1. Introduction

In industry, a wide variety of fluids can be found. The majority of substances are composed of low-molecular-weight particles that fulfill Newton’s postulate of linear dependency of the shear stress (

τ) as the shear rate (

) function. In such cases, the constant of proportionality is called the dynamic viscosity of the fluid (η). Some examples of such fluids are organic and inorganic liquids, solutions of low-molecular-weight inorganic salts, molten metals and salts and gases [

1]. For such fluids, the dynamic viscosity may change with temperature and pressure. Generally for liquids, the viscosity increases with decreasing temperature and with pressure growth, while in the case of gases, the growth of both factors contributes to viscosity increase.

In the mid-twentieth century, scientists realized that there are also numerous fluids, for which the shear stress to the shear ratio rate cannot be described with linear functions [

2]. More importantly, this large group of fluids is commonly used in industry [

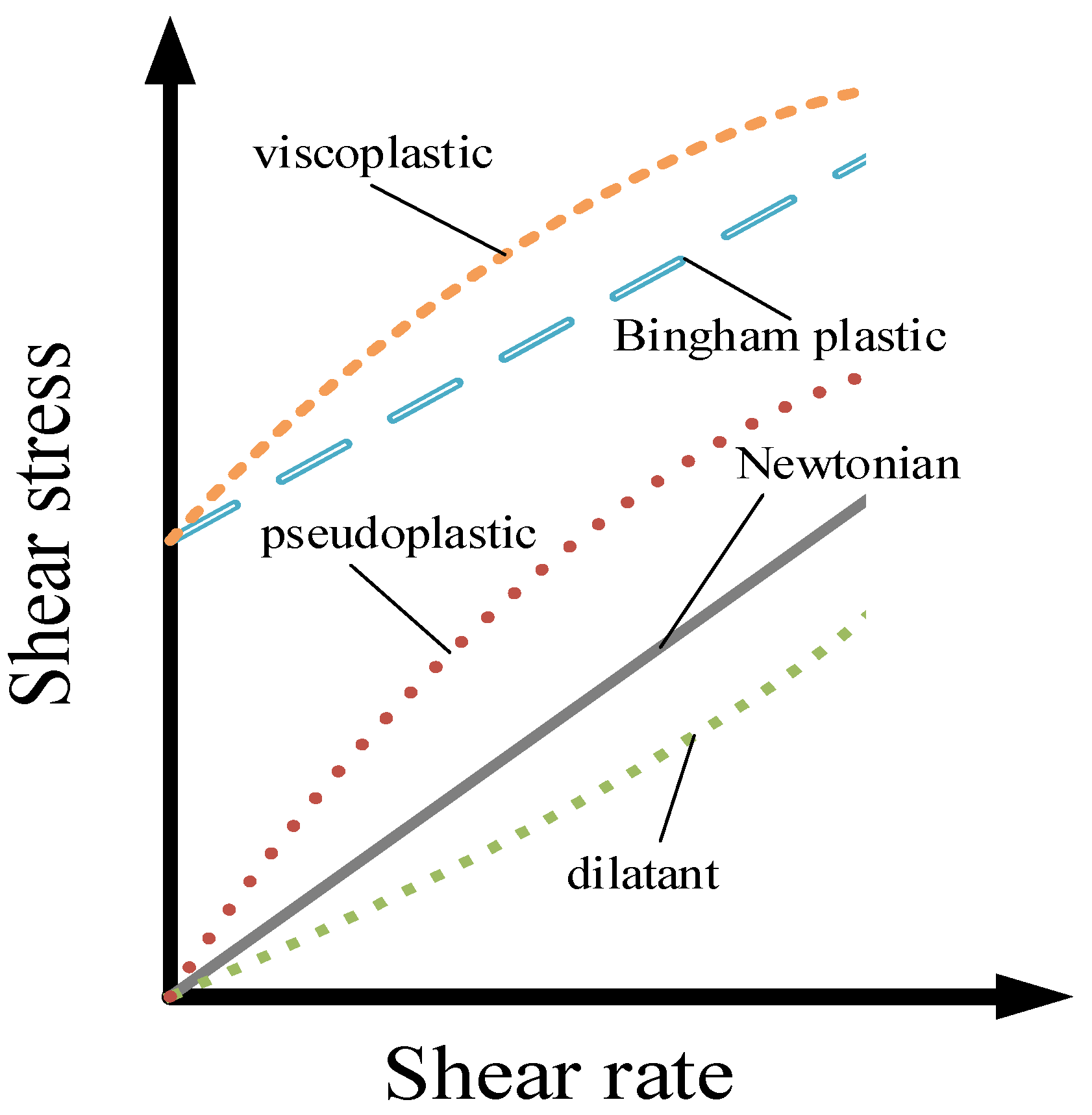

3]. The main groups of such fluids are multi-phase fluids such as foams, emulsions, dispersions, suspensions and slurries, as well as polymeric melts or solutions. It was also discovered, that fluid viscosity may depend or not on the flow kinematic history. In this study we focus on the time-independent fluid behavior. Depending on the function, which may bind shear stress and shear rate, fluids may be divided into the following types: pseudoplastic, viscoplastic, dilatant and Bingham plastic. Examples of such fluids are shown in the

Table 1. The shapes of curves of shear stress as a function of shear rate for these cases are presented in

Figure 1. As it can be observed, there are numerous fluids of high industrial importance that have to be treated as non-Newtonian fluids. Proper modelling of such flows is important during the design and optimization process of technological lines.

Currently, the green energy transformation is shifting energy sources to renewables. One such energy source are biogas power plants. They can be classified as utilization, agricultural and municipal biogas plants. The aim of the study was to determine viscosities of example substrates from such plants, and to describe their rheological properties with a pre-selected mathematical model. The proper measurements of the substrates may contribute to optimizing plants’ designs and operations. Fluid viscosities may influence pumps’ sizes and the energy demands, the amount, shape and distribution of mixers, as well as transport losses in the piping.

