Abstract

Adsorption technology utilizes low-temperature renewable and waste heat sources for cost-effective and environmentally friendly cooling and water desalination systems. However, the problem with existing adsorption refrigerators is the low COP. This is caused by poor heat and mass transfer in existing packed bed designs. The solution to this problem lies in the use of fluidized bed technology, which enhances heat and mass transfer mechanisms. Various approaches to the construction and operation of adsorption systems with a fluidized bed of adsorbent can be found in the literature; hence, the aim of the work is to analyze the existing applications of a fluidized bed in adsorption refrigerators and other systems utilizing sorption beds. There are many methods for improving the energy efficiency of adsorption refrigerators. However, the literature suggests that fluidized bed systems have the potential to significantly improve the energy efficiency of adsorption cooling and desalination systems. Based on the review, it was concluded that using fluidization technology in adsorption cooling and desalination systems can be beneficial and represents significant potential for future research.

1. Introduction

Since the outbreak of the COVID-19 pandemic, the world has experienced strong shocks that have resulted in unstable supply chains for raw materials and rising prices for them. In 2021, high energy prices increased global attention to energy market issues and intensified discussions about renewable and sustainable energy sources [1]. Rising energy prices are not the only factor driving the search for new sustainable energy sources. European Union countries are also committed to meeting increasingly stringent greenhouse gas emission standards [2]. Combining the above facts with the knowledge that 20 of the last 23 years have been among the hottest on record in the world, it somewhat forces us to seek new solutions in cooling production methods. The search for sustainable solutions is also critical because heat and cooling production consumes 51% of the world’s energy demand [3].

Adsorption chillers align perfectly with the trend toward sustainable development and are increasingly in demand due to the growing availability of low-grade waste heat. Another advantage of these chillers is their compatibility with solar thermal energy generation systems, making them a valuable solution given the limited availability of fossil fuels and the increasing use of renewable energy sources] [4,5,6,7,8]. Adsorption chillers also offer several other key benefits, including non-corrosiveness and a lack of moving parts, which enhance their reliability. Additionally, they do not rely on chemicals to produce cooling, making them environmentally friendly and unlikely to contribute to the greenhouse effect as traditional cooling solutions can [4,9]. Moreover, besides cooling, adsorption chillers also produce desalinated water. The observed water scarcity is among the significant global risks as lack of access to clean drinking water has impacted many people, particularly in rural and arid locations [10,11,12].

Processes used for desalinating seawater or brackish water can be classified into two broad categories: membrane and thermal. Among membrane processes, we can list membrane distillation (MD) with its different configurations, i.e., direct contact membrane distillation (DCMD), air gap membrane distillation (AGMD), sweeping gas membrane distillation (SGMD), and vacuum membrane distillation (VMD) [13,14].

Adsorption chillers are an innovative solution for refrigeration and desalination processes [15,16]. Together with absorption chillers, they belong to chiller technologies with thermally driven chillers and can potentially use renewable energy sources [17].

Bel Haj Jrad et al. show the application of solar energy in adsorption systems. The paper emphasizes the eco-friendly and sustainable character of utilizing renewable energy sources [18].

Ben Hamida et al. pointed out that among methods enhancing absorption efficiency, the nanofluids and copper nanoparticles application enhances heat and mass transfer rates and performance of the chiller [19,20]. Ben Jaballah et al. showed that the use of hybrid nanofluids and coolant flow direction can further increase the chiller’s performance [21,22]. While the entire volume of the absorbtion bed is used in absorption chillers, the adsorption chillers employ surface adsorption process on to the surface of the adsorbent in the adsorption bed. The temperature of the refrigerant changes during sorption processes in the bed, generating ice water that can be used in air conditioning systems [23,24,25]. Despite these advantages, adsorption chillers have a crucial disadvantage in their low efficiency [26]. This makes them less competitive in the cold generation market. Therefore, improving their refrigeration efficiency is essential. This can be achieved by enhancing heat and mass transfer conditions in the adsorption chiller’s bed and increasing the thermal conductivity of bulk solids [23,27,28,29]. A study [30] showed that adding aluminum particles to increase thermal conductivity in the adsorption chiller bed results in shorter cycles and higher specific cooling power (SCP).

In their work, Grabowska et al. [25] tested different variants of the adsorption bed, combining different types of silica gel and checking the influence of the bed used for the adsorption process. Scientists are also exploring the use of advanced computational methods and artificial intelligence [30,31,32,33,34] to find optimal parameters that enhance these systems’ overall efficiency. One innovative approach is to leverage fluidization to improve heat and mass transfer within the adsorption chiller’s bed [35]. The fluidization of adsorption beds is a potential solution to the problem of poor heat and mass transfer in traditional adsorption chillers with packed beads. Setting the bed in motion under the influence of gas flowing through it facilitates heat and mass transport processes in the adsorption beds. An attractive option is using moving adsorption beds, as they do not require the input of mechanical energy to improve mass and heat transport [3,36,37]. Due to the ability to improve heat and mass transfer, fluidization has been applied in power boilers and thermochemical energy storage [38,39,40,41]. Improved heat and mass transfer processes contribute to lowering pollutant emissions from fluidized bed boilers [42,43,44]. The proven ability to enhance mass and heat transport means that the fluidization of the adsorption bed can translate into improving chillers, reducing their size. This will increase their competitiveness as devices for air conditioning and cold generation [34,45]. Adsorption refrigeration technology is constantly developing, new solutions are being implemented, which translates into an increase in the cooling power of devices. The devices and methods of intensifying mass and heat transfer using the fluidization phenomenon described in the document have not yet been subjected to a coherent study, especially in the context of improving the efficiency of adsorption refrigerators. Therefore, the authors decided to conduct a short literature review, which aims to present the current research in this area; the work is also intended to provide inspiration and provide a basis for further research and deeper research on the use of fluidization to increase the efficiency of sorption beds.

Fluidization is widely used in various industries, but due to the nature of the phenomenon occurring in adsorption chillers, it was decided to present this paper that can directly influence the development of the applicability of these technologies in adsorption chillers. The accumulated knowledge will enable further growth in adsorption cooling and desalination systems.

The paper reviews the latest technologies in fluidized bed systems for cooling and desalination. Such an innovative approach allows us to identify the best technologies that impact energy efficiency improvement in adsorption cooling and desalination systems. Additionally, adsorption chillers utilize waste heat and low-temperature heat from renewable energy sources, which is why this work aligns with efforts towards sustainable development and introduces concepts for zero-emission energy processes.

2. Main Limitation of Adsorption Cooling Systems

Low thermal conductivity is one of the biggest problems of high porous sorption materials. This results in low heat transfer inside the adsorption chiller bed, which leads to low efficiency of the unit [46]. Therefore, improving the heat transfer inside the bed is one of the critical factors in increasing the performance of the entire adsorption chiller. To date, the most commonly used solution in chillers are units equipped with fixed beds, meaning that the silica gel is packed between the heat exchanger tubes. This solution dramatically limits mass and heat transfer in the bed [34,47]. This is due to the high thermal resistance generated in solid beds. The adsorption bed porosity hinders heat transfer mechanisms. Moreover, the adsorption materials used in the beds are characterized by low thermal conductivity [29,48]. The design of the heat exchangers and the materials in which they are constructed also act as a barrier to high heat transfer rates [49]. This contributes to a significant increase in adsorption and desorption times. This results in low specific cooling power and the large size and weight of the units [47]. The low refrigeration performance of adsorption chillers contributes to their high cost. These chillers require a significant number of materials and must meet strict standards to maintain a vacuum for extended periods, ideally lasting decades. In addition to the need for a high-quality vacuum, the operating costs of the refrigerator also increase. The vacuum is typically restored periodically, usually after a year or longer. The high operating costs pose a challenge to the widespread adoption of refrigerators, which is why it is important to implement various measures to minimize the production and operational expenses of these already expensive devices [46,50].

Due to the mode of operation of the adsorption chiller, another difficulty is the selection of the appropriate working pair. Upgrading the working pairs is another necessary activity to optimize the adsorption chiller. During design of the chiller, the choice of adsorbent and adsorbate must be made carefully because it affects the nature of the chiller’s operation and the temperature it generates. At the same time, the working couple must meet conditions such as: low cost, wide availability, and neutral impact on the environment. The search for the ideal adsorbent is undoubtedly a difficult task, because it must simultaneously meet many conditions. The material should have a high adsorbing capacity when cooled to ambient temperature. It must be easily desorbed when heated. Desorption should occur mostly, preferably completely. Thermal properties of the material should have good thermal conductivity (shortening the cycle time) and low specific heat. Moreover, they should not weaken over time. In addition, the material must interact physically and chemically with the adsorbate, be non-toxic and non-corrosive, be widely available, and be cheap. Adsorption materials should also be highly porous, so that they are able to adsorb a large amount of the medium; however, high porosity contributes to low thermal conductivity [46,50]. Therefore, there is a great difficulty in the selection of materials; however, work is being carried out on the possibility of doping the adsorbent with materials that improve thermal conductivity, which may facilitate the future selection of working pairs [51,52].

An equally important factor as the adsorbent is the adsorbate. In this case, too, it must meet a number of requirements that contribute to optimal operation of the refrigerator. The choice of refrigerant is determined by its evaporating temperature. It should be below 0 °C. In the case of air-conditioning devices, it is allowed to be higher. The size of its molecules should be small to facilitate the adsorption process. The adsorbate must similarly have high thermal conductivity, as it is a key aspect from the point of view of the efficiency of the entire process. Its latent heat of vaporization should be high, while being chemically and thermally stable at operating temperatures. It should be non-flammable, non-toxic, and non-corrosive. In addition, the refrigerant used in adsorption refrigerators must be environmentally neutral, due to the fact that it is a feature that determines the advantage of adsorption refrigerators over the compressor refrigerators used so far [41,46,53].

