Research on Hydrogen Production System Technology Based on Photovoltaic-Photothermal Coupling Electrolyzer

Abstract

1. Introduction

2. Current Status of Photovoltaic-Photothermal Development

2.1. Research Status

| Technology Application | Serial Number | Main Content | Main Conclusions | References |

|---|---|---|---|---|

| PV/T spotlight system design aspect | 1 | Simulation and experimental research were conducted on the thermoelectric output performance of a Fresnel high-power spotlight PV/T system based on direct microchannel cooling. | Stable output performance of the experimental system. | [51] |

| 2 | An optimized calculation method for the curvature radius of cylindrical mirrors was proposed. | Within a small range of the focusing plane, the energy flow density is high, and the uniformity is good, making it suitable for arranging photovoltaic cell modules. | [52,53] | |

| 3 | A study on systems without reflectors was conducted. | Significant improvement in overall efficiency. | [54] | |

| 4 | Proposed a new photovoltaic, photothermal, and integrated solar water supply system installed on the roof of buildings. | The system is more efficient when using thermal siphon fluid flow circulation and larger capacity storage tanks. | [55] | |

| 5 | A new type of PV/T heat pump system was proposed that combines PV panels with the heat pump system. | The photoelectric conversion efficiency of the experimental system can reach up to 15.50%. | [56] | |

| 6 | A new type of flat panel heat pipe solar PV/T system was designed. | The heat transfer performance of flat heat pipes is best when the channel filling rate is 65%. | [57] | |

| 7 | A new type of PV loop heat pipe hot water system was proposed. | In winter, it has higher photoelectric efficiency and comprehensive efficiency. | [58] | |

| 8 | A new type of heat pipe PV/T system was proposed. | The actual energy gain of the system is 29.09% higher than that of the single photovoltaic system. | [59] | |

| Improve the circulation/connection mode of the system | 1 | Using two different configurations of PV/T collectors in series. | At medium mass flow rate, for a large number of PV/T collectors connected in series, the results are basically the same in both cases. | [60] |

| 2 | Proposed a novel hybrid system that uses the cooling water of a spotlight PV/T system as the pre-hot water for the lithium bromide Kalina cycle. | Overall system efficiency improved by 22.00–27.00%. | [61] | |

| 3 | Based on the natural circulation PV/T hot water system, two different connection methods, series and parallel, were compared. | The heat that can be increased by series connection. | [62] | |

| 4 | Designed a direct expansion solar PV/T system using Freon R22 refrigerant as the medium. | Improved photoelectric efficiency by 16.30%. | [63] | |

| 5 | Established heat transfer models for different connection modes. | Obtained the optimal inclination angle combination. | [64] |