The process in a biogas plant begins with substrate storage, where fermentation begins. Solid substrates can be stored in heaps, while liquid substrates are stored in dedicated tanks. Then, substrates are mixed with each other and/or with tap water, in order to obtain the target total solid content (usually several percent). Such a mixture is then pumped to the fermentation chamber, which is equipped with a mixing system. Gaseous product is collected from the top, and the liquid part goes to the secondary fermentation chamber, then finally to the digestate chamber. The whole process requires continuous mixing and pumping. The rheological properties of the fluids are claimed to have a significant influence on system design and energy expenditures of the process [

12]. Plant design usually involves CFD (Computational Fluid Dynamics) methods, which require proper determination of the fluid properties.

In this study, the authors focused on biogas plant substrates that can be classified as non-Newtonian fluids. Mathematical modelling of such fluids still remains a challenge, but is desired due to its wide potential of application [

13]. To simplify the modelling approach, some scientists decided to lead initial calculations with pure water (Newtonian flow) [

14,

15,

16]. This approach has undoubtedly the advantage of its simplicity, but the accuracy of the obtained results may be debatable. They may be treated as initial pre-calculations. An interesting review of applied multi-phase flow treatment of sewage sludge can be found in [

17], but this publication did not address non-Newtonian properties of the analyzed fluids. The literature that refers to the mathematical modelling of sewage sludge, which is the main example of biogas plant substrates, is relatively poor, although the most popular approaches to the mathematical description of such fluids are power laws or Herschel–Bulkley models [

18,

19]. Examples of studies in this area and their modelling approaches are presented in

Table 2.

