Mechanisms and Operational Strategies of Multi-Lateral Steam-Assisted Gravity Drainage (SAGD) for Heterogeneous Reservoirs

Abstract

:1. Introduction

2. Geologic and Recovery Backgrounds of the Heterogeneous Reservoir

3. Mechanisms of Reservoir Dilation Coupled with Multi-Lateral SAGD

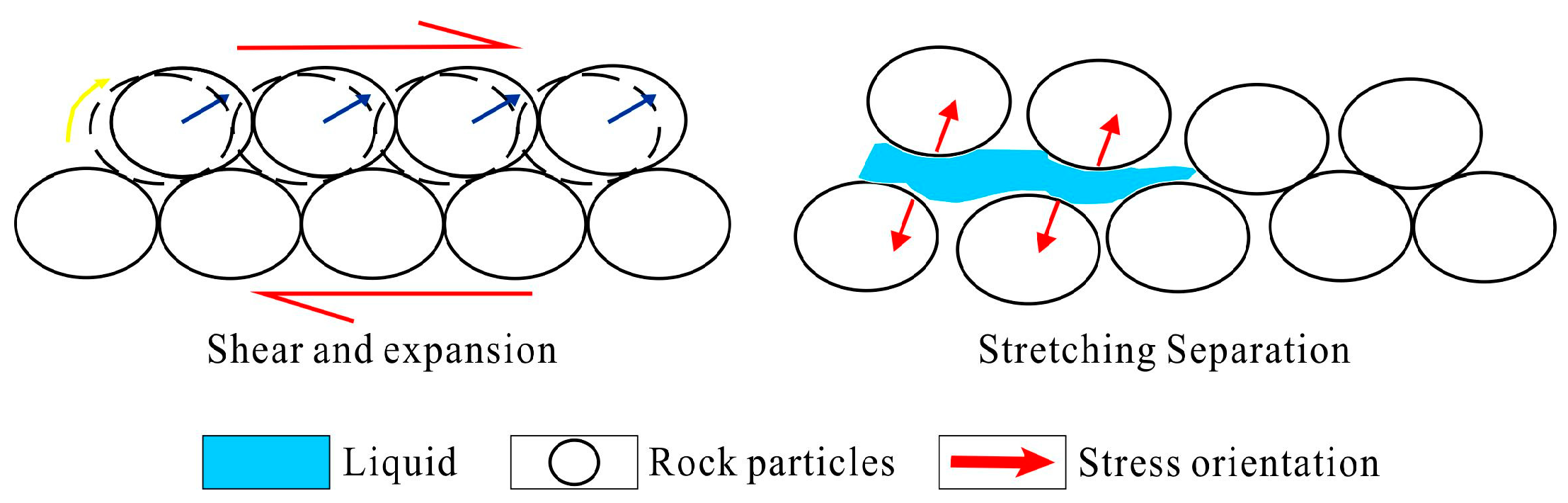

3.1. Mechanisms of Reservoir Dilation

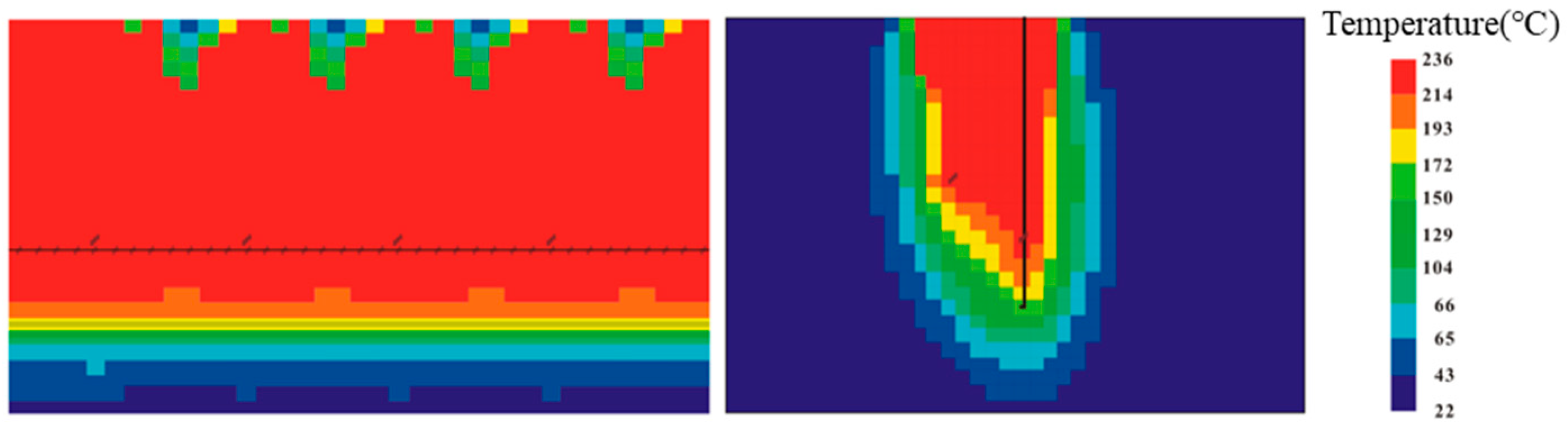

3.2. Physical Simulation

- (1)

- Rock mechanics experiments and analysis

- (2)

- Three-dimensional physical simulation experiment apparatus

- (3)

