Abstract

Conversion efficiency, power production, and cost of PV panels’ energy are remarkably impacted by external factors including temperature, wind, humidity, dust aggregation, and induction characteristics of the PV system such as tilt angle, altitude, and orientation. One of the prominent elements affecting PV panel performance and capability is dust. Nonetheless, dust features including size, shape, type, etc. are geologically known. Several mitigation methods have been studied for the reduction of dust concentration on the exterior face of the PV modules. The outcomes have demonstrated that dust concentration and pollutants remarkably affect the PV panel energy production. This paper reviews the recently developed research on the outcomes of the dust effect on PV panels in different locations and meets the needs of future research on this subject. Moreover, different cleaning methods that could be advantageous for future researchers in opting for the most applicable technique for dust removal are reviewed.

1. Introduction

One of the most promising renewable energy sources to address the world energy crisis and global warming is solar energy [1], which is a convenient alternative for generating electricity from sustainable sources instead of relying on fossil fuels. Solar energy is clean, free, durable, and widely available around the world [2]. Photovoltaic (PV) system technology stands out as one of the most sustainable sources of electrical energy, characterized by its cleanliness, versatility, and CO2-free operation. According to scientific surveys, PV systems have the potential to globally provide sufficient energy capacity and surpass all other energy sources in the coming decade [3]. Moreover, in response to the continuous increase in electricity prices and installation and maintenance costs, optimizing PV systems could reduce expenses and promote widespread domestic implementation [4,5].

Installing PV panels for home electricity generation can reduce annual carbon emissions, leading to a decrease in greenhouse gas production, a crucial issue according to the United Nations agenda [6,7]. Although equipment and installation costs are high, there has been a cost reduction trend [8,9,10] as scientists persistently search for higher PV conversion efficiency to generate more electricity from the same amount of solar energy [11]. However, photovoltaic electricity production has raised many issues, mainly associated with production, optimization, and maintenance problems [12]. It should be noted that the most important environmental parameter for solar electricity production is radiation. Additionally, temperature, dust, relative humidity, wind, shading, and others also influence PV conversion efficiency, therefore having a remarkable effect on PV current and voltage, and consequently on the harnessed PV energy [13,14]. Researchers have found that the performance of PV panels diminishes when the irradiance of solar cells increases, as the semiconducting materials used in solar cells have certain characteristics that, at higher irradiances, make them less efficient at converting sunlight into electricity. In a solar cell, light creates electron–hole pairs, which need to be separated at the interface of the semiconductor material. As irradiance increases, more electron–hole pairs are generated. However, at higher light intensities, there is also a higher probability of recombination, where electrons and holes recombine before they can be collected as current [15,16,17]. This results in a decrease in the overall efficiency of solar cells [18,19,20]. These materials may have reduced charge carrier mobility or increased recombination rates at higher light intensities [21,22,23]. Other studies have shown that low-speed winds assist in removing dust from the solar cell surface, leading to an increase in the productivity of the PV panel, while high-speed winds could damage the cells and break the base on which they are installed [24,25,26]. It is well known that dust deposition and pollutants cause a reduction in the productivity of solar cells, so periodic cleaning of PV panels is required to remove the accumulated dust [27,28,29]. There are two main factors affecting dust concentration: the dust properties and type, such as leaves, bird droppings, and dirt spots; and different climate circumstances enhanced by pollution. Additionally, PV efficiency is affected by the manufacturing and installation processes, such as surface irregularities, panel installation, height, or orientation. Moreover, the physical, artificial, biological, and electrostatic characteristics of the dust have a bulk impact on its efficiency. It is known that dust settlement induces more dust to concentrate, as the deposited dust ingredients cause more particles to settle, resulting in a higher dust collection on the surface of PV modules [30,31]. On the other hand, climate conditions play a key role in the efficiency of solar cells, as their impact varies from location to location. Therefore, there is no fixed rule to ascertain the dust effect [32,33]. External parameters such as ambient temperature, dust, humidity, precipitation, and installation features, including altitude, orientation, tilt angle, periodic tilt regulation, and installation location, are vital factors affecting the efficacy of PV panels. This paper reviews the effect of soiling on the power output and the dust-cleaning methods to enhance the efficiency of photovoltaic technology. As aggregated dust decreases the performance of photovoltaic systems, leading to a rise in cost and time, cleaning these systems is necessary [34]. Therefore, research on soiling properties and their influence on photovoltaic panel efficiency is a major concern for the expansion of this technology.

2. Dust Effect on the Efficiency of PV Panels

Research has shown that the parameters that most influence dust aggregation on PV surfaces are tilt angles, climate conditions, and dust composition [35]. One of the primary issues affecting the efficiency of photovoltaic panels is the aggregation of soiling on the top layer of PV modules, as it reflects and diffuses light, thereby reducing light transmission and power output [36,37]. Figure 1 illustrates dust aggregation on on-grid PV panel modules after a sandstorm day [38]. The various properties of dust elements, such as size, shape, and combination, are prominent characteristics that impact light transmission to photovoltaic modules [39,40,41].

Figure 1.

Accumulated dust on PV module. (Adapted with permission from Ref. [38]. 2020, Elsevier).

Vivar et al. conducted experiments to assess the impact of dust on concentrated photovoltaic (CPV) systems, a type of solar energy technology that focuses sunlight onto a smaller area of solar cells. This technique, employing lenses, mirrors, or other optical devices, aims to increase electricity generation. The results were compared with the impact of dust on flat panels. The purpose of PV concentrators is to enhance the efficiency of solar cells by maximizing the amount of sunlight they receive. In contrast, traditional solar panels, also known as flat-plate solar panels, utilize a large surface area of solar cells to capture sunlight. PV concentrators concentrate sunlight onto a smaller area, reducing the size and number of solar cells required while maintaining or increasing overall energy output. The results indicated that CPV systems are highly likely to be more affected by soiling than horizontal panels. Losses of approximately 14% in short-circuit current were reported in three different tests conducted in the Madrid area. Furthermore, some concentrators experienced losses of up to 26% when the system was exposed to soiling for four months. Generally, linear reflective optics suffer greater losses due to soiling compared to refractive optics [42].

Asl-Soleimani et al. experimentally analyzed the performance of different types of solar modules and tilt angles, investigating their impact on the amount of energy collected by a PV module. They found that a tilt angle of 30° is optimal for a grid-connected system and identified contamination as the cause for a reduction of more than 60% in the output energy of solar modules [43].

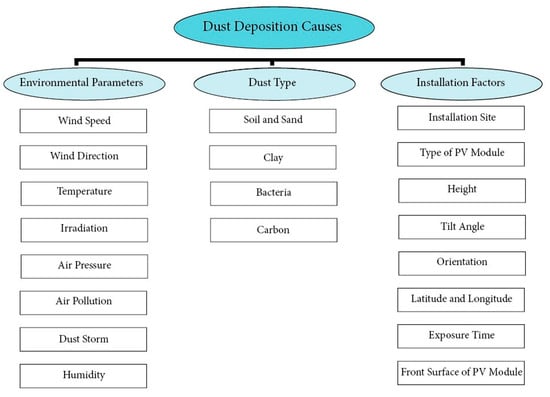

Mustafa et al. studied the influence of various environmental parameters on PV panels, including dust accumulation, bird droppings, shading, etc., as illustrated in Figure 2. They demonstrated that these parameters have a significant impact on both PV current and voltage, and consequently, on the harvested PV energy. Indeed, due to accumulated dust, the power output decreased 8.80% and the efficiency dropped 11.86% for two PV modules [44].

Figure 2.

Factors affecting dust aggregation.

The efficiency of photovoltaic modules and their power output can be dramatically reduced due to dust accumulation, according to recent scientific studies [45]. Aravind et al. [46] and Halbhavi et al. [47] demonstrated that if a solar panel remains dirty for 30 days, its power output could decrease by almost 50%. Kurokawa [48] found that dust settlement is responsible for a 15% reduction in the daily total energy of solar panels, and later, Mondal and Bansal [49] pointed out a 56% overall soiling loss.

The key parameter impacting the efficiency of PV modules is solar radiation, which is hindered by dust settlements [50]. In addition to temperature and irradiance, the power output depends on the type, glass, and electrical features of solar cells [51,52].

Katkar et al. [53] demonstrated that a temperature increase enhanced the conductivity of solar panels by up to 9.7% at 31 °C and up to 12.0% at 36 °C. However, further increases in temperature caused a reduction in performance. Primary surveys revealed that the effectiveness of solar cells depends on the cell temperature. It was observed that the efficiency of solar cells diminished by 69% at 64 °C compared to the measured efficiency at STC [54,55]. When radiation is at 1000 W/m2, in the absence of any cooling systems, the temperature rises to 56 °C, leading to a 3.13% drop in conductivity [56]. As the PV modules are installed directly under solar radiation, their temperature rises, causing a reduction in output voltage and power efficiency. Additionally, the band gap in the silicon film is reduced, and the dark saturation current increases [57].

Siyuan Fan et al. developed a new method based on a dust concentration and photoelectric conversion efficiency (DC-PCE) model that can be used under radiation conditions up to 1000 W/m2. This model examines the effect of dust concentration on energy loss in PV systems. They reported that at low radiation, the performance degradation rate grows with the increase in radiance, and after reaching a certain amount, it stabilizes. They demonstrated that the developed model offers a simple and accurate approach for evaluating dust settlement, with an accuracy of 83.12% [58].

3. Different Dust Properties

One of the principal features of PV power degradation is dust settlement over the PV panel surface, which significantly impacts energy output over an extended period of utilization and damages the panel’s film, resulting in reduced output and a shortened lifetime [59].

