Tariff-Based Optimal Scheduling Strategy of Photovoltaic-Storage for Industrial and Commercial Customers

Abstract

:1. Introduction

- The particle swarm optimization-backpropagation (PSO-BP) neural network algorithm is used to optimize the weights and thresholds of the BP algorithm using PSO to improve the accuracy of the prediction model.

- Based on the PV power prediction, the storage capacity and charging/discharging power under different weather conditions are configured according to the information of TOU tariffs and investment costs of the ESS.

- According to the proposed capacity allocation scheme, different scheduling strategies are developed for different weather conditions to solve the optimization problem caused by TOU tariffs and base tariffs.

2. PV Power Prediction

2.1. PSO-BP PV Power Prediction Model

- Initialization: Determining BP network structure, including the number of nodes and connection weights of the input layer, hidden layer, and output layer, etc. Initializing the relevant parameters of PSO, such as population size, maximum number of iterations, inertia weights, etc.

- Random initialization of the population: A certain number of particles are randomly initialized. Each particle represents a possible BP neural network structure. The speed and position of particles are initialized as required by the PSO algorithm.

- Calculate the fitness value: For each particle, the training set is trained using the BP algorithm based on parameters such as current weights and thresholds, and its error on the validation set is calculated as the fitness, and the current speed and position are updated according to the optimal fitness. The fitness is repeatedly calculated, and the speed and position of particles are updated until the preset maximum number of iterations is reached or the error requirement is met.

- Output the optimal solution: Output the BP neural network with the best fitness and its corresponding weights and thresholds.

- Training the neural network: Based on the derived optimal weights and thresholds, the neural network is trained and the prediction results are output when the accuracy requirements or the maximum number of iterations are met.

