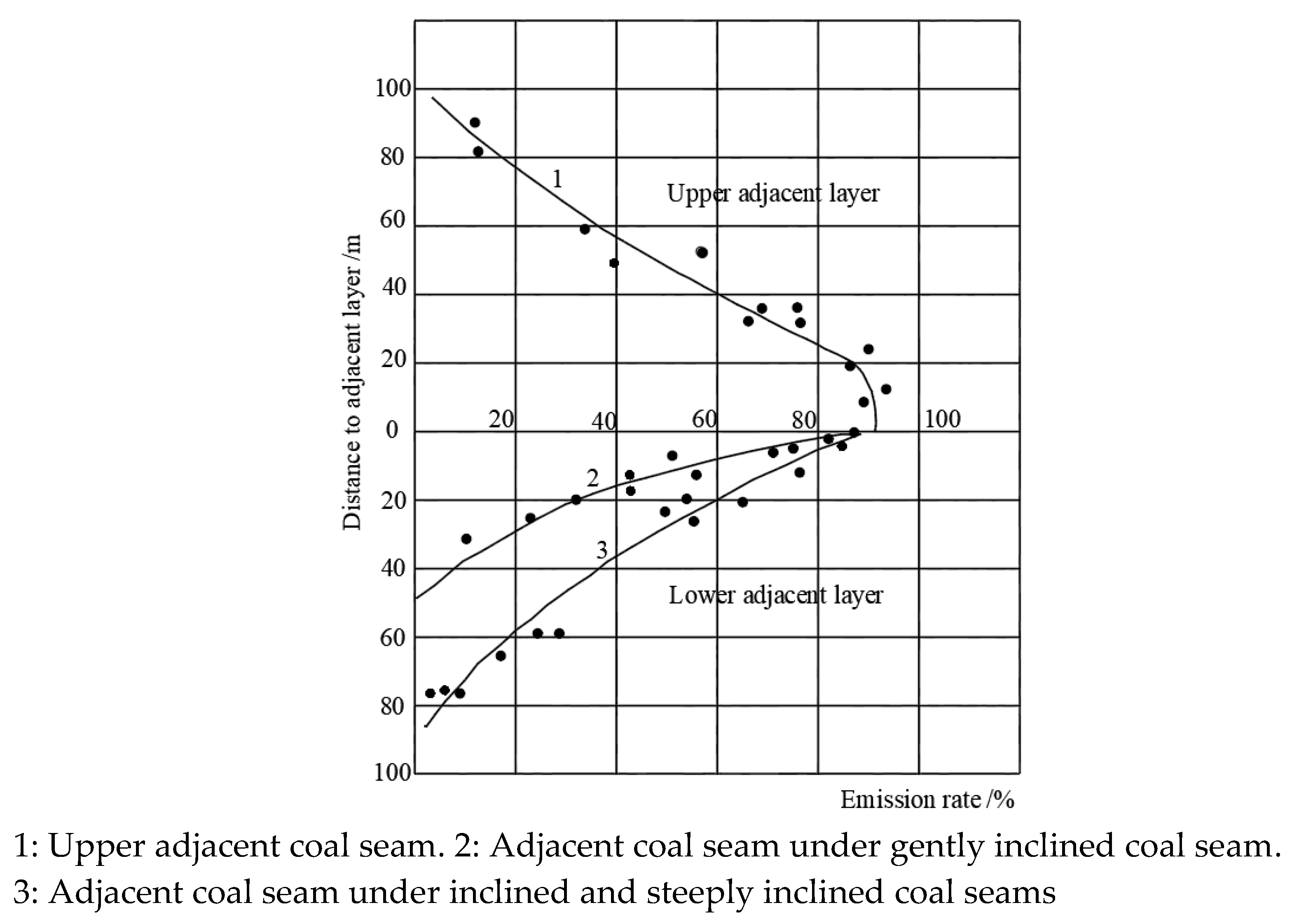

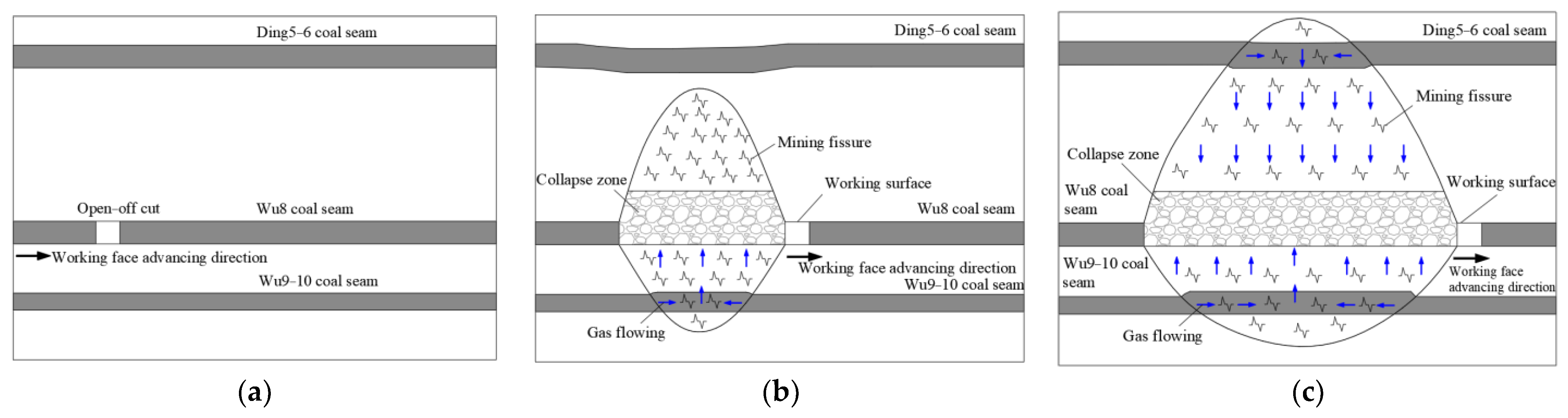

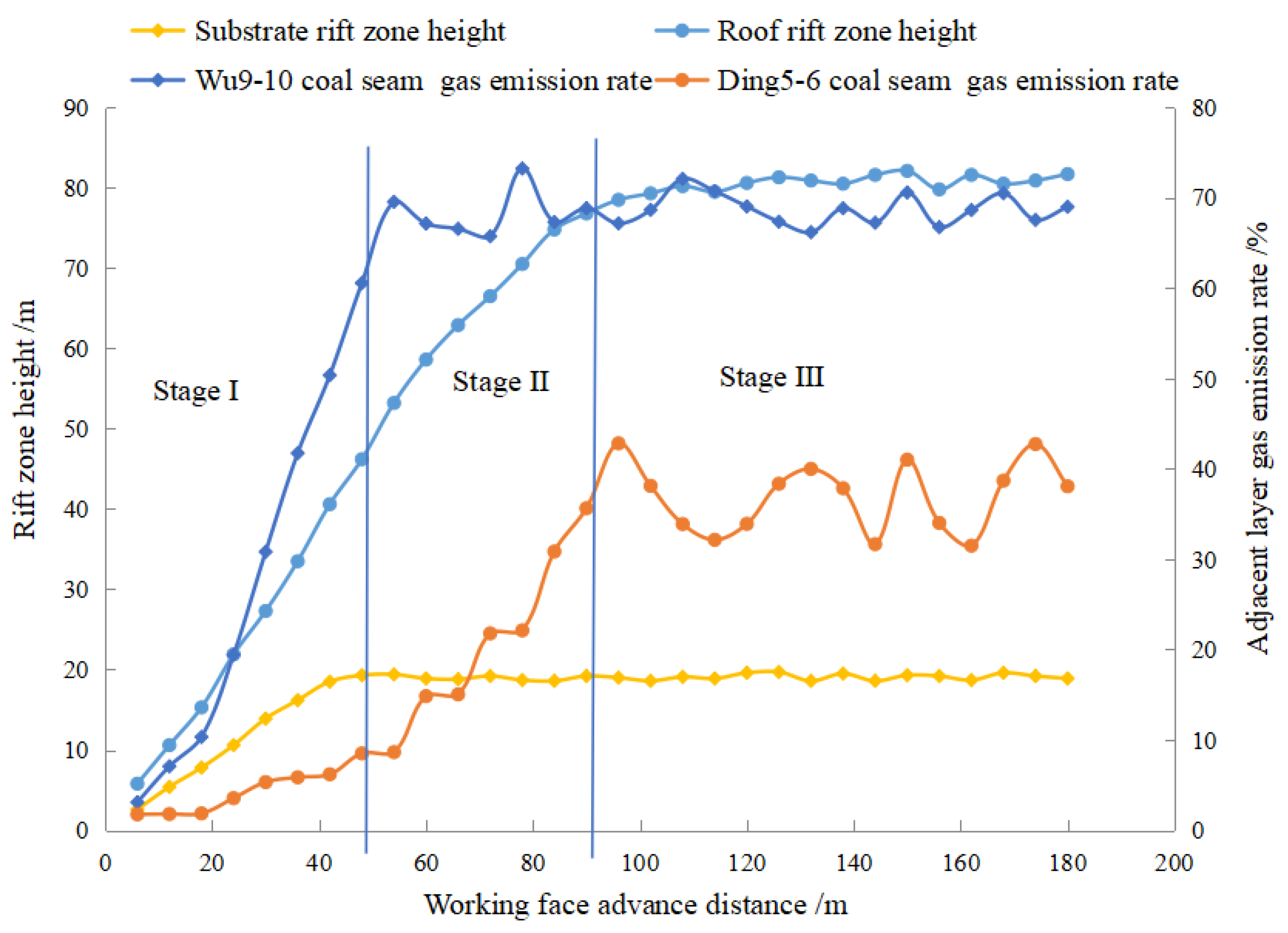

4.2.2. Analysis of Influencing Factors of Gas Emission in Adjacent Coal Seam

- (1)

- In the process of advancing the working face, the height of the mining-induced fracture zone of the coal seam roof and the coal seam floor in stage I shows an increasing trend. Due to the small interlayer spacing between the Wu8 coal seam and the Wu9 –10 coal seam, the Wu9−10 coal seam quickly enters the mining-induced fracture zone of the coal seam floor, so that a large amount of gas in the Wu9−10 coal seam enters the working face through the mining-induced fracture zone of the coal seam floor, resulting in a rapid increase in the gas emission rate of the Wu9−10 coal seam. Although the height of the mining fracture zone of the coal seam roof increases rapidly, due to the large interlayer spacing between the Wu8 coal seam and the Ding5−6 coal seam, the Ding5−6 coal