2.2. PV/T Coupled Electrolysis Cell for Hydrogen Production

3. PV/T-Coupled Electrolysis Cell for Hydrogen Production

3.1. Photovoltaic (PV) Systems

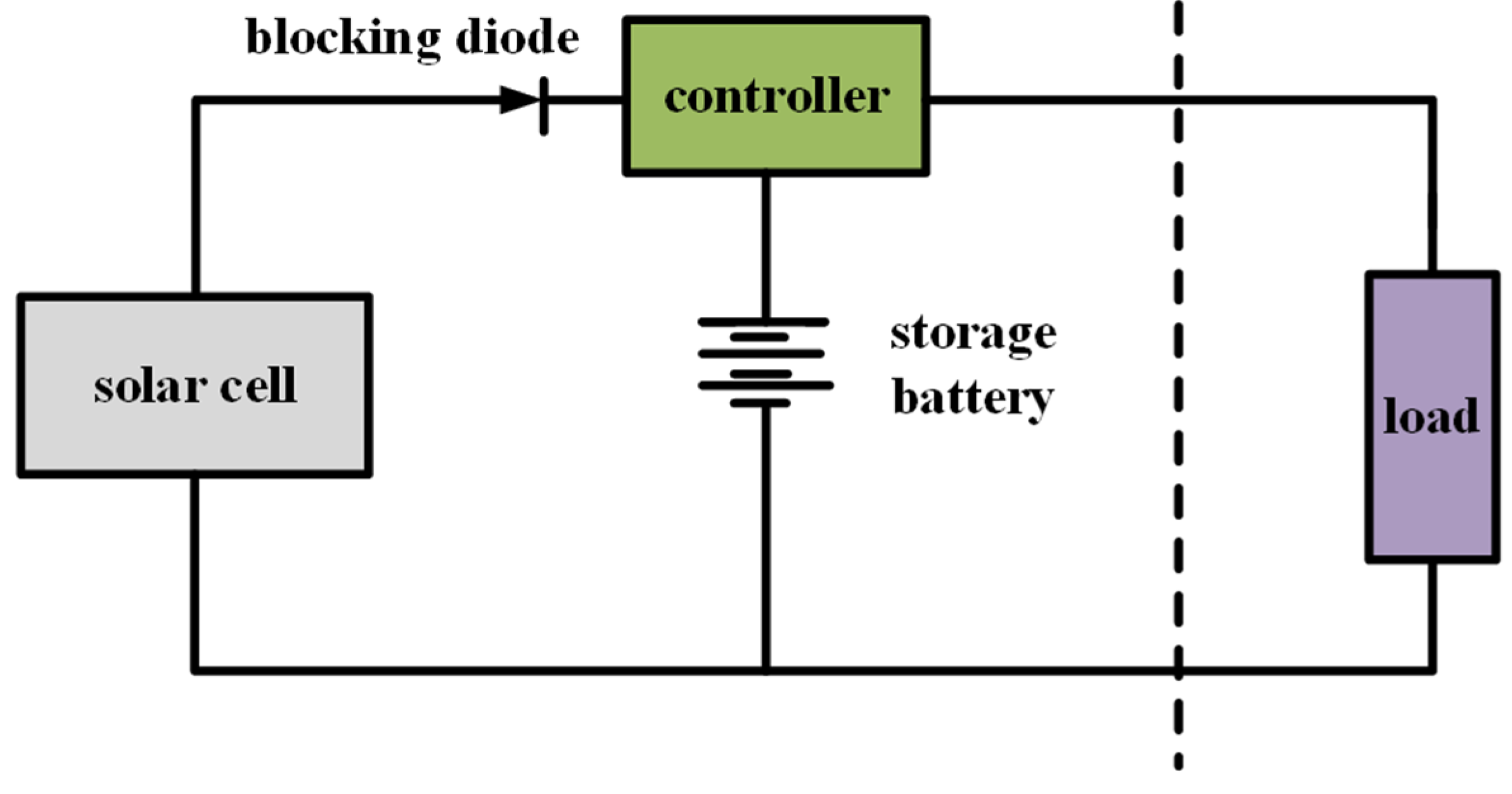

3.1.1. Independent Photovoltaic Power Generation Systems

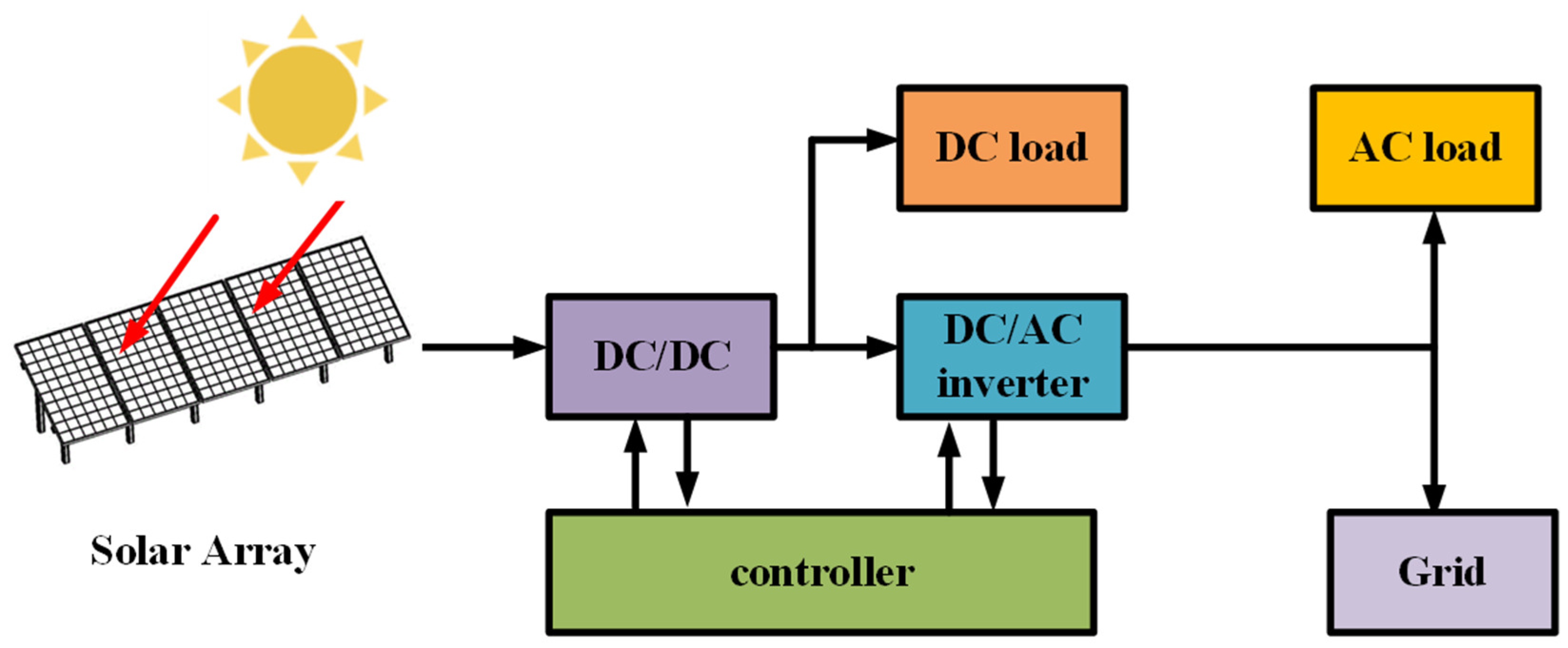

3.1.2. Grid-Connected Photovoltaic Systems

3.1.3. Hybrid Photovoltaic Systems

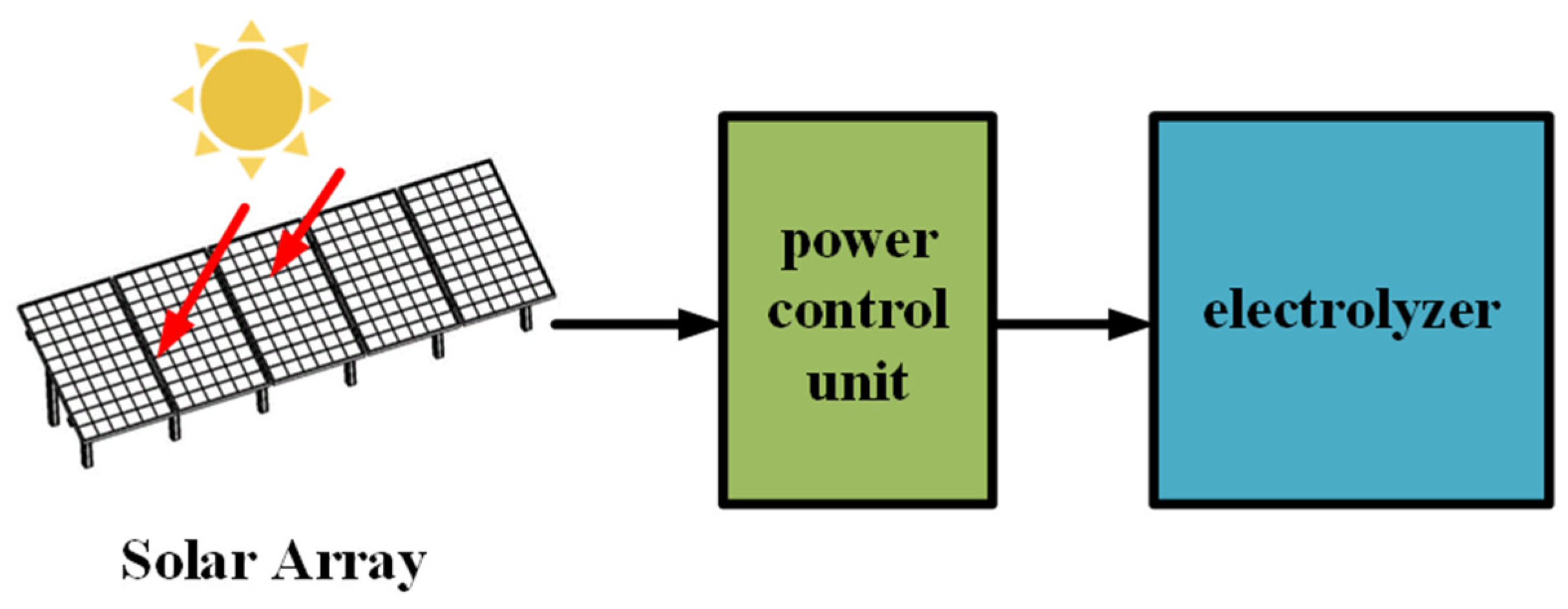

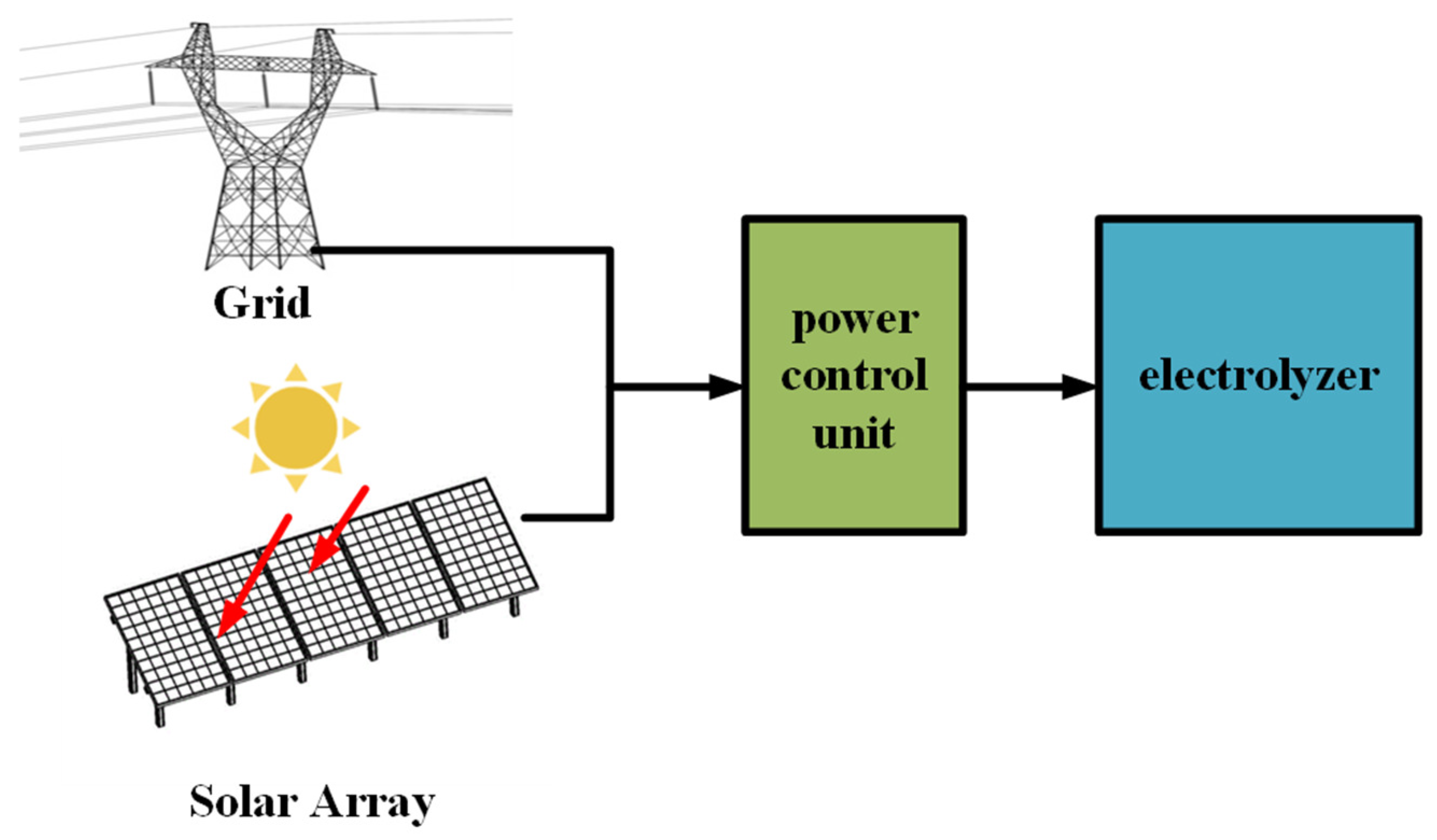

3.1.4. Photovoltaic Systems Coupled with Electrolytic Cell Power Supply

3.2. Photothermal (PT) Systems

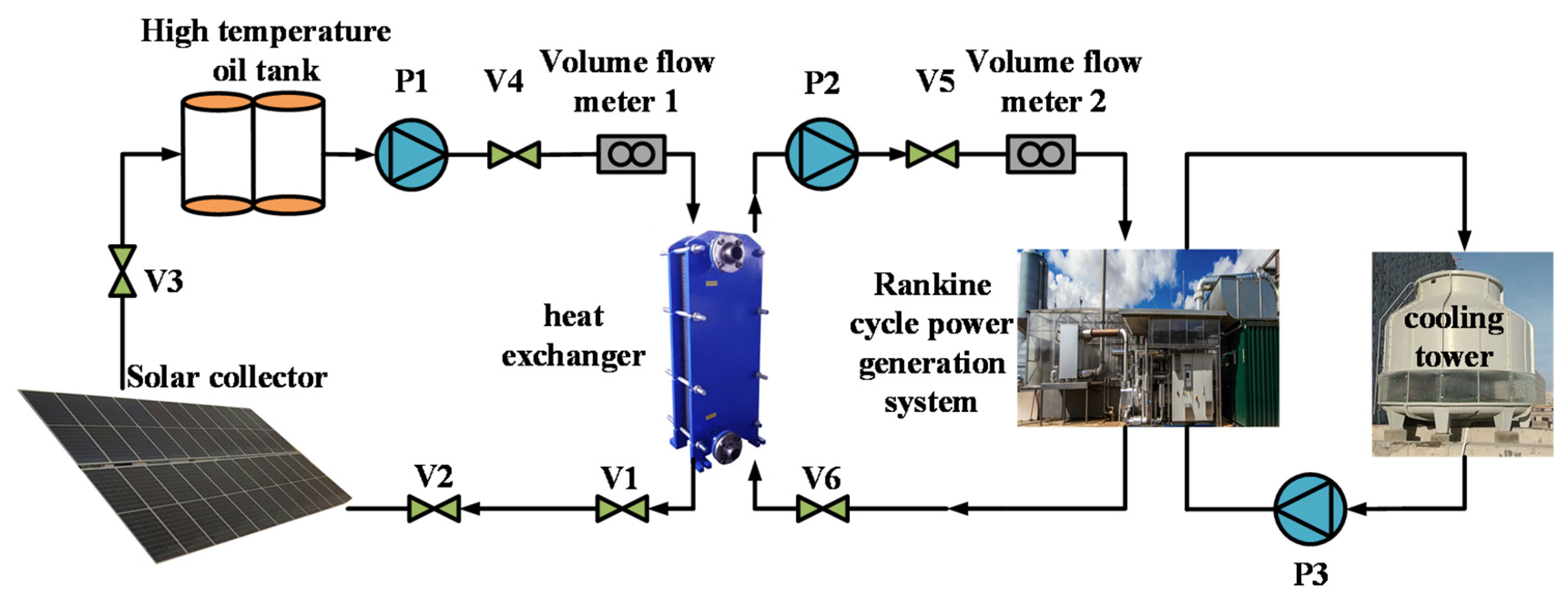

3.2.1. Thermodynamic Cycle Power Generation

3.2.2. Photothermal Systems Coupled with Electrolytic Cell Heating

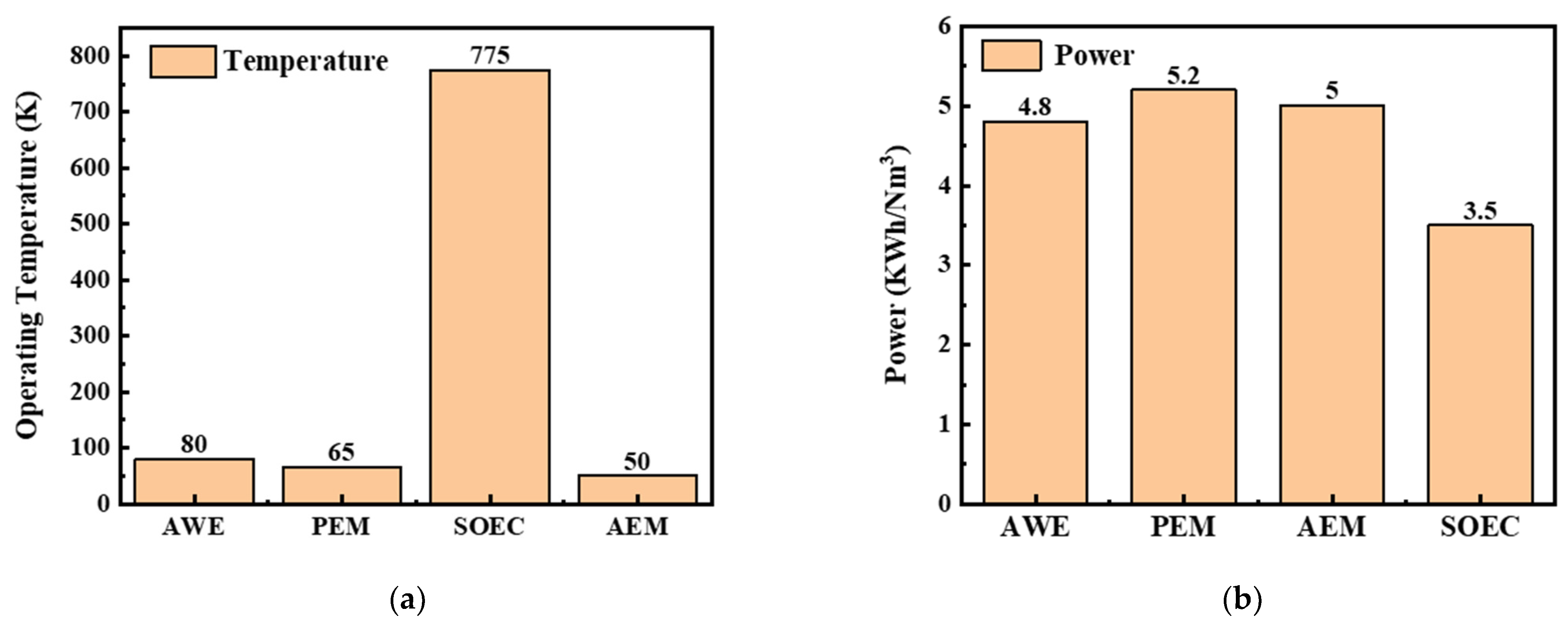

4. Electrolytic Hydrogen Production Methods

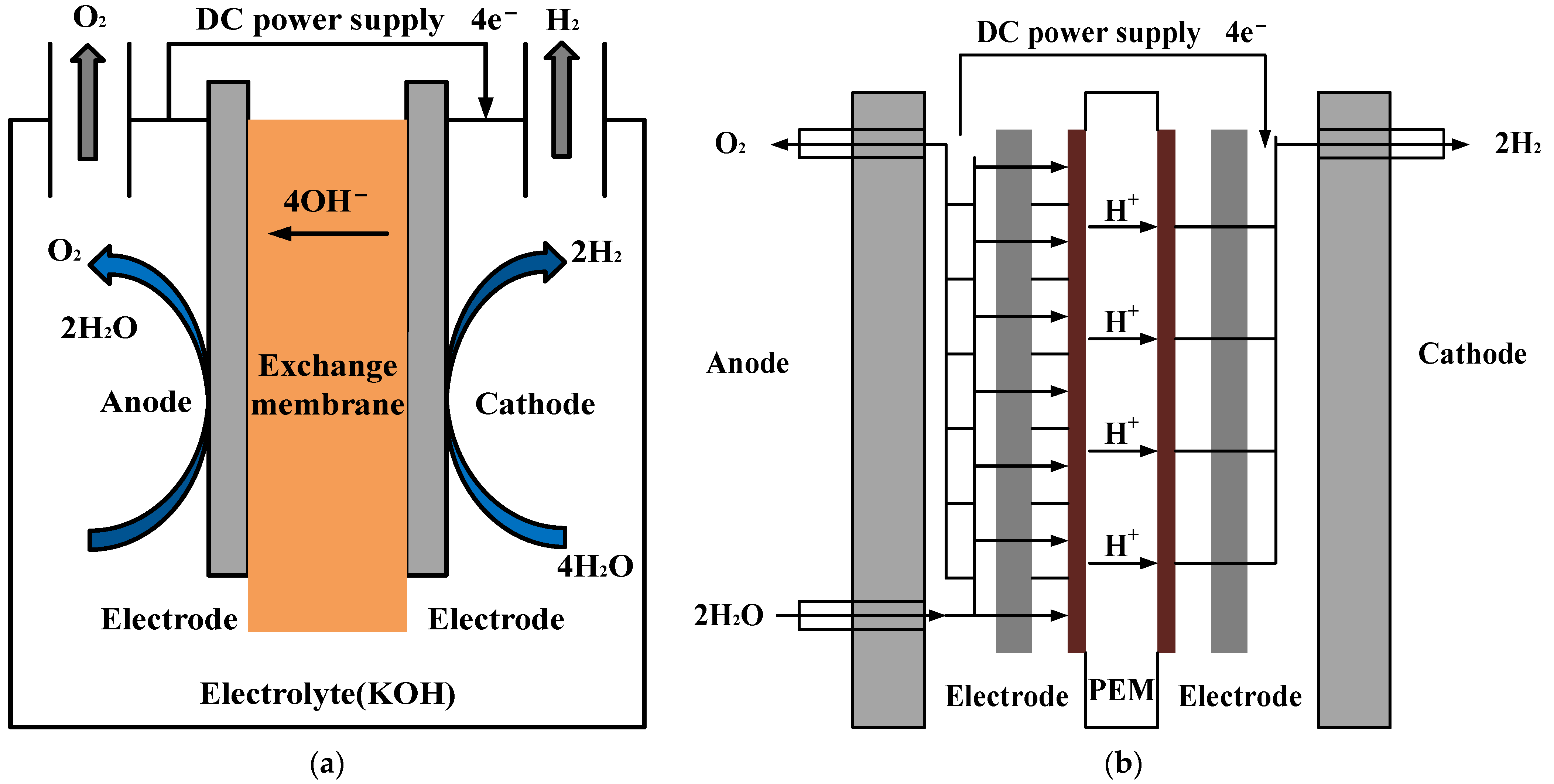

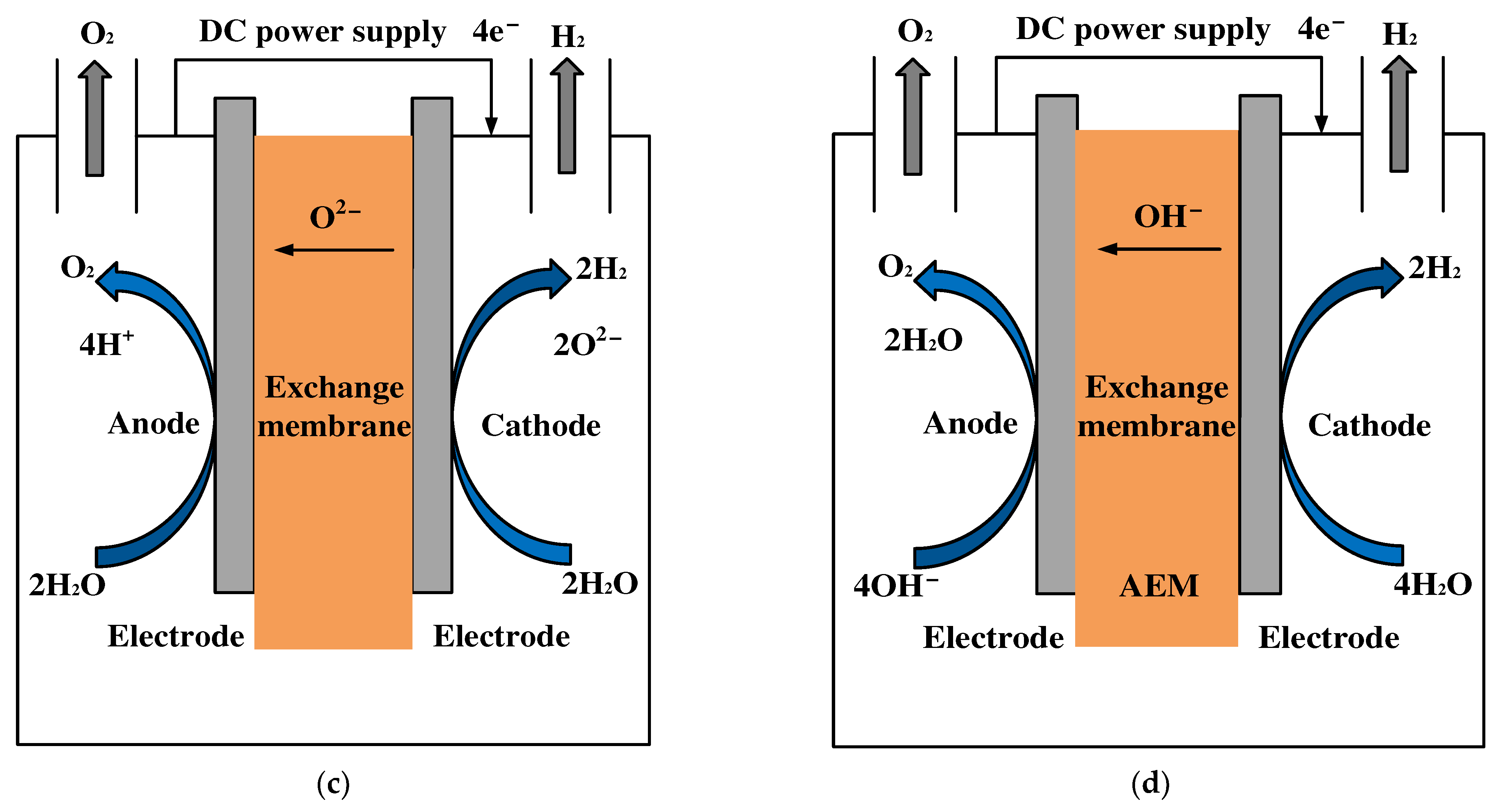

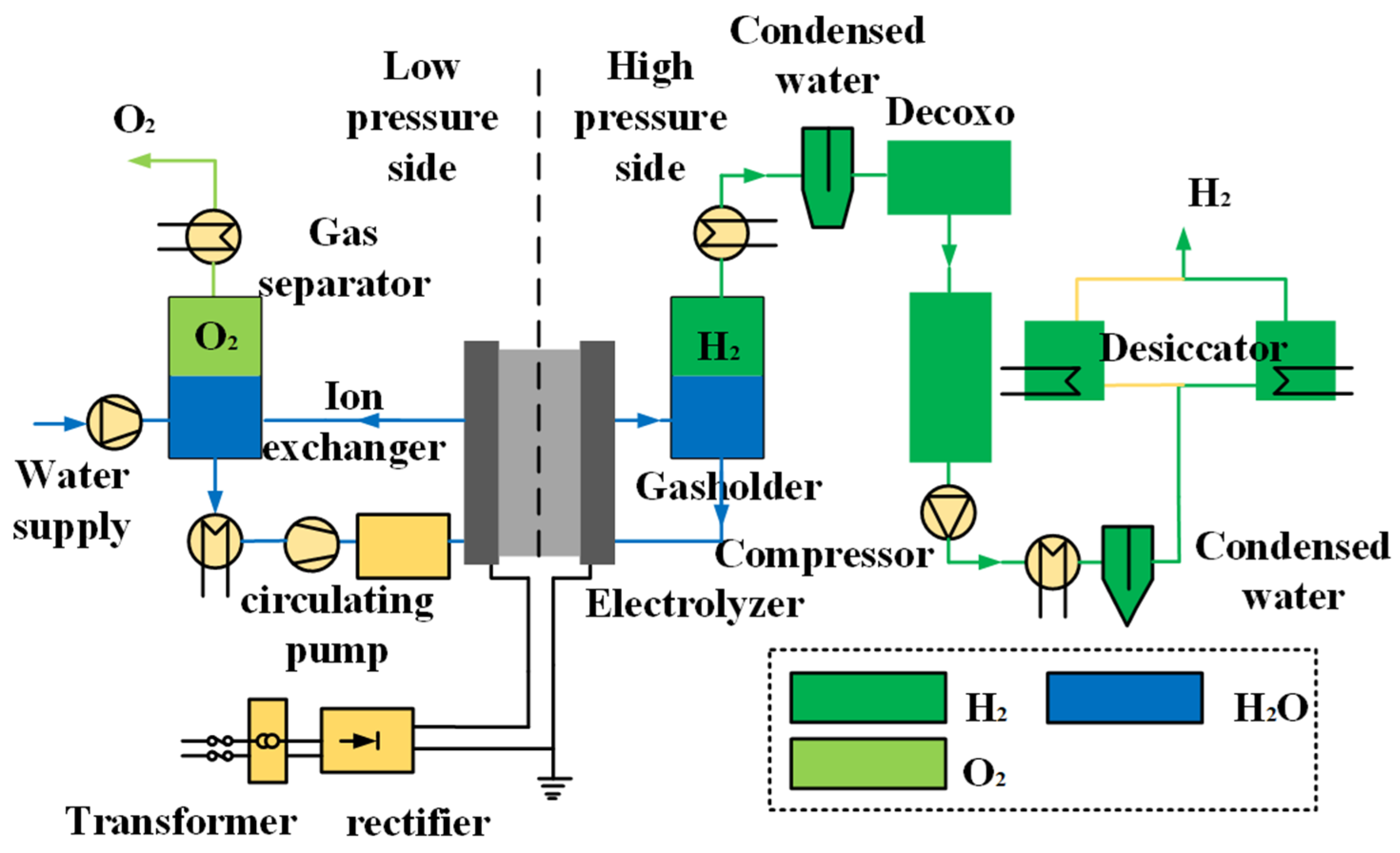

4.1. Hydrogen Production from AWE

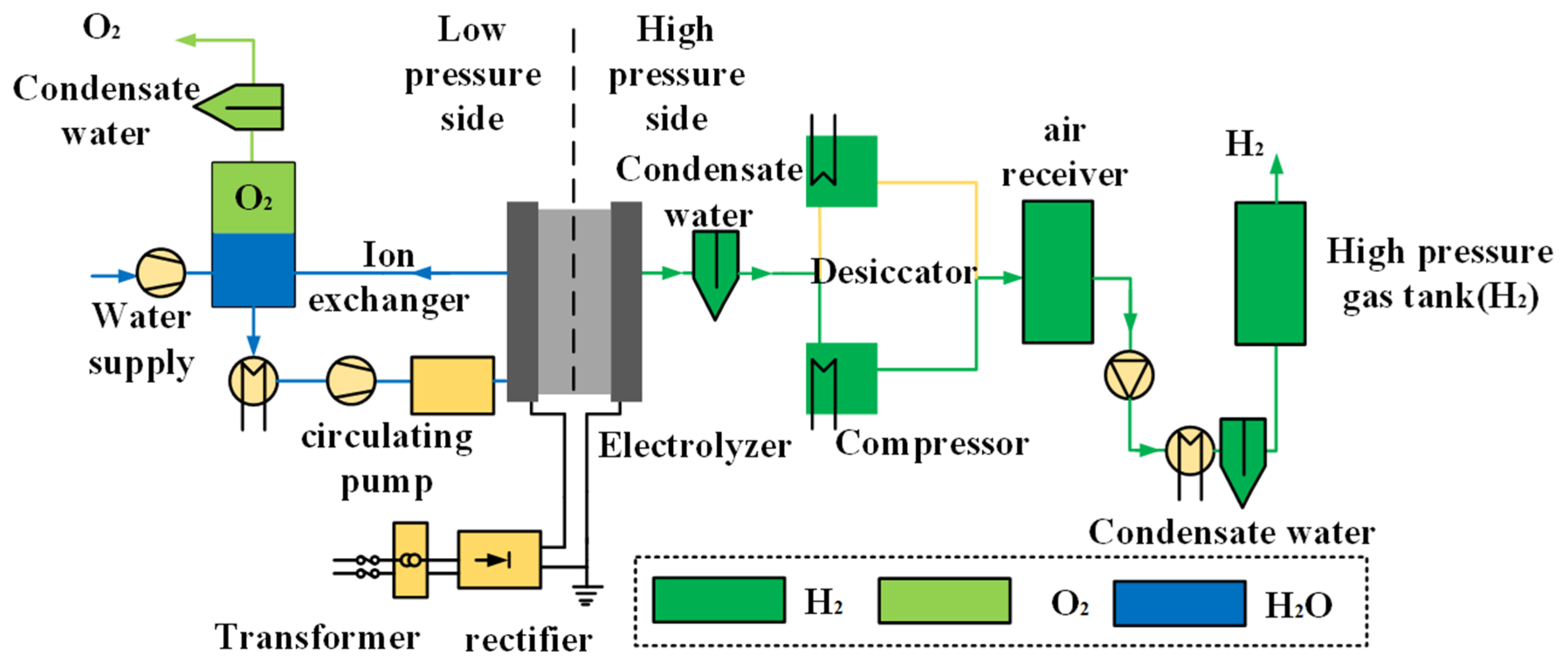

4.2. Hydrogen Production from PEM

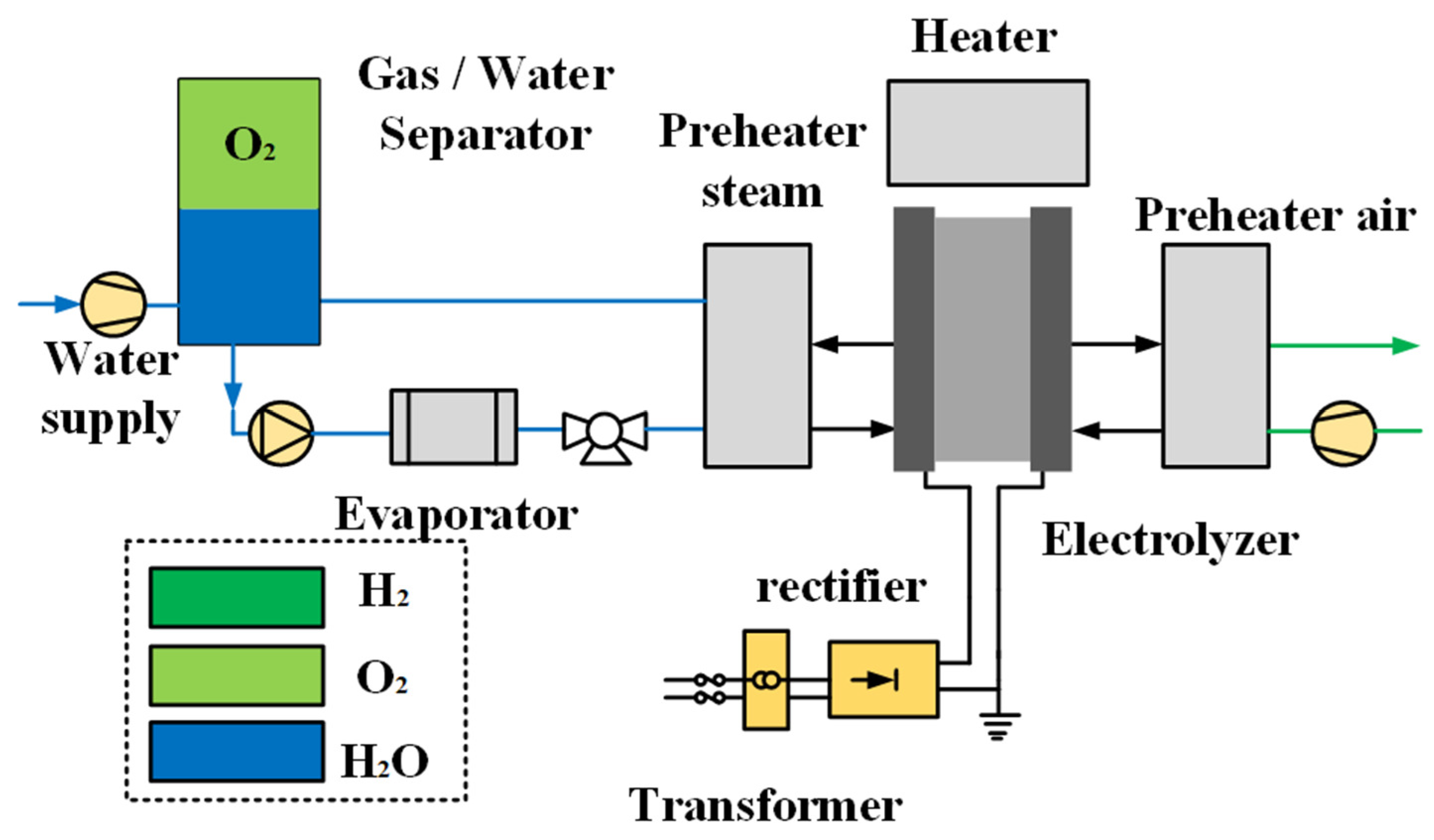

4.3. Hydrogen Production from SOEC

4.4. Hydrogen Production from AEM

5. Economic Analysis and Prospects

5.1. Economic Analysis

