Experimental Investigations of a Single-Slope Solar Still: Energy and Exergy Analysis

Abstract

:1. Introduction

2. Materials and Methods

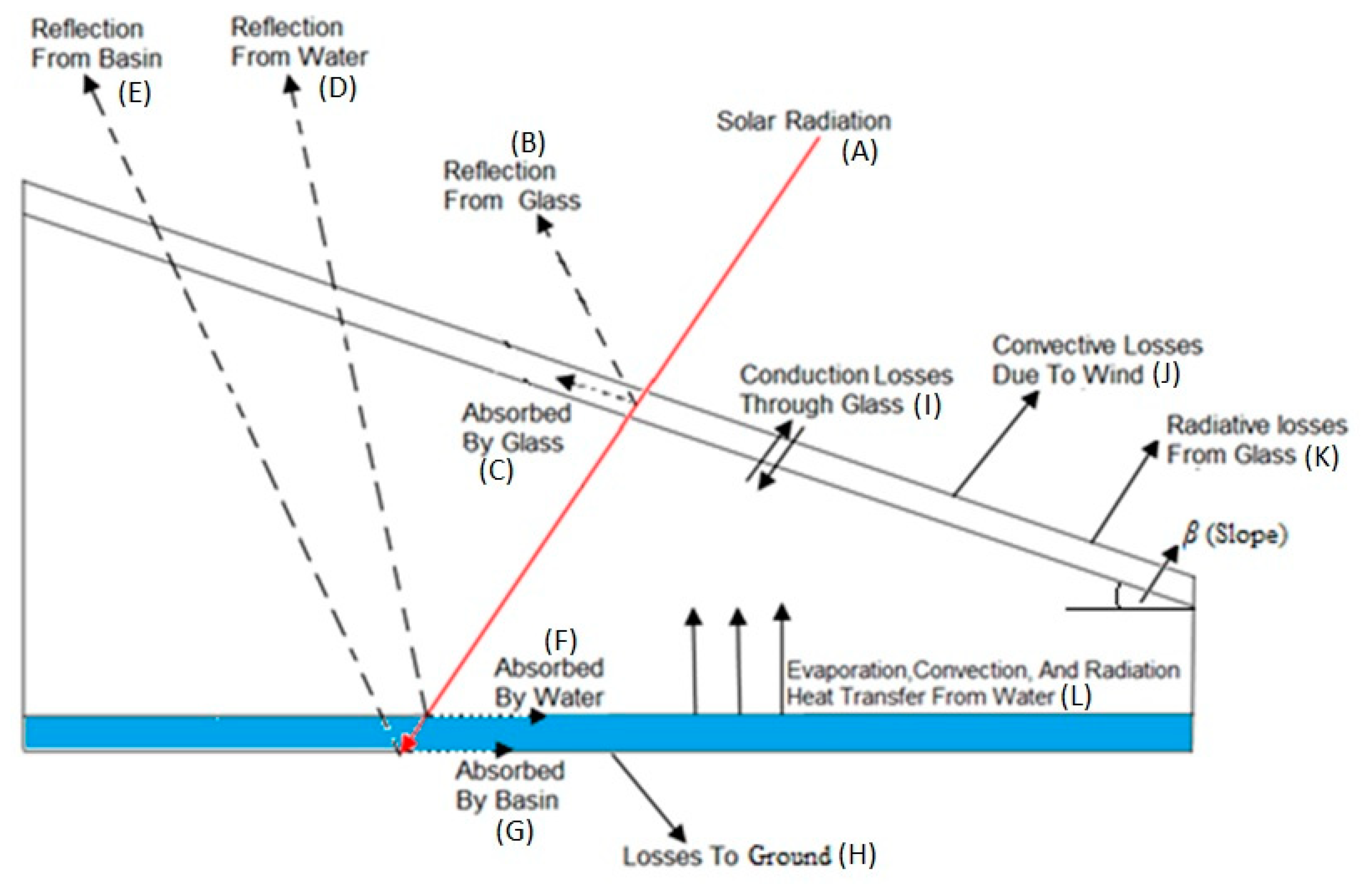

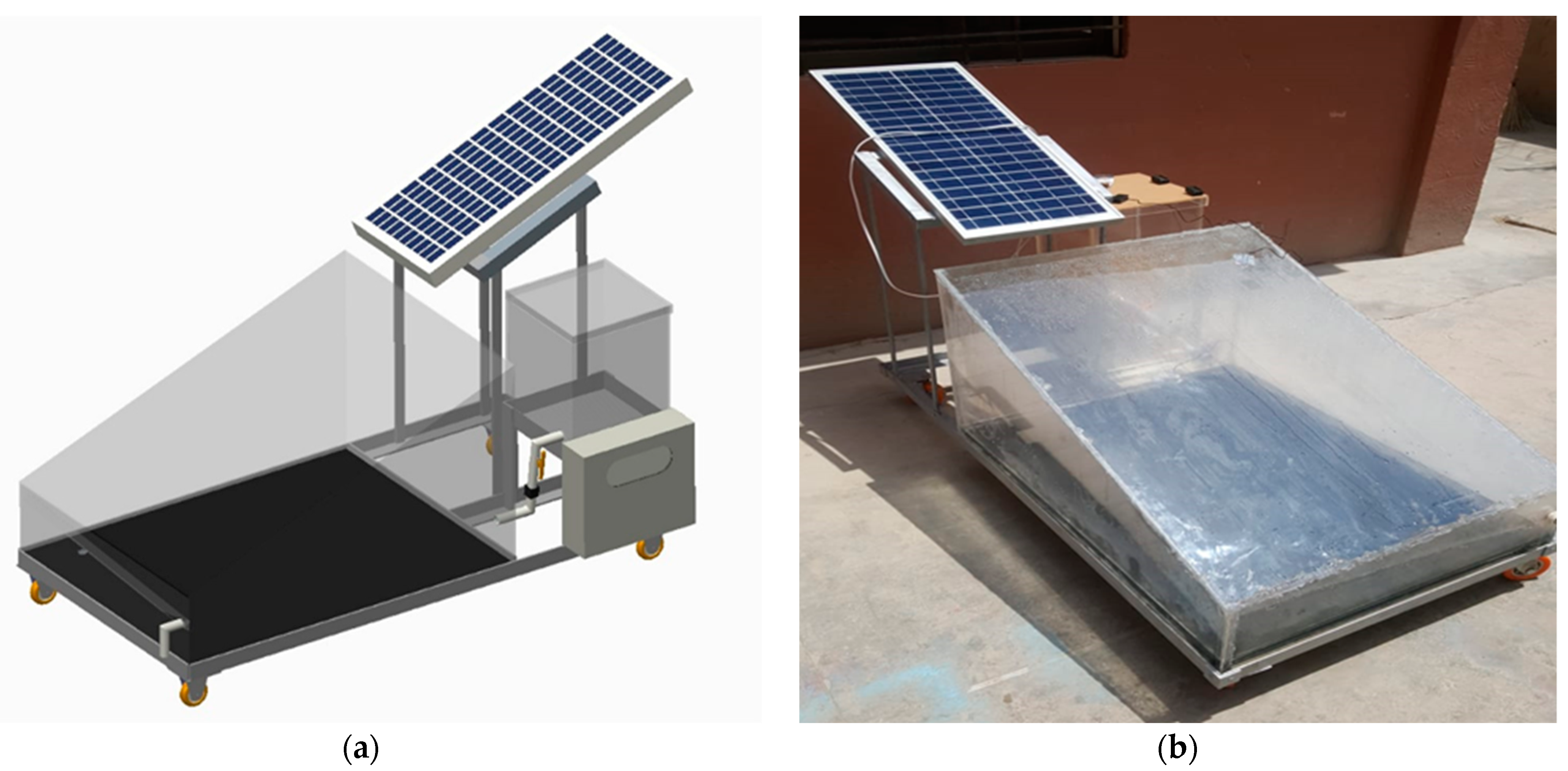

2.1. Design of Solar Still

2.2. Mathematical Modeling

- (i)

- Steady-state conditions occur during the time interval (steady operation over an hour).

- (ii)

- No vapor can escape from the still (no vapor leakage).

- (iii)

- The heat capacity of the glass cover, thermoelectric module surface and basin liner is negligible.

- (iv)

- The level of saline water remains constant in the basin.

