Review of Linear Electric Motor Hammers—An Energy-Saving and Eco-Friendly Solution in Industry

Abstract

:1. Introduction

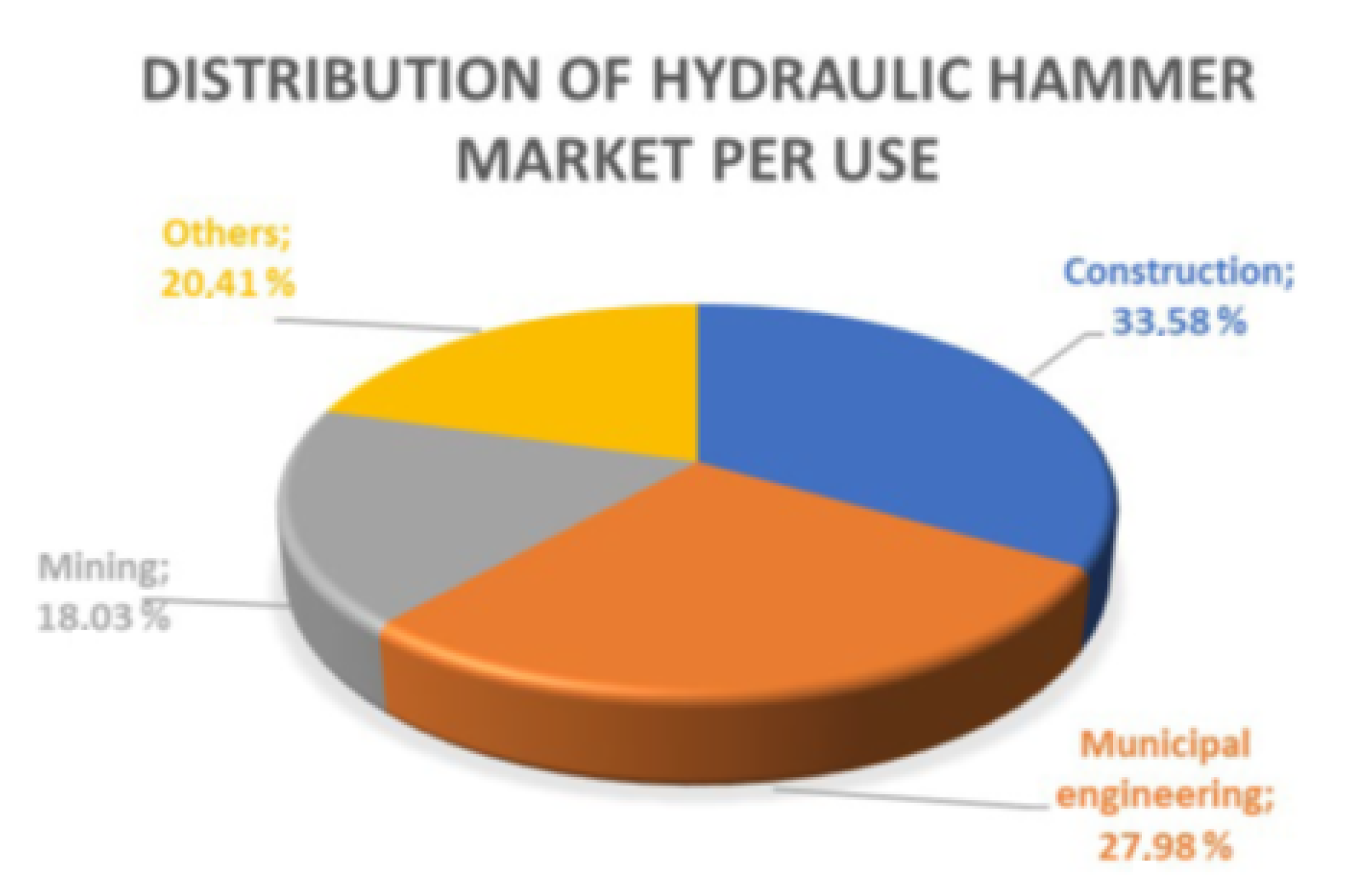

1.1. Market Analysis and Global Players

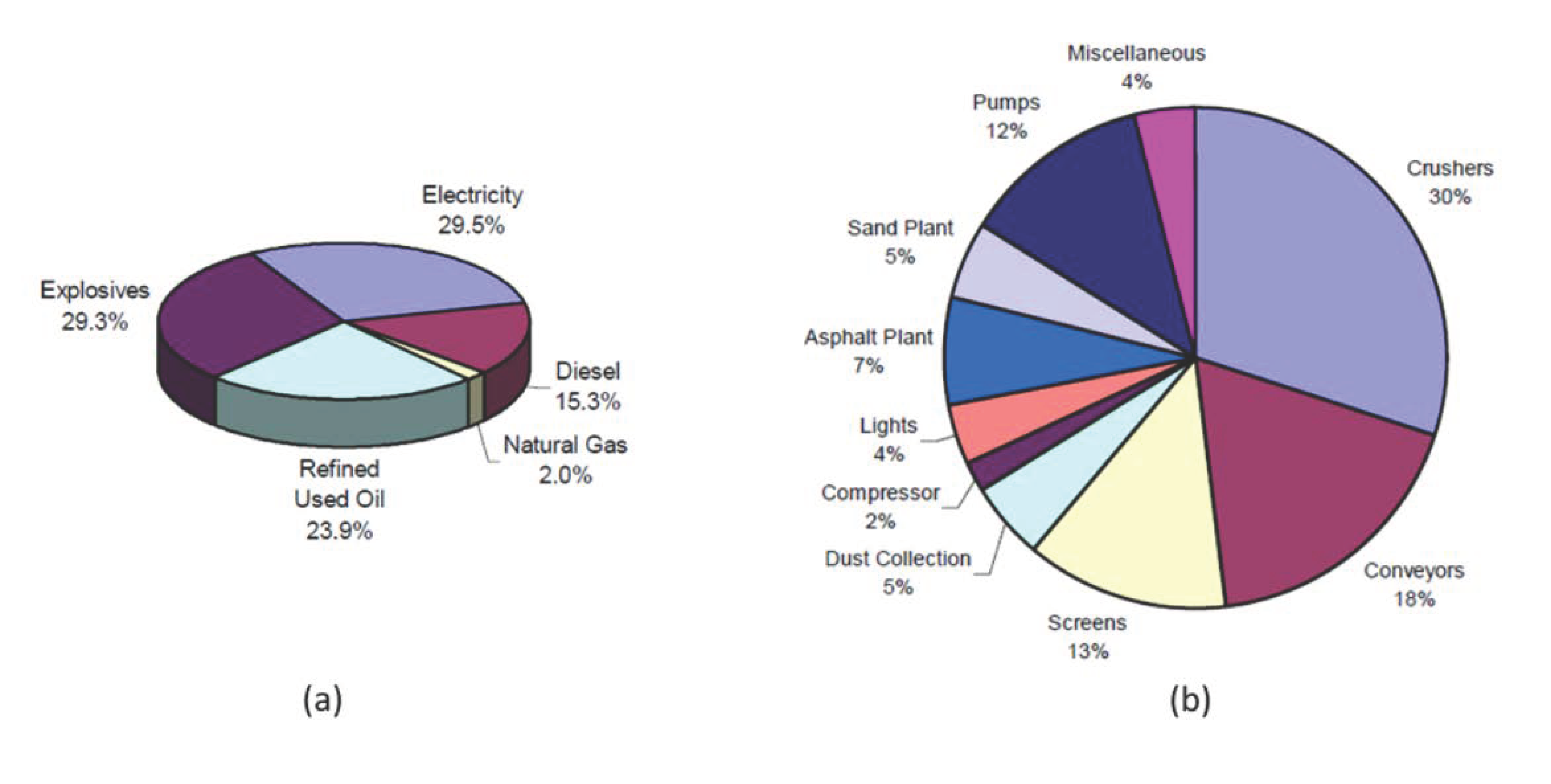

1.2. Energy Consumption

- A 32% decrease in the mean size of rock in the post-blast pile;

- A 37% increase in the amount of rock of less than 8-inch size;

- A 25% reduction in digging time to excavate the pile;

- A 6–10% savings in primary crushing costs measured by power consumption.

2. Problem Formulation

- Sealing damage and oil leakage due to wear and surface contamination;

- Cylinder body deformations due to overloading by high pressure;

- Possible piston rod deformation under load;

- Hydraulic oil consumption and utilization;

- Impossibility of changing hammering parameters online within wide ranges.