5.2. Development Prospects and Prospects

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qiu, Y.; Zhou, S.Y.; Gu, W. Application Prospect Analysis of Hydrogen Enriched Compressed Natural Gas Technologies under the Target of Carbon Emission Peak and Carbon Neutrality. Proc. CSEE 2022, 42, 1301–1321. [Google Scholar]

- Cheng, Y.H.; Zhang, N.; Kang, C.Q. Research Framework and Prospects of Low-carbon Multiple Energy Systems. Proc. CSEE 2017, 37, 4060–4069+4285. [Google Scholar]

- Lin, J.; Yu, Z.P.; Zhang, X.Z.; Li, J.R. On-grid/off-grid Operation Mode and Economic Analysis of Renewable Power to Ammonia System. Proc. CSEE 2023, 1–13. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Zemtsova, N.V. Recent Advantages on Waste Management in Hydrogen Industry. Polymers 2022, 14, 4992. [Google Scholar] [CrossRef] [PubMed]

- National Development and Reform Commission, National Energy Administration. Long-term Plan for the Development of Hydrogen Energy Industry (2021–2035). Fine Spec. Chem. 2022, 30, 27. [Google Scholar]

- European Commission. A Hydrogen Strategy for a Climate-Neutral Europe; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Javaheri, V. Steel pipeline for the hydrogen storage and delivery: Metallurgical viewpoint for Finnish ecosystem. Future Technol. 2023, 2, 58–61. [Google Scholar] [CrossRef]