2.2.1. Heat Transfer Calculations

2.2.2. Energy Balance

Inner Surface of Glass Housing

Basin Liner

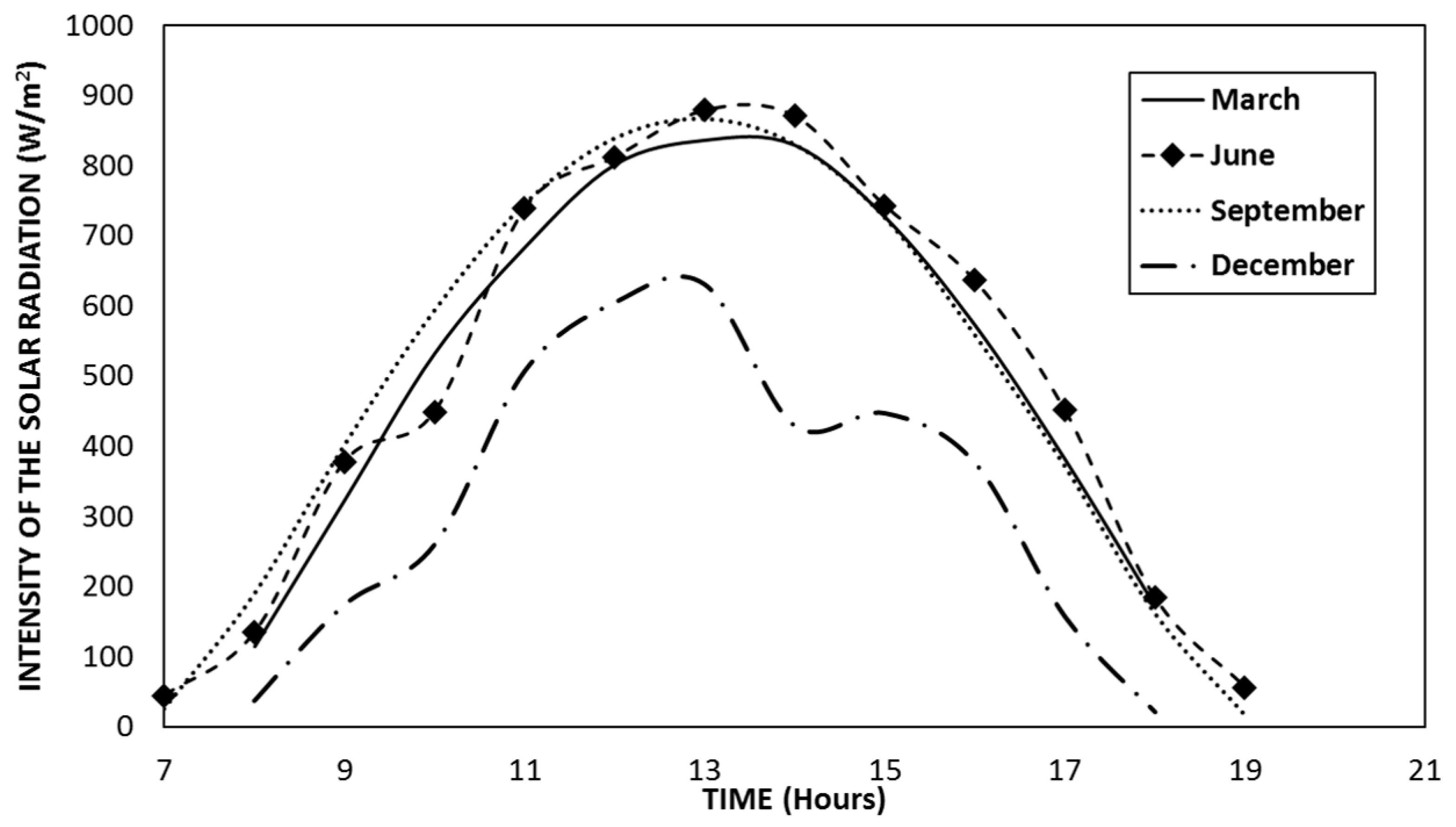

2.2.3. Solar Radiation

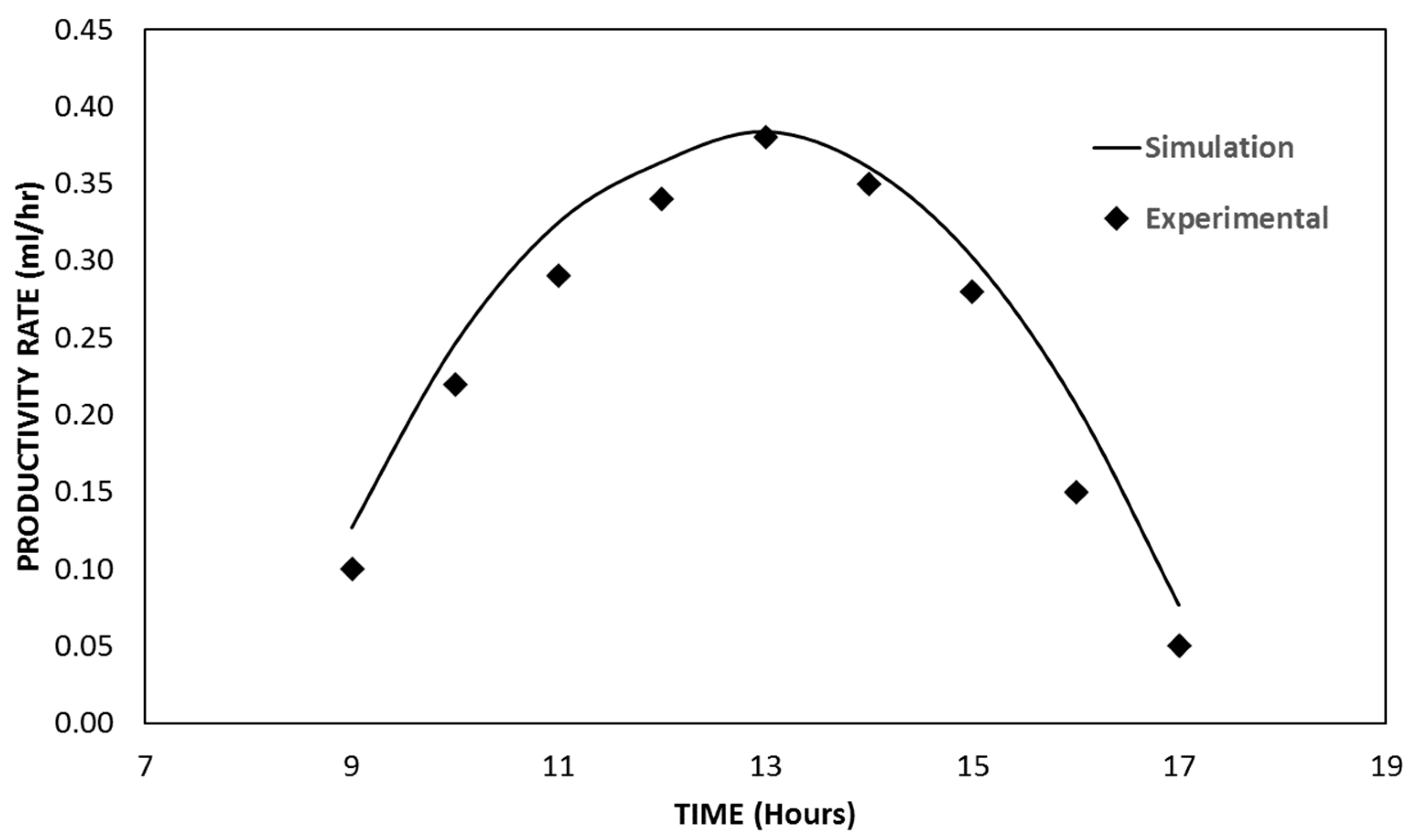

2.2.4. Productivity Rate and Solar Still Efficiency

2.2.5. Solar Still Exergetic Efficiency

2.3. Experimental Setup

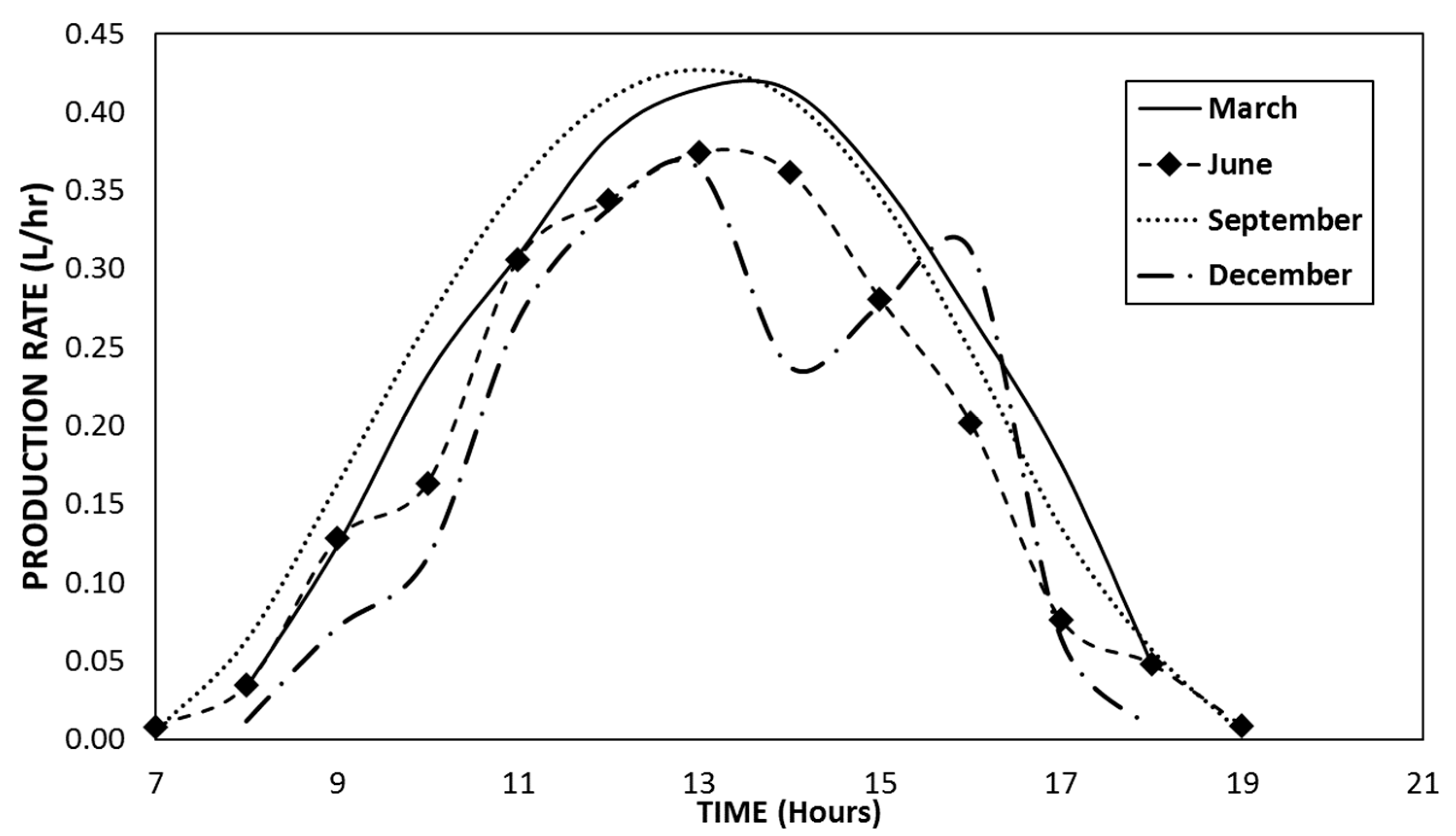

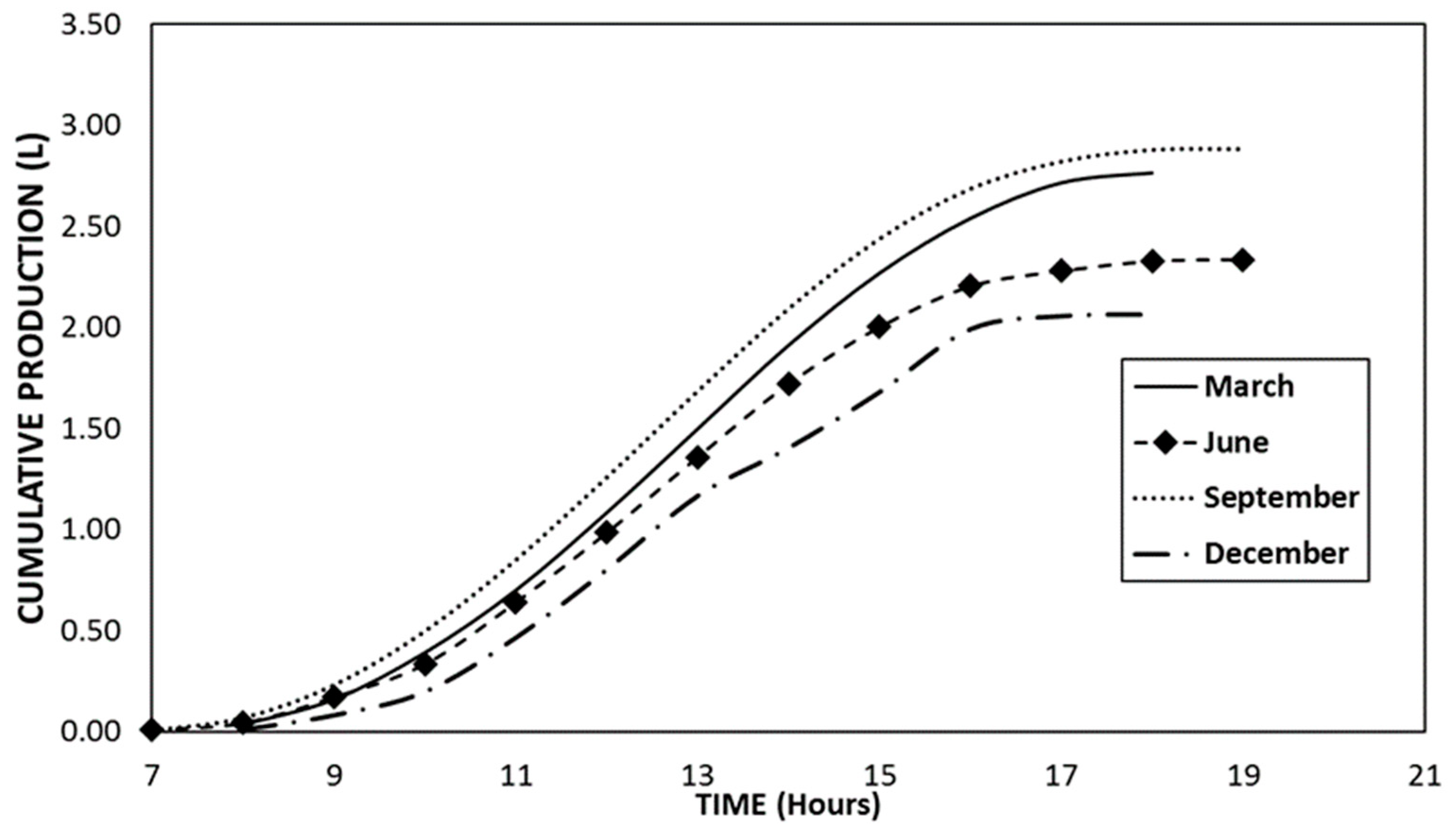

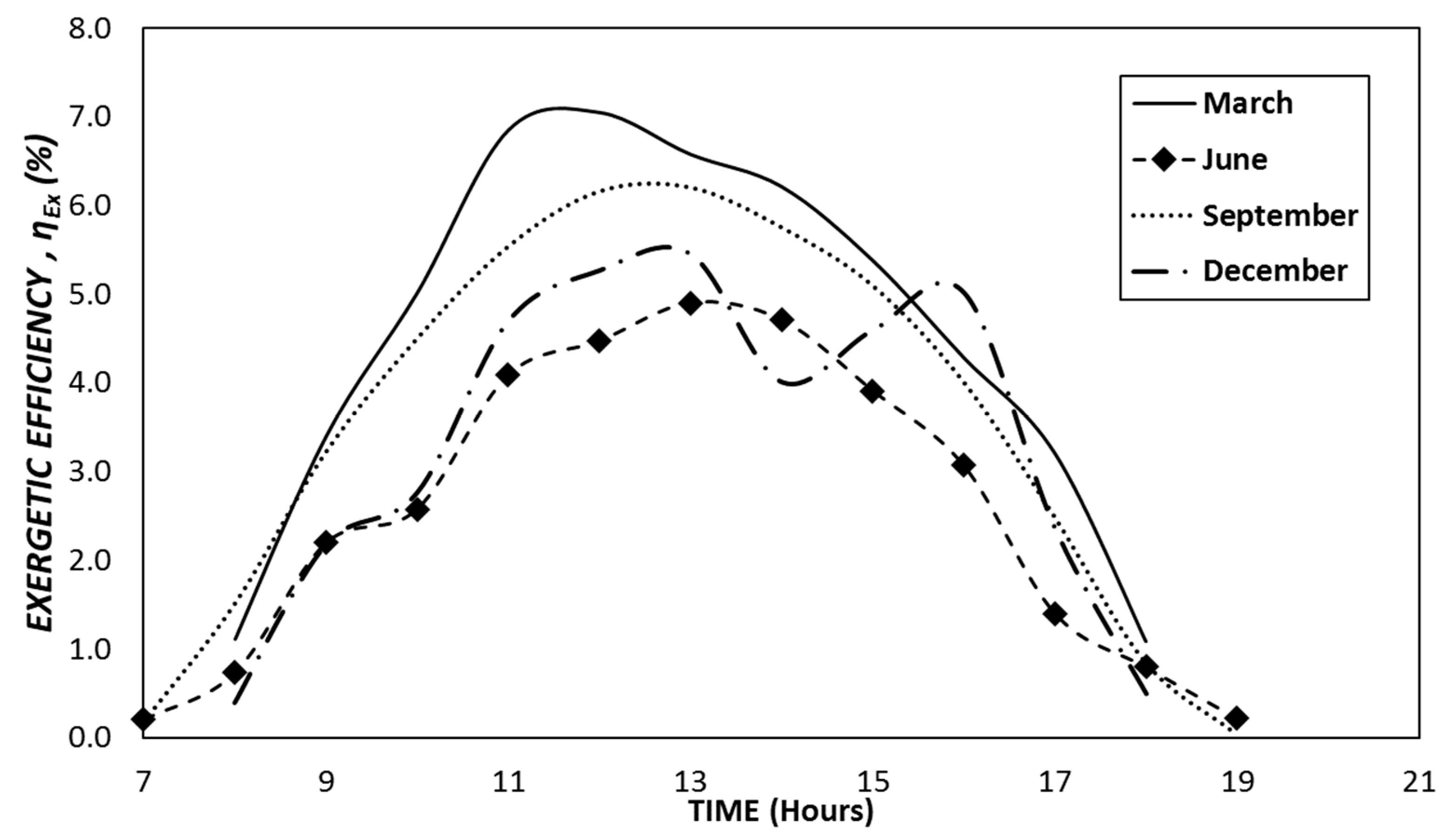

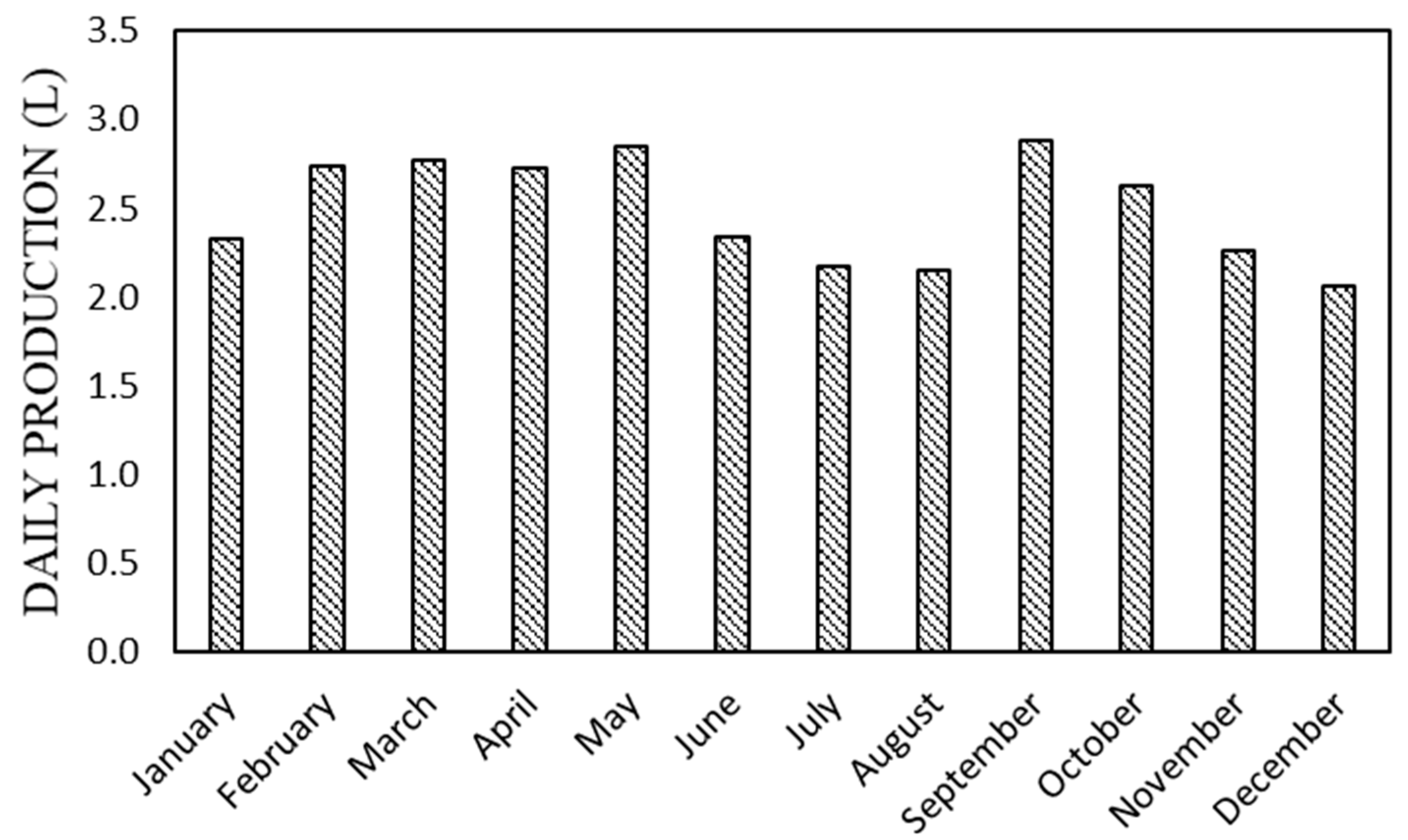

3. Results and Discussion

4. Comparison of Similar Studies

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| CAD | Computer-Aided Design |

| PV | Photovoltaic |

| NED | Nadirshaw Eduljee Dinshaw |

| MSF | Multi-Stage Flash |

| MED | Multi-Effect Distillation |

| VC | Vapor Compression |

| RO | Reverse Osmosis |

| FO | Forward Osmosis |

| ED | Electrodialysis |

| KANUPP | Karachi Nuclear Power Plant |

References