3. State of the Art

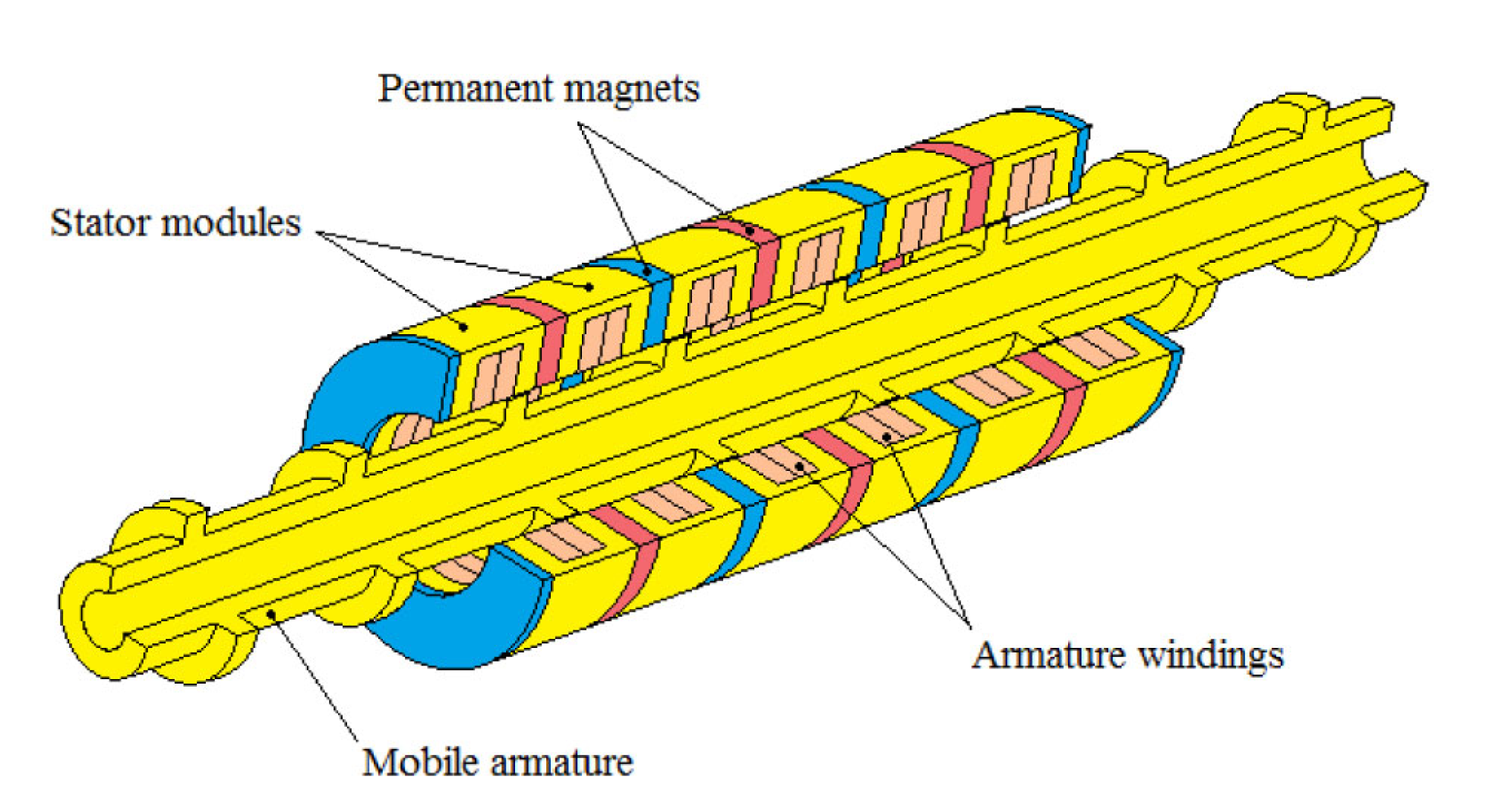

3.1. What Is a Linear Electric Motor

- DC motors;

- Induction motors;

- Synchronous motors, including reluctance and stepping motors;

- Oscillating motors;

- Hybrid motors.