- Hosseini, S.E. Hydrogen has found its way to become the fuel of the future. Future Energy 2022, 1, 11–12. [Google Scholar] [CrossRef]

- Hosseini, S.E. Transition away from fossil fuels toward renewables: Lessons from Russia-Ukraine crisis. Future Energy 2022, 1, 2–5. [Google Scholar] [CrossRef]

- Canan, A.; Dincer, I. Review and Evaluation of Hydrogen Production Options for Better Environment. J. Clean. Prod. 2019, 218, 835–849. [Google Scholar]

- Long, V.P.; Long, H.H.; Tuyen, D.N. A comprehensive review of direct coupled photovoltaic-electrolyser system: Sizing techniques, operating strategies, research progress, current challenge, and future recommendations. Int. J. Hydrogen Energy 2023, 48, 25231–25249. [Google Scholar]

- Fuad, O.A. A new approach for improving the efficiency of the indirectly coupled photovoltaic-electrolyzer system. Int. J. Hydrogen Energy 2023, 48, 8768–8782. [Google Scholar]

- Li, P.; Huang, Y.H.; Zhang, J.P.; Han, P.D. Capacity Coordinated Optimization of Battery, Thermal and Hydrogen Storage System for Multi-energy Complementary Power System. Proc. CSEE 2023, 1–11. [Google Scholar] [CrossRef]