Ilse, Klemens, et al. explained that certain types of soiling elements, such as leaves, bird droppings, dirt spots, etc., as shown in Figure 3, can block some cells and thus create hot spots. Hot spots are localized areas on a solar photovoltaic module or panel where excessive heating occurs [60,61].

Figure 3.

Different types of soiling: (A) mineral dust in a desert; (B) bird droppings; (C) algae, lichen, mosses, or fungi; (D) pollen in wet and moderate climates; (E) engine exhaust from an industrial area; and (F) agricultural emissions (Reprinted with permission from Ref. [61]. 2019, Elsevier).

Abderrezek et al. studied the effect of dust on the electrical and thermal behavior of PV panels. They observed that hot spots can cause module overheating, depending on the nature and density of the dust [62].

The distribution and size of dust particles are key factors in shading and the reduction of PV efficiency. Smaller particles tend to occupy more surface area than coarse particles, thereby reducing radiation and leading to the deterioration of PV performance [63,64,65]. Fine particles are more stably concentrated than coarse ones [66,67], leading to higher light diffusion, especially at lower wavelengths, and more radiation loss [68]. The degradation may increase with high humidity when microscopic dust particles stick to the surface, forming adhesive films that are not easily removed by wind [69].

Khatib et al. studied the impact of five types of air pollutants (red soil, ash, sand, calcium carbonate, and silica) on the degradation of (multicrystalline) PV modules’ performance. The results showed that the reduction of PV voltage and power is directly related to the type and deposition level of the pollutant. They found that ash has the highest effect on the PV module voltage, with a 25% reduction, followed by red soil, calcium carbonate, silica, and sand [70].

Dust is a fine particle under 250 μm, and substances like bird droppings, sand, crops, etc. concentrated on PV modules have similar effects as dust. The proportion of distributed dust depends on characteristics such as artificial ingredients, size, shape, weight, and several external conditions: temperature, blizzard, humidity, dirtiness, and wind speed. Human activities, vehicle exhaust, and volcanic eruptions also lead to an increase in dust deposition [71,72,73]. Some dust types and other pollutants are shown in Table 1.

Table 1.

Different types of dust and some other pollutants [58].

Ash refers to the powdery residue left after the combustion of certain materials, such as wood, coal, or other organic matter. It is primarily composed of inorganic minerals, and its color can vary from light grey to black. It is noteworthy that due to the tiny size and vast area coverage of ash over a PV surface, it can easily absorb detrimental materials from the atmosphere.

Laterite is a type of soil or rock formation packed with iron and aluminum oxides, which develops in tropical and subtropical regions, particularly in areas with high rainfall and warm temperatures. Furthermore, it is composed of a mixture of minerals, including iron and aluminum oxides, as well as clay minerals. It often contains significant amounts of iron and aluminum hydroxides.

Stone dust, also known as limestone, is a powdery substance formed when stone is crushed into smaller fragments. It consists of finely crushed particles, ranging from dust to small gravel-sized pieces. Stone dust is commonly used as a base material for various construction projects, such as roads, driveways, and walkways, providing stability and acting as a foundation for other materials.

Sandy soil is a type of soil with a high proportion of sand particles and is characterized by its gritty texture. It has larger particles compared to other soil types, such as clay or silt, giving sandy soil its distinct properties. Sandy soil is frequently encountered in deserts.

Coal powder refers to fine particles of coal that have been ground into a powdery form, commonly used in construction projects. It is created through the pulverization or grinding of coal, typically in a coal mill. The resulting powder consists of tiny coal particles with size ranging from 1 μm to 100 μm. It is interesting that they are combustible and have high energy content [58].

El-Shobokshy and Hussein simulated synthetic dust using cement, carbon, and limestone. They found that the coarser ingredients can be effortlessly eliminated with high wind speed. The measurements of the ingredients were 5, 10, and 50–80 μm for carbon, cement, and limestone, respectively. They also revealed that due to gravity, the dust settlement rate of fine elements (with a diameter lower than 5 μm) was 5%, while for larger ones, it was 75%. They demonstrated that carbon particles absorb more irradiance than cement or limestone. Consequently, carbon reduces the transmitted light and raises the PV module temperature. They found that fine elements have more dispersion losses and are more consistently concentrated when compared to coarser ones [74].

Guan et al. remarked on the significance of collected dust on the temperature, energy, and glass transmittance of photovoltaic modules. The results indicated that soiling aggregation not only reduced light transmission to the PV film but also lowered the temperature, influencing the energy field. Furthermore, the study revealed that, over 8 days, the transmission of a module dropped by 20% [75].

Mekhilef et al. stated that humidity affects both irradiance and dust concentration. Additionally, they deduced that an increase in wind velocity can remove heat from the PV cell surface. On the other hand, higher air velocity lowers the relative humidity of the atmospheric air in the surroundings, leading to better efficiency. They demonstrated that countries near the ocean experience high humidity, resulting in greater adherence of dust particles to PV surfaces due to increased stickiness. Furthermore, an 80% increase in adhesion was observed due to a rise in relative humidity from 40% to 80%. They also found that ambient temperature and PV module surface temperature influence the dust accumulation process [76].

One of the other dominant parameters in dust accumulation and its elimination is wind. High-speed winds can effectively clean the PV surface, while slower winds might lead to dust concentration due to their lower speed. The rate of soiling aggregation would be lower with less concentrated dust, and vice versa [77]. Additionally, wind velocity can impact the PV structure [78]. Darwish et al. estimated that the extent of this damage could reach up to 25% [79,80]. This results in power output generation irregularities and a decrease in the reliability of solar systems [81]. Consequently, to enhance reliability while reducing the likelihood of degradation and financial losses, appropriate and cost-effective cleaning solutions need to be developed [82,83].

Jiang and Lu demonstrated that the deposition and accumulation of dust on solar modules lead to a significant degradation of the short-circuit current. In contrast, the reduction of the open circuit voltage was insignificant. They also showed that with the rise in the temperature of the PV module’s surface, the dust accumulation densities are reduced. Therefore, a PV module with a higher surface temperature has lower dust settlement densities. This is due to the influence of a factor known as the thermophoresis force, which is generated by the temperature differences between the surrounding air and the PV module’s surface. This temperature difference arises from the absorption of photons and the subsequent conversion of light energy into electrical energy. This force can impact the performance and efficiency of solar cells, acting from regions of higher temperature to lower temperature. Furthermore, the surface material can affect dust deposition and accumulation. It is noteworthy that the polycrystalline silicon module packaged with epoxy degraded faster than other modules with a glass surface under the same dust concentration [84,85,86].

Kalogirou et al. discovered that dust and pollution intercept irradiation on the PV panel’s surface, leading to a decline in power output that can exceed 43% [87]. Boyle et al. assessed bulk settlement and reduced transmission by conducting a natural examination. The outcomes demonstrated that the distributed soiling ratio ranged between 1 and 50 mg/day, varying with time, angle, and location [88]. Laarabi et al. found a positive correlation between density and the loss of light transmission. Additionally, the type of soiling could further reduce light transmission [89].

Kazem et al. demonstrated that the efficiency of PV panels decreased due to dust, ranging from 16% to 8% in a 45-day period in desert areas. In Saudi Arabia, PV panels were placed at a tilt of 26° and, over 45 days, the dust concentration was measured at 5 g/m2, resulting in a reduction in conductivity of around 20% [90,91]. In Kathmandu, accumulated dust on PV panels over a 5-month period reached 9.67 g/m2, leading to a decline in productivity of approximately 29.76% [92]. As a consequence, with several studies focusing on dust concentration and its impact on PV power output, numerous studies have endeavored to develop models for soiling settlement and PV power distribution to enhance PV systems.

4. Dust Effects on Different Locations

The diameter of dirt particles is less than 10 μm [93,94], and this size depends on the location, climate conditions, and ecological features, which in turn influence the efficiency of PV panels [95,96,97]. Additionally, the accumulation of dust on PV systems is controlled by the combination of two main factors: the characteristics of the dust and the local environment [98,99]. For example, while carbon is primarily produced by automobile exhaust in urban areas [100,101], it is produced from bird droppings, soil, and organic pollen in agricultural areas [102]. In contrast, desert regions such as the Arabian Peninsula, Central Asia, North Africa, South Africa, western and eastern China, and North and South America are primarily composed of minerals like quartz, sand, silica, etc. [103,104,105]. As a result, dust deposition affects power generation performance differently [106,107,108]. The quality of the dust varies according to its geographical location worldwide. Moreover, the process of dust deposition is significantly influenced by the physical and chemical properties of the dust components [109].

Sayigh et al. are credited as some of the pioneering researchers in investigating the impact of dust on solar cells in the Middle East. They conducted research on Kuwaiti natural dust and its effects on solar cells’ power output. Furthermore, they also demonstrated the influence of the PV tilt angle on dust settlement [110].

According to Gostein et al., dust settles at high speed in semiarid and desert environments. Low temperatures near the sea may lead to high vapor condensing into water droplets on the surface, increasing stickiness and adhesion, which attracts more airborne dust particles [111].

These research insights provide an understanding of the impact of soiling on the behavior of PV panels in different locations [112,113,114,115]. Julius et al. assessed the impact of dust with various forms from Babuin and Perth, two geographically distinct locations, on the power output degradation of various PV technologies. According to their findings, dust with the same density from Babuin and Perth did not show a significant difference in the performance deterioration of each PV panel. This results in an approximately equal level of transmittance for the two categories of dust [116].