2. Mathematical Models Dedicated to Non-Newtonian Fluids

The choice of a rheological model is determined by the type of medium that is tested. The simplest rheological models, such as the Bingham and power-law models, depend on two parameters. Models that describe non-Newtonian fluids more realistically, such as the Hershel–Bulkley, Robertson–Stiff, or Heinz–Casson models, are described using three parameters. More complex rheological models depend on four or more parameters (Carreaux, Quemada, Maglione) [

22]. A better fit of the rheological model to the experimental data seems to occur when more rheological parameters are used [

22]. However, determining the hydraulic parameters for complex models is difficult and often requires the use of numerical tools. For this reason, rheological models that allow researchers to obtain a faithful representation of the fluid behavior at a lower computation cost are more often used. One such model is the Hershel–Bulkley (H–B), which is described by the following equation:

where

is the yield stress,

K is the consistency index and

n is the flow behavior index. To determine rheological parameters, a linearized form of Equation (1) is often used:

The H–B model can be called the generalized form of Bingham and power-law models. When

n = 1, H–B reduces to the Bingham model:

, when yield stress is equal to zero, the H–B model takes the form of a power-law model:

. Therefore, H–B is often chosen to describe the rheological properties of various non-Newtonian fluids [

23], and is the reason it was chosen in this study.

3. Analyzed Materials

Biogas can be produced in the process of anaerobic digestion from waste of various origins. In this study, substrates from three sources were examined: from a sewage treatment plant, from a sugar refinery and from a utilization biogas plant. The types of substrates used and their sources are presented in

Table 3.

The composition of mixtures used in current biogas utilization plants are variable, and depend on the availability of substrates. The ingredients are mixed with each other and diluted with FVW and/or tap water to a TS content of 6.8% (% of total mass).

Therefore, in this study, samples of different compositions were examined in order to recreate possible substrate mixes that may occur in a biogas utilization plant. The composition of each sample was selected in such a way that it was possible to assess the impact of individual components on the obtained viscosity of the mixture. The types of samples examined in this study are presented in

Table 4 and in

Figure 2.

To prepare a mixture with a total solid (TS) content of 6.8%, it was first necessary to determine the dry matter content of its individual components. For all substrates, the TS was determined experimentally. For this purpose, samples of known mass were dried at 105 °C for 20 h. After this time, the weights of the samples were tested, and they were then left for further drying for 6 h. Then, the weight was re-determined. If no weight loss was observed, then the drying process was considered complete. On the basis of the obtained results, the content of TS was determined. The obtained results are presented in

Table 4. The densities of all of the tested samples were similar, and amounted to about 1 g/cm

3.

The FVW, left without mixing, segregated. After time, light fruit and vegetable particles floated above the drain. Therefore, prior to testing, the sample was gently mixed by hand so that all of the different particles were evenly dispersed in the mixture.

4. Rheological Analyses

Rheological measurements were carried out within 3 days after sampling at 21 °C. Apparent viscosity was determined using a rotational viscometer (Fungilab Viscolead Pro LV) equipped with a set of cylindrical spindles, coupled with Fungilab Data Boss 1.0.16 software. The MTEAS and SBP were stored at a temperature of 10 °C. The FVW, BR and CW were stored in open containers under air-dry conditions. Samples of diluted substrates were prepared at least 1 h before testing. Each of the samples was tested in a 600 mL beaker. Measurements were carried out in several steps in a rotational speed range from 0 to 200 rpm. Several (minimum 5) viscosity measurements were made at each step after the flow had stabilized. Viscosity was determined for laminar flow. Correlations between viscosity value and substrate type, size of particle and solvent type were studied using pairwise Pearson correlation analysis.