- Xin, C.; Rui, L.; Ji, X. Construction and analysis of photovoltaic directly coupled conditions in PEM electrolyzer. Int. J. Hydrogen Energy 2022, 47, 6494–6507. [Google Scholar]

- Ali, S.; Ali, H.; Aref, J. Hydrogen production performance of a photovoltaic thermal system coupled with a proton exchange membrane electrolysis cell. Int. J. Hydrogen Energy 2022, 47, 4472–4488. [Google Scholar]

- Wang, M.J.; Wang, H. Discussion on Status and Development of Solar Photovoltaic Power Generation Technology. Energy Energy Conserv. 2021, 7, 37–38+49. [Google Scholar]

- Youssef, A.; Asmae, B.; Ameur, A. Techno-Economic Assessment of hydrogen production from three different solar photovoltaic technologies. Int. J. Hydrogen Energy 2023, 48, 32261–32276. [Google Scholar]

- Ali, A.; Almutairi, K.; Padmanaban, S. Investigation of MPPT techniques under uniform and non-uniform solar irradiation condition—A retrospection. IEEE Access 2020, 8, 127368–127392. [Google Scholar] [CrossRef]

- Wang, C.J. Research on Maximum Power Point Tracking Algorithm of Photovoltaic Array under Partial Shading. Master’s Thesis, Shandong University, Jinan, China, 2020. [Google Scholar]

- Nu, Q.S.; Shi, J.Q.; Hui, Z.X. Research on photovoltaic MPPT based on improved double fuzzy control. Chin. J. Power Sources 2021, 45, 781–785. [Google Scholar]

- Lui, X.Y. Maximum Power Point Tracking Study of PV Systems under Local Shadi. Master’s Thesis, Shaanxi University of Technology, Hanzhong, China, 2023. [Google Scholar]

- Ola, R.; Hanan, B. A new technique for estimation of photovoltaic system and tracking power peaks of PV array under partial shading. Energy 2023, 268, 126680. [Google Scholar]

- Zhang, D.N. Research on photovoltaic maximum power point tracking strategy based on improved conductance increment method. Acta Energiae Solaris Sin. 2022, 43, 82–90. [Google Scholar]

- Li, Y.B.; Li, L.Y.; Li, W.Y. Research on photovoltaic system MPPT based on TSO-MSMA algorithm. Acta Energiae Solaris Sin. 2023, 44, 324–330. [Google Scholar]

- Titri, S.; Larbes, C.; Toumi, Y.K. A new MPPT controller based on the Ant colony optimization algorithm for Photovoltaic systems under partial shading conditions. Appl. Soft Comput. 2017, 58, 465–479. [Google Scholar] [CrossRef]

- Subhashini, P.; Chitra, P.; Pillai, N.M.; Vanitha, M. Theoretical Enhancement of Energy Production Performance in PV Arrays through Effective Shadow Detection Using Hybrid Technique. Sol. Energy 2023, 264, 112006. [Google Scholar] [CrossRef]

- Shao, R.N.; Yang, B.; Shu, H.C. Optimal Reconfiguration Method for Photovoltaic Arrays Based on Improved Mayfly Algorithm. Autom. Electr. Syst. 2022, 46, 142–150. [Google Scholar]

- Zhang, M.R.; Chen, J.Y. Reconfiguration scheme of photovoltaic array based on minimum equalization difference. Electr. Power Autom. Equip. 2021, 41, 33–38. [Google Scholar]

- Go, T.Z.; Fen, T.B.; Zhang, X. Dynamic Reconfiguration Method of TCT Photovoltaic Array Based on Peak Power Evaluation. Power Syst. Technol. 2022, 46, 4414–4422. [Google Scholar]

- Xia, Y.H.; Li, M.R.; Zeng, F.P. Reconstruction of PV arrays based on TCT structure and switch control. Acta Energiae Solaris Sin. 2018, 39, 2797–2802. [Google Scholar]

- Sahoo, K.M.; Kale, P. Restructured porous silicon for solar photovoltaic: A review. Microporous Mesoporous Mater. 2019, 289, 109619. [Google Scholar] [CrossRef]

- Yang, B.; Wang, J.R.; Huang, J.X. Reconfiguration of PV-TEG Hybrid System Based on Sea Horse Optimizer. Power Syst. Technol. 2023, 47, 1386–1403. [Google Scholar]

- Qiu, Z.; Sun, K. A photovoltaic generation system based on wide voltage-gain DC-DC converter and differential power processors for DC microgrids. Chin. J. Electr. Eng. 2017, 3, 84–95. [Google Scholar]

- Wang, F.; Zhu, T.; Zhuo, F. An improved submodule differential power processing-based PV system with flexible multi-MPPT control. IEEE J. Emerg. Sel. Top. Power Electron. 2017, 6, 94–102. [Google Scholar] [CrossRef]

- Kumar, P.G.; Hrushikesh, N.; Kanungo, M.B. Hybrid TSA-RBFNN based approach for MPPT of the solar PV panel under the effects of tilt angles variations and environmental effects. Int. J. Energy Res. 2021, 45, 20104–20131. [Google Scholar]

- Chu, G.; Wen, H.; Yang, Y. Elimination of photovoltaic mismatching with improved submodule differential power processing. IEEE Trans. Ind. Electron. 2019, 67, 2822–2833. [Google Scholar] [CrossRef]

- Gao, Z.H. Research on Differential Power Processing of Photovoltaic System under Non-Uniform Light Distribution. Master’s Thesis, Xidian University, Xi’an, China, 2022. [Google Scholar]

- Li, Z.; Xu, Y.; Wu, L. A risk-averse adaptively stochastic optimization method for multi-energy ship operation under diverse uncertainties. IEEE Trans. Power Syst. 2020, 36, 2149–2161. [Google Scholar] [CrossRef]

- Amjad, A.; Khursheed, A.; Muhammad, S. Second-law analysis of nanofluid-based photovoltaic/thermal system modeling and forecasting model based on artificial neural network. Eng. Anal. Bound. Elem. 2023, 157, 342–352. [Google Scholar]

- Khalili, W.N.; Othman, M.; Bakar, A.N.M. Modelling of a Single Passage Air PV/T Solar Collector: Experimental and Simulation Design. Processes 2020, 8, 763. [Google Scholar] [CrossRef]

- Mahdavi, S.; Sarhaddi, F.; Hedayatizadeh, M. Energy/exergy based-evaluation of heating/cooling potential of PV/T and earth-air heat exchanger integration into a solar greenhouse. Appl. Therm. Eng. 2019, 149, 996–1007. [Google Scholar] [CrossRef]

- Cucumo, M.A.; Ferraro, V.; Kaliakatsos, D. Equivalent electrical circuit to estimate the PV/T solar collector producibility. Int. J. Heat Technol. 2017, 35, 843–852. [Google Scholar] [CrossRef][Green Version]

- Khani, M.S.; Baneshi, M.; Eslami, M. Bi-objective optimization of photovoltaic-thermal (PV/T) solar collectors according to various weather conditions using genetic algorithm: A numerical modeling. Energy 2019, 189, 116223. [Google Scholar] [CrossRef]

- Shi, J.; Lin, C.X. Computational Simulation and Analysis of Major Control Parameters of Time-Dependent PV/T Collectors. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Salt Lake City, UT, USA, 11–14 November 2019; Volume 59452. [Google Scholar]

- Qiu, S. Flow Heat Transfer Characteristics and Optimization of Photovoltaic/Thermal System Collector. Master’s Thesis, Yangzhou University, Yangzhou, China, 2018. [Google Scholar]

- Cetina-Quiñones, A.J.; Polanco-Ortiz, I.; Alonzo, P.M.; Hernandez-Perez, J.G.; Bassam, A. Innovative heat dissipation design incorporated into a solar photovoltaic thermal (PV/T) air collector: An optimization approach based on 9E analysis. Therm. Sci. Eng. Prog. 2023, 38, 101635. [Google Scholar] [CrossRef]

- Vaishak, S.; Bhale, P.V. Investigation on the effect of different backsheet materials on performance characteristics of a photovoltaic/thermal (PV/T) system. Renew. Energy 2021, 168, 160–169. [Google Scholar] [CrossRef]

- Chong, K.; Yew, T.; Wong, C. Dense-array concentrator photovoltaic prototype using non-imaging dish concentrator and an array of cross compound parabolic concentrators. Appl. Energy 2017, 204, 898–911. [Google Scholar] [CrossRef]

- Amarnath, K.; Gopal, P.; Sridharan, M.; Senthil Kumar, T. Performance Improvement Analysis and Simulation of Solar PV/T Water Collector. J. Trend Sci. Res. Dev. 2018, 2, 960–965. [Google Scholar]

- Weiwei, W.; Yeguo, S.; Sh, H.M. Multi-aspect investigation and multi-criteria optimization of a novel solar-geothermal-based polygeneration system using flat plate and concentrated photovoltaic thermal solar collectors. Process Saf. Environ. Prot. 2023, 174, 485–509. [Google Scholar]

- Yan, S.Y.; Wu, Z.; Wang, F. Simulation and test of thermoelectric output performance of Fresnel high concentration PV/T system. Trans. Chin. Soc. Agric. Eng. 2018, 34, 97–203. [Google Scholar]

- Ma, J.; Liu, C.; Liu, F. Optimization and Concentration Characteristics of Cylindrical Mirrors in Linear Fresnel Reflectors. Acta Optica Sinica 2023, 14, 1–15. [Google Scholar] [CrossRef]

- Maatallah, T.; Ammar, R. Design, modeling, and optimization of a dual reflector parabolic trough concentration system. Int. J. Energy Res. 2020, 44, 3711–3723. [Google Scholar] [CrossRef]

- Kostić, L.T.; Pavlović, T.M.; Pavlović, Z.T. Optimal design of orientation of PV/T collector with reflectors. Appl. Energy 2010, 87, 3023–3029. [Google Scholar] [CrossRef]

- Souliotis, M.; Arnaoutakis, N.; Panaras, G. Experimental study and Life Cycle Assessment (LCA) of Hybrid Photovoltaic/Thermal (PV/T) solar systems for domestic applications. Renew. Energy 2018, 126, 708–723. [Google Scholar] [CrossRef]

- Jiang, C.Y. Performance Study of R290 Solar Photovoltaic Photothermal Integrated Heat Pump Water Heater System. Master’s Thesis, Shanghai Jiao Tong University, Shanghai, China, 2018. [Google Scholar]

- Jiang, J.F. Basic Experimental Study on Flat Plate Heat Pipe Solar Photovoltaic-Thermal Composite Collector. Master’s Thesis, Shanghai Jiaotong University, Shanghai, China, 2020. [Google Scholar]

- Li, H.; Hou, P.W.; Sun, Y. Photoelectricity and photothermal performance experiment on solar photovoltaic/loop-heat-pipe water heating system. Trans. CSAE 2018, 34, 235–240. [Google Scholar]

- Zhang, Y.W.; Guo, X.; Wang, L.F. Experimental study of a new solar hybrid photovoltaic-thermal modules. Renew. Energy Resour. 2018, 36, 1449–1454. [Google Scholar]

- Tiwari, G.N.; Al-Helal, I.M. Analytical expression of temperature dependent electrical efficiency of N-PVT water collectors connected in series. Sol. Energy 2015, 114, 61–76. [Google Scholar]

- Sharadga, H.; Dawahdeh, A.; Al-Nimr, M.A. A hybrid PV/T and Kalina cycle for power generation. Int. J. Energy Res. 2018, 42, 4817–4829. [Google Scholar] [CrossRef]