2.2. PV Power Prediction Results

3. Energy Storage Capacity Configuration

3.1. Cost Analysis of Energy Storage Capacity Configuration

3.1.1. Electricity Cost

3.1.2. Average Daily Investment Cost of Energy Storage

3.1.3. Operation and Maintenance (O&M) Cost

3.1.4. Objective Function

3.2. Restrictions

3.2.1. Power Balance Constraint

3.2.2. State of Charge (SOC) Constraint

3.2.3. Power Balance Constraint SOC Continuity Constraint

3.2.4. Charging/Discharging Power Constraint

3.2.5. Charging/Discharging Status Flag Bit

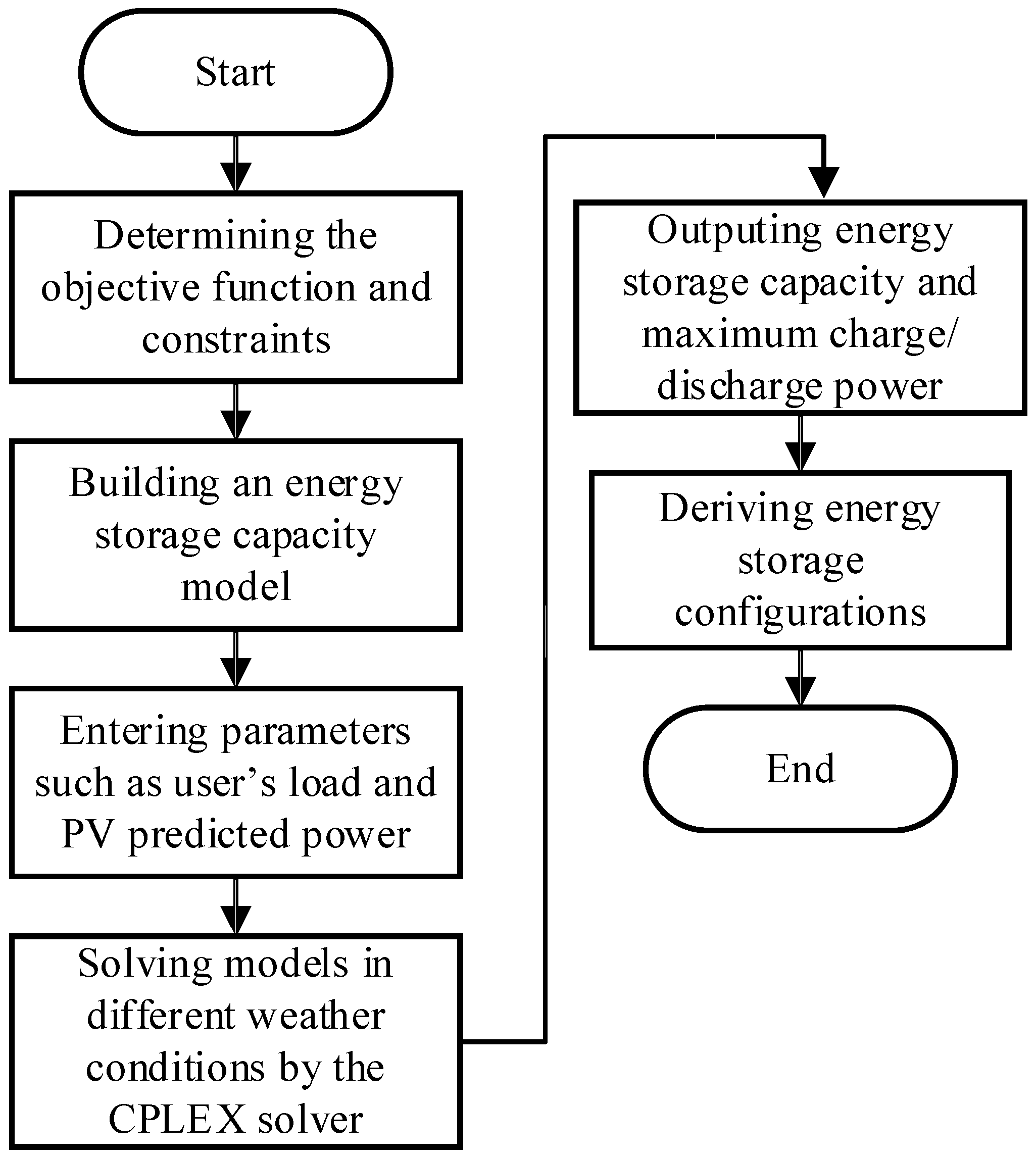

3.3. Energy Storage Configuration Process

- Based on the user’s load and predicted photovoltaic output, priority should be given to meeting the user load, onsite photovoltaic consumption and reducing electricity costs.

- Determine the constraints of the ESS and establish an energy storage capacity configuration model with the sum of the electricity cost, the average daily investment cost and the daily O&M cost as the goal.

- The configuration model is solved using CPLEX on the MATLAB platform to obtain the optimal energy storage capacity and maximum charging and discharging power under different weather conditions.

- After analyzing the obtained results of the solution, this paper designs an ESS that meets practical needs, cooperates with PV power generation, and optimizes scheduling.