- Experimental scheme and result analysis

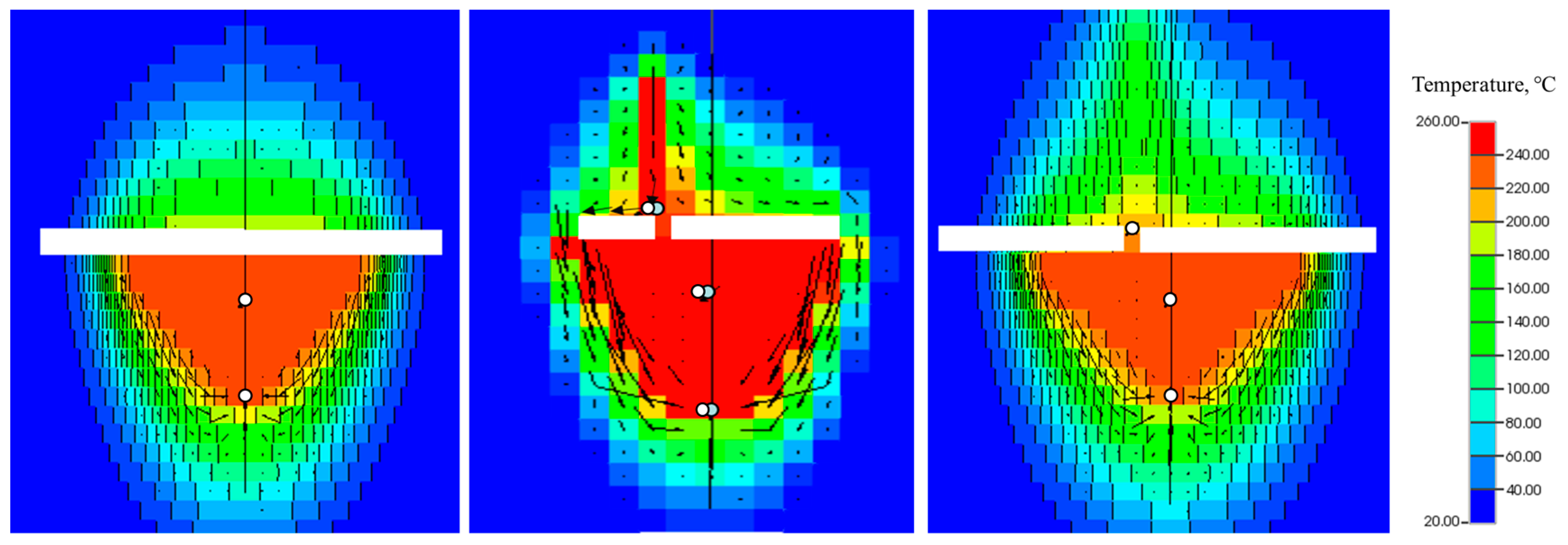

3.3. Numerical Simulation

- (1)