5. Bench Tests Methodology

Rotational rheometers are commonly used to assess the rheological properties of non-Newtonian fluids. A measuring geometry consisting of two coaxial cylinders was used to evaluate the properties of fluids with a low to medium viscosity value. An important limitation of using this type of geometry to determine the shear rate versus shear stress relationship is the requirement for a narrow shearing/measuring gap (NMG) between the cylinders. Direct shear rate measurements can only be made when the shear rate is constant (or very close to) throughout the shearing gap. For geometries where the ratio of the inner to outer radius is greater than 0.99, it is possible to directly determine the shear stress [

25]. However, many commercially available measurement geometries do not satisfy this requirement. Additionally, many (if not the majority of) non-Newtonian fluids that are commonly found in industry may contain relatively large particles or aggregates of particles. Studies [

24] showed that sludge particles can reach sizes up to 1000 μm. The beet pulp, corn waste and beet root particles had even larger sizes (refer to

Table 4). For such systems, the measurement aperture should be correspondingly larger than the size of the largest particle [

25]. This requirement may not be met by measuring systems with an NMG. Therefore, geometries with a wide measuring gap (WMG) should be used to measure the viscosity of such complex systems. A commonly available device in which these conditions could be met is a rotational rheometer that allows measurements to be performed using the Brookfield method.

Determining the correct relationship of shear stress as a function of shear rate for such measurements requires adequate data processing. The basic equation for the coaxial rotational viscometer is a Krieger and Maron equation:

where Ω is the angular velocity of the spindle,

τ is the shear stress,

f(τ) =

is the shear rate and

Rb and

Rc are the spindle (inner cylinder) and the cup (outer cylinder) radius, respectively. In the case of WMG, Equation (3) was solved for a finite cylindrical spindle rotating in a cup of infinite radius, in order for the shear stress on the cup to become equal to zero; Equation (3) could then be written in the following form:

where

and

is shear stress and shear rate on the surface of the spindle, respectively [

3].

The results of measurements carried out using the Brookfield method are apparent viscosity, rotational speed and torque. Knowing the rotational speed, the angular velocity can be estimated. To determine the shear rate from Equation (4), it is necessary to estimate the shear stress value based on the known torque and the geometry of the used spindle. The value of

is determined on the surface of the spindle, according to the following formula:

where

M is a measured torque, and

H and

R are the height and radius of the measuring part of the spindle, respectively. Then, the viscosity curve and the flow curve can be plotted.

6. Methods Dedicated for Determination of the Herschel–Bulkley Parameters

Once dependence of the shear stress on the shear rate (

) is determined, then rheological coefficients are estimated to obtain the best fit of the modelling results to the experimental data. Thus far, various methods have been used to calculate parameters of the H–B model. The standard procedure consists of using non-linear regression to minimize the sum of squares error, and then assessing the fit of the model to the measured values, e.g., with the use of a coloration coefficient

. The disadvantage of this methodology is that sometimes the best model fit is obtained with a negative yield stress, which is meaningless [

23].

To overcome this challenge, various methods have been developed that rely on a preliminary estimation of the

value. Then, from the linearized form of Equation (2), the remaining parameters are determined. The simplest methods rely on extrapolation of the

, either directly from the flow curve or from the redrawn flow curve with

ln along the horizontal axis [

26]. However, these methods may result in the inaccurate estimation of rheological parameters. This is due to the fact that n and K parameters are sensitive to the estimated value of

, as it was shown in [

22]. Moreover, the assumption of the correct value of

is troublesome, because for low values of the shear rate, the uncertainty is the highest [

23]. To properly define

, other approaches such as the golden section search [

22] or genetic algorithms [

27] were proposed.

Another method, based on the inverse-problem-solution procedure, was published in [

28]. In this study, the authors proposed H–B parameters determination in isothermal conditions, based on the modified least squares estimation. The process relied on experimental data from squeeze and capillary flows. This method provided quite occur results with 2–3 unknown parameters, but some difficulties were reported for unique determinations of all five required parameters.

Recently, Moullinex described a method that is dedicated to the flow behavior index, n, estimated independently from the determination of the two other parameters. The author showed that in the case of Herschel–Bulkley fluids, minimizing the least squares error S is equivalent to solving the following equation:

where

and

is one of the m measured pairs of shear stress and shear rate. Therefore, the estimation of

K and

is possible with the use of linear regression based on Equation (2). This method is especially interesting, as it does not require extrapolation on uncertain data, and returns the global optimum value for

n [

23]. Due to advantages of the Moullinex method on the background of other presented approaches to H–B model parameters determination, this method was selected in this study.

