1. Introduction

In 2009, Morocco adopted an energy strategy primarily centered on the utilization of renewable energy sources, enhancing energy efficiency, and bolstering regional integration. This comprehensive approach, implemented through specific programs and supported by pertinent legislative and institutional reforms, has proven its effectiveness and relevance. It has enabled Morocco to transition from a nation heavily reliant on foreign fossil fuels to becoming an energy producer from renewable sources.

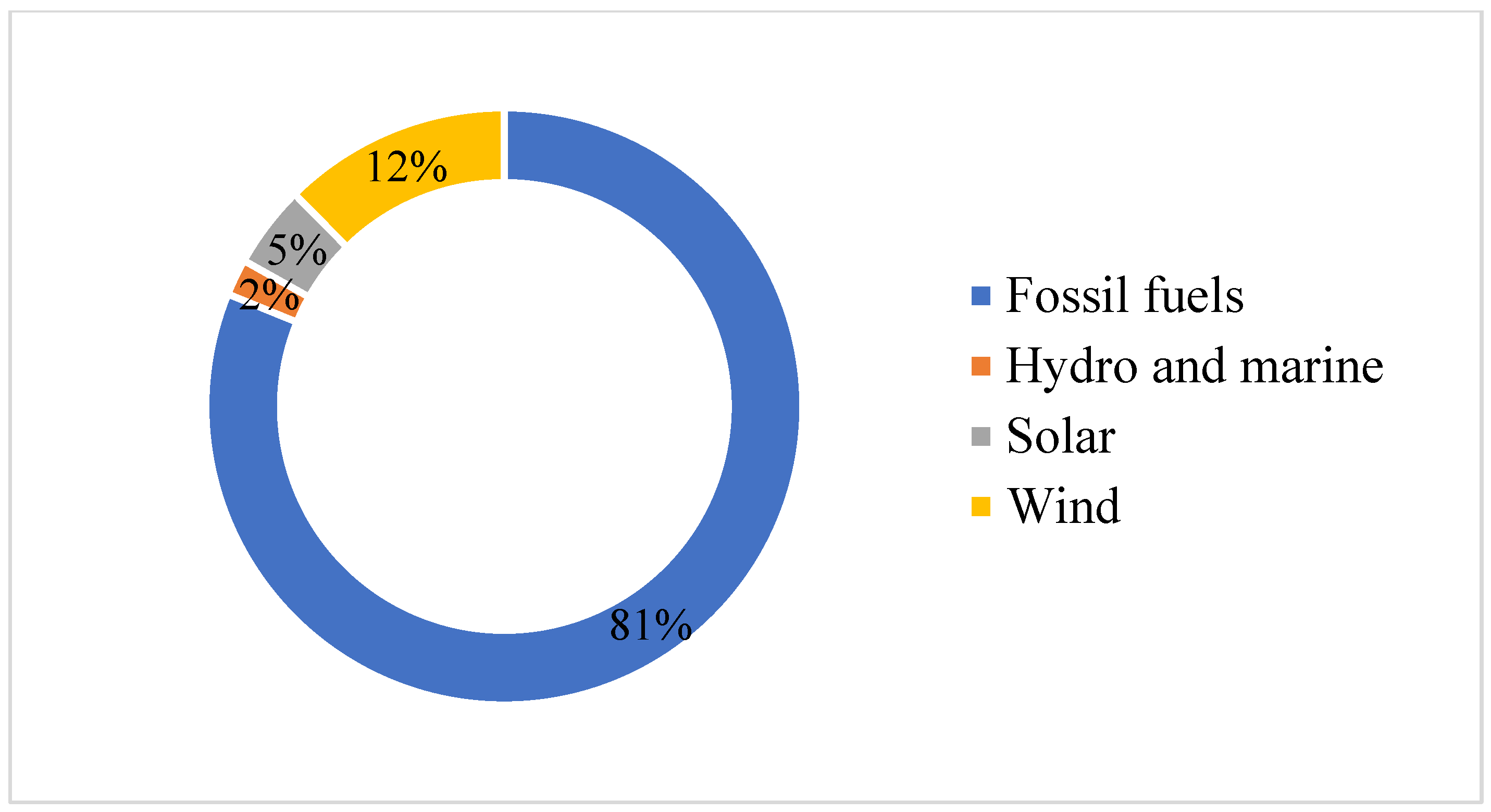

Figure 1 provides a visual representation of the energy production composition in Morocco for the year 2021. Historically, a significant portion of Morocco’s electricity was generated from fossil fuels such as oil, gas, and coal, amounting to approximately 41,343 GWh in 2021, with 19% now originating from renewable sources. Solar energy, especially photovoltaic (PV) solar energy, plays a central role in Morocco’s renewable energy initiatives and is poised to emerge as a leader in the renewable energy sector. Consequently, Morocco has outlined a clear strategy to achieve a 42% share of electricity production from renewable sources.

In pursuit of this objective, Morocco is actively deploying numerous PV installations, as illustrated in

Figure 2, showing the evolution of installed solar power capacities from 2015 to 2021, with a percentage increase reaching up to 80%. These installations are notably concentrated in five key locations: Ouarzazate, Ain Bni Mathar, Foum Al Oued, Boujdour, and Sebkhat Tah. Furthermore, Morocco has set its sights on achieving a planned 52% electricity production from renewable sources by 2030. This strategic approach will reduce energy dependency, promote environmental conservation through the limitation of greenhouse gas emissions, and contribute to the global effort to combat climate change, aligning with commitments made in 2015.

Morocco’s considerable solar energy potential, with approximately 300 sunny days per year and an average annual global solar radiation of 2600 kWh/m2/year, are pivotal factors in meeting investor expectations regarding system performance and economic returns. It is evident that photovoltaic solar energy will emerge as a major future source of electricity production in Morocco, given its favorable climatic conditions and solar potential.