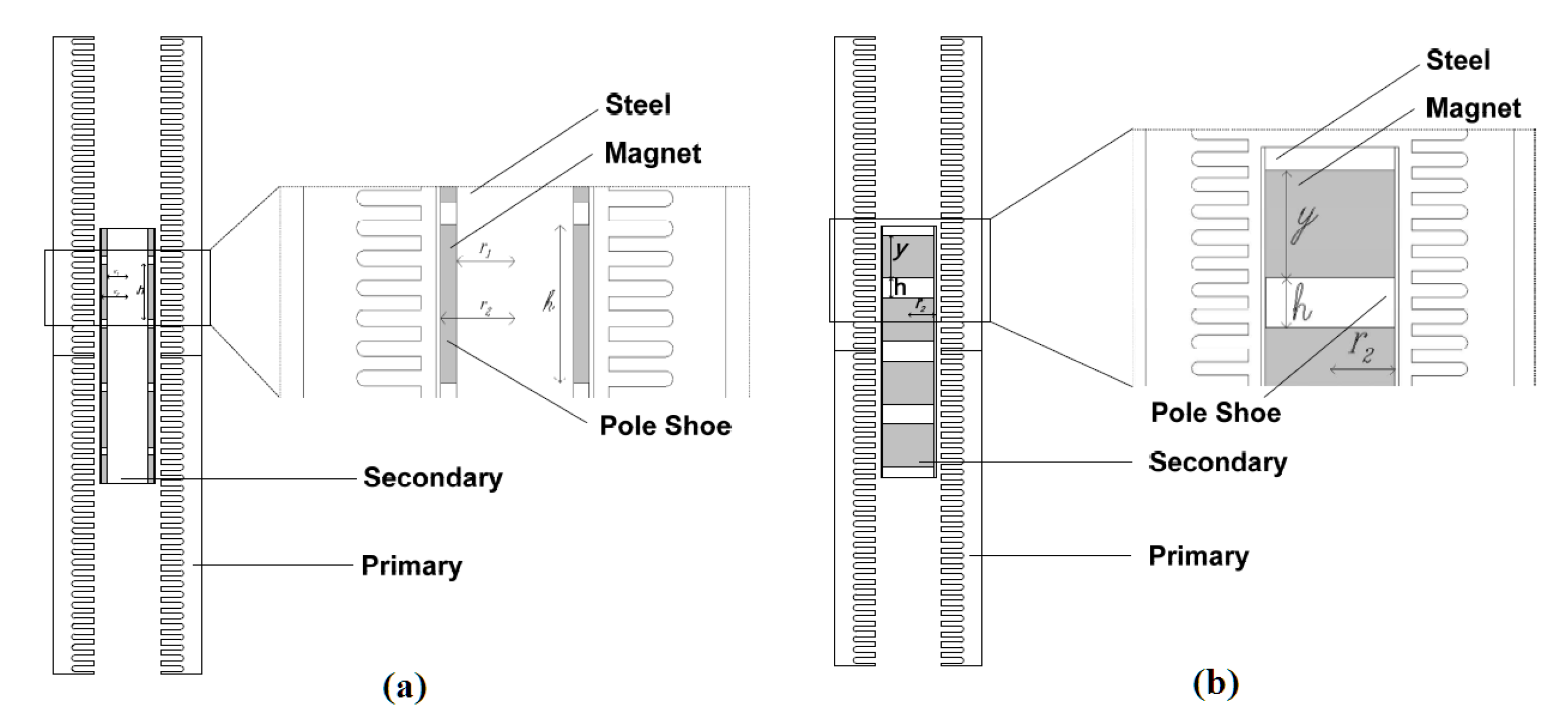

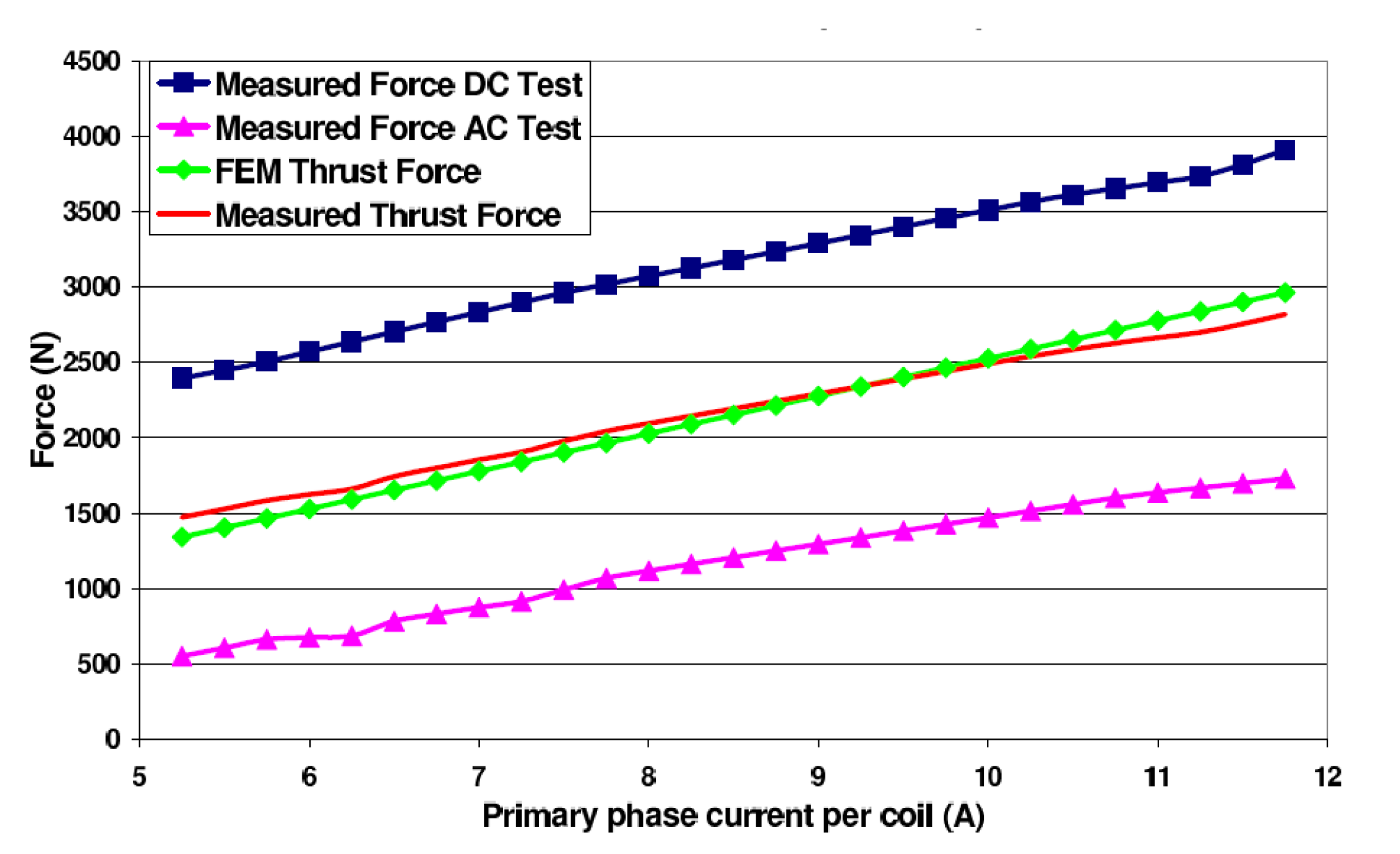

3.2. Design Optimisation

3.3. Material and Topology of Permanent Magnets

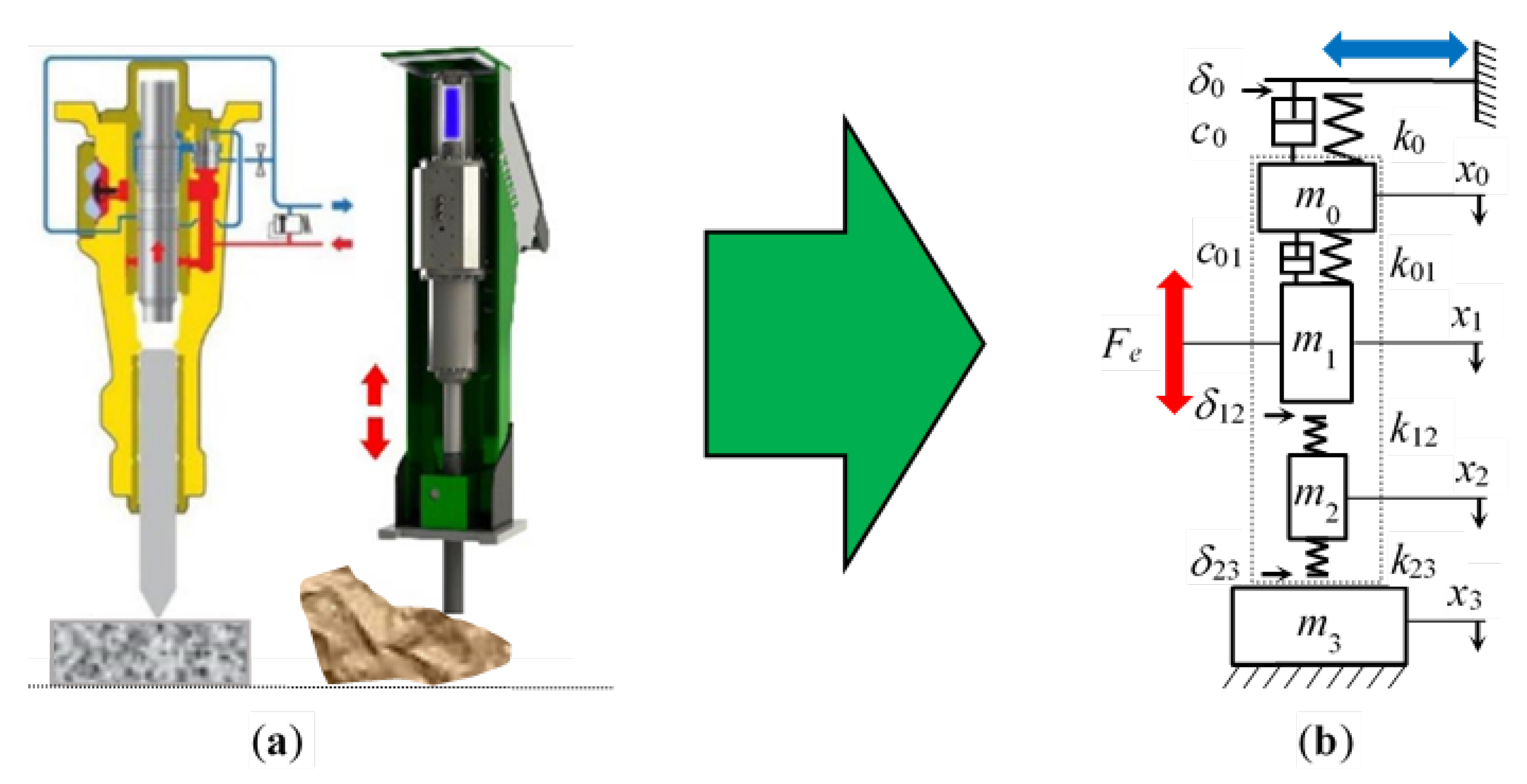

3.4. Dynamical Model of Electric Hammer

3.5. The Diagnostics and Control of Linear Electric Motors

4. Case Studies of Hammers Applications

4.1. Deep Drilling in Oil And Gas

4.2. Metallurgical Forging Press

4.3. Sieving Screens

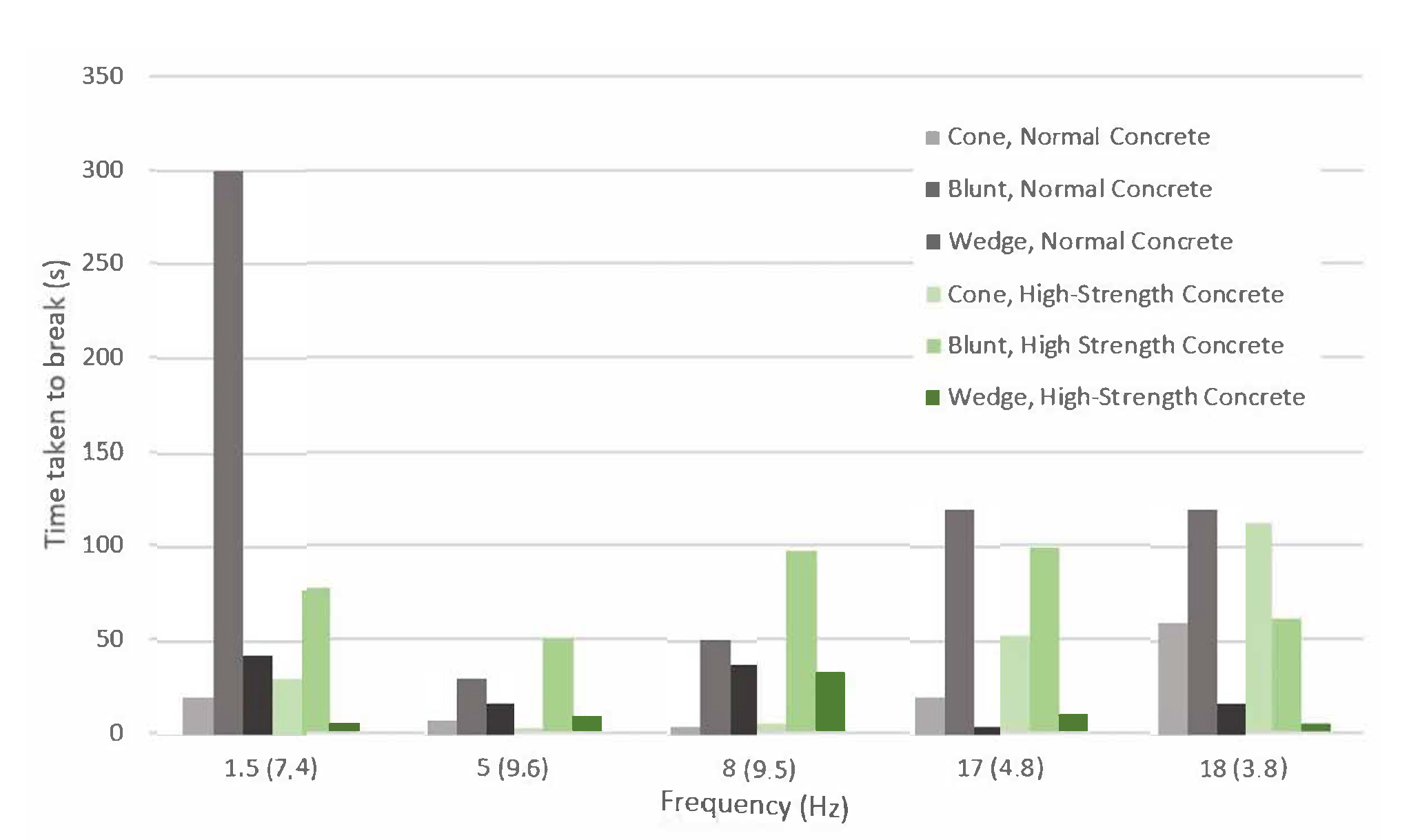

4.4. Crushing Hammers in Mining

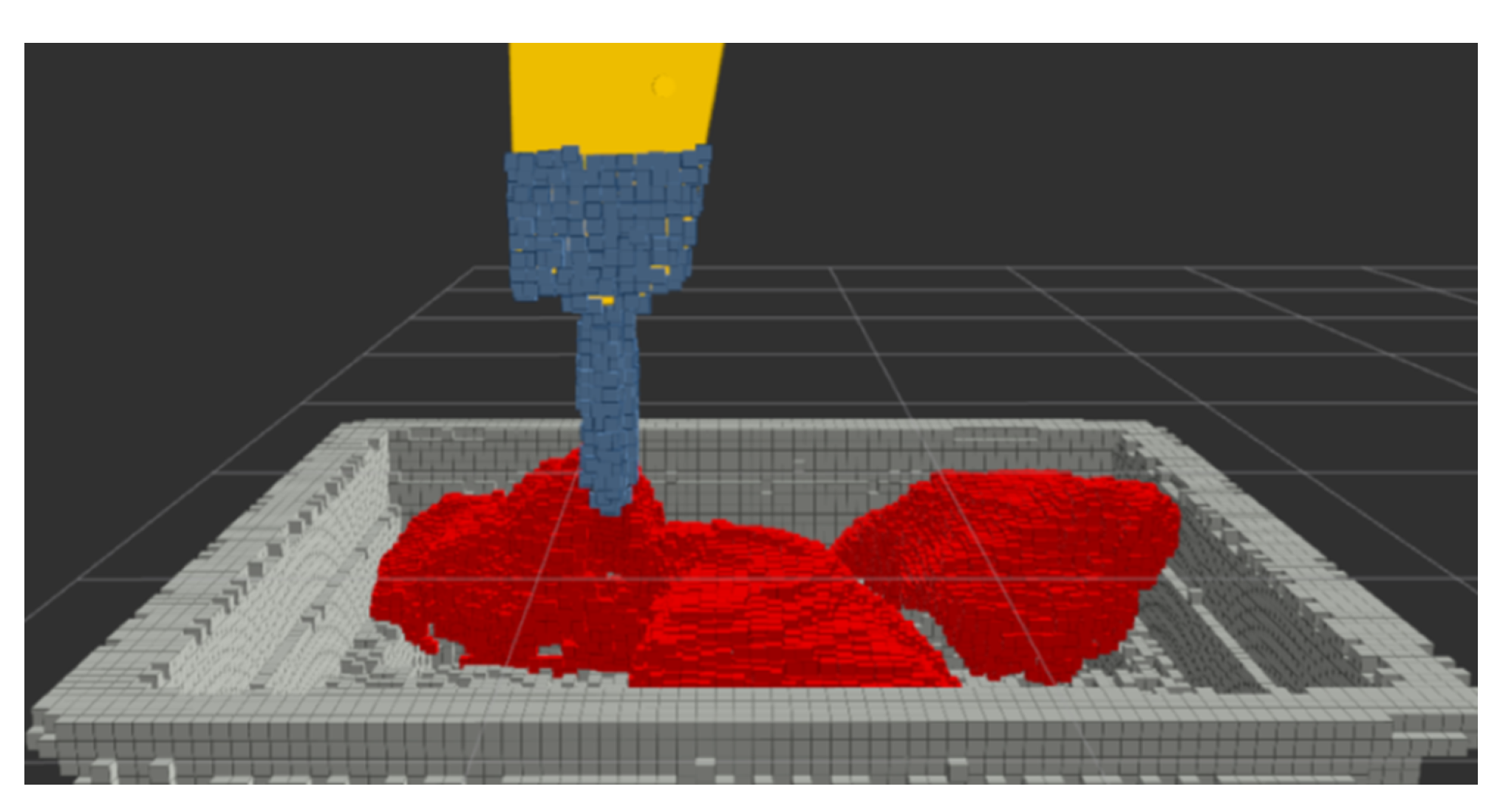

4.5. Application of Electric Hammers in Mining

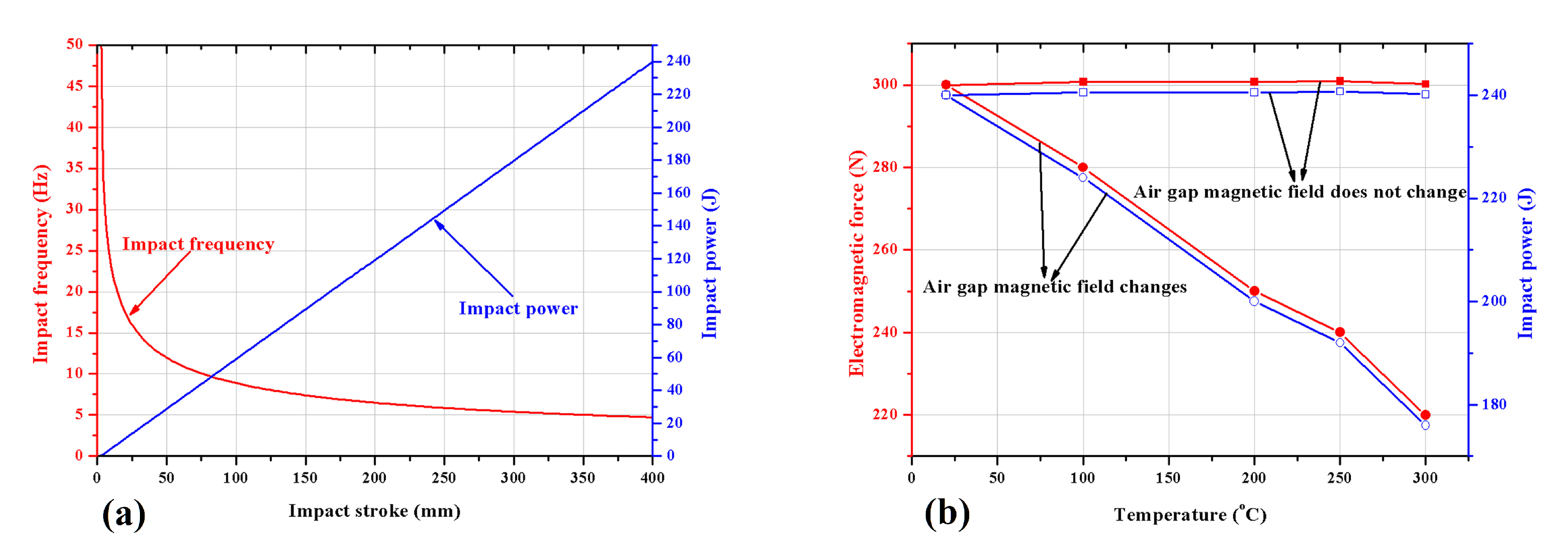

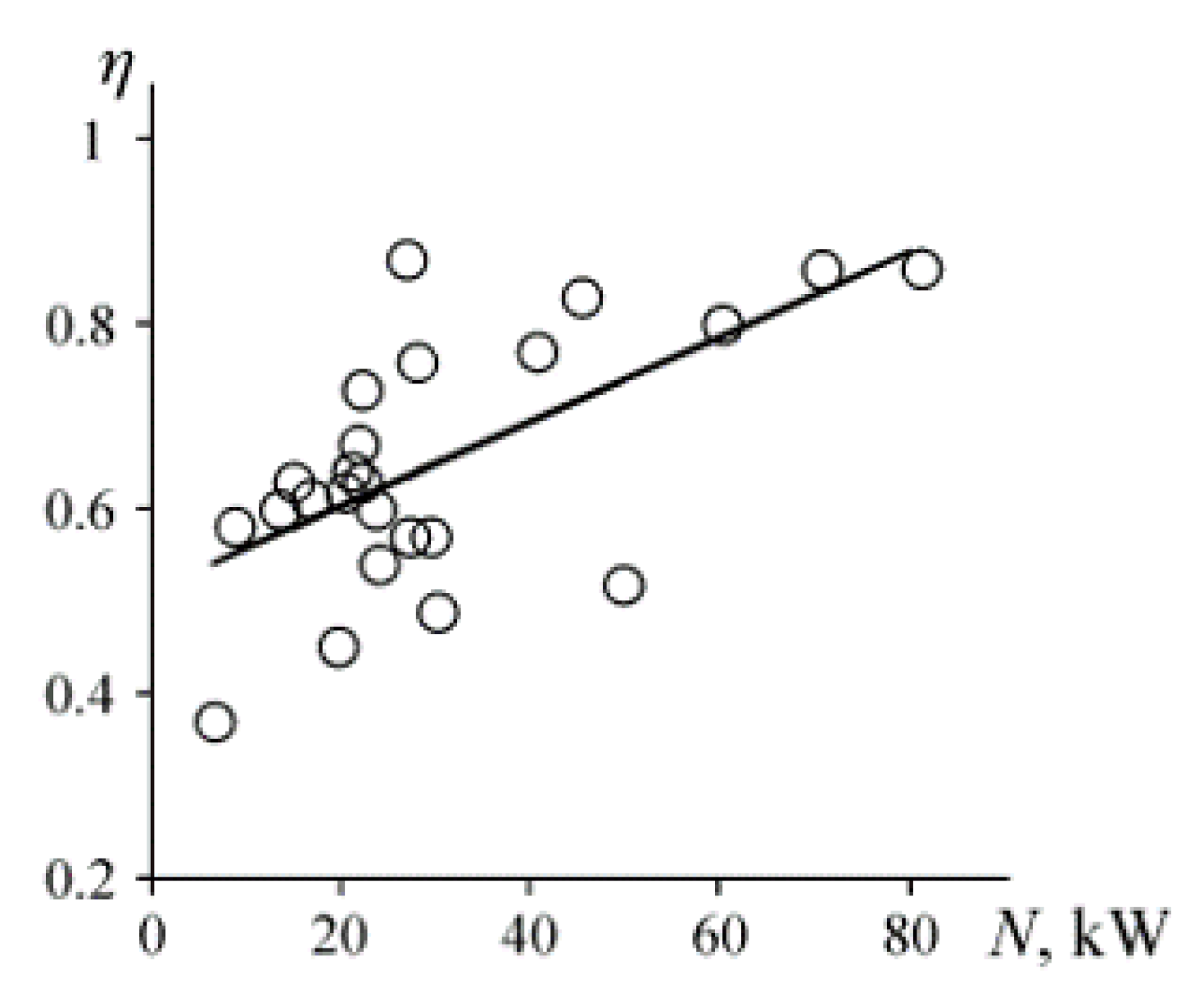

4.6. Prediction of the Impact-Hammer Performance

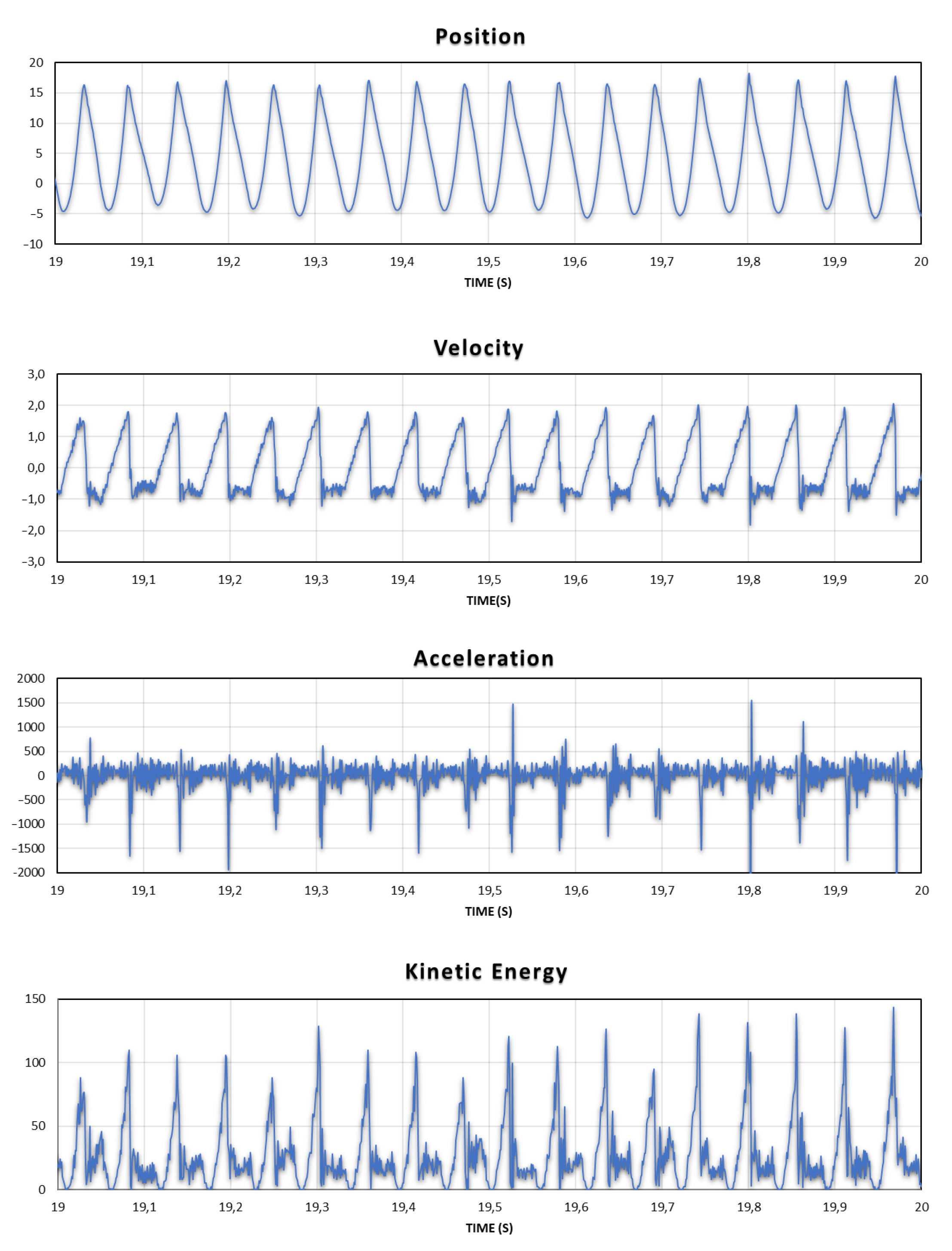

5. Experiments on the Electric Hammer

- Performance assessment of the electric hammer in the various geological conditions of mining companies in Poland, Finland, and Spain;

- Measurement and collection of operational process data;

- Checking the reliability of electric-hammer elements in the conditions of underground and opencast mines;

- Determination of optimal controlled vibration parameters for various materials and grinding tasks.

6. Discussion

- Two separate experiments for both types of hammers in similar working conditions;

- The same mass of spoil (1–5 Mg), grain size (>50 cm), rock type (the same part of the deposit);

- Hammer settings (frequency, energy, etc.) taking into account hydraulic hammer limitations (no parameters adjustment);

- Preferably the same experienced operator in both cases;

- Video recordings of both experiments.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Global Rock Breaker Market. Competition Forecast and Opportunities, 2013–2023. Available online: https://www.techsciresearch.com/report/rock-breaker-market/3530.html (accessed on 24 October 2022).