- Karachi, Pakistan Population (2022)—Population Stat. Available online: https://populationstat.com/pakistan/karachi (accessed on 7 March 2022).

- Ali, S.; Al-Amri, F.; Saeed, F. Numerical and Experimental Performance Evaluation of a Photovoltaic Thermal Integrated Membrane Desalination System. Energies 2022, 15, 7417. [Google Scholar] [CrossRef]

- Hariri, N.G.; Almutawa, M.A.; Osman, I.S.; Almadani, I.K.; Almahdi, A.M.; Ali, S. Experimental Investigation of Azimuth- and Sensor-Based Control Strategies for a PV Solar Tracking Application. Appl. Sci. 2022, 12, 4758. [Google Scholar] [CrossRef]

- Al-Amri, F.; Maatallah, T.S.; Al-Amri, O.F.; Ali, S.; Ali, S.; Ateeq, I.S.; Zachariah, R.; Kayed, T.S. Innovative Technique for Achieving Uniform Temperatures across Solar Panels Using Heat Pipes and Liquid Immersion Cooling in the Harsh Climate in the Kingdom of Saudi Arabia. Alex. Eng. J. 2022, 61, 1413–1424. [Google Scholar] [CrossRef]

- Siddiqui, M.U.; Ali, S.; Khan, S.; Ali, S.; Horoub, M.M. Optimum Tilt Angles of Solar Collectors in Saudi Arabia. In Proceedings of the 2021 International Conference on Electrical, Communication, and Computer Engineering (ICECCE), Kuala Lumpur, Malaysia, 12–13 June 2021; Available online: https://ieeexplore.ieee.org/document/9514079 (accessed on 4 October 2023).

- Khan, S.; Ahmad, N. Renewable Energy Generation and Storage. In Sustainable Energy Storage for Furthering Renewable Energy; Begell House: Danbury, CT, USA, 2022. [Google Scholar] [CrossRef]

- PVWatts Calculator. Available online: https://pvwatts.nrel.gov/pvwatts.php (accessed on 7 March 2022).

- Shukla, D.; Modi, K. Hybrid Solar Still as a Co-Generative System and Desalination System—An Experimental Performance Evaluation. Clean. Eng. Technol. 2021, 2, 100063. [Google Scholar] [CrossRef]

- Essa, F.A.; Abdullah, A.S.; Omara, Z.M. Rotating Discs Solar Still: New Mechanism of Desalination. J. Clean. Prod. 2020, 275, 123200. [Google Scholar] [CrossRef]