seam has not yet entered the mining fracture zone of the coal seam roof, so that only a small amount of the Ding5−6 coal seam gas enters the working face, so the gas emission rate of the Ding5−6 coal seam increases slowly.

- (2)

- In the process of advancing the working face, the height of the mining-induced fracture zone of the coal seam floor in stage II tends to be stable. Because the coal seam of Wu9−10 has entered the mining-induced fracture zone of the coal seam floor in stage I, the gas of the Wu9−10 coal seam entering the working face in stage II will remain in a small fluctuation state, resulting in the gas emission rate of the Wu9−10 coal seam also remaining in a small fluctuation state. In stage II, the height of the mining fracture zone of the coal seam roof is still increasing. With the increase of the height of the mining fracture zone of the coal seam roof, the Ding5−6 coal seam will enter the mining fracture zone of the coal seam roof, so that the gas of the Ding5−6 coal seam enters the working face through the mining fracture zone of the coal seam roof, resulting in the rapid increase of the gas emission rate of the Ding5−6 coal seam in stage II.

- (3)

- With the advance of the working face, in stage III, the mining-induced fracture zone height of the coal seam roof and floor tends to be stable. The Ding5−6 coal seam and the Wu9−10 coal seam also enter into the mining-induced fracture zone of the coal seam roof and floor, respectively, the gas emission rate of adjacent coal seams and the gas emission of adjacent coal seams will remain in a small fluctuation state until the end of working face mining.

4.3. Gas Emission Rate of Adjacent Coal Seams

5. Conclusions

- The CH4 hydrocarbon isotope values in the gas of the Wu8 coal seam, the Wu9−10 coal seam, and the Ding5−6 coal seam are obviously different, which has the conditions to identify the source of gas emission in the working face by using the hydrocarbon isotope method.