- Sun, L.L.; Li, M.; Yuan, Y.P. Effect of tilt angle and connection mode of PVT modules on the energy efficiency of a hot water system for high-rise residential buildings. Renew. Energy 2016, 93, 291–301. [Google Scholar] [CrossRef]

- Chu, L.C.; Zhao, S.G.; Gao, Y.Z. Erimental study on performance of photovoltaic direct-dirven PV/T dual-source heat pump hot water system. Acta Energiae Solaris Sin. 2023, 44, 188–194. [Google Scholar]

- Ouyang, L.P.; Yuan, Y.P.; Sun, L.L. Optimization of collector connection mode of solar photovoltaic photothermal system. Acta Energiae Solaris Sin. 2017, 38, 2811–2820. [Google Scholar]

- Jhina, S.; Hadi, S.; Payman, S. Investigating the thermo-economic performance and modeling of a parabolic solar collector with phase change material in the receiver tube in a solar desalination. Desalination 2024, 572, 116980. [Google Scholar]

- Stanley, C.; Mojiri, A.; Rahat, M. Performance testing of a spectral beam splitting hybrid PVT solar receiver for linear concentrators. Appl. Energy 2016, 168, 303–313. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.A.; Sopian, K.; Chaichan, M.T. Evaluation of the nanofluid and nano-PCM based photovoltaic thermal (PVT) system: An experimental study. Energy Convers. Manag. 2017, 151, 693–708. [Google Scholar] [CrossRef]

- Jing, D.; Hu, Y.; Liu, M. Preparation of highly dispersed nanofluid and CFD study of its utilization in a concentrating PV/T system. Sol. Energy 2015, 112, 30–40. [Google Scholar] [CrossRef]

- Tabet, I.; Touafek, K.; Bellel, N. Thermal performances of vertical hybrid PV/T air collector. Eur. Phys. J. Plus 2016, 131, 1–15. [Google Scholar] [CrossRef]

- Arslan, E.; Aktaş, M.; Can, Ö.F. Experimental and numerical investigation of a novel photovoltaic thermal (PV/T) collector with the energy and exergy analysis. J. Clean. Prod. 2020, 276, 123255. [Google Scholar] [CrossRef]

- Hu, M.; Guo, C.; Zhao, B. A parametric study on the performance characteristics of an evacuated flat-plate photovoltaic/thermal (PV/T) collector. Renew. Energy 2021, 167, 884–898. [Google Scholar] [CrossRef]

- Guan, X.; Wang, Y.D.; Xiang, Y.T. Cascade Utilization of Energy in Solar Photovoltaic Hot Water System. J. Eng. Thermophys. 2012, 33, 1240–1242. [Google Scholar]

- Fui, H.D. Numerical and Experimentalstudy on a Heat Pipephotovoltaic/Thermal System. Master’s Thesis, University of Science and Technology of China, Hefei, China, 2012. [Google Scholar]

- Li, G.M.; Liu, Z.M.; Li, J.T. Experimental Study on A Novel Hybrid Photovoltaic/Thermal Solar System. Proc. CSEE 2013, 33, 83–89+16. [Google Scholar]

- Guo, J.B.; Yu, H.Z.; Yue, V.V. Experimental Study on Application Characteristics of Solar Photovoltaic—Thermal Integrated Module. Acta Energiae Solaris Sin. 2015, 36, 154–161. [Google Scholar]

- Qingchun, Y.; Genyun, C.; Lihao, Z. Pathways toward carbon-neutral coal to ethylene glycol processes by integrating with different renewable energy-based hydrogen production technologies. Energy Convers. Manag. 2022, 258, 115529. [Google Scholar]

- Powell, K.M.; Rashid, K.; Ellingwood, K. Hybrid concentrated solar thermal power systems: A review. Renew. Sustain. Energy Rev. 2017, 80, 215–237. [Google Scholar] [CrossRef]

- Lu, Z.W.; Han, M.F. Design of solar cogeneration system of hydrogen and power with solid oxide cells. Energy Storage Sci. Technol. 2017, 6, 275–279. [Google Scholar]

- Landman, A.; Dotan, H.; Shter, G.E. Photoelectrochemical water splitting in separate oxygen and hydrogen cells. Nat. Mater. 2017, 16, 646–651. [Google Scholar] [CrossRef]

- Amori, K.E.; Salman, S.M.; Kareem, Z.H. Hydrogen Production by Hybrid photovoltaic Thermal System. Al-Nahrain J. Eng. Sci. 2017, 20, 250–261. [Google Scholar]

- Senthilraja, S.; Gangadevi, R.; Marimuthu, R. Performance evaluation of water and air based PVT solar collector for hydrogen production application. Int. J. Hydrogen Energy 2020, 45, 7498–7507. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Gopal, P.; Kumar, C.R.; Geo, V.E. Effect of solar photovoltaic and various photovoltaic air thermal systems on hydrogen generation by water electrolysis. Int. J. Hydrogen Energy 2022, 47, 3211–3223. [Google Scholar] [CrossRef]

- Habibollahzade, A.; Gholamian, E.; Ahmadi, P. Multi-criteria optimization of an integrated energy system with thermoelectric generator, parabolic trough solar collector and electrolysis for hydrogen production. Int. J. Hydrogen Energy 2018, 43, 14140–14157. [Google Scholar] [CrossRef]

- Lin, M.; Haussener, S. Techno-economic modeling and optimization of solar-driven high-temperature electrolysis systems. Sol. Energy 2017, 155, 1389–1402. [Google Scholar] [CrossRef]

- Yadav, D.; Banerjee, R. Economic assessment of hydrogen production from solar driven high-temperature steam electrolysis process. J. Clean. Prod. 2018, 183, 1131–1155. [Google Scholar] [CrossRef]

- Kumar, V.Y.; Jahar, S.; Pradyumna, G. Thermodynamic, economic and environmental analyses of novel concentrated solar-PV-thermal integrated combined power, cooling and desalination system. Desalination 2023, 563, 116721. [Google Scholar]

- Zain, A.U.; Ahmed, R.; Batuhan, T.K. Design and analysis of an innovative photovoltaic-thermal collector with embedded tank. Sol. Energy 2022, 245, 290–298. [Google Scholar]

- El-Hadary, M.I.; Senthilraja, S.; Zayed, M.E. A hybrid system coupling spiral type solar photovoltaic thermal collector and electrocatalytic hydrogen production cell: Experimental investigation and numerical modeling. Process Saf. Environ. Prot. 2023, 170, 1101–1120. [Google Scholar] [CrossRef]

- Miao, Z.C. Research on Multi-Energy Complementary Powergeneration System Based on Photovoltaic-Photothermal Coupling. Master’s Thesis, North China Electric Power University, Beijing, China, 2022. [Google Scholar]

- Mohammadi, A.; Mehrpooya, M. A comprehensive review on coupling different types of electrolyzer to renewable energy sources. Energy 2018, 158, 632–655. [Google Scholar] [CrossRef]

- Wang, K. Research and Implementation of Integrated Controller for Independent Photovoltaic Power Generation System. Master’s Thesis, Tiangong University, Tianjin, China, 2020. [Google Scholar]

- De León, C.M.; Ríos, C.; Brey, J.J. Cost of green hydrogen: Limitations of production from a stand-alone photovoltaic system. Int. J. Hydrogen Energy 2023, 48, 11885–11898. [Google Scholar] [CrossRef]

- Li, C.; Ma, F.; Hu, Q. Virtual Synchronous Generator Control Method Based on Mode Switching in Isolated Power System. High Volt. Eng. 2022, 48, 3474–3483. [Google Scholar]

- Majid, A.; Mujtaba, A.; Ali, M.K. Maximum power point tracking for grid-connected photovoltaic system using Adaptive Fuzzy Logic Controller. Comput. Electr. Eng. 2023, 110, 108879. [Google Scholar]

- Jianhong, L.; Jieyu, W.; Yinglun, T. Solar photovoltaic–thermal hydrogen production system based on full-spectrum utilization. J. Clean. Prod. 2023, 430, 139340. [Google Scholar]

- Yuhang, W.; Hui, D.; Zeqi, C. Simulation study on a novel solid–gas coupling hydrogen storage method for photovoltaic hydrogen production systems. Energy Convers. Manag. 2024, 299, 117866. [Google Scholar]

- Sharma, R.; Almáši, M.; Punia, R.C.; Chaudhary, R.; Nehra, S.P.; Dhaka, M.S.; Sharma, A. Solar-driven polymer electrolyte membrane fuel cell for photovoltaic hydrogen production. Int. J. Hydrogen Energy 2023, 48, 37999–38014. [Google Scholar] [CrossRef]

- Zhongjian, K.; Fengtong, D. A flexible load adaptive control strategy for efficient photovoltaic hydrogen generation system. Sol. Energy 2023, 266, 112150. [Google Scholar]

- Tebibel, H.; Medjebour, R. Comparative performance analysis of a grid connected PV system for hydrogen production using PEM water, methanol and hybrid sulfur electrolysis. Int. J. Hydrogrn Energy 2018, 43, 3482–3498. [Google Scholar] [CrossRef]

- Gibson, T.L.; Kelly, N.A. Predicting efficiency of solar powered hydrogen generation using photovoltaic-electrolysis devices. Int. J. Hydrogen Energy 2010, 35, 900–911. [Google Scholar] [CrossRef]

- Maeda, T.; Ito, H.; Hasegawa, Y. Study on control method of the stand-alone direct-coupling photovoltaic—Water electrolyzer. Int. J. Hydrogen Energy 2012, 37, 4819–4828. [Google Scholar] [CrossRef]

- Atlam, O.; Barbir, F.; Bezmalinovic, D. A method for optimal sizing of an electrolyzer directly connected to a PV module. Int. J. Hydrogen Energy 2011, 36, 7012–7018. [Google Scholar] [CrossRef]

- Islam, S.; Dincer, I.; Yilbas, B.S. System development for solar energy-based hydrogen production and on-site combustion in HCCI engine for power generation. Sol. Energy 2016, 136, 65–77. [Google Scholar] [CrossRef]

- Zhiyu, Z.; Zesen, W.; Yinglin, L. Energy Optimization Model of Multi Energy Interaction in Thermal Power Plants with Wind Power, Photovoltaic, Hydrogen Production and Hydrogen Fuel Cell System. J. Phys. Conf. Ser. 2023, 2474, 012010. [Google Scholar]

- Ganguly, A.; Misra, D.; Ghosh, S. Modeling and analysis of solar photovoltaic-electrolyzer-fuel cell hybrid power system integrated with a floriculture greenhouse. Energy Build. 2010, 42, 2036–2043. [Google Scholar] [CrossRef]

- Biencinto, M.; González, L.; Valenzuela, L. A new concept of solar thermal power plants with large-aperture parabolic-trough collectors and sCO2 as working fluid. Energy Convers. Manag. 2019, 199, 112030. [Google Scholar] [CrossRef]

- Joshi, A.; Dincer, I.; Reddy, V.B. Effects of various parameters on energy and exergy efficiencies of a solar thermal hydrogen production system. Int. J. Hydrogen Energy 2016, 41, 7997–8007. [Google Scholar] [CrossRef]