- Global Hydraulic Hammer Market 2018 by Manufacturers, Regions, Type and Application, Forecast to 2023. Available online: https://www.absolutereports.com/global-hydraulic-hammer-market-13679807 (accessed on 24 October 2022).

- Tatiya, R.R. Surface and Underground Excavations: Methods, Techniques and Equipment; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Zhou, H.; Xie, X.; Feng, Y. Rock breaking methods to replace blasting. IOP Conf. Ser. Mater. Sci. Eng. 2018, 322, 022014. [Google Scholar] [CrossRef]

- Moray, S.; Throop, N.; Seryak, J.; Schmidt, C.; Fisher, C.; D’Antonio, M. Energy efficiency opportunities in the stone and asphalt industry. In Proceedings of the Twenty-Eighth Industrial Energy Technology Conference, New Orleans, LA, USA; 2006; pp. 71–83. [Google Scholar]

- Vukovic, M.; Leifeld, R.; Murrenhoff, H. Reducing Fuel Consumption in Hydraulic Excavators—A Comprehensive Analysis. Energies 2017, 10, 687. [Google Scholar] [CrossRef] [Green Version]

- Ficarella, A.; Giuffrida, A.; Laforgia, D. The Effects of Distributor and Striking Mass on the Performance of a Hydraulic Impact Machine. In Proceedings of the Commercial Vehicle Engineering Congress & Exhibition, Rosemont, IL, USA, 7–9 October 2008. [Google Scholar] [CrossRef]

- Gieras, B.F. Linear Electric Motors. Electric Power Generation, Transmission, and Distribution: The Electric Power Engineering Handbook, 3rd ed.; CRC Press: London, UK, 2012; Chapter 34. [Google Scholar]

- Budig, P.K. The application of linear motors. In Proceedings of the IPEMC 2000. Third International Power Electronics and Motion Control Conference (IEEE Cat. No.00EX435), Beijing, China, 15–18 August 2000; Volume 3, pp. 1336–1341. [Google Scholar] [CrossRef]

- Shen, Y.; Lu, Q.; Ye, Y. Double-Stator Air-Core Tubular Permanent Magnet Linear Motor for Vehicle Active Suspension Systems. In Proceedings of the 2016 IEEE Vehicle Power and Propulsion Conference (VPPC), Hangzhou, China, 17–20 October 2016; pp. 1–6. [Google Scholar]