- The variation law of the proportion of gas emission in each coal seam during the mining process of the working face can be divided into the dominant stage of gas emission in the mining layer (stage I), the stage of gas emission in the long-distance adjacent coal seam (stage II), and the dynamic equilibrium stage of gas emission in each coal seam (stage III). The proportion of gas emission in the Wu8 coal seam decreases from 95% to 60% in stage I, from 60% to 53% in stage II, and stabilizes at about 54% in stage III. The proportion of gas emission in the Wu9−10 coal seam increases from 3% to 30% in stage I, decreases from 30% to 27% in stage II, and stabilizes at about 28% in stage III. The proportion of gas emission in the Ding5−6 coal seam increases from 1% to 5% in stage I, from 5% to 18% in stage II, and stabilizes at about 18% in stage III.

- During the mining process of the working face, the gas emission amount of the Wu8 coal seam remains in a stable state. The gas emission amount of the Wu9−10 coal seam increases rapidly in stage I and remains stable in stage II and stage III. The gas emission amount of the Ding5−6 coal seam increases slowly in stage I, increases rapidly in stage II, and remains stable in stage III. The mixed gas emission of the working face increases rapidly in stage I and stage II and remains stable in stage III.

- The adjacent coal seam gas emission rate is the main influencing factor of the adjacent coal seam gas emission, and the adjacent coal seam gas emission rate is related to the development process of the mining fracture zone. When the height of the mining fracture zone increases, the gas emission rate of the adjacent coal seam increases exponentially, and the gas emission of the working face increases. After the height of the mining fracture zone tends to be stable, the gas emission rate of adjacent coal seams and the gas emission amount of each coal seam remain in a small fluctuation state.

- The calculation formula of the gas emission rate of the adjacent coal seam is established. Compared with the test results, the error of the calculated value is small, which can meet the needs of gas emission prediction of adjacent coal seams in production practice.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kurnia, J.C.; Xu, P.; Sasmito, A.P. A novel concept of enhanced gas recovery strategy from ventilation air methane in underground coal mines –A computational investigation. J. Nat. Gas Sci. Eng. 2016, 35, 661–672. [Google Scholar] [CrossRef]

- Mishra, D.P.; Panigrahi, D.D.; Kumar, P. Computational investigation on effects of geo-mining parameters on layering and dispersion of methane in underground coal mines –A case study of Moonidih Colliery. J. Nat. Gas Sci. Eng. 2018, 56, 110–124. [Google Scholar] [CrossRef]

- Karacan, C.Ö.; Diamond, W.P.; Schatzel, S.J. Numerical analysis of the influence of in-seam horizontal methane drainage boreholes on longwall face emission rates. Int. J. Coal Geol. 2007, 72, 15–32. [Google Scholar] [CrossRef]

- Sander, R.; Connell, L.D. A probabilistic assessment of enhanced coal mine methane drainage (ECMM) as a fugitive emission reduction strategy for open cut coal mines. Int. J. Coal Geol. 2014, 131, 288–303. [Google Scholar] [CrossRef]

- Qi, Q.J.; Xia, S.Y. Construction of sharing platform for the gas emission rate prediction based on source prediction. Min. Saf. Environ. Prot. 2018, 45, 59–64. [Google Scholar]

- Cang, Y.X.; Li, W.G.; Shu, Z.C.; Yan, C.Y. Statistical analysis on coal mine gas explosion and optimization of safety input. Adv. Mater. Resea. 2011, 1043, 1316–1321. [Google Scholar]

- Gas Geology Group of Jiaozuo Mining Institute. Attempt of statistical analysis in prediction of gas outburst. Coalfield Geol. Explo. 1983, 26–30+8. [Google Scholar]

- Lunarzewski, W.L. Gas emission prediction and recovery in underground coal mines. Int. J. Coal Geol. 1998, 35, 117–145. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Ye, Q.; Jia, Z.Z.; Jiang, W.W. The analysis and forecast of gas emission in workface. China Min. J. 2007, 123, 46–49+52. [Google Scholar]

- Whittles, D.N.; Lowndes, I.S.; Kingman, S.W.; Yates, C.; Jobling, S. Influence of geotechnical factors on gas flow experienced in a UK longwall coal mine panel. Int. J. Rock Mech. Min. 2006, 43, 369–387. [Google Scholar] [CrossRef]