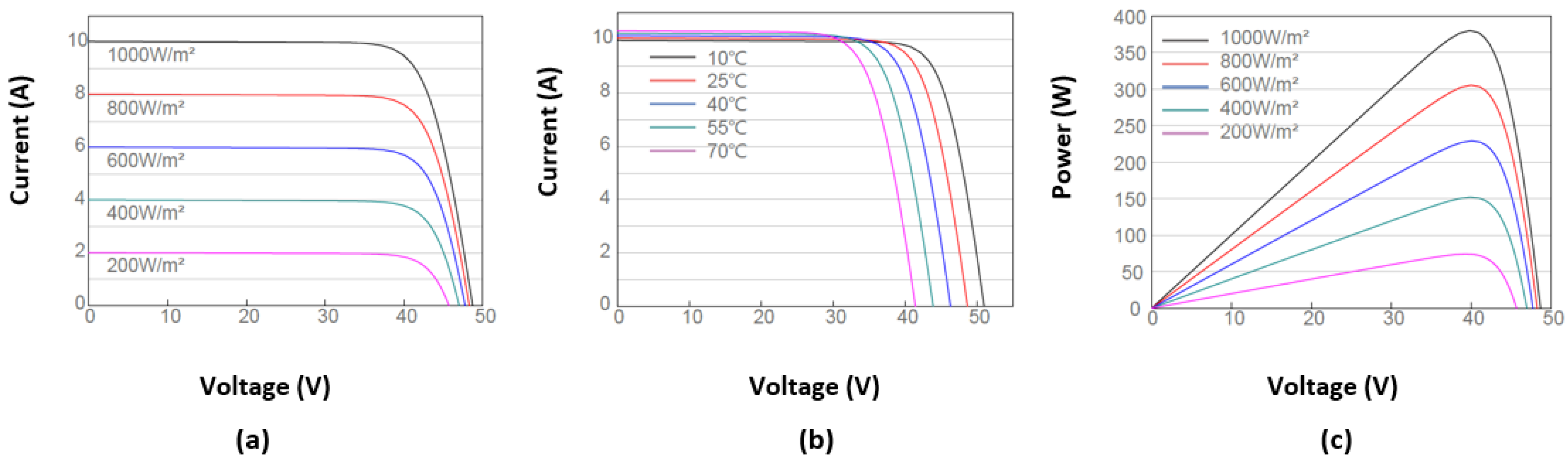

The performance of a grid-connected photovoltaic system relies on a balanced combination of technological factors such as solar cell technology, inverters, and system configuration, as well as meteorological parameters, including global solar irradiance, ambient temperature, and losses in the soil. For instance, research efforts, have scrutinized the performance of photovoltaic systems by comparing various photovoltaic technologies based on simulated energy production [

3]. Furthermore, studies have examined the experimental behavior of two commonly used photovoltaic module technologies, namely, monocrystalline silicon (m-Si) and polycrystalline silicon (p-Si) [

4].

A study closely monitored the performance of four rooftop grid-connected photovoltaic systems in Abu Dhabi, United Arab Emirates (UAE), over the course of one year. Their findings provide valuable insights into the comparative performance of different photovoltaic technologies. They concluded that monocrystalline silicon cells consistently outperformed polycrystalline silicon cells in terms of monthly average final yield, highlighting the advantages of monocrystalline silicon in this specific context [

5]. This underscores the importance of making informed choices regarding photovoltaic technology to optimize the performance of photovoltaic systems, depending on geographical and environmental conditions.

Several research studies have thoroughly examined the performance parameters of photovoltaic power plants installed in different geographical regions and under various climatic conditions [

6]. Respected researchers have also made significant advancements in the field of modeling for solar thermal, photovoltaic, and solar radiation [

7,

8,

9,

10].

It is imperative to determine optimal system configurations to maximize the performance of photovoltaic systems [

11]. Additionally, it is worth noting that the performance of these systems tends to degrade gradually over time, underscoring the importance of continuous performance monitoring and the implementation of strategies to enhance energy yields. Finally, monitoring and evaluating the performance of existing photovoltaic systems remain crucial for assessing the potential for photovoltaic energy production in a given region.

It is also relevant to mention that the evaluation of photovoltaic system performance typically relies on standard test conditions (STCs), which do not comprehensively reflect the real-world operation of modules. Degradation, aging, environmental factors, design, and installation configurations all significantly impact the long-term performance of solar panels. In this regard, numerous studies conducted worldwide have examined the performance of photovoltaic solar systems [

12,

13]. These analyses are critically important for monitoring the performance of installed systems and serve as the foundation for continuous technological improvement.

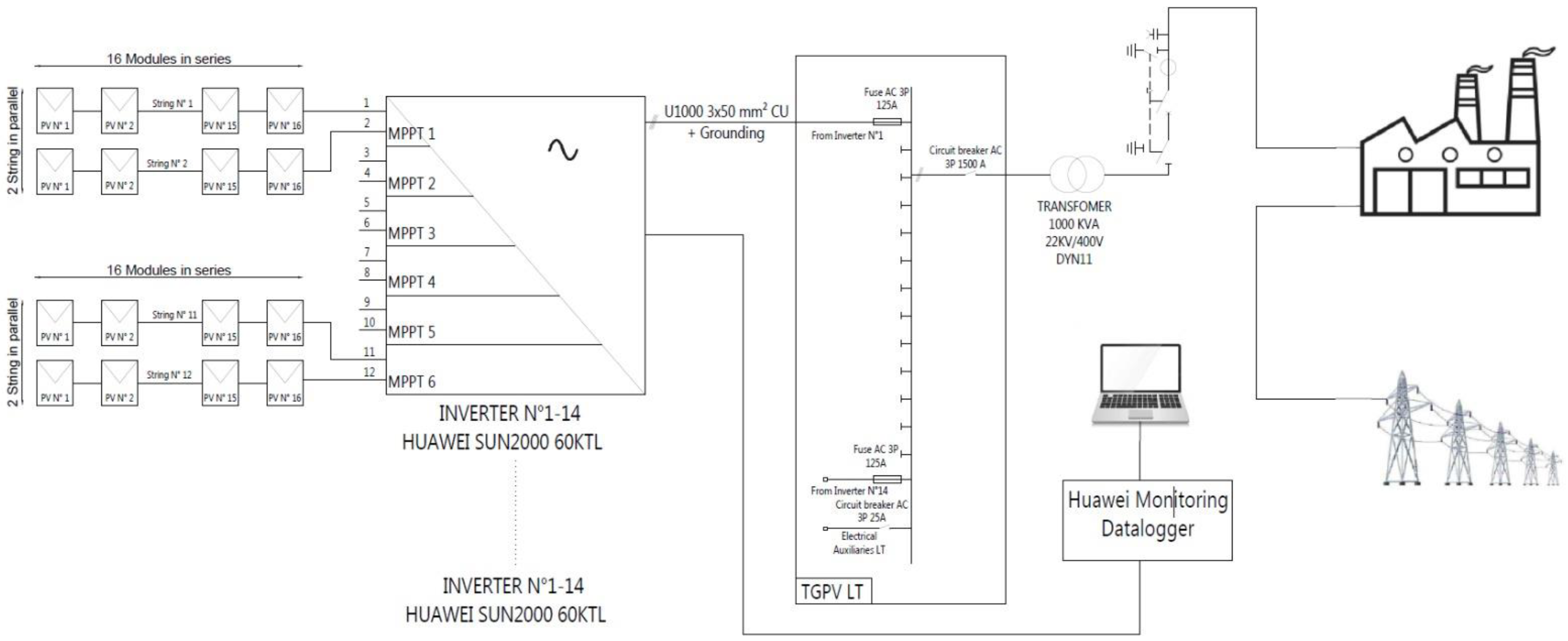

This research focuses on a 1 MW three-phase photovoltaic power station installed at a factory in Morocco. The goal is to assess its performance and efficiency, analyze its operational characteristics, and evaluate its energy generation capabilities. This comprehensive study involves field measurements, data analysis, and simulations to provide insights into the system’s reliability, effectiveness, and economic viability.