Ahmed et al. conducted a study on the types of dust present in the United Arab Emirates and investigated their impact on the behavior of PV panels. They demonstrated that the majority of particles are less than 25 μm, indicating that fine particles have a more pronounced effect on the efficiency of the PV panel. The researchers found a linear relationship between PV power output and dust deposition on the panel surface, resulting in a loss of 1.7% per g/m2, a phenomenon verified for both indoor and outdoor scenarios.

Furthermore, they concluded that the inclination angle and orientation of the PV panel also influence dust deposition. Increasing the inclination angle leads to the removal of dust through gravity. Additionally, they predicted that the dust density would increase by 5.44 g/m2, causing the power of the PV module to decrease by 12.7% after 5 months of exposure [117].

In another study conducted by Mohandes et al. [118], the performance of a 500 W copper indium diselenide (CIS) PV system in the United Arab Emirates was evaluated in relation to various environmental factors, including temperature, humidity, and dust. It is noteworthy that in desert regions, dew easily accumulates on the surfaces of solar systems at night, trapping even the smallest airborne dust particles. As the temperature increases during the day, the dew evaporates, leaving behind a layer of dust. As a result, increased humidity reduces the maximum power output, although it does not have an impact as significant as wind and dust on power output. They also observed a maximum power output loss of 10% over a 5-week period due to dust accumulation. Nevertheless, it has been demonstrated that the primary concern in these locations is dust accumulation, which can lead to a reduction of 50%, or more, in the power output within just six months if not cleaned [119,120].

5. Cleaning Methods

Al-Kouz et al. evaluated how dust and ambient temperature affect PV panels to recommend the optimal cleaning frequency. They employed optimized artificial neural network (ANN) and extreme learning machine (ELM) models to estimate PV conversion efficiency under varying conditions, accounting for actual dust accumulation and temperature. Their findings showed that the optimized ELM method provides more accurate estimates of PV performance than the optimized ANN method. They suggested a cleaning frequency of two weeks, taking into consideration cost loss and cleaning expenses [121]. They also revealed that the optimal cleaning interval, according to the optimized ELM model, is 14 days, while the ANN method indicates a period of 15 days.

In an experimental setup conducted in Egypt, it was demonstrated that dust significantly influences the short-circuit current, while its impact on the open-circuit voltage is insignificant. Furthermore, a suggested cleaning schedule of once every four days was proposed [122].

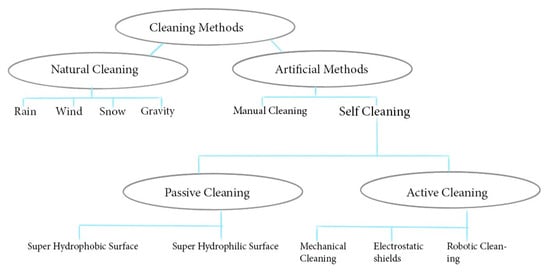

To reduce the effect of dust deposition on PV power generation, different cleaning methods were proposed such as manual, mechanical, chemical, electrostatic, or even natural cleaning with materials as shown in Table 2.

Table 2.

Cleaning methods and cleaning materials/products [123,124].

Figure 4 also shows some mitigation solutions that could be used in some regions to get rid of dust aggregation.

Figure 4.

Various cleaning methods.

5.1. Manual Cleaning Method

A simple and cost-effective method for cleaning PV panels is water washing or manual wiping, which helps rinse off dust from PV surfaces. However, effectively removing dust settlement within the necessary timeframe to improve the performance of PV panels can be challenging. Striking a balance between boosting economic profit and managing cleaning expenses has become an important research topic. Additionally, several techniques can accelerate PV degradation due to their interactions with specific types of contaminants.

As shown in Figure 5, manpower is crucial for manual cleaning, involving the use of various types of cloth to wipe the surface of the PV panel. A significant concern is water usage, particularly in regions where water is scarce, coupled with the substantial energy consumption of the pumping mechanism [125]. Alvarez et al. studied cleaning methods and frequencies from an economic perspective. They proposed a cleaning approach that opts for an efficient strategy by correlating equipment effectiveness with cost and other factors. For PV panels covered with tempered borosilicate glass, water-based cleaning is a straightforward solution. However, for PV panels covered with glass that has minimal reflectivity and aids in light absorption, alternative effective cleaning methods are required. These panels are prone to the deposition and accumulation of tiny nanoparticles [126].

Modern cleaning approaches, including electrostatic power (Jadhao et al.) and novel water-free cleaning robots, have also been proposed (Fan et al.) [127,128]. This approach enhances efficiency through the implementation of a highly reflective water-based cleaning system [129,130,131].

Cleaning activities can be an effective solution to mitigate the decline in PV panel performance and efficiency [132,133,134]. Cleaning methodologies can be either manual or automatic, and they are applicable to both small and large panels [135]. Additionally, natural phenomena such as rain can help alleviate the impact of dust. However, relying solely on rain for cleaning can be a drawback, as it makes PV panels dependent on the frequency of rainfall for their cleanliness [136,137]. This can be a disadvantage, especially in areas with limited rainfall, such as desert regions [138,139,140].

Figure 5.

Manual cleaning (Reprinted with permission from Ref. [141]. 2020, Elsevier).

5.2. Natural Cleaning Method

Dust is not a significant concern in areas with minimal dust deposition and occasional precipitation, as rain can effectively clean dusty PV panels and enhance their efficiency. However, if the frequency and duration of rainfall decrease, the issue of dust deposition could worsen due to the lack of cleaning by rain [142].

Figure 6 depicts water cleaning using channeled flowing water on the PV panel surface to eliminate dust accumulation. This technique requires substantial water volumes and often involves pumping water to the required height. In some cases, pressurized water is combined with detergents to improve dust removal efficiency. However, the challenge of water scarcity in certain regions limits the feasibility of this approach [141].

Figure 6.

Automatic water cleaning system of a solar panel (Reprinted with permission from Ref. [141]. 2020, Elsevier).

Studies by Qasem et al. and Salamah et al. highlighted rainfall cleaning as an effective method to enhance the energy output of PV panels by approximately 1%, as the amount of dust decreases by about 4% [143,144].

Claudio et al. investigated the impact of rain on PV panel systems, revealing that rain can globally offer significant positive benefits to the output of PV systems, particularly during spring and summer. Considering the cleaning effect, it has been estimated that under specific monitoring conditions (30° tilted panels in a non-dusty environment), regular precipitation events prevent the accumulation of particles that could adversely affect PV panel performance. Moreover, rain can potentially lead to a performance improvement of up to 6% in dusty areas, particularly for tilted modules. Notably, heavy rain and melting snow can be effective in removing dust accumulation from panels, either partially or entirely [145].

Şevik and Aktaş studied the impacts of natural and manual cleaning methodologies on the efficiency of a PV panel. They estimated that the PV panel efficiency drops by up to 5.66% during a polluted period of about a year, and rainfall, following a prolonged drought, increases performance by roughly 1%. Simultaneously, snow removal enhances production and reduces stress. Moreover, they demonstrated that a six-month or annual cleaning cycle is sufficient for the studied plant, leading to decreased cleaning costs [146].

To assess the impact of rainfall on PV module cleaning, Haeberlin and Graf, as well as Appels et al., conducted experiments in Switzerland and Belgium, respectively. Based on the results, rainfall effectively restored the efficiency of PV panels, eliminating the need for manual cleaning [147,148]. In areas with low rainfall, dust adheres more firmly to the panel, causing it to transform into mud. Bethea et al. have demonstrated that low rainfall increases dust adhesion, making it challenging to remove, as mechanical methods are required [149].

5.3. Automatic Cleaning Method

Dust mitigation technologies reveal that the increase in total power output depends on seasonality and locations. Abdulsalam et al. conducted research on automatic cleaning of PV modules in Saudi Arabia. They found that soiling significantly affects the performance of PV modules across various areas. Multiple cleaning mechanisms were employed, including vibration, air, water, and combinations thereof. Despite their findings, they discovered that string power output increased by approximately 27% for the water-cleaning mode only. Module vibration and air jets had a lesser effect on dust settlement compared to other methods [150].

Alqatari et al. proposed dust mitigation techniques for a solar PV model using three different methods and compared their performance with a reference based on manual cleaning. The methods included hydrophobic nanocoatings, air-blowing mechanisms, and electrodynamic screens. They used meteorological data from six areas in Saudi Arabia and the results showed that annual power production increased by up to 17% in some locations, leading to a rise in annual energy production that offset the associated costs [151].

Tanesab et al. investigated the influence of dust on the degradation of PV modules in Perth, Western Australia. According to the results, the normalized power output of PV panels varied with the season. Additionally, economic analysis revealed that dust-induced production losses (AUD 5.47) were lower than the overall cleaning costs (AUD 78). They did not suggest a cleaning procedure for their grid-connected PV system simulation [152].

Guo et al. used outdoor soiling microscopy to evaluate the dust removal efficiency of two electrodynamic dust shield (EDS) prototypes in the field. These EDS prototypes were tested in an outdoor environment for two rounds, consistently accumulating dust over four successive days, with the EDS being activated daily. Photomicrography and image methods were employed during EDS activation to measure and estimate the dust removal efficiency over 96 h. They observed that EDS efficiency decreased from 40% to 14% as dust particles remained on EDS surfaces for longer periods, resulting in diminished removal efficiency [153].

Based on two identical monocrystalline PV modules, Ju and Fu et al. reported that robotic cleaning increases installation and maintenance costs while reducing water usage. One of the modules was equipped with an electrical motor and brush for cleaning using spray, while the other module had a natural cleaning system. In their study, the cleaned PV modules generated more power than the PV modules that were not cleaned [154], but the cost of operating the cleaning system over the same period was higher.