- Gu, S.; Cui, H.Q.; Feng, W.L. Mine gas gushing forecasting based on grey model and wavelet neural network. J. China Coal Soc. 2007, 156, 964–966. [Google Scholar]

- Zhang, S.R.; Wang, B.T.; Li, X.E.; Chen, H. Research and application of improved gas concentration prediction model based on grey theory and BP neural network in digital mine. Procedia CIRP 2016, 56, 471–475. [Google Scholar] [CrossRef]

- Zhang, X.L.; Shan, J.P.; Peng, S.P. Mathematical geology technique and method for prediction of gas content and emission. J. China Coal Soc. 2009, 34, 350–354. [Google Scholar]

- Ock, J.H. Activity duration quantification under uncertainty: Fuzzy set theory application. Cost Eng. 1996, 38, 26. [Google Scholar]

- Xiao, J.P.; Dai, G.L. Study on different-source prediction of gas emission in fully mechanized coal face based on BP neural network. J. Anhui Univ. Sci. and Techno. 2011, 31, 51–55. [Google Scholar]

- Zhu, H.Q.; Chang, W.J.; Zhang, B. Different-source gas emission prediction model of working face based on BP artificial neural network and its application. J. China Coal Soc. 2007, 152, 504–508. [Google Scholar]

- Xu, Q.Y.; Zhang, L.; Li, Y.M. Fully mechanized working face gas distribution law and constitution characteristics in BU Ertai coal mine. J. Liaoning Techni. Univ. 2014, 33, 887–891. [Google Scholar]

- Li, S.G.; Ding, Y.; An, Z.F.; Wei, W.B. Research on gas emission and distribution characteristics of fully Mechanized Coal Face in High Methane and Thick Seam. Coal Techno. 2015, 34, 113–116. [Google Scholar]

- Gao, L.; Li, X.J.; Pan, J.C. Main controlling factors and control measures of gas emission in mining face of Buertai mine. J. Saf. Sci. Techno. 2019, 15, 130–135. [Google Scholar]

- Zhang, P.; Wang, W.C. Research on gas emission and distribution of the first face in high gas and thick seam. Sci. Techno. Eng. 2017, 17, 176–180. [Google Scholar]

- Cui, H.L.; Wang, Y.; Zhao, H.B.; Zou, D.L. Distribution of gas emission at fully mechanized top coal caving face in high gas and super thick coal seam in xiagou mine. Saf. Coal Min. 2016, 47, 178–181. [Google Scholar]

- Yuan, L. Gas distribution of the mined-outside and extraction technology of first mined key seam relief-mining in gassy multi-seams of low permeability. J. China Coal Soc. 2008, 33, 1362–1367. [Google Scholar]

- Dai, G.L.; Wang, Y.Q.; Zhang, C.R.; Li, Q.M.; Shao, G.Y. Forecast of the gas effused form the face in protective seam. J. China Coal Soc. 2007, 32, 382–385. [Google Scholar]

- Wu, R.X.; Xiao, Y.L.; Fang, L.C. Geophysical and geochemical prospecting for hard heading gas abnormal places between high gas coal seams. Coal Geol. China. 2014, 26, 74–77. [Google Scholar]

- Huang, H.; Jiang, F.W.; Han, B.W.; Zhang, P.S. Comprehensive detection analysis on the reason of abnormal gas blow-out from the drilling hole through the floor limestone of A group coal seam in Huainan mining area. J. China Coal Soc. 2013, 38, 1988–1992. [Google Scholar]

- Liang, W.X.; Li, J.T.; Fu, W.; Zhang, Y. Research and application of mixed gas source identification technology based on stable isotope. Min. Saf. Environ. Prot. 2022, 49, 56–61. [Google Scholar]

- Zhou, W.; Yuan, L.; Zhang, G.L.; Dou, H.L.; Xue, S.; He, G.H.; Han, Y.C. A new method for determining the individual sources of goaf gas emissions: A case study in Sihe Coal Mine. J. China Coal Soc. 2018, 43, 1016–1023. [Google Scholar]

