1. Introduction

Centralized and decentralized gas equipment maintenance systems should be adopted at compressor stations [

1]. A centralized system covers a particular territorial area [

2]. The maintenance of the compressor station is carried out by on-site crews who repair directly at the station [

3]. With decentralized maintenance, repair personnel are attached to each station, where there is a necessary stock of spare parts, tools, and devices [

4].

The periodicity of significant repair of compressor equipment is approximately determined by accounting for only the service life of the main parts [

5]. Optimal planning of the periodicity of repairs is necessary for analytically solving the problem of increasing the operational reliability of the gas transportation system. From a practical point of view, the optimization of the service life of the equipment realizes the problem of the scientifically based choice of the intensity of deliveries of new units and aggregates [

6]. In this case, inter-repair periods and maintenance bases, the number of teams, and the periodicity of capital repair should be considered.

Therefore, it can be argued that nuclear-based optimization of the equipment maintenance process allows for reducing gas transportation costs with the high reliability of gas supply.

Compressor units and turbines at main gas stations are energy systems that operate with low energy efficiency [

7]. Their exploitation is decreasing over time. Therefore, for effective use of energy resources, measures should be taken to increase it [

8]. For this purpose, each machine undergoes various types of repairs during the service life. Maintenance of the main gas equipment in operating condition and restoration of its operational characteristics are achieved at the expense of scheduled-preventive maintenance (SPM) [

9]. The SPM and technical maintenance include restoration of gas equipment operability by rational technical maintenance, replacement, and repair of worn parts/assemblies produced according to a pre-arranged schedule [

10].

Additionally, Nordal and El-Thalji [

11] developed a predictive maintenance management architecture to meet industry 4.0 requirements, including oil and gas sector case studies. As a result, a maintenance program is created considering different data (e.g., data records, real-time performance measurements, and expert-just-in-time). They also analyzed the lifetime benefits of intelligent maintenance [

12]. As a result, a comprehensive approach for simulation modeling was developed for industrial case studies.

The essence of the SPM system is to prevent emergencies on operating equipment by preventing them [

13]. After the unit has worked for a certain period, preventive inspections are carried out to assess the machine’s technical condition, residual resources, and various scheduled repairs. In this case, the alternation and periodicity of the SPMs are determined by the unit’s operating conditions and design and repair features. Overall, the SPM system increases the reliability of the gas equipment operation and prevents progressive wear and premature failure of equipment [

14]. It also allows for planning and pre-preparing overhaul works and performing them qualitatively [

15].

To determine the scope of maintenance work, the following classes of technical conditions corresponding to a specific type of maintenance are selected [

16,

17]:

- (1)

features the deviation from which does not cause serious consequences. It is enough to monitor the specified features periodically and without disturbing the readiness of the equipment;

- (2)

features, the deviation of which is accompanied by severe consequences. Such features require permanent monitoring;

- (3)

features, the verification of which is possible only with a violation of the equipment’s reliability;

- (4)

features that require preventive work.

However, there is still no methodology for evaluating the quality of performance of the SPM [

18]. It undoubtedly should impact the duration of repairs and operating costs associated with the maintenance process [

19].

The repair cycle depends on the operating conditions and the unit’s type [

20,

21]. The inter-repair period is determined by the service life of parts that wear out rapidly [

22,

23].

The cost of repairs depends on many factors (e.g., type of failure, qualifications, and the number of specialists participating in the overhaul). Since the repair cost can randomly vary, the cost optimization problem becomes more actual [

24,

25]. In this case, the overhaul complexity is estimated by the average value of the total costs for all system repairs for a particular operation period. The time on performing all types of repairs is also considered to quantify the labor intensity.

Delaying repairs can lead to emergencies concerning significant recovery costs. The premature performance of the overhaul does not allow for fully implementing the machine resource, which is also associated with additional costs. Therefore, deciding to carry out repair work leads to an optimization problem. However, the principles of its implementation have not been entirely studied. In this regard, when constructing the objective function (sum of service costs), losses associated with undersupply of gas to consumers should be considered.

The overhaul planning and maintenance should be based on the accounting and evaluation of equipment control data [

26,

27]. The corresponding control eliminates cost minimization problems. To overcome this challenge, patterns of changes in the technical condition of machines during operation should be established, the objective function should be built, and the realization technique should be proposed. Finally, during the operation of gas equipment, a practical method for determining the number of repairs should be developed to predict the expected number of technical services.