7. Results and Discussion

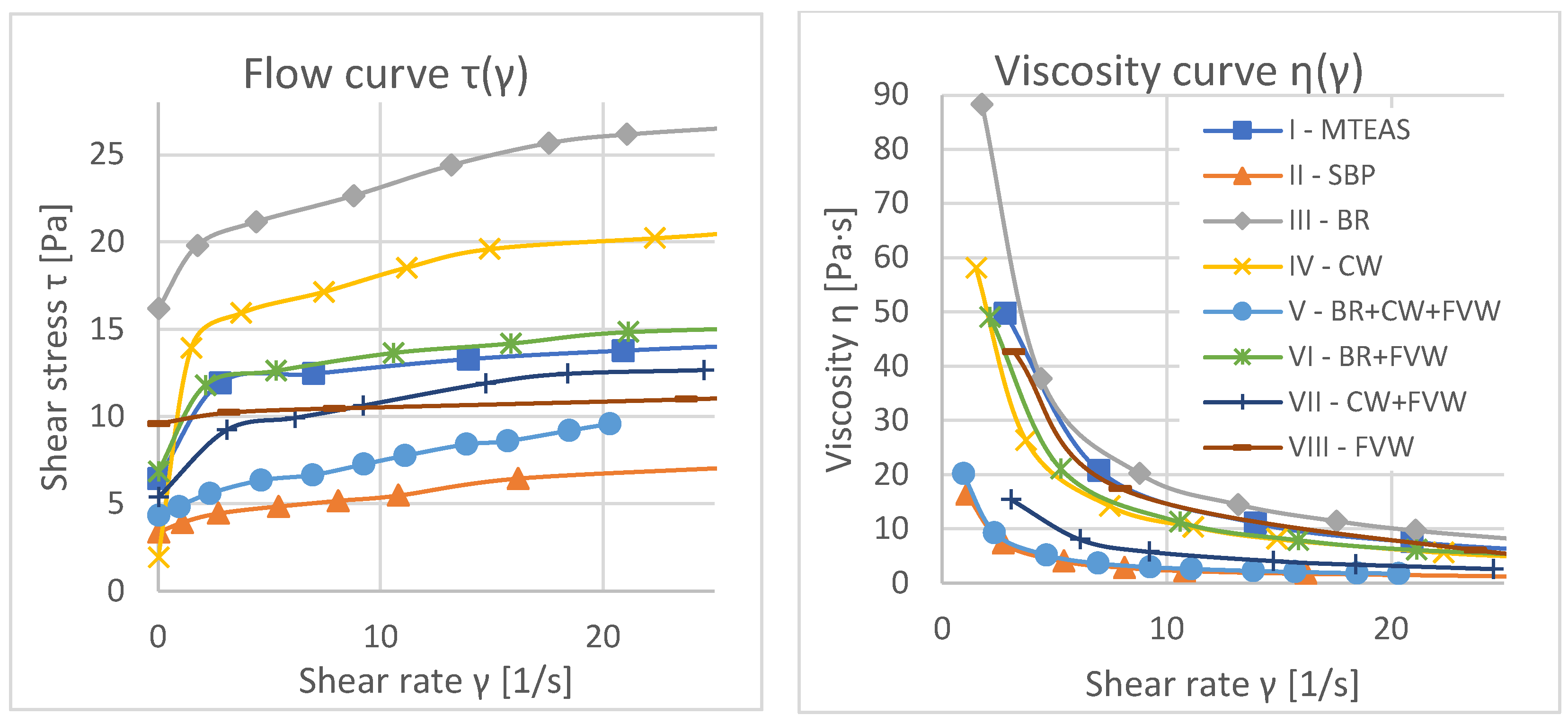

The flow and viscosity curves for all tested samples are shown in

Figure 3. To increase visibility of the data, viscosity curves for all samples—zoomed to the shear rate of 10–25 1/s are presented in the

Figure 4. In all analyzed cases, a non-linear relationship between shear stress and shear rate can be observed. The value of apparent viscosity, along with the increase in the shear rate, initially decreased rapidly and then stabilized. The nature of the curves indicates shear-thinning fluids with a yield stress (viscoplastic or yield-pseudoplastic fluids).