- Yang, W.; Lin, B.Q.; Gao, Y.B.; Lv, Y.; Wang, Y.; Mao, X.; Wang, N.; Wang, D.; Wang, Y. Optimal coal discharge of hydraulic cutting inside coal seams for stimulating gas production: A case study in Pingmei coalfield. J. Nat. Gas Sci. Eng. 2016, 28, 379–388. [Google Scholar] [CrossRef]

- AQ1018 –2006. Prediction method of mine gas emission. Syst. Sci. Control. Eng. 2006, 6, 85–91. [Google Scholar]

- Qin, Y.J.; Su, W.W.; Jiang, W.Z.; Chen, Y.P. Research progress and development direction of mine gas emission forecast technology in china. Saf. Coal Min. 2020, 51, 52–59. [Google Scholar]

- Wang, L.; Li, J.H.; Zhang, W.B.; Li, Y. Research on the gas emission quantity prediction model of improved artificial bee colony algorithm and weighted least squares support vector machine (IABC-WLSSVM). Appl. Bionics Biomech. 2022, 2022, 4792988. [Google Scholar] [CrossRef]

- Xu, G.; Wang, L.; Jin, H.W.; Liu, P.D. Gas emission prediction in mining face by Factor Analysis and BP neural network coupling model. J. Xi’an Univ. Sci. Techno. 2019, 39, 965–971. [Google Scholar]

- Liu, C.; Li, S.; Yang, S. Gas emission quantity prediction and drainage technology of steeply inclined and extremely thick coal seams. Int. J. Min. Sci. Techno. 2018, 28, 415–422. [Google Scholar]

- Li, D.Y. Discussion on gas emission prediction method in adjacent layer of fully mechanized caving face. Coal Min. Saf. 2014, 45, 169–171. [Google Scholar]

- Wang, H.F.; Fang, L.; Cheng, Y.P.; Zhou, H.R. Pressure-relief gas extraction of lower adjacent coal seam based on strata movement and its application. J. Min. Saf. Eng. 2013, 30, 128–131. [Google Scholar]

- Liu, G.F.; Wang, H.X.; Song, Z.M. Numerical simulation study on gas emission rate owing to mining influence of adjacent coal seam. J. Heinan Polytechnic Univ. 2015, 34, 445–450. [Google Scholar]

- Wang, W.; Peng, L.; Wang, X. Prediction of coal mine gas emission quantity based on grey-gas geologic method. Math. Ppobl. Eng. 2018, 2018 Pt 17, 4397237. [Google Scholar]

- Qu, Q.D.; Balusu, R.; Belle, B. Specific gas emissions in Bowen Basin longwall mines, Australia. Int. J. Coal Geol. 2022, 261, 104076. [Google Scholar] [CrossRef]

| Coal Seam | Sample Number | Gas Component/% | Carbon Isotope Values/‰ | Hydrogen Isotope Values/‰ | |||||

|---|---|---|---|---|---|---|---|---|---|

| CH4 | C2H6 | N2 | CO2 | 13C (CH4) | 13C (CO2) | 13C (C2H6) | 2H (CH4) | ||

| Ding5−6 coal seam | 1 | 73.269 | 0.015 | 17.26 | 9.456 | −32.335 | −13.210 | −8.152 | −164.257 |

| 2 | 70.456 | 0.01 | 20.493 | 9.041 | −32.864 | −10.548 | −12.754 | −165.952 | |

| 3 | 74.387 | 0.014 | 18.031 | 7.568 | −29.543 | −9.526 | −11.853 | −172.346 | |

| 4 | 68.14 | 0.009 | 21.752 | 10.099 | −30.790 | −13.284 | −8.265 | −170.765 | |

| Average value | 71.563 | 0.012 | 19.384 | 9.041 | −31.383 | −11.642 | −10.256 | −168.33 | |

| Wu8 coal seam | 1 | 85.562 | 0.021 | 12.06 | 2.357 | −28.250 | −9.518 | −8.265 | −158.359 |

| 2 | 89.843 | 0.024 | 8.541 | 1.592 | −28.652 | −10.475 | −8.351 | −155.458 | |

| 3 | 89.425 | 0.016 | 8.695 | 1.864 | −28.225 | −8.865 | −9.026 | −155.269 | |

| 4 | 84.53 | 0.011 | 13.444 | 2.015 | −28.613 | −9.642 | −8.938 | −156.314 | |

| Average value | 87.340 | 0.018. | 10.685 | 1.957 | −28.435 | −9.625 | −8.645 | −156.35 | |