3. Fluidization Technology for Adsorption Cooling Systems

3.1. Fluidization Phenomenon

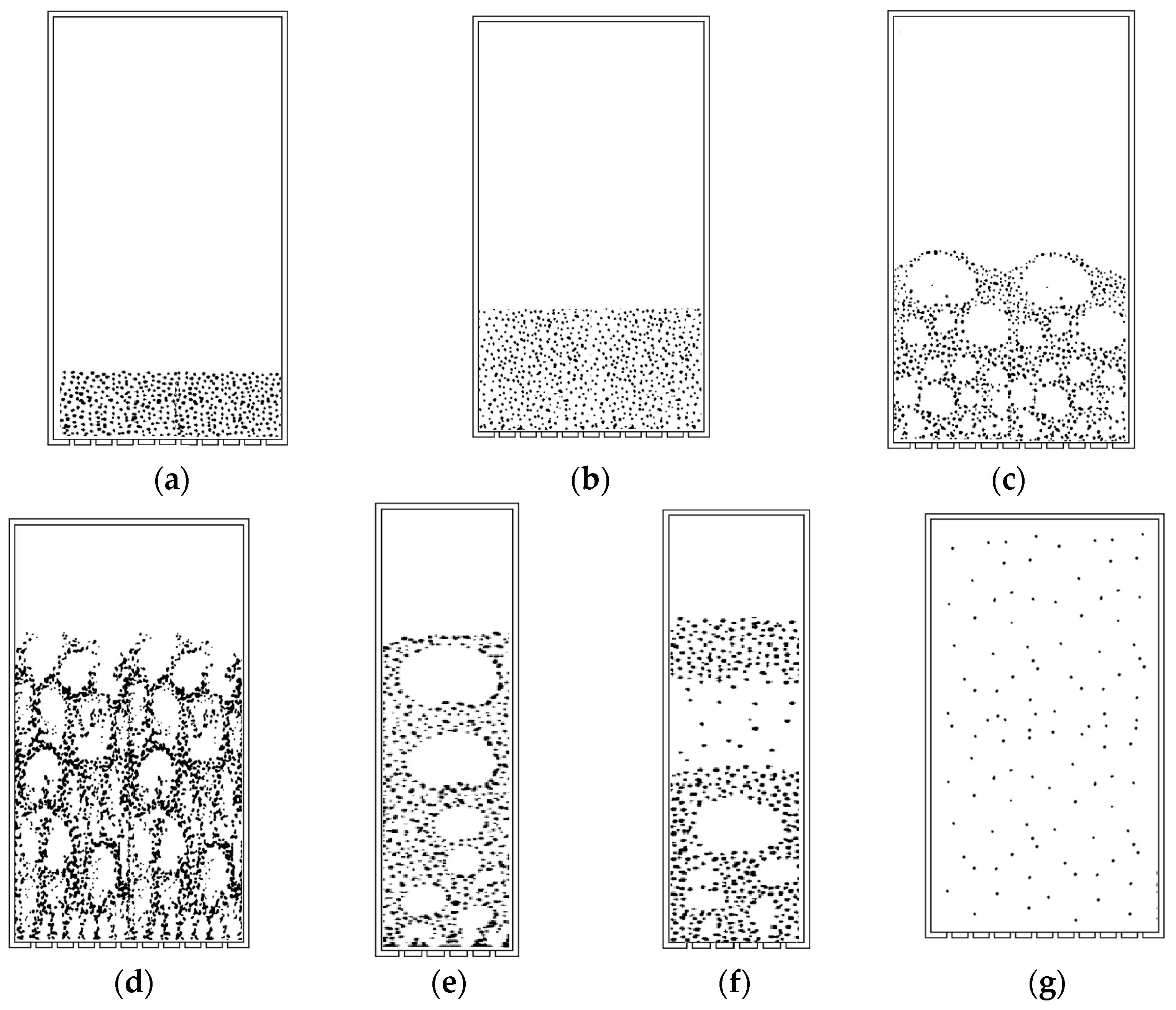

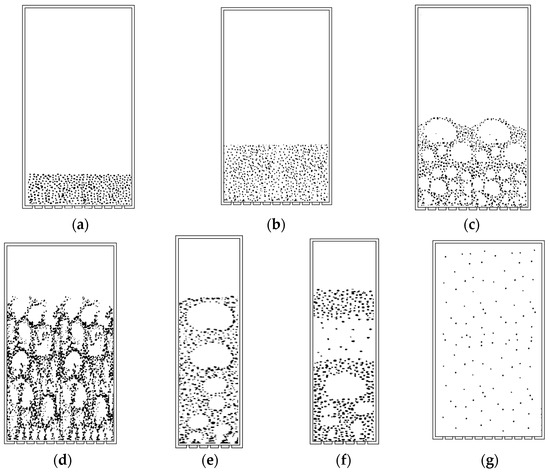

Using efficiency-enhancing methods, such as a suitable heat exchanger design, can partially reduce adsorption chillers’ weaknesses. Therefore, replacing the traditional stationary bed with a fluidized bed is one of the most promising options for improving chiller performance. It is an alternative solution to fixed beds. Fluidization has been used successfully for a long time in many industries, including the combustion of low-quality fuels, desiccation, and biomass gasification [54,55,56,57]. The behavior of the adsorption bed strictly depends on the velocity of the flowing gas. Solid beds used in adsorption chillers have a low gas flow rate. As a result, the gas or liquid only penetrates through the voids between the sorbent particles. By increasing the flow rate, the particles move away from each other, and some begin to vibrate and move in a confined space. Then, we can talk about an expanded bed [58,59,60]. Further increasing the flow rate in the fluidized bed causes the final velocity of the particles to be exceeded, in this state fully turbulent movement of particles and gas voids is observed. The impact of gas with an even higher velocity removes solid particles from the bed together with gas, which in turn turns into a lean-phase fluidized bed with pneumatic transport of solids. Figure 1 shows the above-mentioned types of phenomena occurring in fluidized beds resulting from the gradual increase in the velocity of the gas entering the bed.

Figure 1.

Schematic representation of fluidized bed behavior: (a) fixed bed; (b) fluidized bed at minimum velocity; (c) bubbling fluidized bed; (d) turbulent fluidized bed; (e) slugging (axial slugs); (f) slugging (flat slugs); (g) lean phase fluidization with pneumatic transport [58].

In their work, Wang et al. [61] provided a comprehensive overview of the current state-of-the-art approaches for assessing the applicability of multiscale numerical methods in predicting dense gas and solid flow in fluidized beds under specific fluidization regimes. The authors demonstrated that simulating gas–solid flow in fluidized beds presents challenges related to two key aspects. The first aspect involves the interconnection of submodels and parameters, while the second aspect pertains to the interconnection of operating parameters, solid properties, geometric configurations, polydispersity, and multi-physics forces. A different approach was presented by Marcio L. de Sousa-Santos in the works [62,63] introducing a simplified 1.5D model for bubbling and circulating fluidized beds. The model includes the parameters necessary to characterize fluidization regimes, such as Reynolds number () and Archimedes number ().

where: —Reynolds number, gas density, (kg/m3), —average gas velocity in the fluidized bed, (m/s), —grain diameter, (m), —gas viscosity, (kg/m s), —apparent density of particle (kg/m3), —acceleration of gravity (m/s2).

Differences in the behavior of fluidized beds make it necessary to strictly control the gas flow conditions through the bed; too high gas velocity can disrupt the mass and heat exchange by spreading the particles too far apart. Thus, the obtained type of fluid bed behavior determines the method of bed construction and is a key factor in the selection of process parameters [64,65]. Nevertheless, fluidization significantly increases the heat and mass transfer inside the bed, enables better contact between the gas and the solid, and causes thorough mixing of the adsorbent [66,67]. It also improves the contact between silica gel particles, which are in constant motion, thus increasing the efficiency of adsorption and desorption [67]. Fluidization leads to an increase in the heat transfer coefficient between the exchanger and the adsorbent and an increase in the heat conduction coefficient in the bed, resulting in an improvement in the performance coefficients of the entire unit. Moreover, fluidization has a real impact on the change in heat and mass transfer. The bed-to-wall heat transfer coefficient achieves much higher values with the fluidized bed than with single-phase convection [34,68]. Inside the fluidized bed, individual points with higher temperatures are quickly dissipated and characterized by a uniform temperature distribution [59,66,69]. Rapid temperature equalization throughout the bed volume occurs. This makes it easier to control the temperature value in the deposit [34]. The relationship between the size of the particles undergoing fluidization and pressure drops and the minimum fluidization velocity was also confirmed. The main reasons for improving sorption capacity during fluidization are an increase in the adsorbent’s surface exposed to the adsorbate flow and the destruction of the concentration and moisture gradient in the bed due to the fluidization phenomenon, eliminating the effect of decreasing adsorption and desorption efficiency with bed height [67,70,71,72,73].

Wang et al. [74] developed a reactive discrete element method-computational fluid dynamics model (rDEM-CFD). The model is dedicated to studying the physical-thermal characteristics of dense gas–solid reacting flow related to the pyrolysis of solar panel particles in two typical chemical reactors: a fixed bed (FB) and a bubbling fluidized bed (BFB) reactor. Modeling studies have shown that the BFB reactor exhibits better heat and mass transfer performance than the FB reactor, especially in terms of more uniform temperature distribution, higher heat transfer fluxes, higher Reynolds (Re) and Nusselt (Nu) numbers.

3.2. Experimental Apparatus

So far, the combination of adsorption refrigerators and fluidized beds has not attracted much scientific interest. There is little research carried out on this topic, and therefore, not many working devices have been constructed so far; the fluidized bed is definitely more popular in air conditioning systems. However, the collected knowledge and data from these applications can complement each other [24,59,69,70,71,75,76,77,78,79,80].

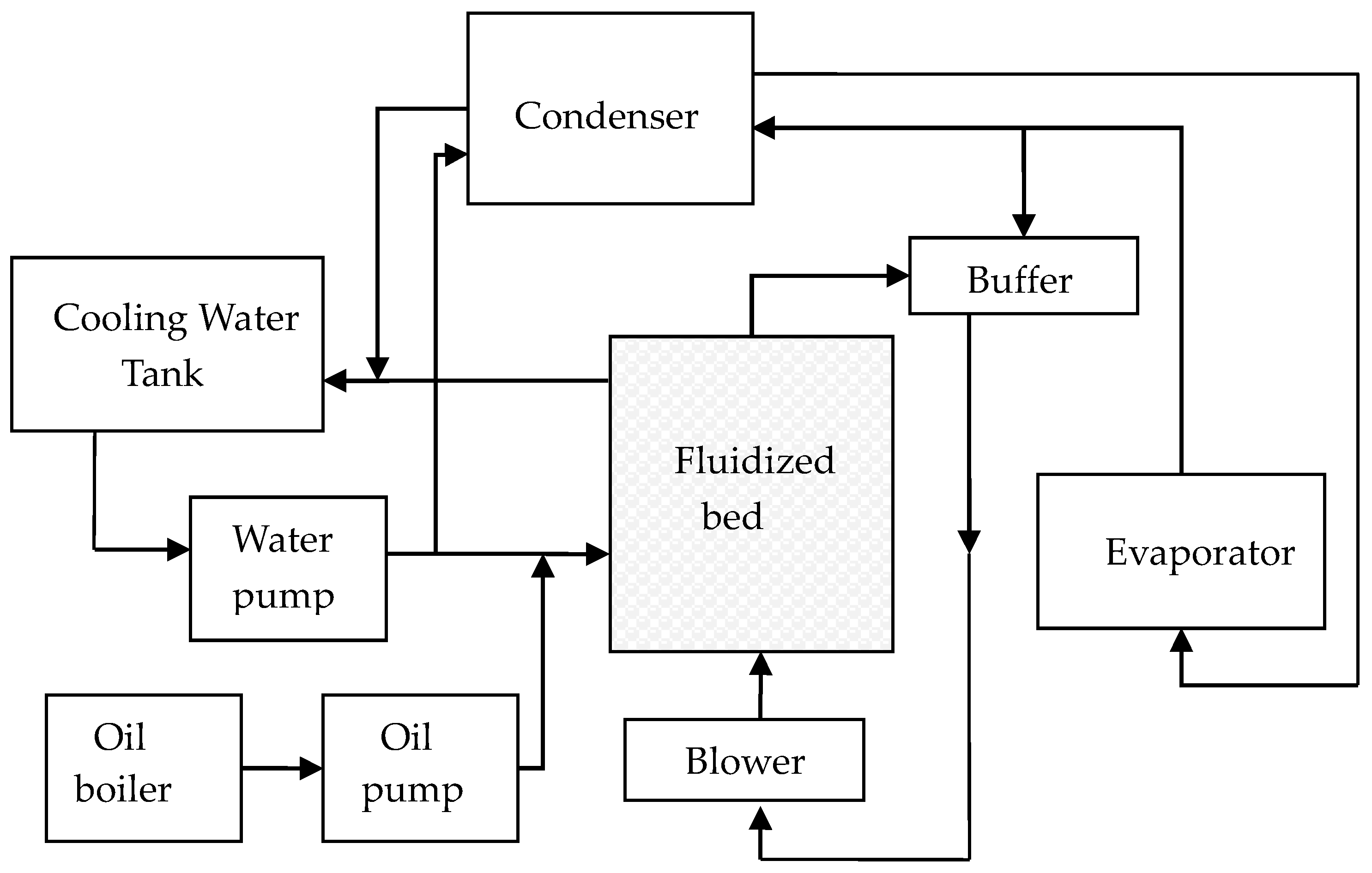

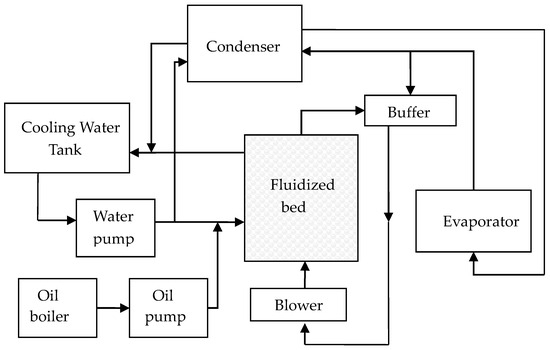

Wang et al. [47] underlined the low thermal conductivity of adsorbent materials as a significant challenge in increasing the cooling capacity of adsorption refrigerators. The porous structure of sorbent materials resulted in low thermal conductivity, both within the porous material and in the spaces between particles. They proposed a novel experimental installation of an adsorption refrigerator with a fluidized bed. The presented apparatus is one of the few examples of an adsorption chiller using a fluidized bed. The fluidized bed described in [47] is a column with a height of 1000 mm and an internal diameter of 159 mm. It is equipped with a serpentine coil with a length of 15 m and a diameter of 16 mm. The bed also ensures an even distribution of refrigerant vapors, and a cyclone separator is placed at the top of the bed to separate the silica gel from the refrigerant. Figure 2 shows a diagram of the fluidized bed adsorption refrigerator proposed in [47].

Figure 2.

Simplified diagram of a fluidized bed adsorber/desorber system.