- Naseri, A.; Bidi, M.; Ahmadi, M.H. Exergy analysis of a hydrogen and water production process by a solar-driven transcritical CO2 power cycle with Stirling engine. J. Clean. Prod. 2017, 158, 165–181. [Google Scholar] [CrossRef]

- Balta, M.T.; Kizilkan, O.; Yılmaz, F. Energy and exergy analyses of integrated hydrogen production system using high temperature steam electrolysis. Int. J. Hydrogen Energy 2016, 41, 8032–8041. [Google Scholar] [CrossRef]

- Seitz, M.; von Storch, H.; Nechache, A. Techno economic design of a solid oxide electrolysis system with solar thermal steam supply and thermal energy storage for the generation of renewable hydrogen. Int. J. Hydrogen Energy 2017, 42, 26192–26202. [Google Scholar] [CrossRef]

- Song, X.; Ru, L.; Yadi, C. Monopolar membrane-assisted acid-alkaline amphoteric water electrolysis towards efficient hydrogen generation. J. Power Sources 2023, 557, 232561. [Google Scholar]

- You, B.; Tang, M.T.; Tsai, C. Enhancing electrocatalytic water splitting by strain engineering. Adv. Mater. 2019, 31, 1807001. [Google Scholar] [CrossRef]

- Yumeng, Z.; Zhuo, W.; Zhiyu, D. Techno-economic analysis of solar hydrogen production via PV power/concentrated solar heat driven solid oxide electrolysis with electrical/thermal energy storage. J. Energy Storage 2023, 72, 107986. [Google Scholar]

- Haeseong, S.; Dohyung, J.; Sangdon, L. Techno-economic evaluation of green hydrogen production with low-temperature water electrolysis technologies directly coupled with renewable power sources. Energy Convers. Manag. 2023, 286, 117083. [Google Scholar]

- Damien, B.L.; Olivier, C.; Philippe, M. Evolutionary Design Optimization of an Alkaline Water Electrolysis Cell for Hydrogen Production. Appl. Sci. 2020, 10, 8425. [Google Scholar]

- Yangyang, L.; Xintao, D.; Tao, Z. Exploration of the configuration and operation rule of the multi-electrolyzers hybrid system of large-scale alkaline water hydrogen production system. Appl. Energy 2023, 331, 120413. [Google Scholar]

- Trasatti, S. Water electrolysis: Who first. J. Electroanal. Chem. 1999, 476, 90–91. [Google Scholar] [CrossRef]

- De Fátima Palhares, D.D.A.; Vieira, L.G.M.; Damasceno, J.J.R. Hydrogen production by a low-cost electrolyzer developed through the combination of alkaline water electrolysis and solar energy use. Int. J. Hydrogen Energy 2018, 43, 4265–4275. [Google Scholar] [CrossRef]

- Wang, B.; Ni, M.; Zhang, S.; Liu, Z.; Jiang, S.; Zhang, L.; Zhou, F.; Jiao, K. Two-phase analytical modeling and intelligence parameter estimation of proton exchange membrane electrolyzer for hydrogen production. Renew. Energy 2023, 211, 202–213. [Google Scholar] [CrossRef]

- Zhang, Q.; Chang, Z.; Fu, M.; Nie, F.; Ren, T.; Li, X. Thermal performance analysis of an integrated solar reactor using solid oxide electrolysis cells for hydrogen production. Energy Convers. Manag. 2022, 264, 115762. [Google Scholar] [CrossRef]

- Zhang, Q.; Chang, Z.; Fu, M.; Ren, T.; Li, X. Thermal and electrochemical performance analysis of an integrated solar SOEC reactor for hydrogen production. Appl. Therm. Eng. 2023, 229, 120603. [Google Scholar] [CrossRef]

- Izhan, N.; Thuushren, R.; Noramelya, Z. Investigation of Performance of Anion Exchange Membrane (AEM) Electrolysis with Different Operating Conditions. Polymers 2023, 15, 301–1301. [Google Scholar]

- Yang, B.; Zhang, R.; Shao, Z. The economic analysis for hydrogen production cost towards electrolyzer technologies: Current and future competitiveness. Int. J. Hydrogen Energy 2023, 48, 13767–13779. [Google Scholar] [CrossRef]

- Wang, Y.; Wen, C.; Tu, J.; Zhan, Z.; Zhang, B.; Liu, Q.; Zhang, Z.; Hu, H.; Liu, T. The multi-scenario projection of cost reduction in hydrogen production by proton exchange membrane water electrolysis in the near future of China. Fuel 2023, 354, 129409. [Google Scholar] [CrossRef]

| Country | Time | Development Goals | Key Content |

|---|---|---|---|

| China | 2025 | Preliminary establishment of hydrogen production and hydrogen production system. | Since 2019, at least 18 provincial-level administrative regions in China have announced their goals for hydrogen energy development. By 2025, China will have at least 762 hydrogen refueling stations, 88,000 fuel cell vehicles, and a hydrogen energy industry scale of nearly 700 billion yuan. |

| 2030 | Forming a relatively complete hydrogen production and supply system. | ||

| 2035 | Forming a hydrogen-energy industry system. | ||

| Japan | 2030 | The cost of hydrogen production has been reduced to 30 yen/Nm3; the hydrogen supply reaches 3 million tons per year. | By 2030, the proportion of hydrogen/ammonia power generation will have achieved a breakthrough, increasing from 0%, as set in the fifth phase plan, to 1%, as set in this project. |

| 2050 | The cost of hydrogen production has been reduced to 20 yen/Nm3; the hydrogen supply reaches 20 million tons per year. | ||

| USA | 2030 | The cost of the electrolytic cell has been reduced to $300 per kilowatt, the operating life has reached 80,000 h, the system conversion efficiency has reached 65%, the hydrogen price for industrial and power sectors has been reduced to $1 per kilogram, and the hydrogen price for transportation sectors has been reduced to $2 per kilogram. | Research, develop and validate technologies related to hydrogen conversion, and address institutional and market barriers, ultimately achieving widespread application across different fields. |

| European Union | 2024 | Install 6 million kW electrolysis facilities to produce 1 million tons of green hydrogen. | This provides direction for the development of the entire hydrogen production, storage, and transportation industry chain in Europe for the next 30 years and outlines a comprehensive investment plan. The total investment is expected to exceed 450 billion euros. |

| 2030 | Install 40 million kW electrolysis facilities to produce 10 million tons of green hydrogen. | ||

| 2050 | All industrial sectors with high decarbonization difficulty coefficients will use green hydrogen as a substitute. |

| Research Method | Serial Number | Technology Application | Main Content | Main Conclusions | References |

|---|---|---|---|---|---|

| Maximum Power Point (MPPT) | 1 | Non-uniform illumination | Uneven illumination of photovoltaic arrays leads to a maximum power point shift, resulting in a decrease in output power. | The MPPT algorithm reduces tracking performance. | [18,19] |

| 2 | Double fuzzy control | A maximum power point tracking method for photovoltaic cells combining dual fuzzy control and PID controller has been proposed. | Improvement of the efficiency and stability of solar energy conversion in photovoltaic cells. | [20] | |

| 3 | Variable step conductance increment method | A composite control strategy based on an improved cuckoo algorithm and variable step conductance increment method was proposed. | Further improvement of local convergence characteristics and enhancement of local convergence stability | [21] | |

| 4 | Artificial neural network method | Using particle swarm optimization algorithm to track maximum values. | in the MPPT tracking algorithm for generating fuzzy logic control laws. | [22] | |

| 5 | Incremental conductance | Propose a concise control method for maximum power point tracking (MPPT) based on the incremental conductance method and the adaptive superposition of stepless voltage disturbances. | Quick and effective achievement of maximum power tracking control. | [23] | |

| Photovoltaic array reconstruction | 1 | TSO, MSMA | Propose a hybrid optimization algorithm based on the tuna algorithm (TSO) and the improved slime mold foraging algorithm (MSMA). | The accuracy is higher than that of the individual TSO and MSMA algorithms, resulting in better tracking speed and accuracy. | [24] |

| 2 | Adjusting the number of battery series and parallel connections | Seriously mismatched battery cells are connected in series. | Increase in the output power of the photovoltaic system and reduction of the impact of adaptation. | [25] | |

| 3 | Shadow detection hybrid method | An effective hybrid method for shadow detection has been proposed, which combines deep neural networks (DNN) and gradient boosting decision trees (GBDT) for joint operation. | Improvement of the energy production performance of photovoltaic arrays. | [26] | |

| 4 | Improving the mayfly algorithm | A reconstruction method based on the improved mayfly algorithm (IMA) was proposed. | Can effectively improve the output power of photovoltaic arrays and reduce mismatch losses. | [27] | |

| 5 | Minimum equilibrium difference method | A photovoltaic array reconstruction method based on the grid connected (TCT) structure has been proposed. | The output power of the reconstructed photovoltaic array has significantly increased. | [28] | |

| 6 | Peak power estimation theory and genetic algorithm | A dynamic reconstruction method based on peak power estimation has been proposed. | Improvement of the efficiency of photovoltaic array power optimization and reconstruction. | [29] | |

| 7 | Switch control method | Control the switch without changing the specific position of the photovoltaic module. | Reduction of the mismatch between photovoltaic modules and increase in the output power of the photovoltaic system. | [30,31] | |

| 8 | System reconstruction based on the hippocampus optimizer | A PV-TEG hybrid system reconstruction method based on the sea horse optimizer (SHO) was proposed. | Improvement of the power of the PV-TEG hybrid system reconstructed through SHO in all three arrays. | [32] | |

| Differential power processing | 1 | Distributed algorithm | Interaction between local voltage measurement and the differential power converter. | Implementation of MPPT tracking of series photovoltaic submodules. | [33] |

| 2 | Processing of resonant switched capacitor converters | Handling differential power among series-connected photovoltaic modules. | Avoidance of losses caused by power mismatch in photovoltaic modules. | [34] | |

| 3 | The combination of membrane swarm algorithm and radial basis function neural network | A hybrid method to improve the performance of photovoltaic systems and achieve optimal output of large system power for solar systems. | Realization of the optimal output of solar energy systems. | [35] | |

| 4 | Differential power processing topology | The use of zero current switches has the ability to monitor local MPPT. | Achievement of local MPPT tracking on a single photovoltaic component. | [36] | |

| 5 | A differential processing architecture system for SLC topology | Designed a differential power processing (DPP) converter with a switched inductor capacitor (SLC) topology structure. | Increase in the output power of photovoltaic systems. | [37] |

| Technology Application | Serial Number | Main Content | Main Conclusions | References |

|---|---|---|---|---|

| Modeling and programming | 1 | Managing various uncertainties, such as solar radiation, through adaptive risk avoidance stochastic programming methods. | The proposed method is very effective in coordinating multi-energy scheduling, minimizing operational costs/risks, and other aspects. | [38] |

| 2 | Studied the irreversibility of Al2O3 single-bond Cu/water hybrid nanofluid (NF) in PVT solar collectors. | Improvement of PV/T efficiency. | [39] | |

| 3 | Introduced theoretical and experimental research on finned one-way air type photovoltaic/thermal (PV/T) solar collectors. | The simulation and experimental results are in good agreement. | [40] | |

| 4 | Theoretical research was conducted on the solar greenhouse of PV/T system from the perspectives of energy and environment. | Optimized energy and energy efficiency. | [41] | |