Field measurements will collect data on solar irradiance, ambient temperature, electrical parameters, and the PV system’s output. These data will be used to evaluate key performance metrics like energy yield, capacity factor, and overall efficiency. Data analysis will identify performance deviations and investigate contributing factors, such as module degradation, shading effects, and electrical losses, to optimize the system’s performance. Computer simulations using advanced PV modeling software will validate the measured data and explore various operational scenarios to enhance configuration and operation.

Our study is part of the broader context of the global transition to renewable energies. Morocco, with its abundance of untapped solar resources, plays a crucial role in this transition. Our goal is to explore how a photovoltaic plant operates in a specific environment, but it goes beyond a mere local analysis. The lessons learned from this study can be applied elsewhere in the world, thus contributing to the global effort to reduce carbon emissions. Drawing from this global renewable energy context that frames our study, and considering that Morocco has unique characteristics in terms of solar resources, climate, and energy policy, our study highlights the challenges the country faces and the solutions it has implemented to develop its photovoltaic sector. This makes it a revealing case study for other countries, especially those sharing geographical or environmental similarities. Furthermore, our work makes a significant contribution to the existing literature on solar energy. It introduces new performance models tailored to specific conditions, which can help researchers and practitioners better understand how to maximize the efficiency of photovoltaic plants in similar environments. Additionally, our analysis of real-world data from the field adds a crucial practical dimension to existing academic research, contributing to the global transition toward cleaner and more sustainable energy. And it is essential to note that our research has significant implications in terms of environmental and economic impact. By promoting the use of solar energy in Morocco, we contribute to reducing greenhouse gas emissions and moving toward energy independence, which can serve as a model for other regions of the world facing similar challenges.

5. Results and Discussion

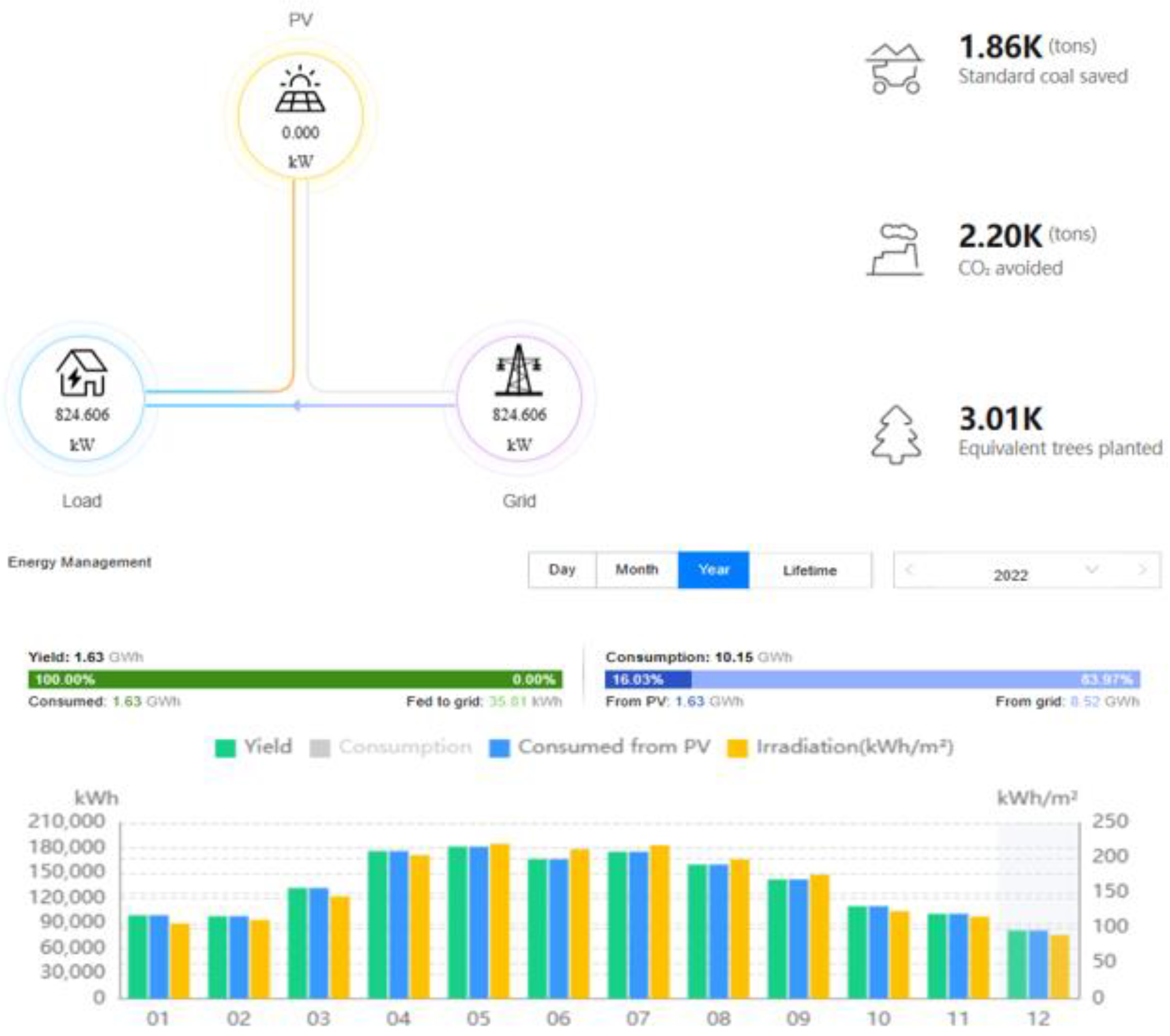

The analysis of the 1001 kWp grid-connected PV system was conducted using data collected over a period of 12 months, spanning from January 2022 to December 2022. The photovoltaic system under study is located in the industrial zone of El Jadida, Morocco, at a latitude of 33.2146° north and a longitude of 8.4886° west. The altitude relative to sea level is 21 m.

The data required for this analysis were retrieved from the PV station monitoring system, encompassing information on PV power, inverter output power, and irradiance.