4. Optimal Scheduling Strategy for PV-ESS Integrated System

4.1. Electricity Cost Analysis

4.1.1. Electricity Tariff Cost

4.1.2. Demand Charge

4.1.3. Objective Function

4.2. Restrictions

4.2.1. Demand Constraint

4.2.2. Maximum Grid Power Constraint

4.3. Solution Method

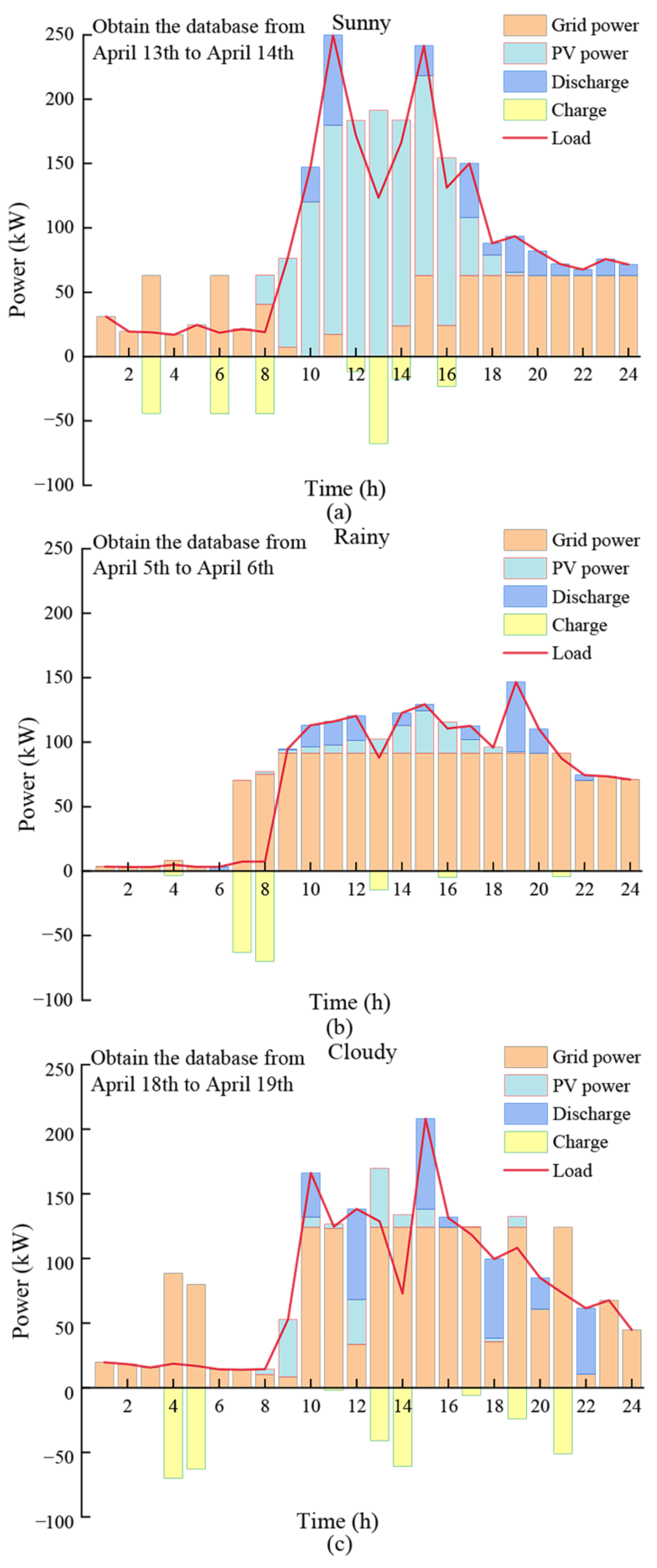

- Based on the plant user load and PV predicted power, the objective function and constraints are determined, and the optimization objective of the PV-BESS is to minimize the total electricity cost. The PV-BESS is subject to several constraints, such as ensuring power balance, adhering to the ESS’s capacity limit, and meeting the maximum demand requirement, among other considerations.

- Based on the objective function and constraints, an optimization model is developed.

- Determine whether it is the new scheduling moment, if it is, execute the next step, otherwise execute the original scheduling policy.

- Utilizing the specified objective function and constraints, the CPLEX solver is employed to solve the model and optimize the charging and discharging power of the ESS. This process yields scheduling results for various weather conditions.

- After analyzing the results obtained from solving the model, the PV-BESS scheduling strategy is designed to meet the actual demand in order to reduce load fluctuations, lower electricity costs, and improve the cost-effectiveness for plant users.

5. Application Case Study

5.1. User Profile

5.2. Analysis of Application Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Torres-Moreno, J.L.; Gimenez-Fernandez, A.; Perez-Garcia, M.; Rodriguez, F. Energy Management Strategy for Micro-Grids with PV-Battery Systems and Electric Vehicles. Energies 2018, 11, 522. [Google Scholar] [CrossRef]

- Nazari, A.A.; Keypour, R. A two-stage stochastic model for energy storage planning in a microgrid incorporating bilateral contracts and demand response program. J. Energy Storage 2019, 21, 281–294. [Google Scholar] [CrossRef]

- Sharma, P.; Mathur, H.D.; Mishra, P.; Bansal, R.C. A critical and comparative review of energy management strategies for microgrids. Appl. Energy 2022, 327, 120028. [Google Scholar] [CrossRef]

- Roberts, M.B.; Bruce, A.; MacGill, I. Impact of shared battery energy storage systems on photovoltaic self-consumption and electricity bills in apartment buildings. Appl. Energy 2019, 245, 78–95. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, Y.; Chang, D.; Xie, J.; Ma, Z.; Sun, Q.; Yin, H.; Wennersten, R. Prediction of short-term PV power output and uncertainty analysis. Appl. Energy 2018, 228, 700–711. [Google Scholar] [CrossRef]

- Rana, M.M.; Uddin, M.; Sarkar, M.R.; Shafiullah, G.M.; Mo, H.; Atef, M. A review on hybrid photovoltaic–Battery energy storage system: Current status, challenges, and future directions. J. Energy Storage 2022, 51, 104597. [Google Scholar] [CrossRef]

- Hongxia, L.; Jianlin, L.; Yang, M. Summary of research on new energy side energy storage optimization configuration technology. Energy Storage Sci. Technol. 2022, 11, 3257. [Google Scholar]

- Xu, G.; Cheng, H.; Ma, Z.; Fan, S.; Fang, S.; Ma, Z. Overview of ESS planning methods for alleviating peak-shaving pressure of grid. Electr. Power Autom. Equip. 2017, 37, 3–11. [Google Scholar]