Based on the analysis of the above sources on the stated problem, it should be concluded that it is not enough to use the factory warranty characteristics of the equipment for predicting the optimal service process. Considering the actual technical condition parameters will lead to the rational use of the service life for particular units and the frequency of repair and replacement. Such an approach will make it possible to reduce operational costs for maintenance and simultaneously increase the operational reliability of the gas supply system.

2. Research Methodology

The study aims to establish scientifically based trends in the maintenance of gas supply systems. They should also be based on regularities of the equipment aging process to reduce the number of emergencies. As a result, the cost of gas transportation should be reduced.

To achieve these goals, the following objectives are set. Firstly, features of changes in the parameters of the distribution density of pre-repair, inter-repair, and total operating time in the entire assessment period should be determined.

Secondly, an objective function should be proposed considering the specific number of unit repairs, the number of elements in the system, the distribution of the duration of work until the first repair, and the maintenance cost. Total repair costs are a component of operating costs.

Finally, a management technique should be developed to evaluate optimal values of technological parameters in the overhaul planning process.

The procedure for optimizing the periodicity of repairs and equipment replacement is based on the construction of the objective function as the dependence of operating costs on the inter-repair period of major repairs.

The optimization problem with a single factor is solved by the method of competing options. This method allows for solving the problem for each possible choice, followed by comparing the results according to the selected optimality criterion. However, within the methodology presented below, calculations can be realized using, e.g., mixed integer nonlinear programming [

28].

The following parameters should be evaluated to increase the operational reliability: the optimal number of repairs to be performed from T1-th till T2-th years; the expected number of units when replenishing it by new parts with the predetermined intensity.

The optimal periodicity of equipment maintenance is considered as a process that corresponds to the minimum costs for its operation and is implemented through control of the technical condition with given reliability. The number of planned repairs of each unit is determined based on data on its actual operating time, starting with maintenance, repair, or exploitation.

The practice of operating gas turbine units shows the expediency of maintenance work according to technical conditions. When evaluating it, it is necessary to know the technical condition of each compressor station unit in the previous period of operation, starting from the initial moment

T0.