5.4. Mechanical Cleaning

Mechanical cleaning, which involves wiping, blowing, and brushing the surface and can be controlled electrically and electronically, represents the simplest dry-cleaning method. However, this process poses a risk to the surface integrity as it may cause scratching on reflective surfaces. An alternative approach involves utilizing air flow (“forced air”) directed at or across the surfaces and vibrations. High-pressure water systems with a water storage tank can also be employed for cleaning, either using robots or engines, as shown in Figure 7 by Mani and Pillai. In the case of high rates of dust settlement, the frequency of these cleaning activities may need to be increased to a daily schedule, whereas periodic PV cleaning is typically conducted once a week during dry days [155,156].

Figure 7.

Automatic cleaning. (Reprinted with permission from Ref. [141]. 2020, Elsevier).

A mechanical device was developed by Anderson et al. that uses water to clean PV panels. An estimated 15% increase in efficiency was observed for the studied PV system [157].

The single-axis solar tracking system, designed by Tejwani and Solanki, uses a stepper motor, microcontroller, and gearbox to rotate 360° throughout the day. They used a sun-tracking and cleaning device, which not only tracks the sun but also cleans the modules automatically. They found that regarding daily energy generation, the tracking and cleaning scheme provides 30% and 15% more energy output when compared to the flat PV module and PV module with single-axis tracking, respectively [158].

Mohammed et al. studied different non-water-based cleaning methods for retrofitting into UAVs/drones for a large-scale PV system. As soiling can be more severe in desert areas, a thin-film PV-cleaning method was developed for winter and summer conditions with a frequency ranging between daily and monthly. Specifically in summer, the most suitable cleaning frequency was weekly. Based on weekly periodic comparisons between a control PV panel and microfiber-based-cloth-wiped panel, the microfiber and vacuum cleaner combination produced 7.7% performance gains over the control panel. The researchers discovered that microfiber-based cloth wipers and brushes are the best options for drone adaptation/retrofitting due to their small size, low weight, and ease of use [159].

5.5. Chemical Cleaning

Chemical cleaning, such as the use of detergents, despite its low cost and suitability for handling and automated mixing, results in a reduction of surface energy tension. This method is safe, non-toxic, and biodegradable. A popular method for producing coatings is dry etching, which employs plasma as an etchant. The desired chemicals are deposited on the substrate as layers through this technique. Laser and chemical etching are other etching methods. The controlled factors in these processes include processing conditions such as gas, power, and processing time [160,161].

According to Mozumder et al., a thin film layer is deposited within a gaseous medium surrounding the substrate at elevated temperatures through chemical reactions. The earthed coated film was then subjected to compressed air from a spray gun to electrostatically charge the dry powders. To achieve success, they carefully managed particle size, chemical composition, fluidity, and powder mass flow uniformity [162]. In a first-of-its-kind study, Firat et al. employed 3D printer technology to remove dust accumulation from solar PV panels under laboratory conditions. The results indicated that using the proposed solution 1 (2-propanol) led to a 15% increase in power output [163].

6. Conclusions

The concentration of lead, zinc, cadmium, nickel, and chromium in street and household dust is generally attributed to heavy metals resulting from automobile pollution, industrial pollution, and weathered materials. Various methods of cleaning PV panels were reviewed in this paper to identify potential solutions for mitigating the effects of dust deposition on PV panel performance. In summary, dust impacts PV performance in the following ways:

- Environmental parameters, such as dust settlement, not only affect the operation of the PV modules but also reduce the lifespan of the PV panels.

- There is no fixed schedule for removing surface PV dust, as it depends entirely on the occurrence of dust storms and rainfall.

- Selecting an efficient mitigation method for cleaning PV modules is quite complex, as it relies on the environmental conditions of the installation site.

- A heavy hailstorm can destroy the PV module as it may crack the front glass of a module, causing a substantial reduction of the PV power output.

- Additional research is required on the issue of the influence of a dust concentration on the PV modules.

Funding

This research has been funded by Aero.Next Portugal-ILAN VR funded by C645727867-00000066 by UniversaPulsar Spinoff of University of Évora. The author Amal Bouich acknowledges MCIN for funding support through Margarita Salas Fellowship (MCIN/AEI/10.13039/501100011033). This work is partially funded by FCT/MCTES through national funds and when applicable co-funded EU funds under the project UIDB/EEA/50008/2020.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ma, T.; Yang, H.; Lu, L. Feasibility study of a stand-alone hybrid solar–wind–battery system for a remote island. Appl. Energy 2014, 121, 149–158. [Google Scholar] [CrossRef]

- Hayat, M.B.; Ali, D.; Monyake, K.C.; Alagha, L.; Ahmed, N. Solar energy—A look into power generation, challenges, and a solar-powered future. Int. J. Energy Res. 2019, 43, 1049–1067. [Google Scholar] [CrossRef]

- Usman, Z.; Tah, J.; Abanda, H.; Nche, C. A critical appraisal of pv-systems’ performance. Buildings 2020, 10, 192. [Google Scholar] [CrossRef]

- Ali, W.; Farooq, H.; Rehman, A.U.; Awais, Q.; Jamil, M.; Noman, A. Design Considerations of Stand-Alone Solar Photovoltaic Systems. In Proceedings of the International Conference on Computing, Electronic and Electrical Engineering (ICE Cube), Quetta, Pakistan, 12–13 November 2018; pp. 1–6. [Google Scholar]

- Khan, S.U.; Wazeer, I.; Almutairi, Z.; Alanazi, M. Techno-economic analysis of solar photovoltaic powered electrical energy storage (EES) system. Alex. Eng. J. 2021, 61, 6739–6753. [Google Scholar] [CrossRef]

- Blum, S.; Buckland, M.; Sack, T.L.; Fivenson, D. Greening the office: Saving resources, saving money, and educating our patients. Int. J. Women’s Dermatol. 2021, 7, 112–116. [Google Scholar] [CrossRef] [PubMed]

- Gołębiowska, A.; Jakubczak, W.; Prokopowicz, D.; Jakubczak, R. The Post-Pandemic Development of the Green Circular Economy and the Declarations Made During the UN Climate Change Conference (COP26) as Security Determinants. Eur. Res. Stud. J. 2021, 24, 251–275. [Google Scholar] [CrossRef]

- Energy Informative. How Much Do Solar Panels Cost. Available online: https://energyinformative.org/solarpanelscost/ (accessed on 25 December 2019).

- Yu, Y.; Wang, K.; Zhang, T.; Wang, Y.; Peng, C.; Gao, S. A population diversity-controlled differential evolution for parameter estimation of solar photovoltaic models. Sustain. Energy Technol. Assess. 2022, 51, 101938. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Y.; Su, J.; Gu, T.; Yang, M. Modeling and prediction of PV module performance under different operating conditions based on power-law I–V model. IEEE J. Photovolt. 2020, 10, 1816–1827. [Google Scholar] [CrossRef]

- National Renewable Energy Laboratory (NREL), Research Cell Efficiency Records. Available online: https://www.nrel.gov/pv/assets/images/efficiency-chart.png (accessed on 19 June 2021).

- Thebault, M.; Gaillard, L. Optimization of the integration of photovoltaic systems on buildings for selfconsumption–Case study in France. City Environ. Interact. 2021, 10, 100057. [Google Scholar] [CrossRef]

- Nezamisavojbolaghi, M.; Davodian, E.; Bouich, A.; Tlemçani, M. Characterization and Sensitivity Analysis of a Photovoltaic Panel. Adv. Energy Convers. Mater. 2023, 4, 164–173. [Google Scholar] [CrossRef]

- Long, W.; Jiao, J.; Liang, X.; Xu, M.; Tang, M.; Cai, S. Parameters estimation of photovoltaic models using a novel hybrid seagull optimization algorithm. Energy 2022, 249, 123760. [Google Scholar] [CrossRef]

- Gueymard, C.A. The sun’s total and spectral irradiance for solar energy application and solar radiation models. Sol. Energy 2004, 76, 423–453. [Google Scholar] [CrossRef]

- Thongpao, K.; Sripadungtham, P.; Raphisak, P.; Sriprapha, K.; Ekkachart, O. Solar cells based on the influence of irradiance and module temperature. In Proceedings of the Electrical Engineering/Electronics Computer Telecommunications and Information Technology (ECTI-CON), International Conference, Chiang Mai, Thailand, 19–21 May 2010; pp. 153–160. [Google Scholar]

- Al-Salihi, A.M.; Kadum, M.M.; Mohammed, A.G. Estimation of global solar radiation on horizontal surface using meteorological measurement for different cities in Iraq. Asian J. Sci. Res. 2010, 3, 240–248. [Google Scholar] [CrossRef][Green Version]

- Dutton, E.G.; Michalsky, J.J.; Stoffel, T.; Forgan, B.W.; Hickey, J.; Nelson, D.W.; Alberta, T.L.; Reda, I. Measurement of broadband diffuse solar irradiance using current commercial instrumentation with a correction for thermal offset errors. J. Atmos. Ocean. Technol. 2001, 18, 297–314. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Kazem, H.A. Experimental analysis of solar intensity on photovoltaic in hot and humid weather conditions. Int. J. Sci. Eng. Res. 2016, 7, 91–96. [Google Scholar]