- Gysen, B.L.J.; Paulides, J.J.H.; Janssen, J.L.G.; Lomonova, E.A. Active Electromagnetic Suspension System for Improved Vehicle Dynamics. IEEE Trans. Veh. Technol. 2010, 59, 1156–1163. [Google Scholar] [CrossRef] [Green Version]

- van Casteren, D.; Gysen, B.; Kessels, J.; Paulides, J.; van den Bosch, P.; Lomonova, E. Non-Linear Full-Car Modeling and Sky-Hook Control for a Direct-Drive Active Suspension System. SAE Int. J. Passeng. Cars Mech. Syst. 2013, 6, 252–268. [Google Scholar] [CrossRef]

- Lo, D.S.; Amara, Y.; Barakat, G.; Chabour, F. Cogging force reduction in linear tubular flux switching permanent-magnet machines. Open Phys. 2018, 16, 243–248. [Google Scholar] [CrossRef]

- Govindpure, N.; Hipparagi, R.; Kumar, A.; Talange, D.B.; Bhole, V. Basic Design equations of Linear Electric Machines. In Proceedings of the 2018 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Chennai, India, 18–21 December 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Grinchenko, V. Justification of the basic design of a linear electric motor. Theor. Appl. Sci. 2013, 7, 58–60. [Google Scholar] [CrossRef]

- Brittain, J.E.; Laithwaite, E.R. A history of linear electric motors. Technol. Cult. 1990, 31, 337. [Google Scholar] [CrossRef]

- Kurilin, S.P.; Rubin, Y.B.; Dli, M.I.; Denisov, V.N. Models and methods of designing linear electric motors for non-ferrous metals industry applications. Non-Ferr. Met. 2021, 11, 83–90. [Google Scholar] [CrossRef]

- Gieras, J.F. Linear electric motors in machining processes. J. Int. Conf. Electr. Mach. Syst. 2013, 2, 380–389. [Google Scholar] [CrossRef] [Green Version]

- Korendiy, V.; Kachur, O.; Zakharov, V.; Kuzio, I. Studying the Dynamics of a Vibratory Finishing Machine Providing the Single-Sided Lapping and Polishing of Flat Surfaces. Eng. Proc. 2022, 24, 9. [Google Scholar] [CrossRef]