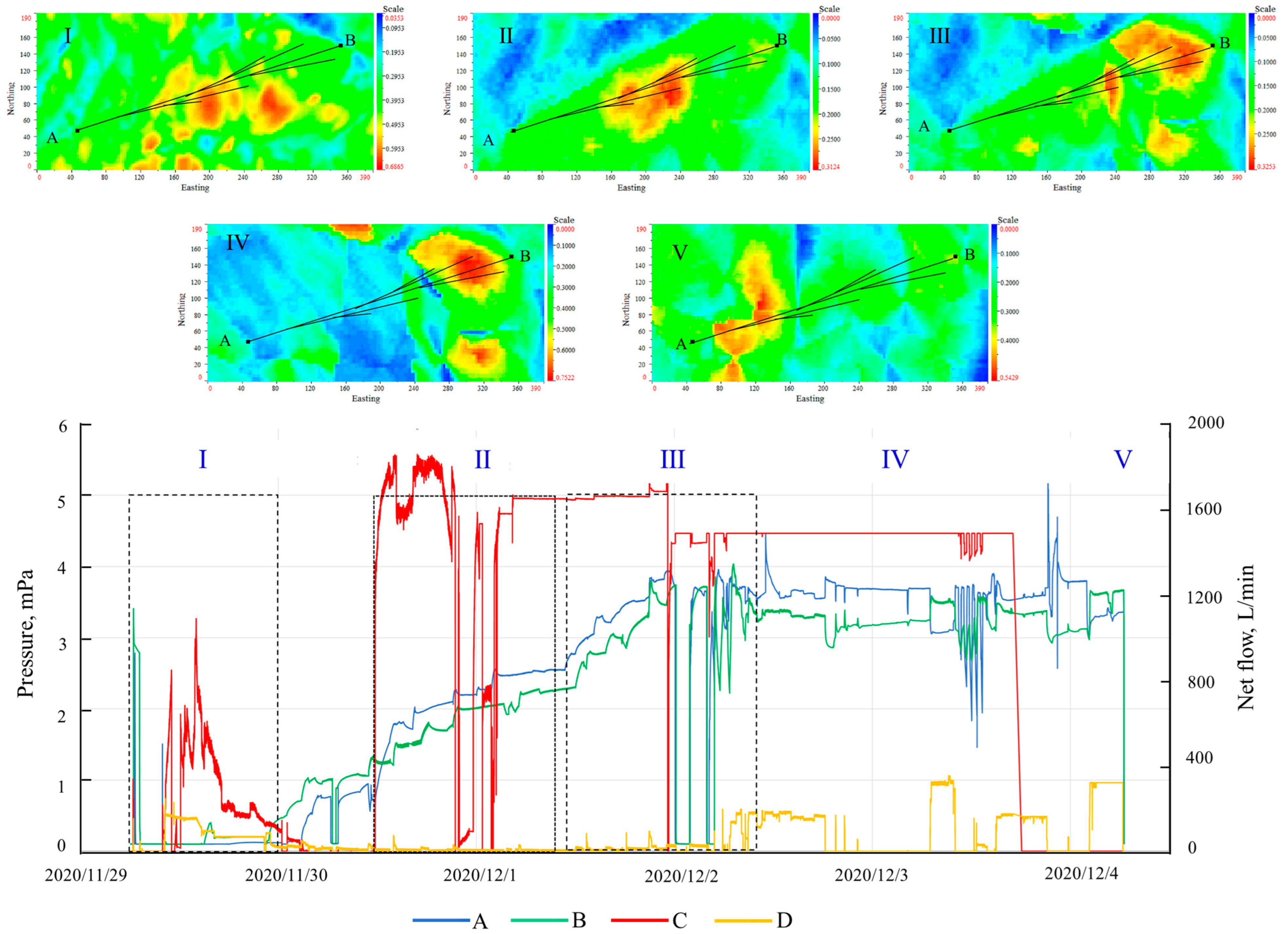

- Pore pressure pre-processing stage: In this stage, the injection of 80 °C hot wastewater into the steam-injection well is conducted. The initial pore pressure for pre-processing in the Z18 well area is set at 6.65 MPa, which closely matches the minimum horizontal principal stress of the formation. The maximum pressure is controlled at 7.5 MPa. The injection volume is 350 cubic meters, and the injection duration spans 3 days.

- (2)

- Main wellbore and branch stress adjustment stage: During this stage, the steam-injection well continues to inject 80 °C hot wastewater, while the production well is shut down. The primary objective is to increase the pore pressure around the steam-injection well branch by approximately 1 m without interfering with the production well and without establishing communication between the steam-injection well and the production well. The optimal effect is achieved when the pressure in the steam-injection well reaches 1.2 times the minimum principal stress (8.25 MPa). The injection volume is 200 cubic meters, and the injection duration spans 2 days with a total treatment time-span of 5 days (Figure 8).

- (3)

- Branch pre-dilation stage: In this stage, a stepped pressure increase and decrease cycle is applied to the steam-injection well to maximize the dilation range. Concurrently, the production well circulates a polymer with a viscosity of 50 mPa·s, synchronized with the pressure variations in the steam-injection well. The primary objective is to achieve a dilation of approximately 1–2 m around the steam-injection well branch without causing plastic deformation or significant communication between the steam-injection well and the production well. The optimal effect is achieved when the maximum pressure during oscillation reaches 1.3 times the minimum principal stress (8.9 MPa). The injection volume is 650 cubic meters, and the injection duration spans 4 days.

- (4)

- Communication stage between steam-injection well and production well: During this stage, the pressure in both the steam-injection well and the production well is reduced through fluid drainage, followed by the dilation of the production well using hot wastewater to establish communication between the wells. The main objective is to create a weak connection between the steam-injection well and the production well. After the pressure reduction through fluid drainage in both wells, the production well circulates hot wastewater at 1.2 times the minimum principal stress. Simultaneously, the pressure difference between the steam-injection well and the production well is controlled within 1 MPa to achieve optimal inter-well communication. The injection volume is 30 cubic meters, and the injection duration is 1 day.

- (5)

- Large-volume dilation stage above the steam-injection well: In this stage, the steam-injection well injects 80 °C hot wastewater, while the production well circulates a polymer with a viscosity of 100 mPa·s, synchronized with the pressure variations in the steam-injection well. The primary objective is to achieve a dilation of 5–8 m above the steam-injection well without affecting the overlying formation. The optimal effect is achieved when the injection pressure reaches 1.4 times the minimum principal stress (9.2 MPa) (Figure 9). Too low a pressure results in an unclear dilation effect, while excessive pressure leads to significant heterogeneity. The injection volume is 2000 cubic meters, and the injection duration spans 10 days.

4. Optimization of the Multi-Lateral SAGD Configuration

- It expands the interface between the oil reservoir and the steam-injection wellbore, augmenting the steam injection capacity and enhancing the reservoir’s steam absorption capability under similar pressure conditions.

- It expands the interface between the oil reservoir and the steam injection wellbore, augmenting the steam injection capacity and enhancing the reservoir’s steam absorption capability under similar pressure conditions.

- It expands the interface between the oil reservoir and the steam injection wellbore, augmenting the steam injection capacity and enhancing the reservoir’s steam absorption capability under similar pressure conditions.

- The relative positioning of the branches in relation to the main wellbore, specifically considering the vertical and horizontal displacements of the branches when inclined upward at a specific angle.

- Determining the number of branches and their distribution with respect to the main wellbore.

- Strategically positioning and orienting the branches in the presence of interbeds.

- (1)