- Kazem, H.A.; Chaichan, M.T.; Alwaeli, A.H.; Mani, K. Effect of shadows on the performance of solar photovoltaic. In Mediterranean Green Buildings & Renewable Energy: Selected Papers from the World Renewable Energy Network′s Med Green Forum; Springer International Publishing: Cham, Switzerland, 2017; pp. 379–385. [Google Scholar]

- Kazem, H.A.; Chaichan, M.T. The impact of using solar colored filters to cover the PV panel on its outcomes. Bull. J. 2016, 2, 464–469. [Google Scholar] [CrossRef]

- Siddiqui, R.; Bajpai, U. Deviation in the performance of solar module under climatic parameter as ambient temperature and wind velocity in composite climate. Int. J. Renew. Energy Res. 2012, 2, 486–490. [Google Scholar]

- Jathar, L.D.; Ganesan, S.; Awasarmol, U.; Nikam, K.; Shahapurkar, K.; Soudagar, M.E.; Fayaz, H.; El-Shafay, A.S.; Kalam, M.A.; Boudila, S.; et al. Comprehensive review of environmental factors influencing the performance of photovoltaic panels: Concern over emissions at various phases throughout the lifecycle. Environ. Pollut. 2023, 326, 121474. [Google Scholar] [CrossRef]

- Winkelmann, U.; Kämper, C.; Höffer, R.; Forman, P.; Ahrens, M.A.; Mark, P. Wind actions on large-aperture parabolic trough solar collectors: Wind tunnel tests and structural analysis. Renew. Energy 2020, 146, 2390–2407. [Google Scholar] [CrossRef]

- Wood, G.S.; Denoon, R.O.; Kwok, K.C. Wind loads on industrial solar panel arrays and supporting roof structure. Wind Struct. 2001, 4, 481–494. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Kazem, H.A.; Kazem, A.A.; Abaas, K.I.; Al-Asadi, K.A.H. The effect of environmental conditions on concentrated solar system in desertec weathers. Int. J. Sci. Eng. Res. 2015, 6, 850–856. [Google Scholar]

- Kazem, H.A.; Chaichan, M.T.; Saif, S.A.; Dawood, A.A.; Salim, S.A.; Rashid, A.A.; Alwaeli, A.A. Experimental investigation of dust type effect on photovoltaic systems in north region, Oman. Int. J. Sci. Eng. Res. 2015, 6, 293–298. [Google Scholar]

- Amer Dahham, I.; Mohd Zainuri, M.A.; Abdullah, A.A.; Fauzan, M.F. Modeling the Effect of Dust and Wind Speed on Solar Panel Performance in Iraq. Energies 2023, 16, 6397. [Google Scholar] [CrossRef]

- Deepak; Malvi, C.S. Experimental investigation of Different types of Dust effect on the Grid-connected Rooftop Solar Power Plant. Energy Sources Part A Recovery Util. Environ. Effects. 2023, 45, 12343–12364. [Google Scholar] [CrossRef]

- Shariah, A.; Al-Ibrahim, E.A. Impact of Dust and Shade on Solar Panel Efficiency and Development of a Simple Method for Measuring the Impact of Dust. J. Sustain. Dev. Energy Water Environ. Syst. 2023, 11, 1–14. [Google Scholar] [CrossRef]

- Ghosh, S.; Yadav, V.K.; Mukherjee, V. Impact of environmental factors on photovoltaic performance and their mitigation strategies–A holistic review. Renew. Energy Focus 2019, 28, 153–172. [Google Scholar] [CrossRef]

- Salim, S.; Narayanan, D. The dust attenuation law in galaxies. Annu. Rev. Astron. Astrophys. 2020, 58, 529–575. [Google Scholar] [CrossRef]

- Ma, X.; Hayward, C.C.; Casey, C.M.; Hopkins, P.F.; Quataert, E.; Liang, L.; Faucher-Giguère, C.A.; Feldmann, R.; Kereš, D. Dust attenuation, dust emission, and dust temperature in galaxies at z ≥ 5: A view from the FIRE-2 simulations. Mon. Not. R. Astron. Soc. 2019, 487, 1844–1864. [Google Scholar] [CrossRef]

- Rajput, P.; Tiwari, G.N.; Sastry, O.S. Thermal modelling with experimental validation and economic analysis of mono crystalline silicon photovoltaic module on the basis of degradation study. Energy 2017, 120, 731–739. [Google Scholar] [CrossRef]

- Al-Shabaan, G.; Shehab, W.A.; Abu-Al-Aish, A.; Al-Sawalmeh, W.; Al-Shaweesh, M. Effects of dust grain size and density on the monocrystalline PV output power. Int. J. Appl. Sci. Technol. 2016, 6, 81–86. [Google Scholar]

- Khan, R.A.; Farooqui, S.A.; Khan, M.H.; Sarfraz, M.; Luqman, M.; Khan, M.F. Dust deposition on PV module and its characteristics. In The Effects of Dust and Heat on Photovoltaic Modules: Impacts and Solutions; Springer: Cham, Switzerland, 2022; pp. 59–95. [Google Scholar]

- Szabó, S.; Moner-Girona, M.; Kougias, I.; Bailis, R.; Bódis, K. Identification of advantageous electricity generation options in sub-Saharan Africa integrating existing resources. Nature Energy 2016, 1, 16140. [Google Scholar] [CrossRef]

- Dida, M.; Boughali, S.; Bechki, D.; Bouguettaia, H. Output power loss of crystalline silicon photovoltaic modules due to dust accumulation in Saharan environment. Renew. Sustain. Energy Rev. 2020, 124, 109787. [Google Scholar] [CrossRef]

- Chanchangi, Y.N.; Ghosh, A.; Sundaram, S.; Mallick, T.K. Dust and PV performance in Nigeria: A review. Renew. Sustain. Energy Rev. 2020, 121, 109704. [Google Scholar] [CrossRef]

- Pan, A.; Lu, H.; Zhang, L. Experimental investigation of dust deposition reduction on solar cell covering glass by different self-cleaning coatings. Energy 2019, 181, 645–653. [Google Scholar] [CrossRef]

- Elminir, H.K.; Ghitas, A.E.; Hamid, R.H.; El-Hussainy, F.; Beheary, M.M.; Abdel-Moneim, K.M. Effect of dust on the transparent cover of solar collectors. Energy Convers. Manag. 2006, 47, 3192–3203. [Google Scholar] [CrossRef]

- Vivar, M.; Herrero, R.; Antón, I.; Martínez-Moreno, F.; Moretón, R.; Sala, G.; Blakers, A.W.; Smeltink, J. Effect of soiling in CPV systems. Sol. Energy 2010, 84, 1327–1335. [Google Scholar] [CrossRef]

- Asl-Soleimani, E.; Farhangi, S.; Zabihi, M.S. The effect of tilt angle, air pollution on performance of photovoltaic systems in Tehran. Renew. Energy 2001, 24, 459–468. [Google Scholar] [CrossRef]

- Mustafa, R.J.; Gomaa, M.R.; Al-Dhaifallah, M.; Rezk, H. Environmental impacts on the performance of solar photovoltaic systems. Sustainability 2020, 12, 608. [Google Scholar] [CrossRef]

- Rashid, M.; Yousif, M.; Rashid, Z.; Muhammad, A.; Altaf, M.; Mustafa, A. Effect of Dust Accumulation on the Performance of Photovoltaic Modules for Different Climate Regions. Heliyon 2023, 9, e23069. [Google Scholar] [CrossRef]

- Aravind, G.; Vasan, G.; Kumar, T.G.; Balaji, R.N.; Ilango, G.S. A control strategy for an autonomous robotic vacuum cleaner for solar panels. In Proceedings of the 2014 Texas Instruments India Educators’ Conference (TIIEC), Bangalore, India, 4–5 April 2014; pp. 53–61. [Google Scholar]

- Halbhavi, S.B.; Kulkarni, S.G.; Kulkarni, D.B. Microcontroller based automatic cleaning of solar panel. Int. J. Latest Trends Eng. Technol. 2015, 5, 99–103. [Google Scholar]

- Kurokawa, K. Energy from the Desert: Feasibility of Very Large Scale Power Generation (VLS-PV) Systems; Taylor and Francis: Abingdon, UK, 2012. [Google Scholar]

- Mondal, A.K.; Bansal, K. Structural analysis of solar panel cleaning robotic arm. Curr. Sci. 2015, 108, 1047–1052. [Google Scholar]

- Siddiqui, R.; Bajpai, U. Correlation between thicknesses of dust collected on photovoltaic module and difference in efficiencies in composite climate. Int. J. Energy Environ. Eng. 2012, 3, 26. [Google Scholar] [CrossRef]

- Agrawal, S.; Tiwari, G.N. Overall energy, exergy and carbon credit analysis by different type of hybrid photovoltaic thermal air collectors. Energy Convers. Manag. 2013, 65, 628–636. [Google Scholar] [CrossRef]

- Diomandé, I.; Bouich, A.; Nezamisavojbolaghi, M.; Tlemçani, M.; Soucasse, B.M.; Boko, A. Optimization of the MA/FA Ratio in the Structure of Absorber Layers Based on MA (1-x) FAxPbI3 Perovskites for Stable and Efficient Solar Cells. Adv. Energy Convers. Mater. 2023, 4, 147–163. [Google Scholar] [CrossRef]

- Katkar, A.A.; Shinde, N.N.; Patil, P.S. Performance & evaluation of industrial solar cell wrt temperature and humidity. Int. J. Res. Mech. Eng. Technol. 2011, 1, 69–73. [Google Scholar]