The highest value of apparent viscosity at 15 RPM was obtained for sample no. III (BR), and the lowest for sample no. II (SBP), as presented in

Table 5.

The results of the correlation analysis showed that the relationship between the viscosity value (measured at 15 RPM) and the properties of the sample (substrate type, particle size, solvent) were stronger within each group of substrates (separated due to substrate type, solvent type) than in all samples. The analysis of samples with BR as the main component showed a strong negative correlation between the viscosity value and the composition of the samples (r = −0.9568). Changing the solvent from tap water to FVW followed by the addition of CW resulted in a decrease in the viscosity values. In the case of samples based on CW, a similar relationship was obtained. A strong negative correlation was found between the viscosity value and the composition of the samples (r = −0.8539). Changing the solvent from tap water to FVW followed by the addition of BR resulted in a decrease in the viscosity values. Comparing the effect of the solvent used on the viscosity value, it was found that its value decreased when using FVW in relation to tap water for CW and BR (strong positive correlation, r = 0.7197). Comparing samples based on one type of solvent, a weak correlation between the viscosity value and the size of the substrate particles was obtained. A weak positive correlation was obtained for FWV (r = 0.2076), and a weak negative correlation was obtained for tap water (r = −0.0012). Analyzing the influence of particle size on the value of viscosity, a weak negative correlation was obtained for all tested samples (r = −0.0868). In

Table 6, the results of the obtained parameters of the Hershel–Bulkley model are presented. In accordance with the obtained R

2 values, a good fit of the model to the experiment results was achieved for all samples.

8. Outcomes

Non-Newtonian fluids are often encountered in engineering applications. A wide group of such fluids are biogas power plants substrates. Correct approaches to modelling such fluids may contribute to the proper design and optimization of biogas power plant installations, as the fluid viscosity is a very important factor to consider in pumps, mixers and in the selection and operation of other auxiliary equipment. This study evaluated the importance of the properties of samples prepared from commercially available substrates (their type and sample composition, particle size, solvent used) on the rheological nature of fluids and the value of viscosity. The correlation analysis showed the influence of the solvent type on the viscosity value. The use of FVW resulted in a decrease in viscosity compared to samples prepared with tap water. It was also shown that samples with complex compositions were characterized by lower viscosity values compared to samples composed of one substrate and solvent.

Based on the literature review, the H–B model was chosen as a proper description for biogas power plant typical substrates. Then, the Moullinex method was applied to determine the rheological parameters of the analyzed fluids. Comparison of the H–B model results with experimental data showed high agreement between obtained values.

The method of determining the relationship between the shear rate and shear stress used in this study (measurements performed in accordance with the Brookfield method (WMG)) were interesting, because it was possible to conduct tests using simpler, more commonly available devices (e.g., rotational viscometers).

Methods applied in this study can be treated as a valuable tool for determining rheological parameters for biogas power plant substrates.

Author Contributions

Conceptualization, H.J. and A.D.; literature studies, H.J. and A.D.; research methodology, H.J.; research and data analysis, H.J.; writing—original draft preparation, H.J., A.D. and P.K.; writing—review and editing, H.J., A.D. and P.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partially founded in the frames of Innovation Incubator 4.0 project, financed by Applied Research Institute, Warsaw University of Technology (internal grant), entitled: Development of an innovative technology of disintegration of substrates for the methane fermentation process under the conditions of biogas utilization plants, arrangement 2/2022,24.02.2022.