- Mitali, J.; Dhinakaran, S.; Mohamad, A. Energy storage systems: A review. Energy Storage Sav. 2022, 1, 166–216. [Google Scholar] [CrossRef]

- Ralon, P.; Taylor, M.; Ilas, A.; Diaz-Bone, H.; Kairies, K. Electricity Storage and Renewables: Costs and Markets to 2030; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2017; Volume 164. [Google Scholar]

- Li, X.; Ma, H.; Jiang, Q. Review of energy storage configuration technology on renewable energy side. Electr. Power 2022, 55, 13–25. [Google Scholar]

- Zheng, Q.; Jiang, L.; Xu, Y.; Gao, S.; Liu, T.; Qu, C.; Chen, H.; Li, X. Research progress and development suggestions of energy storage technology under background of carbon peak and carbon neutrality. Bull. Chin. Acad. Sci. 2022, 37, 529–540. [Google Scholar]

- Kou, L.; Zhang, Y.; Ji, Y.; Wu, M.; Xiong, X.; Hu, C. Typical application scenario and operation mode analysis of distributed energy storage. Power Syst. Prot. Control 2020, 48, 177–187. [Google Scholar]

- Mignoni, N.; Scarabaggio, P.; Carli, R.; Dotoli, M. Control frameworks for transactive energy storage services in energy communities. Control Eng. Pract. 2023, 130, 105364. [Google Scholar] [CrossRef]

- Jeong, H.C.; Jung, J.; Kang, B.O. Development of Operational Strategies of Energy Storage System Using Classification of Customer Load Profiles under Time-of-Use Tariffs in South Korea. Energies 2020, 13, 1723. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.; Zhang, Z.; Li, H.; Wang, X.; Zhang, Q.; Zhou, T.; Zhang, P.; Chang, F. Optimal Scheduling of the Wind-Photovoltaic-Energy Storage Multi-Energy Complementary System Considering Battery Service Life. Energies 2023, 16, 5002. [Google Scholar] [CrossRef]

- Wang, H.; Wu, X.; Sun, K.; Du, X.; He, Y.; Li, K. Economic Dispatch Optimization of a Microgrid with Wind–Photovoltaic-Load-Storage in Multiple Scenarios. Energies 2023, 16, 3955. [Google Scholar]

- Nazir, M.S.; Abdalla, A.N.; Wang, Y.; Chu, Z.; Jie, J.; Tian, P.; Jiang, M.; Khan, I.; Sanjeevikumar, P.; Tang, Y. Optimization configuration of energy storage capacity based on the microgrid reliable output power. J. Energy Storage 2020, 32, 101866. [Google Scholar] [CrossRef]

- Wu, Y.-K.; Huang, C.-L.; Phan, Q.-T.; Li, Y.-Y. Completed review of various solar power forecasting techniques considering different viewpoints. Energies 2022, 15, 3320. [Google Scholar] [CrossRef]

- Ahmed, R.; Sreeram, V.; Mishra, Y.; Arif, M.D.; Kazmerski, L. A review and evaluation of the state-of-the-art in PV solar power forecasting: Techniques and optimization. Renew. Sustain. Energy Rev. 2020, 124, 109792. [Google Scholar] [CrossRef]

- Li, L.-L.; Wen, S.-Y.; Tseng, M.-L.; Wang, C.-S. Renewable energy prediction: A novel short-term prediction model of photovoltaic output power. J. Clean. Prod. 2019, 228, 359–375. [Google Scholar] [CrossRef]

- Das, U.K.; Tey, K.S.; Seyedmahmoudian, M.; Mekhilef, S.; Idris, M.Y.I.; Van Deventer, W.; Horan, B.; Stojcevski, A. Forecasting of photovoltaic power generation and model optimization: A review. Renew. Sustain. Energy Rev. 2018, 81, 912–928. [Google Scholar] [CrossRef]

- Niu, D.; Wang, Y.; Wu, D.D. Power load forecasting using support vector machine and ant colony optimization. Expert Syst. Appl. 2010, 37, 2531–2539. [Google Scholar] [CrossRef]

- Liu, L.; Liu, D.; Sun, Q.; Li, H.; Wennersten, R. Forecasting power output of photovoltaic system using a BP network method. Energy Procedia 2017, 142, 780–786. [Google Scholar] [CrossRef]

- Yang, D.-W.; Li, H.-R.; Xiang, W.-D.; Ren, Z.; Li, Z.-W. Power transformer fault diagnosis based on improved PSO-BP hybrid algorithm. J. Electr. Power Sci. Technol. 2011, 26, 99–103. [Google Scholar]