- Kaldellis, J.K.; Kapsali, M.; Kavadias, K.A. Temperature and wind speed impact on the efficiency of PV installations. Experience obtained from outdoor measurements in Greece. Renew. Energy 2014, 66, 612–624. [Google Scholar] [CrossRef]

- Malik, A.Q.; Damit, S.J. Outdoor testing of single crystal silicon solar cells. Renew. Energy 2003, 28, 1433–1445. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hasanuzzaman, M.; Rahim, N.A. Effects of various parameters on PV-module power and efficiency. Energy Convers. Manag. 2015, 103, 348–358. [Google Scholar] [CrossRef]

- Thong, L.W.; Murugan, S.; Ng, P.K.; Sun, C.C. Analysis of photovoltaic panel temperature effects on its efficiency. In Proceedings of the 2nd International Conference on Electrical Engineering and Electronics Communication System, Ho Chi Minh, Vietnam, 18–19 November 2016. [Google Scholar]

- Fan, S.; Wang, Y.; Cao, S.; Sun, T.; Liu, P. A novel method for analyzing the effect of dust accumulation on energy efficiency loss in photovoltaic (PV) system. Energy 2021, 234, 121112. [Google Scholar] [CrossRef]

- Vedulla, G.; Geetha, A. Dust accumulation on solar photovoltaic panels: An investigation study on power loss and efficiency reduction. Therm. Sci. 2023, 27, 2967–2976. [Google Scholar] [CrossRef]

- Abraim, M.; Salihi, M.; El Alani, O.; Hanrieder, N.; Ghennioui, H.; Ghennioui, A.; El Ydrissi, M.; Azouzoute, A. Techno-economic assessment of soiling losses in CSP and PV solar power plants: A case study for the semi-arid climate of Morocco. Energy Convers. Manag. 2022, 270, 116285. [Google Scholar] [CrossRef]

- Ilse, K.; Micheli, L.; Figgis, B.W.; Lange, K.; Daßler, D.; Hanifi, H.; Wolfertstetter, F.; Naumann, V.; Hagendorf, C.; Gottschalg, R.; et al. Techno-economic assessment of soiling losses and mitigation strategies for solar power generation. Joule 2019, 3, 2303–2321. [Google Scholar] [CrossRef]

- Abderrezek, M.; Fathi, M. Experimental study of the dust effect on photovoltaic panels’ energy yield. Sol. Energy 2017, 142, 308–320. [Google Scholar] [CrossRef]

- Gu, Q.; Li, S.; Gong, W.; Ning, B.; Hu, C.; Liao, Z. L-SHADE with parameter decomposition for photovoltaic modules parameter identification under different temperature and irradiance. Appl. Soft Comput. 2023, 143, 110386. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Ahmed, M.; Rezk, H. Temperature distribution modeling of PV and cooling water PV/T collectors through thin and thick cooling cross-fined channel box. Energy Rep. 2022, 8, 1144–1153. [Google Scholar] [CrossRef]

- Rusănescu, C.O.; Rusănescu, M.; Istrate, I.A.; Constantin, G.A.; Begea, M. The Effect of Dust Deposition on the Performance of Photovoltaic Panels. Energies 2023, 16, 6794. [Google Scholar] [CrossRef]

- Zereg, K.; Gama, A.; Aksas, M.; Rathore, N.; Yettou, F.; Panwar, N.L. Dust impact on concentrated solar power: A review. Environ. Eng. Res. 2022, 27, 210345. [Google Scholar] [CrossRef]

- Picotti, G.; Borghesani, P.; Cholette, M.E.; Manzolini, G. Soiling of solar collectors C Modelling approaches for airborne dust and its interactions with surfaces. Renew. Sustain. Energy Rev. 2018, 81, 2343–2357. [Google Scholar] [CrossRef]

- Alsharif, A.H.; Ahmed, A.A.; Nassar, Y.F.; Khaleel, M.M.; El-Khozondar, H.J.; Alhoudier, T.E.; Esmail, E.M. Mitigation of dust impact on solar photovoltaics performance considering Libyan climate zone: A review. Wadi Alshatti Univ. J. Pure Appl. Sci. 2023, 1, 22–27. [Google Scholar]

- Sahouane, N.; Ziane, A.; Dabou, R.; Neçaibia, A.; Rouabhia, A.; Lachtar, S.; Blal, M.; Slimani, A.; Boudjamaa, T. Technical and economic study of the sand and dust accumulation impact on the energy performance of photovoltaic system in Algerian Sahara. Renew. Energy 2023, 205, 142–155. [Google Scholar] [CrossRef]

- Khatib, T.; Kazem, H.; Sopian, K.; Buttinger, F.; Elmenreich, W.; Albusaidi, A.S. Effect of dust deposition on the performance of multi-crystalline photovoltaic modules based on experimental measurements. Int. J. Renew. Energy Res. 2013, 3, 850–853. [Google Scholar]

- Al-Waeli, A.H.; Chaichan, M.T.; Kazem, H.A.; Sopian, K.; Ibrahim, A.; Mat, S.; Ruslan, M.H. Comparison study of indoor/outdoor experiments of a photovoltaic thermal PV/T system containing SiC nanofluid as a coolant. Energy 2018, 151, 33–44. [Google Scholar] [CrossRef]

- Song, Z.; Liu, J.; Yang, H. Air pollution and soiling implications for solar photovoltaic power generation: A comprehensive review. Appl. Energy 2021, 298, 117247. [Google Scholar] [CrossRef]

- Bombach, E.; Röver, I.; Müller, A.; Schlenker, S.; Wambach, K.; Kopecek, R.; Wefringhaus, E. Technical experience during thermal and chemical recycling of a 23-year-old PV generator formerly installed on Pellworm island. In Proceedings of the 21st European Photovoltaic Solar Energy Conference, Dresden, Germany, 4–8 September 2006; pp. 4–8. [Google Scholar]

- El-Shobokshy, M.S.; Hussein, F.M. Degradation of photovoltaic cell performance due to dust deposition on to its surface. Renew. Energy 1993, 3, 585–590. [Google Scholar] [CrossRef]

- Guan, Y.; Zhang, H.; Xiao, B.; Zhou, Z.; Yan, X. In-situ investigation of the effect of dust deposition on the performance of polycrystalline silicon photovoltaic modules. Renew. Energy 2017, 101, 1273–1284. [Google Scholar] [CrossRef]

- Mekhilef, S.; Saidur, R.; Kamalisarvestani, M. Effect of dust, humidity and air velocity on efficiency of photovoltaic cells. Renew. Sustain. Energy Rev. 2012, 16, 2920–2925. [Google Scholar] [CrossRef]

- Zaihidee, F.M.; Mekhilef, S.; Seyedmahmoudian, M.; Horan, B. Dust as an unalterable deteriorative factor affecting PV panel’s efficiency: Why and how. Renew. Sustain. Energy Rev. 2016, 65, 1267–1278. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Mohammed, B.A.; Kazem, H.A. Effect of pollution and cleaning on photovoltaic performance based on experimental study. Int. J. Sci. Eng. Res. 2015, 6, 594–601. [Google Scholar]

- Darwish, Z.A.; Kazem, H.A.; Sopian, K.; Alghoul, M.A.; Chaichan, M.T. Impact of some environmental variables with dust on solar photovoltaic (PV) performance: Review and research status. Int. J. Energy Environ. 2013, 7, 152–159. [Google Scholar]

- Kaldellis, J.K.; Kokala, A. Quantifying the decrease of the photovoltaic panels’ energy yield due to phenomena of natural air pollution disposal. Energy 2010, 35, 4862–4869. [Google Scholar] [CrossRef]

- Zheng, J.; Chen, K.H.; Yan, X.; Chen, S.J.; Hu, G.C.; Peng, X.W.; Yuan, J.G.; Mai, B.X.; Yang, Z.Y. Heavy metals in food, house dust, and water from an e-waste recycling area in South China and the potential risk to human health. Ecotoxicol. Environ. Saf. 2013, 96, 205–212. [Google Scholar] [CrossRef]

- Pierro, M.; Gentili, D.; Liolli, F.R.; Cornaro, C.; Moser, D.; Betti, A.; Moschella, M.; Collino, E.; Ronzio, D.; van Der Meer, D. Progress in regional PV power forecasting: A sensitivity analysis on the Italian case study. Renew. Energy 2022, 189, 983–996. [Google Scholar] [CrossRef]

- Belsky, A.A.; Glukhanich, D.Y.; Carrizosa, M.J.; Starshaia, V.V. Analysis of specifications of solar photovoltaic panels. Renew. Sustain. Energy Rev. 2022, 159, 112239. [Google Scholar] [CrossRef]

- Jiang, H.; Lu, L.; Sun, K. Experimental investigation of the impact of airborne dust deposition on the performance of solar photovoltaic (PV) modules. Atmos. Environ. 2011, 45, 4299–4304. [Google Scholar] [CrossRef]

- Said, Z.; Hachicha, A.A.; Aberoumand, S.; Yousef, B.A.; Sayed, E.T.; Bellos, E. Recent advances on nanofluids for low to medium temperature solar collectors: Energy, exergy, economic analysis and environmental impact. Prog. Energy Combust. Sci. 2021, 84, 100898. [Google Scholar] [CrossRef]

- Zarei, T.; Abdolzadeh, M. Optical and thermal modeling of a tilted photovoltaic module with sand particles settled on its front surface. Energy 2016, 95, 51–66. [Google Scholar] [CrossRef]

- Kalogirou, S.A.; Agathokleous, R.; Panayiotou, G. On-site PV characterization and the effect of soiling on their performance. Energy 2013, 51, 439–446. [Google Scholar] [CrossRef]