- Korendiy, V.; Kachur, O.; Zakharov, V.; Kuzio, I.; Hurey, I.; Predko, R. Experimental study of the lap motion trajectory of vibratory finishing machine. Vibroengineering PROCEDIA 2022, 46, 1–7. [Google Scholar] [CrossRef]

- Tiunov, V.V. Combined linear electric motors for robotic systems. Russ. Electr. Eng. 2017, 88, 745–749. [Google Scholar] [CrossRef]

- Rudzki, P.; Krot, P. Dynamics control of powered hydraulic roof supports in the underground longwall mining complex. IOP Conf. Ser. Earth Environ. Sci. 2021, 942, 012014. [Google Scholar] [CrossRef]

- Nasar, S.; Xiong, G.; Fu, Z. Eddy-current losses in a tubular linear induction motor. IEEE Trans. Magn. 1994, 30, 1437–1445. [Google Scholar] [CrossRef]

- Kumar, A.; Supare, C. Design, Analysis and Realization of Tubular Linear Induction Motor for Hammering Application. In Proceedings of the 2020 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Jaipur, India, 16–19 December 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Kumar, A.; Hasan, M.; Akhtar, M.J.; Parida, S.; Behera, R. Design optimization of linear induction motor. In Proceedings of the 2015 6th International Conference on Power Electronics Systems and Applications (PESA), Hong Kong, China, 15–17 December 2015; pp. 1–5. [Google Scholar] [CrossRef]

- Bonkobara, Y.; Umemura, H.; Kawano, Y.; Koyanagi, A.; Hamahata, T.; Kondou, T. Development of an electric hammer using self-synchronization phenomena. Proc. Mech. Eng. Congr. Jpn. 2016, 2016, G1000204. [Google Scholar] [CrossRef]

- Harada, M. Vibration damping structure for electric hammer. J. Acoust. Soc. Am. 1997, 101, 3233. [Google Scholar] [CrossRef]

- Goman, V.; Prakht, V.; Dmitrievskii, V.; Sarapulov, F. Analysis of coupled thermal and electromagnetic processes in linear induction motors based on a three-dimensional thermal model. Mathematics 2021, 10, 114. [Google Scholar] [CrossRef]

- Peltola, T.; Peltola, J.; Pyrhonen, J. A Hammer Device. IPC E02F3/96; E01C23/12; E02F5/30; E02F5/32; B25D17/00. International Patent Application No. WO2019068958A1, 11 April 2019. [Google Scholar]

- Peltola, T.; Peltola, J.; Juha, P. A Linear Electric Machine. IPC H02K41/03; B25D11/06; H02K1/04; H02K5/02. International Patent Application No. WO2020058565A1, 26 March 2020. [Google Scholar]

- Peltola, J.; Peltola, T. A Brake for Linear Movement and a Hammer Device Comprising the Same. IPC F16D59/00; F16D63/00; B25D17/24. International Patent Application No. WO2022129680A1, 23 June 2020. [Google Scholar]

- Peltola, T.; Peltola, J.; Pyrhonen, J. A Hammer Device. IPC B25D 11/00. European Patent Application No. EP3692217A1, 10 August 2022. [Google Scholar]

- Milanesi, F. Design Optimization and Control Strategies for PM Multiphase Tubular Linear Actuators. Ph.D. Thesis, University of Bologna, Bologna, Italy, 2009. [Google Scholar]

- van Zyl, A. Design, Construction and Evaluation of a Modified Tubular Linear Synchronous Motor. Ph.D. Thesis, University of the Witwatersrand, Johannesburg, South Africa, 2006. [Google Scholar]

- Wang, J.; Jewell, G.; Howe, D. Design optimisation and comparison of tubular permanent magnet machine topologies. IEE Proc. Electr. Power Appl. 2001, 148, 456–464. [Google Scholar] [CrossRef]

- Jiao, Z.; Cao, Y.; Yan, L.; Li, X.; Zhang, L. Design and Analysis of Novel Linear Oscillating Loading System. Appl. Sci. 2019, 9, 3771. [Google Scholar] [CrossRef] [Green Version]

- Giuffrida, A.; Laforgia, D. Modelling and Simulation of a Hydraulic Breaker. Int. J. Fluid Power 2005, 6, 47–56. [Google Scholar] [CrossRef]

- Gorodilov, L.V. Investigation into Characteristics of Working Cycles of Hydraulic Percussive Machines with Ideal Distributor. J. Min. Sci. 2002, 38, 74–79. [Google Scholar] [CrossRef]

- Neyman, L.A.; Neyman, V.Y.; Markov, A.V. Mathematical model of the technological vibratory unit with electromagnetic excitation. J. Phys. Conf. Ser. 2020, 1661, 012063. [Google Scholar] [CrossRef]

- Neyman, L.; Neyman, V.N. Generalized model of a single-coil synchronous impact electromagnetic machine. Proc. Russ. High. Sch. Acad. Sci. 2019, 2, 56–71. [Google Scholar] [CrossRef] [Green Version]

- Herisanu, N.; Marinca, B.; Marinca, V. Dynamics of the Vibro-Impact Nonlinear Damped and Forced Oscillator under the Influence of the Electromagnetic Actuation. Mathematics 2022, 10, 3301. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, G.; Wu, R.; Wang, L.; Zheng, H.; Chen, S. Dynamic analysis of a planar hydraulic rock-breaker mechanism with multiple clearance joints. Shock Vib. 2019, 2019, 4718456. [Google Scholar] [CrossRef]

- Song, C.; Kim, D.J.; Chung, J.; Lee, K.W.; Kweon, S.S.; Kang, Y.K. Estimation of impact loads in a hydraulic breaker by transfer path analysis. Shock Vib. 2017, 2017, 8564381. [Google Scholar] [CrossRef]

- Ummaneni, R.B.; Jaillot, C.; Nilssen, R.; Brennvall, J. Experimental characterisation of linear permanent magnet actuator with gas springs. In Proceedings of the 2009 IEEE International Electric Machines and Drives Conference, Miami, FL, USA, 3–6 May 2009; pp. 369–372. [Google Scholar] [CrossRef]

- Agnello, G.; Caruso, M.; Di Dio, V.; Miceli, R.; Nevoloso, C.; Spataro, C. Speed control of tubular linear induction motors for industrial automated applications. In Proceedings of the 2016 IEEE International Conference on Renewable Energy Research and Applications (ICRERA), Birmingham, UK, 20–23 November 2016; pp. 1196–1201. [Google Scholar] [CrossRef]

- Wang, W.; Tian, W.; Wang, Z.; Hua, W.; Cheng, M. A Fault Diagnosis Method for Current Sensors of Primary Permanent-Magnet Linear Motor Drives. IEEE Trans. Power Electron. 2021, 36, 2334–2345. [Google Scholar] [CrossRef]

- Yoon, B.J.; Lee, K.S.; Lee, J.H. A Novel Predictable Rock Breaker Using Intelligent Hydraulic Control with ICT Convergences. Appl. Sci. 2019, 9, 3333. [Google Scholar] [CrossRef] [Green Version]

- Szewczyk, K.; Walasek, T. Dynamic diagnostics of moving ferromagnetic material with the linear induction motor. ITM Web Conf. 2017, 15, 07003. [Google Scholar] [CrossRef]

- Ruiz-Carcel, C.; Starr, A. Data-Based Detection and Diagnosis of Faults in Linear Actuators. IEEE Trans. Instrum. Meas. 2018, 67, 2035–2047. [Google Scholar] [CrossRef] [Green Version]

- Ficarella, A.; Giuffrida, A.; Laforgia, D. Investigation on the impact energy of a hydraulic breaker. In Proceedings of the SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2007; Number 2007-01-4229. [Google Scholar]

- Ficarella, A.; Giuffrida, A.; Laforgia, D. Numerical Investigations on the Working Cycle of a Hydraulic Breaker: Off-Design Performance and Influence of Design Parameters. Int. J. Fluid Power 2006, 7, 41–50. [Google Scholar] [CrossRef]

- Park, J.W.; Kim, H.E. Development of the test system for measuring the impact energy of a hydraulic breaker. Proc. JFPS Int. Symp. Fluid Power 2005, 2005, 75–79. [Google Scholar] [CrossRef]

- Wu, T.; Tang, Y.; Tang, S.; Li, Y.; He, W.; Chen, E. Design and analysis of a new down-the-hole electromagnetic hammer driven by tube linear motor. IET Electr. Power Appl. 2017, 11, 1558–1565. [Google Scholar] [CrossRef]

- Wu, T.; Fu, K.; Zhu, J.; Lei, G. The influence analysis of thrust and gap magnetic field of a down-to-hole tubular permanent magnet linear hammer due to high temperature in deep hole. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, NSW, Australia, 11–14 August 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Zhang, S.; Norum, L.; Nilssen, R. Analysis of tubular linear permanent magnet motor for drilling application. In Proceedings of the 2009 International Conference on Electric Power and Energy Conversion Systems, (EPECS), Sharjah, United Arab Emirates, 10–12 November 2009; pp. 1–5. [Google Scholar]

- Wodecki, J.; Góralczyk, M.; Krot, P.; Ziętek, B.; Szrek, J.; Worsa-Kozak, M.; Zimroz, R.; Śliwiński, P.; Czajkowski, A. Process Monitoring in Heavy Duty Drilling Rigs—Data Acquisition System and Cycle Identification Algorithms. Energies 2020, 13, 6748. [Google Scholar] [CrossRef]

- Petit, P. Electric rock drilling system for in-stope mining in platinum operations. In Proceedings of the International Platinum Conference ‘Platinum Surges Ahead, Sun City, South Africa, 8–12 October 2006. [Google Scholar]

- Zhang, G.; Thuro, K.; Konietzky, H.; Menschik, F.M.; Kasling, H.; Bayerl, M. In-situ investigation of drilling performance and bit wear on an electrical drill hammer. Tunn. Undergr. Space Technol. 2022, 122, 104348. [Google Scholar] [CrossRef]

- Antonucci, A.; Barr, A.; Martin, B.; Rempel, D. Effect of bit wear on hammer drill handle vibration and productivity. J. Occup. Environ. Hyg. 2017, 14, 640–649. [Google Scholar] [CrossRef]

- Rempel, D.; Antonucci, A.; Barr, A.; Cooper, M.R.; Martin, B.; Neitzel, R.L. Pneumatic rock drill vs. electric rotary hammer drill: Productivity, vibration, dust, and noise when drilling into concrete. Appl. Ergon. 2019, 74, 31–36. [Google Scholar] [CrossRef]

- SCHULER. First Linear Hammer with ServoDirect Technology. Available online: https://www.schulergroup.com/major/download_center/broschueren_forging/download_forging/forging_flyer_linearhammer_servodirekt_e.pdf (accessed on 5 December 2022).