- Chen, Z.; Peng, J.; Chen, G.; Hou, L.; Yu, T.; Yao, Y.; Zheng, H. Analysis of Heat and Mass Transferring Mechanism of Multi-Stage Stacked-Tray Solar Seawater Desalination Still and Experimental Research on Its Performance. Sol. Energy 2017, 142, 278–287. [Google Scholar] [CrossRef]

- Xie, G.; Sun, L.; Mo, Z.; Liu, H.; Du, M. Conceptual Design and Experimental Investigation Involving a Modular Desalination System Composed of Arrayed Tubular Solar Stills. Appl. Energy 2016, 179, 972–984. [Google Scholar] [CrossRef]

- Sharshir, S.W.; Peng, G.; Yang, N.; El-Samadony, M.O.A.; Kabeel, A.E. A Continuous Desalination System Using Humidification—Dehumidification and a Solar Still with an Evacuated Solar Water Heater. Appl. Therm. Eng. 2016, 104, 734–742. [Google Scholar] [CrossRef]

- Sharshir, S.W.; Peng, G.; Yang, N.; Eltawil, M.A.; Ali, M.K.A.; Kabeel, A.E. A Hybrid Desalination System Using Humidification-Dehumidification and Solar Stills Integrated with Evacuated Solar Water Heater. Energy Convers. Manag. 2016, 124, 287–296. [Google Scholar] [CrossRef]

- Parsa, S.M.; Rahbar, A.; Koleini, M.H.; Aberoumand, S.; Afrand, M.; Amidpour, M. A Renewable Energy-Driven Thermoelectric-Utilized Solar Still with External Condenser Loaded by Silver/Nanofluid for Simultaneously Water Disinfection and Desalination. Desalination 2020, 480, 114354. [Google Scholar] [CrossRef]

- Rahbar, N.; Esfahani, J.A. Experimental Study of a Novel Portable Solar Still by Utilizing the Heatpipe and Thermoelectric Module. Desalination 2012, 284, 55–61. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, D.; Devnani, G.L.; Sinha, S.; Singh, D. Potable Water Production via Desalination Technique Using Solar Still Integrated with Partial Cooling Coil Condenser. Sustain. Energy Technol. Assess. 2021, 43, 100927. [Google Scholar] [CrossRef]