Using these data, various performance indicators were calculated, including average daily energy, yields, performance ratio, capacity factor, and losses. The analysis results comprise average daily DC and AC energy, performance ratio, and capacity factor, as well as module, system, and inverter performance. These results are presented in

Table 6.

5.1. Energy Production

The energy production of a photovoltaic system is closely tied to the level of solar radiation it receives. Photovoltaic systems directly convert sunlight into electricity using solar cells.

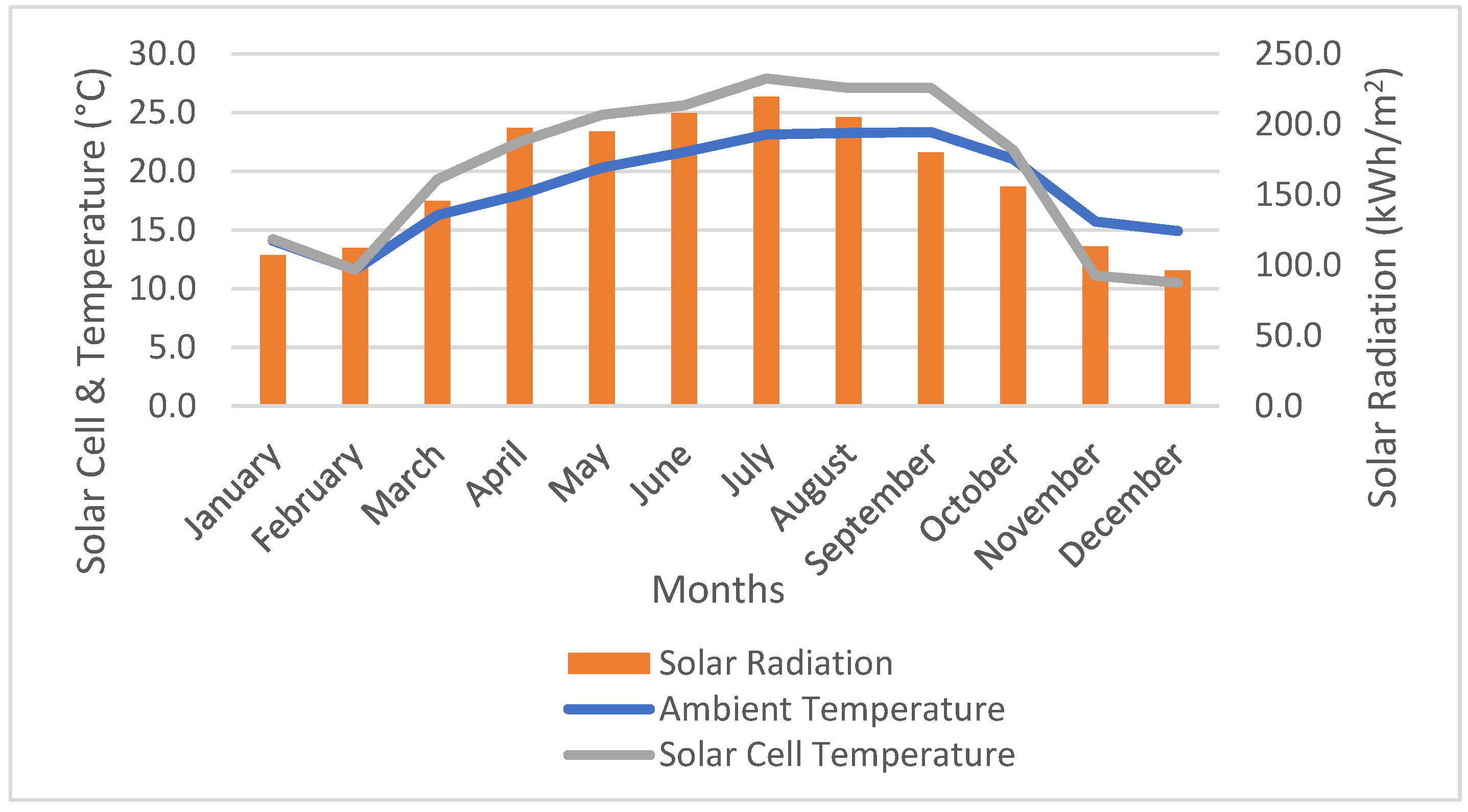

Based on the data provided and as illustrated in

Figure 11, we can observe that the intensity of solar radiation is notably stronger between the months of April and September, with an average radiation of 2008.8 kWh/m

2 per month. During this period, the system’s energy production reaches an average of 162,901 kWh per month.

Conversely, during the other months of the year, the radiation intensity is lower, averaging 121.6 kWh/m2 per month. Consequently, the energy production is also lower, with an average of 105,443 kWh per month.

These findings demonstrate the direct influence of solar radiation intensity on the energy production of a photovoltaic system. Months with higher radiation levels, namely, April to September, are more favorable for increased solar energy generation. On the other hand, the remaining months, characterized by lower radiation levels, result in decreased solar energy production.

In summary, the intensity of solar radiation plays a vital role in determining the energy output of a photovoltaic system.