The authors emphasize that the primary purpose of preparing the apparatus was to compare it with a single-bed adsorption chiller. The installation consisted of three loops. The first loop was an oil loop that provided low-grade thermal energy. The second loop was a cooling water loop responsible for dissipating heat from adsorption and supplying water to the condenser. The last loop was the refrigerant loop connecting the evaporator, condenser, buffer exchanger, and blower. The experimental setup can serve as a basis for further attempts to build a commercial adsorption refrigerator with a fluidized bed. The authors used an adsorption pair of activated carbon and R134a in their experimental setup. The refrigerant and the blower mounted make the presented device suitable for use in places with a high demand for cooling. Fluidized beds are not a common method of improving heat transfer within an adsorption bed; it is much more common to try to add binders or additives to increase thermal conductivity. However, using a fluidized bed can significantly increase mass and heat transfer parameters without any interference with the material used and without the addition of materials increasing thermal conductivity. The amount of adsorbed refrigerant was verified by losing mass in the evaporator [47]. The results demonstrated that the fluidized adsorption bed adsorbed the refrigerant much faster than a fixed bed, with the adsorption time reduced to 250 s from the original 1800 s. The results also showed a similar trend for an increased amount of adsorbent. However, the authors observed incomplete fluidization for a 4 kg load, highlighting the need for optimizing the fluidization process and its parameters. The authors conducted tests for a fixed and fluidized bed in their research. The mass of the fixed bed was 2 kg, and the mass of the fluidized bed charge was 2 kg, 3 kg, and 4 kg, respectively. The results of the experiments performed by the authors are displayed in Table 1.

Table 1.

Examining the sorption rates of a 2 kg fixed bed and a 2 kg fluidized bed [47].

The mass of activated carbon added to the adsorber/desorber is marked as , kg, is the mass variation of R134a adsorbed or desorbed by the activated carbon, kg, t is the time of adsorption or desorption, and are defined as follows:

In fact, the initial cost of an adsorption system does not mainly depend on the adsorbent used, but on the heat transfer area used in the system, which can be clearly observed in a continuous cycle. Better heat and mass transfer in a fluidized bed leads to a smaller heat transfer surface. In other words, you can get more cooling power for a given heat transfer area, but the amount of adsorbent used will also increase. The data presented in Table 1 indicate that the values of the adsorbed and desorbed substances are similar. There was a significant increase in the amount of desorbed substance over time for the fluidized bed compared to the fixed bed. This is the main advantage of using fluidized beds in sorption beds, so significant increases in sorption processes over time are a very promising result. However, the entire equipment has an undoubted disadvantage, which is the blower that maintains the fluidization process of the bed. In practice, when designing refrigerators, great emphasis is placed on making the device as energy-efficient as possible; hence, equipping the device with a blower may decrease energy efficiency [47]. Despite the authors’ claim that fluidizing the bed requires additional electric power to operate the blower, potentially leading to a decrease in device efficiency, the approach used in [25] can solve this issue by eliminating the need for additional equipment during the use of this phenomenon in adsorption refrigerators.

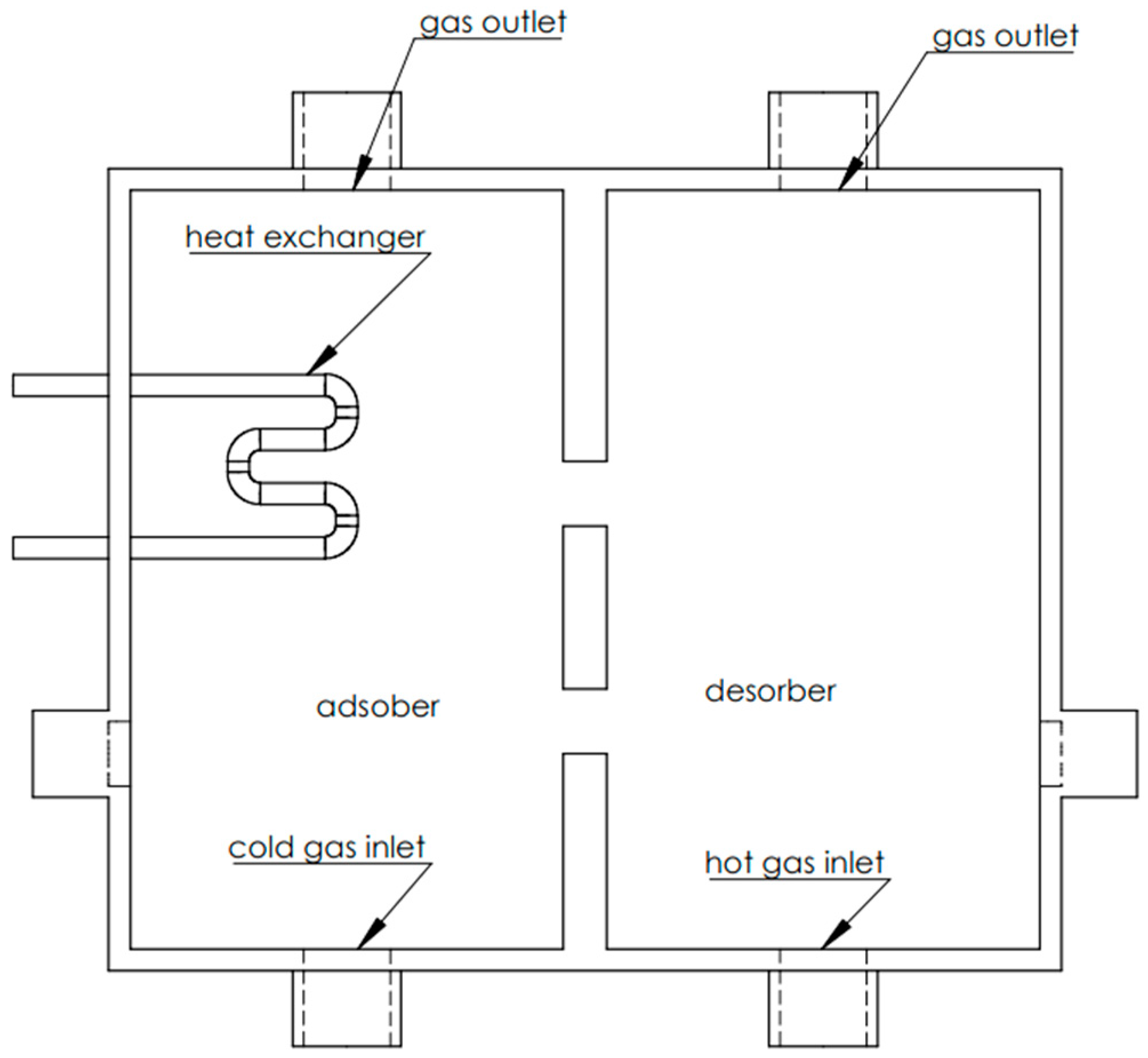

Reichhold et al. [77] proposed a circulating fluidized bed and sorption materials to recover gaseous pollutants and reusable compounds. It was also found that suitable adsorbates for experimental purposes would be methane and carbon dioxide. However, using a fluidized bed removes contaminants such as sulfur dioxide, organic solvent vapors, and other gases. The structure consisted of two fluidized beds with rectangular cross-sections, each with horizontal openings at the top and bottom to allow solids to pass through. Fluidization was carried out at different speeds in both beds, causing the material to circulate between them. The authors emphasized that the proposed structure optimized the adsorption and desorption processes since they occurred in separate beds. In the case of an internally circulating fluidized bed, a crucial aspect was the gas flow velocity. The gas velocity responsible for fluidization in the adsorption part of the bed should not be drastically lowered, as this will have a negative effect on the circulation rate. Similarly, the gas velocity in the desorption section cannot be increased too much, as this could increase the energy expenditure and affect the loss of reservoir material. It was also defined that the material that serves as the adsorbent should be resistant to abrasion, and its size should be chosen to facilitate fluidization. Abrasion resistance is an important parameter during the fluidization of materials, as particle movement increases the risk of erosion of the material and the bed. This has been proven for circulating fluidized bed boilers, where erosion is one of the safety hazards of the combustion chamber. Particle size and fluidization velocity must also be considered when designing fluidized beds, as these are the main factors causing erosion from fluidized beds [81,82]. The basic parameters of an internally circulating adsorption bed were adsorption isotherms, equilibrium load, enthalpy of adsorption, and fluidized behavior. Desorption has been identified as the “bottleneck” of the entire adsorption process. In the case of contaminant removal, molecular pressure has been proven to have less influence than initially assumed. However, the authors of papers [42,77,81] confirmed that fluidization of sorption materials could positively affect adsorption and desorption capacity.

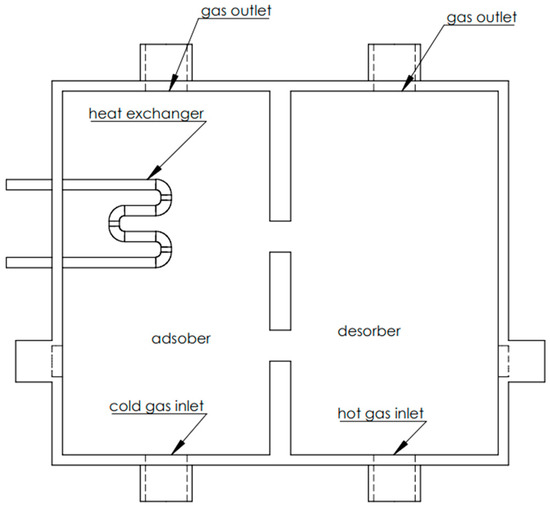

The equipment shown in Figure 3 is used to purify gases from impurities. The design of the device assumes that it will operate continuously, enabling constant purification of the adsorbate. The authors did not use any method for recovering the purified adsorbate in their device, but the authors indicate a solution to this problem, i.e., the use of a vapor-condensing element. This is a major disadvantage when looking for solutions ready for use in adsorption refrigerators because effective adsorbate recovery is one of the elements of the refrigerator’s operation. However, the equipment presented in [77] may constitute the basis for deeper considerations on the use of fluidization in refrigeration and water purification or desalination. The purification process itself was strongly dependent on the adsorbate concentration; the authors achieved the separation peak at a concentration of 6%. It is also worth noting that despite the use of fluidization, it was impossible to achieve complete purification of the adsorbate, which translates into the need for gradual purification and, as a result, higher construction costs.

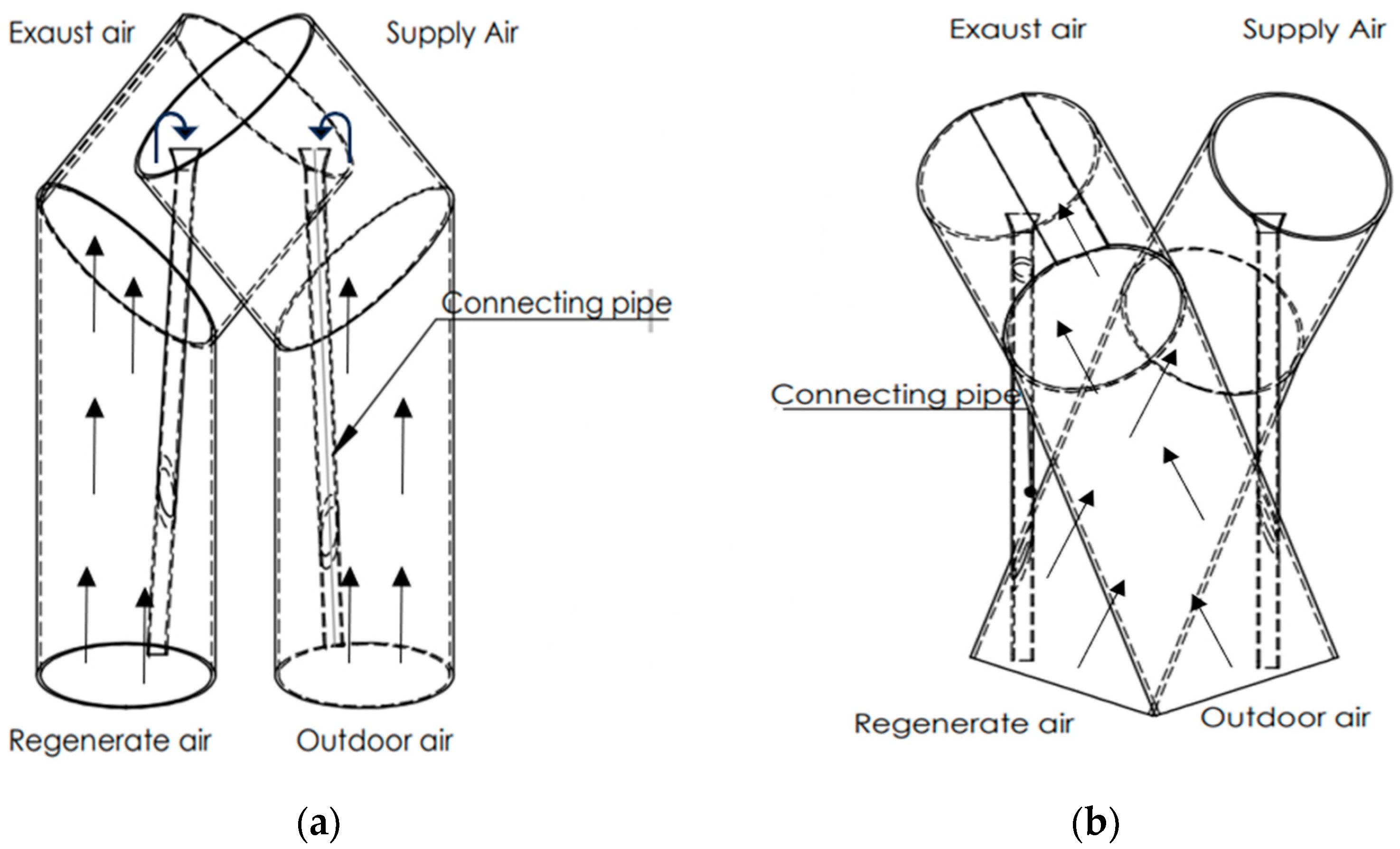

Figure 3.