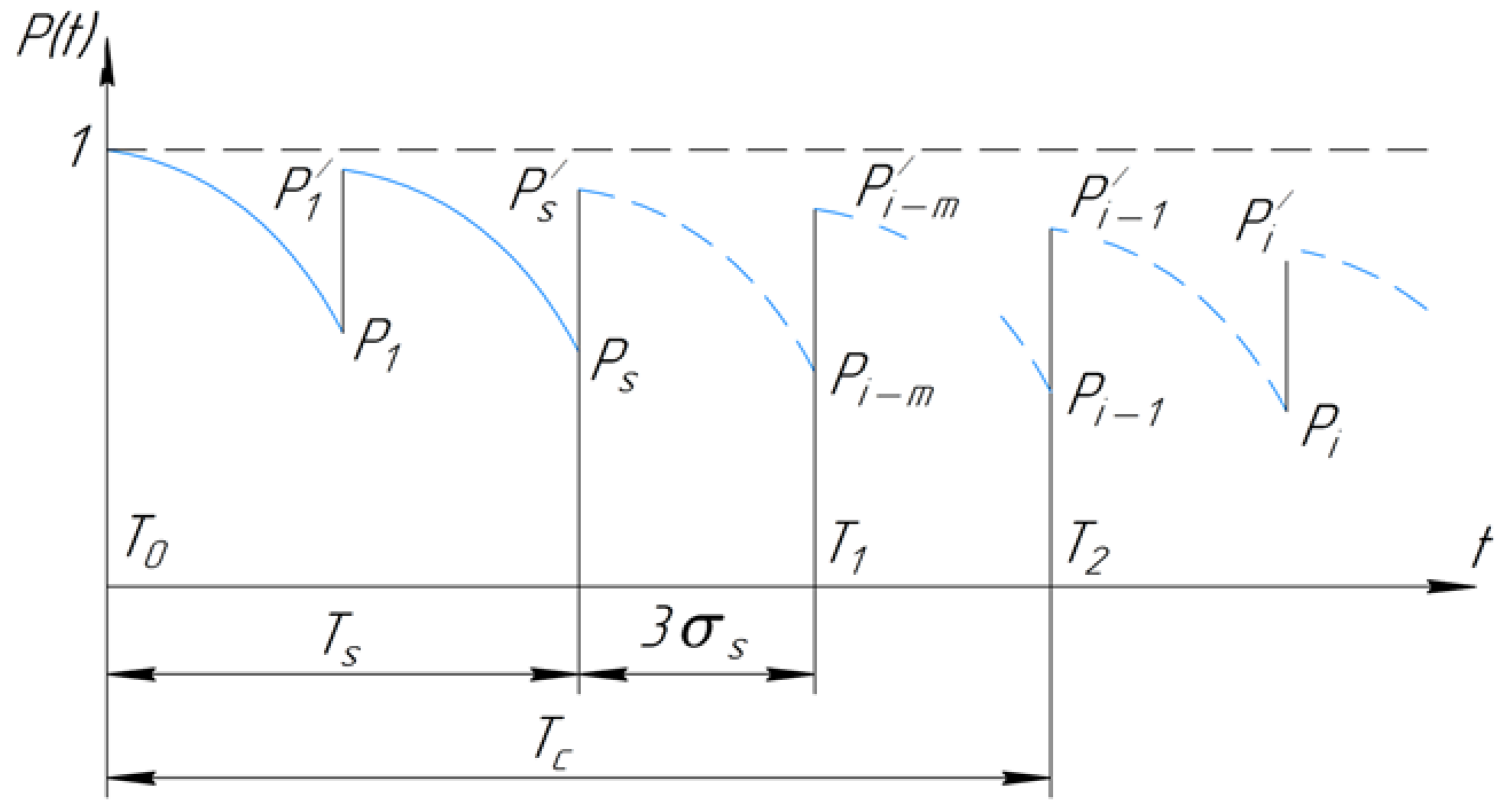

Figure 1 presents a model of changes in the technical condition of machines depending on the operating time.

The following corresponding densities of distribution describe the characteristics of the state of the equipment: pre-repair f(t), inter-repair g(t), and full-service life fs(t). They can change depending on the time of initialization of products in the system. In the process of restoring elements of each type, distributions f(t) and g(t) differ from each other.

The duration of the previous planned period should be less than the difference between T1 and T0.

For more accurate calculation results, especially in the first year of the planning period T1, it is necessary to have information about the supply of products and the distribution of their service life in the previous interval δ and also for each moment of the period Δ = T2 − T1. All the products with an early arrival date will be canceled at the time of T1 (they will not affect the number of repairs).

It is often necessary to determine the scope of repair works only at the moment T2—the end of the last year of the analyzed planning period Tc. Simultaneously, it is necessary to have the following output data: annual supply of elements given as a function of time ν(t) (0 ≤ t ≤ Tc) or tabulated in terms of deliveries by years; distribution type of service life and annual working hours at their average values; changes in the distribution densities f(t) and g(t) in the entire calculation period Tc, which depend on the time of arrival of the unit.

Since the increasing quality of the produced elements, these parameters change only at a particular time. Therefore, the period Tc can be divided into m intervals. In each interval, the parameters of all distributions can be assumed to be constant.

An expected number of unit repairs per unit time at the moment

t for the overall recovery process, when

f(

t) ≠

g(

t):

where

τ–time parameter.

The expected number of elements in the system at time

t is determined as an availability function. It can be determined as follows:

where

n0 is the initial number of elements in the system;

Qs = 1 −

Fs(

t) is the element’s lifetime function.

Additionally, the following life distribution function before canceling

Fs(

t) can be introduced as the expected number of rejected products per time

t:

The necessary number of repairs to maintain the units’ performance is determined by the optimal values of the characteristics (full, pre-repair, and inter-repair service life) and variation coefficients of these characteristics, which significantly impact the calculation results.

The average number of elements (including those that make up the compressor station) in time t is determined by the availability function N(t). At the beginning of the operational period t, the number of elements is equal to A0.

At the end of the service life, each element is canceled. The corresponding intensity for each element depends on the value of N(t) and its lifetime distribution function Fs(t).

The ratio between service life

Ts, availability function

N(

t), equipment’s canceling intensity

νs(

t), and replenishment intensity

ν(

t) is as follows:

To maintain the operation level of gas transportation systems, the number of units at the moment T1 should reach A1 (A1 > A0). Then, N(T1) = A1.