- Bembenek, M.; Zięba, A.; Kopyściański, M.; Krawczyk, J. Analysis of the Impact of the Consolidated Material on the Morphology of Briquettes Produced in a Roller Press. J. Mater. Eng. Perform. 2020, 29, 3792–3799. [Google Scholar] [CrossRef]

- Korendiy, V.; Kachur, O.; Hurey, I.; Predko, R.; Palash, R.; Havrylchenko, O. Modelling and experimental investigation of the vibratory conveyor operating conditions. Vibroengineering Procedia 2022, 47, 1–7. [Google Scholar] [CrossRef]

- METSO Crushing and Screening Handbook. Available online: https://www.mogroup.com/insights/e-books/crushing-and-screening-handbook (accessed on 16 November 2022).

- Makarov, L.N.; Denisov, V.N.; Kurilin, S.P. Designing and modeling a linear electric motor for vibration-technology machines. Russ. Electr. Eng. 2017, 88, 166–169. [Google Scholar] [CrossRef]

- Gursky, V.; Kuzio, I.; Krot, P.; Zimroz, R. Energy-Saving Inertial Drive for Dual-Frequency Excitation of Vibrating Machines. Energies 2021, 14, 71. [Google Scholar] [CrossRef]

- Bardzinski, P.; Walker, P.; Krol, R.; Kawalec, W. Simulation of Random Tagged Ore Flow through the Bunker in a Belt Conveying System. Int. J. Simul. Model. 2018, 17, 597–608. [Google Scholar] [CrossRef] [PubMed]

- Bardzinski, P.; Jurdziak, L.; Kawalec, W.; Król, R. Copper Ore Quality Tracking in a Belt Conveyor System Using Simulation Tools. Nat. Resour. Res. 2019, 29, 1031–1040. [Google Scholar] [CrossRef] [Green Version]

- Bardzinski, P.; Krol, R.; Jurdziak, L. Empirical Model of Discretized Copper Ore Flow within the Underground Mine Transport System. Int. J. Simul. Model. 2019, 18, 279–289. [Google Scholar] [CrossRef] [PubMed]

- Gursky, V.; Krot, P.; Korendiy, V.; Zimroz, R. Dynamic Analysis of an Enhanced Multi-Frequency Inertial Exciter for Industrial Vibrating Machines. Machines 2022, 10, 130. [Google Scholar] [CrossRef]

- Gursky, V.; Krot, P.; Dilay, I.; Zimroz, R. Optimization of the Vibrating Machines with Adjustable Frequency Characteristics. In Nonstationary Systems: Theory and Applications, Proceedings of the 13th Workshop on Nonstationary Systems and Their Applications, Grodek nad Dunajcem, Poland, 3–5 February 2020; Chaari, F., Leskow, J., Wylomanska, A., Zimroz, R., Napolitano, A., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 352–363. [Google Scholar] [CrossRef]

- Krot, P.; Zimroz, R.; Michalak, A.; Wodecki, J.; Ogonowski, S.; Drozda, M.; Jach, M. Development and verification of the diagnostic model of the sieving screen. Shock Vib. 2020, 2020, 8015465. [Google Scholar] [CrossRef]

- Aipov, R.; Linenko, A.; Badretdinov, I.; Tuktarov, M.; Akchurin, S. Research of the work of the sieve mill of a grain-cleaning machine with a linear asynchronous drive. Math. Biosci. Eng. 2020, 17, 4348–4363. [Google Scholar] [CrossRef]

- Doroszuk, B.; Król, R. Analysis of conveyor belt wear caused by material acceleration in transfer stations. Min. Sci. 2019, 26, 189–201. [Google Scholar] [CrossRef]

- Król, R. Studies of The Durability of Belt Conveyor Idlers with Working Loads Taken into Account. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 042054. [Google Scholar] [CrossRef] [Green Version]

- Góralczyk, M.; Krot, P.; Zimroz, R.; Ogonowski, S. Increasing Energy Efficiency and Productivity of the Comminution Process in Tumbling Mills by Indirect Measurements of Internal Dynamics—An Overview. Energies 2020, 13, 6735. [Google Scholar] [CrossRef]

- Bortnowski, P.; Gładysiewicz, L.; Król, R.; Ozdoba, M. Energy efficiency analysis of copper ore ball mill drive systems. Energies 2021, 14, 1786. [Google Scholar] [CrossRef]

- Kujundžić, T.; Klanfar, M.; Korman, T.; Briševac, Z. Influence of Crushed Rock Properties on the Productivity of a Hydraulic Excavator. Appl. Sci. 2021, 11, 2345. [Google Scholar] [CrossRef]

- Krot, P.; Zimroz, R.; Sliwinski, P.; Gomolla, N. Safe Operation of Underground Mining Vehicles Based on Cyclic Fatigue Monitoring of Powertrains. In Structural Integrity and Fatigue Failure Analysis; Lesiuk, G., Szata, M., Blazejewski, W., Jesus, A.M.d., Correia, J.A., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 283–292. [Google Scholar]

- Gorodilov, L.V.; Maslov, N.A.; Korovin, A.N. Evaluation of parameters of hydraulic impact devices of active bucket with direct connection to the hydraulic system of II grade excavator. Interexpo GEO-Sib. 2020, 2, 45–51. [Google Scholar] [CrossRef]

- Gorodilov, L.V.; Korovin, A.N. Analysis of active bucket designs of open-pit and construction excavators. Interexpo GEO-Sib. 2021, 2, 171–179. [Google Scholar] [CrossRef]

- Mazur, M. Determination of crushing energy during vibratory crushing. New Trends Prod. Eng. 2019, 2, 287–294. [Google Scholar] [CrossRef] [Green Version]

- Bond, F.C. The Third Theory of Comminution. In Transactions of the American Institute of Mining, Metallurgical and Petroleum Engineers; American Institute of Mining, Metallurgical, and Petroleum Engineers: New York, NY, USA, 1952; Volume 193, pp. 484–494. [Google Scholar]

- Kabachkov, Y.F.; Vainer, B.M.; Lesnikov, V.V. Use of an electric hammer for splitting oversize magnesite blocks. Refractories 1982, 23, 468–469. [Google Scholar] [CrossRef]

- Minaev, A.G.; Shakhtarin, R.A.; Kabachkov, Y.F. Use of electric hammers to break up concrete foundations in the repair of production equipment. Metallurgist 1986, 30, 376–377. [Google Scholar] [CrossRef]

- Krot, P.; Śliwiński, P.; Zimroz, R.; Gomolla, N. The identification of operational cycles in the monitoring systems of underground vehicles. Measurement 2020, 151, 107111. [Google Scholar] [CrossRef]

- Stefaniak, P.; Wodecki, J.; Jakubiak, J.; Zimroz, R. Development of Test Rig for Robotization of Mining Technological Processes—Oversized Rock Breaking Process Case. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 042028. [Google Scholar] [CrossRef]

- KGHM ZANAM. Stationary Rock Breaker Type URB/Klim. Available online: https://www.kghmzanam.com/wp-content/uploads/2020/06/URB_Klim_PL.pdf (accessed on 5 December 2022).