The schematic diagram of an internally circulating fluidized bed. The diagram shows two chambers, the gas flowing into the chambers causes the sorbent to move, it circulates continuously between the chambers, enabling gas purification. A heat exchanger is placed in the adsorption chamber to cool the adsorbent, which allows adsorption [77].

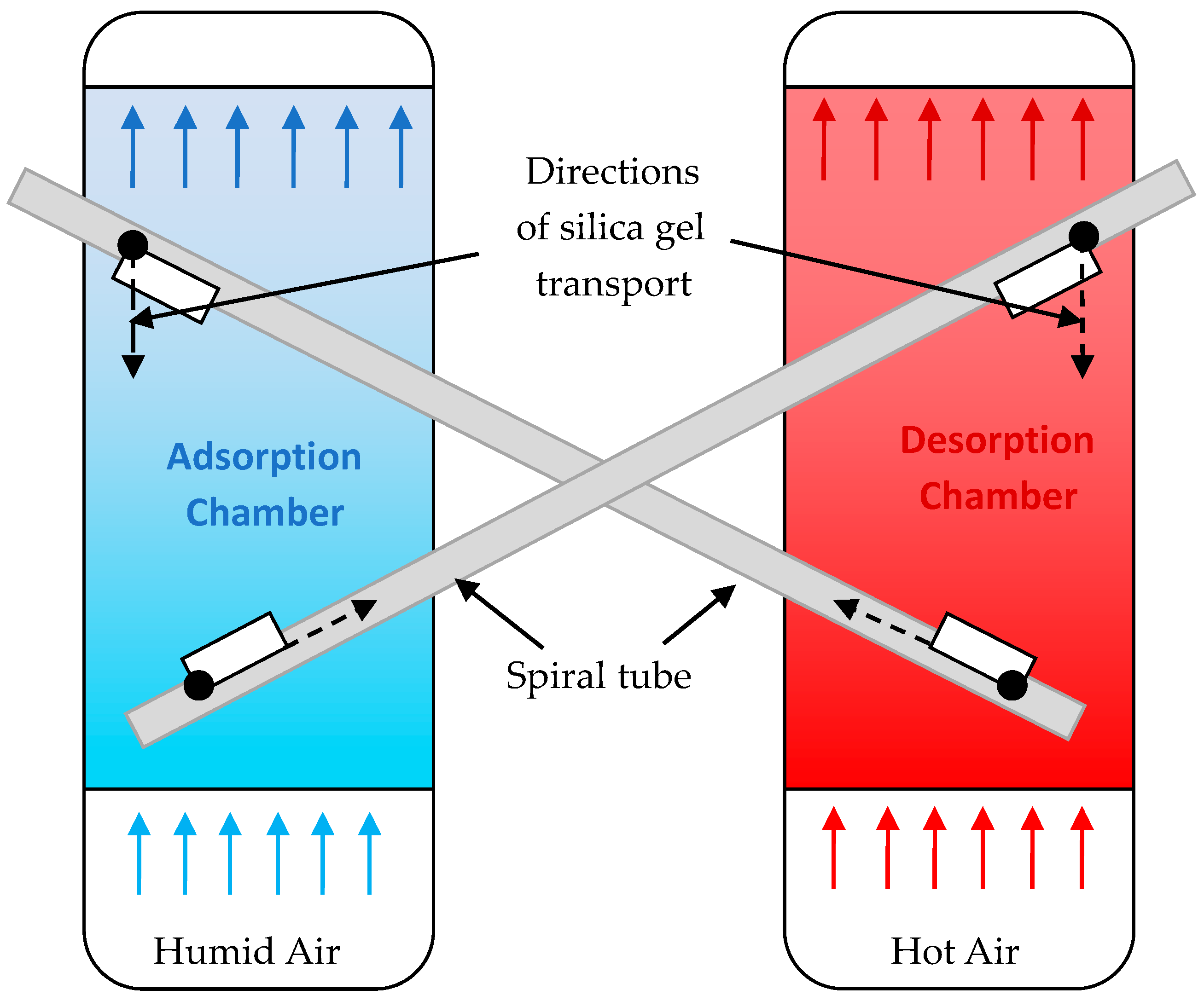

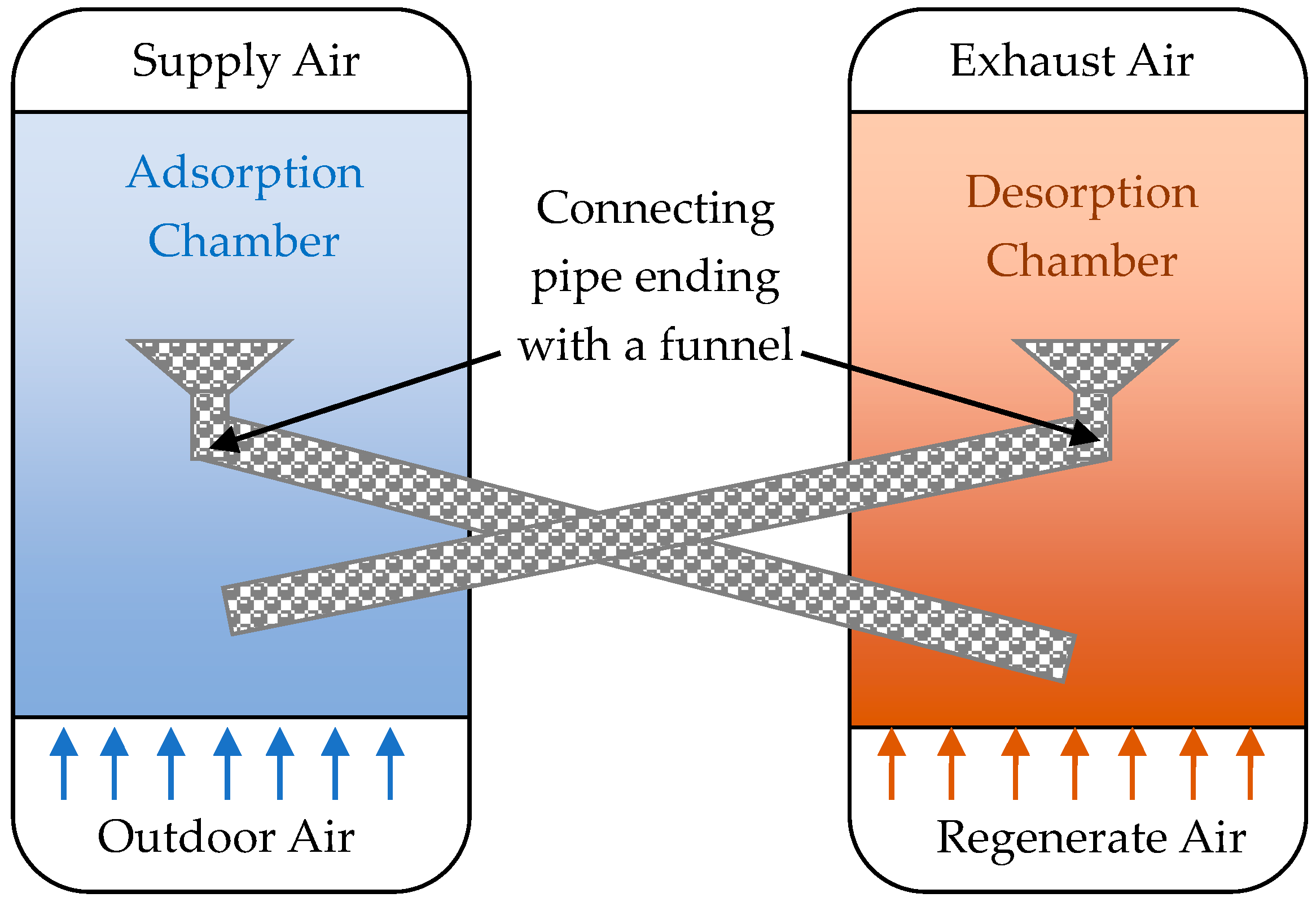

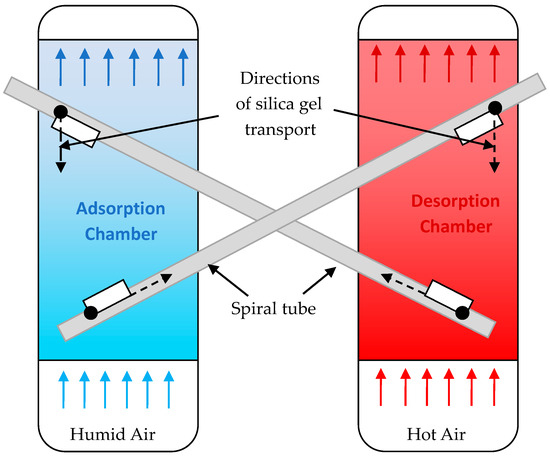

The approach presented in [59] for air-conditioning systems also employed fluidization. The authors also reported that fluidized beds are characterized by increased heat and mass transfer between gas and particles due to the increased contact surface area between them. The apparatus presented in the study consisted of two chambers connected by a spiral for continuous sorbent transfer between the adsorption and desorption chambers. They studied the effect of mass transport velocity, the temperature at the entrance to the desorption chamber, and air velocity in sorption chambers. The apparatus in question is shown in Figure 4. A significant impact of air velocity was observed in both chambers, causing an increase in moisture abatement during adsorption and faster drying during desorption. Increasing air velocity during desorption decreased the boundary layer concentration between air and sorbent, intensifying mixing processes. An increase in the fluidization velocity was also observed to raise the temperature difference between chambers, confirming an increase in mass and heat exchange between air and sorbent. The authors highlighted the importance of the adsorbent regeneration conditions for the overall adsorption capacity [59,69,75].

Figure 4.

Simplified diagram of fluidized bed chamber. The diagram shows two chambers connected by a spiral tube. Silica gel is transported continuously. The air requiring dehumidification flows through the adsorber, encountering the adsorbent, which, after the adsorption process, is transferred to the desorber, where it is regenerated using hot air. After regeneration, it returns through a spiral tube to the adsorber [59].

The test facility described in [59] was utilized for additional studies necessary for fluidization in adsorption cooling and desalination systems. The researchers investigated the effect of the original height of the sorption bed on the ability of the fluidized adsorption bed to remove moisture using the organic sorbent HU720PR, a bridge complex of sodium polyacrylate. The study also included mass transport tests for the apparatus described in [59,75]. Three beds with different heights of 0.016, 0.021, and 0.032 m, corresponding to sorbent masses of 150, 200, and 300 g, respectively, were tested experimentally. It was observed that large air bubbles were flowing in the bed, which meant that the air responsible for the adsorption and desorption process had too little time to contact the sorbet surface. The air contact with the adsorbent was the longest for the bed, with a height of 0.032 m, but this did not translate into achieving the highest degree of drying. This bed was characterized only by the highest temperature among the tested beds. This could have resulted in stopping the sorption processes on the surface of the sorbent, making only the adsorption process possible. The surface vapour pressure must be too low for the adsorbent to bind moisture, and this process could be disturbed by the too-high temperature generated in the adsorbent [61]. In this case, the best results in terms of moisture adsorption were achieved by the bed high of 0.021 m. Based on the research shown in [59], it can be concluded that the regeneration of the adsorption bed plays a crucial role in the efficiency of the adsorption processes. It is worth noting that the moisture adsorption capacity of the sorbent only increased up to a specific exchange rate between the adsorption and desorption chambers. This indicates that for high efficiency in continuous cycle operation, the sorbent must be previously well prepared for resorption, i.e., desorbed and cooled [59,65,75].