During the operation of gas equipment, there are two options for maintenance. Firstly, the required number of units in the gas transportation system can be achieved by intensively replenishing it with units, provided that a shorter service life of the elements is established. This way allows for decreasing the number of repairs and operating costs. However, shortening the service life will cause the cost of purchasing new elements.

Secondly, the lifetime can be increased by limiting the supply of elements. This option allows for reducing the cost of buying new elements. However, it increases operational costs and capital investments in the service system due to the technical characteristics of the elements.

A decrease in the maintenance period increases repair costs. It also increases the reliability of equipment operation. These reduce the probability of emergency failures and related expenses for emergency recovery, gas losses, and undersupply to consumers. Therefore, an optimal maintenance frequency exists at which the total operating costs will be minimal.

In the general case, optimizing the periodicity of repairs requires reducing the costs of purchasing new elements and repairing and operating the installed equipment to a minimum. For this purpose, with a given probability that the number of elements in the repair base reaches the planned value N(t), it is necessary to minimize current operating costs and total repair costs.

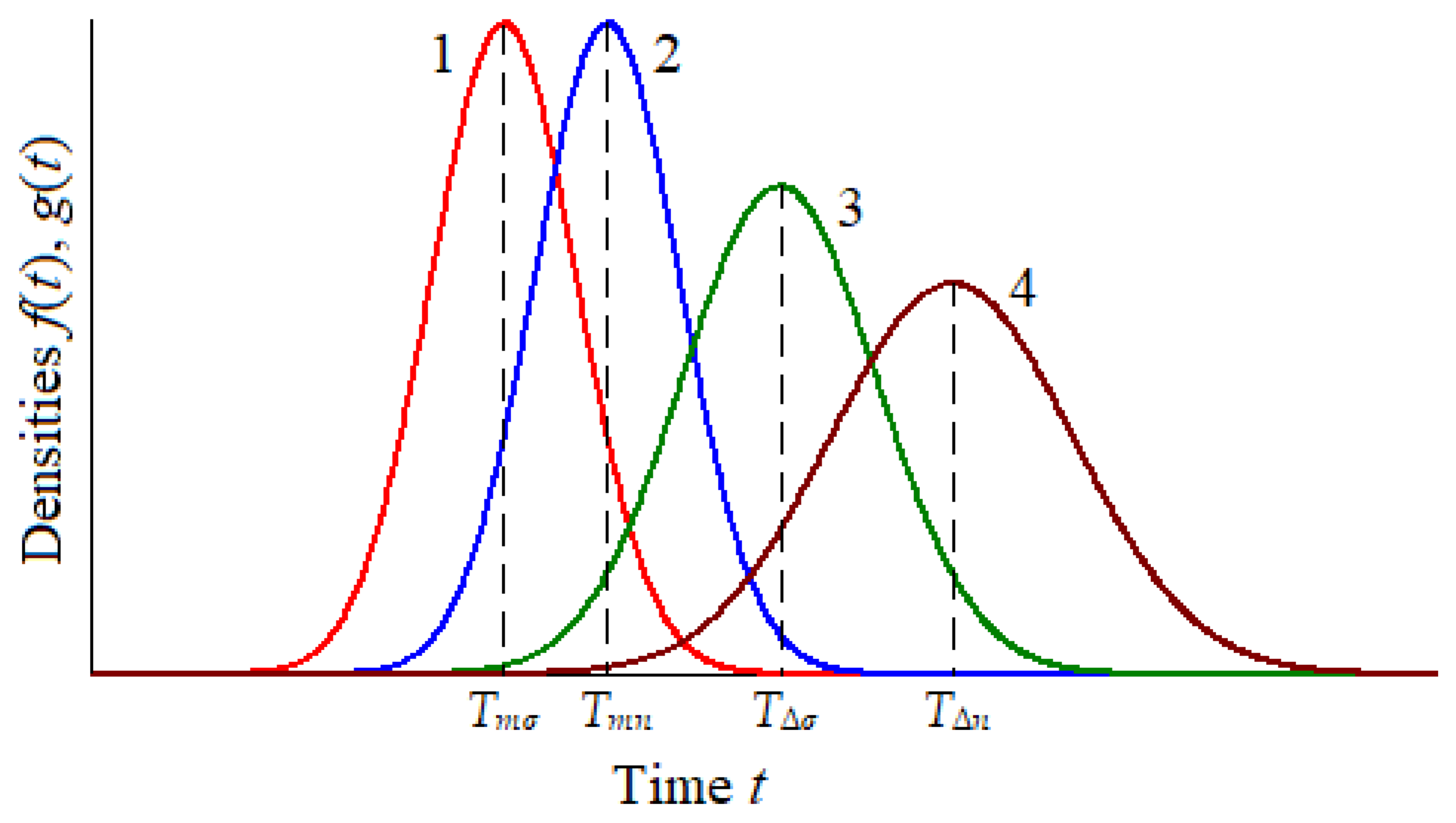

The following parameters are also introduced: fσ(t) is the distribution density for a new element’s reliable operation; gσ(t) is the distribution density of fault-free operation for an element after at least one repair; TΔσ, Tmσ are the mean values of these quantities.

Functions fσ(t) and gσ(t) characterize the reliability of machines before and after the first repair. They also determine the degree of technical reliability of machines. When planned and preventive repairs are not programmed (the normal aging process continues in the machine), the intensity of removing the machine for repair at any time depends on these functions.

After considering planned repairs, it is assumed that machines will be repaired due to failure and after a certain period of service (preventive repair). The corresponding densities are fn(t) and gn(t). The mean values for preventive repairs are TΔn and Tmn, respectively. The types of distributions fn(t) and gn(t) do not change with a change in the normative values of TΔn and Tmn.

The duration of machine operation before and between repairs

TΔσ,

TΔn, and

Tmσ,

Tmn is formed under the influence of two pairs of fail-safe distributions and the lead times of SPMs:

fσ(

t),

fn(

t), and

gσ(

t),

gn(

t), shown in

Figure 2.