| Wu9−10 coal seam | 1 | 90.365 | 0.02 | 8.268 | 1.347 | −26.158 | −7.854 | −6.892 | −155.128 |

| 2 | 86.525 | 0.024 | 8.469 | 4.982 | −28.045 | −8.526 | −7.264 | −153.284 | |

| 3 | 88.942 | 0.028 | 9.251 | 1.779 | −27.816 | −10.365 | −9.350 | −153.649 | |

| 4 | 88.736 | 0.02 | 9.296 | 1.948 | −26.629 | −10.263 | −9.742 | −155.059 | |

| Average value | 88.642 | 0.023 | 8.821 | 2.514 | −27.162 | −9.252 | −8.312 | −154.28 | |

| Measurement Locations | Isotope Category | 7 June | 8 June | 9 June | 10 June | 11 June | 12 June | 13 June | 14 June | 15 June | 16 June |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Upper corner | 13 C(CH4)/‰ | −24.778 | −24.756 | −24.742 | −24.676 | −24.610 | −24.579 | −24.557 | −24.502 | −24.482 | −24.425 |

| 2H(CH4)/‰ | −136.302 | −136.315 | −136.326 | −136.162 | −136.019 | −136.031 | −136.041 | −135.872 | −135.896 | −135.407 | |

| Goaf | 13C (CH4)/‰ | −24.769 | −24.753 | −24.733 | −24.705 | −24.659 | −24.620 | −24.570 | −24.529 | −24.509 | −24.449 |

| 2H(CH4)/‰ | −136.263 | −136.253 | −136.282 | −136.306 | −136.321 | −136.328 | −136.152 | −136.021 | −135.996 | −135.537 | |

| Measurement locations | Isotope category | 17 June | 18 June | 19 June | 20 June | 21 June | 22 June | 23 June | 24 June | 25 June | 26 June |

| Upper corner | 13C (CH4)/‰ | −24.430 | −24.366 | −24.343 | −24.270 | −24.227 | −24.161 | −24.200 | −24.243 | −24.273 | −24.245 |

| 2H(CH4)/‰ | −135.405 | −134.906 | −134.908 | −134.257 | −133.958 | −133.460 | −133.773 | −134.121 | −134.276 | −134.087 | |

| Goaf | 13C (CH4)/‰ | −24.405 | −24.339 | −24.318 | −24.278 | −24.253 | −24.243 | −24.179 | −24.235 | −24.197 | −24.202 |

| 2H(CH4)/‰ | −135.187 | −134.688 | −134.543 | −134.219 | −134.057 | −134.042 | −133.557 | −133.989 | −133.718 | −133.706 | |

| Measurement locations | Isotope category | 27 June | 28 June | 29 June | 30 June | 1 July | 2 July | 3 July | 4 July | 5 July | 6 July |

| Upper corner | 13C (CH4)/‰ | −24.209 | −24.187 | −24.202 | −24.282 | −24.178 | −24.251 | −24.273 | −24.203 | −24.161 | −24.199 |

| 2H(CH4)/‰ | −133.788 | −133.631 | −133.793 | −134.281 | −133.631 | −134.077 | −134.266 | −133.800 | −133.466 | −133.777 | |

| Goaf | 13C (CH4)/‰ | −24.213 | −24.171 | −24.196 | −24.205 | −24.237 | −24.217 | −24.200 | −24.156 | −24.168 | −24.173 |

| 2H(CH4)/‰ | −133.881 | −133.548 | −133.718 | −133.728 | −134.042 | −133.867 | −133.744 | −133.394 | −133.575 | −133.557 |

| Date | 7 June | 8 June | 9 June | 10 June | 11 June | 12 June | 13 June | 14 June | 15 June | 16 June | |

| Category | |||||||||||

| Gas concentration/% | 0.41 | 0.43 | 0.46 | 0.51 | 0.56 | 0.62 | 0.66 | 0.69 | 0.72 | 0.74 | |