- Wang, D.; Yue, C.; ElAmraoui, A. Multi-step-ahead electricity load forecasting using a novel hybrid architecture with decomposition-based error correction strategy. Chaos Solitons Fractals 2021, 152, 111453. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Sharshir, S.W.; Abd Elaziz, M.; Kabeel, A.E.; Guilan, W.; Haiou, Z. Modeling of solar energy systems using artificial neural network: A comprehensive review. Sol. Energy 2019, 180, 622–639. [Google Scholar] [CrossRef]

- Jobayer, M.; Shaikat, M.A.H.; Rashid, M.N.; Hasan, M.R. A systematic review on predicting PV system parameters using machine learning. Heliyon 2023, 9, e16815. [Google Scholar] [CrossRef]

- Teferra, D.M.; Ngoo, L.M.; Nyakoe, G.N. Fuzzy-based prediction of solar PV and wind power generation for microgrid modeling using particle swarm optimization. Heliyon 2023, 9, e12802. [Google Scholar] [CrossRef]

- Li, L.; Xu, Q.; Wang, X.; Ling, J.; Sun, H. Optimal Economic Scheduling of Industrial Customers on the Basis of Sharing Energy-Storage Station. Electr. Power Constr. 2020, 41, 100–107. [Google Scholar]

- Venkatesan, K.; Govindarajan, U. Optimal power flow control of hybrid renewable energy system with energy storage: A WOANN strategy. J. Renew. Sustain. Energy 2019, 11, 015501. [Google Scholar] [CrossRef]

| Optimization of PV-ESS integrated system |

| Basic data for PV power prediction: |

| Temperature, Humidity, Irradiance, Actual PV power. |

| Obtaining the predicted PV power () by using PSO-BP neural network algorithm |

| Capacity configuration and optimized scheduling data input:{, , } |

| Solving the optimization problem by CPLEX solver |

| Output: the capacity configuration of the ESS and charging/discharging power |

| The extra inputs: {the capacity, the charging/discharging power, } |

| Solving the optimization problem by CPLEX solver |

| Outputs: the optimized results |

| Measure | Formula | Judgment |

|---|---|---|

| The higher its value is, the better it is. Range: [0, 1] | ||

| RMSE | The larger the error, the larger the value | |

| MAPE |

| Weather Conditions | Capacity/kWh | Maximum Charge/ Discharge Power/kW |

|---|---|---|

| Sunny | 108.81 | 67.77 |

| Rainy | 204.78 | 68.09 |

| Cloudy | 248.03 | 82.47 |

| Weather Conditions | Peak Load/kW | Grid Power/kW | Energy Charge/CNY | Demand Charge/CNY | Total Charge/CNY |

|---|---|---|---|---|---|

| Sunny | 249.80 | 139.42 | 536.63 | 6637.88 | 7174.51 |

| Rainy | 208.06 | 194.09 | 1027.70 | 6637.88 | 7665.58 |

| Cloudy | 146.70 | 171.24 | 1042.15 | 6637.88 | 7680.03 |

| Weather Conditions | Peak Load/kW | Grid Power/kW | Energy Charge/CNY | Demand Charge/CNY | Total Charge/CNY |

|---|---|---|---|---|---|

| Sunny | 249.80 | 63.01 | 573.75 | 4243.88 | 4817.63 |

| Rainy | 208.06 | 124.09 | 1095.23 | 4243.88 | 5339.11 |

| Cloudy | 146.70 | 91.41 | 1081.13 | 4243.88 | 5325.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Z.; Li, T.; Su, J.; Sun, L. Tariff-Based Optimal Scheduling Strategy of Photovoltaic-Storage for Industrial and Commercial Customers. Energies 2023, 16, 7079. https://doi.org/10.3390/en16207079

Zeng Z, Li T, Su J, Sun L. Tariff-Based Optimal Scheduling Strategy of Photovoltaic-Storage for Industrial and Commercial Customers. Energies. 2023; 16(20):7079. https://doi.org/10.3390/en16207079

Chicago/Turabian StyleZeng, Zhiyuan, Tianyou Li, Jun Su, and Longyi Sun. 2023. "Tariff-Based Optimal Scheduling Strategy of Photovoltaic-Storage for Industrial and Commercial Customers" Energies 16, no. 20: 7079. https://doi.org/10.3390/en16207079

APA StyleZeng, Z., Li, T., Su, J., & Sun, L. (2023). Tariff-Based Optimal Scheduling Strategy of Photovoltaic-Storage for Industrial and Commercial Customers. Energies, 16(20), 7079. https://doi.org/10.3390/en16207079