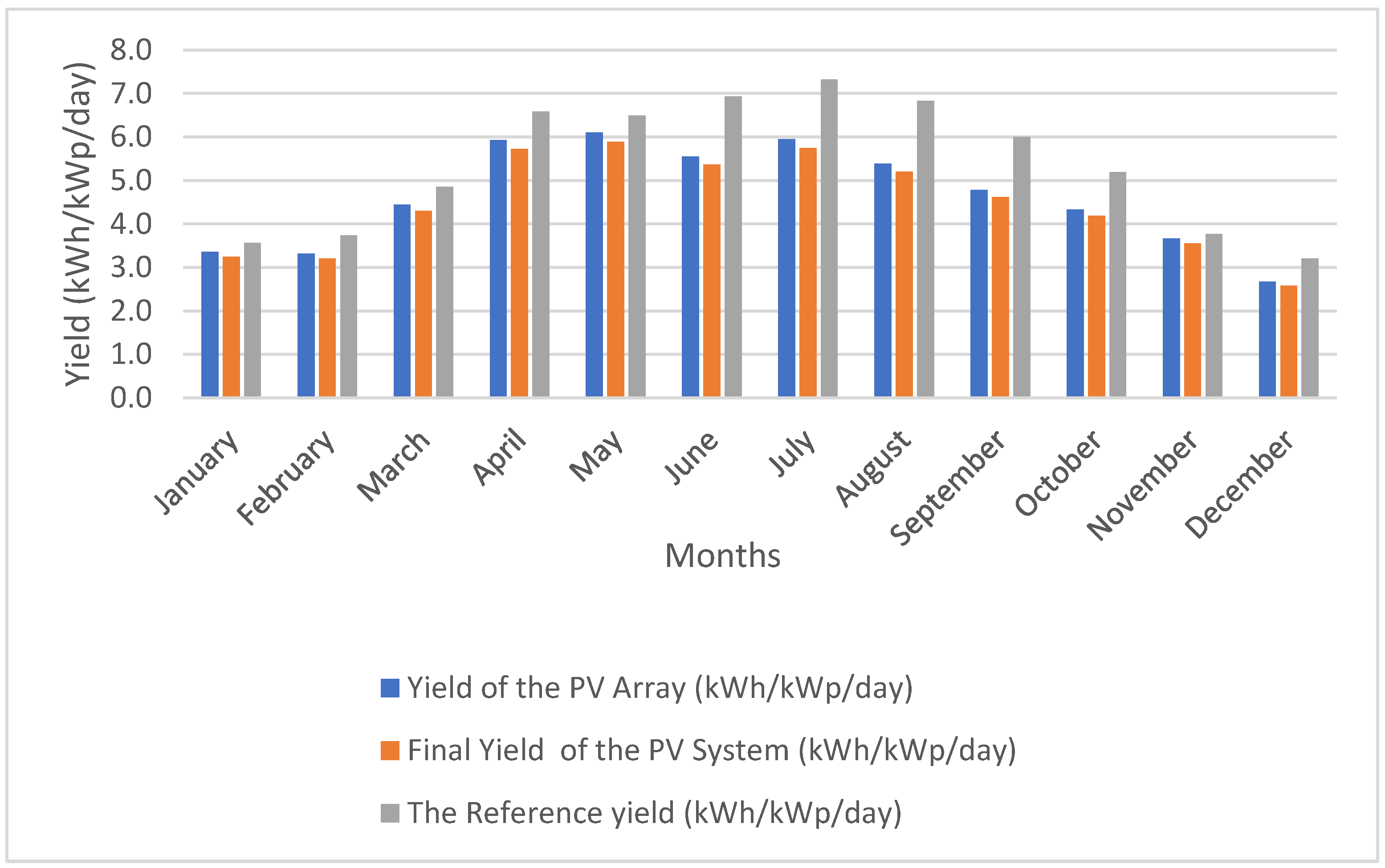

5.2. Yields: Yield of the PV Array, Final Yield of the PV System, and the Reference Yield

Figure 12 illustrates the yield of the PV array, the final yield of the PV system, and the reference yield of the grid-connected PV system throughout the monitored period from January to December 2022.

The average daily final, array, and reference yields varied monthly as follows: In December, the yields were 2.6 kWh/kWp/day, 2.7 kWh/kWp/day, and 3.2 kWh/kWp/day, respectively. In May, the yields increased to 5.9 kWh/kWp/day, 6.1 kWh/kWp/day, and 7.3 kWh/kWp/day, respectively.

The lower yield values observed in December can be attributed to the reduced irradiation and shorter duration of sunshine during this period.

On the other hand, July and May experienced the highest energy production at 172,538 kWh and 176,941 kWh, respectively. July also had a significantly high radiation level of 219 kWh/m2, with a corresponding temperature of 23.14 °C.

It is important to consider that the yield of the PV array, the final yield of the PV system, and the reference yield can vary due to multiple factors, such as the quality of solar panels, panel orientation and inclination, ambient temperature, wiring losses, shading losses, etc.

5.3. Performance Ratio (PR)

The PV energy ratio pertains to the energy efficiency of photovoltaic (PV) solar panels, which enable the conversion of sunlight into electricity using specialized photovoltaic cells. Energy efficiency for solar PV panels is commonly quantified as a percentage, representing the proportion of captured solar energy that is successfully transformed into usable electrical energy.

It is important to note that the PV energy ratio does not directly indicate the power generation capacity of a PV system. For instance, a PV system with a high energy ratio in a location with low solar irradiance might generate less power compared with a PV system with a lower energy ratio in a location with high solar irradiance, and vice versa. The energy ratio is influenced by losses occurring during the conversion of solar energy to electricity, as well as losses associated with the inverter.

In a specific study,

Figure 13 demonstrates that the

PR is not representative of the actual power generation quantity of the PV system. A PV system with a high

PR in a region with low solar irradiance can yield lower power output compared with a PV system with a low

PR in a location with high solar irradiance, and vice versa. The value of PR is affected by losses incurred during the conversion of solar energy to electricity, as well as losses arising from the inverter.

In the aforementioned study, the monthly average PR of the PV system ranged from 76.1% in August to 94.1% in November, with an average of 84%. This indicates that the PV system was capable of converting approximately 84% of the incident solar energy into usable electricity. However, it is worth noting that 16% of the solar energy captured by the photovoltaic generator was not converted into electricity.

To summarize, the PV energy ratio, when considering energy efficiency, denotes the effectiveness of photovoltaic solar panels in converting solar energy into usable electricity.