For each mutual position of pairs of distributions and any moment, the probability density of putting the machine in repair as a complex event, which includes three possibilities, can be calculated: the unit has refused, and the moment of preventive inspection had not come; the time for preventive examination has come before refusal; the start of the SPM has coincided with the appearance of failure.

3. Results

The intensity of repairs

H(

t) depends on the unknown characteristics of the unit’s operation (

TΔn and

Tmn) with known distributions of reliable operation. To its evaluation, it is necessary to first know from Equations (1) and (3). The distribution functions of the reliable operation

Fσ(

t),

Gσ(

t) and the term distribution functions of the SPM

Fn(

t),

Gn(

t). The values of the variation coefficients for these parameters are:

with mean values of

TΔn,

Tmn.

The order of formation f(t) and g(t) is as follows. Firstly, a row of discrete values of the mathematical expectation of the unit’s operation before the first SPM should be set: TΔn1, TΔn2, …, TΔni, …, TΔnk. Each value TΔnk corresponds to a single average service life of the unit between SPMs–TΔni. In this case, operational reliability in the pre-repair period depends on the reliability during preventive periods.

In case the fail-safe distributions fσ(t) and gσ(t) change according to the normal distribution law with equal coefficients of variation, the ratio between TΔn and Tmn characterizes the repair degree.

Considering the equality

VΔn =

Vmn, the following expression can be obtained from Equation (5):

where

q − quality factor of

i-th repair varied in a range from 0 to 1. Particularly, if the scheduled time between inspections

Tmni = 7200 h, and the time of the reliable operation

VΔni = 12,000 h, then the quality factor

q = 7200/12,000 = 0.6.

If the distribution laws fσ(t), gσ(t), and variation coefficient V are known, a pair of distribution functions can be evaluated using Equations (1)–(4): Fni(t) and Gni(t) for each i-th repair (i = 1, 2, …, k).

Therefore, functions

Fσ(

t),

Gσ(

t), and

Fni(

t),

Gni(

t) allow evaluating the distribution function for the unit before the first repair

F(

t) and inter-repair period as follows:

where

F1(

t) is the probability that failure will not occur by time

t, and the machine needs the scheduled repair only;

F2(

t) is the probability that failure will occur by time

t, so SPM is not needed;

F3(

t) is the probability that, by the time

t, works on sudden failures and planned orders are required simultaneously.

The density distribution functions are as follows:

To calculate the intensity of repairs H(t), expressions (7) and (8) should be substituted to expression (3) for each i-th case study TΔni, Tmni or TΔni, qi.