- Sadeghi, G.; Nazari, S. Retrofitting a Thermoelectric-Based Solar Still Integrated with an Evacuated Tube Collector Utilizing an Antibacterial-Magnetic Hybrid Nanofluid. Desalination 2021, 500, 114871. [Google Scholar] [CrossRef]

- Bataineh, K.M.; Abbas, M.A. Improving the Performance of Solar Still by Using Nanofluids, Vacuuming, and Optimal Basin Water Thickness. Desalination Water Treat. 2020, 173, 105–116. [Google Scholar] [CrossRef]

- Bataineh, K.M.; Abbas, M.A. Performance Analysis of Solar Still Integrated with Internal Reflectors and Fins. Sol. Energy 2020, 205, 22–36. [Google Scholar] [CrossRef]

- Sohani, A.; Hoseinzadeh, S.; Berenjkar, K. Experimental Analysis of Innovative Designs for Solar Still Desalination Technologies; An in-Depth Technical and Economic Assessment. J. Energy Storage 2021, 33, 101862. [Google Scholar] [CrossRef]

- Abdelmaksoud, W.; Almaghrabi, M.; Alruwaili, M.; Alruwaili, A. Improving Water Productivity in Active Solar Still. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 2774–2787. [Google Scholar] [CrossRef]

- Bouzaid, M.; Ansari, O.; Taha-Janan, M.; Mouhsin, N.; Oubrek, M. Numerical Analysis of Thermal Performances for a Novel Cascade Solar Desalination Still Design. Energy Procedia 2019, 157, 1071–1082. [Google Scholar] [CrossRef]

- Abujazar, M.S.S.; Fatihah, S.; Kabeel, A.E. Seawater Desalination Using Inclined Stepped Solar Still with Copper Trays in a Wet Tropical Climate. Desalination 2017, 423, 141–148. [Google Scholar] [CrossRef]

- Al-harahsheh, M.; Abu-Arabi, M.; Mousa, H.; Alzghoul, Z. Solar Desalination Using Solar Still Enhanced by External Solar Collector and PCM. Appl. Therm. Eng. 2018, 128, 1030–1040. [Google Scholar] [CrossRef]

- Abu-Arabi, M.; Al-harahsheh, M.; Mousa, H.; Alzghoul, Z. Theoretical Investigation of Solar Desalination with Solar Still Having Phase Change Material and Connected to a Solar Collector. Desalination 2018, 448, 60–68. [Google Scholar] [CrossRef]

- Aqlan, A.M.; Aklan, M.; Momin, A.E. Solar-Powered Desalination, a Novel Solar Still Directly Connected to Solar Parabolic Trough. Energy Rep. 2021, 7, 2245–2254. [Google Scholar] [CrossRef]

- Khanmohammadi, S.; Khanjani, S. Experimental Study to Improve the Performance of Solar Still Desalination by Hydrophobic Condensation Surface Using Cold Plasma Technology. Sustain. Energy Technol. Assess. 2021, 45, 101129. [Google Scholar] [CrossRef]

- Khanmohammadi, S.; Khanmohammadi, S. Energy, Exergy and Exergo-Environment Analyses, and Tri-Objective Optimization of a Solar Still Desalination with Different Insulations. Energy 2019, 187, 115988. [Google Scholar] [CrossRef]

- Asbik, M.; Ansari, O.; Bah, A.; Zari, N.; Mimet, A.; El-Ghetany, H. Exergy Analysis of Solar Desalination Still Combined with Heat Storage System Using Phase Change Material (PCM). Desalination 2016, 381, 26–37. [Google Scholar] [CrossRef]

- Mousa, H.; Naser, J.; Gujarathi, A.M.; Al-Sawafi, S. Experimental Study and Analysis of Solar Still Desalination Using Phase Change Materials. J. Energy Storage 2019, 26, 100959. [Google Scholar] [CrossRef]

- Elbar, A.R.A.; Hassan, H. Enhancement of Hybrid Solar Desalination System Composed of Solar Panel and Solar Still by Using Porous Material and Saline Water Preheating. Sol. Energy 2020, 204, 382–394. [Google Scholar] [CrossRef]

- Mahmoud, A.; Fath, H.; Ahmed, M. Enhancing the Performance of a Solar Driven Hybrid Solar Still/Humidification-Dehumidification Desalination System Integrated with Solar Concentrator and Photovoltaic Panels. Desalination 2018, 430, 165–179. [Google Scholar] [CrossRef]

- Mahmoud, A.; Fath, H.; Ookwara, S.; Ahmed, M. Influence of Partial Solar Energy Storage and Solar Concentration Ratio on the Productivity of Integrated Solar Still/Humidification-Dehumidification Desalination Systems. Desalination 2019, 467, 29–42. [Google Scholar] [CrossRef]

- Kumar, Y.A.; Kim, H.-J. Effect of Time on a Hierarchical Corn Skeleton-like Composite of CoO@ ZnO as Capacitive Electrode Material for High Specific Performance Supercapacitors. Energies 2018, 11, 3285. [Google Scholar] [CrossRef]

- Moniruzzaman, M.; Anil Kumar, Y.; Pallavolu, M.R.; Arbi, H.M.; Alzahmi, S.; Obaidat, I.M. Two-Dimensional Core-Shell Structure of Cobalt-Doped@ MnO2 Nanosheets Grown on Nickel Foam as a Binder-Free Battery-Type Electrode for Supercapacitor Application. Nanomaterials 2022, 12, 3187. [Google Scholar] [CrossRef]

- Kabeel, A.E.; El-Maghlany, W.M.; Abdelgaied, M.; Abdel-Aziz, M.M. Performance Enhancement of Pyramid-Shaped Solar Stills Using Hollow Circular Fins and Phase Change Materials. J. Energy Storage 2020, 31, 101610. [Google Scholar] [CrossRef]

- Kabeel, A.E. Performance of Solar Still with a Concave Wick Evaporation Surface. Energy 2009, 34, 1504–1509. [Google Scholar] [CrossRef]