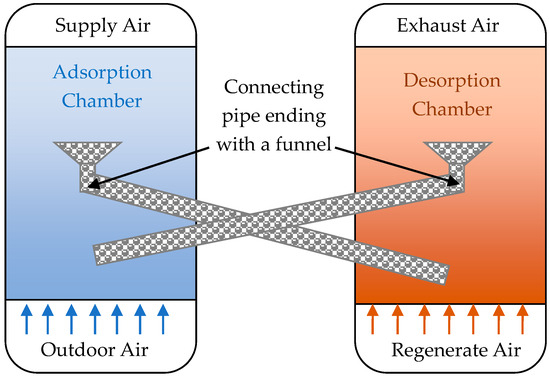

The circulating fluidized bed presented in [76] has great potential for application in dehumidification systems, and the experience gained there will undoubtedly contribute to similar beds in adsorption chillers. The system consisted of two transparent cylinders forming two fluidized beds. One was an adsorption bed and the other was a desorption bed. The two reservoirs were protected against silica gel loss and connected by funnels that allowed silica gel to be transferred between adsorption/desorption beds. The experiments simulated real-world conditions of 33 °C and 60% relative humidity. To find the optimum conditions for bed regeneration, the authors manipulated the silica gel regeneration air velocity in the first experiment while keeping the air temperature the same; in the second experiment, they decided to keep the flow velocity the same and varied the temperature. For the same weight of silica gel desiccant equal to 540 g, the total amount of adsorption and desorption was 61.6 g and 67.1 g for the packed bed and 75.6 g and 80.3 g for the fluidized bed, respectively. Pressure drop was also higher for the packed bed than for the fluidized bed. The fluidized bed was characterised by better mass and heat transfer and homogeneity. The entire system was tested for 40 min of periodic operation. The tests showed a 22.7% increase in moisture adsorption compared to a fixed bed, with a 19.6% increase in desorption. There was also a 29.9% reduction in pressure drop and a 42.8% reduction in system outlet air temperature. The effect of air velocity on fluidized bed performance was also investigated. At a regeneration temperature of 50 °C, both beds were subjected to 60-min experiments at air velocities of 4.0 m/s, 5.0 m/s and 6.0 m/s. As the velocity increased from 4.0 m/s to 5.0 m/s, the total increase in adsorption increased by 37.5%. When the air velocity was 6.0 m/s, the vapor uptake increased by 67.9% compared to the air velocity of 4.0 m/s. In addition, increasing the regeneration temperature improved the adsorption/desorption performance of the system. At regeneration temperatures of 40 °C and 50 °C, the average adsorption rates were 0.054 g/s and 0.077 g/s, respectively. The vapor uptake at 50 °C was 42.6% higher than for the same system at 40 °C. At regeneration temperatures of 40 °C and 60 °C, the amount of adsorption increased by 75.9%. Table 2 shows the results of the tests under different conditions in the fluidized bed.

Table 2.

Dehumidification test of the circulating fluidized bed system under different regeneration temperatures [76].

Despite the significant increase in sorption efficiency, the authors emphasized high bed regeneration temperatures due to the increased energy demand of the system. Thus, the silica gel fluidized bed has better heat and mass transfer efficiency and results in higher dehumidification; therefore, the silica gel fluidized bed system can effectively dehumidify the air and reduce the load on the fan due to the low-pressure drop. The results show that the average adsorption rate performance of a silica gel fluidized bed is better than that of a packed bed for higher heat and mass transfer rates, with greater homogeneity in the fluidized bed [76].

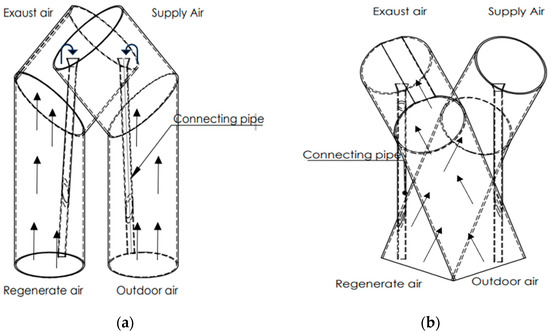

An extension of the fluidized bed idea presented in [76] is the bed shown in [71]. The authors improved this system by tilting the vertical fluidized beds by 20° and obtaining a more regular circulation effect. The schematic diagram of fluidized beds presented in [71,76] are shown in Figure 5 and Figure 6. Moreover, the minimum fluidization velocity and pressure drop were reduced due to the inclination angle. The angle of the connecting pipes was also changed from 45° to 90° to maximize the particle flow velocity in the pipes and enhance the overall circulation effect of the system. The focus was on improving the material’s adsorption and desorption capacity by altering the fluidized bed’s geometry. It was demonstrated that using an inclined circulating bed increased the moisture adsorption level, and the power needed to operate the device was reduced. The inclination of the bed from the vertical axis made the flow direction more regular, enhancing the circulation effect. Furthermore, the tilting of the bed led to a reduction in both the minimum fluidization velocity and pressure drops. The angle of the pipes connecting both deposits was also modified, increasing the maximum flow velocity of the particles in the pipes and thus increasing the overall circulation effect [70,71,76].

Figure 5.

Simplified diagram of circulating fluidized bed. The diagram shows two sorption chambers connected by a tube to a funnel. As a result of the flow of outdoor air through the chamber, the adsorbent is lifted. During this time, the adsorption process takes place. The adsorbent brought to the appropriate height falls into the funnel and moves to the desorption chamber, where an analogous process takes place aimed at desorption of the adsorbent [76].

Figure 6.

(a,b) Schematic diagrams of inclined circulating fluidized bed [71]. The operation of the bed is analogous to that shown in Figure 5. The main difference between both beds is the deflection of the beds, which prevents agglomeration of the adsorbent at the bottom of the bed [71].

Chen et al. [70] described additional benefits of fluidizing adsorption bed application, such as increased adsorption and desorption efficiency, lower pressure drops, and reduced temperature increase during adsorption, which makes the silica gel-filled beds more efficient and energy-saving. The authors also confirmed that silica gel adsorbed about 20% more water in a fluidized bed compared to a fixed bed. This is due to increased heat and mass transfer coefficient and greater homogeneity of the fluidized bed compared to the packed bed. The paper [67] also explores inclined-fluidized bed adsorption and desorption using silica gel as a desiccant. The author says that the non-uniform distribution of gas entering the bed can affect fluidization. He also points out that the most crucial advantage comes from the fact that the solid particles in it are in constant motion and are usually very well mixed; as a result, the “hot spots” are quickly dissipated, and the bed operates in an essentially isothermal manner. In addition, the gas passing through the fixed bed as a result of adsorption causes an increase in temperature, which is an additional heat load for the bed. In the case of adsorption air conditioning systems, it is associated with obtaining a higher air temperature at the outlet from the bed. Therefore, fluidized beds ensuring greater homogeneity of temperature distribution, higher heat transfer coefficients, and maintaining low pressure drops seem to be a good solution for adsorption beds.

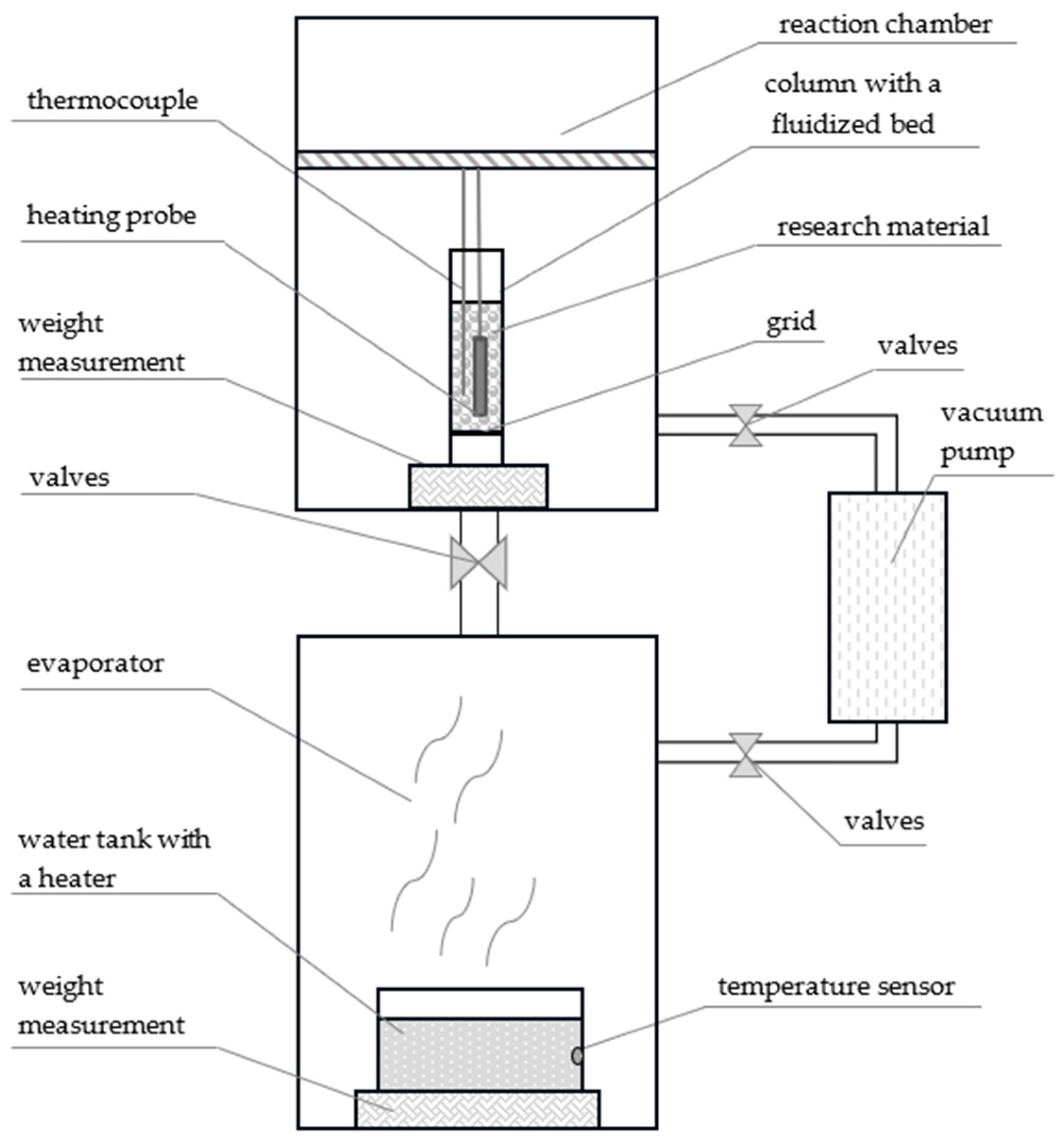

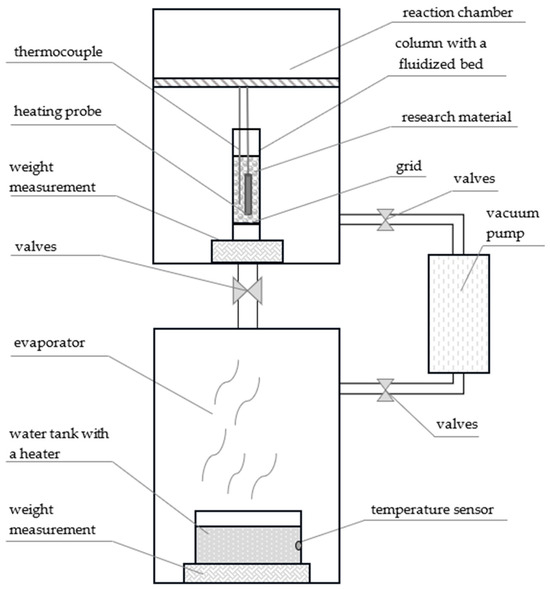

Kulakowska et al. [83] described an Intensified Heat Transfer Adsorption Bed (IHTAB) research stand. The test stand operates at low pressures and fluidization is caused by pressure differences and water vapor flowing between two tanks (Figure 7).

Figure 7.

The scheme of the Intensified Heat Transfer Adsorption Bed facility. The apparatus consists of two columns connected by a valve. A vacuum is maintained in both chambers. This allows water to evaporate in the evaporator at a low temperature. After obtaining the appropriate pressure in the evaporator, the valve opens, allowing the adsorbent to flow and fluidization of the bed in the reaction chamber. Both chambers contain mass, temperature, and pressure sensors that control the entire process [83].

The research unit IHTAB consists of two separate chambers, where the lower chamber functions as an evaporator, and the upper one serves as the main reaction chamber. There is a valve between the chambers. When the valve is opened, steam flows, and pressures equalize, resulting in fluidization as a consequence. Both chambers are connected to a vacuum pump. The reaction chamber is maintained at a pressure of approximately 10 mbar, and the evaporator at approximately 25 mbar.