Intensity H(t) depends on the value of service life Ts and supply function ν(t), as shown in Formula (4). These values are the most critical factors affecting the total cost of operating units. Therefore, their values are closely related to the costs of each type of repair.

The cost function changes over time depending on the service type. In general, the maintenance cost D depends on the replacement cost of the elements Cs, pre-repair costs Cp, and current operating costs Ct.

The coefficient of repair quality can have several values: q1, q2, …, qj. Accordingly, the intensity of repairs Hij can be calculated for each value of the pre-repair term of the SPM and j-th quality factor qj.

The quality factor qj impacts the repair number and costs Cpj = Cp(qj), where j = 1, 2, …, m.

The total repair costs for units put into operation in the planned period can be evaluated as follows:

where

δ =

ln(1 +

E)–parameter, which depends on the efficiency ratio

E.

Therefore, the total repair costs for the entire planning period Δ are calculated for j-th unknown values TΔn and q. Moreover, each option is a function of the mean value Ts and supply function ν(t).

Remarkably, the proposed method for determining the number of repairs and their costs is valid when the distribution density for the operation of new products F(t) in unchangeable on the entire planning interval.

Additionally, optimizing the replacement for each product with the same distribution of failure is necessary.

The costs of current repairs and their intensity depend simultaneously on the operation time and the maintenance features. The decrease in current costs is due to the shortening of the SPM’s term and the increase in costs for major repairs. In turn, this increases the number of repairs and their quality. The intensity of current operating costs depends on the function

N(

t)

, the distribution law

ν(

t), and the characteristics of service life distribution

Ts. The corresponding intensity function is as follows:

where

c,

α1,

α2,

α3–coefficients.

The first term of this equation is related to one-time costs. The second one is related to parameters proportional to service lifetime (e.g., fuel and labor costs). The third term depends on progressive costs.

For the entire planning period, the total operating costs for the elements formed due to the supply after the moment

T0 are as follows:

The following difference expresses the costs associated with the replacement of products in case of failure:

where

Cn is the cost of products that replenish the system within the planned time interval Δ =

T2 −

T1:

Sn(

t) is the cost of a single product;

C0 is the residual cost of the product.

Since each product can have a residual cost depending on the cost of the new product

Sn(

t), the average operating lifetime

Ts within the period of (

T2 −

T1) can be obtained from the following equation:

For a thorough evaluation of replacement costs, it is necessary to determine all the functions included in the general expression: ν(t) is the intensity of element replenishment; Sn(t) is the cost of a new product/element; S0(t) is the residual cost of the element; vs(t) is the intensity of elements’ canceling.

The annual supply of products is always known to start the planning period

T0. In this case, the supply function can be considered a linear one within the planned period:

where

a,

b are coefficients of the supply function.

Additionally, the cost of a new product:

where

Sn0 is the product cost at the initial moment

T0;

γ is the intensity of aging elements.

Functions ν(t) and Sn(t) allow determining the cost of purchasing new elements depending on the values of the coefficients a and b using Equation (13).

Since

S0 depends on service life, it can be written in general form:

where

λ,

d1,

d2 are parameters of the remaining resource of the elements.

Additionally, canceling intensity:

Functions νs(t) and S0(t) also allow determining the total residual costs of entire products based on Equation (14).

To develop a service process management technique, the function of the total costs can be introduced:

For each combination of characteristics, the average time TΔn before the first SPM and quality factor q, the minimum of this function can be found by the appropriate selection of supply intensity costs from Equation (15) and the average service life Ts.

In this case, the following condition should be satisfied. At the moment T1, the availability function N should take a given value of A1. After using this condition, it is possible to express the intensity of supplies in terms of initial conditions A0, A1, and service life Ts.

Thus, optimization of repair and replacement periodicity management is reduced to determining the optimal values of the average service life Ts, the average operation time TΔn before the first SPM, and quality factor q.

For the practical implementation of the problem of optimal management of the service process, the actual results of the history of the gas transportation system operation can be taken as initial data. The corresponding calculation example for determining the number of repairs and the replacement of units of compressor stations is presented below.

The problem is to determine the number of repairs that characterize the optimal process of maintenance and delivery of new equipment in the time interval from 1 September 2001 till 31 December 2021. In this case, it is necessary that by the end of the planned period, their number was 250.

The changes in machine maintenance costs depending on their operation time are shown in

Figure 3.