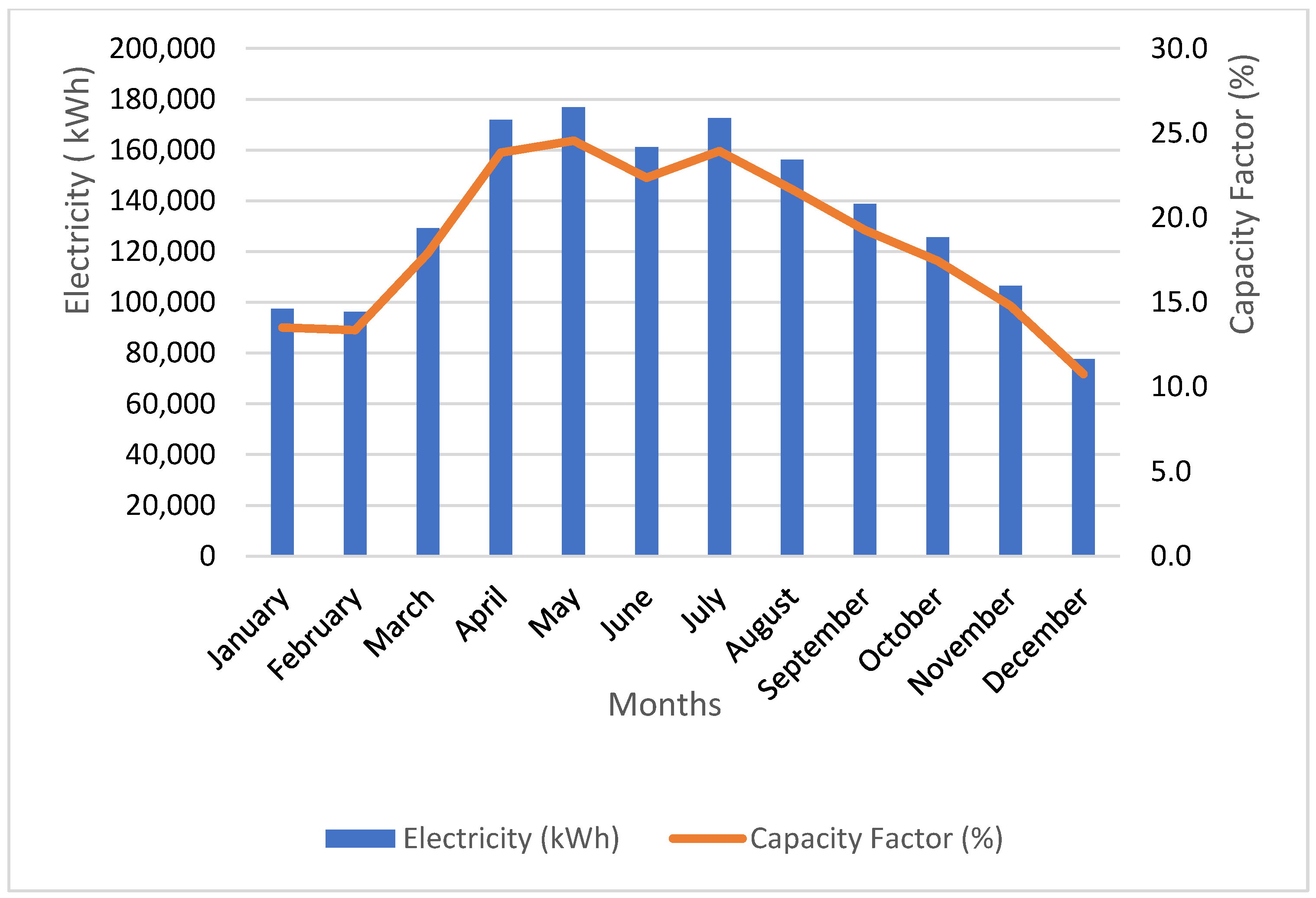

5.4. Capacity Factor (CF)

In this particular study, the capacity factor of a photovoltaic (PV) system was evaluated on a monthly basis, and the average was determined over a 12-month monitoring period spanning from January to December 2022.

The monthly capacity factor of the PV system exhibited variability, ranging from 10.8% in December 2022 to 24.6% in May 2022, with an average of 18.6%. This value represents the proportion of time during the monitoring period when the PV system operated at its maximum power capacity. Specifically, it indicates that the PV system was able to generate electricity at its full power for approximately 68 days out of the 12-month monitoring period (January 2022–December 2022). The relationship between the capacity factor and energy production is depicted in

Figure 14. It is important to note that the capacity factor of a PV system can differ depending on the location and solar radiation conditions.

5.5. Energy Efficiencies

Module efficiency, system efficiency, and inverter efficiency are parameters utilized to assess the performance of photovoltaic (PV) systems.

As illustrated in

Figure 15, the module efficiency varied from 15.4% in August to 19% in November. The system efficiency ranged from 14.8% in August to 17.7% in January, while the inverter efficiency ranged from 96.6% in February to 96.7% in November. On average, the module, system, and inverter efficiencies were measured at 16.9%, 16.4%, and 96.6%, respectively.

The module efficiency exhibited a decline from June to September due to the dry season and increased temperatures compared with other months, leading to a build-up of dust on the PV system. Conversely, the module efficiency increased from October to May as the dust on the PV modules was washed away by rainwater, resulting in improved efficiency. Consequently, we have made the decision this year, in 2023, to strengthen the manual cleaning of the solar panels to prevent dust accumulation and preserve their efficiency. Furthermore, in the upcoming years, we plan to invest in an automatic cleaning robot to further enhance the efficiency of our solar panels.

It is worth noting that system efficiency is influenced by both module efficiency and inverter efficiency. The results demonstrate that system efficiency gradually decreases from June to September and increases from October to May.