| 5 | A new equivalent circuit was established to estimate the output capacity of PV/T solar collectors. | This circuit can be used to evaluate the thermal and electrical energy generated by the system. | [42] | |

| 6 | Developed a program for calculating finite volume, which can accurately obtain the temperature-related performance of the system. | Obtained optimal design parameters with maximum efficiency. | [43] | |

| 7 | Developed and validated a computational model that can be used to evaluate the impact of main control parameters on PV/T collectors. | The calculation results and experimental verification are good. | [44] | |

| Boundary conditions and changes in operating conditions | 1 | A numerical simulation study was conducted on the flow and heat transfer characteristics inside PV/T collectors with different cooling network structures. | Optimized the flow and heat transfer performance of the collector. | [45] |

| 2 | A new method based on 9E analysis was adopted to numerically evaluate the innovative heat dissipation method integrated into solar photovoltaic thermal (PV/T) air collectors. | The quantitative results indicate that the application efficiency of this system in PV/T air collectors is relatively high. | [46] | |

| 3 | Explored the influence of different backplane materials on the performance of PV/T systems. | The temperature of the PV/T collector with a TPT backplane is low, and the COP of the collector with a Cu backplane is the highest. | [47] |

| Serial Number | Main Content | Main Conclusions | References |

|---|---|---|---|

| 1 | Experiments and analysis were conducted on the heat generation characteristics of solar collectors for cogeneration. | When the conversion efficiency is between 10% and 13%, the collector efficiency is between 40% to 50% and 20% at 20 °C and 40 °C brine temperatures, respectively. | [65] |

| 2 | Proposed a method of combining a filter with propylene glycol. | Realized wavelength selective utilization of sunlight. | [66] |

| 3 | Proposed a new type of refrigerant for use in PV/T systems. | Significantly improved the output capacity of photocells. | [67] |

| 4 | Proposed a nanofluid and apply it to a condensing PV/T system as a cooling medium. | The performance of this system is higher than that of the water-cooled type. | [68] |

| Serial Number | Main Content | Main Conclusions | References |

|---|---|---|---|

| 1 | Numerical and experimental were conducted on the heat transfer characteristics of vertical photovoltaic collectors. | The efficiency of the collector increases with the increase of air mass flow rate, which reduces the temperature of the system. | [69] |

| 2 | Designed a new type of finned air fluid photovoltaic collector. | Thermal efficiency and electrical efficiency reach 37.10% and 13.56%, respectively. | [70] |

| 3 | A new type of vacuum flat panel photovoltaic-photothermal collector (E-PV/T) with a vacuum structure inside was proposed. | Under high-temperature conditions, this collector can improve the total efficiency by nearly 10.00%. | [71] |

| 4 | Proposed a parameter that can characterize the energy return of active PV/T systems—actual energy return rate. | The actual energy yield of the heat pipe PV/T system is 29.09% higher than that of the PV system. | [72] |

| 5 | Built a new type of heat pipe PV/T integrated-system experimental testing platform | The photoelectric and photothermal efficiency can reach 14.00% and 45.00%, respectively | [73] |

| 6 | Designed a new PV/T system that combines a metal backplate PV module with a flat box collector. | The photoelectric and photothermal efficiency can reach 14.00% and 37.00%, respectively. | [74] |

| 7 | Proposed a special process for combining photovoltaic silicon cells with copper tube flow channels. | The lower the power generation efficiency of the system, the lower the initial water temperature of the water tank, and the higher the thermal and electrical efficiency. | [75] |

| Serial Number | Main Content | Main Conclusions | References |

|---|---|---|---|

| 1 | This study proposes a new configuration for a photovoltaic (PV) hydrogen production system. | Maximizing system performance and reducing power output and load mismatch caused by renewable energy fluctuations. | [98,99,100] |

| 2 | Three different methods for calculating the optimal electrolytic cell are studied. | The IV estimation method has the best performance, while the PV current method has the best effect. | [101] |

| 3 | Improvements in calculation methods related to electrolytic cells are explored. | Efficiency reaches up to 99%. | [102] |

| 4 | A new system for coupled electrolytic cells is proposed. | The hydrogen gas generated is consumed in the engine to generate electricity, increasing efficiency from 14.90% to 15.70%. | [103] |

| 5 | An energy optimization model for multi energy interactions in wind power, photovoltaic hydrogen production, and hydrogen fuel cell systems (HPHFCS) for thermal power plants has been proposed. | Numerical examples and simulation results have verified the correctness and effectiveness of the model. | [104] |

| 6 | The energy utilization of the hybrid photovoltaic/electrometer/fuel cell system is analyzed, and the photovoltaic array is installed on the roof to provide electricity. | 51 PV cells with a capacity of 75 W, plus a 3.3 KW electrolytic cell, and two 480 W PEM fuel cells can completely supply energy to a 90 m2 greenhouse. | [105] |

| Serial Number | Main Content | Main Conclusions | References |

|---|---|---|---|

| 1 | Thermodynamic research and analysis were conducted on a solar-powered thermal-driven hydrogen production system. | The discharge efficiency of the collector initially increases with the increase of the surface temperature of the collecting fluid, and decreases with further temperature increase after 36 °C. | [107] |

| 2 | A new photothermal system is proposed. | The increase in system power reduces the failure rate of the trans critical CO2 condenser to 50%. | [108] |

| 3 | A new system is proposed, utilizing a solar tower system to produce thermal and electrical energy for a high-temperature electrolytic cell system. | The system can generate 7135 KW of power and 0.05 kg/s of hydrogen. The energy efficiency and thermal efficiency of the hydrogen production system are 87% and 88%, respectively. The efficiency and thermal efficiency of the power generation system are 24.79% and 22.36%, respectively. | [109] |

| 4 | A new system is proposed, using fluorinated molten salt as a heat storage system. | The efficiency of the solar hydrogen production system reaches 12.70%. | [84] |

| 5 | Different scenarios for different solar collectors are defined and compared in terms of energy and economy. | The scheme using a heliostat collector can achieve a maximum efficiency of 10.6%. | [84] |

| 6 | A new system is proposed, with the addition of a PCM storage system. | Reduction in the average cost of hydrogen by 34%. | [110] |

| Serial Number | AWE | PEM | AEM | SOEC |

|---|---|---|---|---|

| Operating temperature | 70–90 °C | 50–80 °C | 40–60 °C | 700–850 °C |

| working pressure | 1–30 bar | <70 bar | <35 bar | 1 bar |

| Electrolyte | KOH 5–7 mol/L | PFSA | DVB polymer carrier doped with KOH or NaHCO3 1 mol−1 | Yttria-stabilized Zirconia (YSZ) |

| Partitive membrane | PPS network fixed ZrO2 | Solid electrolyte | Solid electrolyte | Solid electrolyte |

| Electrode/catalyst (Oxygen side) | Nickel plated perforated stainless steel | Iridium oxide | High surface area Ni or NiFeCo alloy | Perovskite type |

| Current density (A/cm2) | <0.8 | 1.0~4.0 | 1.0~2.0 | 0.2~0.4 |

| Power consumption (KWh/Nm3) | 4.2~5.5 | 4.3~6.0 | 4.5~5.5 | 3.0~4.0 |

| Hydrogen purity | 99.8% | 99.9% | 99.9% | 99.9% |

| Electrode/Catalyst (Hydrogen side) | Nickel-plated perforated stainless steel | Platinum nanoparticles on black carbon | High surface area Ni | Ni/YSZ |

| Porous transport layer anode | Nickel contamination screen | Platinum-plated sintered porous titanium | Nickel foam | Nickel contamination Screen/Nickel foam |

| Porous transport layer cathode | Nickel contamination screen | Sintered porous titanium/Carbon cloth | Nickel foam/Carbon cloth | / |

| Bipolar plate anode | Nickel-plated steel | Platinum-plated titanium | Nickel-plated steel | / |

| Bipolar plate cathode | Nickel-plated steel | Platinum-plated titanium | Nickel-plated steel | Cobalt-plated stainless steel |

| Frame and scalability | PSU, PTFE, EPDM | PTFE, PSU, ETFE | PTFE, Si | Glass-ceramics |

| Maximum single cell size (Nm3/h) | 2000 | 500 | / | / |

| Item | AWE | PEM | ||||

|---|---|---|---|---|---|---|

| Present | 2030 | 2050 | Present | 2030 | 2050 | |

| Electricity price (CNY/kWh) | 0.35 | 0.25 | 0.20 | 0.35 | 0.22 | 0.18 |

| Unit power consumption (kWh/m3) | 5 | 5 | 5 | 5 | 5 | 5 |

| Unit power consumption cost | 1.75 | 1.25 | 1 | 1.75 | 1.10 | 0.90 |

| Hydrogen production capacity of equipment (Nm3/h) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Power (KW) | 5000 | 5000 | 5000 | 5000 | 5000 | 5000 |

| Annual operating hours (h) | 3000 | 3500 | 4000 | 3000 | 4000 | 4500 |

| Equipment unit price (CNY/KW) | 3500 | 2500 | 2000 | 11,000 | 7000 | 5000 |

| Equipment price (ten thousand CNY) | 1750 | 1250 | 1000 | 5500 | 3500 | 2500 |

| Period of depreciation (year) | 20 | 20 | 20 | 15 | 15 | 15 |

| Equipment depreciation (CNY/year) | 875,000 | 625,000 | 500,000 | 3,666,667 | 2,333,333 | 1,666,667 |

| Equipment operation and maintenance (CNY/year) | 200,000 | 200,000 | 200,000 | 200,000 | 200,000 | 200,000 |

| Unit water consumption (kg/m3) | 0.82 | 0.82 | 0.82 | 0.82 | 0.82 | 0.82 |

| Water price (CNY/kg) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 |

| Hydrogen production cost (CNY/m3) | 2.14 | 1.52 | 1.21 | 3.07 | 1.77 | 1.35 |

| Hydrogen production cost (CNY/kg) | 24.07 | 17.07 | 13.58 | 34.52 | 19.85 | 15.15 |

| Proportion of electricity consumption cost (%) | 82 | 82 | 83 | 57 | 62 | 67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Xu, X.; Bao, D.; Rasakhodzhaev, B.; Jobir, A.; Chang, C.; Zhao, M. Research on Hydrogen Production System Technology Based on Photovoltaic-Photothermal Coupling Electrolyzer. Energies 2023, 16, 7982. https://doi.org/10.3390/en16247982

Li Y, Xu X, Bao D, Rasakhodzhaev B, Jobir A, Chang C, Zhao M. Research on Hydrogen Production System Technology Based on Photovoltaic-Photothermal Coupling Electrolyzer. Energies. 2023; 16(24):7982. https://doi.org/10.3390/en16247982

Chicago/Turabian StyleLi, Yuanyuan, Xiaoyu Xu, Daorina Bao, Bakhramzhan Rasakhodzhaev, Akhadov Jobir, Chun Chang, and Mingzhi Zhao. 2023. "Research on Hydrogen Production System Technology Based on Photovoltaic-Photothermal Coupling Electrolyzer" Energies 16, no. 24: 7982. https://doi.org/10.3390/en16247982

APA StyleLi, Y., Xu, X., Bao, D., Rasakhodzhaev, B., Jobir, A., Chang, C., & Zhao, M. (2023). Research on Hydrogen Production System Technology Based on Photovoltaic-Photothermal Coupling Electrolyzer. Energies, 16(24), 7982. https://doi.org/10.3390/en16247982