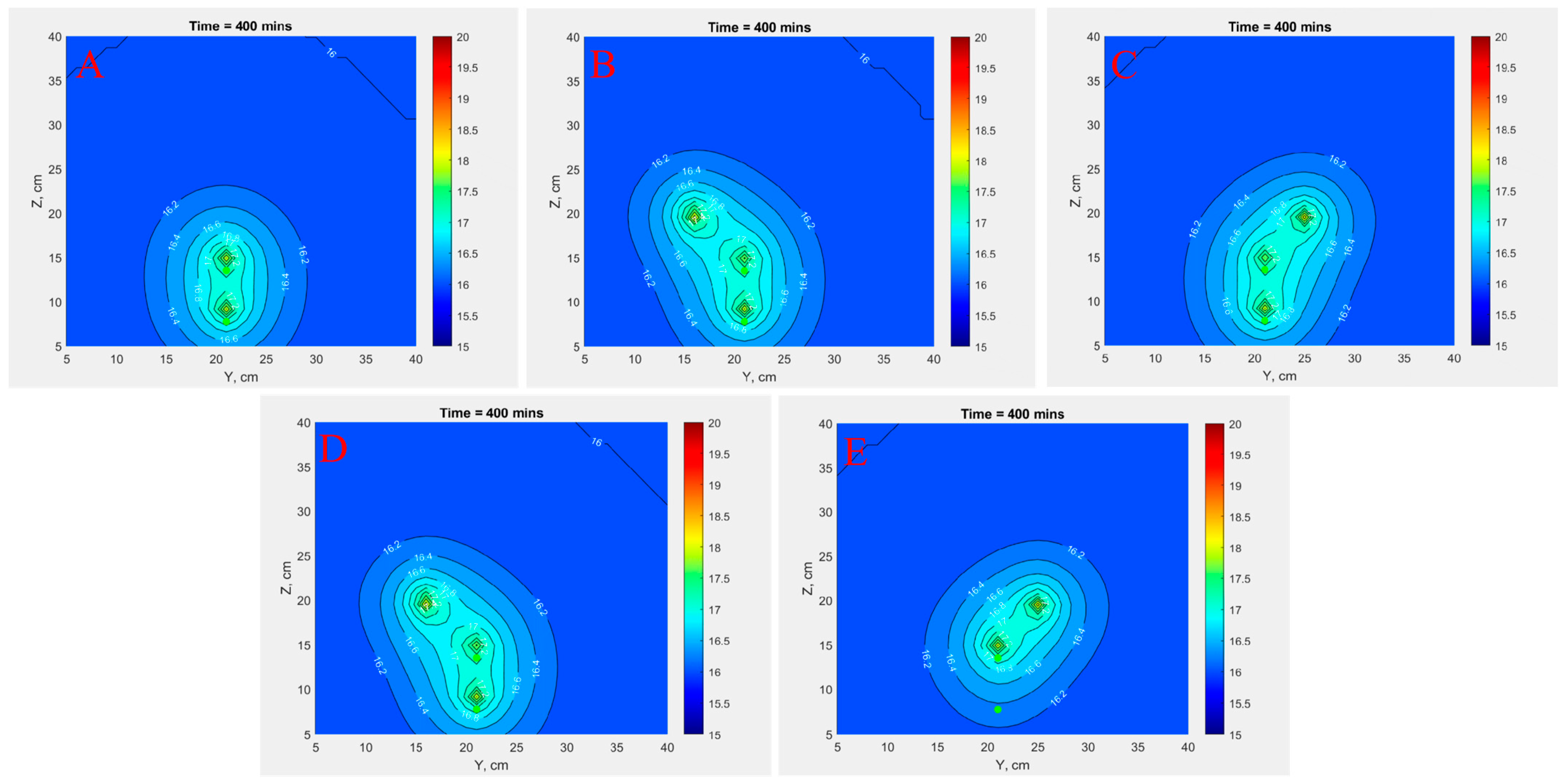

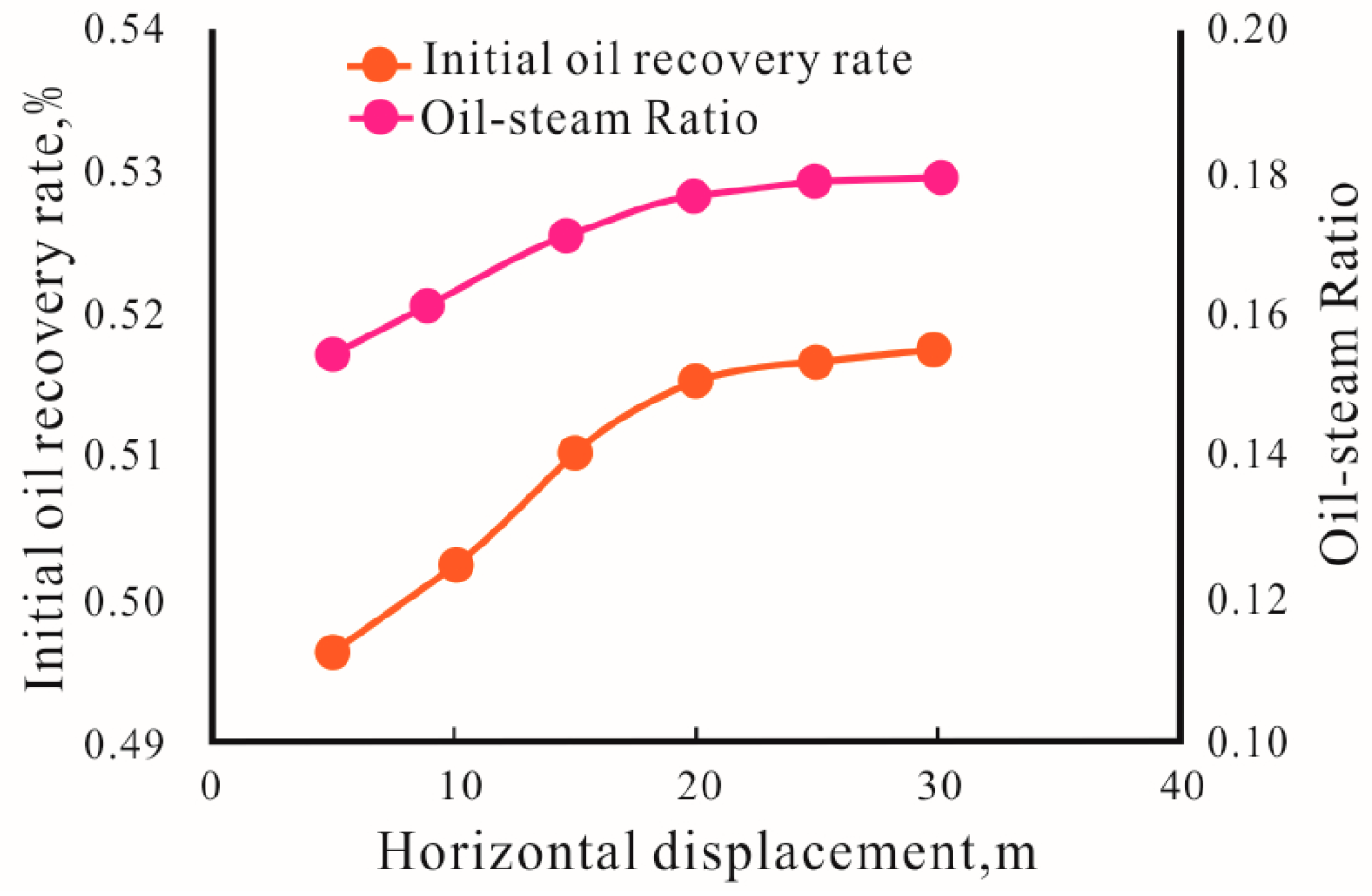

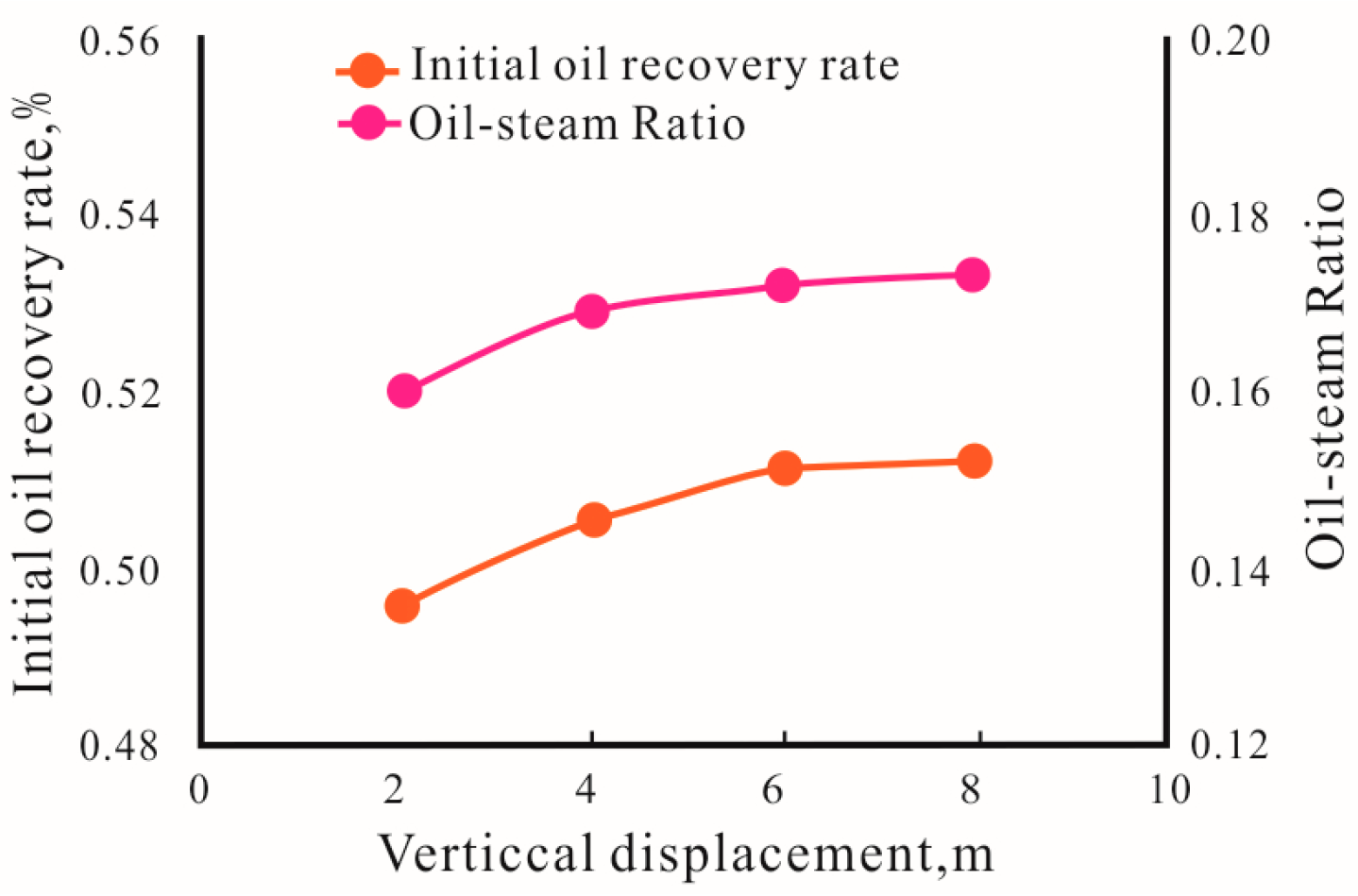

- The spatial position of the upward branches relative to the main wellbore

- (2)