| Wu8 coal seam gas emission/m3t−1 | 4.72 | 4.79 | 5.02 | 5.18 | 5.24 | 5.49 | 5.61 | 5.46 | 5.45 | 5.51 | |

| Wu9−10 coal seam gas emission/m3t−1 | 0.12 | 0.29 | 0.42 | 0.78 | 1.24 | 1.68 | 2.03 | 2.44 | 2.80 | 2.71 | |

| Ding5−6 coal seam gas emission/m3t−1 | 0.08 | 0.08 | 0.08 | 0.16 | 0.24 | 0.26 | 0.28 | 0.38 | 0.39 | 0.67 | |

| Working face gas emission/m3t−1 | 4.92 | 5.16 | 5.52 | 6.12 | 6.72 | 7.44 | 7.92 | 8.28 | 8.64 | 8.88 | |

| Date | 17 June | 18 June | 19 June | 20 June | 21 June | 22 June | 23 June | 24 June | 25 June | 26 June | |

| Category | |||||||||||

| Gas concentration/% | 0.75 | 0.77 | 0.78 | 0.79 | 0.81 | 0.82 | 0.81 | 0.82 | 0.83 | 0.81 | |

| Wu8 coal seam gas emission/m3t−1 | 5.64 | 5.61 | 5.41 | 5.38 | 5.34 | 5.21 | 5.24 | 5.41 | 5.66 | 5.41 | |

| Wu9−10 coal seam gas emission/m3t−1 | 2.68 | 2.65 | 2.95 | 2.71 | 2.77 | 2.71 | 2.77 | 2.91 | 2.85 | 2.78 | |

| Ding5−6 coal seam gas emission/m3t−1 | 0.68 | 0.98 | 1.00 | 1.39 | 1.60 | 1.93 | 1.72 | 1.53 | 1.45 | 1.53 | |

| Working face gas emission/m3t−1 | 9.00 | 9.24 | 9.36 | 9.48 | 9.72 | 9.84 | 9.72 | 9.84 | 9.96 | 9.72 | |

| Date | 27 June | 28 June | 29 June | 30 June | 1 July | 2 July | 3 July | 4 July | 5 July | 6 July | |

| Category | |||||||||||

| Gas concentration/% | 0.82 | 0.81 | 0.81 | 0.82 | 0.83 | 0.81 | 0.81 | 0.83 | 0.82 | 0.81 | |

| Wu8 coal seam gas emission/m3t−1 | 5.40 | 5.25 | 5.24 | 5.71 | 5.27 | 5.50 | 5.54 | 5.38 | 5.19 | 5.23 | |

| Wu9−10 coal seam gas emission/m3t−1 | 2.71 | 2.67 | 2.77 | 2.71 | 2.84 | 2.69 | 2.77 | 2.84 | 2.72 | 2.78 | |

| Ding5−6 coal seam gas emission/m3t−1 | 1.73 | 1.80 | 1.70 | 1.43 | 1.85 | 1.53 | 1.42 | 1.74 | 1.92 | 1.71 | |

| Working face gas emission/m3t−1 | 9.84 | 9.72 | 9.72 | 9.84 | 9.96 | 9.72 | 9.72 | 9.96 | 9.84 | 9.72 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, G.; Hou, Y.; Jin, H.; Wang, Z. Study on Source Identification of Mixed Gas Emission and Law of Gas Emission Based on Isotope Method. Energies 2023, 16, 1225. https://doi.org/10.3390/en16031225

Xu G, Hou Y, Jin H, Wang Z. Study on Source Identification of Mixed Gas Emission and Law of Gas Emission Based on Isotope Method. Energies. 2023; 16(3):1225. https://doi.org/10.3390/en16031225

Chicago/Turabian StyleXu, Gang, Yaping Hou, Hongwei Jin, and Zhongwei Wang. 2023. "Study on Source Identification of Mixed Gas Emission and Law of Gas Emission Based on Isotope Method" Energies 16, no. 3: 1225. https://doi.org/10.3390/en16031225

APA StyleXu, G., Hou, Y., Jin, H., & Wang, Z. (2023). Study on Source Identification of Mixed Gas Emission and Law of Gas Emission Based on Isotope Method. Energies, 16(3), 1225. https://doi.org/10.3390/en16031225