Data Availability Statement

Data sharing not applicable.

Acknowledgments

Authors would like to thank the Biogas Plant in Starorypin, Poland, the Sewage Treatment Plant in Pruszków, Poland, and the Sugar Factory in Glinojeck, Poland, for sharing samples of substrates for the research presented in this paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Deshpande, A.P.; Krishnan, J.M.; Sunil Kumar, P.B. Rheology of Complex Fluids; Springer: Berlin, Germany, 2010. [Google Scholar]

- Dapelo, D.; Bridgeman, J. A CFD strategy to retrofit an anaerobic digester to improve mixing performance in wastewater treatment. Water Sci. Technol. 2020, 81, 1646–1657. [Google Scholar] [CrossRef] [PubMed]

- Lu, G.; Wang, X.D.; Duan, Y.Y. A Critical Review of Dynamic Wetting by Complex Fluids: From Newtonian Fluids to Non-Newtonian Fluids and Nanofluids. Adv. Colloid Interface Sci. 2016, 236, 43–62. [Google Scholar] [CrossRef]

- Laird, W.M. Slurry and Suspension Transport, Industrial and engineering chemistry. Ind. Eng. Chem. 1957, 49, 138–141. [Google Scholar] [CrossRef]

- Liu, K.F.; Mei, C.C. Approximate equations for the slow spreading of a thin sheet of Bingham plastic fluid. Phys. Fluids A Fluid Dyn. 1990, 2, 30. [Google Scholar] [CrossRef]

- Antonio, G.; Faria, F.; Takeiti, C.; Park, K.J. Rheological behavior of blueberry. Food Sci. Technol. 2009, 29, 732–737. [Google Scholar] [CrossRef]

- Poonlarp, P.B.; Pongsirikul, I. Rheological properties of mango puree and process development of mango sheet Rheological Properties of Mango Puree and Process Development of Mango Sheet. Int. Soc. Hortic. Sci. 2014, 1024, 373–380. [Google Scholar] [CrossRef]

- Bridgeman, J. Advances in Engineering Software Computational fluid dynamics modelling of sewage sludge mixing in an anaerobic digester. Adv. Eng. Softw. 2012, 44, 54–62. [Google Scholar] [CrossRef]

- Ding, J.; Tracey, P.J.; Whitten, P.G. Review on shear thickening fluids and applications. Text. Light Ind. Sci. Technol. 2013, 2, 161–173. [Google Scholar]

- Nakanishi, H. Fluid dynamics of dilatant fluids. Phys. Rev. E 2012, 85, 011401. [Google Scholar] [CrossRef]

- Krokida, M.K.; Maroulis, Z.B.; Saravacos, G.D. Rheological properties of fluid fruit and vegetable puree products: Compilation of literature data. Int. J. Food Prop. 2001, 4, 179–200. [Google Scholar] [CrossRef]

- Šafarič, L.; Yekta, S.; Ejlertsson, J.; Safari, M.; Najafabadi, H.; Karlsson, A.; Ometto, F.; Svensson, B.; Björn, A. A comparative study of biogas reactor fluid rheology-implications for mixing profile and power demand. Processes 2019, 7, 700. [Google Scholar] [CrossRef]

- Samstag, R.W.; Ducoste, J.J.; Griborio, A.; Nopens, I.; Batstone, D.; Wicks, J.; Saunders, S.; Wicklein, E.; Kenny, G.; Laurent, J. CFD for wastewater treatment: An overview. Water Sci. Technol. 2016, 74, 549–563. [Google Scholar] [CrossRef] [PubMed]

- Hilares, R.T.; Dionízio, R.; Muñoz, S.S.; Prado, C.; de Sousa Júnior, R.; da Silva, S.; Santos, J. Hydrodynamic cavitation-assisted continuous pre-treatment of sugarcane bagasse for ethanol production: Effects of geometric parameters of the cavitation device. Ultrason. Sonochemistry 2020, 63, 104931. [Google Scholar] [CrossRef]