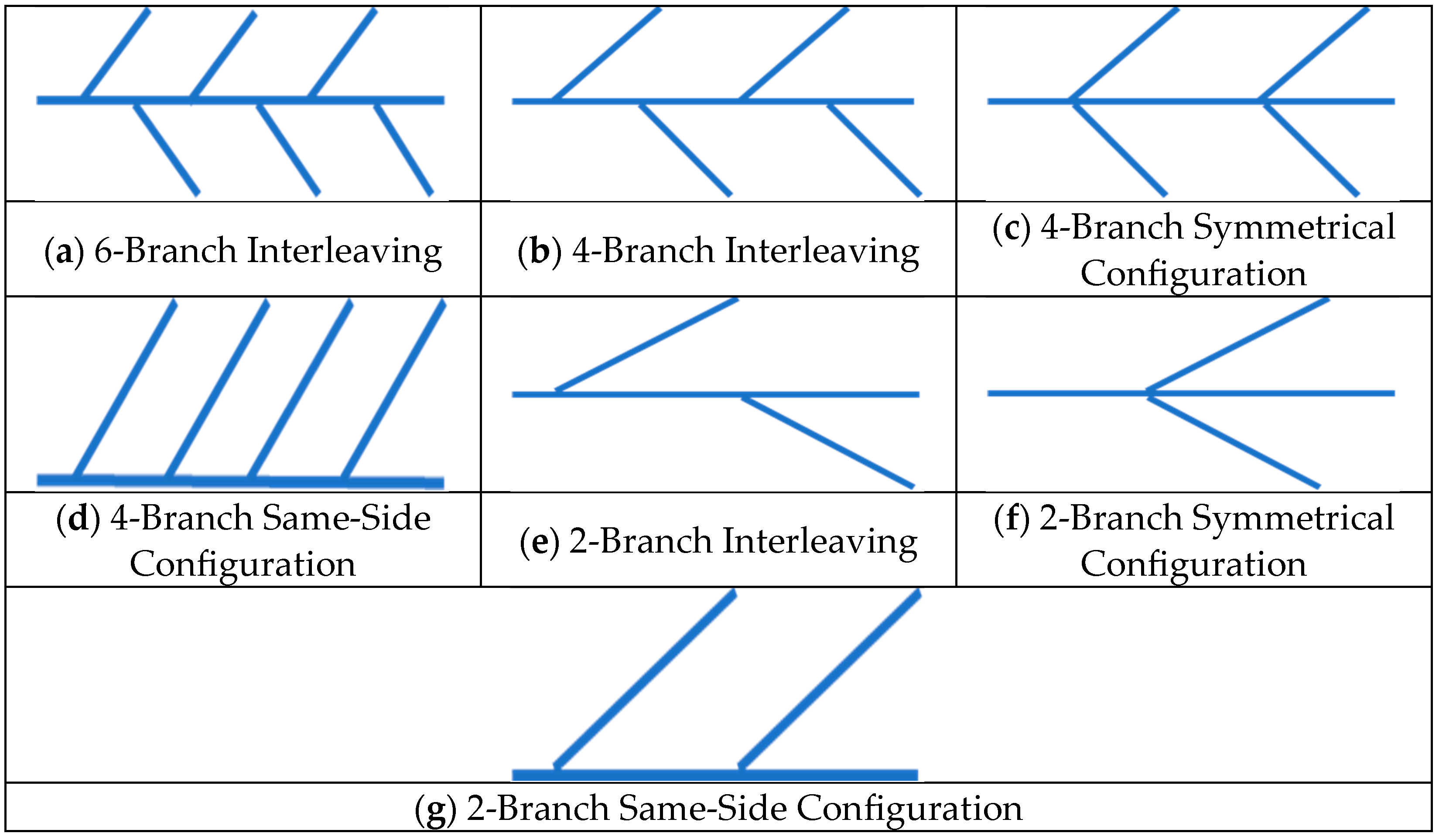

- The number of branches and their distribution relative to the main wellbore

- (3)

- The relative position of the branches to interbeds

5. Pilot Production Performance

6. Conclusions

- (1)

- Multi-lateral SAGD in strongly heterogeneous heavy oil reservoirs in Xinjiang was proposed and investigated in this study. Based on the experimental and numerical simulation results, this approach can effectively break interbeds and improve production performance. The tri-axial experiment results indicate that the rock formations in the heavy oil reservoirs of the F oilfield exhibit significant shear dilation effects under low confinement pressure conditions, with a volumetric dilation capacity of up to 7%. By employing the multi-lateral SAGD approach in conjunction with reservoir segmented dilation, the pore pressure in the vicinity of the branches and interbeds can be altered, creating high-porosity and high-permeability dilation zones. This facilitates the establishment of independent channels for steam injection and oil drainage through the branches, ultimately leading to increased oil production rates in strongly heterogeneous reservoirs.

- (2)

- Based on the numerical simulation results, the branches should be strategically deployed in an interleaved manner, with a horizontal displacement of 20 m and a vertical displacement of 6 m. The best results are achieved when the branches intersect the interbeds, allowing for enhanced steam chamber conformance and volume.

- (3)

- Operational strategies indicate that dilation zones of 3–8 m can be created above the steam-injection horizontal wells and around the branches in the reservoir during the dilation of SAGD steam chambers. It is advisable to limit the maximum volume of dilation fluid used for hydraulic dilation to less than 2000 m3. Additionally, the SAGD steam-injection pressure should be lower than the minimum horizontal principal stress at the bottom of the cap rock. These findings help ensure optimal reservoir dilation and incremental production performance while maintaining the integrity of the cap rock.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Butler, R.M. Steam-Assisted Gravity Drainage: Concept, Development, Performance and future. JCPT 1994, 32, 44–50. [Google Scholar] [CrossRef]

- Ma, Z.; Leung, J.Y. A knowledge-based heterogeneity characterization framework for 3D steam-assisted gravity drainage reservoirs. Knowl.-Based Syst. 2020, 192, 105327. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, L.; Huang, S.; Jia, P.; Chen, M. Evolution characteristics of SAGD steam chamber and its impacts on heavy oil production and heat consumption. Int. J. Heat Mass Transf. 2018, 121, 579–596. [Google Scholar] [CrossRef]

- Gao, C.; Leung, J.Y. Techniques for fast screening of 3D heterogeneous shale barrier configurations and their impacts on SAGD chamber development. SPE J. 2021, 26, 2114–2138. [Google Scholar] [CrossRef]