- Boyle, L.; Flinchpaugh, H.; Hannigan, M.P. Natural soiling of photovoltaic cover plates and the impact on transmission. Renew. Energy 2015, 77, 166–173. [Google Scholar] [CrossRef]

- Laarabi, B.; El Baqqal, Y.; Dahrouch, A.; Barhdadi, A. Deep analysis of soiling effect on glass transmittance of PV modules in seven sites in Morocco. Energy 2020, 213, 118811. [Google Scholar] [CrossRef]

- Kazem, H.A.; Khatib, T.; Sopian, K.; Elmenreich, W. Performance and feasibility assessment of a 1.4 kW roof top grid-connected photovoltaic power system under desertic weather conditions. Energy Build. 2014, 82, 123–129. [Google Scholar] [CrossRef]

- Said, S.A.; Walwil, H.M. Fundamental studies on dust fouling effects on PV module performance. Sol. Energy 2014, 107, 328–337. [Google Scholar] [CrossRef]

- Paudyal, B.R.; Shakya, S.R. Dust accumulation effects on efficiency of solar PV modules for off grid purpose: A case study of Kathmandu. Sol. Energy 2016, 135, 103–110. [Google Scholar] [CrossRef]

- Maghami, M.R.; Hizam, H.; Gomes, C.; Radzi, M.A.; Rezadad, M.I.; Hajighorbani, S. Power loss due to soiling on solar panel: A review. Renew. Sustain. Energy Rev. 2016, 59, 1307–1316. [Google Scholar] [CrossRef]

- Ghosh, A. Soiling losses: A barrier for India’s energy security dependency from photovoltaic power. Challenges 2020, 11, 9. [Google Scholar] [CrossRef]

- Beattie, N.S.; Moir, R.S.; Chacko, C.; Buffoni, G.; Roberts, S.H.; Pearsall, N.M. Understanding the effects of sand and dust accumulation on photovoltaic modules. Renew. Energy 2012, 48, 448–452. [Google Scholar] [CrossRef]

- Hegazy, A.A. Effect of dust accumulation on solar transmittance through glass covers of plate-type collectors. Renew. Energy 2001, 22, 525–540. [Google Scholar] [CrossRef]

- Obaid, N.M.; Sultan, H.S.; Abed, A.M.; Jweeg, M.J.; Abdullah, O. A New Correlation for Solar Radiation Incidence Angle and Dust Accumulation of Photovoltaic PV Systems. Environ. Res. Eng. Manag. 2023, 79, 56–68. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Al-Othman, A.; Kafiah, F.; Abdelsalam, E.; Almomani, F.; Alkasrawi, M. Environmental impacts of solar photovoltaic systems: A critical review of recent progress and future outlook. Sci. Total Environ. 2021, 759, 143528. [Google Scholar] [CrossRef]

- Chen, J.; Pan, G.; Ouyang, J.; Ma, J.; Fu, L.; Zhang, L. Study on impacts of dust accumulation and rainfall on PV power reduction in East China. Energy 2020, 194, 116915. [Google Scholar] [CrossRef]

- Saini, R.K.; Saini, D.K.; Gupta, R.; Verma, P.; Dwivedi, R.P.; Kumar, A.; Chauhan, D.; Kumar, S. Effects of dust on the performance of solar panels—A review update from 2015–2020. Energy Environ. 2023, 34, 2110–2162. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Fragos, P.; Kapsali, M. Systematic experimental study of the pollution deposition impact on the energy yield of photovoltaic installations. Renew. Energy 2011, 36, 2717–2724. [Google Scholar] [CrossRef]

- Moharram, K.A.; Abd-Elhady, M.S.; Kandil, H.A.; El-Sherif, H. Influence of cleaning using water and surfactants on the performance of photovoltaic panels. Energy Convers. Manag. 2013, 68, 266–272. [Google Scholar] [CrossRef]

- Isaacs, S.; Kalashnikova, O.; Garay, M.J.; van Donkelaar, A.; Hammer, M.S.; Lee, H.; Wood, D. Dust soiling effects on decentralized solar in West Africa. Appl. Energy 2023, 340, 120993. [Google Scholar] [CrossRef]

- De Longueville, F.; Hountondji, Y.C.; Henry, S.; Ozer, P. What do we know about effects of desert dust on air quality and human health in West Africa compared to other regions? Sci. Total Environ. 2010, 409, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Middleton, N.J. Desert dust hazards: A global review. Aeolian Res. 2017, 24, 53–63. [Google Scholar] [CrossRef]

- Almukhtar, H.; Lie, T.T.; Al-Shohani, W.A.; Anderson, T.; Al-Tameemi, Z. Comprehensive Review of Dust Properties and Their Influence on Photovoltaic Systems: Electrical, Optical, Thermal Models and Experimentation Techniques. Energies 2023, 16, 3401. [Google Scholar] [CrossRef]

- Chanchangi, Y.N.; Ghosh, A.; Sundaram, S.; Mallick, T.K. An analytical indoor experimental study on the effect of soiling on PV, focusing on dust properties and PV surface material. Sol. Energy 2020, 203, 46–68. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T. Experimental analysis of the effect of dust’s physical properties on photovoltaic modules in Northern Oman. Sol. Energy 2016, 139, 68–80. [Google Scholar] [CrossRef]

- Styszko, K.; Jaszczur, M.; Teneta, J.; Hassan, Q.; Burzyńska, P.; Marcinek, E.; Łopian, N.; Samek, L. An analysis of the dust deposition on solar photovoltaic modules. Environ. Sci. Pollut. Res. 2019, 26, 8393–8401. [Google Scholar] [CrossRef]

- Sayigh, A.; Al-Jandal, S.; Ahmed, H. Dust effect on solar flat surfaces devices in Kuwait. In Proceedings of the Workshop on the Physics of Non-Conventional Energy Sources and Materials Science for Energy, Triest, Italy, 2–20 September 1985; pp. 353–367. [Google Scholar]

- Guo, B.; Javed, W.; Figgis, B.W.; Mirza, T. Effect of dust and weather conditions on photovoltaic performance in Doha, Qatar. In Proceedings of the 2015 First Workshop on Smart Grid and Renewable Energy (SGRE), Doha, Qatar, 22–23 March 2015; pp. 1–6. [Google Scholar]

- Costa, S.C.; Diniz, A.S.; Kazmerski, L.L. Dust and soiling issues and impacts relating to solar energy systems: Literature review update for 2012–2015. Renew. Sustain. Energy Rev. 2016, 63, 33–61. [Google Scholar] [CrossRef]

- Darwish, Z.A.; Kazem, H.A.; Sopian, K.; Al-Goul, M.A.; Alawadhi, H. Effect of dust pollutant type on photovoltaic performance. Renew. Sustain. Energy Rev. 2015, 41, 735–744. [Google Scholar] [CrossRef]

- Tabet, S.; Ihaddadene, R.; Guerira, B.; Ihaddadene, N. Impact of Dust and Degradation on the Electrical Properties of PV Panels. J. Renew. Energy Environ. 2023. [Google Scholar]

- Sarver, T.; Al-Qaraghuli, A.; Kazmerski, L.L. A comprehensive review of the impact of dust on the use of solar energy: History, investigations, results, literature, and mitigation approaches. Renew. Sustain. Energy Rev. 2013, 22, 698–733. [Google Scholar] [CrossRef]

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T. The effect of dust with different morphologies on the performance degradation of photovoltaic modules. Sustain. Energy Technol. Assess. 2019, 31, 347–354. [Google Scholar] [CrossRef]

- Hachicha, A.A.; Al-Sawafta, I.; Said, Z. Impact of dust on the performance of solar photovoltaic (PV) systems under United Arab Emirates weather conditions. Renew. Energy 2019, 141, 287–297. [Google Scholar] [CrossRef]

- Mohandes, B.M.; El-Chaar, L.; Lamont, L.A. Application study of 500 W photovoltaic (PV) system in the UAE. Appl. Sol. Energy 2009, 45, 242–247. [Google Scholar] [CrossRef]

- Adinoyi, M.J.; Said, S.A. Effect of dust accumulation on the power outputs of solar photovoltaic modules. Renew. Energy 2013, 60, 633–636. [Google Scholar] [CrossRef]

- Javed, W.; Wubulikasimu, Y.; Figgis, B.; Guo, B. Characterization of dust accumulated on photovoltaic panels in Doha, Qatar. Sol. Energy 2017, 142, 123–135. [Google Scholar] [CrossRef]

- Al-Kouz, W.; Al-Dahidi, S.; Hammad, B.; Al-Abed, M. Modeling and analysis framework for investigating the impact of dust and temperature on PV systems’ performance and optimum cleaning frequency. Appl. Sci. 2019, 9, 1397. [Google Scholar] [CrossRef]

- Alquthami, T.; Menoufi, K. Soiling of photovoltaic modules: Comparing between two distinct locations within the framework of developing the photovoltaic soiling index (PVSI). Sustainability 2019, 11, 4697. [Google Scholar] [CrossRef]

- Amin, A.; Wang, X.; Alroichdi, A.; Ibrahim, A. Designing and Manufacturing a Robot for Dry-Cleaning PV Solar Panels. Int. J. Energy Res. 2023, 2023, 7231554. [Google Scholar] [CrossRef]

- He, B.; Lu, H.; Zheng, C.; Wang, Y. Characteristics and cleaning methods of dust deposition on solar photovoltaic modules—A review. Energy 2023, 263, 126083. [Google Scholar] [CrossRef]