- Siwulski, T.; Warzynska, U.; Panowska, K.; Wolter, M. Improving the efficiency of a rock breaker hydraulic working system by changing the structure of the hydraulic system. MM Sci. J. 2022, 2022, 5738–5747. [Google Scholar] [CrossRef]

- Krauze, K.; Rączka, W.; Sibielak, M.; Konieczny, J.; Kubiak, D.; Culer, H.; Bajus, D. Automated transfer point URB/ZS-3. Mininig Inform. Autom. Electr. Eng. 2017, 2, 80. [Google Scholar] [CrossRef]

- Duff, E.; Caris, C.; Bonchis, A.; Taylor, K.; Gunn, C.; Adcock, M. The development of a telerobotic rock breaker. In Field and Service Robotics; Springer: Berlin/Heidelberg, Germany, 2010; pp. 411–420. [Google Scholar] [CrossRef]

- Cárdenas, D.; Parra-Tsunekawa, I.; Leiva, F.; Ruiz-del Solar, J. Automatic Determination of Rock-Breaking Target Poses for Impact Hammers. Energies 2022, 15, 6380. [Google Scholar] [CrossRef]

- Correa, M.; Cárdenas, D.; Carvajal, D.; Ruiz-del Solar, J. Haptic Teleoperation of Impact Hammers in Underground Mining. Appl. Sci. 2022, 12, 1428. [Google Scholar] [CrossRef]

- Takahashi, H.; Sano, K. Automatic detection and breaking system for boulders by use of CCD camera and laser pointer. Fragblast 1998, 2, 397–414. [Google Scholar] [CrossRef]

- Lampinen, S.; Niu, L.; Hulttinen, L.; Niemi, J.; Mattila, J. Autonomous robotic rock breaking using a real-time 3D visual perception system. J. Field Robot. 2021, 38, 980–1006. [Google Scholar] [CrossRef]

- Bieniawski, Z.T. Engineering Rock Mass Classifications: A Complete Manual for Engineers and Geologists in Mining, Civil, and Petroleum Engineering; John Wiley & Sons: Nashville, TN, USA, 1989. [Google Scholar]

- Aksoy, C.O. Review of rock mass rating classification: Historical developments, applications, and restrictions. J. Min. Sci. 2008, 44, 51–63. [Google Scholar] [CrossRef]

- Mezentsev, I.V. Influence of Design Factors on the Efficiency of Hydraulic Hammers. J. Min. Sci. 2003, 39, 400–404. [Google Scholar] [CrossRef]

- Aksoy, C.O.; Ozacar, V.; Safak, S. An updated formula and method to predict the performance of impact hammers. Int. J. Rock Mech. Min. Sci. 2013, 61, 289–295. [Google Scholar] [CrossRef]

- Ismael, M.; Abdelghafar, K.; Sholqamy, M.; Elkarmoty, M. Performance prediction of hydraulic breakers in excavation of a rock mass. Min. Geol. Pet. Eng. Bull. 2021, 36, 107–119. [Google Scholar] [CrossRef]

- Kucuk, K.; Aksoy, C.; Basarir, H.; Onargan, T.; Genis, M.; Ozacar, V. Prediction of the performance of impact hammer by adaptive neuro-fuzzy inference system modelling. Tunn. Undergr. Space Technol. 2011, 26, 38–45. [Google Scholar] [CrossRef]

- Tumac, D.; Hojjati, S. Predicting performance of impact hammers from rock quality designation and compressive strength properties in various rock masses. Tunn. Undergr. Space Technol. 2016, 59, 38–47. [Google Scholar] [CrossRef]

- Li, S.; Tian, S.; Li, W.; Yan, T.; Bi, F. Research on the Resonance Characteristics of Rock under Harmonic Excitation. Shock Vib. 2019, 2019, 6326510. [Google Scholar] [CrossRef] [Green Version]

- Chiang, L.E.; Elías, D.A. A 3D FEM methodology for simulating the impact in rock-drilling hammers. Int. J. Rock Mech. Min. Sci. 2008, 45, 701–711. [Google Scholar] [CrossRef]

- Hogan, J.D.; Rogers, R.J.; Spray, J.G.; Boonsue, S. Dynamic fragmentation of granite for impact energies of 6–28J. Eng. Fract. Mech. 2012, 79, 103–125. [Google Scholar] [CrossRef]

- Kumano, A.; Goldsmith, W. Projectile impact on soft, porous rock. Rock Mech. Felsmech. Mec. Des Roches 1982, 15, 113–132. [Google Scholar] [CrossRef]

- Kahraman, S.; Bilgin, N.; Feridunoglu, C. Dominant rock properties affecting the penetration rate of percussive drills. Int. J. Rock Mech. Min. Sci. 2003, 40, 711–723. [Google Scholar] [CrossRef]

- Zhang, P.; Wu, Z.; Sun, J.; Liu, Y.; Chu, Z. Experimental and numerical studies of the impact breakage of granite with high ejection velocities. PLoS ONE 2022, 17, e0266241. [Google Scholar] [CrossRef]

- Gorodilov, L.V.; Efimov, V.P.; Kudryavtsev, V.G. Modeling the striking head-impact tool-rock mass interaction. J. Min. Sci. 2013, 49, 618–624. [Google Scholar] [CrossRef]

- Efimov, V.; Gorodilov, L. Experimental investigation of shock pulses in the piston-bit system in interaction with rock mass. IOP Conf. Ser. Earth Environ. Sci. 2021, 773, 012041. [Google Scholar] [CrossRef]

- Gorodilov, L.V.; Kudryavtsev, V.G. Hydraulic Impactor Control Methods and Charts. J. Min. Sci. 2022, 58, 52–64. [Google Scholar] [CrossRef]

- Corkum, A.G.; Asiri, Y.; Naggar, H.E.; Kinakin, D. The Leeb Hardness Test for Rock: An Updated Methodology and UCS Correlation. Rock Mech. Rock Eng. 2017, 51, 665–675. [Google Scholar] [CrossRef]

- ASTM D5873-14; Standard Test Method for Determination of Rock Hardness by Rebound Hammer Method. ASTM: West Conshohocken, PA, USA. 2005. Available online: https://www.astm.org/d5873-14.html (accessed on 16 November 2022).

- Mayer, T. Investigating Parameter’s of Lekatech’s Electric Hammer; Technical Report; Lekatech: Kausala, Finland, 2021; Available online: https://www.lekatech.fi/site/assets/files/3535/investigating_parameters_of_lekatechs_electric_hammer.pdf (accessed on 11 December 2022).

- Korhonen, S. Reducing Energy Consumption of Hammering With Electric Excavators. Master’s Thesis, University of Oulu, Oulu, Finland, 2006. [Google Scholar]

- Ukkola, J. CE-marking of the electric breaker hammer and product safety requirements for the US and Canadian markets. Master’s Thesis, Lappeenranta–Lahti University of Technology (LUT), Lappeenranta, Finland, 2022. [Google Scholar]

- Lekatech. Linear Electric Technology for Hammering Applications. 2022. Available online: https://www.lekatech.fi/ (accessed on 8 December 2022).

- LEKATECH Electric Hammer Data Sheet. Available online: https://echo.pwr.edu.pl/wp-content/uploads/2022/11/LekaTech_Datasheet.pdf (accessed on 5 December 2022).

- Wagner Edward, P.S. Electric Excavator. International Patent Application No. IPC E02F3/32; International Patent Application No. F15B2211/20515. U.S. Patent Application No. US2021062459A1, 4 March 2021. [Google Scholar]

- Szurgacz, D. Dynamic Analysis for the Hydraulic Leg Power of a Powered Roof Support. Energies 2021, 14, 5715. [Google Scholar] [CrossRef]

- Szurgacz, D.; Brodny, J. Analysis of the Influence of Dynamic Load on the Work Parameters of a Powered Roof Support’s Hydraulic Leg. Sustainability 2019, 11, 2570. [Google Scholar] [CrossRef]

| Parameter | Ferrite | Nd-Fe-B |

|---|---|---|

| Remanence Br [T] | 0.2 ÷ 0.5 | 1.1 ÷ 1.3 |

| Coercive field Hc [kA/m] | 150 ÷ 295 | 700 ÷ 1000 |

| Relative permeability | 1.1 | 1.08 |

| Temp. coeff. of Br [% C] | −0.11/−0.12 | −0.54/−0.60 |

| Temp. coeff. of Hc [% C] | −0.2 | +0.3 |

| Parameter | Value | Units |

|---|---|---|

| Height min | 5.0 | m |

| Width min | 6.0 | m |

| Length min | 10.0 | m |

| Boom reach | 4700 | mm |

| Boom turning angle | ±40 | grad |

| Total weight | 7000 | kg |

| Impact energy | 400 ÷ 1900 | J |

| Working pressure | 10 ÷ 17 | MPa |

| Hydraulic oil flow | 20 ÷ 120 | L/min |

| Material Grade | UCS (MPa) |

|---|---|

| Very soft | 30 |

| Soft | 70 |

| Medium hard | 100 |

| Hard | 130 |

| Extremely hard | 160 |

| Parameter | Value | Units |

|---|---|---|

| Hammer weight | 454 | kg |

| Minimum working weight | 516 | kg |

| Impact frequency (adjustable) | 60–900 | min |

| Impact energy (adjustable) | 500–1500 | J |

| Working tool diameter | 90 | mm |

| Voltage (main) AC | 400 | V |

| 50 | Hz | |

| 3 × 63 | A | |

| Voltage (converter) DC | 700 | V |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wróblewski, A.; Krot, P.; Zimroz, R.; Mayer, T.; Peltola, J. Review of Linear Electric Motor Hammers—An Energy-Saving and Eco-Friendly Solution in Industry. Energies 2023, 16, 959. https://doi.org/10.3390/en16020959

Wróblewski A, Krot P, Zimroz R, Mayer T, Peltola J. Review of Linear Electric Motor Hammers—An Energy-Saving and Eco-Friendly Solution in Industry. Energies. 2023; 16(2):959. https://doi.org/10.3390/en16020959

Chicago/Turabian StyleWróblewski, Adam, Pavlo Krot, Radosław Zimroz, Timo Mayer, and Jyri Peltola. 2023. "Review of Linear Electric Motor Hammers—An Energy-Saving and Eco-Friendly Solution in Industry" Energies 16, no. 2: 959. https://doi.org/10.3390/en16020959

APA StyleWróblewski, A., Krot, P., Zimroz, R., Mayer, T., & Peltola, J. (2023). Review of Linear Electric Motor Hammers—An Energy-Saving and Eco-Friendly Solution in Industry. Energies, 16(2), 959. https://doi.org/10.3390/en16020959