- Ma, Z.; Leung, J.Y. Integration of data-driven models for characterizing shale barrier configuration in 3D heterogeneous reservoirs for SAGD operations. In Proceedings of the SPE Canada Heavy Oil Conference, Calgary, AB, Canada, 13–14 March 2018; SPE: Calgary, AB, Canada, 2018; p. D022S003R001. [Google Scholar]

- Xu, J.; Chen, Z.; Cao, J.; Li, R. Numerical study of the effects of lean zones on SAGD performance in periodically heterogeneous media. In Proceedings of the SPE Canada Heavy Oil Conference, Calgary, AB, Canada, 10–12 June 2014; SPE: Calgary, AB, Canada, 2014; p. D021S005R007. [Google Scholar]

- Amirian, E.; Leung, J.Y.; Zanon, S.D.; Dzurman, P.J. An integrated application of cluster analysis and artificial neural networks for SAGD recovery performance prediction in Heterogeneous Reservoirs. In Proceedings of the SPE Canada Heavy Oil Conference, Calgary, AB, Canada, 10–12 June 2014; SPE: Calgary, AB, Canada, 2014; p. D011S004R003. [Google Scholar]

- Kumar, A.; Hassanzadeh, H. A qualitative study of the impact of random shale barriers on SAGD performance using data analytics and machine learning. J. Pet. Sci. Eng. 2021, 205, 108950. [Google Scholar] [CrossRef]

- Li, X.; Liu, H.; Luo, J.; Jiang, H.; Wang, H. 3D physical simulation on dual horizontal well SAGD in heterogeneous reservoir. Acta Pet. Sin. 2014, 35, 536. [Google Scholar]

- Hampton, T.; Kumar, D.; Azom, P.; Srinivasan, S. Analysis of impact of thermal and permeability heterogeneity on SAGD performance using a semi-analytical approach. In Proceedings of the SPE Heavy Oil Conference-Canada, Calgary, AB, Canada, 11–13 June 2013; OnePetro: Richardson, TX, USA, 2013. [Google Scholar]

- Stone, T.W.; Law, D.H.S.; Bailey, W.J. Control of reservoir heterogeneity in SAGD bitumen processes. In Proceedings of the SPE Canada Heavy Oil Conference, Calgary, AB, Canada, 11–13 June 2013; SPE: Calgary, AB, Canada, 2013; p. SPE-165388. [Google Scholar]

- Govind, P.A.; Das, S.; Srinivasan, S.; Wheeler, T.J. Expanding solvent SAGD in heavy oil reservoirs. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium, Calgary, AB, Canada, 20–23 October 2008; SPE: Calgary, AB, Canada, 2008; p. SPE-117571. [Google Scholar]

- Venkatramani, A.V.; Okuno, R. Mechanistic simulation study of expanding-solvent steam-assisted gravity drainage under reservoir heterogeneity. J. Pet. Sci. Eng. 2018, 169, 146–156. [Google Scholar] [CrossRef]

- Venkat Venkatramani, A.; Okuno, R. Steam-Solvent Coinjection under Reservoir Heterogeneity: Should ES-SAGD be Implemented for Highly Heterogeneous Reservoirs? In Proceedings of the SPE Canada Heavy Oil Conference, Calgary, AB, Canada, 15–16 February 2017; SPE: Calgary, AB, Canada, 2017; p. D021S008R003. [Google Scholar]

- Venkat Venkatramani, A.; Okuno, R. Characterization of Reservoir Heterogeneity for SAGD and ES-SAGD: Under What Type of Heterogeneity is ES-SAGD More Likely to Lower SOR? In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017; OnePetro: Richardson, TX, USA, 2017. [Google Scholar]

- Kumar, A.; Hassanzadeh, H. Impact of shale barriers on performance of SAGD and ES-SAGD—A review. Fuel 2021, 289, 119850. [Google Scholar] [CrossRef]

- Al-Gosayir, M.; Leung, J.; Babadagli, T. Design of solvent-assisted SAGD processes in heterogeneous reservoirs using hybrid optimization techniques. J. Can. Pet. Technol. 2012, 51, 437–448. [Google Scholar] [CrossRef]

- Neeteson, N.; Heukelman, H.; Zhu, D.; Thompson, S. Evaluation, Implementation, and Operations of an FCD for SAGD Producer Wells. In Proceedings of the SPE Thermal Integrity and Design Symposium, Banff, AB, Canada, 19–21 November 2019; SPE: Calgary, AB, Canada, 2019; p. D021S005R001. [Google Scholar]

- Banerjee, S.; Hascakir, B. Flow control devices in SAGD completion design: Enhanced heavy oil/bitumen recovery through improved thermal efficiency. J. Pet. Sci. Eng. 2018, 169, 297–308. [Google Scholar] [CrossRef]

- Gohari, K.; Ortiz, J.; Abraham, A.; Moreno, O.B.; Irani, M.; Nespor, K.; Sanchez, J.; Betancur, A.; Bilic, J.; Duong, K.; et al. Investigating the Performance of Various FCD Geometries for SAGD Applications. In Proceedings of the SPE Thermal Integrity and Design Symposium, Banff, AB, Canada, 29–30 November 2021; OnePetro: Richardson, TX, USA, 2021. [Google Scholar]

- Riel, A.; Burton, R.C.; Vachon, G.P.; Wheeler, T.J.; Heidari, M. An Innovative Modeling Approach to Unveil Flow Control Devices’ Potential in SAGD Application. In Proceedings of the SPE Canada Heavy Oil Conference, Calgary, AB, Canada, 10–12 June 2014; SPE: Calgary, AB, Canada, 2014; p. D031S016R004. [Google Scholar]