Table 3 contains comparative information about the apparatus using the phenomenon of fluidization of the adsorption bed. The type of beds was specified and the differences in the method of obtaining fluidization in individual devices were also described. Although in each of them the refrigerant is mainly responsible for achieving fluidization, it happens in different ways. Wang et al. [47] mentions the acceleration of the refrigerant using a blower in a closed system. Kułakowska et al. [83] writes about obtaining the fluidized state through the pressure difference between the sorption chamber and the evaporator. For the remaining works, the mechanism for obtaining fluidization is similar. In the part of the bed responsible for adsorption, fluidization is caused by the adsorbate flow, and in the desorption part, it is hot air. Temperature ranges are also included. They differ from each other due to the characteristics of the device. For the first two devices, the temperature range covers both adsorption and desorption. The work [77] distinguishes four temperatures due to the structure of the bed, which is in constant motion, so its temperatures are averaged. For the last devices, the temperature at the entrance to the sorption chambers was given.

Table 3.

Compare the apparatus mentioned, its operating temperatures, type of fluidized bed, and methods for obtaining fluidization.

3.3. Integration of Material Solutions with Adsorption Fluidized Beds

The shape of the adsorbent particles also plays a crucial role in the fluidized bed of an adsorption chiller. The studies presented in [25] have shown that the shape of silica gel affects the fluidization process. Moreover, the laboratory bench-scale stand on which the silica gel mixtures were tested is innovative in its design. It experiments with conditions similar to the operating cycle of a fluidized bed adsorption chiller. During the research, two types of silica gel were used. The first one was material from Fuji Silysia Chemical Ltd (Kasugai Aichi, Japan). The second one was from Sigma Aldrich (Saint Louis, MO, USA). Both sorbents were sieved to a granulation size of 160–200 µm, and the samples used for the research weighed 55 g. The Fuji Silysia Chemical Ltd. Silica gel had a spherical shape with a sphericity coefficient of 0.95, a density of 2200 kg/m3, and a bulk density of 780 kg/m3. As a result, the bed void fraction was estimated to be 0.65. The silica gel grains from Sigma Aldrich had an irregular shape with a grain aspect ratio of 0.65, a density of 2200 kg/m3, and a bulk density of 850 kg/m3. The study revealed that the sorbent’s spherical shape positively influences the bed’s fluidization capacity. In addition, it has been demonstrated that achieving a fluidized bed state is possible without additional equipment. This proves the potential to obtain better heat and mass transfer conditions in the beds of the adsorption chiller without incurring additional energy costs, which can increase the adsorption chiller’s efficiency. During the research, it was demonstrated, based on temperature differences between the tested fixed and fluidized beds, that the adsorption process was intensified. The temperature in the fluidized bed increased significantly compared to the fixed bed. The temperature increase in the fluidized bed by nearly 22 degrees Celsius proves the increased efficiency adsorption of the bed compared to the fixed bed, where temperature rises only reached 3 degrees [25].

Kulakowska et al. [51] indicated the importance of homogeneity in the sorption bed. In the paper, the authors validated the impact of metallic additives on the thermal diffusivity of silica gel used in the adsorption bed. The results were not obvious, as the metallic additives that had better thermal properties did not lead to achieving the highest marks. The main reason was the density difference between silica gel and metallic additives influencing the fluidization dynamic of the blended bed material. As a result, the mixture of silica gel and aluminum in 15 wt.% achieved a superior effect of thermal diffusivity. At the same time, the mixtures with the remaining additive were too heterogeneous, which contributed to a decrease in heat transfer in the samples and, consequently, a reduction of thermal diffusivity [51].

Both papers [51,84] also investigated the influence of carbon nanotubes on silica gel properties. Kulakowska et al. [85] emphasized that the agglomeration of nanotube particles caused problems in obtaining a homogeneous sample. Carbon nanotubes can agglomerate into large clusters as a result of inter-particle forces, and this phenomenon plays a crucial role in carbon nanotube behavior. Moreover, particles of carbon nanotubes used in the research tended to accumulate at the surface of silica gel. Therefore, the addition of carbon nanotubes caused a decrease in the sorption capacity in the adsorption bed. The influence of various material mixtures on fluidization was investigated in this study. The research material consisted of silica gel mixed in various proportions with aluminum and carbon nanotubes. The work showed that the adsorption bed consisting of silica gel and 5% carbon nanotubes had the greatest impact on the fluidization process. This mixture was characterized by the largest range of bed mass changes as a result of adsorption/desorption processes. Carbon nanotubes improve the sorption properties of the fluidized bed. This is crucial for adsorption technology dedicated to cooling and desalination applications [83].

However, in the research presented in [84], the authors proved that despite the decline in sorption capacity, the heat transfer between the bed and the heat exchanger increased. Improved heat transfer from the bed to the wall of the heat exchanger is a desirable feature in the context of adsorption chillers because it can make the adsorption and desorption cycle more effective due to better heat collection in the adsorption process or increased heat supply in the desorption. Shorter and more efficient cycles will increase the coefficient of adsorption chillers’ performance. It could also allow the construction of smaller devices with the same cooling power, making adsorption chillers more competitive compared to compressor refrigerators, which are currently winning in terms of popularity of applications.

Despite enriching the adsorption bed with nanoparticles and fluidizing show promising results in improving heat transfer conditions in adsorption chillers, Dasgupta et al. [86] described carbon nanotube fluidization properties and indicated the importance of inter-particles forces in the agglomeration process, crucial to fluidize nanoparticles. When the particle size was smaller than 10 µm, the inter-particle forces became the same order of magnitude as gravity and drag. If the particle size decreased to the nanoscale, the inter-particle forces could increase to almost two orders of magnitude [87]. Therefore, the hydrodynamics of the adsorption bed depended on the shape and density created agglomerates more than primary particles [87]. The authors distinguished between two types of nanoparticle fluidization: agglomerate particulate fluidization (APF) and agglomerate bubbling fluidization (ABF) [85]. In the case of APF, it is characterized by smooth fluidization with practically no bubbles and a high bed expansion ratio of up to 500%. The bed expansion increased with increasing gas velocity, and agglomerates distributed uniformly within the bed.

In contrast to the APF, the ABF type is characterized by a low rate of bed expansion. The authors [88] also observed large bubbles rising very quickly through the bed, and the agglomerates distributed nonuniformly within the bed. From the point of view of fluidized bed design, especially those enriched in carbon nanotubes and other nanoparticles, it is essential to predict the behavior of the bed during operation. This will help eliminate errors resulting from the inappropriate choice of deposit material. In the case of nanoparticle additives, the bulk density of the material also plays a vital role as, together with the size of the particles, it determines the type of fluidization occurring in the bed and, thus, the performance of the entire adsorption chiller [89,90].

A promising concept of the fluidized adsorption bed application in adsorption chillers was proposed in [34]. The authors developed a model for numerical comparison of fixed and fluidized adsorption beds under various operating conditions. Compared to the fixed bed, the innovative approach has succeeded in increasing the thermal conductivity of the fluidized bed for all the tested materials. The study examined mixtures of silica gel, carbon nanotubes, and zeolite with added nanotubes. The highest thermal conductivity test results were obtained for various zeolite and carbon nanotubes, with a heat transfer coefficient of 730.1 W/(m2/K) [34]. These results confirm the assumptions made in [60,61], demonstrating that fluidization and sorbent improvements can significantly reduce the cost of adsorption chillers and increase their competitiveness. The maximum heat transfer coefficient value was achieved at a superficial gas velocity of 0.1 m/s. As the fluidization speed increased, the heat transfer coefficient value decreased. This indicates the nature of the fluidization phenomenon, in which the desired and highest process parameters oscillate near the minimum fluidization velocity. In their paper, the authors also point to the need to keep a balance in modelling fluidized bed phenomena, as the over-complexity of the model may make it impossible to use it in the reasonable prediction of fluidized bed behavior. In the data, the authors confirm that a 10% content of carbon nanotubes can increase the heat transfer coefficient from a level of about 550 W/m2K to nearly 700 W/m2K at a gas flow through the bed of v0 = 0.2 m/s. The work tested several potential silica gel and zeolite mixtures, with 10% and 20% silica gels, respectively. For each converted sample, fluidization led to significant increases in heat transfer coefficient. Considered in the context of the applicability of a combination of fluidization and admixtures to sorption materials, this offers great potential for increasing the heat transfer coefficient, but it is worth bearing in mind that when admixing a fluidized bed, care must be taken with the phenomenon of admixture segregation, which can cancel out the benefits they add. A further line of work will be to develop research on silica gels and zeolites in combination with the addition of carbon nanotubes. The authors claim that applying a fluidized bed can reduce the size of adsorption chillers. However, using an innovative adsorption bed also requires the design of new heat exchangers, adapted in terms of the amount of adsorbent for the new type of adsorption bed [34]. Table 4 includes the mentioned sorbent types utilized in the research for incorporating additives such as aluminum, copper, and carbon nanotubes into materials. Information about the research field of a given publication is also included.

Table 4.

Comparison of the properties of sorbents in the above-mentioned studies. Specific research objectives were also specified.

4. Conclusions

Adsorption chillers used in cooling and desalination systems are characterized by a low coefficient of performance, typically around 0.5–0.6. This is too low for adsorption refrigeration systems to compete effectively with compressor-based refrigerators. The presented review provides possibilities for improving the performance of adsorption refrigerators, from introducing innovations in beds, materials, or process parameters.

The review demonstrates that fluidization can significantly improve heat and mass transfer, which is crucial for increasing the cooling capacity of adsorption refrigerators. Combining fluidization and adding carbon nanotubes as an additive to the sorbent greatly enhanced the heat transfer coefficient.

In summary, applying fluidization in adsorption beds is an innovative approach with the potential to improve the performance of adsorption systems. However, because adsorption refrigerators and laboratory-tested systems are often unique in their construction, further research is required to gain empirical knowledge about the relationship between fluidization conditions and the cooling or heating performance of the device.

The bed geometry, size, sorbent preparation, and the ratio of adsorption and desorption times play a significant role in selecting the optimal device operating conditions. Material solutions, such as the search for alternatives to silica gel or strengthening its properties, are equally important areas for development.

Fluidization certainly increases many of the thermal parameters of sorption beds and it is an important enhancement. However, practical use in adsorption chillers may prove difficult due to the coefficient of performance. The cited studies do not provide much data on the actual energy consumption of fluidized bed equipment, so this issue needs to be studied in detail, as improvements made to the chiller should increase the coefficient of performance each time. At the same time, it makes sense to make improvements to the chiller when it is economically viable so as not to increase the price of the already expensive equipment.

Future studies are planned using a fluidized bed in a full-scale adsorption chiller. The conducted research assesses the possibility of using a fluidized bed in a full-size adsorption refrigerator, thereby filling the gap in research. All of these elements are extremely important from the point of view of the development of adsorption cooling and desalination technology. Combining the knowledge gathered so far will undoubtedly positively impact the competitiveness and increasingly widespread use of adsorption refrigerators.

Author Contributions

Conceptualization, A.Z., W.N. and K.S.; Formal analysis, L.L. and J.K.; Investigation, L.L. and J.K.; Methodology, L.L., J.K. and A.Z.; Supervision, L.L., J.K. and D.S.; Writing— original draft, L.L.; Writing—review and editing, J.K. and A.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data sharing is not applicable.

Acknowledgments

This work was performed within project No. 2018/29/B/ST8/00442, “Research on sorption process intensification methods in modified construction of adsorbent beds” supported by the National Science Centre, Poland.

Conflicts of Interest

The authors declare no conflict of interest.

References

- REN21. Renewables 2022 Global Status Report (Paris: REN21 Secretariat); ISBN 978-3-948393-04-5. Available online: https://www.ren21.net/wp-content/uploads/2019/05/GSR2022_Full_Report.pdf (accessed on 26 September 2023).