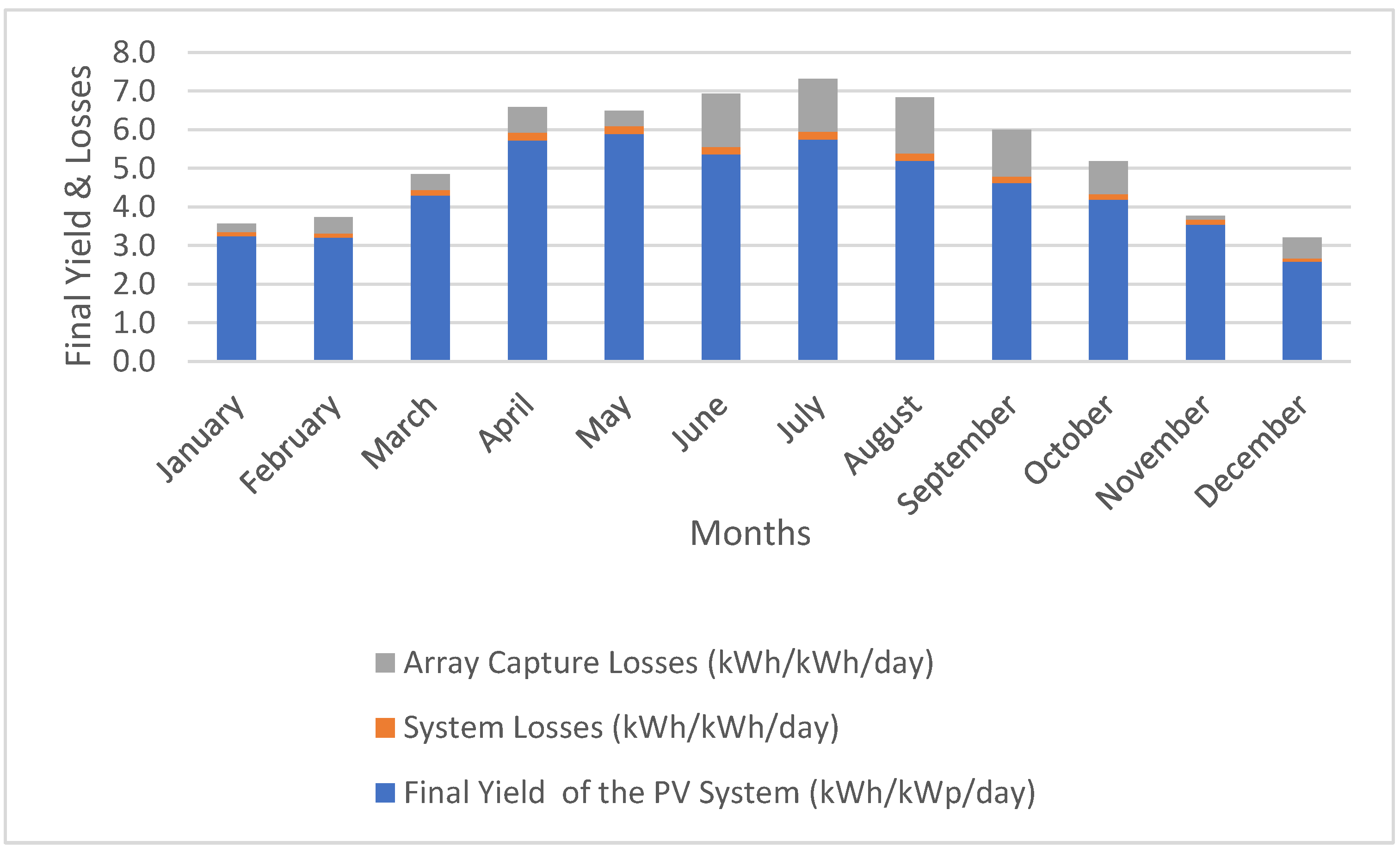

5.6. Losses

Monthly end yield, capture losses, and system losses are indicators utilized to evaluate the performance of a photovoltaic (PV) system.

As depicted in

Figure 16, the value of capture losses increased from June to September. This increase can be attributed to the dry season that started in June and ended in September, resulting in the accumulation of dust and dirt on the PV generator during this period. Conversely, from November to March, high-intensity rains effectively removed the dust and cleaned the PV panels, leading to a reduction in capture losses during these months.

The system loss value has an impact on inverter efficiency, where higher system loss values correspond to lower efficiency. Notably, from April to September, the system loss reached its peak value, which resulted in decreased inverter efficiency during these months.

In this study, the PV system exhibited capture loss values ranging from 0.1 kWh/kWp/day in November to 1.45 kWh/kWp/day in November. The losses of the PV system varied from 0.09 kWh/kWp/day in December to 0.02 kWh/kWp/day in May. The average capture losses and system losses were calculated at 0.75 kWh/kWp and 0.15 kWh/kWp, respectively.

Using an analysis of these parameters, the overall efficiency of a PV system can be assessed and the sources of energy losses can be identified. By reducing these losses, system performance can be improved and solar power generation can be maximized.

5.7. Comparative Analysis of Results: Our Study vs. Previous Research

When carefully analyzing data illustrated in

Table 7 from various studies conducted in different regions of the world on photovoltaic power plants, several parameters stand out in terms of performance. Our study conducted in Morocco in 2022 stands out particularly in these aspects, demonstrating the excellence of its solar installations.

Regarding the final yield kWh/kWp/day, we find that India in 2014 holds the record for the highest final yield (5.14 kWh/kWp/day). This exceptional performance can be attributed to favorable solar conditions, advanced photovoltaic technology, and efficient plant management. However, the lowest final yield value was recorded in a study in Malaysia in 2019 (2.08 kWh/kWp/day). This poor performance can be attributed to reduced sunlight, less efficient photovoltaic technology, or operational issues. In comparison, our solar station demonstrates a high yield of 4.5 kWh/kWp/day, placing it above the average. This outstanding performance can be explained by Morocco’s favorable climate conditions, including generous sunlight, as well as the use of modern photovoltaic technologies in our system. This remarkable performance suggests that Morocco has significant solar potential, and our system effectively harnesses this renewable energy source. However, it is essential to note that several factors, such as weather conditions, technology, and plant management, influence these performances, which can explain the variations observed between studies.

Regarding the performance ratio (%), Serbia, in 2015, achieved the highest performance ratio of 93.6%. This can be attributed to the use of high-quality panels and favorable environmental conditions. In contrast, in Ghana in 2017, a study using CIS panels recorded the lowest performance ratio at 52.8%. This may be due to lower-quality panels or maintenance issues. Our solar system with m-si panels has a performance ratio of 84%. While it is not the maximum, it is a solid result, indicating good overall photovoltaic system efficiency. This is attributed to the quality of the panels used, well-maintained installation, and favorable environmental conditions. The choice of panel type can explain these differences, but other factors such as maintenance, environmental conditions, and installation quality also play a crucial role.

Regarding the capacity factor (%), in 2013, the study conducted in Turkey achieved the highest capacity factor, reaching 23.2%. This exceptional performance can be attributed to Turkey’s abundant sunlight, which allows for more consistent electricity production throughout the day. However, a study in India in 2015 obtained the lowest capacity factor, at only 5.8%. This low value may result from a combination of factors such as unfavorable environmental conditions and system inefficiency. Our study records a capacity factor of 18.6%. While not the maximum, it represents a solid result, indicating efficient utilization of solar energy, with the favorable environmental conditions in Morocco contributing to this result. The capacity factor is influenced by the amount of available sunlight and system performance, explaining the variations observed between these studies.

Regarding panel efficiency (%), our solar installation has the highest value, reaching 16.9%. In contrast, the result found in India in 2014 (a-si) shows a low value of only 6.56%. This difference can be attributed to several factors, such as the type of solar panel. Our system uses monocrystalline silicon (m-si) solar panels, which are generally more efficient than amorphous silicon (a-si) panels. Monocrystalline panels have a better ability to convert sunlight into electricity. Additionally, advancements in solar panel technology have contributed to the efficiency of our system with the use of new technological advancements. Environmental conditions, such as sunlight, can also influence solar panel efficiency. Morocco, due to its climate, can benefit from better sunlight conditions compared with other locations. Furthermore, the size of the installation plays a crucial role, with larger installations having more efficient systems due to better design and more effective use of solar energy, as in our case.

Regarding the maximum inverter efficiency (%), the study conducted in Morocco in 2016 recorded an excellent inverter efficiency of 96.7%, demonstrating the efficient conversion of solar energy into electricity by the inverter. This high efficiency may result from the use of advanced inverter technologies. In contrast, the study in Japan in 2018 displayed the lowest inverter efficiency, at only 85.1%. This lower value can be attributed to less advanced inverter technologies or less optimal operating conditions, such as high temperatures. Our study also presented high inverter efficiency, at 96.6%, approaching the exceptional inverter performance in 2016. This is due to the use of advanced inverter technologies and proper system maintenance.