- Nespor, K.; Chacin, J.; Ortiz, J.; Morter, J.; Romanova, U.; Bilic, J.; Gohari, K.; Becerra, O. An Overview of the Field Performance of Tubing Deployed Flow Control Devices in the Surmont SAGD Project. In Proceedings of the SPE Thermal Integrity and Design Symposium, Banff, AB, Canada, 19–21 November 2019; SPE: Calgary, AB, Canada, 2019; p. D031S009R002. [Google Scholar]

- Burke, L.; Ghazar, C. Flow control devices in SAGD-A system-based technology solution. In Proceedings of the SPE Thermal Integrity and Design Symposium, Banff, AB, Canada, 27–29 November 2018; SPE: Calgary, AB, Canada, 2018; p. D023S005R002. [Google Scholar]

- Yang, Z.; Sun, X.; Luo, C.; Xu, B.; Yang, B.; Li, B. Vertical-well-assisted SAGD dilation process in heterogeneous super-heavy oil reservoirs: Numerical simulations. Undergr. Space 2021, 6, 603–618. [Google Scholar] [CrossRef]

- Kamari, A.; Hemmati-Sarapardeh, A.; Mohammadi, A.H.; Hashemi-Kiasari, H.; Mohagheghian, E. On the evaluation of Fast-SAGD process in naturally fractured heavy oil reservoir. Fuel 2015, 143, 155–164. [Google Scholar] [CrossRef]

- Sarapardeh, A.H.; Kiasari, H.H.; Alizadeh, N.; Mighani, S.; Kamari, A. Application of fast-SAGD in naturally fractured heavy oil reservoirs: A case study. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 10–13 March 2013; SPE: Calgary, AB, Canada, 2013; p. SPE-164418. [Google Scholar]

- Ameli, F.; Mohammadi, K. A novel optimization technique for Fast-SAGD process in a heterogeneous reservoir using discrete variables and repetition inhibitory algorithm. J. Pet. Sci. Eng. 2018, 171, 982–992. [Google Scholar] [CrossRef]

- Mohammadi, K.; Ameli, F. Toward mechanistic understanding of Fast SAGD process in naturally fractured heavy oil reservoirs: Application of response surface methodology and genetic algorithm. Fuel 2019, 253, 840–856. [Google Scholar] [CrossRef]

- Dang, C.T.; Chen, Z.J.; Nguyen, N.T.; Bae, W. Fast-SAGD vs. SAGD: A comparative numerical simulation in three major formations of Alberta’s oil sands. In Proceedings of the SPE Canada Heavy Oil Conference, Calgary, AB, Canada, 12–14 June 2012; SPE: Calgary, AB, Canada, 2012; p. SPE-144149. [Google Scholar]

| Sample Type | Physical Property Parameters | ||||

|---|---|---|---|---|---|

| Porosity /% | Permeability /mD | Young’s Modulus /MPa | Unconfined Compressive Strength /MPa | Density /(g·cm−3) | |

| Remolded oil sand | 29 | 1 600 | 410 | 1.3 | 1.96 |

| Outcrop oil sand | 28 | 800 | 600 | 1.6 | 2.0 |

| Property | Value |

|---|---|

| Porosity | 28.0% |

| Horizontal permeability | 0.96D |

| Vertical permeability | 0.62D |

| Initial reservoir pressure at the depth of 445 m | 4.6 × 103 kPa |

| Initial reservoir temperature | 19.0 °C |

| Initial oil saturation | 66.0% |

| Formation compressibility | 5 × 10−5 kPa−1 |

| Rock heat capacity | 2.1 × 106 J/m3·°C |

| Rock thermal conductivity | 2.0 × 105 J/m·day·°C |

| Average viscosity at 50 °C | 7.47 × 104 cp |

| Young’s modulus | 3.10 × 105 kPa |

| Poisson’s ratio | 0.08 |

| Internal friction angle | 35.39° |

| Cohesion | 0.94 kPa |

| Coefficient of thermal expansion | 2.5 × 10−5/°C |

| Angle of dilation | 20° |

| Symmetrical Conditions | COSR | Recovery Efficiency (%) |

|---|---|---|

| 6-Branch Interleaving | 0.125 | 50.6 |

| 4-Branch Interleaving | 0.127 | 50.7 |

| 4-Branch Symmetrical Configuration | 0.122 | 49.5 |

| 4-Branch Same-Side Configuration | 0.125 | 50.6 |

| 1-Branch Interleaving | 0.124 | 51.0 |

| 1-Branch Symmetrical Configuration | 0.121 | 50.1 |

| 2-Branch Same-Side Configuration | 0.123 | 50.4 |

| No Branching | 0.115 | 48.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, C.; Wu, Y.; He, W.; Gao, Y.; Liu, J. Mechanisms and Operational Strategies of Multi-Lateral Steam-Assisted Gravity Drainage (SAGD) for Heterogeneous Reservoirs. Energies 2023, 16, 7351. https://doi.org/10.3390/en16217351

Luo C, Wu Y, He W, Gao Y, Liu J. Mechanisms and Operational Strategies of Multi-Lateral Steam-Assisted Gravity Drainage (SAGD) for Heterogeneous Reservoirs. Energies. 2023; 16(21):7351. https://doi.org/10.3390/en16217351

Chicago/Turabian StyleLuo, Chihui, Yongbin Wu, Wanjun He, Yu Gao, and Jia Liu. 2023. "Mechanisms and Operational Strategies of Multi-Lateral Steam-Assisted Gravity Drainage (SAGD) for Heterogeneous Reservoirs" Energies 16, no. 21: 7351. https://doi.org/10.3390/en16217351

APA StyleLuo, C., Wu, Y., He, W., Gao, Y., & Liu, J. (2023). Mechanisms and Operational Strategies of Multi-Lateral Steam-Assisted Gravity Drainage (SAGD) for Heterogeneous Reservoirs. Energies, 16(21), 7351. https://doi.org/10.3390/en16217351