- Ahmed, S.; Nguyen, T. Analysis of Future Carbon-Neutral Energy System—The Case of Växjö Municipality, Sweden. Smart Energy 2022, 7, 100082. [Google Scholar] [CrossRef]

- Marie, L.F.; Landini, S.; Bae, D.; Francia, V.; O’Donovan, T.S. Advances in Thermochemical Energy Storage and Fluidised Beds for Domestic Heat. J. Energy Storage 2022, 53, 105242. [Google Scholar] [CrossRef]

- Yin, G.; Wang, Y.; Li, M.; Du, W.; Liu, Q.; Chang, Z. Experimental Investigation on a Two-Bed Adsorption Refrigeration System with Mass Recovery. Appl. Therm. Eng. 2022, 207, 118152. [Google Scholar] [CrossRef]

- Gibelhaus, A.; Postweiler, P.; Bardow, A. Efficient Modeling of Adsorption Chillers: Avoiding Discretization by Operator Splitting. Int. J. Refrig. 2022, 139, 180–191. [Google Scholar] [CrossRef]

- Elsheniti, M.B.; Hassab, M.A.; Attia, A.E. Examination of Effects of Operating and Geometric Parameters on the Performance of a Two-Bed Adsorption Chiller. Appl. Therm. Eng. 2019, 146, 674–687. [Google Scholar] [CrossRef]

- Elsheniti, M.B.; Elsamni, O.A.; Al-dadah, R.K.; Mahmoud, S.; Elsayed, E.; Saleh, K. Adsorption Refrigeration Technologies. In Sustainable Air Conditioning Systems; InTech: London, UK, 2018. [Google Scholar]

- Abedi, M.; Tan, X.; Klausner, J.F.; Bénard, A. Solar Desalination Chimneys: Investigation on the Feasibility of Integrating Solar Chimneys with Humidification–Dehumidification Systems. Renew. Energy 2023, 202, 88–102. [Google Scholar] [CrossRef]

- Denzinger, C.; Berkemeier, G.; Winter, O.; Worsham, M.; Labrador, C.; Willard, K.; Altaher, A.; Schuleter, J.; Ciric, A.; Choi, J.K. Toward Sustainable Refrigeration Systems: Life Cycle Assessment of a Bench-Scale Solar-Thermal Adsorption Refrigerator. Int. J. Refrig. 2021, 121, 105–113. [Google Scholar] [CrossRef]

- Ben Hamida, M.B. Numerical Analysis of Tubular Solar Still with Rectangular and Cylindrical Troughs for Water Production under Vacuum. J. Taibah Univ. Sci. 2023, 17, 2159172. [Google Scholar] [CrossRef]

- Hamida, M.B.B.; Alshammari, F.; Alatawi, I.; Alhadri, M.; Almeshaal, M.A.; Hajlaoui, K. Potential of tubular solar still with rectangular trough for water production under vacuum condition. Therm. Sci. 2022, 26, 4271–4283. [Google Scholar] [CrossRef]

- Kadhim Hussein, A.; El Hadi Attia, M.; Jassim Abdul-Ammer, H.; Arıcı, M.; Ben Hamida, M.B.; Younis, O.; Homod, R.Z.; Abidi, A. Experimental Study of the Impact of Low-Cost Energy Storage Materials on the Performance of Solar Distillers at Different Water Depths. Sol. Energy 2023, 257, 221–230. [Google Scholar] [CrossRef]

- Boukhriss, M.; Khemili, S.; Ben Hamida, M.B.; Ben Bacha, H. Simulation and Experimental Study of an AGMD Membrane Distillation Pilot for the Desalination of Seawater or Brackish Water with Zero Liquid Discharged. Heat Mass Transf. 2018, 54, 3521–3531. [Google Scholar] [CrossRef]

- Boukhriss, M.; Ben Hmida, M.B.; Maatoug, M.A.; Zarzoum, K.; Marzouki, R.; Ben Bacha, H. The Design of a Unit Sweeping Gas Membrane Distillation: Experimental Study on a Membrane and Operating Parameters. Appl. Water Sci. 2020, 10, 110. [Google Scholar] [CrossRef]

- Saha, B.B.; El-Sharkawy, I.I.; Shahzad, M.W.; Thu, K.; Ang, L.; Ng, K.C. Fundamental and Application Aspects of Adsorption Cooling and Desalination. Appl. Therm. Eng. 2016, 97, 68–76. [Google Scholar] [CrossRef]

- Sztekler, K.; Kalawa, W.; Nowak, W.; Mika, L.; Krzywanski, J.; Grabowska, K.; Sosnowski, M.; Alharbi, A. Performance Evaluation of a Single-Stage Two-Bed Adsorption Chiller With Desalination Function. J. Energy Resour. Technol. Trans. ASME 2021, 143, 082101. [Google Scholar] [CrossRef]

- Akhtar, S.; Khan, T.S.; Ilyas, S.; Alshehhi, M.S. Feasibility and Basic Design of Solar Integrated Absorption Refrigeration for an Industry. Energy Procedia 2015, 75, 508–513. [Google Scholar] [CrossRef]

- Jrad, A.B.H.; Ben Hamida, M.B.; Ghnay, R.; Mhimid, A. Contribution to the Study of Combined Adsorption–Ejection System Using Solar Energy. Adv. Mech. Eng. 2017, 9, 1687814017711855. [Google Scholar] [CrossRef]

- Ben Hamida, M.B.; Belghaieb, J.; Hajji, N. Heat and Mass Transfer Enhancement for Falling Film Absorption Process in Vertical Plate Absorber by Adding Copper Nanoparticles. Arab. J. Sci. Eng. 2018, 43, 4991–5001. [Google Scholar] [CrossRef]

- Ben Hamida, M.B.; Belghaieb, J.; Hajji, N. Numerical Study of Heat and Mass Transfer Enhancement for Bubble Absorption Process of Ammonia-Water Mixture without and with Nanofluids. Therm. Sci. 2018, 22, 3107–3120. [Google Scholar] [CrossRef]

- Ben Jaballah, R.; Ben Hamida, M.B.; Saleh, J.; Almeshaal, M.A. Enhancement of the Performance of Bubble Absorber Using Hybrid Nanofluid as a Cooled Absorption System. Int. J. Numer. Methods Heat Fluid Flow 2019, 29, 3857–3871. [Google Scholar] [CrossRef]

- Ben Jaballah, R.; Ben Hamida, M.B.; Almeshaal, M.A.; Chamkha, A. The Influence of Hybrid Nanofluid and Coolant Flow Direction on Bubble Mode Absorption Improvement. Math. Methods Appl. Sci. 2020, 1–15. [Google Scholar] [CrossRef]

- Luo, H.L.; Wang, R.Z.; Dai, Y.J.; Wu, J.Y.; Shen, J.M.; Zhang, B.B. An Efficient Solar-Powered Adsorption Chiller and Its Application in Low-Temperature Grain Storage. Sol. Energy 2007, 81, 607–613. [Google Scholar] [CrossRef]

- Wang, Y.; Li, M.; Ji, X.; Yu, Q.; Li, G.; Ma, X. Experimental Study of the Effect of Enhanced Mass Transfer on the Performance Improvement of a Solar-Driven Adsorption Refrigeration System. Appl. Energy 2018, 224, 417–425. [Google Scholar] [CrossRef]

- Grabowska, K.; Zylka, A.; Kulakowska, A.; Skrobek, D.; Krzywanski, J.; Sosnowski, M.; Ciesielska, K.; Nowak, W. Experimental Investigation of an Intensified Heat Transfer Adsorption Bed (IHTAB) Reactor Prototype. Materials 2021, 14, 3520. [Google Scholar] [CrossRef] [PubMed]

- Grabowska, K.; Krzywanski, J.; Nowak, W.; Wesolowska, M. Construction of an Innovative Adsorbent Bed Configuration in the Adsorption Chiller–Selection Criteria for Effective Sorbent-Glue Pair. Energy 2018, 151, 317–323. [Google Scholar] [CrossRef]

- Rupa, M.J.; Pal, A.; Saha, B.B. Activated Carbon-Graphene Nanoplatelets Based Green Cooling System: Adsorption Kinetics, Heat of Adsorption, and Thermodynamic Performance. Energy 2020, 193, 116774–116968. [Google Scholar] [CrossRef]

- Wang, L.W.; Tamainot-Telto, Z.; Thorpe, R.; Critoph, R.E.; Metcalf, S.J.; Wang, R.Z. Study of Thermal Conductivity, Permeability, and Adsorption Performance of Consolidated Composite Activated Carbon Adsorbent for Refrigeration. Renew. Energy 2011, 36, 2062–2066. [Google Scholar] [CrossRef]

- Grabowska, K.; Sztekler, K.; Krzywanski, J.; Sosnowski, M.; Stefanski, S.; Nowak, W. Construction of an Innovative Adsorbent Bed Configuration in the Adsorption Chiller Part 2. Experimental Research of Coated Bed Samples. Energy 2021, 215, 119123. [Google Scholar] [CrossRef]

- Skrobek, D.; Krzywanski, J.; Sosnowski, M.; Kulakowska, A.; Zylka, A.; Grabowska, K.; Ciesielska, K.; Nowak, W. Implementation of Deep Learning Methods in Prediction of Adsorption Processes. Adv. Eng. Softw. 2022, 173, 103190. [Google Scholar] [CrossRef]

- Krzywanski, J.; Sztekler, K.; Bugaj, M.; Kalawa, W.; Grabowska, K.; Chaja, P.R.; Sosnowski, M.; Nowak, W.; Mika, L.; Bykuc, S. Adsorption Chiller in a Combined Heating and Cooling System: Simulation and Optimization by Neural Networks. Bull. Pol. Acad. Sci. Technol. Sci. 2021, 69, e137054. [Google Scholar] [CrossRef]

- Krzywanski, J.; Skrobek, D.; Zylka, A.; Grabowska, K.; Kulakowska, A.; Sosnowski, M.; Nowak, W.; Blanco-Marigorta, A.M. Heat and Mass Transfer Prediction in Fluidized Beds of Cooling and Desalination Systems by AI Approach. Appl. Therm. Eng. 2023, 225, 120200. [Google Scholar] [CrossRef]

- Grabowska, K.; Sosnowski, M.; Krzywanski, J.; Sztekler, K.; Kalawa, W.; Zylka, A.; Nowak, W. Analysis of Heat Transfer in a Coated Bed of an Adsorption Chiller. In Proceedings of the MATEC Web of Conferences, Cracow, Poland, 21–24 May 2018; Volume 240. [Google Scholar] [CrossRef]

- Krzywanski, J.; Grabowska, K.; Sosnowski, M.; Zylka, A.; Kulakowska, A.; Czakiert, T.; Sztekler, K.; Wesolowska, M.; Nowak, W. Heat Transfer in Adsorption Chillers with Fluidized Beds of Silica Gel, Zeolite, and Carbon Nanotubes. Heat Transf. Eng. 2021, 43, 172–182. [Google Scholar] [CrossRef]

- Krzywanski, J.; Grabowska, K.; Sosnowski, M.; Zyłka, A.; Sztekler, K.; Kalawa, W.; Wójcik, T.; Nowak, W. Modeling of a re-heat two-stage adsorption chiller by AI approach. MATEC Web Conf. 2018, 240, 5014. [Google Scholar] [CrossRef]

- Wahab, M.I.A.; Rheima, K.H. Drying of Solid Materials by Vacuum Fluidized Bed Dryer. Iraqi J. Chem. Pet. Eng. 2009, 10, 1–11. [Google Scholar] [CrossRef]

- Llop, M.F.; Madrid, F.; Arnaldos, J.; Casal, J. A generalized equation for the prediction of minimum fluidization velocity. Chem. Eng. Sci. 1996, 51, 5149–5157. [Google Scholar] [CrossRef]

- De Souza-Santos, M.L. Proposals for Power Generation Based on Processes Consuming Biomass-Glycerol Slurries. Energy 2017, 120, 959–974. [Google Scholar] [CrossRef]

- Krzywanski, J. Heat Transfer Performance in a Superheater of an Industrial CFBC Using Fuzzy Logic-Based Methods. Entropy 2019, 21, 919. [Google Scholar] [CrossRef]

- Rosen, M.A. The exergy of stratified thermal energy storages. Sol. Energy 2001, 71, 173–185. [Google Scholar] [CrossRef]

- Almendros-Ibáñez, J.A.; Fernández-Torrijos, M.; Díaz-Heras, M.; Belmonte, J.F.; Sobrino, C. A Review of Solar Thermal Energy Storage in Beds of Particles: Packed and Fluidized Beds. Sol. Energy 2019, 192, 193–237. [Google Scholar] [CrossRef]

- Muskala, W.; Krzywański, J.; Czakiert, T.; Nowak, W. The research of CFB boiler operation for oxygen-enhanced dried lignite Combustion. Rynek Energii 2011, 92, 172–176. [Google Scholar]

- Krzywanski, J.; Blaszczuk, A.; Czakiert, T.; Rajczyk, R.; Nowak, W. Artificial intelligence treatment of NOX emissions from CFBC in air and oxy-fuel conditions. In Proceedings of the 11th International Conference on Fluidized Bed Technology, Beijing, China, 14–17 May 2014; pp. 619–624. [Google Scholar]