- Amjad, F.; Shah, L.A. Identification and Assessment of Sites for Solar Farms Development Using GIS and Density Based Clustering Technique- A Case of Pakistan. Renew. Energy 2020, 155, 761–769. [Google Scholar] [CrossRef]

- Ali Samee, M.; Mirza, U.K.; Majeed, T.; Ahmad, N. Design and Performance of a Simple Single Basin Solar Still. Renew. Sustain. Energy Rev. 2007, 11, 543–549. [Google Scholar] [CrossRef]

- Jamil, M.A.; Yaqoob, H.; Farooq, M.U.; Teoh, Y.H.; Xu, B.B.; Mahkamov, K.; Sultan, M.; Ng, K.C.; Shahzad, M.W. Experimental Investigations of a Solar Water Treatment System for Remote Desert Areas of Pakistan. Water 2021, 13, 1070. [Google Scholar] [CrossRef]

- Malik, A.; Qureshi, S.R.; Abbas, N.; Zaidi, A.A. Energy and Exergy Analyses of a Solar Desalination Plant for Karachi Pakistan. Sustain. Energy Technol. Assess. 2020, 37, 100596. [Google Scholar] [CrossRef]

- Dehghan, A.A.; Afshari, A.; Rahbar, N. Thermal Modeling and Exergetic Analysis of a Thermoelectric Assisted Solar Still. Sol. Energy 2015, 115, 277–288. [Google Scholar] [CrossRef]

- Elango, C.; Gunasekaran, N.; Sampathkumar, K. Thermal Models of Solar Still—A Comprehensive Review. Renew. Sustain. Energy Rev. 2015, 47, 856–911. [Google Scholar] [CrossRef]

- Hussein, A.K.; Rashid, F.L.; Abed, A.M.; Al-Khaleel, M.; Togun, H.; Ali, B.; Akkurt, N.; Malekshah, E.H.; Biswal, U.; Al-Obaidi, M.A.; et al. Inverted solar stills: A comprehensive review of designs, mathematical models, performance, and modern combinations. Sustainability 2022, 14, 13766. [Google Scholar] [CrossRef]

- Elsaie, Y.; Soussa, H.; Gado, M.; Balah, A. Water Desalination in Egypt; Literature Review and Assessment. Ain Shams Eng. J. 2022, 14, 101998. [Google Scholar] [CrossRef]

- Ouda, O.K.M. Domestic Water Demand in Saudi Arabia: Assessment of Desalinated Water as Strategic Supply Source. Desalination Water Treat. 2015, 56, 2824–2834. [Google Scholar]

- Projects Archive—Water Technology. Available online: https://www.water-technology.net/projects/ (accessed on 24 February 2023).

- Nemmeli Desalination Plant: A Reliable Model for Coastal India—For Pure Water, Think WABAG! Available online: https://www.wabag.com/project/nemmeli-desalination-plant-providing-sustainable-solutions-through-desalination/ (accessed on 24 February 2023).

- Khan, S.U.-D.; Khan, S.U.-D. Karachi Nuclear Power Plant (KANUPP): As Case Study for Techno-Economic Assessment of Nuclear Power Coupled with Water Desalination. Energy 2017, 127, 372–380. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Glass thickness (Lg) | 0.01 m |

| Area of glass (Ag) | 1 × 1.5 m2 |

| Slope | 25° |

| Solar collector (PV panel) | 32 × 14 inch |

| PV panel power | 30 W |

| Depth of water (D) | 0.04 m |

| Temperature inlet (Tin) | 25 °C |

| Thickness of insulator (Lins) | 0.003 m |

| Parameter | Value |

|---|---|

| Thermal conductivity of glass (Kg) | 1 W/m2K |

| Emissivity of glass (g) | 0.1 |

| Absorptivity of glass (g) | 0.1 |

| Reflectivity of glass (Rg) | 0.2 |

| Thermal conductivity of insulator (Kins) | 0.038 W/m2K |

| Emissivity of water (w) | 0.1 |

| Reflectivity of water (Rw) | 0.02 |

| Absorptivity of water (w) | 0.8 |

| Absorptivity of basin (b) | 0.8 |

| ) | 2400 kJ/kg |

| S. No | Authors Name and Year | Plant | Location | Type of Experiment | Yield (m3/Day) |

|---|---|---|---|---|---|

| 1 | Yasser et al. [45] | Ayoun Mosa | Sinai, Egypt | Multi-stage flash | 10,000 |

| 2 | Yasser et al. [45] | El Sokhna | El Sokhna, Egypt | Multiple-effect distillation | 8000 |

| 3 | Omar Ouda [46] | Jubail RO | Jubail, Saudi Arabia | Reverse osmosis | 178,560 |

| 4 | Omar Ouda [46] | Yanbu 2 | Yanbu, Saudi Arabia | Multiple-effect distillation | 68,190 |

| 5 | Water Technology Projects [47] | Minjur | Chennai, India | Reverse osmosis | 100,000 |

| 6 | Nemmeli desalination plant [48] | Nemilli | Chennai, India | Reverse osmosis | 93,000 |

| 7 | Khan & Khan [49] | KANUPP | Karachi, Pakistan | Multi-stage flash | 4550 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, H.; Ali, S.; Khan, S.; Siddiqui, M.U. Experimental Investigations of a Single-Slope Solar Still: Energy and Exergy Analysis. Energies 2023, 16, 7659. https://doi.org/10.3390/en16227659

Ali H, Ali S, Khan S, Siddiqui MU. Experimental Investigations of a Single-Slope Solar Still: Energy and Exergy Analysis. Energies. 2023; 16(22):7659. https://doi.org/10.3390/en16227659

Chicago/Turabian StyleAli, Haider, Sajid Ali, Sikandar Khan, and Muhammad Umar Siddiqui. 2023. "Experimental Investigations of a Single-Slope Solar Still: Energy and Exergy Analysis" Energies 16, no. 22: 7659. https://doi.org/10.3390/en16227659

APA StyleAli, H., Ali, S., Khan, S., & Siddiqui, M. U. (2023). Experimental Investigations of a Single-Slope Solar Still: Energy and Exergy Analysis. Energies, 16(22), 7659. https://doi.org/10.3390/en16227659