Regarding the overall system efficiency (%), our results show the highest system efficiency, with a value of 16.4%. This outstanding performance is the result of an efficient solar system from energy collection to electricity conversion. The reasons for this efficiency include the use of advanced technologies, high-quality components, and favorable environmental conditions. In contrast, India, in 2014, showed the lowest overall system efficiency, with a value of only 6.06%. This lower performance may result from various factors, such as less optimal design, lower-quality components, or unfavorable operational conditions. In conclusion, our system stands out for its high overall efficiency in solar systems, making it a leader among the examined studies.

In comparison with the other listed studies, our study in Morocco clearly stands out for its exceptional solar performance. Our results fall within the upper range of most parameters, indicating the efficiency of solar installations in this region during this period. Variations in performance are often due to specific environmental, technological, and management factors unique to each installation. These results can have significant implications for the future development of solar energy in Morocco and in other regions with similar conditions.

5.8. Results of Analysis by Infrared Thermal Cameras

As illustrated in

Figure 17, the presence of dirt created a partial shading area, which plays a crucial role in the formation of hotspots, as indicated. The hotspot shown in

Figure 16 exhibits a temperature elevation of 3.24 °C compared with the average temperature.

The non-uniform temperature distribution observed in the panel in

Figure 18 is due to the accumulation of dust and dirt on the panel’s surface.

Figure 19 highlights a hotspot on a solar panel cell resulting from the presence of foreign objects on the solar panel’s surface. Partial shading caused by these materials led to a temperature increase of 3.07 °C compared with the average temperature.

Figure 20 displays a single cell with an abnormal overheating of approximately 14 °C compared with the average temperature recorded in the other cells of the module. It is likely that this cell is damaged or defective, which could result in significant electricity production losses.

Figure 21 and

Figure 22 depict a photovoltaic module experiencing a widespread increase in temperature, with average temperatures of 36.56 °C and 36.10 °C, respectively. This condition is likely a result of the widespread accumulation of dust on the surface of the photovoltaic module, leading to the formation of shadows. This accumulation may be due to the limited precipitation recorded in the region, which could contribute to the self-cleaning of the photovoltaic modules.

The thermographic analysis conducted on the 30 selected thermal image samples during this study reveals that 99% of these samples exhibit an average temperature difference of 5.02 °C between the hottest and coldest points. Temperature deviations of 14 °C indicate severe faults, while a temperature range of 10 °C to 30 °C suggests moderate severity issues. Any temperature deviations below 10 °C are considered normal.

Despite the current observation showing relatively minor severity issues with the solar panels, it is advisable to conduct regular thermal inspections in the future as the severity of issues may increase due to operational changes. Temperature variations exceeding 20 °C can lead to gradual system degradation over time, potentially resulting in more severe failures. Therefore, based on the findings of my thermographic analysis conducted on our 1 MW solar station, the photovoltaic system appears to be in good condition. However, more frequent cleaning of the solar panels can contribute to improving system performance.

5.9. Cleaning Photovoltaic Solar Panels

In general, the cleaning methods for photovoltaic solar panels can be classified into three categories: rain cleaning, manual cleaning, and robot cleaning. However, the focus of research on surface cleaning of PV modules has been limited.

For this purpose, we propose two methods for cleaning photovoltaic solar panels:

Method 1: Dry cleaning: This method involves using cotton mops to remove dust from the panels. It is suitable for regular cleaning and can effectively eliminate encrusted stains on the panels. For stubborn stains, a second mop dampened with water should be used. It is important to clean in the direction of the wind to prevent dust from spreading onto already cleaned panels.

Method 2: Cleaning with distilled water: Due to the high cost of distilled water, an alternative approach is to collect water from air conditioners and condensed water from factory boilers. It is important to avoid using brackish water from the mains to prevent potential corrosion issues. Cleaning with distilled water is planned to be carried out twice a year, while dry cleaning will be performed ten times a year. Monthly cleaning is recommended, except during months with high rainfall.

5.10. The Economic Profitability of the Photovoltaic Solar Power Plant

To calculate the levelized cost of electricity (LCOE) for our 1-megawatt (MW) solar station over a 25-year period, we use the following data:

Investment costs: DHS 875,869.

Development and installation costs: DHS 291,956.

- 2.

Operating and Maintenance (O&M) Costs:

Annual O&M costs: DHS 257,000 per year.

- 3.

Electricity Production:

Projected Annual Production: 1600 MWh.

- 4.

Expected Rate of Return:

Discount rate (IRR): 6% per year.

Now, let us calculate the LCOE by following these steps:

- Step 1:

Calculate the total initial costs.

Total Initial Costs = Investment Costs + Development and Installation Costs

Total Initial Costs = 875,869 DHS + 291,956 DHS = 1167,826 DHS.

- Step 2:

Calculate the total operating and maintenance costs over the 25-year lifespan.

Total O&M Costs = Annual O&M Costs × Lifespan

Total O&M Costs = 257,000 DHS per year × 25 years = 642,500 DHS

- Step 3:

Calculate the total electricity production over the 25-year lifespan.

Total Electricity Production = Projected Annual Production × Lifespan

Total Electricity Production = 1600 MWh per year × 25 years = 40,000 MWh

- Step 4:

Use the LCOE formula to calculate the present value cost of electricity.

LCOE = (Total Initial Costs + Total O&M Costs)/(Total Electricity Production discounted over the lifespan)

LCOE = (1,167,826 + 642,500)/(40,000 MWh/1000 MWh per GWh) × (1 GWh/1 MW) = 45.26 DHS/MWh.

Therefore, the LCOE for our solar station is DHS 45.26 per megawatt-hour (MWh) over a 25-year period with an expected rate of return of 6% per year. This means that the average present value cost of producing electricity per MWh from this solar facility is DHS 45.26.

To calculate the payback period for our 1 MW solar station with an initial investment of DHS 12,000,000 and an annual net income of DHS 1,465,485, we use the following formula:

Payback = Initial investment/Annual net income = 12,000,000/1,465,485 ≈ 8.18 years.

The payback period for our solar station is approximately 8.18 years, which means it will take about 8.18 years to recover the initial investment of DHS 12,000,000 with the annual net income generated by the project. After this period, the project will start generating a net profit.

This is a relatively short payback period, which is generally considered a good indicator of profitability for a project.

5.11. Environmental Impacts of the Photovoltaic System

As mentioned earlier, this photovoltaic solar system generated a total of 1600 MWh for the review year of 2022. By applying Equation (17), this generation corresponds to a carbon savings of 1051 tons of CO2 equivalent per year that can be avoided. To put it in perspective, this is equivalent to the emissions from 294 round-trip flights between Casablanca and Sydney or the carbon sequestration provided by 32,627 trees.