- Krzywański, J.; Rajczyk, R.; Nowak, W. Model Research of Gas Emissions from Lignite and Biomass Co-Combustion in a Large Scale Cfb Boiler. Chem. Process Eng. Inz. Chem. I Proces. 2014, 35, 217–231. [Google Scholar] [CrossRef]

- AL-Hasni, S.; Santori, G. The Cost of Manufacturing Adsorption Chillers. Therm. Sci. Eng. Prog. 2023, 39, 101685. [Google Scholar] [CrossRef]

- Fernandes, M.S.; Brites, G.J.V.N.; Costa, J.J.; Gaspar, A.R.; Costa, V.A.F. Review and Future Trends of Solar Adsorption Refrigeration Systems. Renew. Sustain. Energy Rev. 2014, 39, 102–123. [Google Scholar] [CrossRef]

- Wang, Q.; Gao, X.; Xu, J.Y.; Maiga, A.S.; Chen, G.M. Experimental Investigation on a Fluidized-Bed Adsorber/Desorber for the Adsorption Refrigeration System. Int. J. Refrig. 2012, 35, 694–700. [Google Scholar] [CrossRef]

- Sztekler, K.; Kalawa, W.; Mika, Ł.; Mlonka-Medrala, A.; Sowa, M.; Nowak, W. Effect of Additives on the Sorption Kinetics of a Silica Gel Bed in Adsorption Chiller. Energies 2021, 14, 1083. [Google Scholar] [CrossRef]

- Bujok, T.; Boruta, P.; Mika, Ł.; Sztekler, K. Analysis of Designs of Heat Exchangers Used in Adsorption Chillers. Energies 2021, 14, 8038. [Google Scholar] [CrossRef]

- Alghoul, M.A.; Sulaiman, M.Y.; Azmi, B.Z.; Wahab, M.A. Advances on Multi-Purpose Solar Adsorption Systems for Domestic Refrigeration and Water Heating. Appl. Therm. Eng. 2007, 27, 813–822. [Google Scholar] [CrossRef]

- Kulakowska, A.; Pajdak, A.; Krzywanski, J.; Grabowska, K.; Zylka, A.; Sosnowski, M.; Wesolowska, M.; Sztekler, K.; Nowak, W. Effect of Metal and Carbon Nanotube Additives on the Thermal Diffusivity of a Silica-Gel-Based Adsorption Bed. Energies 2020, 16, 1391. [Google Scholar] [CrossRef]

- Sztekler, K.; Kalawa, W.; Mika, Ł.; Sowa, M. Effect of Metal Additives in the Bed on the Performance Parameters of an Adsorption Chiller with Desalination Function. Energies 2021, 14, 7226. [Google Scholar] [CrossRef]

- Sur, A.; Das, R.K. Review on solar adsorption refrigeration cycle. Int. J. Mech. Eng. Technol. 2010, 1, 190–226. [Google Scholar]

- Zhang, H.; Degrève, J.; Baeyens, J.; Dewil, R. The Voidage in a CFB Riser as Function of Solids Flux and Gas Velocity. In Proceedings of the Procedia Engineering; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; Volume 102, pp. 1112–1122. [Google Scholar]

- von Berg, L.; Anca-Couce, A.; Hochenauer, C.; Scharler, R. Multi-Scale Modelling of Fluidized Bed Biomass Gasification Using a 1D Particle Model Coupled to CFD. Fuel 2022, 324, 124677. [Google Scholar] [CrossRef]

- Majumder, P.; Deb, B.; Gupta, R. Design and Development of Solar Assisted Fluidized Bed Dryer Integrated with Liquid Desiccant Dehumidifier: Theoretical Analysis and Experimental Investigation. Energy Convers. Manag. 2022, 270, 116281. [Google Scholar] [CrossRef]

- Jiang, Y.; Bagheri, M.H.; Loibl, R.T.; Schiffres, S.N. Thermodynamic Limits of Adsorption Heat Pumps: A Facile Method of Comparing Adsorption Pairs. Appl. Therm. Eng. 2019, 160, 113906. [Google Scholar] [CrossRef]

- Kunii, D.; Levenspiel, O. Fluidization Engineering; Butterworth-Heinemann: Oxford, UK, 1991; ISBN 0409902330. [Google Scholar]

- Horibe, A.; Sukmawaty; Haruki, N.; Hiraishi, D. Sorption-Desorption Operations on Two Connected Fluidized Bed Using Organic Sorbent Powder. Int. J. Heat Mass Transf. 2013, 65, 817–825. [Google Scholar] [CrossRef]

- Yohana, E.; Haryanto, I.; Dwiputra, M.; Luqmanul, Y. Static and Dynamic Analysis of Vibro Fluidized Bed Dryer Using Finite Element Method. E3S Web Conf. 2018, 73, 05029. [Google Scholar]

- Wang, S.; Hu, C.; Luo, K.; Yu, J.; Fan, J. Multi-Scale Numerical Simulation of Fluidized Beds: Model Applicability Assessment. Particuology 2023, 80, 11–41. [Google Scholar] [CrossRef]

- de Souza-Santos, M.L. Solid Fuels Combustion and Gasification; CRC Press: Boca Raton, FL, USA, 2010; ISBN 9781420047509. [Google Scholar]

- de Souza-Santos, M.L. Solid Fuels Combustion and Gasification; CRC Press: Boca Raton, FL, USA, 2004; ISBN 9780429216497. [Google Scholar]

- Rogala, Z.; Kolasiński, P.; Gnutek, Z. Effect of Operating Conditions on Performance of Silica Gel-Water Air-Fluidised Desiccant Cooler. In Proceedings of the E3S Web of Conferences, Montpellier, France, 3–7 July 2017; EDP Sciences: Les Ulis, France, 2017; Volume 22. [Google Scholar]

- Rogala, Z.; Kolasiński, P.; Gnutek, Z. Modelling and Experimental Analyzes on Air-Fluidised Silica Gel-Water Adsorption and Desorption. Appl. Therm. Eng. 2017, 127, 950–962. [Google Scholar] [CrossRef]

- Nikam, S.; Mandal, D. A Study on Fluidization of Activated Carbon Particles in Gas-Solid Fluidized Bed. Indian Chem. Eng. 2021, 63, 478–490. [Google Scholar] [CrossRef]

- Hamed, A.M. Experimental Investigation on the Adsorption/Desorption Processes Using Solid Desiccant in an Inclined-Fluidized Bed. Renew. Energy 2005, 30, 1913–1921. [Google Scholar] [CrossRef]

- Lienhard, J.H. A Heat Transfer Textbook, 3rd ed.; Phlogiston Press: Cambridge, MA, USA, 2008. [Google Scholar]

- Horibe, A.; Husain, S.; Inaba, H.; Haruki, N. Sorption Characteristics of Organic Powder Sorption Material in Fluidized Bed with a Cooling Pipe. J. Therm. Sci. Technol. 2008, 3, 207–218. [Google Scholar] [CrossRef][Green Version]

- Chen, C.H.; Schmid, G.; Chan, C.T.; Chiang, Y.C.; Chen, S.L. Application of Silica Gel Fluidised Bed for Air-Conditioning Systems. Appl. Therm. Eng. 2015, 89, 229–238. [Google Scholar] [CrossRef]

- Chiang, Y.C.; Chen, C.H.; Chiang, Y.C.; Chen, S.L. Circulating Inclined Fluidized Beds with Application for Desiccant Dehumidification Systems. Appl. Energy 2016, 175, 199–211. [Google Scholar] [CrossRef]

- Hamed, A.M.; Abd El Rahman, W.R.; El-Eman, S.H. Experimental Study of the Transient Adsorption/Desorption Characteristics of Silica Gel Particles in Fluidized Bed. Energy 2010, 35, 2468–2483. [Google Scholar] [CrossRef]

- Hamed, A.M. Theoretical and Experimental Study on the Transient Adsorption Characteristics of a Vertical Packed Porous Bed. Renew. Energy 2002, 27, 525–541. [Google Scholar] [CrossRef]

- Wang, S.; Shen, Y. Particle-Scale Modelling of the Pyrolysis of End-of-Life Solar Panel Particles in Fluidized Bed Reactors. Resour. Conserv. Recycl. 2022, 183, 106378. [Google Scholar] [CrossRef]

- Horibe, A.; Sukmawaty; Haruki, N.; Hiraishi, D. Continuous Sorption and Desorption of Organic Sorbent Powder in Two Connected Fluidized Beds. J. Therm. Sci. Technol. 2012, 7, 563–576. [Google Scholar] [CrossRef][Green Version]

- Chen, C.H.; Ma, S.S.; Wu, P.H.; Chiang, Y.C.; Chen, S.L. Adsorption and Desorption of Silica Gel Circulating Fluidized Beds for Air Conditioning Systems. Appl. Energy 2015, 155, 708–718. [Google Scholar] [CrossRef]

- Reichhold, A.; Hofbauer, H. Internally Circulating Fluidized Bed for Continuous Adsorption and Desorption. Chem. Eng. Process. 1995, 34, 521–527. [Google Scholar] [CrossRef]

- Berggren, J.C.; Eklund, H.; Karlsson, H. 56 Application of Chemical and Physical Operations in a Circulating Fluidized Bed System; Pergamon Press Ltd.: Oxford, UK, 1980; Volume 35. [Google Scholar]

- Chen, C.J.; Wang, R.Z.; Xia, Z.Z.; Kiplagat, J.K.; Lu, Z.S. Study on a Compact Silica Gel-Water Adsorption Chiller without Vacuum Valves: Design and Experimental Study. Appl. Energy 2010, 87, 2673–2681. [Google Scholar] [CrossRef]

- Harriman, L.G. The Dehumidification Handbook; Munters Corporation: Amesbury, MA, USA, 2002; ISBN 0971788707. [Google Scholar]

- Muskała, W.; Krzywański, J.; Rajczyk, R.; Cecerko, M.; Kierzkowski, B.; Nowak, W.; Gajewski, W. Investigation of erosion in CFB boilers. Rynek Energii 2010, 87, 97–102. [Google Scholar]

- Muskała, W.; Krzywański, J.; Sekret, R.; Nowak, W. Model research of coal combustion in circulating fluidized bed boilers. Chem. Process Eng. 2008, 29, 473–492. [Google Scholar]

- Kulakowska, A.; Zylka, A.; Krzywanski, J.; Skrobek, D.; Grabowska, K.; Sosnowski, M.; Nowak, W. Influence of the Adsorption Bed Composition on the Low-Pressure Fluidization. Processes 2023, 11, 1912. [Google Scholar] [CrossRef]

- Pajdak, A.; Kulakowska, A.; Liu, J.; Berent, K.; Kudasik, M.; Krzywanski, J.; Kalawa, W.; Sztekler, K.; Skoczylas, N. Accumulation and Emission of Water Vapor by Silica Gel Enriched with Carbon Nanotubes CNT-Potential Applications in Adsorption Cooling and Desalination Technology. Appl. Sci. 2022, 12, 5644. [Google Scholar] [CrossRef]

- Yao, W.; Guangsheng, G.; Fei, W.; Jun, W. Fluidization and Agglomerate Structure of SiO2 Nanoparticles. Powder Technol. 2002, 124, 152–159. [Google Scholar] [CrossRef]

- Dasgupta, K.; Joshi, J.B.; Banerjee, S. Fluidized Bed Synthesis of Carbon Nanotubes—A Review. Chem. Eng. J. 2011, 171, 841–869. [Google Scholar] [CrossRef]

- Hogg, R. Role of Colloid and Interface Science in Agglomeration. In Proceedings of the 5th International Symposium on Agglomeration, Brighton, UK, 25–27 September 1989; pp. 483–493. [Google Scholar]

- Zhu, C.; Yu, Q.; Dave, R.N.; Pfeffer, R. Gas Fluidization Characteristics of Nanoparticle Agglomerates. AIChE J. 2005, 51, 426–439. [Google Scholar] [CrossRef]

- Krzywanski, J.; Sztekler, K.; Szubel, M.; Siwek, T.; Nowak, W.; Mika, Ł. A Comprehensive, Three-Dimensional Analysis of a Large-Scale, Multi-Fuel, CFB Boiler Burning Coal and Syngas. Part 1. The CFD Model of a Large-Scale Multi-Fuel CFB Combustion. Entropy 2020, 22, 964. [Google Scholar] [CrossRef] [PubMed]

- Krzywanski, J.; Sztekler, K.; Szubel, M.; Siwek, T.; Nowak, W.; Mika, Ł. A Comprehensive, Three-Dimensional Analysis of a Large-Scale, Multi-Fuel, CFB Boiler Burning Coal and Syngas. Part 2. Numerical Simulations of Coal and Syngas Co-Combustion. Entropy 2020, 22, 856. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).