The minimum value of the total maintenance cost function corresponds to the optimal service life Ts*. Costs for the purchase of new products are progressively increasing. Maintenance costs undergo significant changes during operation. They decrease as the number of new machines increases and are associated with an increase in service life. This characteristic of the curve is explained by the fact that the total maintenance costs are distributed over the number of new products, which have constantly increased since the start of the machine’s operation.

Notably, a stepped change in costs is associated with repairs. A smoother transition between repairs is due to eliminating malfunctions and maintenance.

The results of service optimization calculations are summarized in

Table 1.

The obtained results compared with the data given in

Table 1 testify to the effectiveness of the proposed optimization management technique.

4. Discussion

The reliability characteristics of the units and their impact on the repair intensity can be estimated based on the probability theory [

29]. Therefore, the decisive factors characterizing the processes of aging and the restoration of system elements are the distribution density for reliable operation of a new element and an element after at least one repair (

fn(

t),

gn(

t)), as well as mathematical expectations of these quantities.

Using these distribution densities for gas transportation equipment will allow the implementation of the progressive principle of servicing gas pumping units according to their actual conditions. In this regard, an essential parameter of the service system is the intensity of repairs H(t), which depends on the service life and the equipment supply function. Maintenance of the equipment under its actual technical condition is considered optimal under the condition of minimizing the objective function.

Regularities of the distribution density of the duration of machine operation before repair and between repairs made it possible to create the intensity function of the repairs H(t), which is fundamental for optimizing the overhaul planning process.

Optimizing the periodicity of repairs will reduce costs for the repair and operation of installed equipment and the purchase of new elements. For this purpose, minimizing current operating and repair costs is necessary. In this regard, the quality factor q is essential for the number of repairs and their cost.

Since each quality value is associated with a corresponding repair technology, the number of possible values is relatively small. The optimization of the management of the periodicity of repair and replacement is in the following sequence. Firstly, we should specify one of the values of the quality factor qj, particularly q1. Next, the possible values TΔn should be varied. Service life Ts should be found for each combination of q1 and TΔn1. In this case, the function φ should be minimized. Such a procedure is iterated for each quality factor qj.

A set of values Ts, TΔn, and q, in which the cost function takes the minimum value of all the smallest, is optimal management. The corresponding characteristics are optimal for managing the periodicity of repairs and replacements (Ts*, TΔn*, and q*).

Considering the objective function’s complexity, finding a global minimum in an analytical form is impossible. Therefore, the method of competing options provided above is proposed to implement the problem of optimal service.

Notably, the given theoretical substantiations and developed methodological recommendations for optimal overhaul planning are valid for systems whose technological state trend is characterized close to the normal distribution law. In other cases, applying the proposed principle of optimizing the service process management requires additional studies of the densities of the distribution of failure and prevention. Such studies will be realized further.

The proposed stochastic model has some advantages over deterministic ones [

3,

15], since it considers the probabilistic nature of the aging process for technological equipment. A similar approach was used in [

2] to assess changes in the technical condition of the linear part of gas pipelines. The features of the obtained dependences correlate with the results of the studies mentioned above. All this gives a reason to consider the principles for developing the proposed stochastic model as reliable. Moreover, a method for predicting optimal maintenance of technological equipment for compressor stations was improved compared to an approach previously proposed in [

20].

5. Conclusions

Based on the particular case study, it has been established that the optimization of management of the periodicity for repair and replacement of equipment is implemented by determining the optimal values of the average service life, operation of the units until the first SPM, and quality factor.

In practice, the management system’s optimization for the periodicity of repairs and replacements is proposed to be performed in the following sequence. At the initial stage, one of the values of the quality factor is set. Simultaneously, all possible values of the planned pre-repair period are checked. For each combination, a service life is established, at which the function of total costs takes the minimum value. The procedure is repeated for each value of the quality factor.

Finally, the set of values of the average service life, the average duration of operation of units until the first SPM, and the quality factor, in which the cost function takes the minimum value from all the smallest ones, is considered optimal management. In this case, the characteristics of the overhaul planning process will be optimal for managing the periodicity of equipment repair and replacement.

Thus, the optimal service process forecast in this problem statement is based on the service life characteristics and physical features of aging. These features are based on the material of the prehistory of system operation and are formalized based on probability theory. This approach allows for optimizing the equipment maintenance process according to its actual technical condition, which ensures high operational reliability of the gas supply systems.