- Bi, E.G.; Monette, F.; Gasperi, J. Analysis of the influence of rainfall variables on urban effluents concentrations and fluxes in wet weather. J. Hydrol. 2015, 523, 320–332. [Google Scholar]

- Alvarez, D.L.; Al-Sumaiti, A.S.; Rivera, S.R. Estimation of an optimal PV panel cleaning strategy based on both annual radiation profile and module degradation. IEEE Access 2020, 8, 63832–63839. [Google Scholar] [CrossRef]

- Jadhao, M.; Patane, P.; Nadgire, A.; Utage, A. A study on impact of various solar panel cleaning methods on its performance. In Recent Advances in Materials and Modern Manufacturing: Select Proceedings of ICAMMM 2021; Springer Nature Singapore: Singapore, 2022; pp. 839–857. [Google Scholar]

- Fan, S.; Liang, W.; Wang, G.; Zhang, Y.; Cao, S. A novel water-free cleaning robot for dust removal from distributed photovoltaic (PV) in water-scarce areas. Sol. Energy 2022, 241, 553–563. [Google Scholar] [CrossRef]

- Alwaeli, A.A.; Chaichan, K.; Kazem, H.A. Effect of dust on photovoltaic utilization in Iraq: Review Article. Renew. Sustain. Energy Rev. 2014, 37, 734–749. [Google Scholar]

- Dumrul, H.; Fatih, A.R.; Taşkesen, E. Dust Effect on PV Modules: Its Cleaning Methods. Innov. Res. Eng. 2023, 183–200. [Google Scholar]

- Sayyah, A.; Horenstein, M.N.; Mazumder, M.K. Energy yield loss caused by dust deposition on photovoltaic panels. Sol. Energy 2014, 107, 576–604. [Google Scholar] [CrossRef]

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T. Seasonal effect of dust on the degradation of PV modules performance deployed in different climate areas. Renew. Energy 2017, 111, 105–115. [Google Scholar] [CrossRef]

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T. Energy and economic losses caused by dust on residential photovoltaic (PV) systems deployed in different climate areas. Renew. Energy 2018, 120, 401–412. [Google Scholar] [CrossRef]

- Tanesab, J.; Letik, M.D.; Tino, A.A.; Peli, Y.S. Experimental study of dust impact on power output degradation of various photovoltaic technologies deployed in West Timor, Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2018, 188, 012038. [Google Scholar] [CrossRef]

- Kapsalis, V.; Maduta, C.; Skandalos, N.; Wang, M.; Bhuvad, S.S.; D’Agostino, D.; Ma, T.; Raj, U.; Parker, D.; Peng, J.; et al. Critical assessment of large-scale rooftop photovoltaics deployment in the global urban environment. Renew. Sustain. Energy Rev. 2024, 189, 114005. [Google Scholar] [CrossRef]

- Azouzoute, A.; Hajjaj, C.; Zitouni, H.; El Ydrissi, M.; Mertah, O.; Garoum, M.; Ghennioui, A. Modeling and experimental investigation of dust effect on glass cover PV module with fixed and tracking system under semi-arid climate. Sol. Energy Mater. Sol. Cells 2021, 230, 111219. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E. Degradation of electrical performance of a crystalline photovoltaic module due to dust deposition in northern Poland. Renew. Energy 2015, 78, 418–426. [Google Scholar] [CrossRef]

- Massi Pavan, A.; Mellit, A.; De Pieri, D. The effect of soiling on energy production for large-scale photovoltaic plants. Sol. Energy 2011, 85, 1128–1136. [Google Scholar] [CrossRef]

- Ndiaye, A.; Kébé, C.M.; Ndiaye, P.A.; Charki, A.; Kobi, A.; Sambou, V. Impact of dust on the photovoltaic (PV) modules characteristics after an exposition year in Sahelian environment: The case of Senegal. Int. J. Phys. Sci. 2013, 8, 1166–1173. [Google Scholar]

- Shenouda, R.; Abd-Elhady, M.S.; Kandil, H.A. A review of dust accumulation on PV panels in the MENA and the Far East regions. J. Eng. Appl. Sci. 2022, 69, 1–29. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T.; Al-Waeli, A.H.; Sopian, K. A review of dust accumulation and cleaning methods for solar photovoltaic systems. J. Clean. Prod. 2020, 276, 123187. [Google Scholar] [CrossRef]

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T.; Pryor, T. The contribution of dust to performance degradation of PV modules in a temperate climate zone. Sol. Energy 2015, 120, 147–157. [Google Scholar] [CrossRef]

- Qasem, H.; Betts, T.R.; Müllejans, H.; AlBusairi, H.; Gottschalg, R. Dust-induced shading on photovoltaic modules. Prog. Photovolt. Res. Appl. 2014, 22, 218–226. [Google Scholar] [CrossRef]

- Zere, T.; Ramahi, A.; Alamara, K.; Juaidi, A.; Abdallah, R.; Abdelkareem, M.A.; Amer, E.C.; Olabi, A.G. Effect of dust and methods of cleaning on the performance of solar PV module for different climate regions: Comprehensive review. Sci. Total Environ. 2022, 827, 154050. [Google Scholar]

- Del Pero, C.; Aste, N.; Leonforte, F. The effect of rain on photovoltaic systems. Renew. Energy 2021, 179, 1803–1814. [Google Scholar] [CrossRef]

- Şevik, S.; Aktaş, A. Performance enhancing and improvement studies in a 600 kW solar photovoltaic (PV) power plant; manual and natural cleaning, rainwater harvesting and the snow load removal on the PV arrays. Renew. Energy 2022, 181, 490–503. [Google Scholar] [CrossRef]

- Haeberlin, H.; Graf, J.D. Gradual reduction of PV generator yield due to pollution. Power [W] 1998, 1200, 1400. [Google Scholar]

- Appels, R.; Muthirayan, B.; Beerten, A.; Paesen, R.; Driesen, J.; Poortmans, J. The effect of dust deposition on photovoltaic modules. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012; pp. 001886–001889. [Google Scholar]

- Bethea, R.M.; Barriger, M.T.; Williams, P.F.; Chin, S. Environmental effects on solar concentrator mirrors. Sol. Energy 1981, 27, 497–511. [Google Scholar] [CrossRef]

- Alghamdi, A.S.; Bahaj, A.S.; Blunden, L.S.; Wu, Y. Dust removal from solar PV modules by automated cleaning systems. Energies 2019, 12, 2923. [Google Scholar] [CrossRef]

- Alqatari, S.; Alfaris, A.; de Weck, O.L. Cost and performance comparative model of dust mitigation technologies for solar PV in Saudi Arabia. In Proceedings of the International Conference on Environment and Renewable Energy, Bangkok, Thailand, 25–26 October 2015. [Google Scholar]

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T. Dust effect and its economic analysis on PV modules deployed in a temperate climate zone. Energy Procedia 2016, 100, 65–68. [Google Scholar] [CrossRef]

- Guo, B.; Figgis, B.; Javed, W. Measurement of electrodynamic dust shield efficiency in field conditions. J. Electrost. 2019, 97, 26–30. [Google Scholar] [CrossRef]

- Ju, F.; Fu, X. Research on impact of dust on solar photovoltaic (PV) performance. In Proceedings of the 2011 International Conference on Electrical and Control Engineering, Yichang, China, 16–18 September 2011; pp. 3601–3606. [Google Scholar]

- Ochsner, K. Geothermal Heat Pumps: A Guide for Planning and Installing; Routledge: London, UK, 2012. [Google Scholar]

- Mani, M.; Pillai, R. Impact of dust on solar photovoltaic (PV) performance: Research status, challenges and recommendations. Renew. Sustain. Energy Rev. 2010, 14, 3124–3131. [Google Scholar] [CrossRef]

- Anderson, M.; Grandy, A.; Hastie, J.; Sweezey, A.; Ranky, R.; Mavroidis, C.; Markopoulos, Y.P. Robotic device for cleaning photovoltaic panel arrays. In Mobile Robotics: Solutions and Challenges; World Scientific Publishing Co Pte Ltd.: Singapore, 2010; pp. 367–377. [Google Scholar]

- Tejwani, R.; Solanki, C.S. 360 sun tracking with automated cleaning system for solar PV modules. In Proceedings of the 2010 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; pp. 002895–002898. [Google Scholar]

- Al-Housani, M.; Bicer, Y.; Koç, M. Experimental investigations on PV cleaning of large-scale solar power plants in desert climates: Comparison of cleaning techniques for drone retrofitting. Energy Convers. Manag. 2019, 185, 800–815. [Google Scholar] [CrossRef]

- Kim, H.M.; Sohn, S.; Ahn, J.S. Transparent and super-hydrophobic properties of PTFE films coated on glass substrate using RF-magnetron sputtering and Cat-CVD methods. Surf. Coat. Technol. 2013, 228, S389–S392. [Google Scholar] [CrossRef]

- Zhang, M.; Feng, S.; Wang, L.; Zheng, Y. Lotus effect in wetting and self-cleaning. Biotribology 2016, 5, 31–43. [Google Scholar] [CrossRef]

- Mozumder, M.S.; Mourad, A.H.; Pervez, H.; Surkatti, R. Recent developments in multifunctional coatings for solar panel applications: A review. Sol. Energy Mater. Sol. Cells 2019, 189, 75–102. [Google Scholar] [CrossRef]

- Ekinci, F.; Yavuzdeğer, A.; Nazlıgül, H.; Esenboğa, B.; Mert, B.D.; Demirdelen, T. Experimental investigation on solar PV panel dust cleaning with solution method. Sol. Energy 2022, 237, 1–10. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).