- Mancuso, G. Experimental and numerical investigation on performance of a swirling jet reactor. Ultrason. Sonochem. 2018, 49, 241–248. [Google Scholar] [CrossRef]

- Zubrowska-Sudol, M.; Dzido, A.; Garlicka, A.; Krawczyk, P.; Ste, M.; Umiejewska, K.; Walczak, J.; Wołowicz, M.; Sytek-Szmeichel, K. Innovative hydrodynamic disintegrator adjusted to agricultural substrates pre-treatment aimed at methane production intensification—Cfd modelling and batch tests. Energies 2020, 13, 4256. [Google Scholar] [CrossRef]

- Karpinska, A.M.; Bridgeman, J. CFD-aided modelling of activated sludge systems e A critical review Standard Method of Moments. Water Res. 2016, 88, 861–879. [Google Scholar] [CrossRef] [PubMed]

- Schneider, N.; Gerber, M. Rheological properties of digestate from agricultural biogas plants: An overview of measurement techniques and influencing factors. Renew. Sustain. Energy Rev. 2020, 121, 109709. [Google Scholar] [CrossRef]

- Dapelo, D.; Bridgeman, J. Advances in Engineering Software Euler-Lagrange Computational Fluid Dynamics simulation of a full-scale unconfined anaerobic digester for wastewater sludge treatment. Adv. Eng. Softw. 2018, 117, 153–169. [Google Scholar] [CrossRef]

- Craig, K.J.; Nieuwoudt, M.N.; Niemand, L.J. CFD simulation of anaerobic digester with variable sewage sludge rheology. Water Res. 2013, 47, 4485–4497. [Google Scholar] [CrossRef]

- Wei, P.; Uijttewaal, W.; Van Lier, J.; De Kreuk, M. Science of the Total Environment Impacts of shearing and temperature on sewage sludge: Rheological characterisation and integration to flow assessment. Sci. Total Environ. 2021, 774, 145005. [Google Scholar] [CrossRef]

- Kelessidis, V.C.; Maglione, R.; Tsamantaki, C.; Aspirtakis, Y. Optimal determination of rheological parameters for Herschel—Bulkley drilling fluids and impact on pressure drop, velocity profiles and penetration rates during drilling. J. Pet. Sci. Eng. 2006, 53, 203–224. [Google Scholar] [CrossRef]

- Magnon, E.; Cayeux, E. Precise Method to Estimate the Herschel-Bulkley Parameters from Pipe Rheometer Measurements. Fluids 2021, 6, 157. [Google Scholar] [CrossRef]

- Kim, H.; Koo, B.; Sun, X.; Yong, J. Investigation of sludge disintegration using rotor-stator type hydrodynamic cavitation reactor. Sep. Purif. Technol. 2020, 240, 116636. [Google Scholar] [CrossRef]

- Chhabra, R.P.; Richardson, J.F. Non-Newtonian Flow in the Process Industries Non-Newtonian Flow in the Process Industries Fundamentals and Engineering, 2nd ed.; Butterworth Heinemann: Oxford, UK, 2008. [Google Scholar]

- Mullineux, G. Non-linear least squares fitting of coefficients in the Herschel—Bulkley model. Appl. Math. Model. 2008, 32, 2538–2551. [Google Scholar] [CrossRef]

- Rooki, R.; Ardejani, F.; Moradzadeh, A.; Mirzaei, H. Optimal determination of rheological parameters for herschel-bulkley drilling fluids using genetic algorithms (GAs). Korea-Aust. Rheol. J. 2012, 24, 163–170. [Google Scholar] [CrossRef]

- Tang, H.S.; Kalyon, D.M. Estimation of the parameters of Herschel-Bulkley fluid under wall slip using a combination of capillary and squeeze flow viscometers. Rheol. Acta. 2004, 43, 80–88. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).